Abstract

Background

Fretting and corrosion at head-neck junctions of total hip arthroplasties (THAs) have been associated with adverse local tissue reactions in patients with both metal-on-polyethylene (MoP) and metal-on-metal (MoM) prostheses. Femoral head size contributes to the severity of fretting and corrosion in large-diameter MoM THAs, but its impact on such damage in MoP THAs remains unknown.

Questions/purposes

(1) Is femoral head size associated with increased fretting or corrosion at the head-neck junction in MoP total hips? (2) Is duration of implantation associated with increased fretting or corrosion?

Methods

The severity of fretting/corrosion on surfaces of head tapers and stem trunnions was visually examined in 154 MoP THAs retrieved as part of 3282 revision surgeries performed at our institution between January 1, 2007, and December 31, 2013. Fretting and corrosion damage were subjectively graded by two independent observers on a 1 to 4 scale, and their relations to head size, alloy combinations, taper/trunnion design, length of implantation (LOI), and location were investigated. Differences in scores never exceeded one grade, and this occurred in only 17% of examined implants. With the available implants, the study provided 88% power to detect differences of 0.5 in fretting or corrosion scores in these analyses.

Results

Fretting and corrosion of the tapers and the trunnions were not affected by head size (p = 0.247, p = 0.471, p = 0.837, and p = 0.868, respectively), although taper/trunnion design affected taper fretting (p = 0.005) and corrosion (p = 0.0031) and trunnion fretting (p = 0.0028). Head taper fretting (observed in 73% of heads) increased with LOI, but head taper corrosion (noted in 93% of heads) was not affected. Trunnion fretting (observed in 86% of stems) was more severe in mixed-alloy combinations and with increased LOI and was more severe proximally. Trunnion corrosion (noted in 72% of stems) was also location-dependent with greater corrosion distally.

Conclusions

Fretting and corrosion are regular occurrences in MoP THAs, but neither damage type was related to femoral head size. Conversely, taper design, LOI, and alloy combination affected the severity of both fretting and corrosion.

Clinical Relevance

Although it has been suggested that trunnion corrosion seen in MoP bearings is a function of larger diameter heads, our data suggest that larger femoral heads may be used for increased damage at the modular junction of MoP THAs.

Introduction

Modular components in primary THA are attractive because they provide the surgeon with options to correct leg length, improve implant stability, and decrease implant inventory [8]. Unfortunately, with modularity comes the potential for fretting and corrosion at the head-neck modular junction. The mechanism for mechanically assisted crevice corrosion has been studied since the 1980s with few reports of clinical complications with modular junctions until 2010 [13]. Recently, high failure rates of metal-on-metal (MoM) THAs were attributed to adverse local tissue reactions (ALTRs) from exposure to corrosion debris, and surgeons have returned to metal-on-polyethylene (MoP) bearings to avoid ALTR. This has refueled interest in the design, assembly, and performance of these junctions.

Fretting and corrosion at the modular junction may be greater with larger heads. Femoral head size has been associated with the severity of fretting and corrosion at the junction with ultralarge (> 36 mm) MoM THAs, which were used for the advantages of greater ROM and decreased dislocation risk [1, 3, 14, 20, 26, 29]. Larger heads produce increased rotational and bending moments at the junction and can increase micromotion between the junction contact surfaces [20]. This phenomenon was particularly evident with MoM THAs, where simulator data indicated that lack of lubrication between bearing surfaces caused increased friction moments at the head-neck junction [2].

Most surgeons have returned to MoP bearings because of the high rate of early failure, the increased cost, and lack of efficacy of MoM THAs [4, 5, 25] and because of the improved wear resistance of highly crosslinked polyethylene [17]. However, despite the risks of increased polyethylene wear and increased corrosion at the taper junction with larger heads, some surgeons are reluctant to return to smaller heads because of concerns about dislocation. Little is known about the association of head size on fretting and corrosion in modular junctions of MoP THAs. We therefore sought to determine: (1) Is femoral head size associated with increased fretting or corrosion at the head-neck junction in MoP total hips? (2) Is duration of implantation associated with increased fretting or corrosion?

Patients and Methods

Between January 1, 2007, and December 31, 2013, our implant retrieval program collected 3282 total hip devices, including 359 with MoM bearings, 107 with ceramic-on-ceramic bearings, and 2816 MoP bearings. For the current study, we included MoP THA where both the femoral head and stem had been revised simultaneously and, therefore, were available for examination. We excluded 145 implants with the stems that had a dual modular neck, because these implants were implicated in an increased incidence of modularity-related adverse events [16], and 50 implants with titanium alloy heads, because these heads experienced high wear and are no longer in use. That left 154 MoP THAs (from 145 patients) retrieved after a mean length of implantation of 6.0 ± 6.1 years (range, 0–27 years). There were 21 implants retrieved within 6 months, 39 retrieved between 0.5 and 2 years, 29 between 3 and 5 years, 31 between 5 and 10 years, 24 retrieved between 10 and 20 years, and six retrieved after more than 20 years in vivo.

Eighty-five implants were retrieved from 75 men, and 74 implants were retrieved from 70 women (Table 1). The mean age at time of implantation was 62.0 (SD 13.8), and the mean body mass index was 27.9 kg/m2 (SD 6.0). Reasons for revision included infection in 67 THAs (43.5%), aseptic loosening in 64 (41.6%), instability in eight (5.2%), periprosthetic fracture in seven (4.5%), dislocation in five (3.2%), leg length discrepancy in two (1.3%), and implant malpositioning in one (0.7%).

Table 1.

The characteristics of the patients from whom the 154 implants had been retrieved

| Characteristic | Result* |

|---|---|

| Male:female | 75:70 |

| Age (years) at implantation (mean ± SD) | 62 ± 14 |

| Body mass index (kg/m2, mean ± SD) | 28 ± 6 |

| Hip side (right:left) | 77:77 |

| Reason for revision (number of hips) | |

| Infection | 67 (43.5) |

| Aseptic loosening | 64 (41.6) |

| Instability | 8 (5.2) |

| Periprosthetic fracture | 7 (4.5) |

| Dislocation | 5 (3.2%) |

| Leg length discrepancy | 2 (1.3) |

| Implant malpositioning | 1 (0.7) |

*Continuous variables are presented as mean ± SD. Categorical variables are presented as number (%).

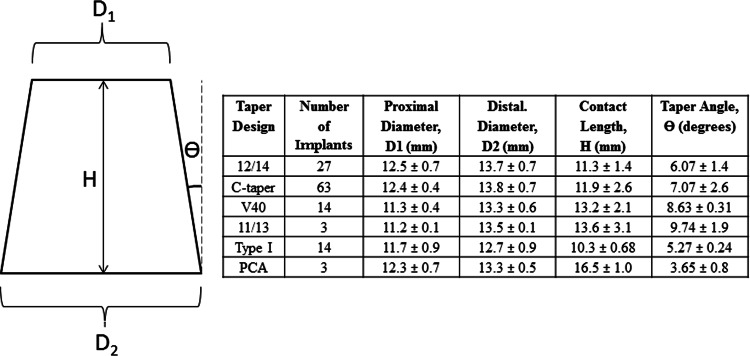

All heads had been fabricated from cobalt-chromium (CoCr) alloy. Heads were grouped by diameter (Table 2): 17% were ≤ 26 mm (n = 26; 20 22-mm and six 26-mm heads), 30% were 28 mm (n = 46), 34% were 32 mm (n = 52), and 20% ≥ 36 mm (n = 30; 22 36-mm heads, one 38-mm head, six 40-mm heads, and one 44-mm head). Implants were grouped into same-alloy (CoCr head with CoCr stem, n = 75) and mixed-alloy combinations (CoCr head with Ti-6Al-4V or Ti-12Mo-6Zr-2Fe stems, n = 79). The taper/trunnion designs included 12/14 (58 implants [38%]), C-tapers (30 [19%]), V40 (15 [10%]), 11/13 (15 [10%]), Type I (eight [5%]), and PCA tapers (six [4%]) (Fig. 1). The method of fixation was cemented for 65 stems and cementless for 89 stems.

Table 2.

The characteristics of the 154 retrieved implants

| Characteristic | Number (%) |

|---|---|

| Head size (number of hips) | |

| 22 mm | 20 (12.9) |

| 26 mm | 6 (3.9) |

| 28 mm | 46 (29.9) |

| 32 mm | 52 (33.8) |

| 36 mm | 22(14.3) |

| 38 mm | 1 (0.65) |

| 40 mm | 6 (3.9) |

| 44 mm | 1 (0.65) |

| Stem material (number of hips) | |

| Co-Cr | |

| Forged | 56 (36.4) |

| Cast | 19 (12.3) |

| Ti | |

| Ti-6Al-4V | |

| Forged | 48 (31.2) |

| Wrought | 14 (9.1) |

| Machined | 11 (7.1) |

| Ti-12Mo-6Zr-2Fe | 6 (3.9) |

| Taper/trunnion design (number of hips) | |

| 12/14 | 58 (37.7) |

| C-taper | 30 (19.5) |

| V40 | 15 (9.7) |

| 11/13 | 15 (9.7) |

| Type I | 8 (5.2) |

| PCA | 6 (3.9) |

| Other | 22 (14.3) |

| Material combination (number of hips) | |

| Same (CoCr-CoCr) | 73 (47.4) |

| Different (CoCr-Ti) | 81 (52.6) |

CoCr = cobalt-chromium; Ti = titanium.

Fig. 1.

The 154 retrieved components included stems with six different taper designs. The taper dimensions were measured on a subset of the retrievals to determine the proximal and distal diameters, the contact length, and the taper height and angle. Please note that measurements were performed on a subset of the 154 retrieved implants.

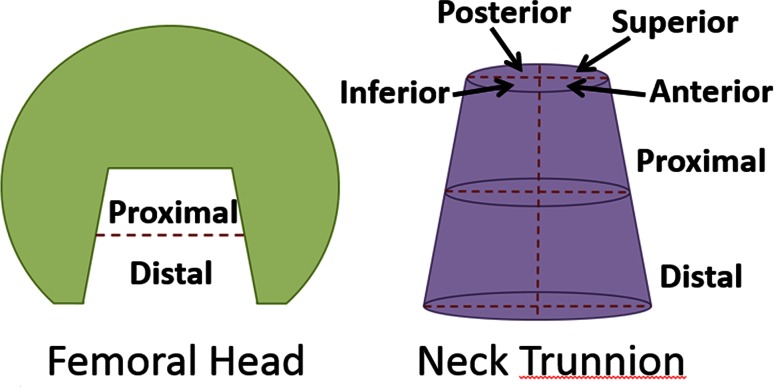

Before examination, retrieved components were disinfected in a 10% bleach solution for 20 minutes, washed with a mild detergent and tap water, rinsed in methanol, and allowed to air-dry overnight. The head taper and stem trunnion surfaces were examined by two independent observers (GKT, MEE) using an optical stereomicroscope (Wild Type 376788, Heerbruug, Switzerland) at magnifications from × 6 to × 12. We used “trunnion” to refer to the male component on the stem and “taper” to describe the female component on the femoral head [26]. The head taper was divided into proximal and distal regions. The stem trunnion was divided into eight quadrants with proximal and distal regions each subdivided into posterior, anterior, superior, and inferior regions (Fig. 2).

Fig. 2.

The head taper (green) and the stem trunnion (purple) were divided into regions, and each region was examined for fretting and corrosion.

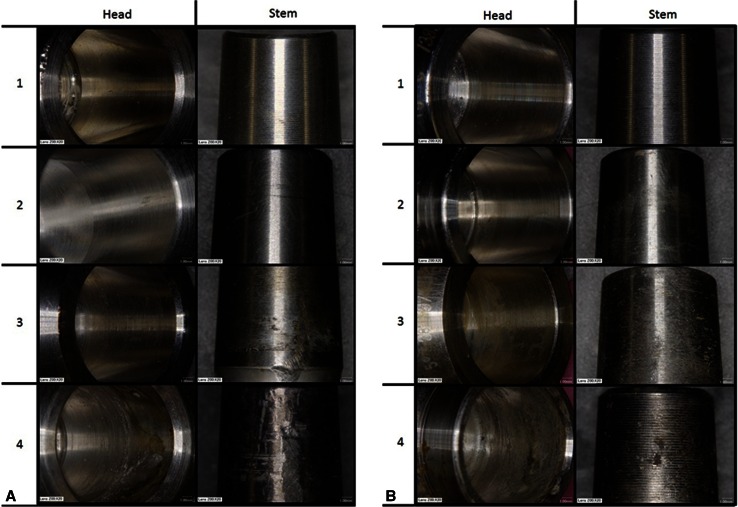

Fretting damage included small scars perpendicular to and interrupting machining lines and irregularly shaped polished areas where machining lines had been worn away [19]. Fretting damage is as significant as corrosion because fretting leads to continuous repassivation of the oxide layer with ultimate consumption of available oxygen in the crevice, alteration of pH, and subsequent initiation of the corrosion process. Discoloration, pits, etching scars, and black debris were attributed to corrosion. Damage from tools used to remove components at surgery was ignored. Each region was graded for fretting and corrosion using the scoring system developed by Goldberg et al. [19] with a minimum score of 1 and a maximum score of 4 (Fig. 3). Two regions were scored for the taper and eight for the trunnion, so the maximum total score for fretting or corrosion was 8 (2 × 4) for the taper and 32 (8 × 4) for the trunnion. When scoring differences arose between the two investigators, a joint examination was conducted to reach consensus; the differences in scores between the two observers never exceeded one grade of the Goldberg scoring scale, and this occurred in 17% of the examined implants (26 of 154).

Fig. 3A–B.

Microscopic images of the head taper and the stem trunnion are shown with sequentially higher scores for fretting (A) and corrosion (B). The left column of each picture represents the scores of the scale [19] with 1 corresponding to the absence of any damage and 4 corresponding to excessive fretting/corrosion.

The numbers and proportions of head tapers and stem trunnions with fretting and corrosion (Goldberg scores ≥ 2) were calculated as were the numbers and proportions falling within each Goldberg class. Univariate analyses were conducted between the revision diagnosis and the related fretting and corrosion scores for the stem trunnions and head tapers. Taper fretting and corrosion scores were not related to the revision diagnosis (p = 0.832 and 0.616, respectively). Similarly, trunnion fretting and corrosion were not related to revision diagnosis (p = 0.104 and 0.587, respectively). Therefore, revision diagnosis was not included in examining associations with the other, nonclinical factors on fretting and corrosion. Repeated-measures generalized estimating equations (GEEs) were used to correlate head size, alloy combination, length of implantation, and location within the taper or trunnion (proximal/distal for tapers, proximal/distal and quadrant for trunnions) to the magnitude of head and stem fretting and corrosion. Separate models were constructed for head fretting, head corrosion, stem fretting, and stem corrosion. All variables and their two-way interactions were initially included; nonsignificant terms were subsequently removed in order of decreasing p value starting with interaction terms. Post hoc tests were adjusted for multiple comparisons with the Tukey-Kramer method. The number of implants obtained for this study provided 88% power to detect differences of 0.5 in fretting or corrosion scores in these analyses. A second set of analyses was performed including taper/trunnion design into the multivariate repeated measures GEEs; however, the number of implants provided only adequate power (80%) to detect a difference of 0.8 between taper groups. As a result of the limited numbers of some taper designs within some of the head size categories, the interaction between taper design and head size was not included in the statistical models. All statistical tests were performed with SAS 9.3 (Cary, NC, USA) with a level of significance of α = 0.05. Descriptive statistics are displayed as means (and 95% confidence intervals) for continuous variables and frequencies and percentages for categorical variables. Results presented are significant unless stated otherwise.

Results

Relationship of Femoral Head Size to Fretting and Corrosion

We found no association between head size and the degree of fretting and corrosion on the tapers or trunnions. For the GEE models, the significance values for fretting of the taper and trunnion and corrosion of the taper and trunnion were p = 0.247, p = 0.471, p = 0.837, and p = 0.868, respectively (Tables 3, 4). Fretting and corrosion were common findings. Taper fretting was observed in 73% of the 154 heads with 23% having moderate or severe (≥ 3) average fretting scores. Taper corrosion was noted in 93% of the 154 heads with 34% having moderate or severe (≥ 3) average corrosion scores. Trunnion fretting was observed in 86% of the 154 stems with 10% of the trunnions having moderate or severe (≥ 3) average fretting scores. Trunnion corrosion was noted in 72% of the stems with 14% having moderate to severe (≥ 3) average corrosion scores.

Table 3.

Probability values from multivariable GEEs examining the relationship between damage and head size, taper, length of implantation, material combination, and location

| Variable | Head fretting | Head corrosion | Stem fretting | Stem corrosion |

|---|---|---|---|---|

| Head size | 0.247 | 0.837 | 0.471 | 0.868 |

| Taper design | 0.028* | 0.031* | 0.005* | 0.107 |

| Length of implantation | < 0.001* | 0.329 | 0.044* | 0.072 |

| Material combination | 0.326 | 0.681 | < 0.001* | 0.432 |

| Location (proximal/distal) | 0.106 | 0.477 | < 0.001* | 0.043* |

| Location (quadrant) | 0.001* | 0.048** | ||

| Location (proximal/distal* quadrant) | 0.013* | – | ||

| Head size* location (quadrant) | – | 0.017* |

Interaction terms are included only where significant; * p < 0.05; GEEs = generalized estimating equations.

Table 4.

Taper and trunnion fretting and corrosion scores according to head size

| Head size (mm) | Taper fretting [mean (95% CI)] | Taper corrosion [mean (95% CI)] | Trunnion fretting [mean (95% CI)] | Trunnion corrosion [mean (95% CI)] |

|---|---|---|---|---|

| ≤ 26 (n = 26) | 2.1 (1.7–2.5) | 2.4 (2.1–2.6) | 1.9 (1.8–2.06) | 1.6 (1.5–1.8) |

| 28 (n = 46) | 1.9 (1.7–2.1) | 2.7 (2.5–2.9) | 1.9 (1.8–2.0) | 1.7 (1.6–1.8) |

| 32 (n = 53) | 2.1 (1.9–2.3) | 2.3 (2.1–2.5) | 2.0 (1.9–2.1) | 1.8 (1.7–1.9) |

| ≥ 36 (n = 30) | 2.2 (1.8–2.6) | 2.4 (2.0–2.8) | 2.1 (1.9–2.2) | 1.9 (1.8–2.1) |

CI = confidence interval.

Relationship Between Length of Implantation and Fretting and Corrosion

Length of implantation was associated with taper fretting (p < 0.001) and trunnion fretting (p = 0.044), but was not associated with corrosion (Table 3). For every 5 years of implantation, the taper fretting score increased by 0.2 points (0.1–0.4), and the trunnion fretting score increased by 0.1 points (0.0–0.2).

Other Factors Associated With Fretting and Corrosion

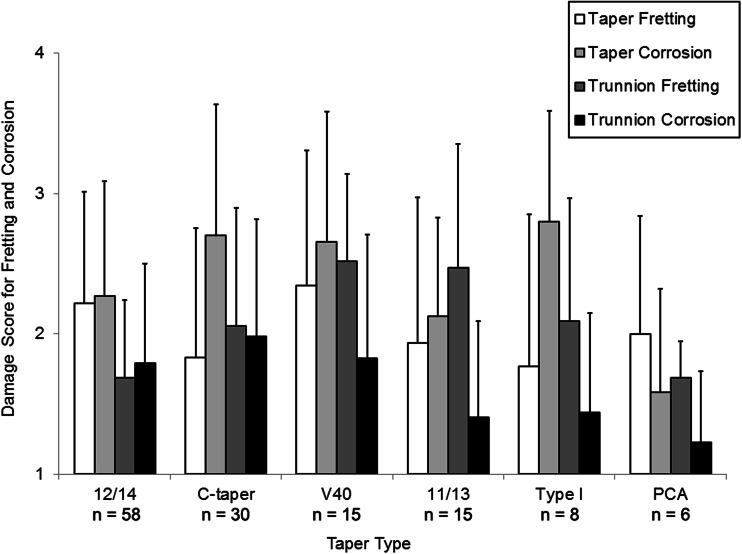

Taper design was associated with taper fretting (p = 0.005), taper corrosion (p = 0.031), and trunnion fretting (p = 0.028) (Table 3). PCA tapers had 0.8 (0.1–1.5) points less fretting than 12/14 (p = 0.010) and 1.1 (0.1–2.0) points less than V40 (p = 0.022) designs (Fig. 4). PCA trunnions had 0.8 (0.0–1.5) points less fretting than V40 trunnions (p = 0.018) and had 1.0 (0.0–1.9) points less fretting than Type I trunnions (p = 0.034). Additionally, 12/14 trunnions had 0.7 (0.2–1.1) points less fretting than V40 trunnions (p = 0.002) and 0.8 (0.0–1.6) points less fretting than Type I trunnions (p = 0.043). When looking at corrosion, PCA tapers had 1.2 (0.3–2.2) points less corrosion than 11/13 tapers (p = 0.004), 1.1 (0.2–2.1) points less than C-tapers (p = 0.009), and 1.1 (0.0–2.1) points less than V40 tapers (p = 0.040).

Fig. 4.

The graph depicts the average fretting and corrosion scores (with SDs) for both the taper and the trunnion. Taper fretting was significantly less for PCA tapers compared with 12/14 and V40 tapers. Moreover, PCA tapers had significantly less taper corrosion in comparison to C-tapers, V40 tapers, and 11/13 tapers. Finally, both PCA and 12/14 trunnions had significantly less fretting when compared with V40 or Type I trunnions.

Trunnion fretting was also associated with alloy combination. When different alloys were combined, trunnion fretting was greater than when the same alloy was used (1.0 [0.6–1.5] points greater, p < 0.001). Interestingly, comparing different alloy treatments (eg, forging versus casting) did not add any predictive value for fretting beyond whether the same or different alloys were used alone.

Trunnion fretting and corrosion were associated with location (Table 3). The stem trunnion fretting scores of the four quadrants differed between the proximal and distal ends of the trunnion. On the proximal end, the posterior quadrant had more fretting than the superior quadrant by 0.2 (0.1–0.4) points (p = 0.001). On the distal end, fretting scores did not differ among quadrants. Trunnion corrosion was greater on the distal compared with the proximal halves of the trunnions with the distal end having 0.2 (0.0–0.3) points more corrosion (p = 0.043). Trunnion corrosion did not differ among quadrants, except in 36-mm heads. In 36-mm heads, the superior quadrant of the trunnion had more corrosion than the posterior quadrant (0.3 [0.0–0.6] points greater, p = 0.036). With the numbers available, associations between increased trunnion corrosion and increased length of implantation (p = 0.075) or between corrosion and trunnion design (p = 0.097) did not reach significance.

Discussion

Fretting and corrosion are regular occurrences in modular connections in THA. Although the problem gained attention in large head MoM implants, in our study of MoP THAs, 93% of 154 femoral heads showed evidence of fretting and corrosion damage. The concern of corrosion and its relation to ALTR in large head sizes led us to question whether the MoM THA findings apply to MoP implants. A recent report [23] described corrosion debris-related ALTR in a small series of patients with MoP THAs, yet we know little about how modular junctions in MoP THAs perform in vivo. In our large collection of retrieved MoP THAs, we found that neither fretting nor corrosion of head tapers or stem trunnions was related to head size. Conversely, the design of the modular junction, the length of implantation, a mixed-alloy combination, and the location along the modular junction were all associated with the severity of fretting and corrosion.

None of the patients in this study were revised for ALTR, so whether a patient is predisposed to an ALTR cannot be determined from our data. Interestingly, revision diagnosis did not affect the fretting and corrosion observed in this large cohort of retrieved THA femoral components, despite the fact that the majority of cases (Table 1) were revised for infection (not necessarily associated with mechanical factors) and aseptic loosening (sometimes associated with an increased mechanical burden in the THA).

Our study had limitations. First, like with all retrieval studies, ours is a retrospective study of a select group of retrieved implants, which might not reflect well-functioning or nonrevised implants. Nonetheless, retrieval analysis is an accepted method for evaluating in vivo implant performance. Second, very small and very large heads were infrequent in our cohort, so we included them in ≤ 26-mm and ≥ 36-mm groups. This approach provided more homogenous group sizes for comparison. However, small but clinically relevant differences might have been missed as a result of insufficient power. Additionally, as a result of limited numbers of some taper designs within some of the head size categories, we were not able to test whether the head size differed among the different taper designs. We also used a subjective scoring system, although one that has been extensively used in evaluating corrosion and fretting; its validity was recently studied, and although substantial inter- and intraobserver reliabilities for corrosion were found, reliability for fretting scores was only slight to fair [21]. In our study, differences in scores between observers never exceeded one grade on the scoring scale and occurred in only 17% of the 154 implants that were examined. Another limitation of the system is that small differences might not be clinically relevant. Lastly, severe corrosion could mask underlying fretting, so fretting might not be assessed in its full extent. However, this is a well-known disadvantage of observing fretting and corrosion under optical microscopy and is a limitation in all similar studies.

We did not find an association between head size and fretting and corrosion. Studies with MoM bearings concluded that larger heads are associated with greater fretting and corrosion severity [3, 20]. In contrast, recent studies associating head size and corrosion in MoP THAs are conflicting. Huot Carlson et al. [22] studied 78 stems and 72 heads and found no correlation between head size and fretting and corrosion. Kurtz et al. [24] reported the same conclusion in their series of 50 implants. Conversely, Dyrkacz et al. [12] compared 15 28-mm and 59 32-mm-diameter heads of MoP THAs, concluding that larger heads had more corrosion on the taper and trunnion, although fretting was not different between the two groups. Early studies of MoP implants did not investigate the association of head diameter with fretting and corrosion [8–11, 15, 19, 27, 28]; it was not until 2010 that ALTR was regularly reported with taper junctions [13]. Whether this is the result of implant design changes, including larger heads and smaller trunnions, or increased recognition by the orthopaedic community remains unknown.

Length of implantation correlated with taper and trunnion fretting. Our cohort spans longer implantations than those of previous studies with 30 retrievals in vivo more than 10 years, six of which were in vivo for over 20 years. Greater length of implantation correlated with increased head and stem fretting but not with corrosion. Conversely, the rate of increase in head taper and stem trunnion fretting was low (0.2 and 0.12 in Goldberg scores after 5 years, respectively), which may explain why ALTR in MoP THAs is rare. Collier et al. [8], in a cohort of 411 modular prostheses, reported a positive correlation between corrosion and length of implantation, although the bearing combinations (eg, MoM and MoP) were not reported. Similar results were reported for MoM cohorts [14, 20]. Interestingly, Goldberg et al. [19] found that although corrosion of the head and neck increased with time, head fretting actually decreased, an effect attributed to etching or buildup of corrosion debris. Conversely, others showed no correlation between length of implantation and fretting or corrosion [11, 12, 24, 29]. The fretting corrosion process starts at the time of implantation, as evident from our < 6-month retrievals, with average head fretting and corrosion scores of 2.07 and 2.1, respectively, and the average stem fretting and corrosion scores of 2.03 and 1.4, respectively.

Taper design was previously shown to influence fretting behavior of the head-neck junction of MoM implants with thicker tapers and thus larger contacting surface areas being related to higher fretting scores [29]. These conclusions were not confirmed by our study of MoP bearings. Head fretting was greater with V40 and 12/14 modular connections as compared with PCA tapers, although the number of PCA tapers in our cohort was small. V40 tapers were designed to have a small diameter, small contact length, and small taper angle. The PCA taper has the largest taper contact length of any of the tapers studied, but what role this may play is unclear. Taper design is challenging, because a balance must be achieved between flexural rigidity of the trunnions, which increases with taper diameter, and impingement-free ROM, which decreases with diameter. A further investigation of the association between taper designs, including surface finish, is warranted to understand their relation to fretting and corrosion. Taper contact area and surface finish have been highlighted as important factors of the fretting corrosion process [30].

Combining different metallic alloys (ie, a CoCr femoral head with a titanium [Ti] alloy stem) has been associated with increased corrosion at the head-neck junction [8, 11, 19, 27]. In our cohort, when a CoCr head was combined with a Ti alloy stem, trunnion fretting was more severe than when the mating components were both CoCr alloy, but no differences were found in taper fretting and taper or trunnion corrosion between same- and mixed-alloy combinations. CoCr alloys have nearly twice the elastic modulus of Ti alloys and are thus more resistant to fretting. Mixed- and same-alloy couplings showed similar fretting corrosion behavior in vitro [33], implying that, even in the mixed-alloy combination, the CoCr alloy determines the outcome. As the environmental pH gets lower and corrosion ensues, dissolution rates become greater for CoCr than for Ti alloys [7]. Thus, despite less resistance to fretting, Ti alloys are less prone to corrosion. This might partly explain the discrepancy of our results regarding fretting and corrosion in same and mixed couples.

Other factors play a role in fretting corrosion, including the fretting regime (full slip versus partial slip or full stick) [32] and the applied [18] and assembly loads [31] to which the junctions are subjected. Microstructure can affect corrosion behavior and can be modified through thermomechanical treatments. For example, wrought alloys have smaller grains than cast alloys; generally, alloys with smaller grains are harder and more resistant to fretting and corrosion [6]. Goldberg et al. [19] reported that wrought CoCr heads had lower fretting and corrosion scores than cast CoCr heads, but for the necks, more corrosion was noted with wrought alloys. However, all differences in fretting and corrosion between alloys and treatments in our study were explained by whether the same or dissimilar alloys were used for the taper and trunnion.

In conclusion, our retrieval study of MoP implants suggests that head size does not influence either fretting or corrosion at the head-neck modular junction. This finding supports the use of larger diameter heads by surgeons reluctant to do so because of concerns for modular junction damage. However, taper/trunnion design and alloy combinations remain substantial concerns because small tapers and dissimilar alloys forming the junction are detrimental. Longer implantation times are also detrimental for head and stem fretting.

Acknowledgments

We thank Chelsea Koch for her assistance in preparing the manuscript.

Footnotes

Financial support provided by the Mary and Fred Trump Institute for Implant Analysis (DEP, TMW).

All ICMJE Conflict of Interest Forms for authors and Clinical Orthopaedics and Related Research ® editors and board members are on file with the publication and can be viewed on request.

Clinical Orthopaedics and Related Research ® neither advocates nor endorses the use of any treatment, drug, or device. Readers are encouraged to always seek additional information, including FDA-approval status, of any drug or device prior to clinical use.

Each author certifies that his or her institution approved the human protocol for this investigation, that all investigations were conducted in conformity with ethical principles of research, and that informed consent for participation in the study was obtained.

References

- 1.Bishop N, Witt F, Pourzal R, Fischer A, Rutschi M, Michel M, Morlock M. Wear patterns of taper connections in retrieved large diameter metal-on-metal bearings. J Orthop Res. 2013;7:1116–1122. doi: 10.1002/jor.22326. [DOI] [PubMed] [Google Scholar]

- 2.Bishop NE, Hothan A, Morlock MM. High friction moments in large hard-on-hard hip replacement bearings in conditions of poor lubrication. J Orthop Res. 2013;5:807–813. doi: 10.1002/jor.22255. [DOI] [PubMed] [Google Scholar]

- 3.Bolland BJ, Culliford DJ, Langton DJ, Millington JP, Arden NK, Latham JM. High failure rates with a large-diameter hybrid metal-on-metal total hip replacement: clinical, radiological and retrieval analysis. J Bone Joint Surg Br. 2011;5:608–615. doi: 10.1302/0301-620X.93B5.26309. [DOI] [PubMed] [Google Scholar]

- 4.Bozic KJ, Lau EC, Ong KL, Vail TP, Rubash HE, Berry DJ. Comparative effectiveness of metal-on-metal and metal-on-polyethylene bearings in Medicare total hip arthroplasty patients. J Arthroplasty. 2012;8(Suppl):37–40. doi: 10.1016/j.arth.2012.03.031. [DOI] [PubMed] [Google Scholar]

- 5.Bozic KJ, Pui CM, Ludeman MJ, Vail TP, Silverstein MD. Do the potential benefits of metal-on-metal hip resurfacing justify the increased cost and risk of complications? Clin Orthop Relat Res. 2010;468:2301–2312. doi: 10.1007/s11999-010-1301-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Brown SA, Flemming CA, Kawalec JS, Placko HE, Vassaux C, Merritt K, Payer JH, Kraay MJ. Fretting corrosion accelerates crevice corrosion of modular hip tapers. J Appl Biomater. 1995;1:19–26. doi: 10.1002/jab.770060104. [DOI] [PubMed] [Google Scholar]

- 7.Chandra A, Ryu JJ, Karra P, Shrotriya P, Tvergaard V, Gaisser M, Weik T. Life expectancy of modular Ti6Al4V hip implants: influence of stress and environment. J Mech Behav Biomed Mater. 2011;8:1990–2001. doi: 10.1016/j.jmbbm.2011.06.018. [DOI] [PubMed] [Google Scholar]

- 8.Collier JP, Mayor MB, Williams IR, Surprenant VA, Surprenant HP, Currier BH. The tradeoffs associated with modular hip prostheses. Clin Orthop Relat Res. 1995;311:91–101. [PubMed] [Google Scholar]

- 9.Collier JP, Surprenant VA, Jensen RE, Mayor MB. Corrosion at the interface of cobalt-alloy heads on titanium-alloy stems. Clin Orthop Relat Res. 1991;271:305–312. [PubMed] [Google Scholar]

- 10.Collier JP, Surprenant VA, Jensen RE, Mayor MB, Surprenant HP. Corrosion between the components of modular femoral hip prostheses. J Bone Joint Surg Br. 1992;4:511–517. doi: 10.1302/0301-620X.74B4.1624507. [DOI] [PubMed] [Google Scholar]

- 11.Cook SD, Barrack RL, Clemow AJ. Corrosion and wear at the modular interface of uncemented femoral stems. J Bone Joint Surg Br. 1994;1:68–72. [PubMed] [Google Scholar]

- 12.Dyrkacz RM, Brandt JM, Ojo OA, Turgeon TR, Wyss UP. The influence of head size on corrosion and fretting behaviour at the head-neck interface of artificial hip joints. J Arthroplasty. 2013;6:1036–1040. doi: 10.1016/j.arth.2012.10.017. [DOI] [PubMed] [Google Scholar]

- 13.Esposito CI, Wright TM, Goodman SB, Berry BJ. Clinical, Biological and Bioengineering Study Groups from the Carl T. Brighton Workshop. What is the trouble with trunnions? Clin Orthop Relat Res. 2014;472:3652–3658. doi: 10.1007/s11999-014-3746-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Fricka KB, Ho H, Peace WJ, Engh CA Jr. Metal-on-metal local tissue reaction is associated with corrosion of the head taper junction. J Arthroplasty. 2012;8(Suppl):26–31.e1. [DOI] [PubMed]

- 15.Gilbert JL, Mehta M, Pinder B. Fretting crevice corrosion of stainless steel stem-CoCr femoral head connections: comparisons of materials, initial moisture, and offset length. J Biomed Mater Res B Appl Biomater. 2009;1:162–173. doi: 10.1002/jbm.b.31164. [DOI] [PubMed] [Google Scholar]

- 16.Gill IP, Webb J, Sloan K, Beaver RJ. Corrosion at the neck-stem junction as a cause of metal ion release and pseudotumour formation. J Bone Joint Surg Br. 2012;7:895–900. doi: 10.1302/0301-620X.94B7.29122. [DOI] [PubMed] [Google Scholar]

- 17.Glyn-Jones S, Thomas GE, Garfjeld-Roberts P, Gundle R, Taylor A, McLardy-Smith P, Murray DW. The John Charnley Award: Highly crosslinked polyethylene in total hip arthroplasty decreases long-term wear: a double-blind randomized trial. Clin Orthop Relat Res. 2015;473:432–438. doi: 10.1007/s11999-014-3735-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Goldberg JR, Gilbert JL. In vitro corrosion testing of modular hip tapers. J Biomed Mater Res B Appl Biomater. 2003;2:78–93. doi: 10.1002/jbm.b.10526. [DOI] [PubMed] [Google Scholar]

- 19.Goldberg JR, Gilbert JL, Jacobs JJ, Bauer TW, Paprosky W, Leurgans S. A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin Orthop Relat Res. 2002;401:149–161. doi: 10.1097/00003086-200208000-00018. [DOI] [PubMed] [Google Scholar]

- 20.Higgs GB, Hanzlik JA, Macdonald DW, Gilbert JL, SM CM, Kurtz CM. Implant Research Center Writing Committee. Is increased modularity associated with increased fretting and corrosion damage in metal-on-metal total hip arthroplasty devices? A retrieval study. J Arthroplasty. 2013;8(Suppl):2–6. doi: 10.1016/j.arth.2013.05.040. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Hothi HS, Matthies AK, Berber R, Whittaker RK, Skinner JA, Hart AJ. The reliability of a scoring system for corrosion and fretting, and its relationship to material loss of tapered, modular junctions of retrieved hip implants. J Arthroplasty. 2014;29:1313–1317. doi: 10.1016/j.arth.2013.12.003. [DOI] [PubMed] [Google Scholar]

- 22.Huot Carlson JC, Van Citters DW, Currier JH, Bryant AM, Mayor MB, Collier JP, Hart AJ. Femoral stem fracture and in vivo corrosion of retrieved modular femoral hips. J Arthroplasty. 2012;7(1389–1396):e1. doi: 10.1016/j.arth.2011.11.007. [DOI] [PubMed] [Google Scholar]

- 23.Jacobs JJ, Skipor AK, Patterson LM, Hallab NJ, Paprosky WG, Black J, Galante JO. Metal release in patients who have had a primary total hip arthroplasty. A prospective, controlled, longitudinal study. J Bone Joint Surg Am. 1998;10:1447–1458. doi: 10.2106/00004623-199810000-00006. [DOI] [PubMed] [Google Scholar]

- 24.Kurtz SM, Kocagoz SB, Hanzlik JA, Underwood RJ, Gilbert JL, Macdonald DW, Lee GC, Mont MA, Kraay MJ, Klein GR, Parvizi J, Rimnac CM. Do ceramic femoral heads reduce taper fretting corrosion in hip arthroplasty? A retrieval study. Clin Orthop Relat Res. 2013;471:3270–3282. doi: 10.1007/s11999-013-3096-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Langton DJ, Jameson SS, Joyce TJ, Hallab NJ, Natu S, Nargol AV. Early failure of metal-on-metal bearings in hip resurfacing and large-diameter total hip replacement: a consequence of excess wear. J Bone Joint Surg Br. 2010;1:38–46. doi: 10.1302/0301-620X.92B1.22770. [DOI] [PubMed] [Google Scholar]

- 26.Langton DJ, Sidaginamale R, Lord JK, Nargol AV, Joyce TJ. Taper junction failure in large-diameter metal-on-metal bearings. Bone Joint Res. 2012;4:56–63. doi: 10.1302/2046-3758.14.2000047. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Lieberman JR, Rimnac CM, Garvin KL, Klein RW, Salvati EA. An analysis of the head-neck taper interface in retrieved hip prostheses. Clin Orthop Relat Res. 1994;300:162–167. [PubMed] [Google Scholar]

- 28.Mathiesen EB, Lindgren JU, Blomgren GG, Reinholt FP. Corrosion of modular hip prostheses. J Bone Joint Surg Br. 1991;4:569–575. doi: 10.1302/0301-620X.73B4.2071637. [DOI] [PubMed] [Google Scholar]

- 29.Nassif NA, Nawabi DH, Stoner K, Elpers M, Wright T, Padgett DE. Taper design affects failure of large-head metal-on-metal total hip replacements. Clin Orthop Relat Res. 2014;472:564–571. doi: 10.1007/s11999-013-3115-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Panagiotidou A, Meswania J, Hua J, Muirhead-Allwood S, Hart A, Blunn G. Enhanced wear and corrosion in modular tapers in total hip replacement is associated with the contact area and surface topography. J Orthop Res. 2013;31:2032–2039. doi: 10.1002/jor.22461. [DOI] [PubMed] [Google Scholar]

- 31.Rehmer A, Bishop NE, Morlock MM. Influence of assembly procedure and material combination on the strength of the taper connection at the head-neck junction of modular hip endoprosthesis. Clin Biomech (Bristol, Avon). 2012;1:77–83. [DOI] [PubMed]

- 32.Swaminathan V, Gilbert JL. Fretting corrosion of CoCrMo and Ti6Al4V interfaces. Biomaterials. 2012;22:5487–5503. doi: 10.1016/j.biomaterials.2012.04.015. [DOI] [PubMed] [Google Scholar]

- 33.Swaminathan V, Gilbert JL. Potential and frequency effects on fretting corrosion of Ti6Al4V and CoCrMo surfaces. J Biomed Mater Res A. 2013;9:2602–2612. doi: 10.1002/jbm.a.34564. [DOI] [PubMed] [Google Scholar]