Abstract

The low-amylose rice flour, seeded banana (Musa balbisiana, ABB) and carambola (Averrhoa carambola L.) pomace blends were extruded to prepare ready to eat breakfast cereal in a single-screw extruder. Response surface methodology using a central composite design was used to evaluate effect of independent variables, namely blend ratio (80:10:10 – 60:30:10 of low-amylose rice flour, seeded banana and carambola pomace), screw speed (200 – 400 rpm), barrel temperature (90 – 130 °C) and feed moisture content (9 – 21 g/100 g, wet basis) on product responses. Quadratic polynomial equations were also obtained by multiple regression analysis. The predicted models were adequate based on lack-of-fit test and coefficient of determination obtained. The feed moisture content had critical effect on all response variables. The compromised optimal conditions obtained by numerical integration for development of extrudates were: screw speed of 350 rpm, barrel temperature of 120 °C, feed moisture content of 12 g/100 g and 65:25:10 of blend ratio of feed. In the optimized condition low-amylose rice blend is found to have better physicochemical properties (water absorption index of 481.79 g/100 g; water solubility index of 44.13 g/100 g) and dietary fiber content of 21.35 g/100 g respectively. The developed breakfast cereal showed considerable amount of minerals (Mg and K) and overall acceptability was found to be 7.8.

Key words: Low-amylose rice, Bhimkol, Seeded banana, Carambola pomace, Extrusion, Feed moisture

Introduction

Extrusion cooking is one of the most versatile food manufacturing processes owing to its capacity to convey, homogenize, gelatinize, denature and cook food materials as applied in many conventional and novel food manufacturing operations. Extruded products are extensively studied (Balasubramanian et al. 2012; Eastman et al. 2001; Parker et al. 2000; Guha and Ali 2006) signifying wide acceptability. However, the characteristics of starch based extrudates depend on many factors, such as feed moisture and lipid content, additives and variables like screw speed, barrel temperature and type of extruder (Jin et al. 1995; Suknark et al. 1997; Singh et al. 1998; Singh et al. 2007). Consequently, changing these factors can influence extrusion behavior and the quality of extruded product.

The low amylose rice varieties are widely cultivated in Assam, India and have been traditionally used for making various rice products. The low amylose content in this rice gives the desirable eating quality to the products. Guha and Ali (2006) reported lower bulk density (BD) and better water solubility index (WSI) for low-amylose rice variety as compared to high amylose variety but needs more specific mechanical energy (SME) since break-down occurs to a greater extent. The banana type scientifically named as Musa balbisiana, ABB is a heavily seeded big sized banana which is found to be very rich in macro- and micronutrients and traditionally fed to the infants (Barthakur & Barthakur and Arnold 1990) and the dried banana pulp is marketed as baby food. It has been reported that 100 g of fresh banana pulp satisfies the RDA for K, Mn, Zn and Se of six month infants. The seeds of this banana are rich in dietary fiber. The seeds along with pulp have not been incorporated in extruded foods. Carambola (Averrhoa carambola L.) commonly known as star fruit is quite a popular fruit and largely planted in Southeast Asia and many other countries. Shui and Leong (2004) reported that star fruit is a good source of natural antioxidants, and the antioxidants in star fruit were found to be proanthocyanidins, (_) epicatechin and vitamin C. After extraction of juice from carambola, a considerable amount of pomace is left behind which is a rich source of dietary fiber (Chau et al. 2004). Chau et al. (2004) also reported a high level of insoluble fiber-rich fractions (FRFs) including insoluble dietary fibers, alcohol insoluble solid and water-insoluble solid (46.0–58.2 g/100 g of pomace). Incorporation of the pomace in extruded food will facilitate by-product utilization to enhance dietary fiber content. Nutritional features of food are becoming increasingly relevant determinants of consumption patterns of the people. Foods containing fiber can prevent constipation and provide other health benefits as well, such as helping to maintain a healthy weight and lowering your risk of diabetes and heart disease. Thus keeping in view the commercial potential of low amylose rice extrudates enriched with nutrients from seeded banana and functional ingredients from carambola pomace, the present study was planned and executed to optimize the process parameters to develop mineral and dietary fiber rich low cost extruded products.

Material and methods

Preparation of composite flour

The rice used in the study is low amylose rice called choukua and is referred to as low-amylose rice here after. Seeded banana (Musa balbisiana, ABB, locally called as bhimkol) is hereafter referred to as banana. Low-amylose rice and banana and carambola were procured from local market. Rice was cleaned to remove foreign matter. Rice grains were ground in the hammer mill (ALFA Instruments, Delhi) to pass through 1 mm sieve to get fine flour. Seeded banana was sliced into pieces and dried in a tray drier (Labotech, India) at 55 °C for 10 h followed by grinding along with the seeds in the hammer mill (ALFA, Instruments, India). The juice from carambola fruits was squeezed out and the pomace obtained was dried in the tray drier at 55 °C for 18 h followed by grinding in the hammer mill. The low-amylose rice, banana and carambola pomace flours were blended in definite ratios and conditioned with water for 24 h to achieve feed moisture level between 9 g/100 g and 21 g/100 g (wb).

Extrusion cooking conditions

Extrusion cooking was performed in a single screw extruder (G. L. Extrusion Systems Pvt. Ltd., India), driven by a 5 HP Induction motor. The feed and cutter were controlled with 1HP AC motor, separately. The composite flour was fed into the extruder with a pre-calibrated feeding screw and temperature was controlled by means of water circulation system. Steady state condition was assumed to have been reached when there were no visible drifts in product temperature. Extrudate was allowed to pass through 2 mm circular die and cut with a constant cutter speed (600 rpm). Extrudates were collected, cooled to room temperature under natural convection conditions and stored in low density polyethylene (LDPE) bags for further analysis.

Experimental design and statistical analysis

Response Surface Methodology (RSM) was applied to the experimental data using the package ‘Design expert’ version 7.0.0 (Stat-Ease Inc 2000). The same software was used for generation of response surface plots, superimposition of counter plots and optimization of process variables (Altan et al. 2008a; Yagci and Gogus 2008; Ding et al. 2005; Dhingra and Paul 2005). The results are reported as mean of three replicates. A four variable (five level of each variable) central composite design was employed (Montgomery 1984; Yagci and Gogus 2008). The parameters and their levels were chosen based on literature available on rice based extrudates (Yagci and Gogus 2008; Ding et al. 2005; Upadhyaya 2008). The ingredients used for the dietary fiber rich extrudates were: low-amylose rice flour, banana powder, carambola pomace. The independent variables included screw speed (SS), barrel temperature (BT), feed moisture content (FMC) and blend ratio (BR). Response variables were expansion index (EI), sectional expansion index (SEI), hardness (HRD), puncture force (PF), breaking strength (BS), bulk density (BD), and colour (hunter Lab) values. The five levels of the four process variables namely SS, BT, FMC and BR were coded as −2, −1, 0, 1, 2 (Montgomery 2001) and the design in coded and un-coded forms is given in Table 1.

Table 1.

Experimental design for extrusion with coded and actual levels of the variables

| Run | X1 | X2 | X3 | X4 | SS | BT | FMC | Blend ratio |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | −2 | 0 | 300 | 110 | 9 | 70:20:10 |

| 2 | 0 | 0 | 0 | 0 | 300 | 110 | 15 | 70:20:10 |

| 3 | −1 | −1 | −1 | 1 | 250 | 100 | 12 | 65:25:10 |

| 4 | −1 | −1 | 1 | −1 | 250 | 100 | 18 | 75:15:10 |

| 5 | 0 | 0 | 0 | 2 | 300 | 110 | 15 | 60:30:10 |

| 6 | 0 | 0 | 0 | 0 | 300 | 110 | 15 | 70:20:10 |

| 7 | −1 | −1 | 1 | 1 | 250 | 100 | 18 | 65:25:10 |

| 8 | 0 | 0 | 0 | −2 | 300 | 110 | 15 | 80:10:10 |

| 9 | 2 | 0 | 0 | 0 | 400 | 110 | 15 | 70:20:10 |

| 10 | 0 | 0 | 2 | 0 | 300 | 110 | 21 | 70:20:10 |

| 11 | 0 | 0 | 0 | 0 | 300 | 110 | 15 | 70:20:10 |

| 12 | −1 | 1 | 1 | −1 | 250 | 120 | 18 | 75:15:10 |

| 13 | 0 | 0 | 0 | 0 | 300 | 110 | 15 | 70:20:10 |

| 14 | 1 | −1 | 0 | 0 | 350 | 100 | 12 | 75:15:10 |

| 15 | 1 | 1 | −1 | 1 | 350 | 120 | 12 | 65:25:10 |

| 16 | 0 | 2 | 0 | 0 | 300 | 130 | 15 | 70:20:10 |

| 17 | 0 | −2 | 0 | 0 | 300 | 90 | 15 | 70:20:10 |

| 18 | 1 | −1 | −1 | 1 | 350 | 100 | 12 | 65:25:10 |

| 19 | −2 | 0 | 0 | 0 | 200 | 110 | 15 | 70:20:10 |

| 20 | 0 | 0 | 0 | 0 | 300 | 110 | 15 | 70:20:10 |

| 21 | −1 | 1 | 1 | 1 | 250 | 120 | 18 | 65:25:10 |

| 22 | 0 | 0 | 0 | 0 | 300 | 110 | 15 | 70:20:10 |

| 23 | 1 | 1 | 1 | 1 | 350 | 120 | 18 | 65:25:10 |

| 24 | 1 | 1 | −1 | −1 | 350 | 120 | 12 | 75:15:10 |

| 25 | 1 | −1 | 1 | −1 | 350 | 100 | 18 | 75:15:10 |

| 26 | 1 | −1 | 1 | 1 | 350 | 100 | 18 | 65:25:10 |

| 27 | −1 | −1 | −1 | −1 | 250 | 100 | 12 | 75:15:10 |

| 28 | 1 | 1 | 1 | −1 | 350 | 120 | 18 | 75:15:10 |

| 29 | −1 | 1 | −1 | −1 | 250 | 120 | 12 | 75:15:10 |

| 30 | −1 | 1 | −1 | 1 | 250 | 120 | 12 | 65:25:10 |

| 31 | 0 | 0 | 0 | 0 | 300 | 110 | 15 | 70:20:10 |

Physicochemical analysis

Expansion index

Expansion of extrudate was measured in terms of diameter, at three points on each piece, of the extruded product to the die diameter by using a vernier caliper (Ding et al. 2005; Ding et al. 2006) to measure the average thickness of the extrudates. Measurements were taken on ten randomly selected pieces of extrudates.

| 1 |

| 2 |

Bulk density

Bulk density (BD) of extrudates was determined following glass bead displacement method using a 100 ml graduated cylinder. The cylinder was tapped soundly 20 times. The weight of each sample was weighed with an electronic balance. The bulk density (g/cm3) was calculated by dividing the weight of the extrudates by the volume displaced. Ten measurements were taken for each treatment (Bhatnagar and Hanna 1995).

Textural measurement

Texture evaluation of the extrudates was performed with texture analyzer (TA-HD-plus, Stable Micro Systems,UK). Hardness (HRD), Puncture force (PF) were determined by using P-75 and P-5 as the maximum force offered by the extrudates during 40 g/100 g compression. Breaking strength (BS) of extrudates was determined as the peak breaking force offered by extrudates during three point cutter test, respectively (Onwulata et al. 2001).

| 3 |

Color

The color of the raw materials and ground extrudates were measured using the color measurement spectrophotometer (Hunter Lab, Ultra-scan VIS) as lightness (L), redness (a) and yellowness (b). Extrudates were cooled and dried at room temperature (35 °C) for 1 h, then milled to pass through a 0.21 mm screen for color analysis. For each sample, four measurements were taken and averaged. The total color change (∆E) was calculated as

| 4 |

Where, L, a and b are Hunter Lab - values for the product and Lo, bo and ao are Hunter Lab - values for the raw composite flour.

Rheological properties

Pasting properties of extrudate powders were determined using a Rapid Visco Analyser (RVA) model 2-D (Newport Scientific Instrument) with Thermocline software (3.0 version) Standard Method No. 162 of ICC (1995). Briefly, sample suspension was prepared by placing 3.5 g extrudate powder, in an aluminum canister containing 25 g distilled water. A programmed heating and cooling cycle was used. Each sample was stirred at 960 rpm for 10 s while heating at 50 °C, and then constant shear rate (160 rpm) was maintained for the rest of the process. Sample was held at 50 °C for 1 min. Then the samples were heated from 50 °C to 95 °C within 3 min 42 s and held at 95 °C for 2 min 30 s. Subsequently samples were cooled down from 95 °C to 50 °C within 3 min 48 s and then held at 50 °C for 2 min. A RVA plot of viscosity (cp) versus time (s) was used to determine peak viscosity (PV) and final viscosity (FV).

Water absorption index (WAI) and water solubility index (WSI)

WAI and WSI were determined following the procedure of Anderson et al. (1969). Flour (2.5 g) was suspended in 30 ml of distilled water in a tared 60 ml centrifuge tube. The slurry was stirred with a glass rod for 1 min at room temperature and centrifuged at 3000 x g for 10 min. The supernatant was poured carefully into a tared evaporating dish. WAI was calculated from the weight of the remaining gel and expressed as g gel/100 g (dry sample). WSI, expressed as g solids/100 g original solids, was calculated from the weight of dry solids recovered by evaporating the supernatant overnight at 110 °C.

Nutritional evaluation

Energy value was estimated in a bomb calorimeter (model LECO AC-350, LECO Corp.) and protein content was determined by Micro Kjeldhal method. Moisture, fat, crude fiber and ash were determined by standard methods (AOAC 2000). Carbohydrate was determined by difference. Dietary fiber content was determined by AOAC enzymatic – gravimetric method of Prosky et al. (1988). Magnesium and potassium content were determined using flam-mode in an Atomic Absorption Spectrophotometer (model 3600, Thermofisher).

Sensory evaluation

A semi-trained panel consisting of 11members evaluated the extrudates. The sensory attributes such as color, flavour, surface finish, taste, crispiness and over all acceptability of extrudates were evaluated using a 9-point Hedonic scale (1–4 dislike extremely to slightly, 5-neither like nor dislike, 6–9 like slightly to extremely). Samples were heated for 3 min at 105 °C before serving to the panelists.

Results and discussions

Table 2 gives the values of the response variables (EI, SEI, HRD, PF, BS, BD, Hunter -L and Hunter -∆E) of extrudates along with independent variables of screw speed (SS), barrel temperature (BT), feed moisture (FMC) and blend ratio (BR). A complete second order model was tested for its adequacy to decide the variation of responses with independent variables. To aid visualization of variation in responses with respect to processing variables, series of three dimensional response surface (Figs. 1, 2, 3, 4 and 5) were drawn using design expert software (State-ease 7.0.0).

| 5 |

Table 2.

Coefficients of variables in the predictive model for response variables (coded units)

| Variables | EI | SEI | BD | HRD | PF | BS | Hunter value | |

|---|---|---|---|---|---|---|---|---|

| L | ∆E | |||||||

| x1 | 0.22** | 1.46** | - 0.022** | - 0.29 | - 1.59** | - 0.15** | 1.08*** | - 1.11*** |

| x2 | 0.10 | 0.65 | - 0.011 | - 5.70*** | - 3.64*** | - 0.20*** | - 0.71** | 0.71** |

| x3 | - 0.23** | - 1.57** | 0.022** | 1.79** | 1.89** | 0.18** | 0.46* | - 0.45* |

| x4 | 0.10 | 0.59 | - 8.8 × 10−3 | - 0.25 | - 0.57 | - 0.097* | 0.62** | - 0.75** |

| x1 2 | 9.79 × 10−3 | 0.12 | 1.36 × 10−3 | 0.93 | 0.13 | 0.011 | 0.17 | - 0.17 |

| x2 2 | - 0.08 | - 0.51 | 6.76 × 10−3 | 1.11 | 0.21 | 0.093** | 0.11 | 0.11 |

| x3 2 | 5.21 × 10−3 | 0.12 | 4.81 × 10−3 | 2.87** | 1.99*** | 0.081 | 5.31 × 10−3 | - 7.19 × 10−3 |

| x4 2 | 0.026 | - 0.20 | - 4.27 × 10−3 | 0.74 | 0.42 | 0.015 | - 0.50** | 0.51** |

| x1 x2 | 0.11 | 0.72 | - 0.015* | 0.23 | 1.76** | - 2.16 × 10−3 | 0.14 | - 0.16 |

| x1 x3 | - 0.18** | - 1.17** | 0.016* | - 0.071 | 0.67 | 0.12* | 0.77** | - 0.7** |

| x1 x4 | - 0.086 | - 0.56 | 8.52× 10−3 | 1.03 | 0.70 | 0.076 | 0.12 | - 4.93 × 10−3 |

| x2 x3 | 0.021 | 0.10 | - 1.23 × 10−3 | - 0.37 | 0.055 | - 0.015 | - 0.46 | 0.48 |

| x2 x4 | - 0.071 | - 0.48 | 8.62 × 10−3 | 0.024 | 0.63 | 0.069 | - 0.20 | 0.18 |

| x3 x4 | 0.017 | 0.12 | - 4.01 × 10−3 | 0.19 | 0.050 | - 1.1 × 10−3 | - 0.19 | 0.18 |

| Model (F-value) | 2.86 | 2.81 | 2.65 | 4.49 | 7.58 | 4.33 | 4.41 | 4.47 |

| R2 | 0.714 | 0.711 | 0.69 | 0.797 | 0.869 | 0.7912 | 0.794 | 0.796 |

| Adj R2 | 0.464 | 0.458 | 0.436 | 0.619 | 0.755 | 0.609 | 0.614 | 0.618 |

| Adeq Precision | 6.523 | 6.548 | 6.625 | 7.516 | 11.091 | 8.335 | 8.844 | 9.049 |

| Lack of Fit | 2.15 | 2.15 | 3.78 | 1.18 | 0.59 | 2.33 | 1.18 | 1.19 |

x1 screw speed (rpm), x2 extrusion temperature (oC), x3 feed moisture content (%), x4 blend ratio

*Significant at p < 0.1

**Significant at p < 0.05

***Significant at p < 0.001

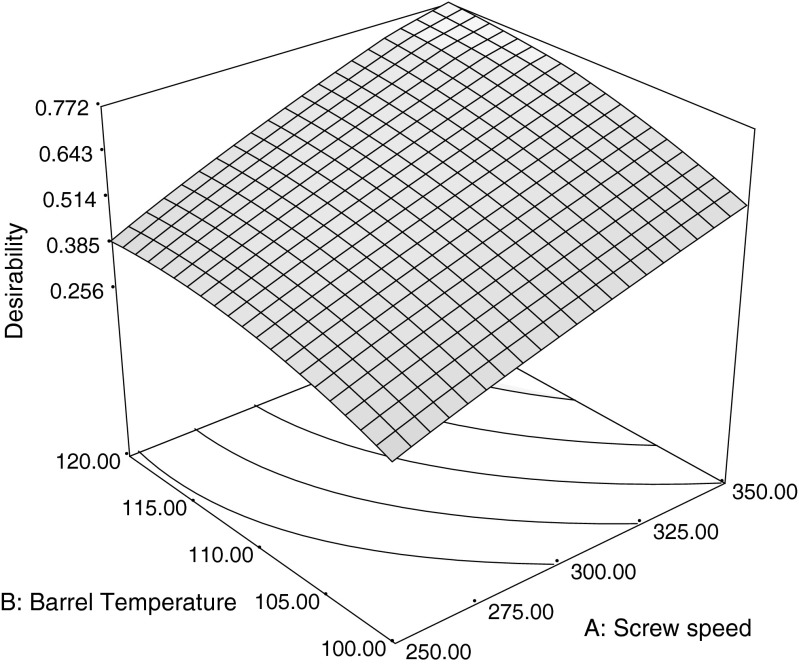

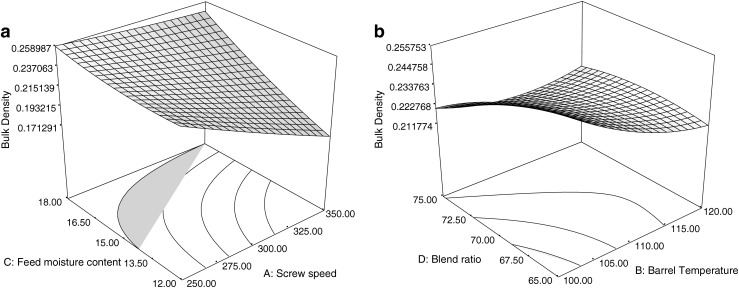

Fig. 1.

Effect of processing variables on EI (a-b) and SEI (c-d) of the extruded products

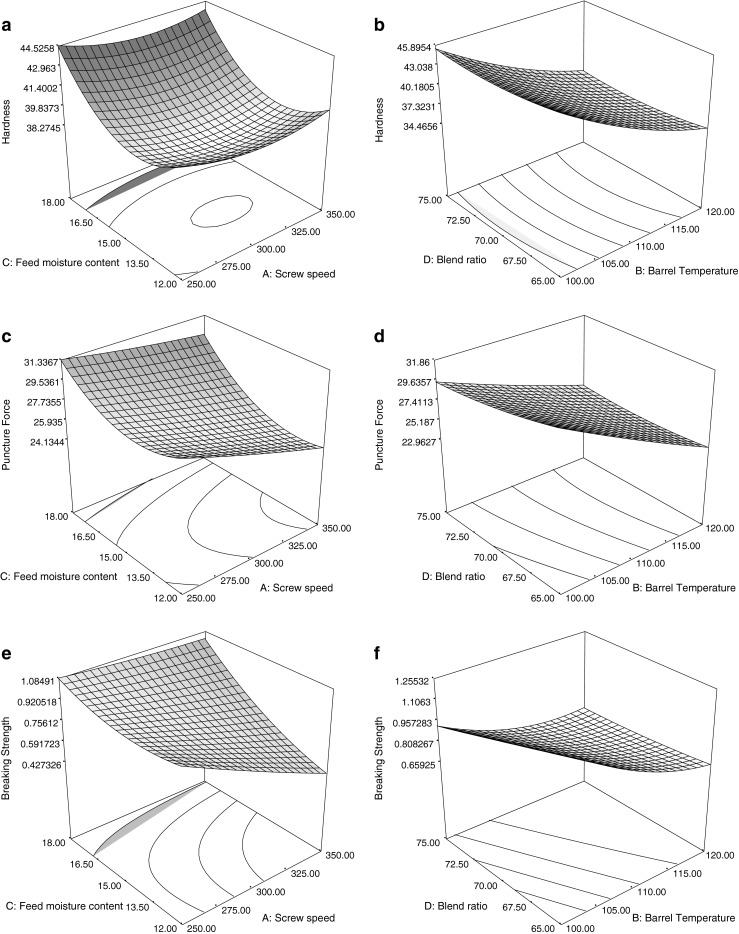

Fig. 2.

Effect of processing variables on BD (a-b) of the extruded products

Fig. 3.

Effect of processing variables on HRD (a-b), PF(c-d) and BS (e-f) of the extruded products

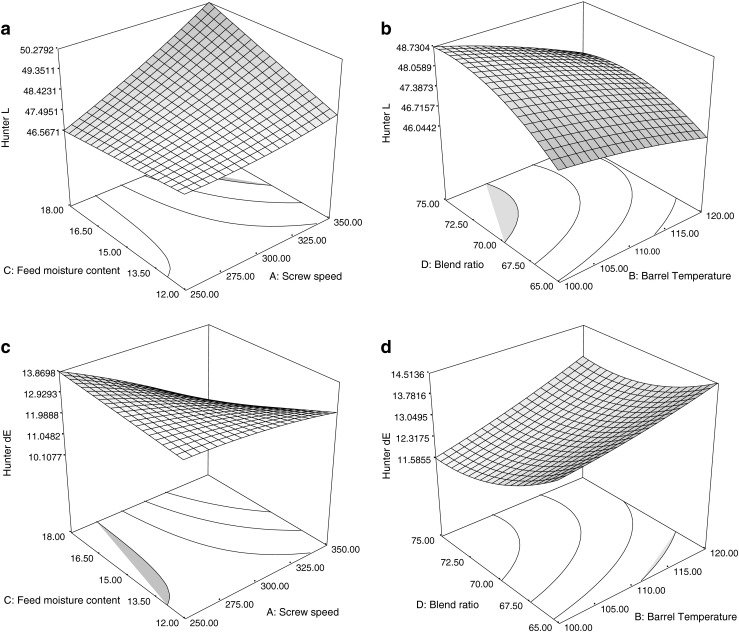

Fig. 4.

Effect of processing variables on on Hunter L- value (a-b) and Hunter ∆E (c-d) of the extruded products

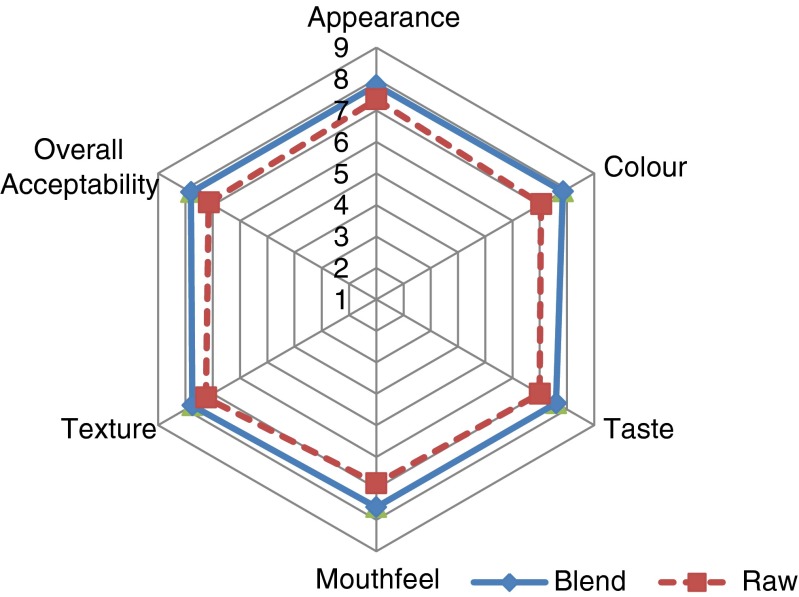

Fig. 5.

Desirability function response surface at FMC of 12 % for Blend of low amylose rice: seeded banana: carambola pomace at 65:25:10

Where, x1, x2, x3 and x4 are coded variables of screw speed, barrel temperature, feed moisture and blend ratio, respectively. The coefficients of the polynomial were represented by bo (constant); b1, b2, b3, b4 (linear effects); b1b2, b1b3, b1b4, b2b3, b2b4, b3b4 (interaction effects); b11, b22, b33, b44 (quadratic effects) and ɛ (random errors).

Effect of extrusion cooking on expansion of extrudates

Multiple regression equations for Expansion Index (EI) and Sectional Expansion Index (SEI) as a function of screw speed (X1), barrel temperature (X2), feed moisture (X3) and blend ratio (X4) of low-amylose rice extrudates are given below.

| 6 |

| 7 |

Expansion index (EI) and Sectional Expansion Index (SEI) of extrudates ranged between 2.55 to 4.15 and 6.49 to 17.25 respectively. The coefficient of x3 was negative but those of x1, x2 and x4 were positive. Therefore, increase in FMC may reduce expansion whereas increase in screw speed, barrel temperature and blend ratio may increase the expansion. Since coefficients of x22 and x42 are negative, a maximum expansion will occur in the range of BT and BR selected for study. On the other hand x12 and x32 are positive, a minimum expansion will occur in the selected range of SS and FMC. The coefficients of the model and other statistics are given in Table 2. The model F-value of 2.86 and 2.81 implies model was significant (p < 0.05) for both EI and SEI. The coefficient of determination (R2) for EI and SEI were 0.7143 and 0.7109, respectively. Analysis of variance of Eq.6 showed that F-value for linear terms of SS and FMC were 11.16 and 12.40 and p-values 0.0041 and 0.0028 (p < 0.05), signifying that x1 and x3 were significant terms. F and p value for interacting terms x1x3 were 0.18 and 0.0374 (p < 0.05), signifying that interacting term is also significant. F-value for square terms of SS, BT, FMC and BR were found to be non significant.

It may be observed from Fig. 1 that the expansion increases with the increase in BT and SS, which may be due to higher shear resulting in higher expansion (Ding et al. 2006). Ding et al. (2006) also reported rapid increase in lateral expansion with the increase in barrel temperature which may be due to higher degree of superheating of water in the extruder encountering bubble formation. The increase in FMC and BR reduces the friction between the feed material, screw and barrel and also has a negative effect on the starch gelatinization and consequently reduces product expansion (Liu et al. 2000). Tang and Ding (1994) also reported reduced expansion ratio due to increase in fibre content in feed. According to Lue et al. (1991) the presence of fiber ruptured the cell walls and prevented the gas bubbles from expanding to their maximum potential. The increase in FMC caused decrease in expansion which may occur due to reduction of elasticity of dough through plasticization of melt (Ding et al. 2005, Ding et al. 2006). Altan et al. (2008b) also reported significant effect of barrel temperature on SEI of barley flour extrudates. According to Chinnaswamy and Hanna (1988), expansion of corn starch extrudates increased as the barrel temperature increased from 110 to 140 °C and declined with further increase in temperature.

Effect of extrusion cooking on bulk density of extrudates

The regression equation relating the response function expansion measured as bulk density (BD) and independent variable is represented in terms of coded variable as given below.

| 8 |

Bulk density of extrudates ranged from 0.160 to 0.32 g/cm3. The maximum bulk density at coded point (0, 0, 2, 0) was about 2 times more than the minimum expansion at coded point (0,0,-2,0). The model F-value of 2.65 implies model is significant (p < 0.05). R2 and adjusted R2 value of the model are 0.699 and 0.4357 respectively. The coefficient of x3 is positive but those of x1, x2 and x4 are negative and the average is 0.23. Therefore increase in feed moisture content may increase bulk density whereas increase in screw speed and barrel temperature may reduce bulk density. Since coefficients of x12, x22 and x32 are positive; a minimum BD will occur in the range of SS, BT and FMC selected for study. In contrast coefficients of x42 is negative so we could expect a maximum BD in the range of BR selected for study. ANOVA of Eq. 8 showed that F-value for linear terms of SS and FMC were 10.47 and 10.64 and p-values 0.0052 and 0.0049 (p < 0.01), showed that x1 and x3 are significant terms. F-value for square terms of SS, BT, FMC and BR were found to be non significant. F value for interacting terms x1x2 and x1x3 were 3.19 and 3.79 and p values 0.0932 and 0.0692 (p < 0.1), signifying that interacting term is also significant.

It was perceived from Fig. 2 that with the increase in barrel temperature BD decreased which may be attributed to higher expansion (Ding et al. 2006). Suksomboon et al. (2011) reported similar effect of barrel temperature on the BD of extrudates developed from Hom Nil rice. Altan et al. (2008a) described that the degree of superheating of water in the extruder would increase along with rise in BT, also leading to higher expansion with resultant lower bulk density. The increase in BD due to higher FMC may be because of reduction in elasticity of dough and lower expansion (Ding et al. 2006). At comparatively higher temperatures melt viscosity get reduced hence bubble walls become too thin to contain the vapor pressure, resulting in more bubble fracture, thus increasing rate of collapse and overall expansion decreased, which is sufficient enough to favor the quadratic effect on BD (Fletcher et al. 1985).

Effect of extrusion cooking on Textural properties of extrudates

The regression equation for hardness (HRD), puncture force (PF) and breaking strength (BS) as textural attributes were determined in terms of coded variables as follows:

| 9 |

| 10 |

| 11 |

Acceptable coefficients of determination values (R2 = 0.832, R2 = 0.869 and R2 = 0.7912) were obtained for significant models of HRD, PF and BS with non-significant lack of fit variations. The coefficients of x3 is positve and those of x1, x2 and x4 negative,thus increase in FMC may increase hardness whereas SS and, BT and BR may reduce the extent of hardness. Analysis of variance of Eq. 9 showed that F-value for linear terms of BT and FMC were 40.18 and 4.75 and p-values 0.0001 (p < 0.01) and 0.0466 (p < 0.05), showed that x2 and x3 are significant terms. F-value and p value for square terms of FMC 14.6 and 0.0015, found to be significant (p < 0.01). ANOVA of Eq. 10 showed that that x1, x2 and x3 are the significant terms. F-value for linear terms of SS, BT and FMC were 9.75, 51.37 and 13.79 with p-values 0.006 (p < 0.05), 0.0001 (p < 0.001), and 0.0019 (p < 0.05) respectively. F and p value for interacting terms x1x2 were 7.95 and 0.0123(p < 0.05), signifying that interacting term is also significant. Similarly Analysis of variance of Eq. 11 had showed that x1, x2 x3 and x4 all are significant terms.

In Fig. 3a it can be observed that with the increase in FMC hardness increased which may be due to reduced expansion. Ding et al. (2006) also reported increase in hardness with increase in SS due to lower melt density. It is evident from Fig. 3(c-f.) that PF and BS decrease with increase in SS and BT. BT and FMC were found to have the most significant effect on the low amylose rice flour blended extrudates. Similarly Altan et al. (2008a) also reported decrease in PF with increase in BT for snack foods from barley-tomato pomace blends. Liu et al. (2000) reported that increase in FMC reduced expansion and provided a dense product that required higher force to break the sample. Sacchetti et al. (2005) reported direct correlation between hardness and density of extruded cereal blend, better expansion results in more friable product that requires less force/energy to break. Suksomboon et al. (2011) reported lower hardness values for extrudates developed from Hom Nil rice at higher barrel temperature. An increase in processing temperature will cause drop in melt viscosity favoring bubble growth, signifying better expansion and lower density to have softer extrudates (Yulini et al. 2006).

Effect of extrusion cooking on Hunter L, a, b values of extrudates

Multiple regression equations for Hunter L value and total color difference (∆E) as a function of screw speed (X1), barrel temperature (X2), feed moisture (X3) and blend ratio (X4) of low-amylose rice extrudates are given below.

| 12 |

| 13 |

The significance of Hunter L and ∆E is given in Table 2 and lack of fit (P < 0.05) was found to be significant for both. The choosen processing condition did not influence significantly (P > 0.05) either Hunter a or b color value, thus detailed analyses of the two color values are not further explained in this study. The coefficient of determination (R2) for the Hunter L- value and ∆E were 0.7943 and 0.7963 respectively. In Eq. 12 it has been observed that the coefficients of x2 is negative and those of x1, x3 and x4 are positve, thus increase in BT may decrease Hunter L- value whereas SS, FMC and BR may increase Hunter L- value. On the contrary from Eq. 13 it could be observed that the coefficients of x2 is positve and those of x1, x3 and x4 are negative, thus increase in BT may increase total color difference whereas SS, FMC and BR may reduce Hunter ∆E - value. The analysis of variance of Eq. 12 and Eq. 13 has shown that F- value for all the linear terms of SS, BT, FMC and BR are significant (Table 2). The effect of independent variables on Hunter L value is shown in Fig. 4(a-b). Increase in processing temperature results in decrease in Hunter L, a, b value, due to Maillard browning of sugar present in bhimkol powder. The expansion gets reduced at high feed moisture and resulted in higher Hunter L, a, b values. Ilo et al (1999) also reported similar decrease in Hunter L value due to rise in extrusion cooking temperature of maize grits. Increase in processing temperature results increased rate of browning reactions, which increased the total color difference, ∆E (Fig. 4). Increase in BR and SS resulted in slight increase in total color difference; ∆E varied from 9.532 to 15.722.

Multiple response optimizing

In order to optimize processing condition for extrusion cooking of low-amylose rice blend by numerical optimization, which finds a point that maximizes the desirability function, equal importance of 3, was given to all the 4 parameters and the entire 8 responses (Table 3). The optimal combination for SS, BT, FMC and BR was 350 rpm, 120 °C, 12 g/100 g and 65:25:10 (Table 4), which corresponds to run-15. The overall desirability, which ranges from zero outside of the limits to one at the goal, was 0.789 (Fig. 5).

Table 3.

Optimized parameters in the response optimizer

| Response | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance |

|---|---|---|---|---|---|---|

| EI | Maximum | 2.55 | 4.15 | 1 | 1 | 3 |

| SEI | Maximum | 6.49 | 17.25 | 1 | 1 | 3 |

| HRD | Minimum | 32.66 | 58.64 | 1 | 1 | 3 |

| PF | Minimum | 18.20 | 41.01 | 1 | 1 | 3 |

| BS | Minimum | 0.42 | 1.86 | 1 | 1 | 3 |

| BD | Minimum | 0.16 | 0.32 | 1 | 1 | 3 |

| Hunter L-value | Minimum | 44.5 | 50.85 | 1 | 1 | 3 |

| Hunter ∆E-value | Minimum | 9.53 | 15.72 | 1 | 1 | 3 |

Table 4.

Optimized solution obtained using the response optimizer

| Optimal solution | Predicted responses | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| x1 (rpm) | x2 (oC) | x3 (g/100 g) | x4 | EI | SEI | HRD (N) | PF (N) | BS, (N/mm2) |

BD, (g/cm3) |

Hunter value | |

| L | ∆E | ||||||||||

| 350 | 120 | 12 | 65:25:10 | 4.08 | 16.36 | 36.02 | 22.45 | 0.32 | 0.148 | 47.26 | 13.08 |

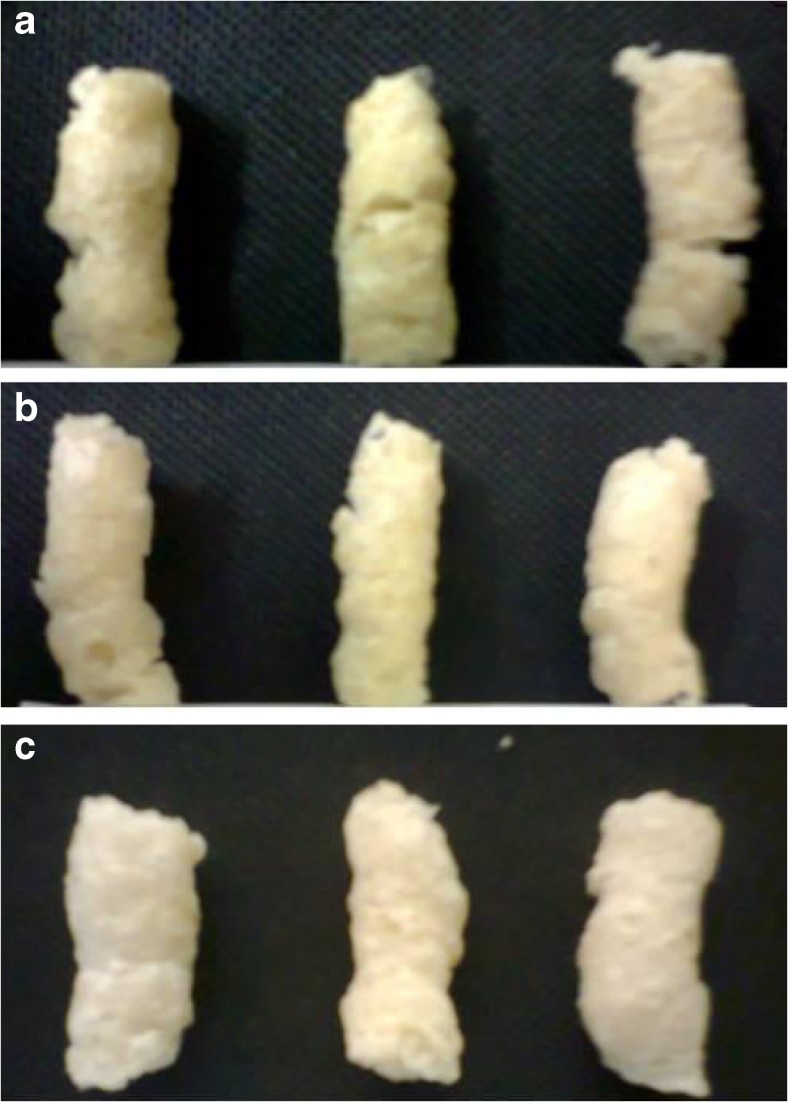

Sensory attributes

Overall acceptability of the extrudates at the optimized condition was found to be 7.8 and the colour was affected by the levels of seeded banana and caramblola pomace, which may be attributed to the inherent colour (Fig. 6). As compared to rice extrudates alone appearance, texture and mouth feel were found to be better for the extrudates at the optimized condition may be due to macromolecular degradation of the available starch.

Fig. 6.

Hedonic scores of extrudates made of blend of low amylose rice: seeded banana: carambola pomace at 65:25:10 as compared to low-amylose rice extrudates

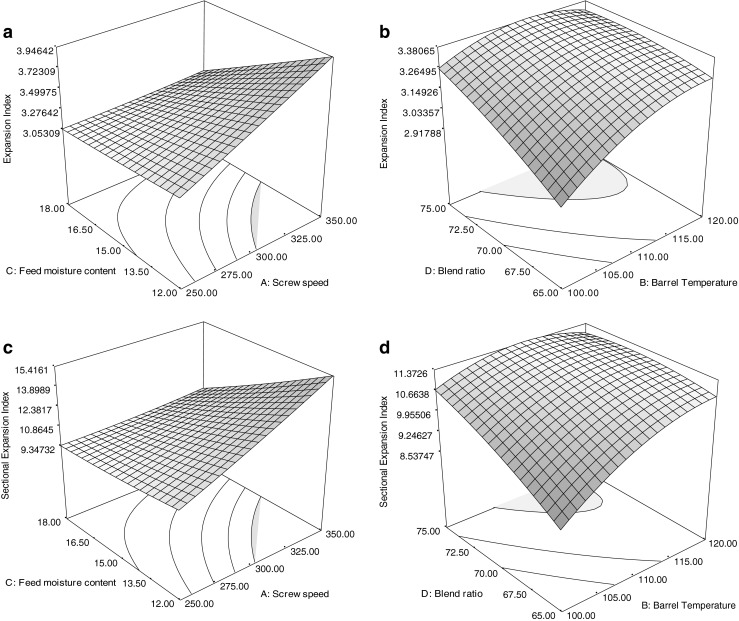

Physicochemical and nutritional characteristics of optimized extruded flour

Fig. 7 shows that better expansion and texture could be observed in the extrudate of optimal condition (run 15) as compared to extrudate from non optimized conditions (obtained from selected runs 4 and 5). Extrudates produced in the optimal condition (run-15) were cooled and dried at room temperature (35 °C) for 1 h, then milled to pass through a 0.21 mm screen, packed in plastic bags and stored at 4 °C. Physicochemical and nutritional properties of the low-amylose rice blend (low-amylose rice flour, banana flour and carambola pomace) compared to low-amylose rice flour alone is shown in Table 5. The low-amylose rice blend and low-amylose rice flour have low PV and FV which could be attributed to high BT and SS at the optimized condition (Guha et al. 1998). In the optimized condition low-amylose rice blend is found to have better physicochemical properties as well as nutritive value (WAI of 481.79 g/100 g; WSI of 44.13 g/100 g; energy value of 405.5Kcal/100 g; protein content of 8.92 g/100 g; crude fiber content of 2.12 g/100 g and dietary fiber content of 21.35 g/100 g). Above all due to incorporation of seeded banana powder low-amylose rice blend has showed considerable amounts of minerals like Mg and K respectively (Table 5).

Fig. 7.

View of extrudates (a) Run 4 (moisture 18 g/100 g), (b) Run 5 (moisture 21 g/100 g), and (c) optimized condition (moisture 12 g/100 g)

Table 5.

Physicochemical properties and nutritional profile of extruded products

| Properties | Extrudate | |

|---|---|---|

| Blenda | Low amylose rice | |

| WAI, g/100 g | 481.79 ± 9.19 | 497.07 ± 7.76 |

| WSI, g/100 g | 44.13 ± 1.41 | 42.62 ± 3.14 |

| Peak Viscosity, cp | 703.00 ± 7.07 | 298.50 ± 6.36 |

| Final Viscosity, cp | 124.50. ± 2.12 | 269.00 ± 1.41 |

| Energy, Kcal/100 g | 405.50 ± 2.12 | 390.25 ± 3.54 |

| Moisture, g/100 g | 7.08 ± 0.03 | 7.35 ± 0.035 |

| Protein, g/100 g | 8.92 ± 0.0.2 | 7.15 ± 0.24 |

| Fat, g/100 g | 0.67 ± 0.014 | 0.52 ± 0.002 |

| Crude Fiber, g/100 g | 2.12 ± 0.04 | 0.67 ± 0.004 |

| Dietary Fiber, g/100 g | 21.35 ± 0.17 | 3.6 ± 0.24 |

| Ash, g/100 g | 1.125 ± 0.028 | 0.43 ± 0.01 |

| Carbohydrate, g/100 g | 80.08 ± 0.015 | 83.86 ± 0.018 |

| Mg, mg/100 g | 14.54 ± 0.17 | 10.62 ± 0.18 |

| K, mg/100 g | 29.24 ± 0.3 | 17.41 ± 0.21 |

aBlend of low amylose rice: seeded banana: carambola pomace at 65:25:10

Conclusions

During extrusion cooking decrease in expansion due to increasing amounts of seeded banana flour and carambola pomace can attribute to dilution of starch content and increase in fibre content. The partially molten starch granules adheres to the cellulosic walls which results in formation of a complex wall (cellulose, gelatinize starch and cellular protein) and hence expansion gets reduced. The optimal condition for extrusion cooking of low-amylose rice blend corresponds to screw speed of 350 rpm, barrel temperature of 120 °C and feed moisture content of 12 g/100 g respectively. Due to high mineral content, seeded banana flour has a great potential as a food ingredient in making different ready to eat cereal products as well as snack foods. The incorporation of seeded banana in extruded snack products offers a desirable variation in diet and can take advantage of the nutritional quality of banana (Musa balbisiana, ABB). The incorporation of carambola pomace, a by-product of the carambola juice industry increases the dietary fiber content of the extruded food products. This study thus standardized an extruded product using low amylose rice, seeded banana flour (Musa balbisiana, ABB) and pomace obtained as the by-product of carambola juice industry that helped to enrich the product with minerals and functional ingredients.

Acknowledgment

One of us is thankful to the Ministry of Food Processing Industries, New Delhi for grant of a Senior Research Fellowship.

References

- Altan A., McCarthy K.L., Maskan M. Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. J Food Eng. 2008;84:231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Altan A, McCarthy K L., Maskan M. Extrusion cooking of barley flour and process parameter optimization by using response surface methodology. J Sci Food Agric. 2008;88:1648–1659. doi: 10.1002/jsfa.3262. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. 17th. Washington, DC: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Balasubramanian S., Borah A., Singh K.K., Patil R.T. Effect of selected dehulled legume incorporation on functional and nutritional properties of protein enriched sorghum and wheat extrudates. J Food Sci Technol. 2012;49(5):572–579. doi: 10.1007/s13197-010-0209-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Barthakur N.N., Arnold N.P. Chemical evaluation of Musa 'Bhimkol' as a baby food. J Sci Food Agric. 1990;53(4):497–504. doi: 10.1002/jsfa.2740530408. [DOI] [Google Scholar]

- Bhatnagar S., Hanna M.A. Physical, Mechanical and Thermal Properties of Starch-Based Plastic Foams. Trans of the ASAE. 1995;38(2):567–571. doi: 10.13031/2013.27867. [DOI] [Google Scholar]

- Chau C.F., Huang Y.L., Lee M.H. Insoluble fibre rich fractions derived from Averrhoa carambola: hypoglycemic effects determined by invitro methods. Lebensm-Wiss U Technol. 2004;37:331–335. doi: 10.1016/j.lwt.2003.10.001. [DOI] [Google Scholar]

- Chinnaswamy R., Hanna M.A. Optimum extrusion-cooking conditions for maximu expansion of corn starch. J Food Sci. 1988;53:834–836. doi: 10.1111/j.1365-2621.1988.tb08965.x. [DOI] [Google Scholar]

- Dhingra D., Paul S. Optimization of drying condition s of garlic slices. J Food Sci Technol. 2005;42:348–352. [Google Scholar]

- Ding Q., Ainsorth P., Tucker G., Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based snacks. J Food Eng. 2005;66:283–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- Ding Q., Ainsorth P., Tucker G., Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73:142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Eastman J., Orthoefer F., Solorio S. Using extrusion to create breakfast cereal products. Cereal Foods World. 2001;46:468–471. [Google Scholar]

- Fletcher S.I., Richmond P., Smith A.C. An experimental study of twin-screw extrusion cooking of maize grits. J Food Eng. 1985;4:291–231. doi: 10.1016/0260-8774(85)90009-3. [DOI] [Google Scholar]

- Guha M., Ali S.Z. Extrusion cooking of rice: Effect of amylase content and barrel temperature on product profile. J Food Process Preserv. 2006;30:706–716. doi: 10.1111/j.1745-4549.2006.00099.x. [DOI] [Google Scholar]

- Guha M., Ali S.Z., Bhattacharya S. Effect of barrel temperature and screw speed on rapid viscoanalyser pasting behaviour of rice extrudate. Int J Food Sci Technol. 1998;33:259–266. doi: 10.1046/j.1365-2621.1998.00189.x. [DOI] [Google Scholar]

- ICC. (1995). Rapid pasting method using the Newport rapid visco analyser. ICC-Draft Standard No. 162, Int Assoc Cereal Sci and Technol

- Ilo S., Liu Y., Berghofer E. Extrusion cooking of rice flour and amaranth blends. Wiss Technol. 1999;32(2):79–88. doi: 10.1006/fstl.1998.0497. [DOI] [Google Scholar]

- Jin Z., Hsiehl F., Huff H.E. Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. J Cereal Sci. 1995;22:185–194. doi: 10.1016/0733-5210(95)90049-7. [DOI] [Google Scholar]

- Liu Y., Hsieh F., Heymann H., Huff H.E. Effect of process conditions on the physical and sensory properties of extruded oatcorn puff. J Food Sci. 2000;65:1253–1259. doi: 10.1111/j.1365-2621.2000.tb10274.x. [DOI] [Google Scholar]

- Lue S., Hsiieh F., Huff H. E. Extrusion cooking of corn meal and sugar beet fiber: effects on expansion properties, starch gelatinization and dietary fiber content. Cereal Chem. 1991;68:227–234. [Google Scholar]

- Montgomery, D.C. (1984). In Design and analysis of experiments (2nd ed., pp. 445–474). New York: John, Wiley and Sons.

- Onwulata C.I., Konstance R.P., Smith P.W., Holsinger V.H. Co extrusion of dietary fiber and milk proteins in expanded corn products. Lebensm Wiss Technol. 2001;34:424–429. doi: 10.1006/fstl.2000.0742. [DOI] [Google Scholar]

- Parker J.K., Hassell G.M., Mottram D.S., Guy R.C. Sensory and instrumental analyses of volatile generated during the extrusion cooking of oat flours. J Agri Food Chem. 2000;48:3497–3499. doi: 10.1021/jf991302r. [DOI] [PubMed] [Google Scholar]

- Prosky L., Asp N.-G., Schweizer T.F., DeVries J.W., Furda I. Determination of insoluble, soluble, and total dietary fibre in foods and food products. J Assoc Off Anal Chem. 1988;71:1017. [PubMed] [Google Scholar]

- Sacchetti G., Pittia P., Pinnavaia G.G. The effect of extrusion temperature and drying-tempering on both the kinetics of hydration and the textural changes in extruded ready-to-eat breakfast cereals during soaking in semi-skimmed milk. Int J Food Sci Technol. 2005;40:655–663. doi: 10.1111/j.1365-2621.2005.00976.x. [DOI] [Google Scholar]

- Shui G. H., Leong L. P. Analysis of polyphenolic antioxidants in star fruit using liquid chromatography and mass spectrometry. J Chromatogr. 2004;1022:67–75. doi: 10.1016/j.chroma.2003.09.055. [DOI] [PubMed] [Google Scholar]

- Singh N., Smith A.C., Frame N.D. Effect of process variables and monoglycerides on extrusion of maize grits using two sizes of extruder. J Food Eng. 1998;35:91–109. doi: 10.1016/S0260-8774(98)00002-8. [DOI] [Google Scholar]

- Singh S., Gamlath S., Wakeling L. Nutritional aspects of food extrusion: a review. Int J Food Sci Technol. 2007;42:916–925. doi: 10.1111/j.1365-2621.2006.01309.x. [DOI] [Google Scholar]

- Stat-Ease Inc . Design expert user guide. USA: The Stat-Ease Inc; 2000. [Google Scholar]

- Suknark K., Phillips R.D., Chinnan M.S. Physical properties of directly expanded extrudates formulated from partially defatted peanut flour and different types of starch. Food Res Int. 1997;30:515–583. doi: 10.1016/S0963-9969(98)00016-7. [DOI] [Google Scholar]

- Suksomboon A., Limroongreungrat K., Sangnark A., Thititumjariya K., Noomhorm A. Effect of extrusion conditions on the physicochemical properties of a snack made from purple rice (Hom Nil) and soybean flour blend. Int J Food Sci Technol. 2011;46:201–208. doi: 10.1111/j.1365-2621.2010.02471.x. [DOI] [Google Scholar]

- Tang J., Ding X. L. Relationship between functional properties and macromolecular modifications of extruded corn starch. Cereal Chem. 1994;71:364–369. [Google Scholar]

- Upadhyaya A (2008) Optimization of carrot pomace powder incorporation on extruded product quality by response surface methodology. Ph.D. thesis, Mahatma Gandhi Chitrakoot Gramoday Vishwavidyalys, Satna, MP

- Yagci S., Gogus F. Response surface methodology for evaluation of physical and functional properties of exruded snack foods developed from food-by-products. J Food Eng. 2008;86:122–132. doi: 10.1016/j.jfoodeng.2007.09.018. [DOI] [Google Scholar]

- Yulini S., Torley P. J., D’Arcy B., Nicholson T., Bhandari B. Effect of extrusion parameters on flavor retention, functional and physical properties of mixtures of starch and D-limonene encapsulated in milk protein. Int J Food Sci Technol. 2006;41:83–94. doi: 10.1111/j.1365-2621.2006.01409.x. [DOI] [Google Scholar]