Abstract

The interest for producing wheat flour with health promoting effect and improved functionality has led to investigate new milling techniques that can provide finer flours. In this study, jet milling treatment was used to understand the effect of ultrafine size reduction onto microstructure and physicochemical properties of wheat flour. Three different conditions of jet milling, regarding air pressure (4 or 8 bars) feed rate and recirculation, were applied to obtain wheat flours with different particle size (control, F1, F2 and F3 with d50 127.45, 62.30, 22.94 and 11.4 μm, respectively). Large aggregates were gradually reduced in size, depending on the intensity of the process, and starch granules were separated from the protein matrix. Damaged starch increased while moisture content decreased because of milling intensity. Notable changes were observed in starch hydrolysis kinetics, which shifted to higher values with milling. Viscosity of all micronized samples was reduced and gelatinization temperatures (To, Tp, Tc) for F2 and F3 flours increased. Controlling jet milling conditions allow obtaining flours with different functionality, with greater changes at higher treatment severity that induces large particle reduction.

Keywords: Jet milling, Wheat flour, Starch hydrolysis, Pasting properties, Thermal parameters

Introduction

Nowadays, alternative milling procedures and micronizing technologies are tested in order to produce flours with enhanced functional properties, which are suitable for making new edible products or for improving the properties of the current ones. Milling technologies focused on producing finer flours with improved properties are getting increased attention (de la Hera et al. 2013; Protonotariou et al. 2014; Sakhare et al. 2015). Jet milling is a new technological development that aims at the production of super fine flours by accelerating the particles in a high-velocity air stream, the size reduction being the result of inter-particle collisions or impacts against solid surface (Létang et al. 2002; Protonotariou et al. 2014, 2015). The particles impact at high velocities produces superfine powders and reduces the size of all aggregates (Létang et al. 2002). It is a fluid energy impact-milling technique, commonly used to produce particle sizes lower than 40 μm (Chamayou and Dodds 2007), which are greatly appreciated in the chemical, pharmaceutical and mineral industry (Midoux et al. 1999). In food applications, smaller particle size results in faster starch digestion (de la Hera et al. 2014). Small particles have high surface-to-volume ratio increasing the access of enzymes to the interior of the particle taking advantage of the absence of intact cell walls (Heaton et al. 1988). An increased surface area of food materials could increase the rate of water absorption of materials, improving solubility of dry products, and increase site accessibility for chemical reactions (e.g., oxidation, digestion, flavor release, catalyst, and enzyme activity) (Augustin and Sanguansri 2009). Jet milling combined with air classification has been successfully used to separate starch from protein in order to produce starch-rich fine flours (Graveland and Henderson 1991). Furthermore, differential scanning calorimetry showed lower gelatinization enthalpy values for the doughs (flour:water, 60:40) of fine flours than their coarse flour counterparts (6.76–7.09 and 9.92–10.12 mJ/mg respectively) (Vouris et al. 2013). Overall, particle size of wheat flour seems to have an impact on dough mechanical and starch gelatinization properties. Therefore, there is a consensus that particle size reduction promotes changes in the majority of physicochemical properties due to the increase of a particle’s surface area (Tóth et al. 2006), although it must be assessed if there is a critical point that leads to an increase of damaged starch (Protonotariou et al. 2014). The higher the specific surface area per weight unit, the higher the rate of hydration and water absorption is (Manley et al. 2011). Generally, starch granules become physically injured with milling’s shearing and scrapping, i.e., starch damage occurs (Oladunmoye et al. 2010), which could also increase water holding capacity. Moreover the production of ultrafine powders from cereals flours may present benefits to human health. Sanguansri and Augustin (2006) suggested that jet milling may be useful for modifying or improving functionality and availability of bioactive compounds.

Therefore, the objective of the present study was to determine the impact of jet milling conditions on the wheat flour characteristics compared to conventional wheat flour. Specifically, this study evaluate the enzymatic starch hydrolysis, chemical composition, thermal and pasting features of different mill fractions of wheat flour obtained from jet milling varied in the severity of the process.

Materials and methods

Flour

Commercial soft wheat flour (T70) donated by the Company Loulis Mills S.A was pulverized in a jet mill (Model 0101S Jet-O-Mizer Milling, Fluid Energy Processing and Equipment Company, Telford, Pennsylvania, USA) using three different conditions regarding air pressure, feed rate, vibration rate of the feeder and feedback (Table 1).

Table 1.

Samples codes describing the jet mill settings for the samples treatment

| Flour code | Air pressure (bar) | Feed Rate (kg/h) | Vibration Rate of Feeder (%) | Feedback | Particle size d50 (μm) |

|---|---|---|---|---|---|

| Control | – | – | – | – | 127.45 |

| F1 | 4 | 2.71 | 100 | No | 62.30 |

| F2 | 8 | 4.08 | 100 | No | 22.94 |

| F3 | 8 | 1.93 | 100 | Yes | 11.44 |

Particle size distribution

Particle size distributions were determined by laser technology with a Malvern Mastersizer 2000 diffraction laser particle sizer (Malvern Instruments, Worcestershire, UK), equipped with a Scirocco dry powder unit (Malvern Instruments, Worcestershire, UK). Median diameter (d50) is the value of the particle size, which divides the population exactly into two equal halves i.e., there is 50 % of the distribution above this value and 50 % below. The particles were assumed to have a refractive index of 1.53.

Scanning electronic microscopy (SEM)

Wheat flours were mounted on metal stubs with double-sided stick tape and sputter-coated with a 100–200 Å thick layer of gold and palladium by ion sputter (Bio-Rad SC-500, Aname, Madrid, Spain). Analysis of the specimens was performed at 10 kV accelerating voltage with a SEM (S-4800, Hitachi, Ibaraki, Japan) equipped with a field emission gun, a backscattered detector of RX Bruker, transmission detector, the QUANTAX 400 programmed for microanalysis and the five motorized axes Scanning electron microscope with a spotlight of field emission (FEG) and a resolution of 1.4 nm at 1KV. The microstructure analysis was carried out in the Central Service for Experimental Research of the Universidad de Valencia.

Flours composition

Moisture and protein content were determined in all the samples. Moisture content was determined by ICC Standard Method (ICC 2011) and protein content was determined according to AACC method (AACCI 2012) with a Foss 2300 Kjeltec Analyzer Unit (Foss, Hillerød, Denmark). Starch damage (iodine absorption) was measured with a SDmatic (Chopin, Villeneuve-la-Garenne, France) according to AACC (AACCI 2012). These measurements were carried out in Loulis Mills S.A company. All determinations were carried out in triplicate.

Pasting properties

The pasting properties were determined with rapid visco analyser (RVA) (model 4-SA, Perten, Instruments, Hägersten, Sweden) by following the AACC Method (AACCI 2012), with minor modifications. Distilled water (25 mL) was added to 3.5 g of flour placed into the aluminum RVA canister. RVA settings during assessment were: heating from 50 to 95 °C in 282 s, holding at 95 °C for 150 s and then cooling to 50 °C. Each cycle was initiated by a 10 s at 960 rpm paddle speed for getting an even suspension followed by 160 rpm paddle speed for the rest of the assay. Viscosity was recorded during a heating–cooling cycle using Thermocline software for Windows (Newport Scientific Pvt. Limited, Warriewood, Australia). Peak onset, peak viscosity, holding through, breakdown, final viscosity and setback (difference between final viscosity and peak viscosity) were evaluated.

Thermal parameters

Thermal behavior from wheat flour samples were determined using a differential scanning calorimeter (DSC) from Perkin–Elmer (DSC 7, Perkin–Elmer Instruments, Norwalk, CT), equipped with a thermal analysis data station (Pyris software, Perkin–Elmer Instruments, Norwalk, CT). For the study, flour samples were accurately weighed into aluminum DSC pans, and de-ionized water was added by micropipette to achieve a water-sample ratio of 3:1 (9 mg : 3 mg). The sample pans were sealed and equilibrated at room temperature for one hour before analysis. Nitrogen was used to purge analyses cells. Instruments were calibrated with indium, using an empty pan as reference. Thermal analysis consisted on heating from 30 to 120 °C at a rate of 5 °C/min. The onset temperature To, peak temperature Tp, and conclusion temperature Tc were determined from the heating DSC curves. Gelatinization enthalpy (ΔH) was evaluated based on the area of the main endothermic peak, and peak height index (PHI) was calculated as PHI = ΔH/(Tp – To). All DSC experiments were run three times.

Starch hydrolysis kinetics

Starch hydrolysis was measured following the method described by Gularte and Rosell (2011) with minor modifications. Briefly, for free sugars removal, flour samples (0.1 g) suspended in 2 mL of 80 % ethanol was kept in a shaking water bath at 85 °C for 5 min, and then centrifuged for 10 min at 1000×g. Supernatant was separated to measured free sugar (FS) released.

The remaining pellet was incubated with porcine pancreatic –α-amylase (0.24 U/mg sample) (Type VI-B, ≥10 units/mg solid, Sigma Chemical, St. Louis, USA) in 4 mL of 0.1 M sodium maleate buffer (pH 6.9) in a shaking water bath at 37 °C. Aliquots of 200 μL were withdrawn during the incubation period (0.25–16 h) and mixed with 200 μL of ethanol (96 %, w/w) to stop the enzymatic reaction and the sample was centrifuged at 10,000 ×g for 5 min at 4 °C. The precipitate was washed twice with 50 % ethanol (200 μL) and the supernatants were pooled together and kept at 4 °C for further glucose enzymatic release. Supernatant (100 μL) was diluted with 850 μL of 0.1 M sodium acetate buffer (pH 4.5) and incubated with 50 μL amyloglucosidase (AMG 1100 BG, 1100 AGU/g, Novozyme A/S, Bagsvaerd, Denmark) at 50 °C for 30 min in a shaking water bath. For resistant starch (RS) determination after 16 h of hydrolysis the sediment was solubilized with 2 mL of 2 M KOH using a Polytron ultraturrax homogenizer IKA-T18 (IKA works, Wilmington, NC, USA) during 1 min at speed 3. The homogenate was diluted with 8 mL 1.2 M sodium acetate (pH 3.8) and incubated with 100 μL amyloglucosidase (33 U/mL) at 50 °C for 30 min in a shaking water bath. After centrifuging at 2,000 ×g for 10 min, supernatant was kept for glucose determination. Digestible starch (DS) was determined in the supernatant after 16 h of incubation. The glucose content was measured using a glucose oxidase–peroxidase (GOPOD) kit (Megazyme, Dublin, Ireland). The absorbance was measured using an Epoch microplate reader (Biotek Instruments, Winooski, USA) at 510 nm. Starch was calculated as glucose (mg) × 0.9. Replicates (n = 4) were carried out for each determination.

Experimental data were fitted to a first-order equation (Goni et al. 1997):

| 1 |

Where Ct is the concentration of product at time t, C∞ is the concentration at the end point, and k is the pseudo-first order rate constant. The plot of ln [(C∞- Ct)/ C∞] = −kt against t was used to estimate the slope that corresponded to –k.

Statistical analysis

Experimental data were statistically analyzed using Statgraphics V.7.1 program (Bitstream, Cambridge, MN) to determine significant differences among them. ANOVA test was applied in order to compare the mean values of studied properties at 95 % level of confidence. A correlation analysis was also carried out to determine possible relationships among parameters.

Results and discussion

Microstructure and particle size of samples

Jet milling process resulted in a significant reduction of median particle size that depended on the process conditions (Table 1). As the intensity of milling conditions increased (feedback or increase of pressure), the size of particles decreased gradually. Milling at 4 bar pressure (F1) decreased the median diameter (d50) from 127.45 to 62.3 μm, while at 8 bar pressure, particle size decreased to 22.94 (F2) or 11.44 μm (F3) depending on the feeding rate 4.08 kg/h or 1.93 kg/h, respectively. A relationship between pressure applied and the particle size of the samples obtained by jet mill was found (r = −0.9915, P < 0.01).

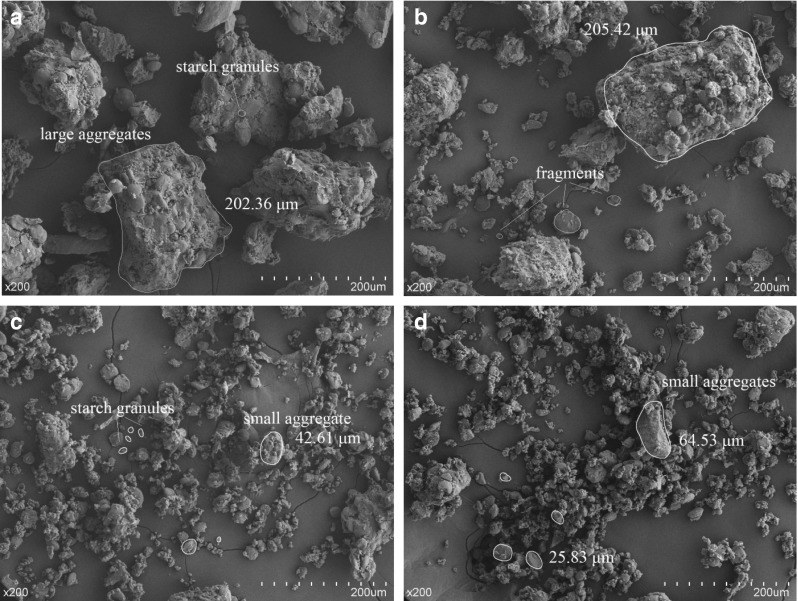

To find out any changes in terms of flour structure with intense milling SEM pictures are presented (Fig. 1). According to SEM micrographs, a gradual flour components’ disaggregation was observed according to the severity of jet mill treatment. Control flour (Fig. 1a) showed large aggregates (≥200 μm length) of protein matrix embedding starch granules. These aggregates displayed smaller size and they were largely fragmented and more separated from the protein matrix as the process became more intense (Fig. 1b-d). F1 sample showed larger particles than F2 and F3, whereas slight differences between F2 and F3 microstructure were detected. Some starch granules (10–35 μm) appeared deformed, separated from matrix, with rounder shape, disengaged from the protein that was eroded and appeared in smaller aggregates or completely shed having a polygonal shape, as a consequence of milling. The starch granules released from the protein matrix agrees with previous studies confirming that this technology might be an efficient process for the separation of starch and proteins (Sanguansri and Augustin 2006).

Fig. 1.

Scanning electron micrograph of (a) control sample of wheat flour and jet milled samples grinded under different milling conditions; (b) F1, (c) F2 and (d) F3. Magnification 200x

Chemical composition

As a consequence of jet milling, physicochemical properties of wheat flour changed (Table 2). Moisture content of jet milled flours was reduced gradually, depending on the severity of the process and it was significantly correlated with d50 (r = 0.9925, P < 0.01). Treated flours at 8 bars pressure, presented the higher loss of moisture (51 % in F3 sample) indicating that pressure affected significantly the moisture content (r = −0.9803, P < 0.05). Moisture content decreased as the particle size diminished, because higher surface area was available to interact. Moreover, jet milling reduces moisture content of flours due to their exposure to dry air of high flow rate as has been already observed (Protonotariou et al. 2015).

Table 2.

Chemical composition of wheat flour and jet milled wheat flours F1, F2 and F3, expressed as percentage of dry basis (d.b.)

| Name | Moisture (%) | Damaged starch (%, db) | Protein content (%, db) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 15.56 | ± | 1.17 | c | 2.37 | ± | 0.33 | a | 9.80 | ± | 0.03 | a |

| F1 | 10.17 | ± | 0.17 | b | 4.61 | ± | 0.30 | b | 10.28 | ± | 0.02 | c |

| F2 | 7.83 | ± | 0.34 | a | 6.26 | ± | 0.08 | c | 10.05 | ± | 0.09 | b |

| F3 | 7.62 | ± | 0.22 | a | 6.51 | ± | 0.13 | c | 9.69 | ± | 0.02 | a |

Values followed by different letters in each column indicate significant differences (P ≤ 0.05)

Concerning damaged starch, it increased owing to milling (Table 2). A positive significant correlation was found between damaged starch and air pressure (r = 0.9967, P < 0.01). However, there was no significant difference between the samples F2 and F3. Feedback did not increase further the amount of damaged starch, as was observed in F3, indicating that the intensity of the process induced an increase in damaged starch up to certain limit. Thus, it was confirmed that one of the advantages of jet mill is the reduced damaged starch promoted in comparison to other milling processes. Hossen et al. (2011a) reported that jet milled white rice flour with d50 45 μm had less starch damage than rice flour processed by a hammer mill, with d50 53 μm, in spite of similar mean size.

Protein amount ranged from 9.69 to 10.28 %. Differences in the protein content were statistically significant for F1 and F2 (Table 2), but, there was no general trend considering treatment conditions. It has been reported that finer fractions had lower ash and higher dry gluten than coarser fractions when wheat flour was fractioned by sieving (Sakhare et al. 2014). Nevertheless, Protonotariou et al. (2015) do not observed any trend when studying the impact of jet milling intensity on the protein and ash content of whole wheat flour.

Pasting properties

figure 2 illustrates RVA pasting curves for control flour and jet milled flours. Viscosity of all micronized samples decreased because of milling and changes in the pasting curves were readily evident during heating and cooling stages. The diverse damaged starch content, changes in the particle size of the flour or differences in starch accessibility might explain the different pasting performance. Barrera et al. (2013) mentioned that damaged starch granules facilitated hydration and swelling, increasing the viscosity of unheated starches. In the present study, in spite of the damaged starch content of the samples was significant different, pasting plots did not reveal differences on the shoulder exhibited during heat, which has been related to the amount of damaged starch (Fig. 2). In addition, it has been reported that particle size distribution affects pasting properties of rice flour (Hossen et al. 2011a), but it seems that pasting properties become independent on the particle size with fine flours (<132 μm) (Martínez et al. 2014). Nevertheless, in the present study particle size was much lower than 132 μm and viscosity plots revealed great impact of particle size on the pasting properties of wheat flour.

Fig. 2.

RVA profiles of control sample of wheat flour ( ) and jet milled flours, F1 (

) and jet milled flours, F1 ( ), F2 (

), F2 ( ) and F3 (

) and F3 ( ) with (

) with ( ) Temperature

) Temperature

Calculated pasting parameters from RVA curves can be seen in Table 3. Peak viscosity, which had a negative correlation with feedback (r = −0.9596, P < 0.05), was significantly reduced (control>F1>F2>F3), likewise breakdown viscosity and total setback. It has been reported that peak viscosity was affected linearly by percentage of damaged starch (Hasjim et al. 2013; Hossen et al. 2011b), which agrees with results of the present study, although a non-significant negative correlation was found between peak viscosity and damaged starch content (r = −0.9132, P > 0.05). Hossen et al. (2011a) reported that peak viscosity was almost constant for dry jet milled rice flour with d50>50 μm but decreased gradually at lower mean size, and dramatically at d50<10 μm. Therefore, reduced peak viscosities of the processed flours indicated that smaller particles are more resistant to swelling or required longer periods and RVA measurements are affected at those levels of particle size. Hossen et al. (2011b) suggested that after pulverization, peak and final viscosities of all flours (rice, wheat, corn maize, potato, sweet potato, cassava) decreased. Final viscosity and setback were progressively reduced according to the intensity of the jet milling treatment. Final viscosity and holding strength differed significantly for samples F2 and F3. This reduction might be attributed to either the breakage of amylose chains with lower ability to retrograde during cooling as has been reported for extrusion (Martínez et al. 2014), or differences in the amylose chains leakage during gelatinization associated to particle size that consequently affected amylose retrogradation. In fact, larger flour particles have greater physical barrier for both heat transfer and water diffusion (Hasjim et al. 2013).

Table 3.

RVA pasting properties of wheat flour and jet milled wheat flours F1, F2 and F3

| Sample | Pasting onset (°C) | Peak viscosity (cP) | Holding strength(cP) | Breakdown (cP) | Final viscosity(cP) | Total Setback (cP) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 64.5 | ± | 1.17 | 3412 | ± | 16.97 | d | 1923 | ± | 33.23 | c | 1490 | ± | 16.26 | c | 3599 | ± | 43.84 | c | 1677 | ± | 10.61 | d |

| F1 | 65.8 | ± | 0.64 | 3121 | ± | 16.97 | c | 1901 | ± | 26.87 | c | 1220 | ± | 43.84 | b | 3545 | ± | 17.68 | c | 1644 | ± | 9.19 | c |

| F2 | 63.2 | ± | 3.04 | 2846 | ± | 6.36 | b | 1653 | ± | 20.51 | b | 1193 | ± | 14.14 | b | 3187 | ± | 24.75 | b | 1534 | ± | 4.24 | b |

| F3 | 65.3 | ± | 1.31 | 2407 | ± | 25.46 | a | 1520 | ± | 5.66 | a | 887 | ± | 19.80 | a | 2973 | ± | 9.90 | a | 1453 | ± | 4.24 | a |

Values followed by different letters in each column indicate significant differences (P ≤ 0.05)

Thermal parameters

Thermal properties of jet milled samples were investigated to assess the possible impact of this treatment at molecular level (Table 4). In the range of temperature tested (30 to 110 °C), flours exhibited one endothermic peak corresponding to amylopectin gelatinization. Specific differences among the treated samples were observed, which grouped the samples in control and F1, and on the other hand F2 and F3. The change in the size of the granules influenced the gelatinization temperatures (To, Tp, Tc) and samples F2 and F3 (the lowest particle size), showed significantly higher values comparing to control and F1 samples. Therefore, gelatinization temperatures were progressively shifted to higher values when flours were treated at high milling intensity (8 bar and/or feedback), but the temperature range was not affected significantly. Martínez et al. (2014) stated that gelatinization temperatures were dependent on the particle size, but the present study shows that when applying jet milling no direct correlation was detected between particle size and To, Tp, Tc. Gelatinization enthalpy (ΔH) differed significantly only between F2 and F3 but no trend was observed with the intensity of the treatment. Emami et al. (2010) observed that micronization in barley slightly increased To, Tp, Tc and reduced ΔH. Moreover, Münzing (1991) referred that gelatinization peak temperature (Tp) increased slightly by milling because of damaged starch. In the present study damaged starch correlated positively with To, Tp, Tc, but no significantly.

Table 4.

Thermal parameters of wheat flour (control) and jet milled wheat flours F1, F2, F3 determined by DSC

| Sample | To (°C) | Tp (°C) | Tc(°C) | Tp-To(°C) | ΔH (J/g) | PHI = ΔH/To-Tp | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 57.14 | ± | 0.79 | a | 61.34 | ± | 0.75 | a | 66.12 | ± | 0.92 | a | 4.20 | ± | 0.39 | 3.02 | ± | 0.44 | ab | 0.72 | ± | 0.05 | ab |

| F1 | 56.79 | ± | 0.25 | a | 61.21 | ± | 0.17 | a | 67.24 | ± | 0.38 | a | 4.42 | ± | 0.24 | 2.77 | ± | 0.49 | ab | 0.62 | ± | 0.08 | ab |

| F2 | 59.25 | ± | 0.73 | b | 63.87 | ± | 0.65 | b | 70.20 | ± | 1.05 | b | 4.62 | ± | 0.26 | 3.34 | ± | 0.35 | a | 0.76 | ± | 0.10 | b |

| F3 | 60.36 | ± | 0.04 | b | 64.63 | ± | 0.34 | b | 69.20 | ± | 0.67 | b | 4.27 | ± | 0.13 | 2.43 | ± | 0.37 | b | 0.57 | ± | 0.10 | a |

Values followed by different letters in each column indicate significant differences (P ≤ 0.05)

To, gelatinization onset; Tp, peak temperature; Tc, conclusion temperature, Tp-To, gelatinization range, ΔH, enthalpy and PHI, peak high index

Hydrolysis of starch

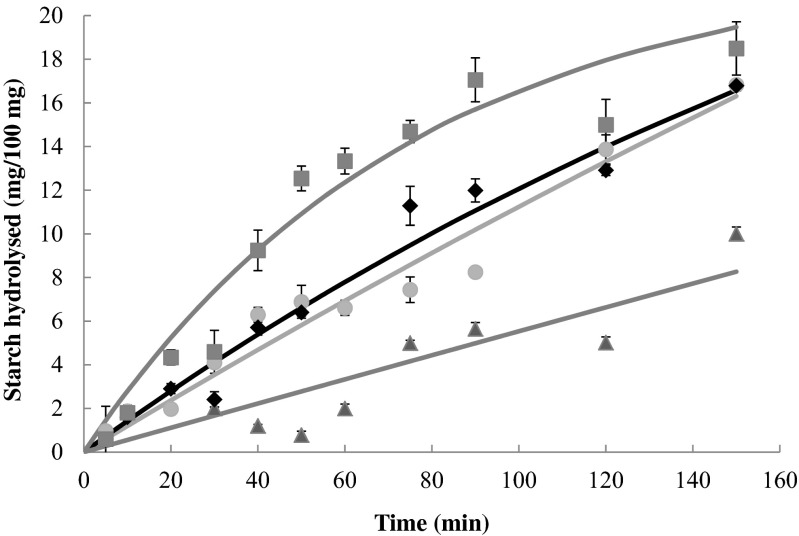

The potential impact of the jet milling on the integrity of the starch granules was assessed by evaluating the starch susceptibility to enzymatic hydrolysis. The digestion curves of the processed samples were slightly higher than those of the control (Fig. 3). Jet milled samples presented faster starch hydrolysis compared to control. The finer flours the wider surface area of granules. High surface area of flour particles increases the water diffusion and enzyme accessibility according to de la Hera et al. (2013). The disaggregation of wheat flour constituents favored the alfa amylase accessibility, increasing the starch susceptibility to be hydrolyzed. Detached starch granules from protein matrix could also lead to rapid hydrolysis of starch. F3 sample showed the higher values of hydrolyzed starch (Fig. 3) and this can be ascribed to the intensity of the process, since F3 was re-milled. The kinetics parameters, confirmed that jet milled samples showed augmented rate of hydrolysis with significant differences on the hydrolysis constant (k) (Table 5). C∞ was positively correlated with d50 (r = 0.9738, P < 0.05) and moisture (r = 0.9927, P < 0.01) and negatively with damaged starch (r = −0.9671, P < 0.05). Results suggested that by decreasing particle size (d50), which simultaneously increases damaged starch, lower hydrolysis plateau would be reached. Presumably smaller particles favor the rapid accessibility to the amorphous part of the starch granules, reaching earlier the more resistant crystalline structure of the granules, which would explain the lower plateaus. Starch granules were faster and in lesser extent hydrolyzed at sample F3. Surface components of starch granule, such as proteins, can create a surface membrane that acts as a physical barrier to digestion, proteins layers should be significantly degraded before starch digestion takes place (Svihus et al. 2005).

Fig. 3.

Effect of different jet milling conditions in the enzymatic starch hydrolysis kinetics of wheat flour; control ( ), F1 (

), F1 ( ), F2 (

), F2 ( ) and F3 (

) and F3 ( )

)

Table 5.

Kinetic parameters of the starch hydrolysis of wheat flour samples (control) and jet milled flours (F1, F2, F3)

| Sample | Free sugars (mg/100 mg, db) | Resistant Starch (mg/100 mg, db) | Digestible starch (mg/100 mg, db) | C ∞ | k | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 0.54 | ± | 0.01 | a | 6.85 | ± | 3.42 | 58.94 | ± | 5.86 | 321.51 | ± | 24.74 | a | 0.0002 | ± | 0.0000 | a |

| F1 | 0.82 | ± | 0.00 | b | 9.58 | ± | 2.88 | 58.78 | ± | 2.14 | 85.79 | ± | 1.40 | b | 0.0014 | ± | 0.0000 | a |

| F2 | 0.94 | ± | 0.00 | b | 9.75 | ± | 2.88 | 57.85 | ± | 0.39 | 33.97 | ± | 5.66 | c | 0.0046 | ± | 0.0011 | b |

| F3 | 1.25 | ± | 0.01 | c | 11.64 | ± | 0.79 | 57.84 | ± | 4.43 | 21.59 | ± | 1.41 | c | 0.0135 | ± | 0.0004 | c |

Values followed by different letters in each column indicate significant differences (P ≤ 0.05

Resistant starch was also measured to determine the potential impact of the jet mill on the structural level of starch (Table 5). RS increased in jet milled samples but differences were not significant. During jet milling, flours were not exposed to thermal stress that may affect the RS amount, which explained the absence of differences. The amount of free sugars was low, but as the intensity of the process increased the amount of FS also augmented. F3 differed significantly from the other samples and presented the higher percentage of free sugars, indicating a high correlation between FS and feedback (r = 0.9856, P < 0.05).

Conclusions

Jet milling is an alternative method to produce ultra-fine flour. Milling conditions determine the final particle size and the thereafter flour properties. In the present study, particle size was reduced up to ten times (mean diameter 11.44 μm in F3). Decrease in particle size led to starch granules detached from protein matrix and a significant breakage of aggregates took place. Damaged starch increased but not to a dramatic extent. As long as the treatment was mild (F1), similarities to the control samples were shown in terms of pasting properties. When the process became more intense, small particles presented a retardation to gelatinize and pastes were less viscous either in gelatinization or in the gel forming process. Moreover, starch hydrolysis increased in terms of particle size reduction as higher surface area led to higher starch susceptibility. Therefore, a treatment of 8 bar pressure without feedback (F2) could be used to achieve high particle size reduction. More intense milling treatment, as in F3 with feedback, would not lead additional changes in flour functionality, likely due to reaching the limit of particle sizes. Thermal parameters, hydration and pasting properties of flours are crucial for the developing food products. Therefore, the incorporation of jet milled flours in food process would be of great interest.

Acknowledgments

Part of this work was financed through the project “IKY Scholarships” from resources of operational program (OP) “Education and Lifelong Learning”, the European Social Fund (ESF) of the (National Strategic Reference Framework NSRF) 2007-2013-WP2-SHORT TERMS-19078. Financial support of Spanish Scientific Research Council (CSIC) and Generalitat Valenciana (Spain, Project Prometeo 2012/064) is acknowledged. The authors are also grateful to Christos Ritzoulis (Thessaloniki, Greece) for his help in particle size measurements.

Footnotes

Highlights

• The effect of jet milling settings on wheat flour characteristics was evaluated.

• Large aggregates were reduced in size separating starch granules and proteins.

• Jet milled flours showed lower viscosity and faster enzymatic starch hydrolysis.

• Controlling jet milling settings allow obtaining flours with diverse functionality.

References

- AACC International . Approved Methods of Analysis. 11. St. Paul: AACC International; 2012. [Google Scholar]

- Augustin MA, Sanguansri P (2009) Nanostructured Materials in the Food Industry. In: Steve LT (ed) Advances in Food and Nutrition Research. Academic, pp 183–213 [DOI] [PubMed]

- Barrera GN, Bustos MC, Iturriaga L, Flores SK, León AE, Ribotta PD. Effect of damaged starch on the rheological properties of wheat starch suspensions. J Food Eng. 2013;116:233–239. doi: 10.1016/j.jfoodeng.2012.11.020. [DOI] [Google Scholar]

- Chamayou A, Dodds AJ (2007) Air jet milling. In: Salman DS, Ghadiri M, Hounslow JM (eds) Handbook of Powder Technology, Particle Breakage. pp 421–435

- de la Hera E, Gómez M, Rosell CM. Particle size distribution affecting the starch enzymatic digestion and hydration of rice flour carbohydrates. Carbohydr Polym. 2013;98:421–427. doi: 10.1016/j.carbpol.2013.06.002. [DOI] [PubMed] [Google Scholar]

- de la Hera E, Rosell CM, Gómez M. Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem. 2014;151:526–531. doi: 10.1016/j.foodchem.2013.11.115. [DOI] [PubMed] [Google Scholar]

- Emami S, Meda V, Pickard MD, Tyler RT. Impact of micronization on rapidly digestible, slowly digestible, and resistant starch concentrations in normal, high-amylose, and waxy barley. J Agric Food Chem. 2010;58:9793–9799. doi: 10.1021/jf101702e. [DOI] [PubMed] [Google Scholar]

- Goni I, Garcia-Alonso A, Saura-Calixto F. A starch hydrolysis procedure to estimate glycaemic index. Nutr Res. 1997;17:427–437. doi: 10.1016/S0271-5317(97)00010-9. [DOI] [Google Scholar]

- Graveland A, Henderson MH (1991) Improved flour, EP 0459551 A1

- Gularte MA, Rosell CM. Physicochemical properties and enzymatic hydrolysis of different starches in the presence of hydrocolloids. Carbohydr Polym. 2011;85:237–244. doi: 10.1016/j.carbpol.2011.02.025. [DOI] [Google Scholar]

- Hasjim J, Li E, Dhital S. Milling of rice grains: effects of starch/flour structures on gelatinization and pasting properties. Carbohydr Polym. 2013;92:682–690. doi: 10.1016/j.carbpol.2012.09.023. [DOI] [PubMed] [Google Scholar]

- Heaton KW, Marcus SN, Emmett PM, Bolton CH. Particle size of wheat, maize, and oat test meals: effects on plasma glucose and insulin responses and on the rate of starch digestion in vitro. Am J Clin Nutr. 1988;47:675–682. doi: 10.1093/ajcn/47.4.675. [DOI] [PubMed] [Google Scholar]

- Hossen MS, Sotome I, Takenaka M, Isobe S, Nakajima M, Okadome H. Starch damage and pasting properties of rice flours produced by dry jet grinding. Cereal Chem. 2011;88:6–11. doi: 10.1094/CCHEM-04-10-0061. [DOI] [Google Scholar]

- Hossen MS, Sotome I, Takenaka M, Isobe S, Nakajima M, Okadome H. Effect of particle size of different crop starches and their flours on pasting properties. Jpn J Food Eng. 2011;12:29–35. [Google Scholar]

- ICC (2011) International Association of Cereal Chemists. Vienna (Austria). Standard Methods 173; 110/1

- Létang C, Samson MF, Lasserre TM, Chaurand M, Abécassis J. Production of starch with very low protein content from soft and hard wheat flours by jet milling and air classification. Cereal Chem. 2002;79:535–543. doi: 10.1094/CCHEM.2002.79.4.535. [DOI] [Google Scholar]

- Manley D, Pareyt B, Delcour JA (2011) Wheat flour and vital wheat gluten as biscuit ingredient. In: Manley D, (ed) Manley’s technology of biscuits, crackers and cookies. Cambridge, pp 109–33

- Martínez M, Calviño A, Rosell C, Gómez M. Effect of different extrusion treatments and particle size distribution on the physicochemical properties of rice flour. Food Bioprocess Technol. 2014;7:2657–2665. doi: 10.1007/s11947-014-1252-7. [DOI] [Google Scholar]

- Midoux N, Hosek P, Pailleres L, Authelin JR. Micronization of pharmaceutical substances in a spiral jetmill. Powder Technol. 1999;104:113–120. doi: 10.1016/S0032-5910(99)00052-2. [DOI] [Google Scholar]

- Münzing K. DSC studies of starch in cereal and cereal products. Thermochim Acta. 1991;193:441–448. doi: 10.1016/0040-6031(91)80196-P. [DOI] [Google Scholar]

- Oladunmoye OO, Akinoso R, Olapade AA. Evaluation of some physical-chemical properties of wheat, cassava, maize and cowpea flours for bread making. J Food Qual. 2010;33:693–708. doi: 10.1111/j.1745-4557.2010.00351.x. [DOI] [Google Scholar]

- Protonotariou S, Drakos A, Evageliou V, Ritzoulis C, Mandala I. Sieving fractionation and jet mill micronization affect the functional properties of wheat flour. J Food Eng. 2014;134:24–29. doi: 10.1016/j.jfoodeng.2014.02.008. [DOI] [Google Scholar]

- Protonotariou S, Mandala I, Rosell CM. Jet milling effect on functionality, quality and in vitro digestibility of whole wheat flour and bread. Food Bioprocess Technol. 2015;8:1319–1329. doi: 10.1007/s11947-015-1494-z. [DOI] [Google Scholar]

- Sakhare SD, Inamdar AA, Indrani D, Venkateswara Rao G. Effect of flour particle size on microstructural, rheological and physico-sensory characteristics of bread and south Indian parotta. J Food Sci Technol. 2014;51:4108–4113. doi: 10.1007/s13197-013-0939-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sakhare SD, Inamdar AA, Indrani D, Madhu Kiran MH, Venkateswara Rao G. Physicochemical and microstructure analysis of flour mill streams and milled products. J Food Sci Technol. 2015;52:407–414. doi: 10.1007/s13197-013-1029-4. [DOI] [Google Scholar]

- Sanguansri P, Augustin MA. Nanoscale materials development – a food industry perspective. Trends Food Sci Technol. 2006;17:547–556. doi: 10.1016/j.tifs.2006.04.010. [DOI] [Google Scholar]

- Svihus B, Uhlen AK, Harstad OM. Effect of starch granule structure, associated components and processing on nutritive value of cereal starch: a review. Anim Feed Sci Technol. 2005;122:303–320. doi: 10.1016/j.anifeedsci.2005.02.025. [DOI] [Google Scholar]

- Tóth Á, Prokisch J, Sipos P, Széles É, Mars É, Győri Z. Effects of particle size on the quality of winter wheat flour, with a special focus on macro‐ and microelement concentration. Commun Soil Sci Plant Anal. 2006;37:2659–2672. doi: 10.1080/00103620600823117. [DOI] [Google Scholar]

- Vouris D, Lazaridou A, Biliaderis C (2013) Effect of flour particle size on rheology and starch gelatinisation of wheat doughs. Proceedings Cereals & Europe Spring Meeting 2013 - Unlocking the full potential of cereals: Challenges for science based innovation (Leuven, Belgium)