Abstract

The objective of this work was to study quality parameters of enriched wheat bread with calcium citrate (Ca3CI2) or lactate (CaLA2) and inulin (In), also to optimize bread formulation. Fermentation time (tf), specific volume (Vs), browning index of crust (BI) and crumb properties (moisture, alveolus, texture) were studied. Generally, tf and Vs decreased with prebiotic increment. Ca3CI2 did not change Vs at equal inulin quantity, whereas with CaLA2 smaller breads were obtained (at 6.5 % In). Moisture of crumbs decreased with an increase in Ca3CI2 (at ≤ 6.5 %); while for CaLA2 was more influenced by the prebiotic. Up to 6.5 % In, the addition of both salts decreased crumb firmness and increased cohesiveness. Using a desirability function, the optimum calcium-prebiotic bread obtained with Ca3CI2 contained 2.40 g/kg Ca and 7.49 % In and with CaLA2 presented 1.33 g/kg Ca and 4.68 % In. Breads of high-quality with higher calcium and prebiotic quantity were able to obtain with Ca3CI2.

Keywords: Calcium citrate, Calcium lactate, Inulin, Wheat bread, Quality optimization

Introduction

Bread has been a staple food for centuries; its consumption is among the highest in the world. Therefore, fortifying wheat flour with essential vitamins and minerals is seen as one of the most effective and inexpensive ways of improving diet (WHO/UNICEF/MI 2003; WHO/EMRO 2009). In Argentina, wheat flours are fortified with iron, thiamine, riboflavin, niacin and folic acid, contributing to the elimination of nutritional deficiencies and to improving health of the population. Therefore, deficiencies of some essential nutrients are covered, but not all of them such as calcium. According to the Nutrition and Health National Inquest (NSNH 2007), in Argentina calcium was one of the most critical nutrients fundamentally in children and women. Besides, white wheat flour is a very poor source of calcium. Most of the calcium provided by refined cereal foods comes from calcium containing ingredients that are usually added to bread and biscuits as functional ingredients.

Ranhotra et al. (1999) fortified wheat flour with calcium from 2.11 to 14.12 g/kg. These authors stablished that a value of 2.11 provided only between 6 and 8 % of the reference value (1000 mg Ca per day) when a 50-g of bread was consumed. Calcium carbonate was added at levels higher than 2.11 g/kg without adversely affecting bread quality and calcium was retained in bones (Ranhotra et al. 1999).

Not only the calcium quantity used for fortification is important, also its bioavailability. Calcium bioavailability increases in the presence of inulin (Scholz-Ahrens and Schrezenmeir 2002; Weaver 2005) therefore both components should be incorporated together in bread formulation.

Prebiotics (non-digestible carbohydrates) resist gastric acidity and mammalian enzymes, are susceptible to fermentation by gut bacteria and enhance the viability and/or activity of beneficial microorganisms (Rastall and Gibson 2006). They are usually fermentable carbohydrates which stimulate preferentially the growth of probiotic bacteria (bifidobacteria and lactic acid bacteria), enhancing gastrointestinal and immune systems. Galacto, fructo-oligosaccharides and inulin are the most commonly known prebiotics. Inulin and inulin-type fructans are recognized as soluble dietary fiber (Roberfroid 2005).

The use of inulin as prebiotic and fat-replacing ingredient in breadmaking (Peressini and Sensidoni 2009, Poinot et al. 2010) and in cookie formulations (Hempel et al. 2007, Vitali et al. 2009) were reported.

In a previous work the optimization of the formulation of breads with calcium carbonate and inulin was studied (Salinas and Puppo 2015). These authors found that inulin increased crumb firmness (until 6.5 % In, wheat flour basis) and crust colour. Nevertheless, cohesiveness, elasticity and moisture of crumbs were reduced. Specific volume of all breads was almost the same (2.5 cm3/g); however, breads with the highest inulin content (13 % In) and calcium carbonate (1.80 g/kg Ca) presented the highest volume with the lowest firmness. Although the prebiotic negatively affected breadmaking quality, the presence of CaCO3 not only softened crumbs becoming less firm and chewable, also favored crumb elasticity and particle integration.

Even though the effect of an inorganic salt such as calcium carbonate jointly with inulin as prebiotic on bread quality was previously studied, another great challenge is the utilization of other calcium sources in bread formulation. Therefore, the objective of this work was to study the impact of organics calcium salts (citrate or lactate)-inulin on different wheat bread properties and to obtain the fortified bread with the highest quality by optimization through the desirability function.

Materials and methods

Materials used were wheat flour (type 0000, Molino Campodónico Ltda., La Plata, Argentina) (AAC 2014) with 9.92 % proteins, 0.86 % fat, 0.382 % ash and 11.8 % moisture. Alveographic parameters were: P = 132 mm, L = 47 mm and W = 264. Farinographic parameters of this flour were 57.9 ml, 18 min, 38.0 min and 12 BU for water absorption, development time, stability and softening degree, respectively. Other ingredients used were sodium chloride (CELUSAL, Argentina), yeast fresh (CALSA, Argentina), calcium citrate [Ca3CI2, Ca3(C6H5O7)2.4H2O, Sigma-Aldrich, S.A., (PubChem CID 13136)], calcium lactate [CaLA2, Ca(C3H5O3)2, Sigma-Aldrich,(PubChem CID 13144)] and inulin with fructo-oligosacharides (Synergy 1, BENEO Orafti, Belgium, 92.7 % db). Synergy1 is a combination of longer and shorter chain inulin to achieve specific physiological effects. It is an oligofructose-enriched Inulin in proportion (30:70).

Experimental design

Mixtures of wheat flour, calcium salt and inulin were prepared using the factor levels proposed by Salinas et al. (2012). A central composite design (CCD) with two factors (Calcium and inulin) was utilized. Factor levels utilized were: from 1.08 to 2.52 g/kg Ca and from 0 to 13 % In (Table 1). Full factorial designs are the optimal experimental strategy to simultaneously study the effect of several factors on some bread response, and to estimate linear and quadratic effects and interactions between those factors. A second order model was proposed according to Salinas et al. (2012). Control bread without calcium nor In outside to the CCD was analyzed.

Table 1.

Second-order designs matrix used for evaluating bread Quality of blend

| Samples # |

Coded | Uncoded | Ca3CI2 | CaLA2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ca | In | Ca (g/Kg) |

In

(%) |

Wabs

(%) |

td

(min) |

tf

(min) |

Wabs

(%) |

td

(min) |

tf

(min) |

|

| 1 | −1 | −1 | 1.20 | 1 | 53.4 | 9 | 75 ± 7 g | 51.3 | 17 | 66 ± 4bc |

| 2 | 1 | −1 | 2.40 | 1 | 53.5 | 25 | 47 ± 1b | 52.0 | 13 | 81 ± 15d |

| 3 | −1 | 1 | 1.20 | 12 | 52.0 | 31 | 32 ± 2a | 53.0 | 34 | 49 ± 9a |

| 4 | 1 | 1 | 2.40 | 12 | 52.5 | 33 | 49 ± 9bc | 52.6 | 29 | 62 ± 5ab |

| CP | 0 | 0 | 1.80 | 6.5 | 52.0 | 34 | 56 ± 3 cd | 51.2 | 23 | 70 ± 15bcd |

| 8 | −1.2 | 0 | 1.08 | 6.5 | 50.2 | 21 | 65 ± 1de | 51.3 | 20 | 76 ± 15bcd |

| 9 | 0 | +1.2 | 1.80 | 13 | 52.8 | 29 | 39 ± 2a | 54.0 | 30 | 63 ± 9ab |

| 10 | 1.2 | 0 | 2.52 | 6.5 | 49.6 | 20 | 62 ± 3de | 51.0 | 18 | 48 ± 4a |

| 11 | 0 | −1.2 | 1.80 | 0 | 53.7 | 24 | 65 ± 2ef | 53.3 | 11 | 79 ± 4cd |

| C | 0 | 0 | 0 | 0 | 56.0 | 12 | 67 ± 4f | 56.0 | 12 | 67 ± 4bcd |

Different letters in the same column indicate significant differences (p < 0.05). Mean ± SD

CP Central Point (3 replicates), C Control (outside of the design), W abs water absorption, t d development time, t f fermentation time

Data obtained were analyzed using RSM with a Software Statgraphics plus for Windows 5.1 (Cambridge, MN, USA).

Dough formulation

Solids ingredients (wheat flour, 2 % NaCl, citrate or lactate calcium salts and inulin according to CCD were mixed in a small scale kneader (Kenwood Major, Milano, Italy) for one minute. The optimum quantity of water (Wabs) and mixing time (td) were established according Salinas and Puppo (2013) (Table 1). Fresh yeast (3 %) was incorporated to water and was added to solids. The first minute was kneaded at 50 rpm (speed 1) and then at 90 rpm (speed 2) until reaching development time. Dough was rested for 10 min at 25 °C, covered with a plastic film to avoid water loss; before and after being laminated (4 times).

Breadmaking process

Baking process

Dough (90 g) was rounded, left resting for 15 min and then shaped into a bread shipowning (MPZ, Buenos Aires, Argentina). The optimum fermentation time was determined according Salinas and Puppo (2015). These pieces were proofed (to 30 °C for tf) and baked at 210 °C for 26 min in a convection oven (Ariston, Buenos Aires, Argentina). Bread quality was evaluated at 20 °C two-hours after baking.

Bread quality evaluation

Bread specific volume

Specific volume (Vs) was determined as a ratio of volume and weight (AACC 2000). Four breads of each formula were analyzed.

Crust colour

Colour measurements were performed on crust bread using a tristimulus colour analyzer (Chroma Meter CR 400, Konica Minolta, Osaka, Japan). Forty measurements per formula were analyzed. Values of L*, a* and b* were measured and combined in the browning index (BI) parameter (Buera et al. 1985) according to Eqs. 1 and 2:

| 1 |

| 2 |

Crumb moisture

Moisture was determined employing to AACC Method 44–19 (AACC 2000). Values obtained were the mean of three replicates.

Crumb structure

Images (10x10cm2) of slices obtained from the middle of bread were acquired at 138 dpcm with a HP scanner 4070 model. A square on the slice center (217 × 217 mm2) was considered for the analysis. The image was converted to grey-level image (8 bits) and then was binarized using the algorithm Isodata employing a threshold value (209) using ImageJ software. Black dots represent alveoli. Image imperfections were considered with an alveolar threshold of 0.005 cm2; minor threshold values were not counted as alveoli. The numbers of cell per area (N) (cm−2), mean cell area (AM) (cm2) and the void fraction or total area occupied by alveoli (AT) (%) were calculated.

Crumb texture

Texture profile analysis (TPA) of bread slices was performed using a texture analyzer TA.XT2i (Stable Micro Systems, Surrey, UK) equipped with a 25-kg load cell. From the middle part of each bread loaf two slices of 2 cm height were obtained. Slices were subjected to a double compression cycle (deformation: 40 %, crosshead speed: 0.5 mm/s) with a cylindrical probe (diameter = 2.5 cm). Parameters determined were: firmness, cohesiveness and chewiness. Eight replicates were analyzed for formulation.

Optimization of bread formulation

The multi response (moisture, specific volume, chewiness and cohesiveness) optimization process was selected according to a desirability function for each calcium salt-inulin design (CCD) (Khuri and Cornell 1996, Montgomery 1997). The maximum value of the overall desirability function (D) was utilized for obtaining the adequate levels of calcium and inulin used in the formulation of the optimum quality bread. These optimum values of Ca and In were therefore utilized in the model generated previously by RSM for calculating water absorption (Wabs), mixing (td) and fermentation (tf) times, according to the second order polynomial equations for Ca3CI2 (Eqs. 3, 4, and 5) and CaLA2 (Eqs. 6, 7, and 8) salts:

| 3 |

| 4 |

| 5 |

| 6 |

| 7 |

| 8 |

Considering these variables, the optimum bread of each CCD was prepared. This bread was experimentally analyzed and the results were statistically compared to the predicted values by the mathematical model.

Statistical analysis

Variable results were subjected to one-way ANOVA according to the general linear model procedure with least-square mean effects. Significantly different means (p < 0.05) were determined according to Fisher’s least significant differences (LSD) test. Mean and standard deviation were calculated for each parameter.

Results and discussion

Fermentation times (tf) are summarized in Table 1. In the absence of In, the addition of calcium salts did not change the tf in comparison with C-dough. At 1 % In, an increase in Ca3CI2 reduced tf (47 min), whereas with CaLA2 the tf increased from 66 to 81 min.

However, with 12%In, different behaviors were observed in tf, depending on the type and quantity of calcium salt: an increase in CaLA2 did not significantly modify tf, while this time increased when Ca3CI2 was added. Formulation with 2.52 g/kg Ca (CaLA2) presented the minor tf (48 min). Moreover, at 6.5%In, the increase in Ca3CI2 did not modified tf, while CaLA2 decreased this parameter.

The same formulation in both CCD contains an equal number of calcium moles but different number of anions. These anions contribute with different negative charge, affecting the fermentation process. At 1.2 g/kg Ca, an increase in prebiotic decreased tf with both calcium salts, nevertheless at 2.4 g/kg Ca, tf was not modified with high In quantity for Ca3CI2, but significantly diminished in the case of CaLA2.

In a previous work we studied the effect of these organics calcium salts and inulin system on hydration and rheological properties of dough. We proposed that different negative charge proportion and/or different electrostatic interaction between the anion and gluten proteins could generate structures with different consistency and stability during kneading, also affecting the rheological properties (Salinas and Puppo 2013, 2014).

In general, tf was lower when high quantity of In was used, indicating that in the presence of prebiotic less fermentation time was needed. A low fermentation time is a required aspect in breadmaking industry because contributes to shorten bread preparation. This behavior could be due to the content of oligosaccharides present in inulin sample (30 %) that are available for yeast fermentation.

Quality of bread

Technological quality of bread was evaluated by determining the specific volume, crust color, and crumb properties such as moisture, alveoli and texture.

For breads with Ca3CI2 the highest values of Vs were obtained without In (Fig. 1a). At the same inulin quantity, the increase of calcium concentration did not cause significant differences of Vs.

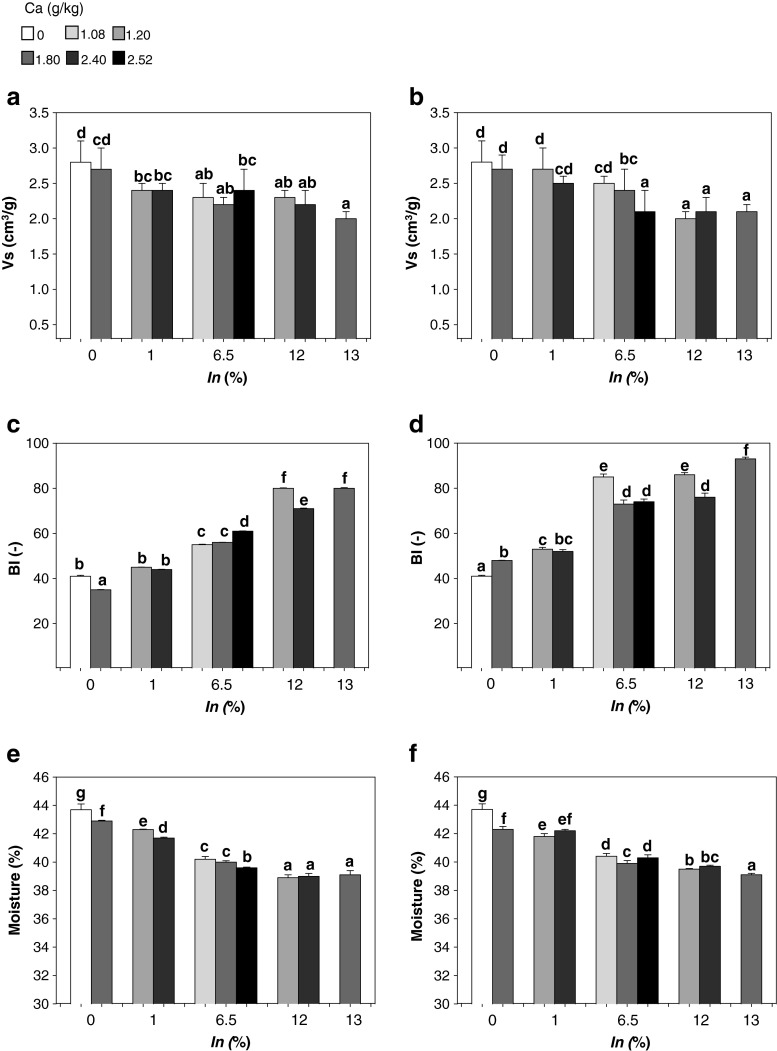

Fig. 1.

Parameters of bread quality. a, b Specific volume (Vs), c, d Crust browning index (BI), e, f Crumb moisture. Bread with: Ca3CI2 (a, c, e), CaLA2 (b, d, f). Errors bars: standard deviations. Different letters in the same graphics indicate significant differences (p < 0.05)

At 6.5 % In, an increase of calcium up to 2.52 g/kg (CaLA2) significantly decreased Vs (Fig. 1b). A destabilizing effect of lactate anion on gluten network was previously detected using scanning electron microscopy (Salinas and Puppo 2014). Therefore, in fermentation step, this unstable network could collapse during expansion producing breads with low Vs, especially with 12 and 13 % In.

The model obtained applying RSM for Vs for Ca3CI2 was: 2.245 - 0.116In (R2 = 0.68, RMSE = 0.14), and for CaLA2: 2.34 - 0.264In (R2 = 0.87, RMSE = 0.13). These models show that Vs varied in an indirectly form with In, principally with CaLA2. Several authors also found that Vs decreased with increasing prebiotic content, although in the absence of calcium salt (Morris and Morris 2012). These organic salts produced different behavior in bread quality compared to an inorganic salt such as calcium carbonate. In the last case, an increase in Vs with higher amounts of inulin was detected (Salinas and Puppo 2015). Differences could be attributed to the distinct interaction of the ion carbonate with wheat proteins in gluten network, in spite of the presence of inulin.

Colour of the bread crust is one of the most important parameter in the choice by consumers. Crust colour exhibited by a bread loaf depends mainly on the type of flour, the quality and quantity of the ingredients used (Komlenić et al. 2010), and also the baking temperature and time (Shittu et al. 2007). Browning index (BI) indicates the level of brown colour and was reported as an important parameter of bread quality, related to Maillard reactions (Saricoban and Yilmaz 2010). Due to the issue that baking time and temperature were the same for all formulations, we can infer that the change in formulation caused plainly visible changes in the colour of the functional bread, compared to the control bread. Ca3CI2 breads with 1.80 g/kg Ca and 0 % In presented lower BI, the opposite behavior for CaLA2 was observed. At 6.5 % In, Ca3CI2 favored bread browning (Fig. 1c) while with CaLA2 BI decreased (Fig. 1d). At 12 % In, BI decreased with the increase of calcium level, independently of the type of calcium organic salt utilized.

Generally, browning was favored by the prebiotic. This trend is due to the reducing power of the oligosaccharides present in Synergy1. Frutos et al. (2008) also found that the increase of amount of artichoke fiber up to 12 % incremented bread colour. A darker curst colour was reported by Peressini and Sensidoni (2009) for all levels (2.5; 5 and 7.5 %) and two types of inulin; and by Poinot et al. (2010) and Hager et al. (2011) with inulin between 3 and 10 %.

Control bread crumb was the wettest one; calcium salts without inulin (1.80 g/kg Ca) caused significantly decrease in crumb moisture, consistent with a lower water absorption (Fig. 1e, f).

At ≤ 6.5%In, an increase in Ca3CI2 caused less moist crumbs, behaviour that could be attributed to the positive net charge (+2) of salt in dough. Salinas and Puppo (2013) established that at the acid pH conferred to dough by citrate salt (5.66–5.77), one carboxyl ion of Ca3CI2 is protonated, therefore calcium cations contribute with +6 of positive charge, while citrate anions contribute to −4. This positive net charge affects interactions of ions with water, leading to high quantity of water in a high-energy state, i.e. more loosely linked. On the other hand, crumb moisture decreased with prebiotic regardless of CaLA2 quantity (Fig. 1f). The effect of CaLA2 in moisture was controlled for the prebiotic. Lactate anions are totally deprotonated, therefore the net charge of CaLA2 is zero, with a different interaction with water molecules.

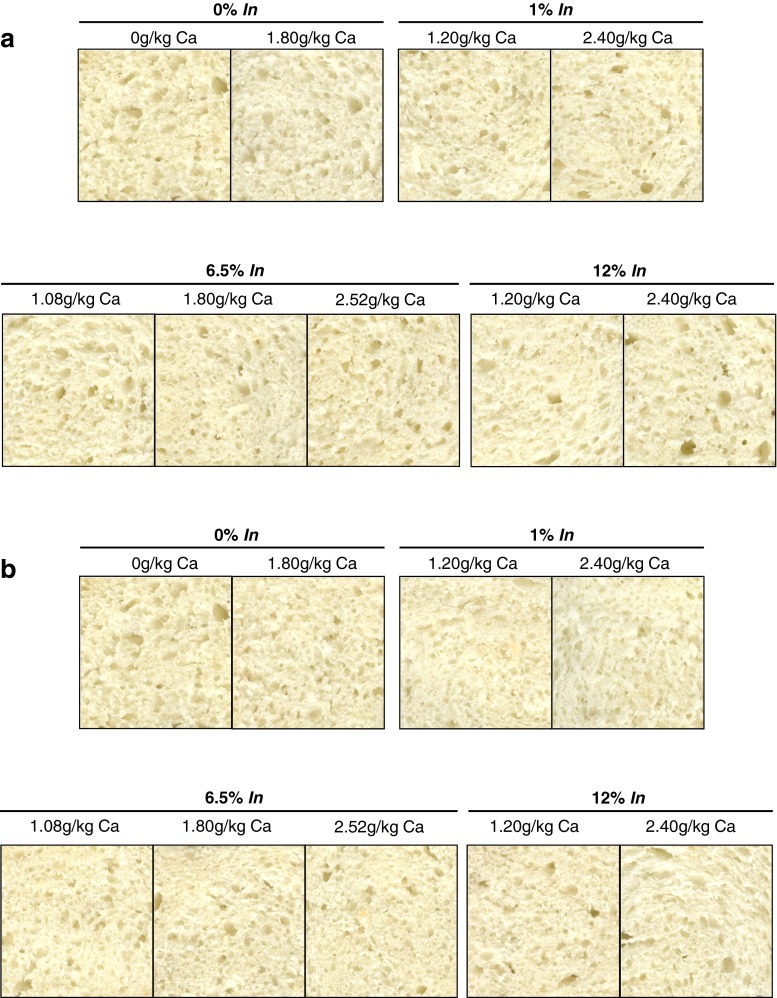

Images of structure of bread crumb centers can be observed in Fig. 2a (Ca3CI2) and Fig. 2b (CaLA2). Structure parameters: number of alveoli per area (N), mean alveolus area (AM) and percentage of total air trapped (AT) of bread crumbs are shown in Table 2.

Fig. 2.

Bread crumb images. a Ca3CI2, b CaLA2

Table 2.

Parameters obtained from analysis of crumbs images

| Samples # |

Coded | Uncoded | Ca3CI2 | CaLA2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ca | In | Ca (g/Kg) | In (%) | N (cm2) | AM .103 (cm2) | AT (%) | N (cm2) | AM .103 (cm2) | AT (%) | |

| 1 | −1 | −1 | 1.20 | 1 | 246 d | 14 a | 15 cd | 203 e | 11 a | 10 bcd |

| 2 | 1 | −1 | 2.40 | 1 | 226 d | 14 a | 14 bcd | 145 d | 19 b | 11 bcd |

| 3 | −1 | 1 | 1.20 | 12 | 114 ab | 22 b | 11 a | 126 bcd | 19 b | 10 bcd |

| 4 | 1 | 1 | 2.40 | 12 | 115 ab | 23 b | 11 a | 130 cd | 19 b | 10 bcd |

| CP | 0 | 0 | 1.80 | 6.5 | 144 c | 21 b | 13 ab | 104 b | 19 b | 9 ab |

| 8 | −1.2 | 0 | 1.08 | 6.5 | 104 a | 29 c | 13 abc | 76 a | 21 bc | 7 a |

| 9 | 0 | +1.2 | 1.80 | 13 | 145 c | 26 bc | 16 d | 116 bcd | 24 c | 13 d |

| 10 | 1.2 | 0 | 2.52 | 6.5 | 145 c | 25 bc | 16 cd | 98 ab | 25 c | 11 bcd |

| 11 | 0 | −1.2 | 1.80 | 0 | 143 bc | 29 c | 19 e | 123 bcd | 22 bc | 12 cd |

| C | 0 | 0 | 0 | 0 | 138 bc | 25 bc | 15 cd | 138 d | 25 b | 15 e |

Different letters in the same column indicate significant differences between means (p < 0.05)

CP Central Point (3 replicates), C Control (outside of the design), N Numbers of cells per area, A M .10 3 mean cell area, A T void fraction

For bread crumbs with Ca3CI2, AT increased when 1.80 g/kg Ca was added (0 % In), these results could be associated with softer crumb in the presence of calcium compared to control crumb. At equal inulin quantity (1, 6.5 and 12 %), an increase in calcium content did not modify structural parameters. However, at the same calcium amount (1.20 and 2.40 g/kg), in spite of alveoli presented larger area (AM) as it can be seen in the photographs, N and AT diminished due to the increment of prebiotic; accordingly to the more closed crumb matrix obtained in the presence of prebiotic.

In the case of lactate salt, the opposite behavior comparing to Ca3CI2 was observed, parameter AT decreased when 1.80 g/kg Ca was added. Breads with CaLA2 and inulin presented less percentage of air trapped than control crumb (Fig. 2b, Table 2). At 1 % In, an increase in CaLA2 resulted in the formation of fewer alveoli (<N) of larger area (> AM); although the total air retained by crumbs (AT) was the same. In general, breads with CaLA2 presented more compact crumbs than those made with equal amounts of calcium added as citrate; this behavior reaffirm the concept of the destabilizing effect on gluten structure of lactate anion, previously observed by Salinas and Puppo (2013).

Generally, the firmness presented by a baked product will be lower at higher moisture and volume values. Moreover, size and distribution of the cells as well, influence crumb texture (Cauvain 2004).

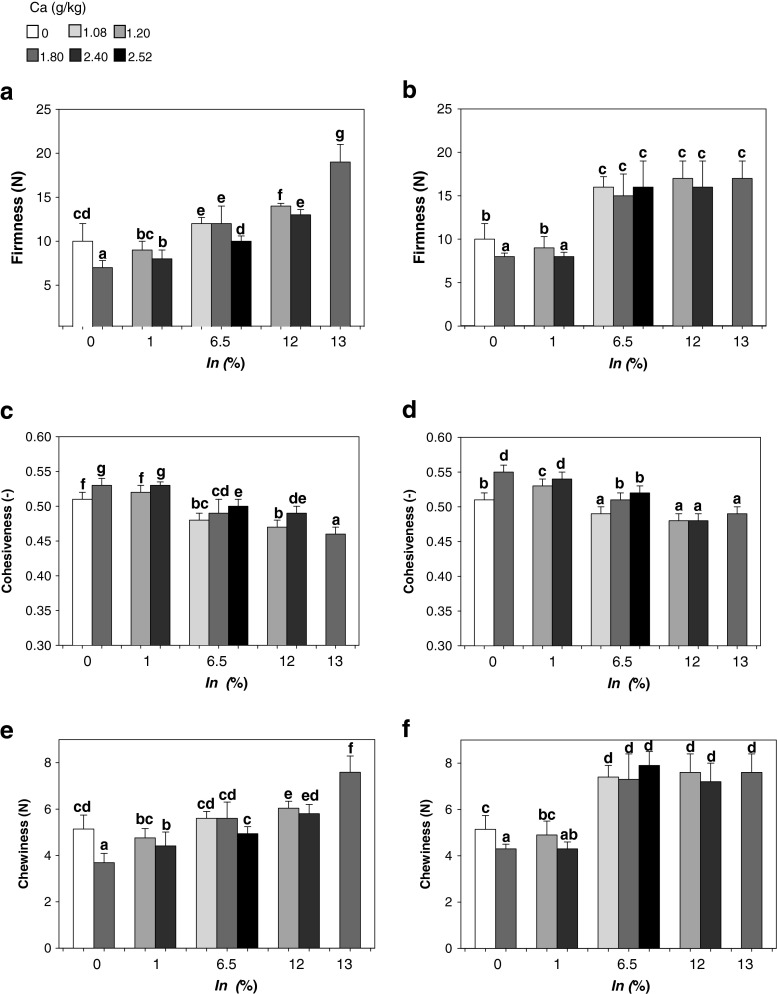

In the absence of In, calcium salts diminished crumb firmness (Fig. 3a, b). An increase of Ca3CI2 caused a decrease in firmness at 6.5 and 12 % In (Fig. 3a). However, at ≥6.5 % In, crumbs with CaLA2 were firmest due to only the prebiotic effect, independently of the calcium salt quantity (Fig. 3b).

Fig. 3.

Textural parameters of bread crumb. a, b Firmness, c, d Cohesiveness, e, f Chewiness. Bread with: Ca3CI2 (a, c, e), CaLA2 (b, d, f). Errors bars: standard deviations. Different letters in the same graphics indicate significant differences (p < 0.05)

In general, the increment of In above 6.5 % caused an increase in crumb firmness (Fig. 3a, b). This increase was consistent with the lower moisture beside a more closed crumb structure. Morris and Morris (2012) reported in a review an increase in crumb firmness with the addition of inulin for several wheat and gluten-free bread systems.

Cohesiveness is a parameter related to forces that bind together the components of the matrix; lower values of cohesiveness are associated with high integration of crumb structure. Up to 6.5%In, an increment in calcium content, increased cohesiveness (Fig. 3c, d). At 12 % In, an increase in Ca3CI2 increased cohesiveness, unlike CaLA2 did not change this parameter. The significant regression coefficients obtained from the cohesiveness model varied indirectly with In. The model proposed for Ca3CI2 was: 0.488–0.025 In (R2 = 0.93, RMSE = 0.01) and for CaLA2: 0.511–0.026 In (R2 = 0.93, RMSE = 0.01).

In the absence of prebiotic, chewiness diminished with both calcium salts; they would facilitate mastication work due to a softer crumb was formed. In the presence of inulin, no significant differences were observed in this parameter with the addition of crescent quantities of calcium salts. Breads with CaLA2 presented higher chewiness than those with Ca3CI2, reaching almost the same value at 13 % In.

The regression model of chewiness obtained for Ca3CI2 was: 5.596 + 1.073In (R2 = 0.84, RMSE = 0.57); and for CaLA2 was: 7.731 + 1.570In + 1.324In2 (R2 = 0.91, RMSE = 0.68).

In brief, in both calcium-inulin systems, texture parameters varied mainly with the prebiotic; at high In quantity, higher firmness and chewiness and lower cohesiveness values were obtained.

Optimization and verification of the models with both calcium salts

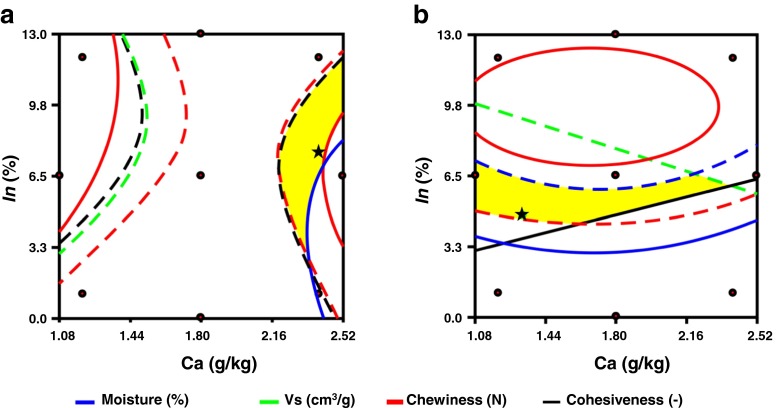

The contour plots were superimposed according to Capanzana and Buckle (1997) and a yellow area of optimum performance was located for all the response variables in which limits of each response have been established (Fig. 4). Variables were included in ranges of 40.2–42.0 % moisture, 2.5–3.0 cm3/g Vs, 0.40–0.50 cohesiveness and 5.50–6.40N chewiness. By the analysis of contour plots from both CCD and the evaluation of the relationships between response and variables, an optimum formulation of bread with both calcium salts was obtained. The region that satisfied all the limits was selected as the area of optimum performance (yellow area). Within this area, the formulation with the highest overall desirability (D = 0.97 for Ca3CI2, D = 0.99 for CaLA2) was selected (star point) as the optimum one for breadmaking. Based on these superimposed plots, it is suggested that the optimum formulation of bread with Ca3CI2 was the one prepared with 2.40 g/kg Ca and 7.49 % In, and for breads formulated with CaLA2 was the one that presented 1.33 g/kg Ca and 4.68 % In. Once the optimal formulations were determined, they were used to produce baked breads and all the response variables of the final products were analyzed. Predicted and experimental values of different response variables of breads of each CCD are shown in Table 3. Experimental and predicted values were within the range proposed by the model, and were not statistically different (p < 0.05); with the exception of Vs and chewiness. Thus, the model can be used to optimize the basic formulation of nutritional breads formulated with organic calcium salts and inulin.

Fig. 4.

Graph of superimposed plots of the four responses variables of bread: moisture, specific volume, chewiness, cohesiveness. Yellow area: feasible region;  : Upper bound;

: Upper bound;  : lower bound. Optimal formulation: black star on the yellow area. a CCD with Ca3CI2, b CCD with CaLA2. Desirability value (D): 0.97 for Ca3CI2, 0.99 for CaLA2

: lower bound. Optimal formulation: black star on the yellow area. a CCD with Ca3CI2, b CCD with CaLA2. Desirability value (D): 0.97 for Ca3CI2, 0.99 for CaLA2

Table 3.

Predicted and experimental value of the responses variables at optimum formulation

| Responses variables | Optimal bread | |||

|---|---|---|---|---|

| Predicted value | Experimental value | Range | ||

| Ca 3 CI 2 | Moisture (%) | 39.2 | 40.2 ± 0.5 | 37.35–40.94 |

| Cohesiveness (−) | 0.48 | 0.52 ± 0.01 | 0.44–0.55 | |

| Chewiness (N) | 6.0 | 4.8 ± 0.5 | 5.1–7.0 | |

| Vs (cm3/g) | 2.20 | 2.50 ± 0.04 | 2.00–2.30 | |

| CaLA 2 | Moisture (%) | 40.6 | 40.6 ± 0.1 | 40.33–40.80 |

| Cohesiveness (−) | 0.51 | 0.50 ± 0.01 | 0.50–0.52 | |

| Chewiness (N) | 7.0 | 5.3 ± 0.6 | 6.07–7.93 | |

| Vs (cm3/g) | 2.5 | 2.3 ± 0.9 | 2.37–2.61 | |

Mean ± SD. Range: Confidence interval of the numerical optimization (95 %)

In a previous work (Salinas and Puppo 2015) we found that the optimum content of calcium carbonate and inulin were 2.19 g/kg Ca and 9.63 % In. Behavior of Ca3CI2 salt was similar to that of the inorganic salt (CaCO3). With these salts, unlike CaLA2, breads of good quality were obtained with high levels of calcium and inulin.

Conclusions

Variables studied fundamentally changed with the prebiotic quantity. An increase of In caused a decrease of tf, Vs and crumb moisture but an increase of bread color as well as firmness and chewiness of crumbs.

Without In, the addition of calcium salt (citrate or lactate) did not change tf nor Vs; although crumbs were softer, more cohesive and with less moisture.

However, breads with Ca3CI2 showed less brownness crust, and crumbs were more aerated; unlike breads with CaLA2 that presented the opposite effect for both variables.

The major differences between both calcium salts were found at 6.5 % In. With this content of inulin, the increase in Ca3CI2 level did not modify bread volume and crumbs retained less amount of water; therefore darker breads although with softer crumbs were obtained. By contrast, an increase in CaLA2 content conducted to smaller and less dark breads but with similar values of moisture and firmness of crumb. Fortification with Ca3CI2 permitted to obtain breads of higher quality than with CaLA2; in addition, optimum bread with a high-inulin quantity was able to be obtained with the former salt. It can be conclude that the achievement of a high-quality bread fortified with calcium and inulin is significantly dependent on the calcium source utilized.

Acknowledgments

Authors would like to acknowledge CONICET and FCAyF (UNLP) of Argentina for the financial support.

References

- AAC (2014) Argentinean Alimentarius Codex. Chapter IX. (Art 661-Res.167) http://www.anmat.gov.ar/alimentos/normativas_alimentos_caa.asp. Accessed 05/05/2015

- AACC . American Association of Cereal Chemists. 10. St. Paul: The Association; 2000. [Google Scholar]

- Buera MP, Retriella C, Lozano RD. Definition of colour in the non-enzymatic browning. Die Farbe. 1985;33:316–326. [Google Scholar]

- Capanzana MV, Buckle KA. Optimization of germination conditions by response surface methodology of a high amylose rice (Oryza sativa) cultivar. Lebensm Wiss Technol. 1997;30(2):155–163. doi: 10.1006/fstl.1996.0142. [DOI] [Google Scholar]

- Cauvain SP (2004) Improving the texture of bread. Texture in food: solid foods. In: Kilcast D (ed) Woodhead Publishing Ltd. Cambrige-England 2: 432–450

- Frutos MJ, Guilabert-Antón L, Tomás-Bellido A, Hernández-Herrero JA. Effect of artichoke (Cynarascolymus L.) fiber on textural and sensory qualities of wheat bread. Food Sci Technol Int. 2008;14(5):49–55. doi: 10.1177/1082013208094582. [DOI] [Google Scholar]

- Hager A, Ryan LAM, Schwab C, Gaenzle MG, O’Doherty JV, Arendt EK. Influence of the soluble fibres inulin and oat beta-glucan on quality of dough and bread. Eur Food Res Technol. 2011;232(3):405–413. doi: 10.1007/s00217-010-1409-1. [DOI] [Google Scholar]

- Hempel S, Jacob A, Rohm H. Influence of inulin modification and flour type on sensory quality of prebiotic wafer crackers. Eur Food Res Technol. 2007;224(3):335–341. doi: 10.1007/s00217-006-0326-9. [DOI] [Google Scholar]

- Khuri AI, Cornell JA. Response surfaces: designs and analyses. 2. New York, USA: Marcel Dekker; 1996. [Google Scholar]

- Komlenić DK, Ugarčić-Hard Ž, Jukić M, Planinić M, Bucić-Kojić A, Strelec I. Wheat dough rheology and bread quality effected by Lactobacillus brevis preferment, dry sourdough and lactic acid addition. Int J Food Sci Technol. 2010;45(7):1417–1425. doi: 10.1111/j.1365-2621.2010.02282.x. [DOI] [Google Scholar]

- Montgomery DC. Design and analysis of experiments. 4. New York: John Wiley and Sons; 1997. [Google Scholar]

- Morris C, Morris GA. The effect of inulin and fructo-oligosaccharide supplementation on the textural, rheological and sensory properties of bread and their role in weight management: a review. Food Chem. 2012;133(2):237–248. doi: 10.1016/j.foodchem.2012.01.027. [DOI] [PubMed] [Google Scholar]

- NSNH (2007) National Survey on Nutrition and Health. Ministerio de Salud. Buenos Aires, Argentina. www.msal.gov.ar. Accessed 02/20/2015

- Peressini D, Sensidoni A. Effect of soluble dietary fibre addition on rheological and breadmaking properties of wheat doughs. J Cereal Sci. 2009;49(2):190–201. doi: 10.1016/j.jcs.2008.09.007. [DOI] [Google Scholar]

- Poinot P, Arvisenet G, Grua-Priol J, Fillonneau C, Le-Bail A, Prost C. Influence of inulin on bread: kinetics and physico-chemical indicators of the formation of volatile compounds during baking. Food Chem. 2010;119(4):1474–1484. doi: 10.1016/j.foodchem.2009.09.029. [DOI] [Google Scholar]

- Ranhotra GS, Gelroth JA, Leinen SD. Increase in bone calcification in young rats fed breads highly fortified with calcium. Cereal Chem. 1999;76(3):325–327. doi: 10.1094/CCHEM.1999.76.3.325. [DOI] [Google Scholar]

- Rastall B, Gibson G (2006) Prebiotics: development and application. Willey

- Roberfroid MB. Introducing inulin-type fructans. Br J Nutr. 2005;93(1):S13–S25. doi: 10.1079/BJN20041350. [DOI] [PubMed] [Google Scholar]

- Salinas MV, Puppo MC. Effect of organic calcium salts–inulin systems on hydration and thermal properties of wheat flour. Food Res Int. 2013;50(1):298–306. doi: 10.1016/j.foodres.2012.10.036. [DOI] [Google Scholar]

- Salinas MV, Puppo MC. Rheological properties of bread dough formulated with wheat flour–organic calcium salts–FOS-enriched inulin systems. Food Bioprocess Technol. 2014;7(6):1618–1628. doi: 10.1007/s11947-013-1180-y. [DOI] [Google Scholar]

- Salinas MV, Puppo MC. Optimization of the formulation of nutritional breads based on calcium carbonate and inulin. LWT Food Sci Technol. 2015;60(1):95–101. doi: 10.1016/j.lwt.2014.08.019. [DOI] [Google Scholar]

- Salinas MV, Zuleta A, Ronayne P, Puppo MC. Wheat flour enriched with calcium and inulin: a study of hydration and rheological properties of dough. Food Bioprocess Technol. 2012;5(8):3129–3141. doi: 10.1007/s11947-011-0691-7. [DOI] [Google Scholar]

- Saricoban C, Yilmaz MT. Modelling the effects of processing factors on the changes in colour parameters of cooked meatballs using response surface methodology. World Appl Sci J. 2010;9(1):14–22. [Google Scholar]

- Scholz-Ahrens KE, Schrezenmeir J. Inulin, oligofructose and mineral metabolism-experimental data and mechanism. Br J Nutr. 2002;87(2):179–186. doi: 10.1079/BJN/2002535. [DOI] [PubMed] [Google Scholar]

- Shittu TA, Raji AO, Sanni LO. Bread from composite cassava-wheat flour I. Effect of baking time and temperature in some physical properties of bread loaf. Food Res Int. 2007;40(2):280–290. doi: 10.1016/j.foodres.2006.10.012. [DOI] [Google Scholar]

- Vitali D, Dragojevic IV, Sebecic B. Effects of incorporation of integral raw materials and dietary fibre on the selected nutritional and functional properties of biscuits. Food Chem. 2009;114(4):1462–1469. doi: 10.1016/j.foodchem.2008.11.032. [DOI] [Google Scholar]

- Weaver CM. Inulin, oligofructose and bone health: experimental approaches and mechanisms. Br J Nutr. 2005;93(1):99–103. doi: 10.1079/BJN20041358. [DOI] [PubMed] [Google Scholar]

- WHO/EMRO (2009) Draft nutrition strategy and plan of action for the Eastern Mediterranean Region 2010–2019. http://www.emro.who.int/nutrition/pdf/nutrition_strategy_2010_2019.pdf. Accessed 05/01/2011

- WHO/UNICEF/MI (2003) Flour fortification: reporting accomplishments. Report of a joint WHO/UNICEF/MIinter-country technical review meeting on flour fortification. Cairo, Egypt