Abstract

A protein-rich puffed snack was produced using a twin screw extruder and the effects of varying levels of tapioca starch (11 to 40 parts), rennet casein (6 to 20 parts) and sorghum flour (25 to 75 parts) on physico-chemical properties and sensory attributes of the product studied. An increasing level of sorghum flour resulted in a decreasing whiteness (Hunter L* value) of the snack. Although the starch also generally tended to make the product increasingly darker, both starch and casein showed redness parameter (a* value) was not significantly influenced by the ingredients levels, the yellow hue (b* value) generally declined with the increasing sorghum level. Tapioca starch significantly increased the expansion ratio and decreased the bulk density and hardness value of the snack, whereas the opposite effects seen in case of sorghum flour. While the water solubility index was enhanced by starch, water absorption index was appreciably improved by sorghum. Incorporation of casein (up to 25 %) improved the sensory color and texture scores, and so also the overall acceptability rating of the product. Sorghum flour had an adverse impact on all the sensory attributes whereas starch only on the color score. The casein or starch level had no perceivable effect on the product’s flavor score. The response surface data enabled optimization of the snack-base formulation for the desired protein level or desired sensory characteristics.

Keywords: Extrusion cooking, Tapioca starch, Rennet casein, Sorghum flour, Expanded snack

Introduction

Extrusion cooking is a well established industrial process in today’s food industry. It is used to produce a wide variety of breakfast cereals and snacks, textured vegetable protein, animal feed, etc. Advantages of extrusion cooking include time saving, energy efficiency, freedom from effluent generation etc. (Riaz 2000). It is known to help bring down the level of anti-nutritional factors in cereals and improves their digestibility.

Most extruded and puffed snacks are often termed as “junk food” (Kumar et al. 2010) because they are typically fried, and are not seen as contributing towards general health and nutrition. With growing concerns for weight control and general health, more and more health oriented snacks are preferred. “Healthy snacking” is important for children and adolescents to help meet their energy and nutrient needs for growth and development.

Milk proteins have long been known for their nutritional and therapeutic value (Zimecki and Kruzel 2007). Besides their very good digestibility (Hambraeus 1992), whey protein has a Protein Efficiency Ratio (PER) of 3.2 and casein has a PER of 2.6 (Walzem et al. 2002). Hence, incorporation of milk protein helps to enhance the nutritional status of extruded snacks. Many researchers had tried to incorporate whey protein products in extruded puffed products and reported adverse effect on textural properties of puffed products (Onwulata et al. 1998; Martinez-Serena and Villota 1992; Brncic et al. 2008; Onwulata and Konstance 2006). Matthey and Hanna (1997) reported that addition of whey protein concentrate (WPC) more than 10 % increased the color parameter and reduced the expansion index.

Cassava (Manihot esculenta subsp. esculenta Crantz) also known as manioc, tapioca or yucca (Olsen and Schaal 2001), cultivated in India and several other tropical countries, is used in the preparation of various traditional dishes, snacks such as wafers, fried chips and also used as animal feed at household level. Industrial utilization of cassava includes production of sago, starch, modified starches, starch based adhesives, sweeteners, biodegradable plastics and alcohol (Balagopalan 1990). Extruded, ready-to-eat snacks based on cassava are not yet available in the Indian snack market.

Sorghum (Sorghum bicolor L. Moench) is an important drought resistant cereal crop (Sang et al. 2008) and fifth most important cereal in the world after wheat, rice, barley and maize (Asare et al. 2010). It is a good source of antioxidant phenolic compounds and cholesterol-lowering waxes (Taylor et al. 2006). However, sorghum contains anti-nutritive factors such as tannin, Kafirins and phytate, which reduce protein and starch digestibility and reduce minerals bioavailability (Mohammed et al. 2011; Zhang and Hamaker 1998; Etuk et al. 2012). Processing techniques such as pressure-cooking, popping, extrusion, baking, nixtamalization (an alkali process for removing pericarp from the grains), and flaking with and without reducing agents, have been suggested as ways of increasing sorghum digestibility and reduce the level of antinutritional factors (Glennie 1987; Gomez et al. 1989; Elkhalifa et al. 2006). The most common cereals used in the extrusion of snacks and breakfast cereals are corn, wheat, rice and oats. Sorghum is not a major ingredient in extruded snacks and breakfast cereals (Riaz 1997).

Hence, combining milk protein with sorghum would potentially enhance the nutritional status of extrusion-cooked snacks. Starch is important to puffing of extruded foods. Presence of casein and sorghum are likely to influence the extrusion cooking behavior of starch. Therefore, in order to optimize the formulation of a milk protein-rich extruded snack, the present study was conducted with the objective of quantifying the effects of the levels of tapioca starch, rennet casein and sorghum flour on the properties of the puffed snack obtained by extrusion cooking of the mixture.

Materials and methods

Raw materials

Tapioca starch (moisture 11.21 %, ash 0.13 %, and starch 88.45 % including 22.57 % amylose, w.b.) having mean particle size of 33.91 μm (range, 15.04 to 58.64 μm) was purchased from Subham Starch Chemical Pvt. Ltd., Faridabad (India). Rennet casein (8.90 % moisture, 81.92 % protein, 0.96 % fat, 8.02 % ash and 0.201 % lactose, w.b.) having mean particle size of 115.23 μm (range, 42.38–181.32 μm) was procured from M/s Modern Dairies Ltd., Karnal (India). Sorghum grains (variety GJ-38), procured from Navsari Agricultural University, Navsari (India), were milled to a fine flour (particle size, 21.15–310.26 μm; mean, 147.80 μm) using a stone mill. The flour had a moisture content 7.28 %, protein 9.20 %, fat 3.75 %, ash 1.58 %, starch 63.58 %, amylose 26.91 % of starch and total dietary fibre 8.44 %, w.b. The Hunter color profile of these three ingredients is given in Table 1.

Table 1.

Color characteristics of raw materials used in the production of extruded snack base

| Hunter L* value | Hunter a* value | Hunter b* value | |

|---|---|---|---|

| Tapioca starch | 90.33 | −0.1 | 5.4 |

| Rennet casein | 86.57 | −1.06 | 10.14 |

| Sorghum flour | 81.88 | 0.22 | 12.67 |

Experimental design and statistical analysis

The levels of sorghum flour, tapioca starch and rennet casein were optimized using Central Composite Rotatable Design (CCRD) of Response Surface Methodology (RSM) using Design-Expert® software (version 7.1.5). The independent factors (x) were the levels of rennet casein (A), tapioca starch (B) and sorghum flour (C) in the pre-mix. The range of the variables was established by preliminary tests. Early on it was observed that the extrusion mixture with less than 20 parts of sorghum flour in it tended to clog the extruder barrel and made it impossible to obtain an extrudate that could be subjected to the planned analyses. Hence the lowest level of sorghum flour used in the experiment was 25parts. Thus, with tapioca starch 11–40 parts, rennet casein 6 – 20parts and sorghum flour 25–75 parts, 20 experiments (eight axial, six factorial and six central points) were performed in triplicate according to second order central composite rotatable design (Khuri and Cornell 1989) with coded and actual levels of sorghum flour, tapioca starch and rennet casein as shown in Table 2. The response functions (y) were the physiochemical and sensory properties given below.These responses were related with the coded factors (expressed in parts) by a second-degree polynomial equation (Eq. 1) using the method of least squares:

| 1 |

where, b0 (constant term), b1, b2,b3 (linear terms), b11, b22,b33 (quadratic terms) and b12, b13, b23 (interactive terms) and ε (random error)represent the coefficients of the polynomial.

Table 2.

Details of the CCRD response surface experiment with three independent variables: rennet casein, tapioca starch and Sorghum flour levels

| Standard Order | Block | Factor 1 | Factor 2 | Factor 3 | Coefficient assessed by |

|---|---|---|---|---|---|

| Rennet casein (parts) | Tapioca starch (parts) |

Sorghum flour (parts) |

|||

| 1 | Block 1 | 13 (14.69) | 25.5 (28.81) | 50 (56.50) | Center |

| 2 | Block 1 | 1.23 (1.60) | 25.5 (33.23) | 50 (65.16) | Axial |

| 3 | Block 1 | 6 (4.96) | 40 (33.06) | 75 (61.98) | Factorial |

| 4 | Block 1 | 13 (11.52) | 49.89 (44.19) | 50 (44.29) | Axial |

| 5 | Block 1 | 13 (9.96) | 25.5 (19.53) | 92.04 (70.51) | Axial |

| 6 | Block 1 | 13 (14.69) | 25.5 (28.81) | 50 (56.50) | Center |

| 7 | Block 1 | 13 (14.69) | 25.5 (28.81) | 50 (56.50) | Center |

| 8 | Block 1 | 20 (23.53) | 40 (47.06) | 25 (29.41) | Factorial |

| 9 | Block 1 | 13 (20.28) | 1.11 (1.73) | 50 (77.99) | Axial |

| 10 | Block 1 | 20 (14.81) | 40 (29.63) | 75 (55.56) | Factorial |

| 11 | Block 1 | 13 (14.69) | 25.5 (28.81) | 50 (56.50) | Center |

| 12 | Block 1 | 20 (35.71) | 11 (19.64) | 25 (44.64) | Factorial |

| 13 | Block 1 | 6 (8.45) | 40 (56.34) | 25 (35.21) | Factorial |

| 14 | Block 1 | 13 (27.98) | 25.5 (54.89) | 7.96 (17.13) | Axial |

| 15 | Block 1 | 20 (18.87) | 11 (10.38) | 75 (70.75) | Factorial |

| 16 | Block 1 | 13 (14.69) | 25.5 (28.81) | 50 (56.50) | Center |

| 17 | Block 1 | 6 (6.52) | 11 (11.96) | 75 (81.52) | Factorial |

| 18 | Block 1 | 13 (14.69) | 25.5 (28.81) | 50 (56.50) | Center |

| 19 | Block 1 | 6 (14.29) | 11 (26.19) | 25 (59.52) | Factorial |

| 20 | Block 1 | 24.77 (24.70) | 25.5 (25.43) | 50 (49.87) | Axial |

Figures in parentheses indicate percentage of the ingredient in the premix

Preparation of the composite pre-mix and its conditioning for extrusion cooking

Sorghum flour, tapioca starch and rennet casein were blended in a Hobart mixer (speed, 60 rpm) for 10 min and based on its initial moisture content, calculated quantity of water was added to get 12 % moisture in the mixture (as determined in preliminary studies on the extruder performance). After further mixing for 10 min, the mixture was passed through a 2 mm size sieve and once more blended in the mixer for 10 min in order to ensure uniform mixing. The resulting mixture was transferred to 1 kg PE bag and kept overnight in a refrigerator for preconditioning of the premix.

Extrusion cooking

Extrusion runs were performed on a twin-screw extruder (capacity, 15 kg/hr), (M/s Basic Technology Pvt. Ltd., Kolkata, India). Based on preliminary studies, first & second heating sections of extruder were kept at constant temperatures of 40 and 120 °C, respectively. The feeder-screw and extruder-screw speeds were kept constant at 40 and 370 rpm, respectively. The extruder barrel was fitted with a 4 mm diameter die at its exit. The cutter at the exit set at a constant speed of 20 rpm. The extrudate was dried in a tray dryer for 30 min at 60° ± 2 °C to equilibrate product at 4 % moisture.

Determination of product physical properties (responses)

‘Expansion ratio’ was determined as the ratio of diameter of the extrudate to that of the die; it expressed radial expansion of the extrudate (Fan et al. 1996). The extrudate diameter was determined as the mean of 10 random measurements made with vernier calipers.

Bulk density was measured by modified method of Hwang and Hayakawa (1980), using mustard seeds instead of glass beads, as displacement medium for measuring the volume of extrudate.

The color of the snacks was measured using a HunterLab Colorflex colormeter (Hunter Associated Laboratory, Inc., USA) using the Universal software version 4.10. Measurement was done by taking finely ground sample [milled to particle size of 0.25 mm using 1093 Cyclotec™ sample mill, (FOSS TECATOR AB, Sweden)] in the glass sample holder up to 2 cm height followed by gently tapping the sample cup ten times on a bench-top.

Modified method of Onwulata et al. (2001) was used for determination of extrudate hardness using TA-XT2i (Stable Micro Systems, UK) Texture Analyzer fitted with a 25 kg load-cell. Warner-Bratzler Blade was used at pre-test, test and post-test speeds of 1, 1 and 2 mm/sec respectively. The peak force during compression the product was taken as a measure of hardness. Ten measurements were conducted on an extrudate and the resulting force-time curves were examined to obtain mean hardness.

Water solubility index (WSI) was determined as an index of starch dextrinization and water absorption index (WAI) as that of starch gelatinization in the extrudate, using the method described by Anderson et al. (1969). The extruded snack was ground first in a pestle & mortar and then milled to fine particle size (0.25 mm) using 1093 Cyclotec™ sample mill (FOSS TECATOR AB, Sweden). Extrudate powder (2.5 g) and water (30 mL) were vigorously mixed in a 50 mL centrifuge tube, incubated in a 37 °C water bath for 30 min, and then centrifuged (3,500 rpm, 15 min). The supernatant was collected in a pre-weighed aluminum dishes and the residue was weighed after water was evaporated below 105 °C. The percentage of dry residue with respect to the dry weight of extrudate powder used in the test was taken as water solubility index (WSI). The weight ratio of centrifuged precipitate to the dry weight of extrudate powder used in the test was taken as the water absorption index (WAI).

Where,

- Wd

Weight of dry solids

- Wp

Weight of precipitate

- Wds

Weight of dissolved solids in supernatant

Chemical analysis

Samples milled in Cyclotec™ sample mill were used to analyze moisture content by the gravimetric method (AOAC 2000). The crude fat of extruded product was estimated using the standard extraction method (AOAC 1995) employing SOCS Plus Extractor (Pelican, India). The protein content of extrudates was determined by micro-Kjeldahl method as described in AOAC (2000) using conversion factor 6.38 for casein and 6.25 for sorghum. The ash content was estimated by using standard method of AOAC (2000). Total dietary fibre content in the optimized product was determined using ‘Total Dietary Fibre Assay Kit’ (TDF-100A) Sigma Aldrich Inc. according to AOAC (2000).

Sensory evaluation

Experimental samples of the extruded snack were organoleptically evaluated by a panel of seven judges selected from the faculty of Dairy Technology Division using a 9-point hedonic scale in which 1 indicated ‘Dislike extremely’ and 9 ‘Like extremely’.

Results and discussion

Model fitting and ANOVA

The effects of independent variables on product characteristics are summarized in Tables 3 and 4. The non-significant lack of fit and significant F value (except for Hunter a* value) suggest that the respective quadratic models could be effectively used to predict the effect of the ingredients level on physical properties and sensory attributes of extruded snack base.

Table 3.

Regression coefficients and ANOVA of the quadratic model for physical parameters and protein content of the extruded snack base as influenced by ingredients levels

| Particulars | Hunter lab color parameter | Expansion ratio | Bulk density | Hardness | Water solubility index | Water absorption index | Protein content | ||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | |||||||

| Intercept | 77.10 | 1.02 | 14.23 | 3.51 | 0.10 | 11.75 | 17.73 | 4.19 | 17.73 |

| Casein (A) | 0.40NS | 0.11 NS | −0.045 NS | 0.04* | −0.01** | −0.61 NS | 5.61** | −0.10 NS | 5.61** |

| Starch (B) | −0.83** | 0.22 NS | 0.01 NS | 0.09** | −0.01** | −1.28* | −3.22** | −0.27** | −3.22** |

| Sorghum (C) | −0.92** | −0.13 NS | −0.44* | −0.14** | 0.01** | 2.23** | −2.89** | 0.41** | −2.89** |

| A2 | 0.64* | −0.079 NS | −0.27 NS | −0.04** | 0.005* | 1.18* | −0.40* | 0.02 NS | −0.40* |

| B2 | −0.30* | 0.027 NS | −0.20 NS | −0.04** | 0.003 NS | 0.39 NS | 0.51** | −0.02 NS | 0.51** |

| C2 | 0.55 NS | 0.01 NS | 0.051 NS | 0.01 NS | 0.002 NS | 1.53** | 0.63** | −0.10 NS | 0.63** |

| AB | −0.75* | 0.07 NS | 0.96** | 0.02 NS | 0.001 NS | −0.08 NS | −0.74** | 0.04 NS | −0.74** |

| AC | 0.15 NS | 0.01 NS | 0.20 NS | −0.03 NS | −0.001 NS | 0.89 NS | −1.52** | −0.05 NS | −1.52** |

| BC | −0.48 NS | −0.21 NS | −0.42 NS | 0.02 NS | −0.008* | −0.67 NS | 1.45** | −0.003 NS | 1.45** |

| R2 | 0.86 | 0.41 | 0.77 | 0.95 | 0.87 | 0.87 | 0.99 | 0.90 | 0.99 |

| Model F value | 7.14** | 0.79 NS | 3.81* | 21.77** | 7.4** | 7.43** | 234.46** | 9.65** | 234.46** |

| Adequate precision | 9.50 | 3.33 | 8.01 | 17.43 | 10.15 | 8.72 | 63.95 | 12.13 | 63.95 |

| Lack of fit | NS | S | NS | NS | NS | NS | NS | NS | NS |

** Highly Significant (p < 0.01)

* Significant (p < 0.05)

NS Non-significant (p > 0.05)

Significant (S)

Table 4.

Regression coefficients and ANOVA of the quadratic model for sensory attributesa of extruded snack base: effect of ingredients level

| Particulars | Sensory parameter | |||

|---|---|---|---|---|

| Flavor | Color & appearance | Texture | Overall acceptability | |

| Intercept | 7.10 | 7.22 | 7.30 | 7.21 |

| Casein (A) | 0.10 NS | 0.21** | 0.19** | 0.17** |

| Starch (B) | 0.04 NS | −0.08* | 0.17** | 0.05 NS |

| Sorghum (C) | −0.14* | −0.14** | −0.20** | −0.16** |

| A2 | −0.11 NS | −0.09* | −0.12** | −0.12** |

| B2 | 0.02 NS | −0.06 NS | −0.18** | −0.07 NS |

| C2 | 0.05 NS | −0.01 NS | 0.03NS | 0.01 NS |

| AB | 0.15* | 0.23** | 0.17** | 0.13* |

| AC | 0.12 NS | −0.01 NS | 0.15* | 0.10 NS |

| BC | 0.12 NS | −0.01 NS | 0.15* | 0.12* |

| R2 | 0.74 | 0.91 | 0.93 | 0.87 |

| Model F value | 3.28* | 11.32** | 15.92** | 7.56** |

| Adequate precision | 6.43 | 13.52 | 14.32 | 9.425 |

| Lack of fit | NS | NS | NS | NS |

**Highly Significant (p < 0.01)

* Significant (p < 0.05)

NS Non-significant (p > 0.05)

a Scored on a 9-point hedonic scale

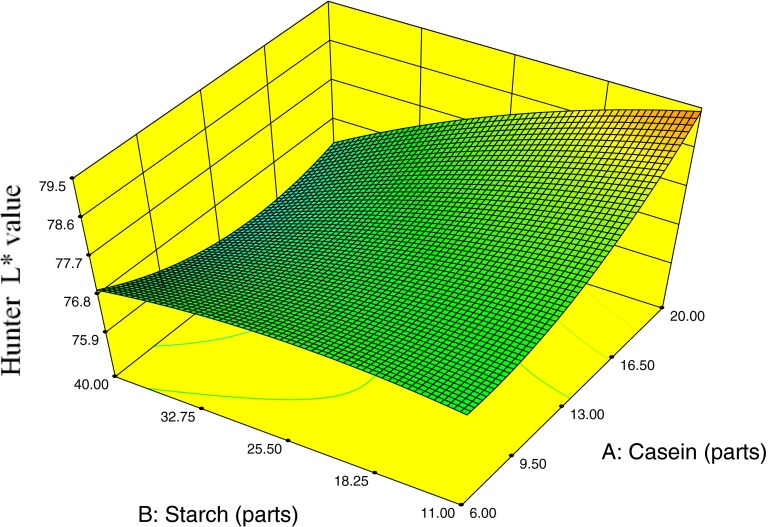

Instrumental color parameters

The extruded snack base was analyzed for its color coordinates viz. Hunter L* (lightness or whiteness) and b* (yellowness) values as influenced by the level of rennet casein, tapioca starch and sorghum flour. At linear level, tapioca starch and sorghum flour tended to significantly (p < 0.01) decrease the whiteness of snack base (Table 3). Fernandez-Gutierrez et al. (2004) found that color intensity increased by high starch concentration in wheat starch and acid casein extrudate due to the presence of reducing sugar resulting from starch dextrinization. The darkening effect of sorghum flour may also be ascribed to the lower L* value of sorghum flour itself (Table 1). At quadratic level, rennet casein and starch had significant (p < 0.05) effects on L* value, the former positive and later negative. The negative interaction (p < 0.05) between rennet casein and tapioca starch suggested that at lower levels of starch, increasing casein level resulted in increasing L* value but at higher starch levels, casein had the opposite effect (Fig. 1). Thus, the starch level appeared to be the limiting factor in Maillard reaction between the casein and reducing sugar generated from starch. Wen et al. (1990) reported that Maillard reaction between dextrinized starch and amino groups of casein changed the color intensity of extrudates. The maximum L* value (80.18) was obtained at lowest starch and highest rennet casein levels in the formulations (Fig. 1).

Fig. 1.

Response surface plots relating to Hunter L* value of extruded snack base influenced by the levels of tapioca starch and rennet casein

The Hunter L* value of extruded snack base could be predicted by the equation (for actual factors) given below:

| 2 |

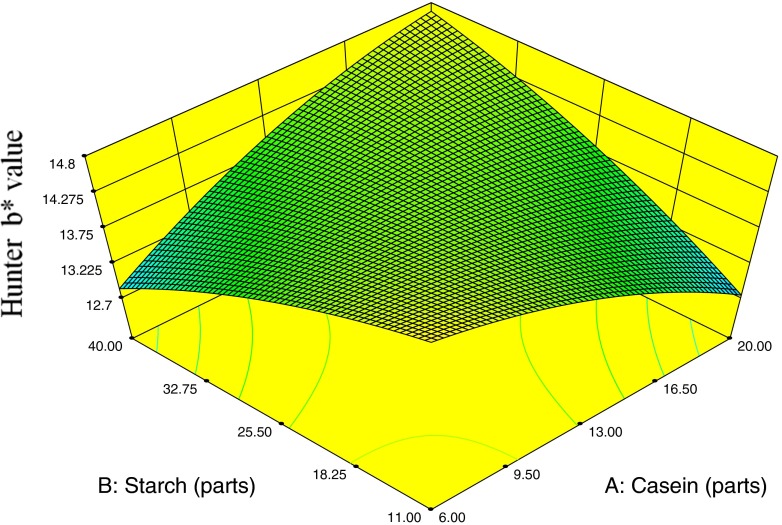

The model for the Hunter a* value is not significant. The Hunter b* value, representing ‘yellowness’ of the product, decreased linearly with an increasing level of sorghum flour (p < 0.05). The effects of rennet casein and tapioca starch were however non-significant, but their interaction (p < 0.01) displayed that at lower level of starch, casein decreased the b* value whereas at higher starch levels, casein had a positive effect (Fig. 2). The highest b* value (15.57) was obtained at the highest starch and highest casein levels (Fig. 2) presumably due to maximized Maillard reaction between dextrinized starch and amino groups from casein (Wen et al. 1990).

Fig. 2.

Response surface plots relating to Hunter b* value of extruded snack base influenced by the levels of sorghum flour, tapioca starch and rennet casein

The Hunter b* value of extruded snack base could be predicted by the equation (for actual factors) given below:

| 3 |

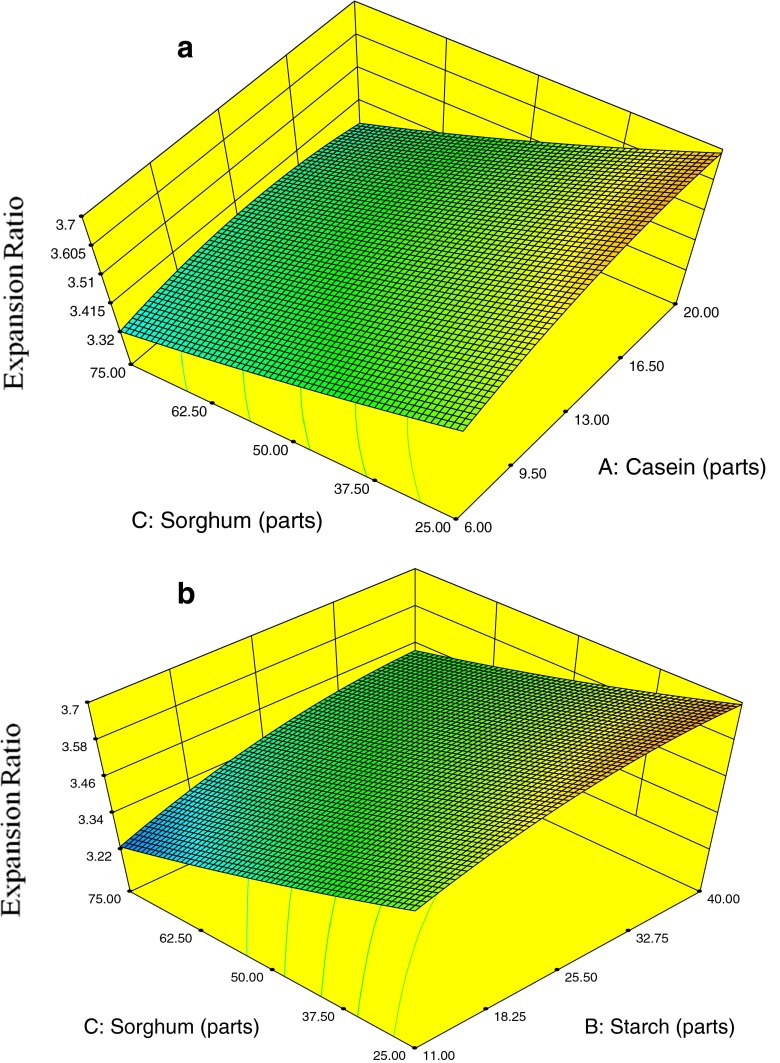

Expansion ratio

The radial expansion ratio of the extruded snack base ranged between 3.15 and 3.81. The coefficient of regression model indicated that the increasing level of rennet casein (p < 0.05) or tapioca starch (P < 0.01) resulted in a significant increase in the expansion ratio, while sorghum flour suppressed the expansion ratio (p < 0.01), the decline in the latter being linear (Table 3). Linko and Linko (1981) concluded that the degree of expansion increased with starch concentration. Expanded volume of cereals and starches decrease with increasing amount of protein (Faubion et al. 1982 and Peri et al. 1983) in feed material. The large molecular structure of casein, hydrophobic properties and random coil conformation were considered to contribute towards maintaining expansion in comparison to whey protein concentrate and isolate (Onwulata et al. 2001). Fernandez-Gutierrez et al. (2004) found that at low moisture (<20 %) and higher barrel temperature (>125 °C), the expansion ratio increased with increasing acid casein content in the mixture with wheat starch. Further, in the present study, an increased level of sorghum flour apparently increased the proportion of fibre in the formulations which presumably caused reduction in the expansion ratio (Fig. 3a and b). There were no significant interactions among the three ingredients. Hashimoto and Grossmann (2003) reported that with increase in the level of bran (carrying considerable insoluble fibre) in extrusion-cooked cassava starch, expansion decreased and bulk density increased. Many other researchers have reported that radial expansion decreased with increasing dietary fibre content (Camire and King 1991; Badrie and Mellowes 1992a; Jin et al. 1994). Lue et al. (1991) reported that the walls of air cells in the extrudate structure were ruptured due to the presence of fibre which prevented the air bubbles from expanding to their full potential. Guy (1985) suggested that bran interferes with bubble expansion by reducing the extensibility of vapour cell walls.

Fig. 3.

Response surface plots relating to expansion ratio of extruded snack base influenced by the levels of sorghum flour, tapioca starch and rennet casein

The expansion ratio of protein rich extruded snack base could be predicted by the equation (for actual values of the variables) given below:

| 4 |

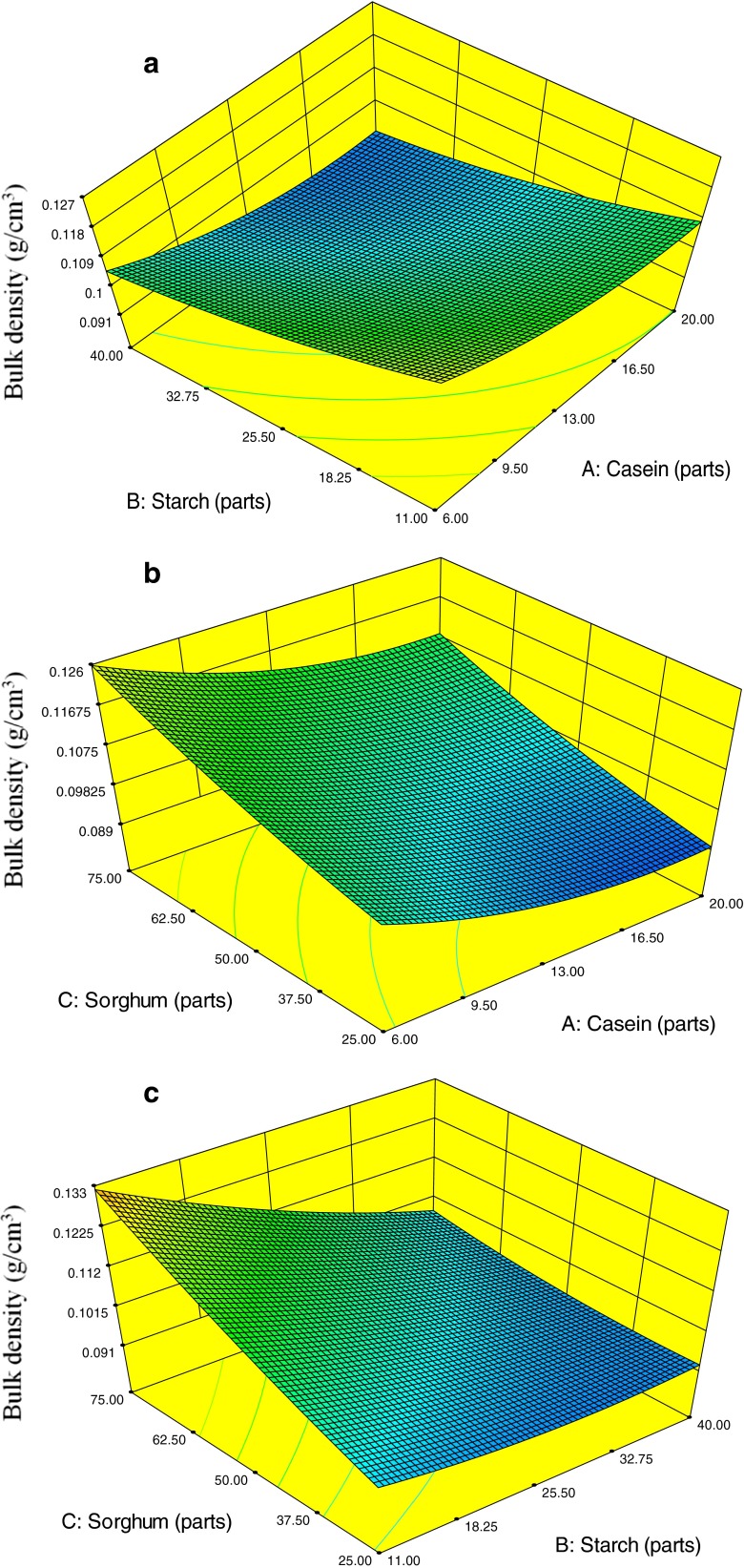

Bulk density

The bulk density of the extruded snack base was in the range of 0.083–0.142 g/cm3. The linear terms of the model for rennet casein and tapioca starch were negative (p < 0.01) while that for sorghum flour was positive (p < 0.01). Thus, with the increasing sorghum flour level, the bulk density progressively increased but the reverse was the case with rennet casein and tapioca starch. Unit density of the extrudate is inversely related to the degree of expansion that occurs during extrusion processing (Colonna et al. 1989). It was therefore obvious that increasing the level of tapioca starch led to increased expansion ratio which was responsible for lower density of the extrudate and the opposite in case of sorghum flour. Fernandez-Gutierrez et al. (2004) found that at low moisture (<20 %) and higher barrel temperature (>125 °C) increasing the acid casein content (up to 35 %) decreased the bulk density of wheat starch extrudates. At quadratic level, rennet casein exhibited a significant positive effect (p < 0.05) which indicated that higher values of bulk density were obtained at higher and lower casein levels (Fig. 4a and b). The interaction between tapioca starch and sorghum flour was significant (p ≤ 0.05), implying that the sorghum caused increase in the bulk density was much more prominent at lower levels of starch than at higher levels. The lowest bulk density was obtained at higher starch and lower sorghum flour levels (Fig. 4 and c).

Fig. 4.

Response surface plots relating to bulk density of extruded snack base influenced by the levels of sorghum flour, tapioca starch and rennet casein

The bulk density of protein rich extruded snack base could be predicted by the equation (for actual factors) given below:

| 5 |

Hardness

The hardness measured as an instrumental indicator of the product’s texture can be considered to be a function of the strength of the walls of air i.e. lamellae in the expanded snack as well as the degree of porosity and pore distribution, which all are expected to be affected by the composition. The hardness of the extruded snack base was in the ranged of 9.79–19.76 N. The coefficients of the linear terms of the quadratic regression model indicated that the tapioca starch had a negative (p < 0.05) and sorghum flour (p < 0.01) positive effects on the hardness value of the extrudate. Increasing the level of tapioca starch led to increased expansion and hence, decreased hardness. Texture properties of extrudates are highly influenced by expansion degree (Anton et al. 2009).Rennet casein, overall, tended to decrease the hardness; while the linear-term coefficient was negative but non-significant, the quadratic term was positive (p < 0.05), thereby suggesting that increasing casein level initially, at lower levels, decreased the hardness followed by gradual increase at higher levels irrespective of the level of starch or sorghum (Table 3). Voort and Stanley (1984) found that incorporation of rennet casein (10 to 30 %) had no significant effect on hardness value of wheat flour extrudates. On the other hand, as the level of sorghum-flour level in the extrusion premix increased, the hardness increased significantly (p < 0.01) and the quadratic term was positive (p < 0.01), indicating that the increase in the hardness was rather slow at lower levels of sorghum but much faster at higher levels (Table 3). Increased bulk density and breaking force were found to be accompanied by decreased radial expansion attributable to the increased fibre content in corn meal extrudates (Hsieh et al. 1989). Incorporation of fibre in extruded products also resulted in increased density and hardness (Mendonca et al. 2000; Yanniotis et al. 2007; Ainsworth et al. 2007).

The extrudate’s hardness could be predicted by the equation (for actual values or variables) given below:

| 6 |

Effect of the ingredients level on water solubility index (WSI)

Water solubility index (WSI) and water absorption index (WAI) reflect the changes in starch molecules as a result of extrusion cooking. Higher values of WSI indicates extensive dextrinization of starch molecules, whereas higher values of WAI indicates presence of large fragments of gelatinized starch molecules (Gomez and Aguilera 1984; Tang and Ding 1994; Seker 2005; van den Einde et al. 2003). The solubility and water absorption behaviour of the expanded snack are expected to potentially influence the mouth-feel characteristics of the product.

As shown in Fig. 5, both rennet casein and sorghum flour significantly (p < 0.01) decreased the WSI of the snack, whereas the starch level had the opposite effect (p < 0.01). The positive quadratic coefficient for sorghum flour indicated that with increasing sorghum level WSI decreased, the rate of decrease being initially faster than later at higher flour levels. On the other hand, the negative quadratic-term coefficient for starch (p < 0.01) suggested that the response surface was convex upward i.e. the early rapid rise in WSI was followed by a declining increase with increasing starch level (Fig. 5).The effect of one ingredient was influenced by the others as is evident from the fact that all the interactions were significant (Table 3). Thus, at lower levels of starch the effect of casein was significantly more prominent than at higher starch levels (p < 0.05). Similarly, at lower levels of sorghum flour, the casein-caused decline in WSI was greater (p < 0.01) than that at higher flour levels. Figure 5 further shows that at lower levels of starch, the WSI decreased more with increasing sorghum flour as compared to higher starch levels.

Fig. 5.

Response surface plots relating to water solubility index of extruded snack base influenced by the levels of sorghum flour, tapioca starch and rennet casein

Badrie and Mellowes (1992b) reported that addition of cassava starch to cassava flour increased total carbohydrates, and correspondingly increased the amount of reducing sugar produced by extrusion cooking which, in turn increased WSI of the extrudate. Increasing casein levels in extruded blends of casein and wheat starch were reported to decrease WSI of the resulting extrudate, as protein lost solubility on account of ‘denaturation’ or aggregation (Fernandez-Gutierrez et al. 2004).

WSI had significant positive correlation with expansion index (r = 0.61, p < 0.01) while negative correlation with bulk density (r = −0.52, p < 0.05). It was related to the quantity of soluble molecules which increased with expansion (Mercier et al. 1989). Extrudates with higher expansion ratio have been reported to have a lower bulk density and higher water solubility index when operating with lower moisture content and higher screw speed (Charunuch et al. 2003).

The water solubility index of protein rich extruded snack base could be predicted by the equation (for actual values of the variables) given below:

| 7 |

Water absorption index (WAI)

The negative and positive coefficients of linear terms for starch and sorghum flour in of the regression model for WAI indicate that starch decreased (p < 0.01) and sorghum flour increased the WAI of the extrudate (p < 0.01). As shown in Table 3, the quadratic and interaction terms were all found to be non-significant which suggested that there was largely a linear dependence of the extrudate’s WAI on tapioca starch and sorghum levels. The positive effect of sorghum flour on WAI was associated with the increasing proportion of non-starch portion, particularly fibre, in the extruder feed with increasing sorghum-flour level. Increasing the cassava bran content of the cassava starch extrudates resulted in increased WAI as reported by Hashimoto and Grossmann (2003). WAI had significant negative correlation with expansion index (r = −0.83, p < 0.01) while positive correlation with bulk density (r = 0.79, p < 0.01) and hardness value (r = 0.66, p < 0.01).

The water absorption index of protein rich extruded snack base could be predicted by the equation (for actual values of the variables) given below:

| 8 |

Protein content

The protein content of the extruded snack base ranged between 7.54 and 34.30 %. The coefficients of the linear terms of the model indicated that the increase in rennet casein level significantly (p < 0.01) increased the protein content while increase in tapioca starch and sorghum flour levels significantly (p < 0.01) decreased the same (Table 3). The quadratic term for rennet casein was negative (p < 0.05), and those for tapioca starch and sorghum flour were positive (p < 0.01). The interactions between rennet casein & tapioca starch and between rennet casein & sorghum flour were negative (p < 0.01). The decrease may be to increase in level of starch and sorghum flour, both together decreased the proportion of casein in the mixture. Interaction between sorghum flour and tapioca starch found to be positively highly significant (p < 0.01).

The extrudate protein content could be predicted by the equation (for actual values or variables) given below:

| 9 |

Sensory attributes

Sensory attributes namely color and appearance, flavor, texture and overall acceptability were monitored as responses in the RSM experiment to provide a basis for the optimization of the milk-protein rich extruded snack base.

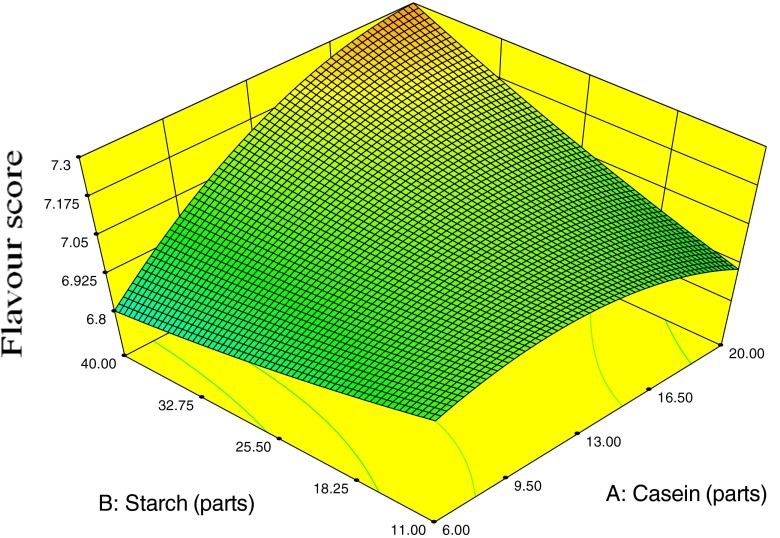

The flavor score of the extruded snack base ranged from 6.50 to 7.44.on a 9-point hedonic scale. Of the three ingredients, however, only sorghum flour had a significant (p < 0.05) impact on this sensory attribute, an increasing sorghum-flour level decreasing the flavor score (Table 4). Although individually casein and starch exhibited little effect on the flavor score, the significant interaction between the two (p < 0.05) suggested that at lower levels of casein, flavor score decreased with increasing starch level but at higher casein levels, the opposite was true (Fig. 6) Voort and Stanley (1984) reported that rennet casein at 10 to 30 % did not significantly influence the flavor of wheat extrudates.

Fig. 6.

Response surface plots relating to sensory flavor score of extruded snack base influenced by the levels of sorghum flour, tapioca starch and rennet casein

The flavor score of protein rich extruded snack base could be predicted by the equation (for actual factors) given below:

| 10 |

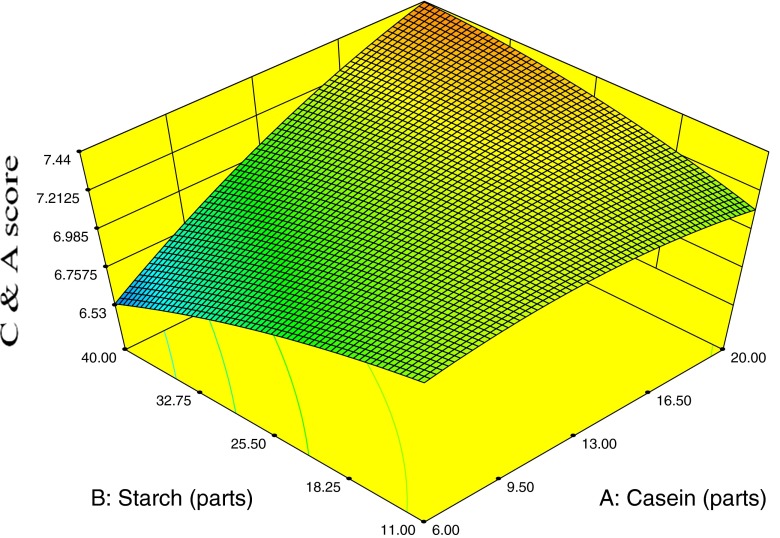

The color and appearance score of the snack base ranged between 6.38 and 7.59. The coefficient estimates of the model reveal that with increasing rennet casein the color and appearance score increased significantly (p < 0.01), the increase being represented by convex upward response surface (p < 0.05). Tapioca starch (p < 0.05) and sorghum flour (p < 0.01) had negative impact on color and appearance score (Table 4). As noted above, incorporation of starch decreased the Hunter L* value while sorghum flour decreased the same, the Hunter L* values which apparently led to reduction in color and appearance score (Table 3). The interaction effect of rennet casein and tapioca starch was positive (p < 0.01); the maximum color and appearance score was obtained at higher levels of rennet casein and tapioca starch (Fig. 7). A moderate correlation was found between color & appearance score and Hunter b* value (r = 0.55, p < 0.05).

Fig. 7.

Response surface plots relating to sensory color & appearance score of extruded snack base influenced by the levels of sorghum flour, tapioca starch and rennet casein

The color & appearance score of extruded snack base could be predicted by the following equation (for actual factors):

| 11 |

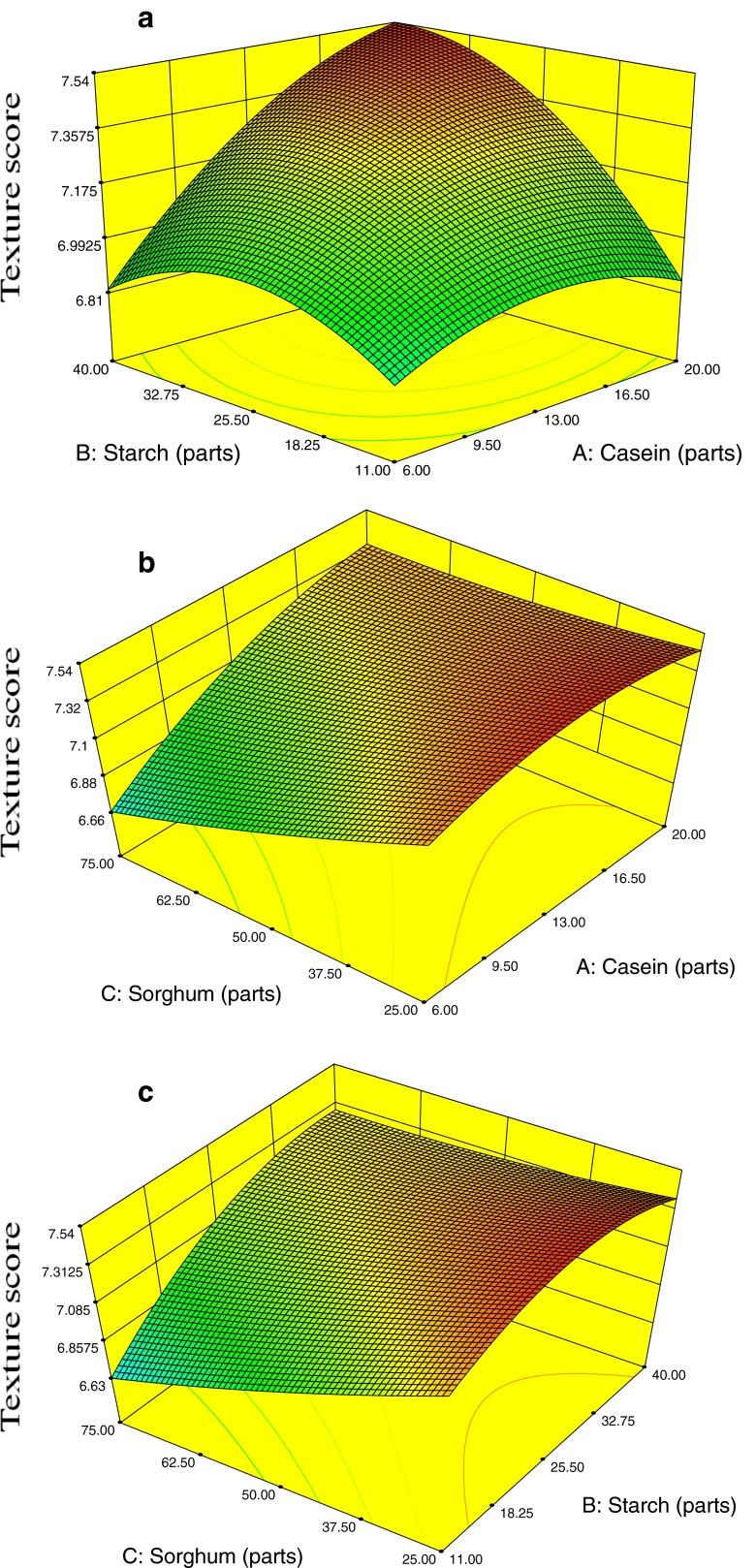

The texture score of extruded snack base ranged between 6.31 and 7.59. The linear coefficients for rennet casein and tapioca starch were positive (p < 0.01) while sorghum flour had a negative effect on the texture score of the snack (p < 0.05). With an increase in the starch or rennet casein levels, the texture score increased, but the score decreased with increasing sorghum flour level (Fig. 8). At quadratic level, rennet casein and tapioca starch exhibited negative effects (p < 0.01), which indicated that with the level of either factor increasing there was an initial increase in texture score but at higher levels the effect was reversed (Fig. 8a). Also, the interaction effects of these three factors on texture score were significant. However, Voort and Stanley (1984) reported that rennet casein had no significant effect on the sensory texture score of wheat-flour extrudates. The texture score exhibited significant correlations with expansion index (r = 0.734, p < 0.01), bulk density (r = −0.81, p < 0.01), hardness value (r = −0.57, p < 0.01), WSI (r = 0.50, p < 0.05) and with WAI (r = −0.60, p < 0.01).

Fig. 8.

Response surface plots relating to sensory texture score of extruded snack base influenced by the levels of sorghum flour, tapioca starch and rennet casein

The texture score of the extruded snack base could be predicted by the equation (for actual factors) given below:

| 12 |

The overall acceptability score of the extruded snack base ranged from 6.5 to 7.5. The partial co-efficient of the regression model indicated that the level of rennet casein significantly (p < 0.01) increased whereas the sorghum flour decreased the overall acceptability score (Table 4). The quadratic term of rennet casein was negative. The interactions between rennet casein and tapioca starch, and tapioca starch and sorghum flour were positive (p ≤ 0.05). The correlations of overall acceptability score with expansion index (r = 0.64) and bulk density (r = −0.79), were significant (p < 0.01).

The overall acceptability score of protein rich extruded snack base could be predicted by the equation (for actual values of the variables) given below:

| 13 |

Numerical optimization of formulations

Optimization of the levels of rennet casein, tapioca starch and sorghum flour level was attempted using CCRD Response Surface Design setting the conditions (constraints) as shown in Table 5. The five optimized solutions were found and the solution obtained with highest desirability (0.899) was selected as the optimum one and was verified by using the suggested levels of rennet casein, tapioca starch and sorghum flour in the premix for the preparation of an extruded snack base and comparing the predicted values with observed values for the physico-chemical properties and sensory characteristics of the resulting extruded snack base. The results obtained are presented in Table 6. The observed values and the predicted values were subjected to t-test. The t-test indicated that there was no significant difference between the predicted and observed values except for flavor score, water solubility index. These differences may be ascribed to the experimental error.

Table 5.

Goals set for constraints to optimize the formulation of extruded snack base

| Constraint | Goal set | Lower limit | Upper limit |

|---|---|---|---|

| Rennet casein level (parts) | in range | 6 | 20 |

| Tapioca starch level (parts) | in range | 11 | 40 |

| Sorghum flour level (parts) | in range | 25 | 75 |

| Hunter L* value | in range | 74.29 | 80.19 |

| Hunter a* value | in range | 0.22 | 1.81 |

| Hunter b* value | in range | 12.1 | 15.57 |

| Expansion ratio | target = 3.6 | 3.146 | 3.806 |

| Bulk density (g/cm3) | in range | 0.0834 | 0.1421 |

| Protein content (%) | in range | 7.54 | 34.3 |

| Hardness (N) | minimize | 9.79 | 19.76 |

| Flavor score | maximize | 6.5 | 7.44 |

| Color & appearance score | maximize | 6.38 | 7.59 |

| Texture score | maximize | 6.31 | 7.59 |

| Overall acceptability score | maximize | 6.5 | 7.5 |

| Water solubility index (%) | in range | 23.06 | 53.68 |

| Water absorption index | in range | 3.18 | 5.04 |

Table 6.

Predicted and observed values for optimized extruded snack base formulation

| Parameter | Predicted value | Actual valuea | t0.05 | |

|---|---|---|---|---|

| Physico-chemical properties | Hunter L* Value | 76.54 | 76.87 | 2.20 NS |

| Hunter b* Value | 14.82 | 14.49 | -1.38 NS | |

| Expansion Ratio | 3.60 | 3.57 | -2.29 NS | |

| Bulk Density (g/cm3) | 0.0912 | 0.092 | 1.56 NS | |

| Hardness (N) | 10.92 | 11.37 | 2.43NS | |

| Protein Content (%) | 20.12 | 19.75 | -2.46 NS | |

| Sensory attributes | Flavor | 7.28 | 7.89 | 9.54* |

| Color & Appearance | 7.47 | 7.61 | 0.73NS | |

| Texture | 7.52 | 7.63 | 1.48 NS | |

| Overall Acceptability | 7.34 | 7.66 | 2.54 NS | |

| Solubility and pasting properties | WSI (%) | 44.96 | 43.16 | -5.04* |

| WAI | 3.78 | 3.85 | 0.87 NS | |

tcrit (one-tail) = 2.13

tcrit (two-tail) = 2.78

a Means from triplicate experiments

The optimized extruded snack base was analysed for its chemical composition (Table 7). The snack base had 19.75 % protein, 0.75 % fat with total dietary fibre content of 3.39 %, w.b.

Table 7.

Compositional characteristics of the optimized extruded snack base formulation

| Constituent | % by wt. |

|---|---|

| Moisture | 3.96 ± 0.10 |

| Fat | 0.75 ± 0.021 |

| Protein | 19.75 ± 0.26 |

| Ash | 2.5 ± 0.021 |

| Total dietary fibre | 3.39 ± 0.36 |

| Carbohydratesa | 73.04 |

Values are mean ± standard error (from three determinations)

aCalculated by difference

Conclusion

The regression models for various physicochemical parameters namely, color profile, expansion ratio, bulk density, instrumental hardness, water-solubility index and water-absorption index, and sensory attributes viz., flavor, color and appearance, texture and overall acceptability ratings of the extrudate as determined by the major ingredients viz., rennet casein, tapioca starch and sorghum flour taken as independent factors could be developed based on the data generated through the response surface methodology experiment. Diagnostic check of the resulting quadratic models revealed that all important model parameters (responses) could be fairly accurately predicted. Significantly, no adverse effects of rennet casein were observed on the physical properties of the extrudates while the reverse was true for the sorghum flour. Rennet casein and tapioca starch exerted no adverse effect on the sensory scores but the sorghum flour generally tended to depress the sensory scores of the snack base. However, favourable interactions (p < 0.05) between casein and sorghum flour levels, and starch and sorghum flour levels with respect to texture and overall acceptability score of snack base, made it possible to strike a right balance between the ingredients so as to obtain an optimum combination. The optimized base could potentially be converted into a highly palatable expanded snack.

Acknowledgments

The authors would like to thank Prof. A. K. Srivastava, Director, N.D.R.I. for his keen interest in the study. The first author gratefully acknowledges the support received in form of junior research fellowship through Indian Council of Agricultural Research which enabled him to conduct this research.

References

- Ainsworth P, Ibanoglu S, Plunkett A, Ibanoğlu E, Stojceska V. Effect of brewers spent grain addition and screw speed on the selected physical and nutritional properties of an extruded snack. J Food Eng. 2007;81:702–709. doi: 10.1016/j.jfoodeng.2007.01.004. [DOI] [Google Scholar]

- Anderson RA, Conway HF, Pfeifer VF, Griffin EL. Gelatinization of corn grits by roll and extrusion cooking. Cereal Sci Today. 1969;14(1):4–7. [Google Scholar]

- Anton AA, Fulcher RG, Arntfield SD. Physical and nutritional impact of fortification of corn-starch based extruded snacks with common bean (Phaseolus vulgaris L.) flour: effects of bean addition and extrusion cooking. Food Chem. 2009;113:989–996. doi: 10.1016/j.foodchem.2008.08.050. [DOI] [Google Scholar]

- AOAC (1995) Official methods of analysis (16th ed.). Association of Official Analytical Chemists Washington

- AOAC (2000) Official methods of analysis (17th ed.). Association of Official Analytical Chemists Washington

- Asare EK, Sefa-Dedeh S, Afoakwa EO, Sakyi-Dawson E, Budu AS (2010) Modelling the effects of feed moisture and ingredient variations on the physical properties and functional characteristics of extruded sorghum-groundnut-cowpea blends using response surface methodology. Int J Food Eng 6(4): Art. 4

- Badrie N, Mellowes WA. Soybean flour/oil and wheat bran effects on characteristics of cassava (ManihotesculentaCrantz) flour extrudate. J Food Sci. 1992;57:108–111. doi: 10.1111/j.1365-2621.1992.tb05435.x. [DOI] [Google Scholar]

- Badrie N, Mellowes WA. Cassava starch or amylose effect on characteristics of cassava (Manihotesculenta Crantz) extrudate. J Food Sci. 1992;57(1):103–107. doi: 10.1111/j.1365-2621.1992.tb05434.x. [DOI] [Google Scholar]

- Balagopalan C (1990) Utilization of cassava in India: research and developmental need. In: Howeler RH (ed) Proc. 8thSymp. Int. Soc. Trop. Root Crops. Held in Bangkok Thailand. Oct 30- Nov 5. 1988. 363

- Brncic M, Karlovic S, Bosiljkov T, Tripalo B, Jezek D, Cugelj I, Obradovic V. Enrichment of extruded snack products with whey proteins. Mljekarstvo. 2008;58(3):275–295. [Google Scholar]

- Camire ME, King CC. Protein and fiber supplementation effects on extruded corn meal snack quality. J Food Sci. 1991;56:760–763. doi: 10.1111/j.1365-2621.1991.tb05376.x. [DOI] [Google Scholar]

- Charunuch C, Boonyasirikool P, Tiengpook C. Physical properties of direct expansion extruded snack in utilization from Thai brown rice. Kasetsart J (Nat Sci) 2003;37(3):368–378. [Google Scholar]

- Colonna P, Tayeb J, Mercier C. Extrusion cooking of starch and starchy products. In: Mercier C, Linko P, Harper JM, editors. Extrusion cooking. St. Paul: American Association of Cereal Chemists Inc.; 1989. pp. 247–319. [Google Scholar]

- Elkhalifa AO, Bernhardt R, Bonomi F, Iametti S, Pagani MA, Zardi M. Fermentation modifies protein/protein and protein/starch interactions in sorghum dough. Eur Food Res Technol. 2006;222:559–564. doi: 10.1007/s00217-005-0124-9. [DOI] [Google Scholar]

- Etuk EB, Okeudo NJ, Esonu BO, Udedibie ABI. Antinutritional factors in sorghum: chemistry, mode of action and effects on livestock and poultry. J Anim Feed Res. 2012;2(2):113–119. [Google Scholar]

- Fan J, Mitchell JR, Blanchard JMV. The effect of sugars on the extrusion of maize grits: I. The role of the glass transition in determining product density and shape. Int J Food Sci Technol. 1996;31:55–65. doi: 10.1111/j.1365-2621.1996.22-317.x. [DOI] [Google Scholar]

- Faubion JM, Hoseney RC, Seib PA. Functionality of grain components in extrusion. Cereal Foods World. 1982;27:212. [Google Scholar]

- Fernandez-Gutierrez JA, Martin-Martinez ES, Martinez-Bustos E, Cruz-Orea A. Physicochemical properties of casein-starch interaction obtained by extrusion process. Starch. 2004;56:190–198. doi: 10.1002/star.200300211. [DOI] [Google Scholar]

- Glennie CW. Physico-chemical properties of sorghum starch thermally treated by different methods. Starch. 1987;39:273–276. doi: 10.1002/star.19870390805. [DOI] [Google Scholar]

- Gomez MH, Aguilera JM. A physicochemical model for extrusion of corn starch. J Food Sci. 1984;49(1):40–43. doi: 10.1111/j.1365-2621.1984.tb13664.x. [DOI] [Google Scholar]

- Gomez MH, McDonough CM, Rooney LW, Waniska RD. Changes in corn and sorghum during nixtamalization and tortilla baking. J Food Sci. 1989;54:330–336. doi: 10.1111/j.1365-2621.1989.tb03074.x. [DOI] [Google Scholar]

- Guy RCF. The extrusion revolution. Food Manuf. 1985;60:26–29. [Google Scholar]

- Hambraeus (1992) Nutritional aspects of milk proteins. In: Fox PF (ed) Advanced dairy chemistry. Vol. 12nd edn. Elsevier Applied Science

- Hashimoto JM, Grossmann MEV. Effects of extrusion conditions on quality of cassava bran/cassava starch extrudates. Int J Food Sci Technol. 2003;38:511–517. doi: 10.1046/j.1365-2621.2003.00700.x. [DOI] [Google Scholar]

- Hsieh F, Mulvaney SJ, Huff HE, Lue S, Brent J. Effect of dietary fibre and screw speed on some extrusion processing and product variables. Lebensm Wiss Technol. 1989;22:204–207. [Google Scholar]

- Hwang MP, Hayakawa HI. Bulk densities of cookies undergoing commercial baking processes. J Food Sci. 1980;45:1400–1407. doi: 10.1111/j.1365-2621.1980.tb06563.x. [DOI] [Google Scholar]

- Jin Z, Hsieh F, Huff HE. Extrusion cooking of corn meal with soy fiber salt and sugar. Cereal Chem. 1994;71:227–234. [Google Scholar]

- Khuri AI, Cornell JA. Responses surfaces designs and analysis. NY: Marcel Dekker; 1989. [Google Scholar]

- Kumar N, Sarkar BC, Sharma HK. Development and characterization of extruded product of carrot pomace rice flour and pulse powder. Afr J Food Sci. 2010;4(11):703–717. [Google Scholar]

- Linko P, Linko YY. Bioconversion processes. In: Pomeranz Y, Munck L, editors. Cereals: a renewable resource: theory and practice. St. Paul: American Association of Cereal Chemists Inc.; 1981. pp. 339–494. [Google Scholar]

- Lue S, Hsieh F, Huff HE. Extrusion cooking of corn meal and sugar beet fiber: effects on expansion properties starch gelatinization and dietary fiber content. Cereal Chem. 1991;68:227–234. [Google Scholar]

- Martinez-Serena MD, Villota R (1992) Reactivity functionality and extrusion performance of native and chemically modifided whey proteins. In: Kokini JL, Ho CT, Karwe MV (eds) Food Extrusion Science and Technology

- Matthey FP, Hanna MA. Physical and functional properties of twin screw extruded whey protein concentrate corn starch blends. Lebensm Wiss Technol. 1997;30:359–366. doi: 10.1006/fstl.1996.0189. [DOI] [Google Scholar]

- Mendonca S, Grossmann MVE, Verhe R. Corn bran as a fibre source in expanded snacks. Lebensm Wiss Technol. 2000;33:2–8. doi: 10.1006/fstl.1999.0601. [DOI] [Google Scholar]

- Mercier C, Linko P, Harper JM. Extrusion cooking. St.Paul: American Association of Cereal Chemists Inc; 1989. [Google Scholar]

- Mohammed NA, Mohammed IAM, Barbiker EE. Nutritional evaluation of sorghum flour (Sorghum bicolour L. Moench) during processing of injera. World Acad Sci Eng Technol. 2011;54:72–76. [Google Scholar]

- Olsen KM, Schaal BA. Microsatellite variation in cassava (Manihot esculenta, Euphorbiaceae) and its wild relatives: further evidence for a southern Amazonian origin of domestication. Am J Bot. 2001;88:131–142. doi: 10.2307/2657133. [DOI] [PubMed] [Google Scholar]

- Onwulata CI, Konstance RP. Extruded corn meal and whey protein concentrate: effect of particle size. J Food Process Preserv. 2006;30:475–487. doi: 10.1111/j.1745-4549.2005.00082.x. [DOI] [Google Scholar]

- Onwulata CI, Smith PW, Konstance RP, Holsinger VH. Physical properties of extruded products as affected by cheese whey. J Food Sci. 1998;63:814–818. doi: 10.1111/j.1365-2621.1998.tb17906.x. [DOI] [Google Scholar]

- Onwulata CI, Konstance RP, Smith PW, Holsinger VH. Co-extrusion of dietary fibre and milk proteins in expanded corn products. Lebensm Wiss Technol. 2001;34:424–429. doi: 10.1006/fstl.2000.0742. [DOI] [Google Scholar]

- Peri C, Barbieri R, Casiraghi EM. Physical chemical and nutritional quality of extruded corn germ flour and milk protein blends. Int J Food Sci Technol. 1983;18(1):43–52. doi: 10.1111/j.1365-2621.1983.tb00243.x. [DOI] [Google Scholar]

- Riaz M (1997) Technology of producing snack food by extrusion. Research Department Technical Bulletin XIX (2) AIB

- Riaz MZ (2000) Introduction to extruders and their applications. In: Extruders in food applications. CRC Press, Boca Raton. pp. 3

- Sang Y, Bean S, Seib PA, Pedersen J, Shi YC. Structure and functional properties of sorghum starches differing in amylose content. Agric Food Chem. 2008;56:6680–6685. doi: 10.1021/jf800577x. [DOI] [PubMed] [Google Scholar]

- Seker M. Selected properties of native or modified maize starch/soy protein mixtures extruded at varying screw speed. J Sci Food Agric. 2005;85:1161–1165. doi: 10.1002/jsfa.2086. [DOI] [Google Scholar]

- Tang J, Ding XL. Relationship between functional properties and macromolecular modification of extruded corn starch. Cereal Chem. 1994;71(4):364–369. [Google Scholar]

- Taylor JRN, Schoberb TJ, Beanb SR. Novel food and non-food uses for sorghum and millets. J Cereal Sci. 2006;44:252–271. doi: 10.1016/j.jcs.2006.06.009. [DOI] [Google Scholar]

- van den Einde RM, van der Goot AJ, Boom RM. Understanding molecular weight reduction of starch during heating–shearing processes. J Food Sci. 2003;68(8):2396–2404. doi: 10.1111/j.1365-2621.2003.tb07036.x. [DOI] [Google Scholar]

- Voort FR, Stanley DW. Improved utilization of dairy proteins: co- extrusion of casein and wheat flour. J Dairy Sci. 1984;67(4):749–758. doi: 10.3168/jds.S0022-0302(84)81365-X. [DOI] [Google Scholar]

- Walzem RL, Dillard CJ, German JB. Whey components: millennia of evolution create functionalities for mammalian nutrition: what we know and what we may be overlooking. Crit Rev Food Sci Nutr. 2002;42(4):353–375. doi: 10.1080/10408690290825574. [DOI] [PubMed] [Google Scholar]

- Wen LF, Rodis P, Wassermant BP. Starch fragmentation and protein insolubilization during twin-screw extrusion of corn meal. Cereal Chem. 1990;67:268–275. [Google Scholar]

- Yanniotis S, Petraki A, Soumpasi E. Effect of pectin and wheat fibres on quality attributes of extruded cornstarch. J Food Eng. 2007;80:594–59. doi: 10.1016/j.jfoodeng.2006.06.018. [DOI] [Google Scholar]

- Zhang G, Hamaker BR. Low α-amylase starch digestibility of cooked sorghum flours and the effect of protein. Cereal Chem. 1998;75:710–713. doi: 10.1094/CCHEM.1998.75.5.710. [DOI] [Google Scholar]

- Zimecki M, Kruzel ML. Milk-derived proteins and peptides of potential therapeutic and nutritive value. J Exp Ther Oncol. 2007;6(2):89–106. [PubMed] [Google Scholar]