Abstract

The U.S. Environmental Protection Agency (EPA) established strict regulations for highway diesel engine exhaust emissions of particulate matter (PM) and nitrogen oxides (NOx) to aid in meeting the National Ambient Air Quality Standards. The emission standards were phased in with stringent standards for 2007 model year (MY) heavy-duty engines (HDEs), and even more stringent NOX standards for 2010 and later model years. The Health Effects Institute, in cooperation with the Coordinating Research Council, funded by government and the private sector, designed and conducted a research program, the Advanced Collaborative Emission Study (ACES), with multiple objectives, including detailed characterization of the emissions from both 2007- and 2010-compliant engines. The results from emission testing of 2007-compliant engines have already been reported in a previous publication. This paper reports the emissions testing results for three heavy-duty 2010-compliant engines intended for on-highway use. These engines were equipped with an exhaust diesel oxidation catalyst (DOC), high-efficiency catalyzed diesel particle filter (DPF), urea-based selective catalytic reduction catalyst (SCR), and ammonia slip catalyst (AMOX), and were fueled with ultra-low-sulfur diesel fuel (~6.5 ppm sulfur). Average regulated and unregulated emissions of more than 780 chemical species were characterized in engine exhaust under transient engine operation using the Federal Test Procedure cycle and a 16-hr duty cycle representing a wide dynamic range of real-world engine operation. The 2010 engines’ regulated emissions of PM, NOX, nonmethane hydrocarbons, and carbon monoxide were all well below the EPA 2010 emission standards. Moreover, the unregulated emissions of polycyclic aromatic hydrocarbons (PAHs), nitroPAHs, hopanes and steranes, alcohols and organic acids, alkanes, carbonyls, dioxins and furans, inorganic ions, metals and elements, elemental carbon, and particle number were substantially (90 to >99%) lower than pre-2007-technology engine emissions, and also substantially (46 to >99%) lower than the 2007-technology engine emissions characterized in the previous study.

Implications: Heavy-duty on-highway diesel engines equipped with DOC/DPF/SCR/AMOX and fueled with ultra-low-sulfur diesel fuel produced lower emissions than the stringent 2010 emission standards established by the U.S. Environmental Protection Agency. They also resulted in significant reductions in a wide range of unregulated toxic emission compounds relative to older technology engines. The increased use of newer technology (2010+) diesel engines in the on-highway sector and the adaptation of such technology by other sectors such as nonroad, displacing older, higher emissions engines, will have a positive impact on ambient levels of PM, NOx, and volatile organic compounds, in addition to many other toxic compounds.

Background

It was recognized soon after the discovery and development of the compression-ignition engine by Rudolph Diesel more than a century ago that those engines emitted high concentrations of particulate matter (PM), nitrogen oxides (NOx), sulfur oxides (SOx), and carbon monoxide (CO). Concern for the PM emissions initially focused on the impact on visibility. Moreover, the pungent characteristic odor of diesel exhaust attributed to aldehydes was viewed as an annoyance. Later, it was discovered that NOx interacting with volatile organic compounds (VOCs) in the presence of sunlight formed the potent oxidant ozone. The 1970 Amendments to the Clean Air Act (CAA) created a national strategy to improve air quality in the United States and to reduce the impact of air pollution on human health and welfare. A key provision of these amendments required that the U.S. Environmental Protection Agency (EPA) establish National Ambient Air Quality Standards (NAAQS) for criteria pollutants, which included PM, NOx, SOx, CO, and ozone. Lead was later added as a criteria pollutant. The transportation sector, including spark-ignition engines and compression-ignition engines along with their fuels, was recognized prior to the passage of the CAA as a significant contributor to air pollution. Hence, the CAA contains multiple provisions that allow the EPA to regulate both engine emissions and fuels. It is widely acknowledged that a major success story in this arena was the removal of tetraethyl lead from gasoline, thereby reducing the levels of ambient airborne lead and also enabling the use of three-way exhaust catalysts on gasoline-fueled engines, which in turn reduced CO, NOx, and HC emissions.

In the 1970s, increased concern developed for PM emissions from mobile sources as detrimental to the human respiratory system. More importantly, diesel exhaust PM was recognized as having the potential to cause cancer. In 1988, the International Agency for Research on Cancer (IARC) categorized whole diesel exhaust as a probable human carcinogen (International Agency for Research on Cancer [IARC], 1989). The IARC review stimulated the EPA to conduct an independent review of the health effects of diesel exhaust. That review was protracted, starting in 1990 and not concluding until 2002 (EPA, 2002). Nonetheless, early draft reports indicated there was reasonable cause for concern for diesel exhaust exposures to have adverse health impacts. In this same time period, as a result of periodic scientific reviews, the indicator for the PM NAAQS shifted from total suspended particulate (TSP) (promulgated in 1971) to PM less than or equal to 10 microns aerodynamic diameter (PM10) (1987), and then to PM less than or equal to 2.5 microns (PM2.5) (1996), and with each review the PM NAAQS became more stringent. With each shift in the PM indicator, diesel exhaust particulate emissions, which are in the smallest size fraction, were identified as being an important contributor to ambient PM. The attendant health concerns provided the basis for the EPA in 2000 to promulgate stringent engine and emission standards, along with associated requirements for the manufacture and distribution of ultra-low-sulfur fuel (<15 ppm S) (EPA, 2000). Those requirements placed responsibility for meeting the standards on the manufacturers of diesel engines and vehicles, and of diesel fuels.

It was fully anticipated that individual vehicle manufacturers would meet their legal requirements. However, interest developed from both the public and private sectors in assessing any unforeseen changes in the emissions and effects as a result of the technology. This led to the development and conduct of a multifaceted program to evaluate the impact of the major regulatory and technology developments on emissions composition and potential health implications of exposure to these emissions. The Health Effects Institute (HEI), a nonprofit entity jointly funded by public agencies and the private sector, took the lead in creating the program, the Advanced Collaborative Emissions Study (ACES). A key component of ACES, overseen by the Coordinating Research Council (CRC), was the detailed characterization of the emissions of both 2007-compliant and 2010-compliant engines. Results from testing of the 2007 engines were previously reported (Khalek et al., 2009, 2011). Following the detailed emission characterization of the 2007-compliant engines, one of the four engines was subsequently used to provide diluted diesel exhaust for animal exposure studies conducted at the Lovelace Respiratory Research Institute (LRRI) under contract to HEI. The results of both short-term and life-span studies in rodents of a range of health indicators have now been reported by McDonald et al. (2012, 2015). McClellan et al. (2012) have previously summarized the remarkable success story of the revolutionary changes in diesel technology drawing on the emissions testing data for 2007-compliant engines and early results from the animal bioassays. The work reported in this paper focuses on the emissions characterization of the 2010-technology engines.

Introduction

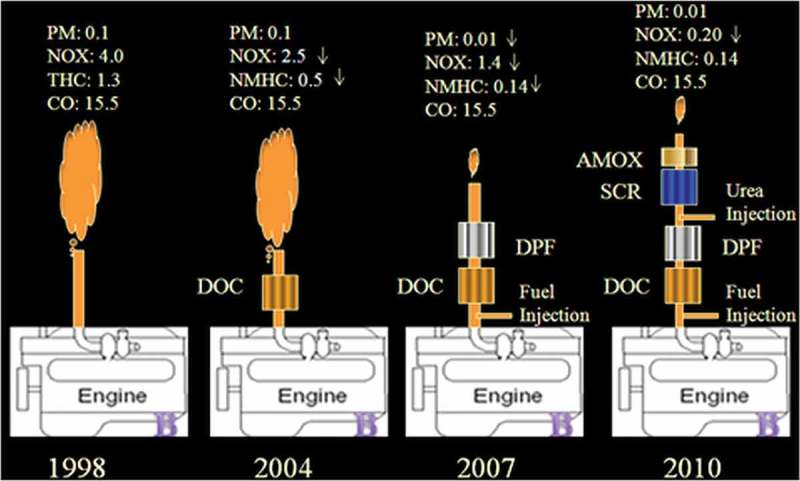

Significant changes in on-highway heavy-duty diesel engine technology took place between 1998 and 2010 to meet order of magnitude changes in EPA emissions regulations. While there were many improvements made in engine combustion, fuel injection systems, turbochargers, and exhaust gas recirculation to reduce emissions (Johnson, 2010, 2011), such improvements alone were not sufficient to meet EPA 2007 and 2010 emissions standards (EPA, 2000). As depicted in Figure 1, engine manufacturers utilized four different aftertreatment technologies to assist in meeting the 2007 and 2010 on-highway emissions limits. In 2007, due to a stringent PM standard of 0.01 g/hp-hr (90% below 1998 emissions limit), diesel oxidation catalysts (DOCs) followed by high-efficiency catalyzed diesel particle filters (DPFs) were introduced to reduce diesel PM. A diesel fuel injector was also added in the exhaust upstream of the DOC to assist in regenerating or cleaning the DPF as needed to prevent deposit buildup and/or plugging resulting in high back-pressure. To meet the 2010 oxides of nitrogen (NOX) standard of 0.20 g/hp-hr (92% below the 2004 emissions limit), a urea-based selective catalytic reduction (SCR) catalyst for NOX reduction was added downstream of the DPF followed by an ammonia oxidation (AMOX) catalyst to minimize ammonia slip into the atmosphere. A separate urea dosing system upstream of the SCR and a urea tank were also required for onboard production of the ammonia required for NOX reduction over the SCR catalyst.

Figure 1.

Changes in the exhaust of on-highway heavy-duty diesel engine technology between 1998 and 2010.

In anticipation of those technological changes in 2007 and later in 2010, there was a strong interest in thoroughly characterizing the emissions of regulated and unregulated pollutants from these new engine technologies along with their potential health effects. In 2007, the CRC ACES panel (listed in the Acknowledgments section) launched the ACES Phase 1 project (Khalek et al., 2009, 2011), where a detailed emissions characterization on four 2007-compliant heavy-duty on-highway technology engines was performed. One of these engines was selected for a detailed health study by the Lovelace Respiratory Research Institute (LRRI) as a part of ACES Phase 3 (McDonald et al., 2012, 2015). In 2010, the CRC ACES panel launched the ACES Phase 2 project as a continuation of ACES Phase 1 to fully characterize the emissions from 2010-compliant heavy-duty on-highway technology engines, which is the subject of this paper.

This paper summarizes the exhaust emissions data measured and analyzed from three 2011 model-year heavy-duty on-highway diesel engines operated on an engine dynamometer. The regulated exhaust emissions data are compared with the regulatory standards. The unregulated engine exhaust emissions data are compared with data available in the literature using pre-2007 engines and with our published data reporting on Phase 1 of ACES for the 2007-technology engines. Throughout this paper, the 2011 model-year engines are referred to as 2010-technology engines to reflect the significance of the 2010 emissions regulations.

Approach

2010 emissions-compliant engines

The engines used in this work were 2011 model-year six-cylinder in-line diesel engines that included a Cummins ISX (500 hp), a Detroit Diesel DD15 (455 hp), and a Mack MP8 (415 hp). All three engines are considered to be heavy heavy-duty on-highway diesel engines that are currently being marketed in the United States as compliant with the EPA 2010 emissions standards. The engines and aftertreatment systems were all brand new, except for 125 hr of a manufacturer-run break-in operation before they were shipped to Southwest Research Institute (SwRI) for testing. All engines were equipped with turbochargers and water-cooled high-pressure loop exhaust gas recirculation (EGR) systems in which the exhaust is routed from the exhaust manifold to the high-pressure side of the intake air compressor. The induction system is air-to-air-cooled in truck operation, but was water-cooled in the laboratory setting used for this project. All three engines were equipped with exhaust NOX sensors for active NOX emissions control. Each of the three engines was equipped with an exhaust DOC followed by a catalyzed DPF followed by an SCR catalyst and an AMOX catalyst. The engine blow-by stream path included a separator for oil mist removal before being vented to the atmosphere. In order to regenerate or clean the DPF, diesel fuel is injected into the exhaust stream upstream of the DOC from a diesel fuel injector located in the engine exhaust. The injected fuel reacts with oxygen over the surface of the DOC, leading to an increase in exhaust temperature at the outlet of the DOC, which is the inlet of the DPF. The high exhaust temperature triggers the oxidation of elemental carbon particles previously trapped by the DPF. The decision to trigger active regeneration is made by the engine control module (ECU), depending on a number of parameters such as time of operation, pressure differential across the DPF, engine operation, and temperature history, as well as modeling that accounts for soot accumulation and soot oxidation. The SCR system reduces NOX through an ammonia reaction over the SCR honeycomb catalyst. Ammonia is made available from the thermolysis of an aqueous urea solution that is injected into the engine exhaust upstream of the SCR catalyst. The aqueous urea solution is stored in a separate urea tank. The urea consumption represents approximately 2% to 3% of the diesel fuel consumed.

With the improvement in engine-out soot emissions and aftertreatment control strategies, none of the 2010-technology engines tested in this program triggered an active DPF regeneration during emissions testing over 48 hr of engine operation. That was one of the most significant operational differences between these engines and the 2007-technology engines, where active DPF regeneration occurred one to three times during emissions testing over the 16-hr test cycle. The lack of active DPF regeneration with the 2010 technology engines may have had some impacts on some emissions results that are reviewed in more detail in the Discussion section of this paper.

Fuel, lubricant, and urea

The fuel used in Phase 2 of the ACES program was a commercial ultra-low-sulfur diesel (ULSD) fuel that conformed to EPA fuel specifications for 2007 on-highway engines (Electronic Code of Federal Regulations [e-CFR], 2015). The selected fuel properties shown in Table 1 are typical for ULSD and similar to those reported for the fuel used in ACES Phase 1. For results reported for pre-2007 engines, it is important to note that the fuel was typically low-sulfur diesel with a sulfur content of 500 ppm or less (Federal Register, 1990).

Table 1.

ULSD fuel properties used in the ACES Phase 2 program

| ASTM test | Test property/description | Units | Values |

|---|---|---|---|

| D1319 | Aromatics | vol% | 31.9 |

| D5453 | Sulfur content | ppm | 6.5 |

| D4052 | API gravity at 60°F | dimensionless | 36.5 |

| Specific gravity at 60°F | dimensionless | 0.8418 | |

| D5291 | Carbon content | wt% | 86.44 |

| Hydrogen content | wt% | 13.35 | |

| Oxygen by difference | wt% | 0.21 | |

| D613 | Cetane number | dimensionless | 48.1 |

The fresh engine lube oil properties used in ACES Phase 2 are shown in Table 2. The oil is a typical API CJ-4 commercial lube oil suitable for post-2006 engines (McGeehan et al., 2007). Its properties are similar to those reported for the lube used in ACES Phase 1. The most dominant elements in the fresh lube oil were sulfur, calcium, zinc, and phosphorus. Engine wear appeared in the lube oil after 125 hr of engine operation. The most notable engine wear elements were copper, iron, magnesium, and silicon that can be picked up from lubricated surfaces in the engine powertrain. For results reported on pre-2007 engines, the lube oil typically had higher ash, phosphorus, and sulfur levels (McGeehan et al., 2002).

Table 2.

Average lube oil properties for fresh oil and after 125 hr of engine operation (ACES Phase 2)

| ASTM test | Test property description | Units | Fresh lube oil | Used oil (Avg.)a | Used oil (min/max) |

|---|---|---|---|---|---|

| D445 | Viscosity at 100°C | cSt | 15.38 | 16 | 13/21 |

| D445 | Viscosity at 40°C | cSt | 116.8 | 97 | 79/112 |

| D5185S | Sulfur by ICP | ppm | 4018 | 3467 | 3144/3660 |

| D5185 | Elemental Analysis | ||||

| Boron | ppm | 1 | 5 | 2/10 | |

| Calcium | ppm | 2233 | 2166 | 2022/2212 | |

| Copper | ppm | <1 | 38 | 8/98 | |

| Iron | ppm | 2 | 15 | 13/17 | |

| Lead | ppm | <1 | 3 | 2/3 | |

| Magnesium | ppm | 6 | 124 | 71/190 | |

| Manganese | ppm | <1 | 4 | 2/6 | |

| Phosphorus | ppm | 1020 | 971 | 964/981 | |

| Silicon | ppm | 4 | 21 | 4/30 | |

| Sodium | ppm | <5 | 6 | 5/8 | |

| Tin | ppm | <1 | 3 | 3/3 | |

| Zinc | ppm | 1157 | 1164 | 1136/1187 | |

Notes: aAverage was based on three analyses of the used lube oil, one per engine.

The urea used in this program is commonly known as diesel exhaust fluid (DEF). It is a 32.5% aqueous urea solution that meets ISO 22241-1:2006. It also meets the quality standard specified in the engine manufacturers’ service warranties.

Experimental setup and procedures

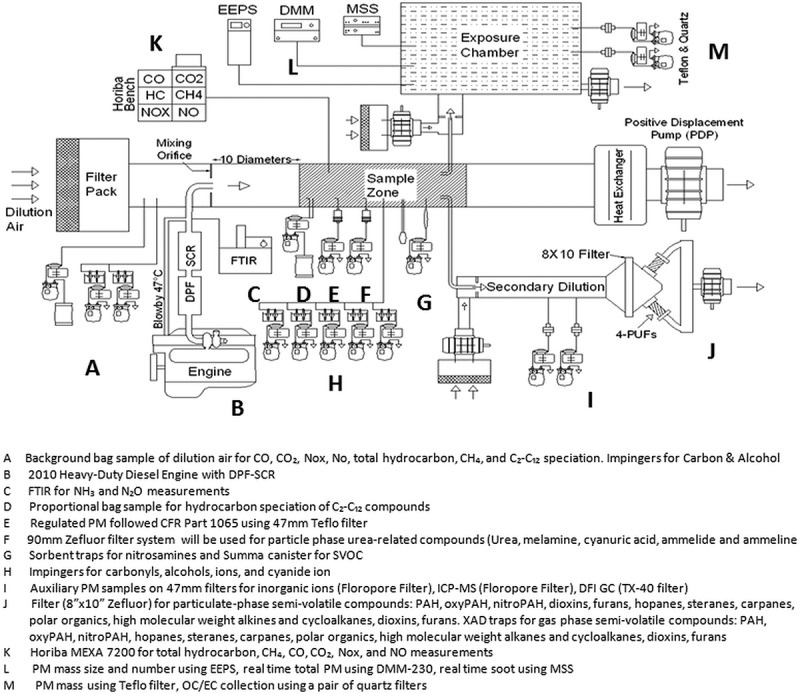

The exhaust sampling system for this study using 2010 emission-compliant technology engines is shown in Figure 2 and is identical to that described by Khalek et al. for the 2007 technology engine emissions characterization under ACES Phase 1. Additional details can be also found in the ACES Phase 2 report (Khalek et al., 2013). For this work, however, we added a separate 47°C filter sampling train from the Constant Volume Sampler (CVS) for the collection and analyses of PM phase urea-related compounds such as urea, melamine, cyanuric acid, ammeline and ammelide collected by the filter.

Figure 2.

Experimental setup for engine and sampling system.

The three 2010-compliant engines were tested for regulated and unregulated emissions using the hot-start Federal Test Procedure (FTP) and the 16-hr transient cycle (Clark et al., 2007) that was used in ACES Phase 1. The 16-hr cycle is comprised of a 4-hr segment that is repeated four times for a total of 16 hr. The 4-hr segment was developed to represent realworld urban and rural operation (50/50 time split). It covers a wide range of activities that includes repeats of idle, creep, transient, cruise, and high-speed cruise derived from in-use activities taken from 84 heavy heavy-duty diesel trucks. It also encompasses three repeats of the 20-min FTP transient cycle that are placed at the beginning, middle, and end of each 4-hr segment. To account for the contribution of the filtered blow-by emissions, all measurements were performed with engine blow-by routed to the exhaust downstream of the urea SCR/AMOX catalyst, as described by Khalek et al. (2013).

Prior to using the engines for the official measurement of regulated and unregulated emissions, the engines were tested using a composite of a cold-start and a hot-start FTP to verify their compliance with the 2010 standards. Regulated emissions measurements included carbon monoxide (CO), nonmethane hydrocarbon (NMHC), oxides of nitrogen (NOx), and particulate matter (PM). Unregulated emissions included total hydrocarbon (THC), methane (CH4), carbon dioxide (CO2), nitric oxide (NO), nitrogen dioxide (NO2), ammonia (NH3), particle size distribution and number concentration, organic carbon, elemental carbon, metals and elements, inorganic ions, polynuclear aromatic hydrocarbon (PAH), nitroPAH, oxyPAH, polar compounds, alkanes, hopanes, steranes, cyanide ion, organic acids, gas phase acids, nitrosamines, detailed speciation of C2–C12 hydrocarbons, aldehydes and ketones, dioxins and furans, and six particle phase urea-related compounds. The analytical methods used for the measurement of the different species are identical to those reported by Khalek et al. for the 2007-technology engines. For more details, the readers are referred to Khalek et al. (2009, 2011, 2013). Table 3 shows the test matrix that is presented and discussed in this paper.

Table 3.

Cycle used for each engine test and the number of repeats for regulated and unregulated species

| Cycle | Regulated pollutants | Unregulated |

|---|---|---|

| One cold-start + hot-start FTP | 1 | a |

| 16-hr Cycle | 3 | 3 |

| 16-hr Cycle for dioxins and furans | 1 | |

| 16-hr Tunnel background for dioxins and furans | 1 |

Notes: aOnly real time particle size, number, total mass, and soot mass were performed for these tests.

bData to be shared with each engine manufacturer to make sure that the engine emissions performance complied with the manufacturer’s expectation and to get approval to proceed with the program.

dDioxins and furans were collected separately for 16 hours on Engines X, Y, and Z using 8 x 10 Zefluor filters followed by four XAD traps.

eTunnel background is a 16-Hour test where samples are taken from the dilution air immediately downstream of the CVS HEPA filter.

Results

The current study involves an assessment of 2010-technology on-highway heavy-duty diesel engines. Throughout this paper, the results are compared with our previous similar testing with 2007-technology engines to document the progress made in the short time frame between 2007 and 2010 compliant engines. As stated earlier, the fuel and oil used for the 2007- and 2010-technology engines were very similar, and the experimental method was the same. The results are also compared to pre-2007-technology engines, where applicable, to give a historical perspective about how emissions from diesel engines have evolved and improved over the years.

The average result and standard deviation are based on a total of nine repeats of the 16-hr cycle (three repeats per engine) for the 2010-technology engines, and a total of 12 repeats (three repeats per engine) for the 2007-technology engines. The results presented for the 2010 and 2007 technology engines are for the 16-hr transient cycle unless otherwise specified. It is important to note that the 16-hr cycles with the 2010-technology engines did not include any contribution from active DPF active regenerations, while the 2007-technology engines included at least one active regeneration of the DPF per engine during the 16-hr cycle.

The database for the ACES Phase 2 results is publicly available at the CRC website (ACES Ph2 Database, 2015).

Compliance with 2010 emissions standard

Table 4 shows the average regulated emissions for the three 2010-technology engines. The average results show that the emissions were substantially below the 2010 and the 1998 emissions limits. As shown in Table 5, these engines also exhibited much lower NOX and NMHC emissions compared to the 2007-technology engines used in our previous study under ACES Phase 1. The average reduction (relative to 2007-technology engines) in NOX mass was 93% and more than 99% for NMHC. Carbon monoxide and PM emissions were comparable for the two engine technologies. Overall, the 2010-technology engines not only met the 2010 regulatory standard with a comfortable margin in the laboratory, but also had better emissions performance than the 2007 engines, especially in NOX and NMHC, although the emissions limits for the latter species were unchanged between 2007 and 2010.

Table 4.

Average regulated emissions summary for three FTP composite cycles (1/7 × cold-start + 6/7 × hot-start), one per 2010 engine

| 1998 EPA standard (g/bhp-hr) | 2010 EPA standardd (g/bhp-hr) | 2010 Average emissions (g/bhp-hr) | Percent reduction relative to 1998 standard | Percent reduction relative to 2010 standard | |

|---|---|---|---|---|---|

| PM | 0.1 | 0.01 | 0.0008 ± 0.0008 | 99 | 92 |

| CO | 15.5 | 15.5 | 0.50 ± 0.71 | 97 | 97 |

| NMHCc | 1.3a | 0.14 | 0.000 ± 0.000 | >99 | >99 |

| NOX | 4.0b | 0.20 | 0.078 ± 0.038 | 98 | 61 |

Notes: aEPA limit was based on total hydrocarbon including methane.

bEPA limit went to 2.4 g/hp-hr in 2004.

cNMHC is reported as the difference between measured THC and methane.

dOnly NOX standard was lower in 2010 compared to 2007.

Table 5.

Regulated emissions comparison for FtP composite between 2010- and 2007-technology engines

| 2007 Average emissions (g/bhp-hr) | 2010 Average emissions (g/bhp-hr) | Percent reduction relative to 2007 | |

|---|---|---|---|

| PM | 0.0014 ± 0.0007 | 0.0008 ± 0.0008 | a |

| CO | 0.48 ± 0.33 | 0.50 ± 0.71 | a |

| NMHC | 0.015 ± 0.024 | 0.000 ± 0.000 | >99 |

| NOX | 1.09 ± 0.15 | 0.078 ± 0.038 | 93 |

Note: aNo discernible change within the measurement uncertainties.

Greenhouse gas species, other gases, and PM for 16-hr cycle

Greenhouse gases (GHG) are a subject of great concern due to climate change. Diesel engines are subject to regulatory limits for GHG starting in 2014. Additional tightening of the GHG limits is currently under consideration by the EPA. The 2010- and the 2007-technology engines are not subject to any GHG regulations. Nonetheless, in Table 6, we report on GHG emission species for the 2010- and 2007-technology engines. Note that for CO2, which is a surrogate for fuel consumption, the difference was within measurement uncertainty between 2010- and 2007-technology engines. Methane emissions were below the detection limit with 2010-technology engines and much lower than 2007-technology engine emissions. N2O emissions, however, were significantly higher with the 2010 technology engines, compared to the emissions from the 2007-technology engines. The N2O is formed as a by-product of the SCR and ammonia slip catalyst functions, resulting in higher N2O. The N2O emissions, however, were still below the 2014 limit of 0.1 g/hp-hr. To determine and compare the global warming potential (GWP) between 2007- and 2010-technology engines, we used the 100 year GWP, as defined by EPA greenhouse gas rulemaking for medium- and heavy-duty engines (EPA, 2011). GWP is a relative measure of the amount of heat trapped from the instantaneous release of 1 kg of a trace substance relative to that from 1 kg of a reference gas. For the purpose of our calculation, we used CO2 as the reference and we multiplied CH4 by 25 and N2O by 298 to get the 100-yr GWP. Based on our calculations, the there was no discernible difference in the 100-yr GWP between the two engine technologies.

Table 6.

Greenhouse gas species, other gases and regulated (16-hr cycle)

| Name | 2007 Engines | 2010 Engines | Percent reduction relative to 2007 technology engines |

|---|---|---|---|

| Greenhouse gases, g/bhp-hr | |||

| CO2 | 590.2 ± 22.7 | 571.3 ± 41.4 | a |

| CH4 | 0.0104 ± 0.0080 | <0.0001 | >99 |

| N2O | 0.010 ± 0.003 | 0.073 ± 0.030 | –630 |

| 100 Year CO2eq GWP | |||

| GWP | 593.2 | 592.8 | a |

| Other gases and PM, g/bhp-hr | |||

| NO2 | 0.73 ± 0.20 | 0.046 ± 0.029 | 94 |

| SO2 | 0.00112 ± 0.00025 | 0.00033 ± 0.00016 | 71 |

| NH3 | <0.0001 | 0.0025 ± 0.0014 | ≤2400 |

| CO | 0.20 ± 0.16 | 0.056 ± 0.032 | a |

| NMHC | <0.0001 | <0.0001 | a |

| NOX | 1.37 ± 0.12 | 0.081 ± 0.030 | 94 |

| PM | 0.0012 ± 0.0005 | 0.0004 ± 0.0003 | 67 |

Note: aNo discernible change within the measurement uncertainties.

Table 6 shows the emissions of NO2, SO2, NH3, CO, NMHC, NOX, and PM for the 2010- and 2007-technology engines. With the 2007-technology engines, we showed that the direct emissions of NO2 exceeded that of 1998-technology engines (Khalek et al., 2011). This was mainly due to the exhaust DOC that promotes the oxidation of NO to NO2. With 2010-technology engines, however, due to the presence of urea-based SCR for NOX reduction, NO2 emissions were 94% below those emitted from 2007 technology engines and 84% below a typical level for 1998-technology engines (EPA, 2003, 2009). Although the fuel and lube oil sulfur contents were comparable between the 2010- and 2007-technology engine studies, SO2 emissions from the 2010-compliant engines were 71% lower than those from 2007 engines. The issue of sulfur adsorption by the aftertreatment systems is discussed in greater detail later in the paper. Ammonia is the main by-product of urea injection to promote the reduction of NOX over the SCR catalyst. In a typical system, not all of the ammonia is consumed in NOX reduction over the SCR catalyst, resulting in a small amount of ammonia slip. The 2010-technology engines used in this study were equipped with an ammonia oxidation catalyst (AMOX) located downstream of the SCR to minimize ammonia slip. European Union (EU) regulations limit exhaust ammonia slip to less than or equal to 10 ppm (Johnson, 2009), and a similar limit may be adapted in the United States. Although ammonia emissions from 2010-technology engines were higher than those emitted from 2007-technology engines as shown in Table 6, the average exhaust ammonia level measured during the 16-hr cycle was 0.82 ± 0.49 ppmv, much lower than the 10 ppm limit. For CO and NMHC, no discernible difference between 2010- and 2007-technology engines was observed, and the NOX reduction was similar to that of NO2. The average PM emissions for the 2010 engines were 67% lower than those observed with the 2007 engines.

Important components of the more than 780 unregulated engine exhaust emission species investigated during the ACES Phase 2 program

Table 7 shows a summary of several classes of unregulated emissions compounds. The 2010-technology engines showed much lower emissions compared to both pre-2007-technology engines (Clark et al., 2007; EPA, 2006) and 2007-technology engines. Compared to pre-2007-technology engines without DPF and SCR, the emissions reduction ranged from 90% for single ring aromatics to more than 99% for hopanes and steranes as well as dioxins and furans (relative to 1998 technology engines). Compared to the 2007-technology engines, the emissions reduction ranged from no discernible difference for organic carbon to more than 99% for dioxins and furans. Table 8 shows 41 compounds that are considered to be toxic air contaminants by the California Air Resources Board (CARB, 2010). The emission level for every compound on the list for the 2010-technology engines was substantially below the emission level from the pre-2007-technology engines, ranging between 71% and more than 99% lower. Also, the great majority of the other measured compounds were below the levels emitted from 2007-technology engines. Table 9 shows some polycyclic aromatic hydrocarbons (PAHs) and nitroPAHs (N-PAHs) emissions that are part of the CARB toxic air contaminants list. The PAHs were dominated by two-ring compounds, especially naphthalene. Once again, all PAH emissions from the 2010-technology engines were more than 99% below the pre-2007 technology engine emissions and between 58% and 98% lower than the 2007-technology engine emissions. For N-PAHs, all listed compounds were substantially lower than the pre-2007-technology engine emissions, ranging between 97% and 99% lower. The N-PAHs from 2010-technology engines were also between 58% and 99% lower than the 2007-technology engines.

Table 7.

Summary of average unregulated emissions for 9 and 12 repeats of the 16-hour cycles for 2010 and 2007 ACES engines, and for 2004-technology engines used in CRC E55/E59 (with dioxins compared to 1998 levels)

| 1.0 | 2.0 2004 Engines avg. ± SD, mg/hr | 3.0 2007 Engines avg. ± SD, mg/hr | 4.0 2010 Engines avg. ± SD, mg/hr | 5.0a2010 Engines avg. ± SD, mg/bhp-hr | 2010 Average percent reduction relative to 2004-technology engines | 2010 Average percent reduction relative to 2007-technology engines |

|---|---|---|---|---|---|---|

| Single-ring aromatics | 405.0 ± 148.5 | 71.6 ± 32.97 | 40.63 ± 49.04 | 0.38 ± 0.44 | 90 | c |

| PAH | 325.0 ± 106.1 | 69.7 ± 23.55 | 2.4 ± 1.0 | 0.021 ± 0.009 | 99 | 97 |

| Alkanes | 1030.0 ± 240.4 | 154.5 ± 78.19 | 11.9 ± 3.0 | 0.110 ± 0.027 | 99 | 92 |

| Hopanes and steranes | 8.2 ± 6.9 | 0.1 ± 0.12 | 0.010 ± 0.007 | 0.0001 ± 0.0001 | >99 | 90 |

| Alcohols and organic acids | 555.0 ± 134.4 | 107.4 ± 25.4 | 4.62 ± 0.1.74 | 0.042 ± 0.016 | 99 | 96 |

| NitroPAH | 0.3 ± 0.0 | 0.1 ± 0.0 | 0.0011 ± 0.0005 | 0.00001 ± 0.0000 | >99 | 99 |

| Carbonyls | 12500.0 ± 3535.5 | 255.3 ± 95.2 | 57.4 ± 39.1 | 0.52 ± 0.35 | >99 | 78 |

| Inorganic ions | 320.0 ± 155.6 | 92.3 ± 37.7 | 14.23 ± 1.36 | 0.13 ± 0.01 | 96 | 85 |

| Metals and elements | 400.0 ± 141.4 | 6.7 ± 3.0 | 1.4 ± 1.0 | 0.012 ± 0.009 | >99 | 79 |

| OC | 1180.0 ± 70.7 | 52.8 ± 47.1 | 39.2 ± 33.6 | 0.35 ± 0.30 | 97 | c |

| EC | 3445.0 ± 1110.2 | 22.6 ± 4.7 | 12.2 ± 6.2 | 0.11 ± 0.06 | >99 | 46 |

| Dioxins/furans | N/A | 6.2E-05 ± 5.2E-05 | 8.5E-09 ± 1.1E-08 | 7.7E-11 ± 1.0E-10 | >99b | >99 |

Notes: aData shown in brake-specific emissions for completeness. No comparable brake-specific emissions data were available with 2004 engines.

bRelative to 1998-technology engines.

cNo discernible change within the measurement uncertainties.

Table 8.

CARB toxic air contaminant average emissions for all 12 repeats of the 16-hr cycles for all four 2007 ACES engines and all three 2010 engines, and for 1994 to 2000 technology engines running over the FTP transient cycle

| California ARB toxic air contaminants | ||||||

|---|---|---|---|---|---|---|

|

d1994 to 2000 Technology engines |

a2007 Technology engines |

a2010 Technology engines |

||||

| TAC number | Compound | (mg/bhp-hr) | (mg/bhp-hr) | (mg/bhp-hr) | Percent reduction relative to 1994 to 2000 engines | Percent reduction relative to 2007-technology engine engines |

| 1 | Acetaldehyde | 10.3 | 0.61 ± 0.27 | 0.1 ± 0.06 | 99 | 84 |

| 2 | Acrolein | 2.7 | <0.01 | 0.02 ± 0.01 | 99 | f |

| 3 | Aniline | c | 0.000150 ± 0.000075 | 0.000048 ± 0.000120 | c | 68 |

| 4 | Antimony compounds | c | <0.001 | <0.001 | c | e |

| 5 | Arsenic | c | <0.0002 | <0.0002 | c | e |

| 6 | Benzene | 1.82 | <0.01 | <0.01 | >99 | e |

| 7 | Beryllium compounds | c | <0.0003 | <0.0003 | c | e |

| 8 | Biphenyl | c | 0.0137800 ± 0.0017160 | 0.0006310 ± 0.0003160 | c | 95 |

| 9 | Bis[2-ethylhexyl]phthalate | c | 0.0029950 ± 0.0017970 | 0.0006320 ± 0.0001130 | c | 79 |

| 10 | 1,3-Butadiene | 1.7 | <0.01 | <0.01 | >99 | e |

| 11 | Cadmium | c | <0.00003 | <0.00003 | c | e |

| 12 | Chlorine (chloride) | 0.18 | 0.0009 ± 0.0010 | 0.0003 ± 0.0003 | >99 | 67 |

| 13 | Chlorobenzene and derivatives | c | b | b | c | e |

| 14 | Chromium compounds | c | 0.0007 ± 0.0003 | <0.00013 | c | >81 |

| 15 | Cobalt compounds | c | <0.0001 | <0.0001 | c | e |

| 16 | Cresol isomers | c | 0.02727 ± 0.01233 | 0.00460 ± 0.00432 | c | 83 |

| 17 | Cyanide compounds | c | <0.05 | <0.05 | c | e |

| 18 | Di-n-butyl phthalate | c | 0.0065690 ± 0.0021740 | 0.0003390 ± 0.0003190 | c | 95 |

| 19 | Dioxins and dibenzofurans | 6.6E-5 | 6.6E-7 ± 5.5E-7 | 7.7E-11 ± 1E-10 | >99 | >99 |

| 20 | Ethylbenzene | 0.49 | 0.05 ± 0.04 | <0.01 | >98 | >80 |

| 21 | Formaldehyde | 25.9 | 1.90 ± 1.01 | 0.13 ± 0.03 | 99 | 93 |

| 22 | Hexane | 0.14 | < 0.01 | <0.01 | >93 | e |

| 23 | Inorganic lead | 0.0009 | <0.0001 | <0.0001 | >89 | e |

| 24 | Manganese | 0.0008 | <0.00022 | <0.00022 | >73 | e |

| 25 | Mercury | c | <0.00016 | <0.00016 | c | e |

| 26 | Methanol | c | 0.07 ± 0.13 | 0.22 ± 0.13 | c | f |

| 27 | Methyl ethyl ketone | c | <0.01 | <0.01 | c | e |

| 28 | Naphthalene | 0.4829 | 0.0982000 ± 0.0423000 | 0.0019050 ± 0.0013350 | >99 | 98 |

| 29 | Nickel | 0.01 | 0.0002 ± 0.0001 | <0.0001 | 99 | >50 |

| 30 | 4-Nitrobiphenyl | c | <0.00000001 | <0.00000001 | c | e |

| 31 | Phenol | c | 0.009050 ± 0.004140 | 0.001445 ± 0.001943 | c | 84 |

| 32 | Phosphorus | c | 0.013000 ± 0.006400 | 0.000254 ± 0.000236 | c | 98 |

| 33 | POM (polycyclic organic matter), including PAHs and derivatives | See Table 9 | See Table 9 | See Table 9 | See Table 9 | See Table 9 |

| 34 | Propionaldehyde | 1.8 | 0.03 ± 0.04 | .02 ± 0.00 | 99 | f |

| 35 | Selenium | c | <0.0001 | <0.0001 | c | e |

| 36 | Styrene | 0.73 | <0.01 | <0.01 | c | e |

| 37 | Toluene | 0.64 | 0.26 ± 0.28 | 0.18 ± 0.09 | 72 | f |

| 38 | Xylene isomers and mixtures | 2.2 | 0.33 ± 0.10 | 0.47 ± 0.28 | 79 | f |

| 39 | o-Xylene | 0.99 | 0.13 ± 0.07 | 0.11 ± 0.01 | 89 | f |

| 40&41 | m&p-Xylenes | 1.21 | 0.20 ± 0.08 | 0.35 ± 0.28 | 71 | f |

Notes: aThe significant figures signify the detection limit in mg/bhp-hr.

bNot measured.

cNot available.

dStandard deviation data were not provided by reference 15 and 16.

eBoth values are below detection limit.

fNo discernible change within the measurement uncertainties.

Table 9.

PAH and nitro-PAH average emissions for all 12 repeats of the 16-hr cycles for all four 2007 ACES engines and all three 2010 engines, and for 2000-technology engine running over the FTP transient cycle

| PAH and nitroPAH compounds | a,b2000-Technology engines, mg/bhp-hr | a2007-Technology engines, mg/bhp-hr | a2010-Technology engines, mg/bhp-hr | aPercent reduction relative to 2000 technology engines | aPercent reduction relative to 2007 technology engines |

|---|---|---|---|---|---|

| Naphthalene | 0.4829 | 0.0982000 ± 0.0423000 | 0.0019050 ± 0.0013350 | >99 | 98 |

| Acenaphthylene | 0.0524 | 0.0005000 ± 0.0005000 | 0.0000397 ± 0.0000413 | >99 | 92 |

| Acenaphthene | 0.0215 | 0.0004000 ± 0.0001000 | 0.0000529 ± 0.0000349 | >99 | 87 |

| Fluorene | 0.0425 | 0.0015000 ± 0.0009000 | 0.0001217 ± 0.0000637 | >99 | 92 |

| Phenanthrene | 0.0500 | 0.0077000 ± 0.0025000 | 0.0004535 ± 0.0001218 | 99 | 94 |

| Anthracene | 0.0121 | 0.0003000 ± 0.0001000 | 0.0000207 ± 0.0000150 | 100 | 93 |

| Fluoranthene | 0.0041 | 0.0006000 ± 0.0006000 | 0.0000339 ± 0.0000053 | 99 | 94 |

| Pyrene | 0.0101 | 0.0005000 ± 0.000400 | 0.0000233 ± 0.0000078 | >99 | 95 |

| Benz[a]anthracene | 0.0004 | 0.0000071 ± 0.0000055 | 0.0000030 ± 0.0000027 | 99 | 58 |

| Chrysene | 0.0004 | <0.0000001 | <0.0000001 | >99 | c |

| Benzo[b + j + k]fluoranthene | <0.0003 | .0000170 ± .0000151 | 0.0000004 ± 0.0000003 | >99 | 98 |

| Dibenzo[a,e]pyrene | <0.0003 | 0.0000022 ± 0.0000018 | <0.0000001 | >99 | >95 |

| Perylene | <0.0003 | 0.0000055 ± 0.0000068 | <0.0000001 | >99 | >98 |

| Indeno[123-cd]pyrene | <0.0003 | 0.0000027 ± 0.0000015 | <0.0000001 | >99 | >96 |

| Dibenz[ah + ac]anthracene | <0.0003 | 0.0000031 ± 0.0000021 | <0.0000001 | >99 | >97 |

| Benzo[ghi]perylene | <0.0003 | 0.0000046 ± 0.0000013 | 0.0000002 ± 0.0000001 | >99 | 96 |

| 2- Nitrofluorene | 0.0000650 | 0.00000360 ± 0.00000410 | <0.00000001 | >99 | >97 |

| 9-Nitroanthracene | 0.0007817 | 0.0000148 ± 0.0000213 | 0.00000050 ± 0.0000002 | >99 | 97 |

| 2-Nitroanthracene | 0.0000067 | 0.00000040 ± 0.00000090 | <0.00000001 | 98 | >75 |

| 9-Nitrophenanthrene | 0.0001945 | 0.00002110 ± 0.00002090 | 0.00000020 ± 0.0000002 | >99 | 99 |

| 4-Nitropyrene | 0.0000216 | <0.0000001 | <0.00000001 | >99 | c |

| 1-Nitropyrene | 0.0006318 | 0.0000197 ± 0.0000243 | <0.00000001 | >99 | >99 |

| 7-Nitrobenz[a]anthracene | 0.0000152 | 0.00000020 ± 0.00000020 | <0.00000001 | >99 | >50 |

| 6-Nitrochrysene | 0.0000023 | <0.0000001 | <0.00000001 | >96 | c |

| 6-Nitrobenzo[a]pyrene | 0.0000038 | <0.0000001 | <0.00000001 | >97 | c |

Notes: aThe significant figures signify the detection limit in mg/bhp-hr.

bStandard deviation data were not reported.

c Both values are below detection with similar resolution.

Tables 10 and 11 show metallic and some nonmetallic elements, such as sulfur, chloride, and phosphorus, emitted from the various engine technologies. Calcium, zinc, sulfur, and phosphorus are dominant elements in the lube oil and additive package. The other elements are present in the lube oil and the result of engine wear. The emissions of the elements presented in Tables 10 and 11 were substantially lower with the 2010-technology engines compared to 2007-technology engines, and compared to pre-2007-technology engines. Relative to older technology engines, the reduction was 85% for calcium, 95% for silicon, and more than 99% for the rest of the elements listed in Table 10. Relative to 2007-technology engines, calcium, zinc, and phosphorus were 7, 78, and 98% lower, respectively, with the 2010 engines. In addition, sulfur emissions were substantially lower with the 2010-technology engines compared to the 2007-technology engines, although the fuel and lubricant sulfur levels were comparable.

Table 10.

Elemental average emissions for 2010 (9 repeats) and 2007 technology engines (12 repeats) for 16-hr cycle, and for 1994 to 2000 technology engines running over the FTP transient cycle

| a,b1994 to 2000 Technology engines, mg/bhp-hr | a2007-Technology engines, mg/bhp-hr | a2010-Technology engines, mg/bhp-hr | Percent reduction relative to 1994 to 2000 technology engines | Percent reduction relative to 2007-technology engines | |

|---|---|---|---|---|---|

| Zinc | 1.16 | 0.0027 ± 0.0020 | 0.0025 ± 0.0032 | >99 | c |

| Sulfur | 2.89 | 0.2910 ± 0.1290 | 0.0030 ± 0.0023 | >99 | 99 |

| Calcium | 0.02 | 0.0115 ± 0.0078 | 0.0030 ± 0.0019 | 85 | 74 |

| Silicon | 0.02 | 0.0022 ± 0.0014 | 0.0009 ± 0.0008 | 96 | c |

| Copper | 0.78 | 0.0004 ± 0.0002 | 0.00001 ± 0.00004 | >99 | 98 |

| Lead | 1.83 | 0.0784 ± 0.0731 | <0.0001 | >99 | >99 |

| Iron | 1.66 | 0.0152 ± 0.0092 | 0.0014 ± 0.0012 | >99 | 91 |

| Chloride | 0.18 | 0.0009 ± 0.0010 | 0.0003 ± 0.0003 | >99 | c |

Notes: aThe significant figures signify the detection limit in mg/bhp-hr.

bStandard deviation data were not given, as reported in Khalek et al. (2011)

cNo discernible change within the measurement uncertainties.

Table 11.

Additional elements for comparison between 2010- and 2007-technology engines (16-hr cycle)

| 2007-Technology engines average emissions, mg/bhp-hr | 2010-Technology engines average emissions, mg/bhp-hr | Percent reduction relative to 2007-technology engines | |

|---|---|---|---|

| Sodium | 0.0244 ± 0.0094 | 0.0006 ± 0.0015 | 98 |

| Magnesium | 0.0036 ± 0.0014 | <0.0001 | >97 |

| Aluminum | 0.0025 ± 0.0004 | 0.0005 ± 0.0005 | 80 |

| Phosphorous | 0.0133 ± 0.0066 | 0.0003 ± 0.0003 | 98 |

| Potassium | 0.0011 ± 0.0011 | 0.0002 ± 0.0000 | 82 |

| Titanium | 0.00038 ± 0.00043 | <0.0001 | >73 |

| Vanadium | <0.0001 | <0.0001 | a |

| Chromium | 0.00070 ± 0.00030 | <0.00013 | >81 |

| Nickel | 0.00022 ± 0.0001 | <0.0001 | >56 |

Note: aBoth values are below detection with similar resolution.

Particle-phase urea-related compounds

Because urea is injected into the engine exhaust upstream of the SCR catalyst, we designed a high-volume sampling system for PM collection for the purpose of analyzing the filter for urea, melamine, cyanuric acid, ammelide, ammeline, and biuret. Out of these six compounds, only urea and cyanuric acid were detected for the 16-hr cycle. Urea average emissions were 0.87 ± 0.75 µg/hp-hr and cyanuric acid average emissions were 9.0 ± 9.0 µg/hp-hr. This reflects a very low mass concentration (9 ppb) of cyanuric acid in diesel engine exhaust.

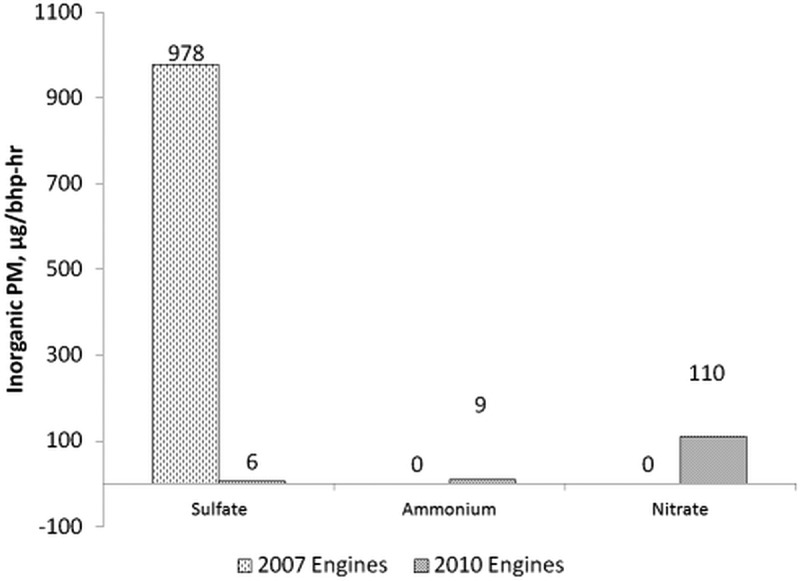

Inorganic ions

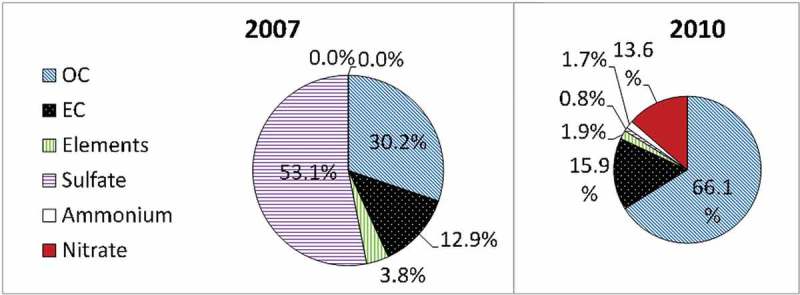

Figure 3 shows the inorganic ion emissions for the 2010- and the 2007-technology engines. We detected ammonium and nitrate ions with the 2010-technology engines, compared to undetected levels with the 2007-technology engines. It is likely that these ions are a by-product of the urea-based SCR system. Sulfate emissions were substantially below the 2007 emissions level. The sulfate reduction with 2010 engines is trending with the SO2 and sulfur reduction discussed earlier in this paper.

Figure 3.

Emissions of inorganic ions (16-hr cycle).

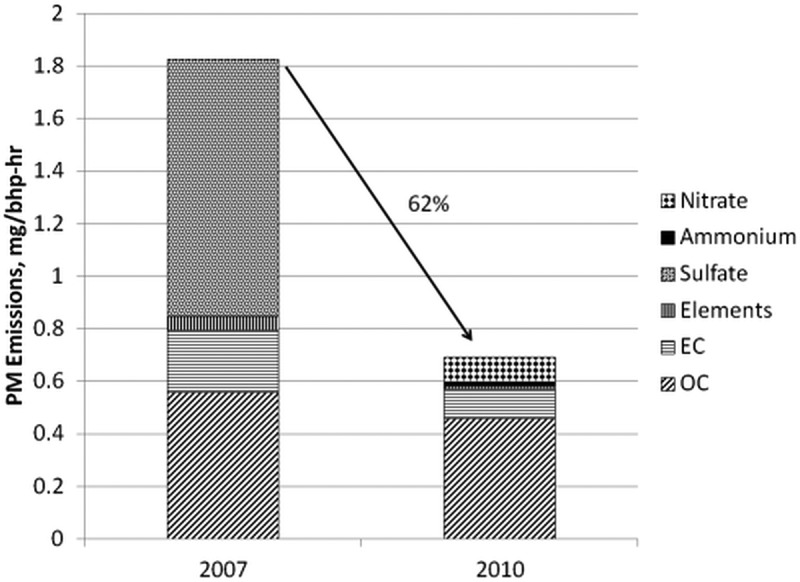

Particulate matter composition

Figure 4 shows the PM emissions contribution of each class of particle-phase compounds. First, the absolute level of PM emissions was very low, well below the regulatory limit of 0.01 g/bhp-hr. Second, there was a substantial reduction in PM for the 2010-technology engines compared to the 2007-technology engines, including a reduction in elemental carbon and organic carbon. Third, there were low but detectable levels of urea-SCR-derived inorganic ions, such as ammonium and nitrate, with the 2010-technology engines. Finally, there was a substantial reduction in sulfate with the 2010-technology engines compared to the 2007 engines. Note that the emission levels reported in Figure 4 are slightly different than those reported in Table 5 because the engine cycles are different (FTP vs. 16-hr). Furthermore, data in Table 5 and Table 6 were based on filter collection and weighing in accordance with the CFR Part 1065, while Figure 4 is based on the chemical composition of the PM collected. Thus, there are some differences due to the different method used.

Figure 4.

Particulate matter emissions and composition (16-hr cycle, 2007- and 2010-technology engines).

Figure 5 shows the PM percent composition for 2010- and 2007-technology engines. Besides the low level of absolute PM emissions for both engine technologies, the contribution of elemental carbon constitutes less than 16% of total PM for both technology engines. For the 2007-technology engines, the PM composition was dominated by sulfate at 53%, followed by organic carbon at 32%. For the 2010-technology engines, organic carbon constitutes 66%, but with the virtual absence of sulfate at less than 1%. The elements for the 2010-technology engines comprise a lower percentage of total PM, compared to 2007-technology engines.

Figure 5.

Particulate matter composition (16-hr cycle, 2007- and 2010-technology engines). (Right figure made smaller to reflect lower PM emissions but was not scaled down by 62%.)

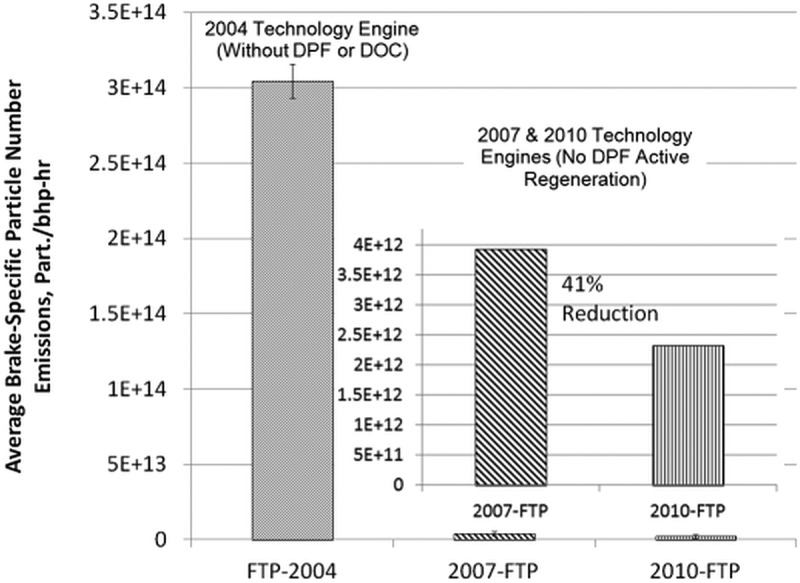

Total particle number and size

Figure 6 shows the total particle number (PN) emissions for the hot-start FTP transient cycle for 2010-, 2007-, and 2004-technology engines. Total PN includes both the solid and volatile particles in the size range between 5.6 nm and 560 nm. It is more inclusive than the EU-based solid PN that focuses on solid particles larger than 23 nm diameter. With the 2010- and 2007-technology engines, PN emissions were more than two orders of magnitude lower than the 2004-technology engines. Furthermore, the PN emissions from the 2010-technology engines were 41% below the PN emitted from the 2007-technology engines.

Figure 6.

Particle number emissions for hot-start FTP transient cycle.

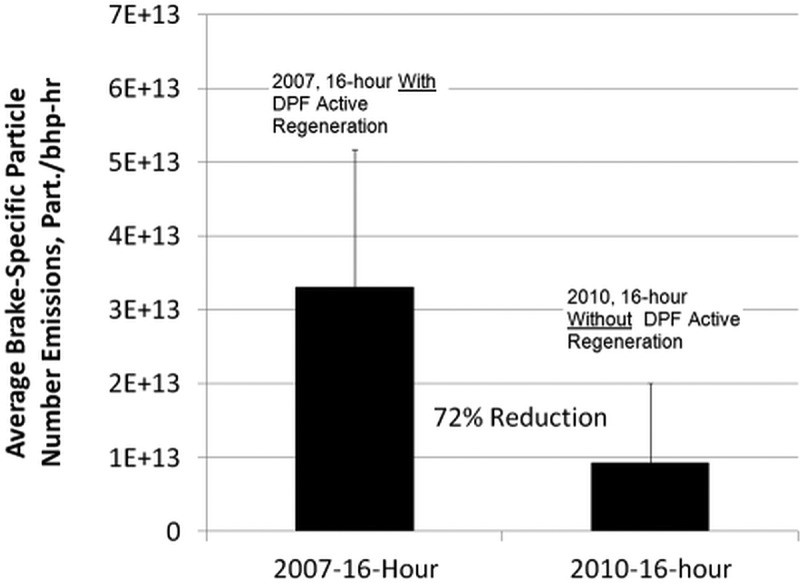

Figure 7 shows the average differences in PN emissions between the 2010- and 2007-technology engines for the 16-hr cycle. For the 16-hr cycle, PN emissions with the 2010-technology engines were 72% below the PN emissions from the 2007-technology engines.

Figure 7.

Particle number emissions for the 16-hr cycle.

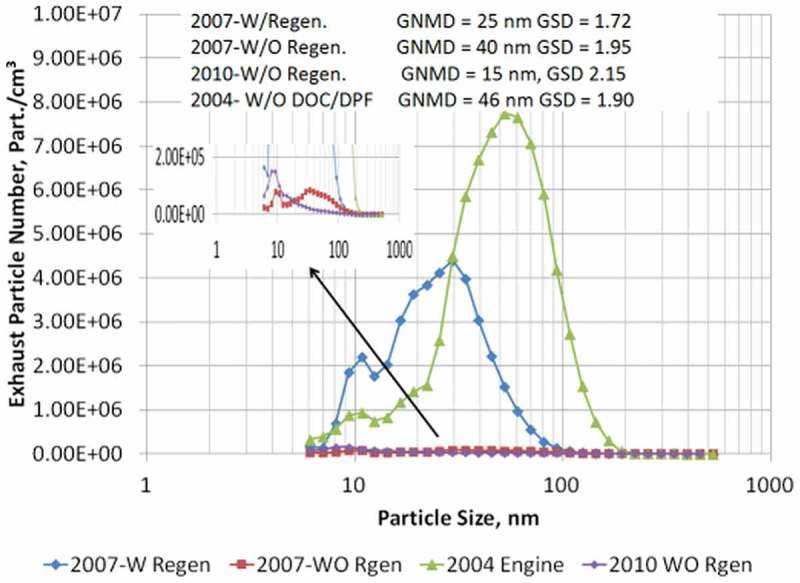

Figure 8 shows the particle size distribution for the 2010-technology engines compared to 2004- and 2007-technology engines. The magnitude of the PN concentration as a function of particle size for the 2010-technology engines is substantially lower than for the 2004- and 2007-technology engines with active DPF regeneration. When we plotted the 2007 number-weighted size distribution using 4-hr segments without DPF active regeneration, the total PN concentration as a function of particle size dropped to the 2010 level. However, the concentration of particles >20 nm remained much lower (90% lower) with the 2010-technology engines compared to 2007-technology engines. This is likely due to a better filtration efficiency of the DPF, coupled with lower engine-out soot with the 2010-technology engines.

Figure 8.

Particle number-weighted size distribution for different technology engines (W & WO: with and without active DPF regeneration; GNMD: geometric number mean diameter; GSD: geometric standard deviation).

Discussion

In the Results section, we provided comparisons in emissions performance between the 2010-technology engines used in this study and the 2007-technology engines used in our previous study under ACES Phase 1. We also provided comparisons relative to pre-2007-technology engines without exhaust aftertreatment done by other researchers. For the comparisons with pre-2007-technology engines, post-2007-technology engines showed a dramatic reduction in most regulated and unregulated emissions. Furthermore, regulated emissions for both the 2010- and 2007-technology engines were substantially below their respective emissions standard limits. The aftertreatment systems of DOC/DPF/SCR/AMOX and improved control of engine-out emissions are largely responsible for the substantial emissions reductions observed with modern heavy-duty diesel engines (Johnson, 2010, 2011).

For the comparison between 2010-technology engines and 2007-technology engines, it was notable that the 2010-technology engines resulted in much lower regulated emissions compared to the 2007-technology engines. In addition, the 2010-technology engines showed much lower emissions for the majority of unregulated compounds, compared to the 2007-technology engines. The most notable emissions reductions from 2010 engines were the sulfur-related compounds such as sulfur, SO2, and SO4. Sulfate and/or sulfuric acid can serve as a precursor for nanoparticle formation (Khalek et al., 2000; Tobias et al., 2001). The lack of sulfate/sulfuric acid in engine exhaust can be one of the main reasons for the lower PN concentration with the 2010 engines, compared to the 2007 engines. Sulfur and sulfur compounds are known to adsorb onto the surfaces of engine exhaust aftertreatment systems such as those used with the 2010- and 2007-technology engines (Smith et al., 2014; Kumar et al., 2014). Desulfation or the desorption of sulfur from aftertreatment systems typically starts to occur at high temperatures greater than 400°C (Smith et al., 2014), but it is time dependent. With the 2007-technology engines, active DPF regeneration occurred at least once during a 16-hr transient cycle. During active regeneration, the DOC temperature can exceed 700°C due to fuel injection upstream of the DOC, and the DPF temperature can exceed 700°C during soot oxidation under active regeneration. Thus, the majority of the sulfur-related compounds adsorbed during normal engine operation without active regeneration could be released during DPF active regeneration. With the 2010-technology engines, active DPF regeneration did not occur and the exhaust temperature did not exceed 500°C. Thus, a substantial amount of sulfur and sulfur-related compounds is expected to remain on the surface of the aftertreatment systems. Furthermore, 2010-technology engines included an SCR catalyst and AMOX that can provide additional surface area for sulfur compound adsorption. This is especially true for the SCR catalyst, which typically contains a large surface area of zeolites (Dathe et al., 2004), which are known for their high adsorption capacity of sulfur compounds (Kumar et al., 2014). While the 2010-technology engines did not trigger any active DPF regeneration in this study, the engine manufacturers have suggested that the engines would eventually trigger a regeneration with longer operating hours. It is of future interest to investigate and document engine emissions under active regeneration for 2010-technology engines, including sulfate and nanoparticle emissions.

Another notable observation with the 2010 technology engines is the reduced level of metallic elements and elemental carbon particle emissions, compared to the 2007-technology engines. We and others have reported in the past that the DPF filtration efficiency is typically lower for a clean DPF compared to a DPF loaded with soot (Khalek et al., 1998). Because of the lack of active DPF regeneration with 2010-technology engines, the DPF is likely to stay at a soot loaded state all the time, resulting in a better DPF average efficiency over the 16-hr cycle, compared to 2007-technology engines. This was indeed observed in Figure 8, where the 2010-technology engines emitted lower PN concentrations in the size range from 20 nm to a 100 nm, compared to 2007-technology engines operating without active DPF regenerations during selected 4-hr segments of the 16-hr cycle. These particles are likely to be solid particles that were filtered at higher efficiency with the 2010-technology engines. The operating efficiency of the DPF in 2010-technology engines also yielded some emissions benefits in elemental carbon and metallic ash.

Particle and gas-phase hydrocarbon species such as PAHs, alkanes, and other species also showed a reduced emissions level with the 2010-technology engines compared to 2007-technology engines. It is plausible that some of those compounds can be oxidized by the platinum-loaded AMOX catalyst located downstream of the SCR catalyst, thus reducing their emissions below the 2007 level. Another reason for the lower organic carbon with the 2010 technology engines could be lower engine-out emissions. Because of the addition of SCR catalyst to reduce NOX, 2010-technology engine calibration is geared toward improving fuel economy by advancing fuel injection timing over 2007 technology engines. Advancing fuel injection timing should result in higher NOX, lower soot, and most likely lower organic carbon due to better combustion efficiency. Because of the lack of active DPF regeneration with 2010 technology engines, it is plausible that organic carbon adsorbs onto surfaces of the catalyzed DPF and the SCR catalyst. Our previous work showed that a catalyzed DPF can be a storage and release site for hydrocarbons at higher temperature (Khalek, 2005). Others showed that the SCR catalyst can be a site for hydrocarbon adsorption (Montreuil et al., 2008; Girard et al., 2008). Additional surface adsorption by the DPF/SCR could be another reason for the reduced level of organic carbon with 2010-technology engines, compared to 2007-technology engines. During DPF active regeneration, however, exhaust gas temperature increases to more than 600ºC at the outlet of the DOC. At such a high temperature some of the organic carbon adsorbed onto the aftertreatment surfaces may be oxidized and/or desorbed. Previous work showed evidence of organic carbon desorption from the surface of a platinum-loaded DPF during regeneration. For a copper–zeolite SCR catalyst or similar one, organic carbon desorption is highly likely. However, the platinum-loaded AMOX catalyst located downstream of the SCR may be a good candidate to oxidize the escaping organic carbon from the surfaces of DPF/SCR. Thus, during active regeneration, due to the presence of AMOX, we hypothesize that organic carbon may not slip into the atmosphere with the same magnitude as 2007 technology engines. However, this will be still required to be demonstrated in future research, providing more complete information on average emissions from 2010 engines with very infrequent active regeneration.

Conclusions

Phase 2 of the ACES program included a comprehensive characterization of regulated and unregulated emission species from 2010-technology engines that utilized a DOC/DPF/SCR and AMOX in the engine exhaust. The engines were new with only 125 hr of break-in engine operation before the start of emissions testing. ACES Phase 2 was very similar to the emissions characterization performed earlier under ACES Phase 1 using 2007-technology engines that utilized DOCs and catalyzed DPFs. Regulated species of CO, NMHC, NOX, and PM emitted from the 2010-technology engines were substantially lower (61% to >99%) than the 2010 emissions standard. Very substantial reductions (90% to >99%) in average regulated and unregulated emissions were also observed from 2010-compliant on-highway heavy-duty diesel engines compared with pre-2007 on-highway diesel engine emissions. The emissions reductions were also significant relative to 2007-technology engines, in the range from 46% to more than 99%. The classes of compounds for such reductions included polycyclic aromatic hydrocarbons (PAHs), N-PAHs, hopanes and steranes, alcohols and organic acids, alkanes, carbonyls, dioxins and furans, inorganic ions, metals and elements, elemental carbon (EC), and PN. N2O (greenhouse gas) showed an increase relative to 2007-technology engines, but it remained below the 2014 cap for N2O emissions.

The PM emissions from 2010-technology engines for the 16-hr cycle were 62% lower than the already very low level observed with 2007-technology engines. The 2010 PM composition was dominated by organic carbon (66%), followed by elemental carbon (16%), followed by nitrate (14%). The remainder of the composition included ammonium, sulfate, and elements at less than 2% each. The most notable difference in the PM composition from the 2010- and 2007-technology engines was the virtual absence of sulfate with the 2010-technology engines and to a lesser degree the increase in ammonium and nitrate inorganic ions that can be produced by the urea-based SCR system. The storage of sulfur at the surface of DOC/DPF/SCR/AMOX and the lack of high-temperature active regeneration may be responsible for the very low sulfate emissions from 2010-technology engines. With 2007-technology engines, the DPFs regenerated at least one to three times during a 16-hr cycle, causing a rise in DOC and DPF temperatures that led to sulfate desorption. Future testing with 2010-technology engines should shed some light on the effects of active DPF regeneration on average emissions from 2010-technology engines. Overall, the 2010-technology engines represent a remarkable advancement toward truly green diesel technologies, especially when compared with pre-2007-technology engines. Dramatic reductions in regulated emissions and unregulated emissions were observed in the new engines tested, which have the potential to significantly reduce adverse health effects from diesel-related air pollution.

Funding

Preparation of this paper was funded by the Truck and Engine Manufacturers Association. We gratefully acknowledge the comments of Roger O. McClellan, an independent consultant to the EMA. The interpretations of the data and the conclusions drawn are those of the authors and may not necessarily be those of the sponsors of the research, the manufacturers of the engines or the Truck and Engine Manufacturers Association or their representatives.

Acknowledgments

The research reported was conducted as part of the ACES program organized and managed by the Health Effects Institute and the Coordinating Research Council. The emissions characterization research was funded by the Department of Energy (DOE) Office of Vehicle Technologies, Truck and Engine Manufacturers Association (EMA), California Air Resources Board (CARB), and American Petroleum Institute (API). We acknowledge the in-kind support of urea-related compound analyses by Oak Ridge National Laboratory (Dr. John Storey).

The key sponsors’ project coordinators were Dr. Christopher Tennant (CRC), and Drs. Maria Costantini and Dr. Rashid Shaikh from HEI. Cummins, Detroit Diesel, and Volvo Powertrain provided the engines and engine support. Key contacts were Dr. Shirish Shimpi, Cummins; Donald Keski-Hynnila, Detroit Diesel; and Jeff Schaffer, Volvo Powertrain. Lubrizol provided the lube oil, and the key contact was Dr. Ewa Bardasz. The authors also acknowledge the following CRC ACES panel members for their comments and feedback on this paper and throughout Phase 2 of the ACES: Reynaldo Agama, Caterpillar; Ewa Bardasz, Lubrizol Corporation; Nicholas Barsic, John Deere; Maria Costantini, HEI; Christopher Dea, Caterpillar, Dominic DiCicco, Ford Motor Company; Timothy French, EMA; Rob Graze, Caterpillar; Garry Gunter, Phillips 66; Thomas Hesterberg, Navistar, Inc; Donald Keski-Hynnila, Detroit Diesel Corporation; Dan Kieffer, Paccar, Inc; George Lin, Caterpillar, Inc; Chris Laroo, EPA; Hector Maldonado, CARB; M. Matti Maricq, Ford Motor Company; Jeff Marley, Volvo Group Trucks Technology; Carl Maronde, National Energy Technology Laboratory; Mani Natarajan, Marathon Petroleum Company LP; Ralph Nine, National Energy Technology Laboratory; Jeff Shaffer, Volvo Powertrain North America; Rashid Shaikh, HEI; Shirish Shimpi, Cummins; Joseph H. Somers, EPA; John Storey, Oak Ridge National Laboratory; Chris Tennant, CRC; Steven Trevitz, Volvo Powertrain North America; Annemoon van Erp, HEI; Timothy Wallington, Ford Motor Company; Matt Watkins, ExxonMobil Research & Engineering; and Andre Welch, Ford Motor Company.

Biography

Imad A. Khalek is a senior program manager, Matthew G. Blanks is a senior research engineer, and Patrick M. Merritt is a principal scientist with Southwest Research Institute. Barbara Zielinska is a research professor with Desert Research Institute.

Funding Statement

Preparation of this paper was funded by the Truck and Engine Manufacturers Association. We gratefully acknowledge the comments of Roger O. McClellan, an independent consultant to the EMA. The interpretations of the data and the conclusions drawn are those of the authors and may not necessarily be those of the sponsors of the research, the manufacturers of the engines or the Truck and Engine Manufacturers Association or their representatives.

References

- ACES Ph2 Database [accessed February 6, 2015).];2015 http://crcao.org/publications/emissions/index.html

- California Air Resources Board [accessed May 7;, 2015).];Toxic air contaminant (TAC) identification list. 2010 http://www.arb.ca.gov/toxics/cattable.htm#Note 9.

- Clark N., Gautam M., Wayne W, Lyons D., Thompson G., Zielinska B. [accessed Feb 24;, 2015).];Heavy-duty vehicle chassis dynamometer testing for emissions inventory, air quality modeling, source apportionment and air toxics emissions inventory. 2007 http://www.crcao.com/reports/recentstudies2007/E-55-59/E-55_59_Final_Report_23AUG2007.pdf CRC report no. E55/E59, August.

- Clark N., Zhen F., Bedick C., Gautam M., Wayne W., Thompson G., Lyons D. Creation of the 16-hour engine test schedule from the heavy heavy-duty diesel engine test schedule. CRC report no. ACES-1-a. CRC [accessed Feb 6;, 2015).];2007 http://www.crcao.org/reports/recentstudies2007/ACES-1a/CRC%20ACES-1a%20Final%20Report%2007-11-2007.pdf

- Dathe H., Sedlmair C., Jentys A., Lercher A. Adsorption of SO2 on different metal impregnated zeolites. Stud. Surface Sci. Catal. 2004;154:3003–9. doi: 10.1016/S0167-2991(04)80584-6. 2004. (Part C) [DOI] [Google Scholar]

- Electronic Code of Federal Regulations [accessed Feb 6;, 2015).];Engine fluids, test fuels, and analytical gases and other calibration standards. 2015 http://www.ecfr.gov/cgi-bin/text-idx?SID=8fd541a6e8abdc22894e831f4a2d5f29&node=sp40.33.1065.h&rgn=div6

- Regulation of fuel and fuel additives: Fuel quality regulations for highway diesel fuel sold in 1993 and later calendar years. Federal Register. 1990;55(34):120. [Google Scholar]

- Girard J., Snow R., Cavataio G., Lambert C. SAE Technical Paper. 2008. Influence of hydrocarbon storage on the durability of SCR catalysts. 2008-01-0767. [Google Scholar]

- Khalek I.A., Kittelson D., Brear F. SAE Technical Paper No. 1998. Diesel trap performance: Particle size measurements and trends; p. 982599. [Google Scholar]

- International Agency for Research on Cancer . Monograph, Vol. 46, Diesel and gasoline engine exhausts and some nitroarenes. Lyon, France: World Health Organization, International Agency for Research on Cancer; 1989. [Google Scholar]

- Johnson T.V. Diesel emission control in review. SAE Technical Paper; 2009. 2009-01-0121. [Google Scholar]

- Johnson T.V. Review of diesel emissions and control. SAE Int. J. Fuels Lubr. 2010;3(1):16–29. doi: 10.4271/2010-01-0301. [DOI] [Google Scholar]

- Johnson T.V. Diesel emissions in review. SAE Int. J. Engines. 2011;4(1):143–157. doi: 10.4271/2011-01-0304. [DOI] [Google Scholar]

- Khalek I.A. [accessed Feb 24;, 2015];2007 Diesel particulate measurement research. CRC report E-66 Phase 1. 2005 http://www.crcao.org/publications/emissions/index.html

- Khalek I., Blanks M., Merritt P. Phase 2 of the Advanced Collaborative Emissions Study. CRC report: ACES Phase 2. CRC. November; 2013. [accessed Feb 6;, 2015).]. http://crcao.org/reports/recentstudies2013/ACES%20Ph2/03-17124_CRC%20ACES%20Phase2-%20FINAL%20Report_Khalek-R6-SwRI.pdf [Google Scholar]

- Khalek I., Bougher T., Merritt P. Phase 1 of the Advanced Collaborative Emissions Study. CRC Report: ACES Phase 1. Coordinating Research Council; 2009. [accessed Feb 6;, 2015).]. http://www.crcao.org/reports/recentstudies2009/ACES%20Phase%201/ACES%20Phase1%20Final%20Report%2015JUN2009.pdf [Google Scholar]

- Khalek I., Bougher T., Merritt P., Zielinska B. Regulated and unregulated emissions from highway heavy-duty diesel engines complying with U.S. Environmental Protection Agency 2007 emissions standards. J. Air Waste Manage. Assoc. 2011;61:427–42. doi: 10.3155/1047-3289.61.4.427. [DOI] [PubMed] [Google Scholar]

- Khalek I.A., Kittelson D., Brear F. SAE Technical Paper. 2000. Nanoparticle growth during dilution and cooling of diesel exhaust: Experimental investigation and theoretical assessment. No. 2000-01-0515. [Google Scholar]

- Kumar A, Kamasamudram S., Currier N., Yezerets A. Impact of different forms of feed sulfur on small-pore cu-zeolite catalyst. Catal. Today. 2014;231:75–82. doi: 10.1016/j.cattod. 2013.12.038. [DOI] [Google Scholar]

- McClellan R.O., Hesterberg T.W., Wall J.C. Evaluation of carcinogenic hazard of diesel engine exhaust needs to consider revolutionary changes in diesel technology. Regul. Toxicol. Pharmacol. 2012;63:225–58. doi: 10.1016/j.yrtph. [DOI] [PubMed] [Google Scholar]

- McDonald J., Bemis J., Hallberg L., Conklin D., Kong M. [accessed Feb 6;, 2015).];Advanced Collaborative Emissions Study (ACES) subchronic exposure results: Biologic responses in rats and mice and assessment of genotoxicity. HEI research report no. 166. HEI. 2012 http://pubs.healtheffects.org/view.php?id=377

- McDonald J., Bemis J., Hallberg L., Conklin D., Kong M. [accessed Feb 6;, 2015).];Advanced Collaborative Emissions Study (ACES): Lifetime cancer and non-cancer assessment in rats exposed to new-technology diesel exhaust. HEI research report no. 184. HEI. 2015 http://pubs.healtheffects.org/view.php?id=430

- McGeehan J., J. Moritz G., Shank S., Kennedy D., Stehouwer M., Urbank M., Belay S., Goodier A., Cassim B., Runkle H., Debaun S., Harold K., Chao S., Herzog R., Stockwell C., Passut P., Fetterman D., Taber L., Williams W., Kleiser J., Zalar P., Scinto E., Santos and, Rutherford J. SAE Technical Paper. 2007. API CJ-4: Diesel oil category for pre-2007 engines and new low emission engines using cooled exhaust gas recirculation and diesel particulate filters. 2007-01-1966. [Google Scholar]

- McGeehan J., J. Wells S., Kennedy A., Huang G., Shank D., Stehouwer D., Larkin D., Tharp F., Bondarowicz K., Chao R., Stockwell C., Passut W., Kleiser L., Williams P., Fetterman J., Zalar J., Rutherford P., Scinto and, Malandro D. SAE Technical Paper. 2002. API CI-4: The first oil category for diesel engines using cooled exhaust gas recirculation. 2002-01-1673. [Google Scholar]

- Montreuil C., Lambert C. The effect of hydrocarbons on the selective catalyzed reduction of NOx over low and high temperature catalyst formulations. SAE Int. J. Fuels Lubr. 2008;1(1):495–504. doi: 10.4271/2008-01-1030. [DOI] [Google Scholar]

- National Center for Environmental Assessment, Office of Research and Development, U.S. Environmental Protection Agency . An inventory of sources and environmental releases of dioxin-like compounds in the United States for the years 1987. Washington, DC: 2006. [accessed February 24, 2015).]. http://www.epa.gov/ncea/pdfs/dioxin/2006/dioxin.pdf 1995, and 2000. [Google Scholar]

- Smith M, Kamasamudram K., Szailer T., Kumar A., Yezerets A. SAE Technical Paper. 2014. Impact of sulfur-oxides on the ammonia slip catalyst performance. 2014-01-1545. [Google Scholar]

- Tobias H.J., Beving D., Ziemann P., Sakurai H., Zuk M., McMurry P., Zarrling D., Waytulonis R., Kittelson D. Chemical analysis of diesel engine nanoparticles using a nano DMA/thermal desorption particle beam mass spectrometer. Environ. Sci. Technol. 2001;35(11):2233–43. doi: 10.1021/es0016654. [DOI] [PubMed] [Google Scholar]

- U.S. Environmental Protection Agency. 2000. Heavy-duty engine and vehicle standards and highway diesel fuel sulfur control requirements . Regulatory announcement. Washington, DC: U.S. EPA Office of Transportation and Quality; 2000. EPA420-F-00-057. [Google Scholar]

- U.S. Environmental Protection Agency . Transportation and air quality. Available from: National Technical Information Service; Springfield, VA: 2002. EPA/600/8-90/057F. PB2002-107661. [Google Scholar]

- U.S. Environmental Protection Agency [accessed Feb 6;, 2015).];Test report of mobile source emission control devices: Donaldson Series 6100 diesel oxidation catalyst muffler. U.S. EPA Environmental Technology Verification (ETV) 2003 http://www.epa.gov/etv/pubs/05_vr_6100.pdf

- U.S. Environmental Protection Agency [accessed Feb 6;, 2015).];Test report of mobile source emission control devices: Johnson Matthey PCRT2® 1000, Version 2, Filter + diesel oxidation catalyst. U.S. EPA Environmental Technology Verification (ETV) 2009 http://www.epa.gov/etv/pubs/600etv09007.pdf

- U.S. Environmental Protection Agency [accessed May 8;, 2015).];Final rulemaking to establish greenhouse gas emissions standards and fuel efficiency standards for medium- and heavy-duty engines and vehicles. 2011 http://www.epa.gov/otaq/climate/documents/420r11901.pdf U.S. EPA, August.