Abstract

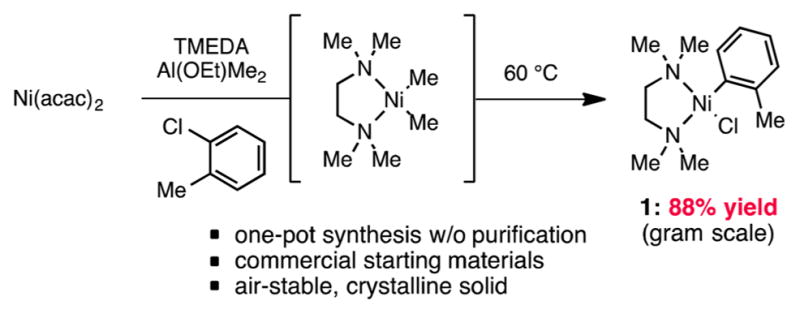

The synthesis and catalytic activity of [(TMEDA)Ni(otolyl) Cl], an air-stable, crystalline solid, is described. This complex is an effective precatalyst in a variety of nickel-catalyzed transformations. The lability of TMEDA allows a wide variety of ligands to be used, including mono- and bidentate phosphines, diimines, and N-heterocyclic carbenes. Preliminary mechanistic studies are also reported, which suggest that [(TMEDA)Ni(o-tolyl)Cl] can activate by either a Ni–B or Ni–Ni transmetalation event, depending on the reaction conditions.

The past two decades have witnessed rapid growth in the area of homogeneous nickel catalysis owing to the base metal’s low cost and unique properties compared to its precious metal sibling, palladium.1 This transition metal is not only three orders of magnitude less expensive than palladium on amole-for-mole basis,2 but nickel is also more electropositive and smaller than palladium, enabling more facile oxidative addition and access to more diverse oxidation states. Nevertheless, palladium still overwhelmingly dominates the landscape of group 10 metal catalysis.3 A major cause of this disparity is the diversity, accessibility, and robustness of Pd(0) precursors as compared to Ni(0) catalysts. The most common Ni(0) source for catalysis is Ni(cod)2, which is expensive and must be stored and used under rigorously air-free conditions. These limitations hinder both large-scale applications of nickel catalysis and small-scale reaction discovery efforts. To circumvent these problems, air-stable, well-defined Ni(II) precatalysts have been developed, ranging in complexity from NiX2 salts to carefully designed organometallic complexes. Despite these advances, Ni(cod)2 remains the most general nickel precatalyst.

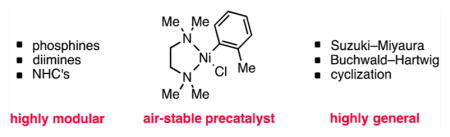

The ideal precatalyst would satisfy four criteria: (1) low cost, (2) air stability, (3) modularity—compatibility with any desired ligand class, and (4) generality—activity in a wide range of reactions. Previously reported precatalysts fall short in at least one of these areas. Ni(cod)2 and methallylnickel chloride dimer can be used with many different ligands but are expensive and air sensitive (Figure 1). NiX2 salts and their glyme adducts are relatively inexpensive, but modularity is a problem since polynuclear complexes can be formed upon ligation, leading to inactive species.4,5 Furthermore, reducing conditions are often required in order to activate the NiX2 precatalyst, limiting the scope of possible transformations.6,7 Yang, Hartwig, Jamison, Buchwald, and Percec have recently developed air-stable precatalysts that are all highly active for specific reactions.8–12 Crucially, however, they are all bound to phosphine ligands, meaning that their generality is inherently limited to reactions in which that exact ligand is competent.13 The same limitation applies to NiL2X2 complexes like Ni(PCy3)2Cl2, which have been used in Suzuki reactions.14

Figure 1.

Prior art in nickel precatalysts.

We aimed to design an air-stable Ni(II) precatalyst with high modularity and generality. We speculated that the use of weakly binding amine ligands in place of phosphine ligands would permit facile ligand exchange, allowing a much wider scope of σ-donating ligands to bind to the nickel center. Based on the precedent for using N,N,N′,N′-tetramethylethylenediamine (TMEDA) as a dummy ligand in the inorganic synthesis of both diamine and phosphine-ligated nickel and palladium complexes, we selected this ligand for the preparation of a modular precatalyst.15 Although [(TMEDA)Ni(Ph)Cl] is reported to be thermally unstable and air sensitive,16 Shaw and Yamamoto have shown that use of an o-tolyl or other hindered aryl substituent on Ni(II)(aryl)Cl complexes bearing phosphine or bpy ligands confers air stability by shielding nickel from associative substitution.17,18 On this basis, we hypothesized that [(TMEDA)Ni(o-tolyl)Cl] (1) would serve as an air-stable and modular Ni precatalyst.

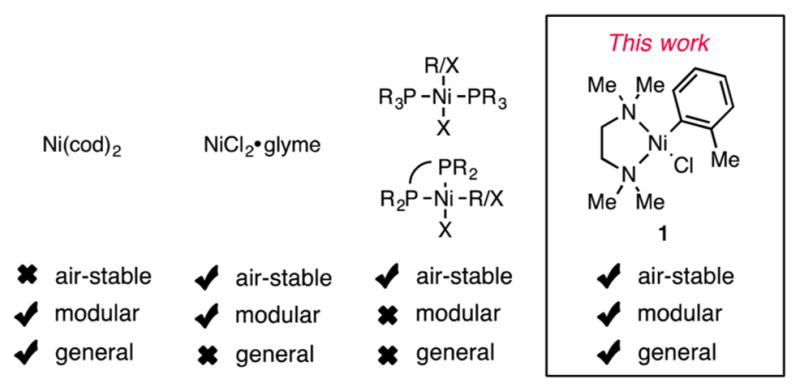

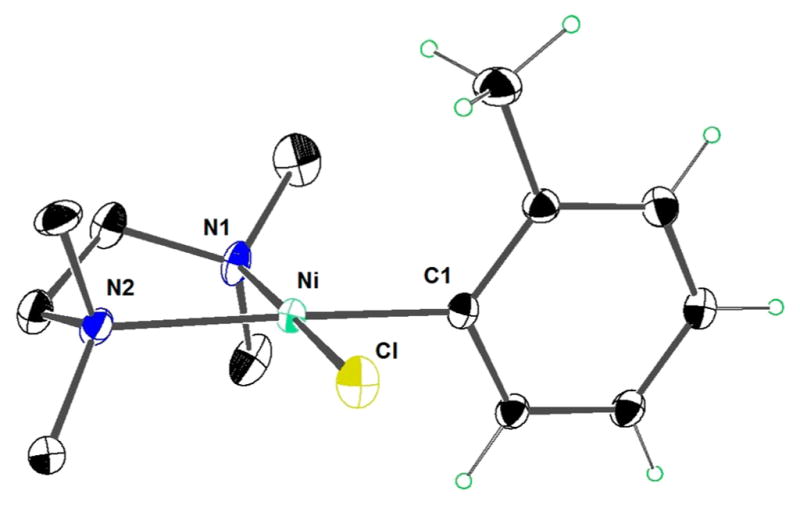

Initially, our synthesis of 1 began from (TMEDA)NiMe2, originally prepared by Wilke in his seminal studies of organonickel chemistry.15b We were pleased to find that 1 was indeed stable to air and ambient temperature. Samples have been stored for 3 months on the benchtop with no detectable decomposition. In a second generation synthesis, we used o-chlorotoluene as the reaction solvent in a one-pot reaction from commercially available Ni(acac)2 and Al(OEt)Me2 (Scheme 1). Under these conditions, which have been run on a gram scale with 88% yield, complex 1 crashes out of the reaction solution as red crystals, obviating the need for a purification step. X-ray crystallography of these crystals confirms the structure of complex 1 (Figure 2).19 The complex is square planar, as expected for tetravalent Ni(II), and the methyl group from the tolyl substituent projects above the plane of the complex, as predicted by Shaw.17

Scheme 1.

Synthesis of Nickel Precatalyst 1

Figure 2.

X-ray crystal structure of complex 1. Ellipsoids are set to 30% probability. Hydrogen atoms on the TMEDA ligand have been removed for clarity.

In order to probe the generality of this precatalyst, we selected nine nickel-catalyzed reactions, including Suzuki–Miyaura (sp2 and sp3 electrophiles), Buchwald–Hartwig, cyclization, and oxidative coupling reactions (Table 1).9,11,14a,20–25 In each case, the original precatalyst was replaced with equimolar quantities of complex 1; the same stoichiometry of ligand was then used. Empirically, we found that the addition of K3PO4 improved the reaction yields with precatalyst 1, so it was included in reactions even if the original report did not do so.26 The other reaction components, solvents, and temperatures were identical to the original literature reports, with the exception of entry 9, which was run at 100 °C instead of 30 °C (vide inf ra).

Table 1.

Activity of Precatalyst 1 in Reactions Selected from the Literature

| entry | reactiona | yield w/ precatalyst 1 | literature precatalyst (literature yield) |

|---|---|---|---|

| 1 |

|

98% yield (87% yield)b |

(96% yield) ref 14a |

| 2 |

|

96% yield | [(dppf)Ni(cinnamyl)Cl] (91% yield) ref 9 |

| 3 |

|

43% yield | Ni(cod)2 PPh3 (68% yield) ref 20 |

| 4 |

|

98% yield | Ni(cod)2 PCy3 (93% yield) ref 21 |

| 5 |

|

80% yield | Ni(cod)2 bathophen (67% yield) ref 22 |

| 6c |

|

83% yield | [(dppf)Ni(o-tolyl)Cl] (85% yield) ref 11 |

| 7 |

|

79% yield | Ni(cod)2 PCy3 (88% yield) ref 23 |

| 8 |

|

65% yield | Ni(cod)2 SIPr (95% yield) ref 24 |

| 9 |

|

86% yield | Ni(cod)2 IPr (98% yield) ref 25 |

The scale and concentrations were identical to the original report. See the Supporting Information for full details.

This reaction was also run on 4 mmol (~1 g) scale.

Entry 6 was run without K3PO4 as this was empirically found to result in higher yield.

The results indicate a high degree of modularity. In addition to monodentate and bidentate phosphines, diimine ligands (entry 5) and N-heterocyclic carbene (NHC) ligands (entries 8 and 9) can be used. This wide range of ligand classes highlights the importance of modularity to precatalyst design. For example, complex 1 would be an effective nickel source for the large ligand screening efforts that accompany reaction development. Furthermore, the diversity in ligands allows an expansive scope of reactions that can conceivably be run with precatalyst 1. This feature distinguishes 1 from the air-stable Ni(II) precatalysts recently reported in the literature, which all require ligation of a phosphine in a previous synthetic step.

Heterocyclic coupling partners are tolerated (entries 2, 3, and 5), as are other polar coordinating groups (entries 1, 6, 7, and 9). Precatalyst 1 also tolerates a variety of solvents, ranging in polarity from toluene (entries 4 and 7) to s-butanol (entry 5). Inmost cases, the yield was equivalent or superior to the original report. For entries 3 and 8, it was found that TMEDA poisons the original catalyst system;27 this is an inherent limitation of precatalyst 1, but it should be noted that free 1,5-cyclooctadiene can also negatively affect reactions when Ni(cod)2 is used as a precatalyst.10a,28 Precatalyst 1 works on gram scale (87% yield, entry 1) and with low catalyst loadings (0.5 mol %, entry 2). Control reactions for each entry were conducted using NiCl2·glyme as the precatalyst, as this nickel source is low cost and air stable, and in every example except entries 1 and 2, the yield with this precatalyst was substantially lower than with complex 1 after the same reaction time.27

Temperature is the main limitation to the generality of complex 1. The precatalyst does not activate at room temperature, and the test reactions suggest that 60 °C is the lower bound of activation. For example, the oxidative coupling reported by Dong in entry 9 takes place at 30 °C with Ni(cod)2, but no conversion to product is observed with precatalyst 1 at this temperature. Attempts to preactivate complex 1 by heating it in the presence of ligand and various other reaction components prior to conducting the reaction were unsuccessful. However, simply running the oxidative coupling at elevated temperature recovered reactivity (86% yield).

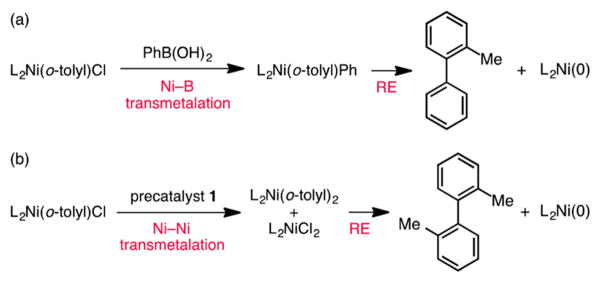

The success of precatalyst 1 in a wide variety of reactions prompted us to investigate its mechanism of activation. For entries 1–5, a fairly straightforward mechanism may explain the generation of the presumed Ni(0) active catalyst. Namely, a boron-to-nickel transmetalation would produce a nickel biaryl species and rapidly generate Ni(0) upon reductive elimination (Scheme 2a). Similarly, coordination of morpholine and subsequent reductive elimination could furnish Ni(0) in the Buchwald–Hartwig reaction (entry 6). The [4 + 2], the [2 + 2 + 2], and the dehydrogenative coupling reactions shown in entries 7–9, however, do not have an obvious transmetalating agent or amide ion. Instead, we speculated that a nickel–nickel transmetalation event was taking place, leading to an inactive nickel dihalide and an active nickel biaryl species (Scheme 2b).10a Indeed, our observation of 2,2′-dimethylbiphenyl in the [4 + 2] reaction (entry 7) indicates a nickel–nickel transmetalation pathway is operative. However, the Suzuki–Miyaura cross-coupling reaction with aryltosylates (entry 1) yielded 2-methylbiphenyl rather than 2,2′-dimethylbiphenyl, suggesting boron-to-nickel transmetalation is preferred in the presence of boronic acid. These observations demonstrate that, depending on the reaction conditions, either nickel–boron or nickel–nickel transmetalation are possible mechanisms for precatalyst activation.

Scheme 2.

Mechanisms for Precatalyst Activation

Nickel catalysis has a rich history in spite of the air sensitivity of Ni(0). Numerous cross-coupling, cyclization, and redox reactions have been developed despite the lack of a low-cost, air-stable, modular, and general precatalyst. With the introduction of complex 1, which satisfies all of these criteria, we anticipate that nickel catalysis will become even more practical and widespread. The modularity of complex 1 renders it ideal for reaction development, and its low cost and stability may make it applicable on large scale. Future work will focus on expanding the temperature range for activation, thus increasing the generality of precatalyst 1 still further.

Supplementary Material

Acknowledgments

Financial support from NIGMS (R01 GM100985-02) and Princeton University is acknowledged. This material is based upon work supported by the National Science Foundation Graduate Research Fellowship under Grant No. DGE-1148900 (to E.E.G.). We thank Phil Jeffrey of Princeton University for X-ray crystallographic structure determination and Grant Margulieux of Princeton University for helpful discussions. Precatalyst 1 will be commercially available from Sigma-Aldrich.

Footnotes

Notes

The authors declare no competing financial interests.

Experimental procedures, spectroscopic data, and X-ray crystallographic data. This material is available free of charge via the Internet at http://pubs.acs.org.

References

- 1.Tasker SZ, Standley EA, Jamison TF. Nature. 2014;509:299. doi: 10.1038/nature13274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Rosen BM, Quasdorf KW, Wilson DA, Zhang N, Resmerita AM, Garg NK, Percec V. Chem Rev. 2011;111:1346. doi: 10.1021/cr100259t. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.SciFinder searches for the phrases “palladium-catalyzed crosscoupling” and “Pd-catalyzed cross-coupling” yielded 4315 hits, while the equivalent searches for “nickel” and “Ni” yielded only 487. A similar order of magnitude difference is observed when “cross-coupling” is omitted. (accessed 13 March 2015)

- 4.(a) Handley DA, Hitchcock PB, Leigh GJ. Inorg Chim Acta. 2001;314:1. [Google Scholar]; (b) Jensen KL, Standley EA, Jamison TF. J Am Chem Soc. 2014;136:11145. doi: 10.1021/ja505823s. [DOI] [PubMed] [Google Scholar]

- 5.Additionally, NiX2 and their glyme adducts are hygroscopic, limiting their air-stability. NiCl2·glyme has also been shown to dissociate glyme spontaneously even in an anhydrous environment: Prinsell MR, Everson DA, Weix DJ. Chem Commun. 2010;46:5743. doi: 10.1039/c0cc01716g.

- 6.(a) Colon I, Kelsey DR. J Org Chem. 1986;51:2627. [Google Scholar]; (b) Montgomery J. Angew Chem, Int Ed. 2004;43:3890. doi: 10.1002/anie.200300634. [DOI] [PubMed] [Google Scholar]

- 7.Garg has shown that NiCl2·glyme can be reduced to Ni(0) by sacrificial arylboronate ester, but this strategy is not always successful. Hie L, Ramgren SD, Mesganaw T, Garg NK. Org Lett. 2012;14:4182. doi: 10.1021/ol301847m.

- 8.(a) Chen C, Yang LM. Tetrahedron Lett. 2007;48:2427. [Google Scholar]; (b) Chen C, Yang LM. J Org Chem. 2007;72:6324. doi: 10.1021/jo0709448. [DOI] [PubMed] [Google Scholar]; (c) Fan XH, Yang LM. Eur J Org Chem. 2011:1467. [Google Scholar]

- 9.Ge S, Hartwig JF. Angew Chem, Int Ed. 2012;51:12837. doi: 10.1002/anie.201207428. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.(a) Standley EA, Jamison TF. J Am Chem Soc. 2013;135:1585. doi: 10.1021/ja3116718. [DOI] [PMC free article] [PubMed] [Google Scholar]; (b) Standley EA, Smith SJ, Müller P, Jamison TF. Organometallics. 2014;33:2012. doi: 10.1021/om500156q. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Park NH, Teverovskiy G, Buchwald SL. Org Lett. 2014;16:220. doi: 10.1021/ol403209k. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Jezorek RL, Zhang N, Leowanawat P, Bunner MH, Gutsche N, Pesti AKR, Olsen JT, Percec V. Org Lett. 2014;16:6326. doi: 10.1021/ol503061c. [DOI] [PubMed] [Google Scholar]

- 13.[(PPh3)2Ni(1-naphthyl)(Cl)] has been used in conjunction with an NHC ligand (ref 8b) to obtain reactivity in a Buchwald–Hartwig reaction. However, the generality of this method has not been tested nor has it been demonstrated that the excess PPh3 is tolerated in a wide variety of reactions.

- 14.(a) Zim D, Lando VR, Dupont J, Monteiro AL. Org Lett. 2001;3:3049. doi: 10.1021/ol016526l. [DOI] [PubMed] [Google Scholar]; (b) Quasdorf KW, Antoft-Finch A, Liu P, Silberstein AL, Komaromi A, Blackburn T, Ramgren SD, Houk KN, Snieckus V, Garg NK. J Am Chem Soc. 2011;133:6352. doi: 10.1021/ja200398c. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.(a) Byers PK, Canty AJ, Jin H, Kruis D, Markies BA, Boersma J, van Koten G, Hill GS, Irwin MJ, Rendina LM, Puddephatt RJ. Inorg Synth. 1998;32:162. [Google Scholar]; (b) Kaschube W, Pörschke KR, Wilke G. J Organomet Chem. 1988;355:525. [Google Scholar]

- 16.Marshall WJ, Grushin VV. Can J Chem. 2005;83:640. [Google Scholar]

- 17.Moss JR, Shaw BL. J Chem Soc A. 1966:1793. [Google Scholar]

- 18.Uchino M, Asagi K, Yamamoto A, Ikeda S. J Organomet Chem. 1975;84:93. [Google Scholar]

- 19.The structure shown represents the majority conformation (~80%). See SI for a whole molecule disorder model.

- 20.Graham TJA, Doyle AG. Org Lett. 2012;14:1616. doi: 10.1021/ol300364s. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Tobisu M, Shimasaki T, Chatani N. Angew Chem, Int Ed. 2008;47:4866. doi: 10.1002/anie.200801447. [DOI] [PubMed] [Google Scholar]

- 22.Zhou J, Fu GC. J Am Chem Soc. 2004;126:1340. doi: 10.1021/ja039889k. [DOI] [PubMed] [Google Scholar]

- 23.Ohashi M, Takeda I, Ikawa M, Ogoshi S. J Am Chem Soc. 2014;133:18018. doi: 10.1021/ja208162w. [DOI] [PubMed] [Google Scholar]

- 24.Kumar P, Thakur A, Hong X, Houk KN, Louie J. J Am Chem Soc. 2014;136:17844. doi: 10.1021/ja5105206. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Whitaker AM, Dong VM. Angew Chem, Int Ed. 2015;54:1312. doi: 10.1002/anie.201410322. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.The positive effect of K3PO4 additive in most of the test reactions suggests the possible intermediacy of a Ni-hydroxo complex as described by Monfette and coworkers at Pfizer: Christian AH, Muller P, Monfette S. Organometallics. 2014;33:2134.. We have been unable to isolate any such intermediates, though work in this area is ongoing.

- 27.See the Supporting Information for details.

- 28.Shields JD, Ahneman DT, Graham TJA, Doyle AG. Org Lett. 2014;16:142. doi: 10.1021/ol4031364. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.