When pursuing a degree in fine arts 15 years ago, Matthew Shlian never dreamed that he would one day be the coauthor of scientific research papers on nanoengineering and solar power (1, 2). But, the Ann Arbor-based artist and designer was exactly that earlier this year. A collaboration between Shlian and engineering colleagues at the University of Michigan is now coming to fruition in the form of technology inspired by the paper-cutting art known as kirigami. The Michigan work exemplifies how some cutting edge technology research has been shaped by the ancient craft.

Matthew Shlian incorporates elements of kirigami into his science research collaborations as well as his paper sculptures, such as this one. Image courtesy of Matthew Shlian (mattshlian.com).

In essence, kirigami is a variant of origami, the art of paper folding. The words derive from the Japanese for cutting (kiru), folding (oru), and paper (kami). Folding and cutting of paper to create ceremonial or decorative objects dates back centuries in Asia and Europe. The modern notion of origami as an art and recreational craft (and eschewing all cuts in its purest form) took shape last century.

Standard origami starts with a pristine sheet of paper, most often square, and proceeds solely by adding folds: no cutting or gluing is allowed. In contrast, kirigami, relies on both cutting and folding. Designs range from flat symmetrical cut-out decorations like schoolroom snowflakes to elaborate patterns that form 3D models similar to book pop-ups. (Early in his paper-sculpting career, Shlian worked on pop-up books, among other pursuits.)

Making the Cut

Why has this low-tech art form found a home in science and technology pursuits? One attraction is the ability to turn 2D materials into 3D structures solely by introducing cuts and folds. For example, John A. Rogers of the University of Illinois at Urbana–Champaign and collaborators have shown how membranes can be designed to form predictable 3D structures ranging from the nanoscale to the mesoscale (3). The group used lithographic techniques to build membranes of silicon, metal, and polymer (in various combinations), with specific geometries and patterns of cuts. Each flat unit is anchored at a number of points to a stretched elastomer substrate. When the tension is relaxed, the substrate contracts, dragging these anchor points closer together, like a person pushing together corners of a paper sheet; the precut membranes buckle out of the plane. The kirigami cuts help determine the final 3D shapes and alleviate stresses that could otherwise cause the material to fracture. Researchers are interested in such 3D structures for uses such as optoelectronics and nanostructured biomedical devices.

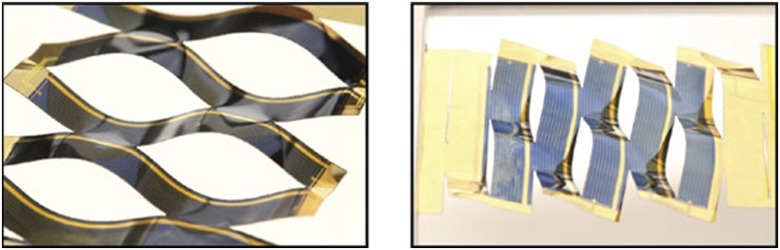

Solar cells, such as these made from thin-film crystalline gallium arsenide, were designed with kirigami cutting techniques. Adapted from ref. 2.

Kirigami structures also confer elasticity. For example, Hanqing Jiang of Arizona State University and his coworkers developed lithium-ion batteries that are cut and folded into a flexible chain, which can be worn as an elastic armband to power wearable technology (4). Kirigami can make a sheet of paper stretchable, like a spring, just by adding parallel cuts, dividing it into an array of thin strips with short cross connections. When the paper is pulled perpendicular to the cuts, they open up and allow the sheet to stretch, while the strips buckle into a tilted wavy arrangement. At longer extensions, the result looks more like a fishnet than a sheet of paper. Paul McEuen, Melina Blees, and colleagues at Cornell University built a version of this springy structure out of graphene, the single-atom-thick sheets of carbon that nanotechnologists are studying for a plethora of applications (5). McEuen’s group also measured the bending stiffness of micrometer-sized graphene sheets and obtained values that show graphene is as suitable for kirigami as standard paper.

Creative Collaboration

Shlian first began interacting with scientists and engineers at Michigan in 2006, after finishing up his master of fine arts at the Cranbrook Academy of Art in Bloomfield, Michigan. “My work was leaning more toward design,” he says, “and people were seeing scientific principles and architecture in the work.” Hoping for collaborations, he sent a letter and DVD of his work to about 50 University of Michigan faculty. One response led to a meeting with Max Shtein, an associate professor of Materials Science and Engineering, and before long they were coteaching an undergraduate course on problem-solving and visualization of science to a mixture of art, engineering, and architecture students. Shlian became the artist-in-residence in the materials science department and a lecturer in the School of Art and Design.

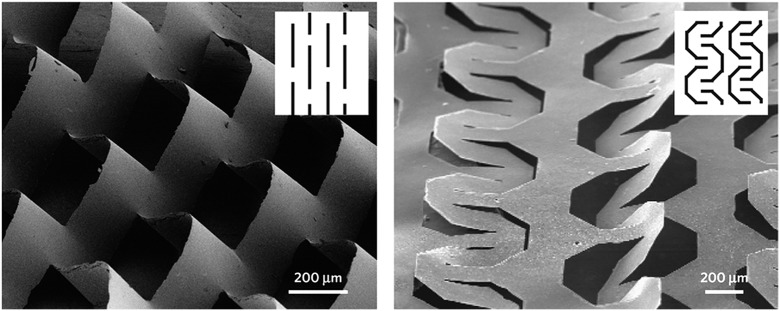

Five years later they saw another collaboration opportunity when the National Science Foundation solicited proposals on origami design for engineering, part of the agency’s Emerging Frontiers in Research and Innovation program. Shtein is principal investigator on the four-year grant; coprincipal investigators include University of Michigan materials scientists Sharon Glotzer and Nicholas Kotov, whose focus has included kirigami elastic nanocomposites (1). The collaboration has led to work on an innovative mechanism for helping solar cells track the sun (2), using a macroscopic version of the same pattern of cuts as in McEuen’s tiny stretchable graphene. Shtein first envisaged the tracking application when he saw Shlian demonstrate twisting turning paper strips in this kirigami pattern.

Nanocomposite materials, here made of graphene oxide and polyvinyl alcohol, are cut following kirigami techniques to allow for elasticity and expand functionality. The Insets show the corresponding kirigami cuts. Adaped from ref. 1, with permission from Macmillan Publishers Ltd: Nature Materials, copyright (2015).

To construct the kirigami tracking system, Shtein’s team bonded photovoltaic cells made of thin, flexible gallium arsenide crystals to a polymer sheet and then cut the kirigami pattern. The resulting strips can be adjusted to an optimum angle to maximize sun exposure by stretching the overall sheet while keeping it within a relatively flat glass enclosure, avoiding the need to tilt the entire panel. However, the system is far from ready for commercialization. The current design, assuming daily cycles of movement, has only been demonstrated to last for about a year. Moreover, the demonstrated models are small; the mechanical performance of larger sheets requires further study.

The art hasn’t only influenced the science; the science has influenced Shlian’s artwork as well. One of his projects entailed working with University of Michigan life sciences professor Daniel Klionsky to make paper models that help illustrate processes related to double-layer membranes in cellular structures called autophagosomes. With a series of cuts and folds to a sheet of paper, Shlian created a 3D form from the 2D surface. “That’s something I’ve worked with for years,” Shlian says, “but looking at it from a scientific standpoint changes some of the parameters. Certain things have to fold only to certain points, or maybe they have to rotate a certain way, and those are interesting limitations to push against artistically.”

Shlian’s interdisciplinary forays have helped him appreciate scientists’ activities and motivations. In school, he thought science was rote and by the book. “You find it’s not really like that with this cutting edge work,” he says. “Scientists are just as curious as artists are; they’re just as excitable as we are about new things.”

References

- 1.Shyu TC, et al. A kirigami approach to engineering elasticity in nanocomposites through patterned defects. Nat Mater. 2015;14(8):785–789. doi: 10.1038/nmat4327. [DOI] [PubMed] [Google Scholar]

- 2.Lamoureux A, Lee K, Shlian M, Forrest SR, Shtein M. Dynamic kirigami structures for integrated solar tracking. Nat Commun. 2015;6:8092. doi: 10.1038/ncomms9092. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Zhang Y, et al. A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes. Proc Natl Acad Sci USA. 2015;112(38):11757–11764. doi: 10.1073/pnas.1515602112. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Song Z, et al. Kirigami-based stretchable lithium-ion batteries. Sci Rep. 2015;5:10988. doi: 10.1038/srep10988. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Blees MK, et al. Graphene kirigami. Nature. 2015;524(7564):204–207. doi: 10.1038/nature14588. [DOI] [PubMed] [Google Scholar]