Abstract

This study evaluated the effects of adding glasswort hydrate containing non-meat ingredient (GM, carboxy methyl cellulose; GC, carrageenan; GI, isolated soy protein; GS, sodium caseinate) on the quality characteristics of reduced-salt, reduced-fat frankfurters. The pH and color evaluation showed significant differences, depending on the type of glasswort hydrate added (p<0.05). In the raw batters and cooked frankfurters, the addition of glasswort hydrate decreased the redness and increased the yellowness in comparison with frankfurters without glasswort hydrate. The reduction in salt and fat content significantly increased cooking loss and decreased hardness, tenderness and juiciness (p<0.05). Glasswort hydrate containing non-meat ingredient improved cooking loss, water holding capacity, emulsion stability, hardness, and viscosity of reduced-salt, reduced-fat frankfurters. The GM treatment had the highest myofibiliar protein solubility among all treatments, which was associated with emulsion stability and viscosity. The GC treatment had higher values for all texture parameters than the control. In the sensory evaluation, the addition of glasswort hydrate with non-meat ingredient improved tenderness and juiciness of reduced-salt, reduced-fat frankfurters. GM, GC, and GI treatments improved not only the physicochemical properties but also the sensory characteristics of reduced-salt, reduced-fat frankfurters. The results indicated that the use of glasswort hydrate containing non-meat ingredient was improved the quality characteristics of reduced-salt, reduced-fat frankfurters.

Keywords: glasswort, non-meat ingredient, reduced-salt, reduced-fat, frankfurter

Introduction

Recently, consumer interest in health has been increasing, thus, reduction in salt and fat is an important issue in the food industry. Excessive sodium intake from salt contained in processed foods is the primary cause for the rising of blood pressure and cardiovascular disease (Chobanian and Hill, 2000). In addition, high fat diets are related to several diseases, such as obesity, hypertension, cerebral apoplexy, myocardial infarction, diabetics, and coronary heart diseases (Vural and Javidipour, 2002). Consumers may evade meat products because they are generally recognized as having high content of salt and fat.

Salt and fat are consistently used in the manufacture of meat products despite health problems, since they have various functions in the texture and sensory properties of meat products. Commonly, salt solubilizes myofibrillar proteins (salt soluble proteins) which associate into a gel when heated (Tobin et al., 2012), also positively influences the texture, flavor and shelf life of the final products (Moon et al., 2008). In meat products, fat plays important roles in product quality by stabilizing meat emulsions, reducing cooking loss, and providing juiciness and hardness (Hughes et al., 1997; Pietrasik and Duda, 2000). Hence the food industry is faced with the problems of needing to find for solutions the resulting negative influences on product quality. Several strategies have been proposed to improve the quality properties of reduced-salt, reduced-fat meat products, and most of them consist of the replacement of salt and/or fat with natural sources such as dietary fiber, and non-meat protein (soybean protein, egg protein, etc.). In this study, seaweed, including natural salt component and dietary fiber, along with already known non-meat ingredients were used for the substitution of salt and fat.

Glasswort (Salicornia herbacea L.) is a halophyte that grows on the Korean seashore and foreshore. Glasswort includes 73.31-74.11% total dietary fiber and 3.40-20.19% NaCl (Han, 2004). In addition, glasswort was found to contain several bioactive compounds contributing to beneficial impacts on human health, and showed antimicrobial, anticancer, and antioxidant activities (Kim and Lee, 2009). Previously, the effects of glasswort on the quality characteristics of various products such as yogurt (Cho et al., 2008), soybean dasik (Kim and Hong, 2011), and tofu (Kim et al., 2010) were examined. In meat products, Lim et al. (2013) indicated that addition of glasswort to jerky inhibited the growth of microorganisms and lipid oxidation of jerky. In addition, Kim et al. (2014a) reported that the addition of glasswort improved the texture properties in reduced-salt frankfurters, suggesting the improvement mainly resulted from dietary fiber and salt present in glasswort. Kim et al. (2014b) also indicated that the color characteristics of cooked sausages were greatly affected by the addition of glasswort. Thus, there are limitations for the practical use of glasswort alone as both a salt and fat replacer.

Carboxymethyl cellulose, carrageenan, isolated soy protein, and sodium caseinate have been extensively used in the production of low-salt and/or low-fat meat product. Also, these ingredients successfully improved the functional properties such as water holding capacity, gel strength, and emulsion stability (Ahmad et al., 2010; Defreitas et al., 1997; Youssef et al., 2011). Thus, it is expected that the combination of glasswort and non-meat ingredients would improve the quality characteristics of reduced-salt, reduced-fat meat products.

Therefore, the aim of this study was to investigate the effect of glasswort hydrate containing non-meat ingredient (carboxymethyl cellulose, carrageenan, isolated soy protein, and sodium caseinate) on the physicochemical, textural, and sensory characteristics of reduced-salt, reduced-fat frankfurters.

Materials and Methods

Glasswort hydrates preparation and processing

In this study, glasswort hydrates were used as a simultaneous replacement of salt and fat. Freeze-dried glasswort powder was purchased from a local market. Glasswort powder (4.2% salt content) was washed to reduce salt content in glasswort powder. For washing, glasswort powder and distilled water (20 volumes) were stirred with a magnetic bar for 24 h at room temperature, and then centrifuged at 6,000 g for 15 min. After centrifugation, the supernatant (2.13% salt content) was removed and the residue (1.3% salt content) was taken. The washed glasswort powder was mixed with ice and each non-meat ingredient by using a silent cutter (Nr-963009, Scharfen, Germany). Glasswort hydrate ratio was as follows; non-meat ingredient (carboxymethyl cellulose, carrageenan, isolated soy protein, sodium caseinate):washed glasswort:ice=2:2:6. In preliminary study, when glasswort hydrate mixed difference ratio (non-meat ingredient:washed glasswort:ice=1:1:8), a lot of water and fat separation occurred in complete products. Glasswort hydrates were then individually placed in polyethylene bags and vacuum-packaged using a vacuum packaging system (FJ-500XL, Fujee Tech, Korea) and stored at 4℃ until required for product manufacture.

Frankfurters preparation and processing

Fresh pork ham (M. biceps femoris, M. semitendinosus, M. semimembranosus) and pork back fat (moisture 12.61%, fat 85.64%) were purchased from a local processor at 48 h postmortem. All subcutaneous and intramuscular fat and visible connective tissue were removed from fresh ham muscle. Lean meat and back fat were ground though 8 mm plate using a meat grinder (PM-70, Mainca, Spain), separately. The ground tissue was then placed in polyethylene bags, vacuum-packaged using a vacuum packaging system and stored at 0℃ until required for product manufacture. Suitable amounts of the muscle and fat were tempered at 4℃ for 24 h prior to frankfurter preparation.

Formations of reduced-salt, reduced-fat frankfurters are given in Table 1. The control formulation was prepared with 1.5% NaCl and 20% back fat. The reduced-salt, reduced-fat treatment (RSF) was made with 1.0% NaCl and 10% back fat (replacement of back fat with only ice). The glasswort hydrate treatments were replaced with 10% glasswort hydrate containing carboxymethyl cellulose (GM), carrageenan (GC), isolated soy protein (GI), sodium caseinate (GS), respectively. For each batch of frankfurters, ground meat, ground fat, ice, and other ingredients were emulsified by using a silent cutter, and the final temperature was below 10℃. After emulsification, meat batters were stuffed into collagen casings (#240, NIPPI Inc., Japan; approximate diameter of 25 mm) using a stuffer (Stuffer IS-8, Italy). The meat batters were then heated at 75±2℃ for 30 min in a water bath (Model 10-101, Dae Han Co., Korea) until the core temperature of 75℃. The cooked frankfurters were then cooled and used to analysis physicochemical, textural, and sensory properties.

Table 1. Formulations of reduced-salt, reduced-fat frankfurters with glasswort hydrate.

| Ingredients (units: %) | Treatments1) |

|||||

|---|---|---|---|---|---|---|

| Control | RSF | GM | GC | GI | GS | |

| Pork meat | 60 | 60 | 60 | 60 | 60 | 60 |

| Ice | 20 | 30 | 20 | 20 | 20 | 20 |

| Back fat | 20 | 10 | 10 | 10 | 10 | 10 |

| Glasswort hydrate | 10 | 10 | 10 | 10 | ||

| Total | 100 | 100 | 100 | 100 | 100 | 100 |

| Sodium chloride (NaCl) | 1.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Sodium nitrite (NaNO2) | 0.012 | 0.012 | 0.012 | 0.012 | 0.012 | 0.012 |

| STPP2) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Ascorbic acid | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Galric powder | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Onion powder | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Seasening | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate).

2)STPP: sodium tri-polyphosphate.

Proximate composition

Proximate composition of the frankfurters was determined using AOAC (1995). Moisture content was determined by weight loss after 12 h of drying at 105℃ in an oven (SW-90D, Sang Woo Scientific Co., Korea). Fat content was determined by a Soxhlet solvent extraction system (Soxtec Avanti 2050 Auto System, Foss Tecator AB, Sweden) and protein was determined by an automatic Kjeldahl nitrogen analyzer (Kjeltec2300Analyzer Unit, Foss Tecator AB, Sweden). Ash was determined according to AOAC method 923.03.

Salt content

The salt content of frankfurters was determined by homoginized 5 g sample with 20 mL distilled water for 60 s in a homogenizer (Ultra-Turrax T25, Janke and Kunkel, Germany) at 8,000 rpm speed. Then determined with a salimeter (TM-30D, Takemura Electric Works Ltd., Japan).

pH measurement

The pH values of raw batters and cooked frankfurters were measured in a homogenate prepared with 5 g of sample and 20 mL distilled water, using a pH meter (Model 340, Mettler-Toledo GmbH, Switzerland). All determinations were performed in triplicate.

Color measurement

The color of raw batters and cooked frankfurters were measured by the CIE LAB system using a colorimeter (Minolta Chroma meter CR-210, Japan; illuminate C, calibrated with white plate, L*=+97.83, a*=−0.43, b*=+1.98). All determinations were performed in triplicate, and ten measurements were obtained for each replicate. CIE L* (lightness), CIE a* (redness), and CIE b* (yellowness) values were recorded.

Water holding capacity (WHC)

The water holding capacity (WHC) was measured according to the procedure of Grau and Hamm (1953) with suitable modification. Briefly, the sample (300 mg each) was placed in a filter-press device and compressed for 3 min. The outline area of the expressible juice and the meat film was traced, and the two areas were determined using a compensating polar planimeter (Type KP-21, Japan). WHC was calculated from duplicate samples as a ratio of the meat film area to the total area; hence, a larger value suggests a higher WHC.

WHC (%) = (meat batter area / total area) × 100

Cooking loss

Cooking loss was determined by calculating the weight differences before and after cooking as follows;

Cooking loss (%) = [(weight of raw batter (g) − weight of cooked frankfurter (g)) / weight of raw batter (g)] × 100

Emulsion stability

The meat batters were analyzed for emulsion stability using the method of Blouka and Honikel (1992) with suitable modifications. At the middle of a 15 mesh sieve, pre-weighed graduated glass tubes were filled with batter. The glass tubes were closed and heated for 30 min in a boiling water bath to a core temperature of 75±1℃. After cooling to approximately 4±1℃, to facilitate fat and water layer separation, the fat and water release in the bottom of each tube were measured (Choi et al., 2007).

Water released (%) = [the water layer (mL) / weight of raw meat batter (g)] × 100

Fat released (%) = [the fat layer (mL) / weight of raw meat batter (g)] × 100

Protein solubility

Protein solubility was measured according to the procedure of Joo et al. (1999) with suitable modification. Sarcoplasmic protein solubility was determined by dissolving 2 g of raw meat emulsion in 20 mL of ice-cold 25 mM potassium phosphate buffer (pH 7.2). The samples and buffer were homogenized on ice with a homogenizer (Model AM-7, Nihonseiki Kaisha Ltd., Japan), and were left to stand on a shaker at 4℃ overnight. The mixtures were centrifuged at 6,000 g for 15 min and the protein concentrations of the supernatants determined using the Biuret method (Gornall et al., 1949). Total protein solubility was determined by homogenizing 2 g of meat emulsion in 20 mL of ice-cold 1.1 mol/L potassium iodide in 100 mol/L phosphate buffer (pH 7.2). The procedures for homogenization, shaking, centrifugation, and protein determination were described as above. Myofibrillar protein solubility was obtained by calculating the difference between total and sarcoplasmic protein solubility.

Texture profile analysis (TPA)

Texture measurements in the form of texture profile analysis were performed at room temperature with a texture analyzer (TA-XT2i, Stable Micro Systems, England). Frankfurter samples were taken from the central portion of each frankfurter. Prior to analysis, samples were allowed to equilibrate to room temperature (20℃, 3 h) (Kim et al., 2014a). The conditions of texture analysis were as follows: pre-test speed 2.0 mm/s, post-test speed 5.0 mm/s, maximum load 2 kg, head speed 2.0 mm/s, distance 8.0 mm, force 5 g. The calculation of TPA values was obtained by graphing a curve using force and time plots. Values for hardness (N), springiness, cohesiveness, gumminess (N), and chewiness (N) were determined as described (Bourne, 1978).

Apparent viscosity

The meat batter viscosity was measured in triplicate using a rotational viscometer (HAKKE Viscotester® 500, Thermo Elctron Corporation, Germany) set at 10 rpm. The standard cylinder sensor (SV-2) was positioned in a 25 mL metal cup filled with batter and allowed to rotate under a constant share rate at s−1 for 30 s before each reading was taken. Apparent viscosity values in centipoises were obtained. The temperature of each sample at the time (18±1℃) of viscosity testing was also recorded (Choi et al., 2011; Shand, 2000). All determinations were performed in triplicate, and six measurements were obtained for each replicate.

Sensory evaluation

Each frankfurter was evaluated for color, appearance, flavor, tenderness, juiciness, salty taste and overall acceptability. The panel consisted of 10 members from the department of food sciences and biotechnology of animal resources at Konkuk University in Korea. Each member was distributed to the age range of 25 between 30, even up the proportion of experienced men and women. Frankfurter were cooked a center temperature of 75℃ and cooled to room temperature at 21℃, then cut into quarters and served to the panelists in random order. Each sample cut into 1 cm length, were served to the panelists in random order. Sensory evaluations were performed by the panelists under fluorescent lighting. Panelists were instructed to cleanse their palates between samples using water. The color (1=extremely undesirable, 10=extremely desirable), appearance (1=extremely undesirable, 10=extremely desirable), flavor (1=extremely undesirable, 10= extremely desirable), tenderness (1=extremely tough, 10= extremely tender), juiciness (1=extremely dry, 10=extremely juicy), salty taste (1=much too weak, 10=much to intense), and overall acceptability (1=extremely undesirable, 10=extremely desirable) of the cooked samples were evaluated using a 10 point descriptive scale.

Statistical analysis

All tests were done at least three times for each experimental condition and mean values were reported. The statistical analysis of all data was performed by SPSS Ver. 18.0 (SPSS Inc., USA). The one-way ANOVA (one-way analysis of variance) and Duncan’s multiple range comparison were used to find the level of significant differences (p<0.05).

Results and Discussion

Proximate composition and physicochemical properties

Proximate composition and salt content of reduced-salt, reduced-fat frankfurters are given in Table 2. Reduced-salt, reduced-fat frankfurters with glasswort hydrate had higher moisture content than control (p<0.05). Dietary fiber in glasswort and non-meat ingredients might be associated with increased moisture content due to an improvement of water retention within the meat emulsion system. Protein content of GI and GS treatments were higher than other treatments (p<0.05), because isolated soy protein and sodium caseinate were protein based ingredients (Jiménez-Colmenero et al., 2005; Nishinari et al., 2014). Ash content of reduced-salt, reduced-fat frankfurters with glasswort hydrate was higher than RSF treatment (p<0.05) due to minerals in glasswort. Commonly, as the mineral content increases, ash content increases. As expected, control presented the highest fat and salt content among all treatments (p<0.05). Salt content of reduced-salt, reduced fat frankfurters with glasswort hydrate ranged from 1.4% to 1.21%, and there was no significant difference in compared to RSF treatment (p>0.05).

Table 2. Proximate composition (g/100 g) and salt content (%) of reduced-salt, reduced-fat frankfurters with glasswort hydrate.

| Parameters | Control1) | RSF | GM | GC | GI | GS |

|---|---|---|---|---|---|---|

| Moisture | 61.97±0.63b | 68.34±0.2.58a | 68.57±1.07a | 68.55±1.46a | 68.31±0.23a | 68.76±0.72a |

| Protein | 14.71±0.85bc | 14.08±0.18c | 14.34±1.45c | 14.72±0.93bc | 16.29±1.07ab | 16.83±1.09a |

| Fat | 20.38±1.88a | 14.21±0.62b | 12.15±1.25b | 12.73±2.23b | 12.92±2.01b | 12.88±1.94b |

| Ash | 2.36±0.04b | 1.89±0.11d | 2.04±0.05c | 2.86±0.12a | 2.03±0.07c | 2.10±0.11c |

| Salt content | 1.73±0.08a | 1.09±0.01b | 1.17±0.04b | 1.21±0.01b | 1.20±0.08b | 1.14±0.08b |

All values are mean±standard deviation of three replicates.

a-dMeans within a row with different letters are significantly different (p<0.05).

1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate).

The pH, lightness (L*-value), redness (a*-value), and yellowness (b*-value) values of raw batters and cooked frankfurters are given Table 3. The pH of raw meat batters ranged from 5.97 to 6.02, and that of cooked frankfurters ranged from 6.08 to 6.15. Except for the GM treatment, the pH values of the raw meat batters and cooked frankfurters prepared with glasswort hydrate were higher than those of the control and RSF treatments (p<0.05). Kim et al. (2014a) noted that the pH value of reduced sodium frankfurters with glasswort powder were similar to the control. This result might be affected by non-meat ingredients added. In previous studies, the addition of non-meat ingredients (carrageenan, isolated soy protein, and sodium caseinate) increased pH of meat products (Bloukas et al., 1996; Chin et al., 2000; Kilic, 2003).

Table 3. pH and color parameters of reduced-salt, reduced-fat frankfurters with glasswort hydrate.

| Parameters | Control1) | RSF | GM | GC | GI | GS | |

|---|---|---|---|---|---|---|---|

| Raw batters | pH | 5.98±0.01b | 5.97±0.03b | 5.98±0.01b | 6.02±0.01a | 6.02±0.01a | 6.01±0.01a |

| L*-value | 67.20±0.84a | 55.61±1.30e | 63.38±0.71b | 62.54±0.90b | 61.19±1.09c | 59.33±1.26d | |

| a*-value | 12.35±0.35a | 11.69±0.50b | 8.82±0.27d | 9.24±0.42c | 9.04±0.24cd | 9.07±0.20cd | |

| b*-value | 18.09±0.69b | 14.01±0.51c | 18.45±0.39b | 20.53±0.54a | 18.33±0.44b | 18.29±0.37b | |

| Cooked frankfurters | pH | 6.09±0.01c | 6.08±0.01c | 6.10±0.01b | 6.15±0.01a | 6.15±0.01a | 6.15±0.01a |

| L*-value | 71.32±0.44a | 69.78±0.45bc | 70.98±0.49a | 69.00±0.75d | 69.84±0.27b | 69.37±0.42c | |

| a*-value | 10.21±0.20b | 10.79±0.33a | 6.87±0.16d | 7.27±0.14c | 6.90±0.16d | 7.24±0.13c | |

| b*-value | 11.03±0.21d | 10.77±0.36e | 12.76±0.28c | 14.38±0.25a | 12.81±0.26c | 13.11±0.25b |

All values are mean±standard deviation of three replicates.

a-eMeans within a row with different letters are significantly different (p<0.05).

1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate).

The addition of glasswort hydrate affected the color attributes (L*, a*, and b*) of reduced-salt, reduced-fat frankfurters. The lightness and redness values of reduced-salt, reduced-fat frankfurters with glasswort hydrate were significantly lower than the control and RSF treatments in both raw batters and cooked frankfurters (p<0.05), on the other hand the yellowness values presented the opposite results. Similar trends in the color values were observed in studies by Kim et al. (2014b). They reported that the addition of glasswort powder in reduced-salt frankfurters decreased the yellowness value, and increased the lightness and redness values. Also, Cofrades et al. (2008) found similar results when added edible seaweeds. RSF treatment had lower lightness and yellowness values compared to control (p<0.05), due to the salt and fat content. In previous studies, the color attributes were affected depending on salt and fat content (Carballo et al., 1996; Fernández-López et al., 2004).

Water holding capacity (WHC), cooking loss, and emulsion stability

The WHC, cooking loss, and emulsion stability of reduced-salt, reduced-fat frankfurters are given in Table 4. The WHC of the control was higher than that of the other treatments (p<0.05). However, glasswort hydrate improved the WHC of reduced-salt, reduced-fat frankfurters in comparison with RSF treatment. According to Desmond (2006), a wide variety of ingredients such as functional proteins, fibers, hydrocolloids and starches enhance the binding of meat pieces in restructured or reformed meat products, and increase the WHC of the finished products. Several studies, the non-meat ingredients when used this study improved the WHC of low-salt/fat products (Bloukas et al., 1996; Jiménez-Colmenero et al., 2010; Zayas, 1985).

Table 4. Effects of glasswort hydrate on water holding capacity, cooking loss, and emulsion stability of reduced-salt, reduced-fat frankfurters.

| Parameters | Control1) | RSF | GM | GC | GI | GS |

|---|---|---|---|---|---|---|

| WHC (%) | 96.61±0.58a | 82.96±2.21c | 94.81±1.76b | 94.71±2.09b | 95.99±1.17ab | 95.71±1.03ab |

| Cooking loss (%) | 5.89±0.18d | 8.30±0.88a | 7.00±1.14b | 6.24±0.14cd | 6.66±0.17bc | 6.52±0.29bcd |

| Emulsion stability | ||||||

| Total released (%) | 4.01±1.04d | 21.01±0.33a | 5.82±1.16cd | 5.65±1.63cd | 8.19±2.00bc | 9.33±0.41b |

| Water released (%) | 3.64±1.04d | 20.65±0.33a | 5.43±1.15cd | 5.34±1.56cd | 7.80±2.01bc | 8.94±0.41b |

| Fat released (%) | 0.36±0.01ab | 0.36±0.01ab | 0.39±0.01a | 0.31±0.07b | 0.39±0.01a | 0.39±0.01a |

All values are mean±standard deviation of three replicates.

a-dMeans within a row with different letters are significantly different (p<0.05).

1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate).

In RSF treatment, a significant increase of cooking loss was observed in comparison with control (p<0.05). Generally, the reduction of salt and fat affected cooking loss, due to reduced water binding and lower concentration of the protein which forms the gel/emulsion matrix (Jiménerz-Comenero et al., 1996). Reduced-salt, reduced-fat frankfurters with glasswort hydrate presented a decrease of cooking loss in comparison with RSF treatment (p<0.05). Kim et al. (2014a) reported that increase in the level of glasswort added to reduced-salt frankfurter led to the improvement of cooking yield. They suggested that such result was due to improvement of the ionic strength and water binding capacity by the salt and dietary fiber of glasswort. In addition, carrageenans, isolated soy proteins, and sodium caseinates are also known to increase the yield in meat products (Bloukas et al., 1996; Kassem and Emara, 2010; Kezban and Kolsarici, 2003; Youssef et al., 2011).

For the emulsion stability, there was no significant difference in fat released between the control and other treatments (p>0.05). However, there was a significant difference in the water released (p<0.05). The control had lower water released than the other treatments (p<0.05), on the other hand, RSF treatment had the highest water released (p<0.05). Although reduced-salt, reduced-fat frankfurters with glasswort hydrate had higher water released than the control, they were improved in comparison to RSF treatment. The results might be affected dietary fiber in glasswort and non-meat ingredients. Cofrades et al. (2008) reported that low-salt (0.5% salt) emulsion meat systems with edible seaweeds had greater emulsion stability than the control (2% salt) despite having less added salt. They suggested that two of the chemical component of seaweeds, dietary fiber and protein, may influence the emulsion stability of meat systems. Previous studies have reported that the addition of various types of dietary fiber to meat products, such as wheat (Choi et al., 2007), hazelnut pellicle (Turhan et al., 2005), and rice bran (Choi et al., 2011) help to improve the emulsion stability and rheological properties. Also, there was study about the effects of non-meat ingredients on the emulsion stability of meat products (Schuh et al., 2013). The combination of glasswort and non-meat ingredients affected to the processing yield, due to improvement of the water binding ability.

Protein solubility

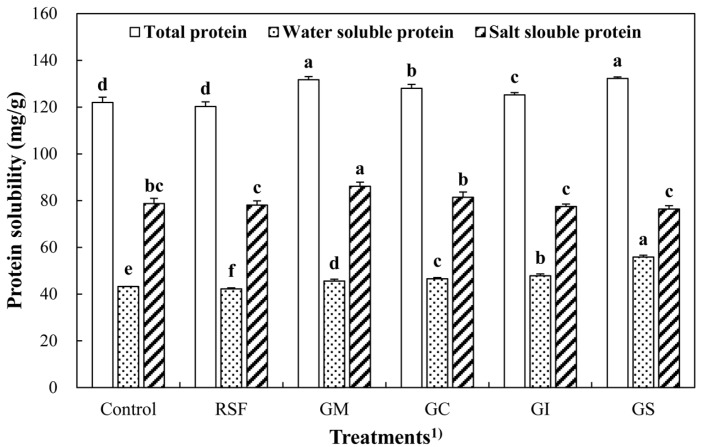

The solubility of total, sarcoplasmic, and myofibrillar proteins in reduced-salt, reduced -fat frankfurters are presented in Fig. 1. Protein solubility is an important factor related to emulsion formation. In particular, myofbrillar proteins (salt soluble proteins) are the most functional proteins in processed meat product, and are comprised primarily of myosin and actin (Smith, 1988). Myosin is responsible for most of the gelation and water holding properties of processed meat, whereas the other myofibillar proteins influence the behavior of myosin (Smith, 1988; Wang and Smith, 1994). Generally, the solubility of myofibrillar proteins is affected by salt content (Swift and Sulzbacher, 1963). The myofibrillar protein solubility of control was higher than that of RSF treatment (p<0.05). Total protein solubility of frankfurters with glasswort hydrate was higher than the control and RSF treatments (p<0.05). According to Kim et al. (2014b), the addition of glasswort to reduced-salt meat batters increased total and myofibilliar protein solubility, which was suggested to be affected by the pH, ionic strength, type of salt, and mineral concentrations. In myofbrillar proteins solubility, GM and GC treatments were higher than control (p<0.05). In the study of Choi et al. (2011), the increase of rice bran fiber contributed to improvement of protein solubility. In contrast, Kim et al. (2013) indicated that the increase of brewer’s spent grain dietary fiber contributed to a decline of protein solubility. Protein solubility was affected by the addition of ingredients. Thus, the results of this study might be attributed to the characteristics of each non-meat ingredient and glasswort such as pH, solubility, and dispersibility.

Fig. 1. Effects of glasswort hydrate on protein solubility of reduced-salt, reduced-fat frankfurters. 1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate). a-fMeans in the treatments with different letters are significantly different (p<0.05).

Texture profile analysis (TPA)

Texture profile analysis of reduced-salt, reduced-fat frankfurters is presented in Table 5. Reduced-salt, reduced-fat frankfurters with glasswort hydrates improved texture properties, despite a decrease of hardness caused by the reduction of salt and fat. According to Hsu and Sun (2006), the reduction of fat caused decreased hardness, chewiness, and gumminess in meat products. GC treatment had higher values than control in all of the texture parameters. This result might be attributed to the synergy effect of glasswort and carrageenan, in that carrageenan is a soluble fiber that can form a gel network like glasswort. Similar trends were observed in the study by Jiménez-Colmenero et al. (2010). They reported that reduced/low-fat, low-salt frankfurters with konjac and seaweed had similar hardness as that of the control (21.1% fat and 2% salt). Kim et al. (2014a) reported that the addition of glasswort powder increased hardness in reduced-salt frankfurters. In addition, previous studies reported that carrageenan and isolated soy protein increased hardness in sausages (García-García and Totosaus, 2008; Matulis et al., 1995). There was no significant differences in springiness of the frankfurters (p>0.05).

Table 5. Effects of glasswort hydrate on texture profile analysis (TPA) of reduced-salt, reduced-fat frankfurters.

| Parameters | Control1) | RSF | GM | GC | GI | GS |

|---|---|---|---|---|---|---|

| Hardness (N) | 4.23±0.21b | 3.10±0.11d | 3.82±0.17c | 5.36±0.40a | 4.19±0.13b | 3.75±0.10c |

| Springiness | 0.86±0.01 | 0.87±0.03 | 0.88±0.01 | 0.87±0.04 | 0.88±0.01 | 0.87±0.02 |

| Cohesiveness | 0.41±0.01c | 0.44±0.02ab | 0.43±0.01bc | 0.46±0.03a | 0.45±0.02ab | 0.45±0.02ab |

| Gumminess (N) | 1.74±0.08c | 1.36±0.08d | 1.65±0.07c | 2.47±0.22a | 1.89±0.05b | 1.67±0.08c |

| Chewiness (N) | 1.50±0.06c | 1.19±0.07d | 1.45±0.07c | 2.14±0.29a | 1.67±0.06b | 1.46±0.09c |

All values are mean±standard deviation of three replicates.

a-dMeans within a row with different letters are significantly different (p<0.05).

1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate).

Apparent viscosity

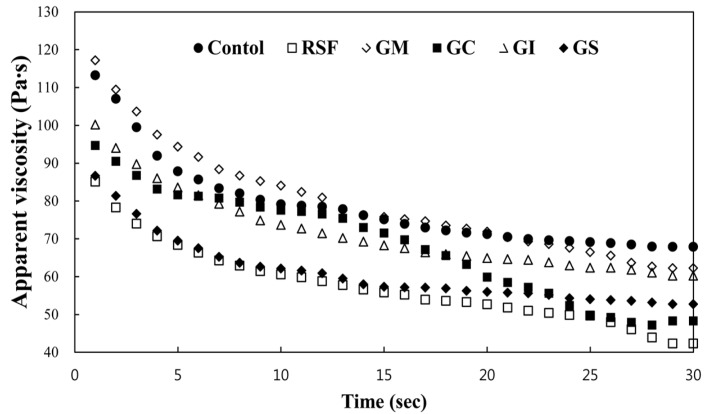

The addition of glasswort hydrate obviously affected the apparent viscosity of reduced-salt, reduced-fat meat batters (Fig. 2). All samples showed a decreased apparent viscosity of meat batter with increase in the rotation time. The apparent viscosity of RSF treatment was lower than the other treatments. Except for GS treatment, the apparent viscosity of other treatments with glasswort hydrate was higher than RSF treatment. In GM treatment, which showed the highest myofibrillar protein solubility, the highest maximum apparent viscosity was observed. Farouk et al. (2002) reported that protein solubility can influence textural and rheological properties. According to Shand (2000) and Turgut et al. (1981) showed that there is a high correlation between emulsion viscosity and emulsion stability in meat emulsion systems. In this study, emulsion stability of GI and GS treatments was lower than the other glasswort treatments, and similar trends were observed for viscosity.

Fig. 2. Effects of glasswort hydrate on apparent viscosity of reduced-salt, reduced-fat frankfurters. 1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate).

Sensory evaluation

The sensory traits of reduced-salt, reduced-fat frankfurters with glasswort hydrate are shown in Table 6. The mean values of color, appearance, flavor, tenderness, juiciness and salty taste were evaluated to determine the overall acceptability. In color scores, all frankfurters with glasswort hydrate had lower scores than RSF treatment (p<0.05). There was no significant difference in flavor, appearance, and salty taste scores (p>0.05). These results were due to unfamiliarity with the green color and unique flavor of glasswort. Although the tenderness and juiciness scores of frankfurters with glasswort hydrates were improved in compared to RSF treatment (p<0.05). These results were associated with the improvement of cooking loss, WHC, emulsion stability, and texture properties by the addition of glasswort hydrate in reduced-salt, reduced-fat frankfurters. In overall acceptability scores, frankfurters with glasswort hydrate and RSF treatment had no significant difference (p>0.05), but GM, GC, and GI treatments were higher than RSF treatment. Tobin et al. (2012) found that lower salt levels resulted in darker/deeper color than higher salt levels. They also found high positive correlation between juiciness and higher levels of salt and fat. Jimenez-Colmenero et al. (2010) reported that frankfurters with added seaweed gained lower scores than control in overall acceptability, otherwise received similar scores in texture acceptability as the control. On sensory evaluation, the addition of glasswort hydrate to reduced-salt, reduced-fat frankfurters improved texture properties such as tenderness and juiciness, but it is necessary to promote understanding about the color and flavor characteristics of glasswort and non-meat ingredients.

Table 6. Effects of glasswort hydrate on sensory properties of reduced-salt, reduced-fat frankfurters.

| Parameters | Control1) | RSF | GM | GC | GI | GS |

|---|---|---|---|---|---|---|

| Color | 8.30±0.67a | 8.20±0.63a | 7.00±0.67b | 7.20±0.42b | 7.20±0.42b | 7.20±0.42b |

| Appearance | 8.10±0.74 | 8.00±0.82 | 8.00±0.82 | 7.90±0.74 | 8.00±0.82 | 7.80±0.79 |

| Flavor | 8.13±0.64a | 7.38±0.74b | 7.25±0.46b | 7.13±0.83b | 7.13±0.64b | 7.00±0.76b |

| Tenderness | 8.10±0.74a | 6.60±0.84b | 7.60±0.84a | 7.50±0.71a | 7.50±1.08a | 7.50±0.97a |

| Juiciness | 8.20±0.79a | 6.60±0.97b | 7.50±1.08ab | 7.50±1.18ab | 7.40±0.97ab | 7.50±0.53ab |

| Salty taste | 7.20±1.48a | 5.90±1.60b | 5.30±1.25b | 5.00±0.82b | 5.50±1.08b | 5.40±0.84b |

| Overall acceptability | 8.13±0.64a | 7.25±0.71b | 7.38±0.52b | 7.38±0.92b | 7.50±0.53b | 7.13±0.64b |

All values are mean±standard deviation of three replicates.

a,bMeans within a row with different letters are significantly different (p<0.05).

1)Control, frankfurter formulated with 1.5% salt and 20% back fat; RSF, reduced salt, reduced-fat frankfurter with 1% salt and 10% back fat; GM, GC, GI and GS, reduced salt, reduced-fat frankfurter with 1% salt, 10% back fat and 10% glasswort hydrate (GM, glasswort hydrate containing carboxy methyl cellulose; GC, glasswort hydrate containing carrageenan; GI, glasswort hydrate containing isolated soy protein; GS, glasswort hydrate containing sodium caseinate).

Conclusions

The use of glasswort hydrate containing non-meat ingredient improved the cooking loss, WHC, hardness, emulsion stability, and viscosity of reduced-salt, reduced-fat frankfurters. GM, GC, and GI treatments had improvement of not only the physicochemical properties but also the sensory attributes related to the texture (tenderness and juiciness) of reduced-salt, reduced-fat frankfurters. Thus, the use of glasswort hydrate containing non-meat ingredient was improved the quality characteristics of reduced-salt, reduced-fat frankfurters.

Acknowledgments

The authors were supported by the Brain Korean 21 Plus (BK 21 PLUS) Project from Ministry of Education and Human Resources Development. This research was supported Technology Development Program (PJ009237042014) for Rural Development Administration, Republic of Korea.

References

- 1.Ahmad S., Rizawi J. A., Srivastava P. K. Effect of soy protein isolate incorporation on quality characteristics and shelf-life of buffalo meat emulsion sausage. J. Food Sci. Tech. Mys. 2010;47:290–294. doi: 10.1007/s13197-010-0045-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.AOAC. Official methods of analysis of AOAC. (16th ed.) Association of Official Analytical Chemists; Washington DC: 1995. [Google Scholar]

- 3.Bloukas I., Honikel K. O. The influence of additives on the oxidation of pork back fat and its effect on water and fat binding in finely comminuted batters. Meat Sci. 1992;32:31–43. doi: 10.1016/0309-1740(92)90015-V. [DOI] [PubMed] [Google Scholar]

- 4.Bloukas J. G., Paneras E. D., Paradima S. Effect of carrageenan on processing and quality characteristics of low-fat frankfurters. J. Muscle Food. 1996;8:63–83. [Google Scholar]

- 5.Bourne M. C. Texture profile analysis. Food Technol. 1978;32:62–66. [Google Scholar]

- 6.Carballo J., Frenández P., Barreto G., Solas M. T., Jiménez-Colmenero F. Characteristics of high- and low-fat bologna sausages as affected by final internal cooking temperature and chilling storage. J. Sci. Food Agr. 1996;72:40–48. [Google Scholar]

- 7.Chin K. B., Keeton J. T., Miller R. K., Longnecker M. T., Lamkey J. W. Evaluation of konjac blends and soy protein isolate as fat replacements in low-fat bologna. J. Food Sci. 2000;65:756–763. [Google Scholar]

- 8.Chobanian A. V., Hill M. National heart, lung, and blood institute workshop on sodium and blood pressure: A critical review of current scientific evidence. Hypertension. 2000;35:858–863. doi: 10.1161/01.hyp.35.4.858. [DOI] [PubMed] [Google Scholar]

- 9.Choi Y. S., Choi J. H., Han D. J., Kim H. Y., Lee M. A., Kim H. W., Jeong J. Y., Kim C. J. Effects of rice bran on heat-induced gel prepared with pork salt-soluble meat proteins in model system. Meat Sci. 2011;88:59–66. doi: 10.1016/j.meatsci.2010.12.003. [DOI] [PubMed] [Google Scholar]

- 10.Choi Y. S., Lee M. A., Jeong J. Y., Choi J. H., Han D. J., Kim H. Y., Lee E. S., Kim C. J. Effects of wheat fiber on the quality of meat batter. Korean J. Food Sci. An. 2007;27:22–28. [Google Scholar]

- 11.Cofrades S., López-López I., Solas M. T., Bravo L., Jiménez-Colmenero F. Influence of different types and proportions of added edible seaweeds on characteristics of low-salt gel/emulsion meat systems. Meat Sci. 2008;79:767–776. doi: 10.1016/j.meatsci.2007.11.010. [DOI] [PubMed] [Google Scholar]

- 12.Defreitas Z., Sebranek J. S., Olson D. G., Carr J. M. Carrageenan effects on salt-soluble meat protein in model systems. J. Food Sci. 1997;62:539–543. [Google Scholar]

- 13.Desmond E. Reducing salt: A challenge for the meat industry. Meat Sci. 2006;74:188–196. doi: 10.1016/j.meatsci.2006.04.014. [DOI] [PubMed] [Google Scholar]

- 14.Farouk M. M., Wieliczko K., Lim R., Turnwald S., Macdonald G. A. Cooked sausage batter cohesiveness as affected by sarcoplasmic proteins. Meat Sci. 2002;61:85–90. doi: 10.1016/s0309-1740(01)00168-1. [DOI] [PubMed] [Google Scholar]

- 15.Fernández-López J., Sayas-Barberá E., Pérez-Alvarez J. A., Aranda-Catalá V. Effects of sodium chloride, sodium tripolyphosphate and pH on color properties of pork meat. Color Res. Appl. 2004;29:67–74. [Google Scholar]

- 16.García-García a E., Totosaus A. Low-fat sodium-reduced sausages: Effect of the interaction between locust bean gum, potato starch and -carrageenan by a mixture design approach. Meat Sci. 2008;78:406–413. doi: 10.1016/j.meatsci.2007.07.003. [DOI] [PubMed] [Google Scholar]

- 17.Gornall A. G., Bardawill C. J., David M. M. Determination of serum proteins by means of the biuret reaction. J. Biol. Chem. 1949;177:751–766. [PubMed] [Google Scholar]

- 18.Grau W. R., Hamm R. Muscle as food In: Bechtel P. J., editor. Food Science and Technology. A Series of Monographs, 1985. Academic Press; New York: 1953. [Google Scholar]

- 19.Han S. Antioxidant effect of fermented salicornia herbacea L. liquid with EM (Effective Microorganism) on pork. Korean J. Food Sci. An. 2004;24:298–302. [Google Scholar]

- 20.Hsu S. Y., Sun L. Y. Comparisons on 10 non-meat protein fat substitutes for low-fat kung-wans. J. Food Eng. 2006;74:47–53. [Google Scholar]

- 21.Hughes E., Cofrades S., Troy D. J. Effects of fat level, oat fiber and carrageenan on frankfurters formulated with 5, 12 and 30% fat. Meat Sci. 1997;45:273–281. doi: 10.1016/s0309-1740(96)00109-x. [DOI] [PubMed] [Google Scholar]

- 22.Jiménez-Colmenero F., Ayo M. J., Carballo J. Physicochemical properties of low sodium frankfurter with added walnut: effect of transglutaminase combined with caseinate, KCl and dietary fibre as salt replacer. Meat Sci. 2005;69:781–788. doi: 10.1016/j.meatsci.2004.11.011. [DOI] [PubMed] [Google Scholar]

- 23.Jiménez-Colmenero F., Barreto G., Fernández P., Carballo J. Frozen storage of bologna sausage as a function of fat content and levels of added starch and egg white. Meat Sci. 1996;42:325–332. doi: 10.1016/0309-1740(94)00039-5. [DOI] [PubMed] [Google Scholar]

- 24.Jiménez-Colmenero F., Cofrades S., López-López I., Ruiz-Capillas C., Pintado T., Solas M. T. Technological and sensory characteristics of reduced/low-fat, low-salt frankfurters as affected by the addition of konjac and seaweed. Meat Sci. 2010;84:356–363. doi: 10.1016/j.meatsci.2009.09.002. [DOI] [PubMed] [Google Scholar]

- 25.Joo S. T., Kauffman R. G., Kim B. C., Park G. B. The relationship of sarcoplasmic and myofibrillar protein solubility to colour and water-holding capacity in porcine longissimus muscle. Meat Sci. 1999;52:291–297. doi: 10.1016/s0309-1740(99)00005-4. [DOI] [PubMed] [Google Scholar]

- 26.Kassem M. A. G., Emara M. M. T. Quality and acceptability of value-added beef burger. World J. Dairy Food Sci. 2010;5:14–20. [Google Scholar]

- 27.Kezban C., Kolsarici N. The effects of carrageenan and pectin on some quality characteristics of low-fat beef frankfurters. Meat Sci. 2003;64:199–206. doi: 10.1016/s0309-1740(02)00181-x. [DOI] [PubMed] [Google Scholar]

- 28.Kilic B. Effect of microbial transglutaminase and sodium caseinate on quality of chicken döner kebab. Meat Sci. 2003;63:417–421. doi: 10.1016/s0309-1740(02)00102-x. [DOI] [PubMed] [Google Scholar]

- 29.Kim H. J., Lee J. H. Physicochemical properties of Salicornia herbacea powder as influenced by drying methods. Food Eng. Prog. 2009;13:105–109. [Google Scholar]

- 30.Kim H. W., Hwang K. E., Song D. H., Lee S. Y., Choi M. S., Lim Y. B., Choi J. H., Choi Y. S., Kim H. Y., Kim C. J. Effects of dietary fiber extracts from brewer’s spent grain on quality characteristic of chicken patties cooked in convective over. Korean J. Food Sci. An. 2013;33:45–52. [Google Scholar]

- 31.Kim H. W., Hwang K. E., Song D. H., Kim Y. J., Lim Y. B., Ham Y. K., Yeo E. J., Chang S. J., Choi Y. S., Kim C. J. Effect of glasswort (Salicornia herbacea L.) on the texture of frankfurters. Meat Sci. 2014a;97:513–517. doi: 10.1016/j.meatsci.2014.03.019. [DOI] [PubMed] [Google Scholar]

- 32.Kim H. W., Hwang K. E., Song D. H., Kim Y. J., Ham Y. K., Yeo I. J., Jeong T. J., Choi Y. S., Kim C. J. Effects of red and green glasswort (Salicornia herbacea L.) on physicochemical and textural properties of reduced-salt cooked sausages. Korean J. Food Sci. An. 2014b;34:378–386. doi: 10.5851/kosfa.2014.34.3.378. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Kim M. H., Shin M. K., Hong G. J., Kim K. S., Lee K. A. Quality assessment of soybean curd supplemented with saltwort (Salicornia herbacea L.) Korean J. Food Cookery Sci. 2010;26:406–412. [Google Scholar]

- 34.Lim D. G., Choi K. S., Kim J. J., Nam K. C. Effects of Salicornia herbacea powder on quality traits of sundried hanwoo beef jerky during storage. Korean J. Food Sci. An. 2013;33:205–213. [Google Scholar]

- 35.Matulis R. J., Mckeith F. K., Sutherland J. W., Brewer M. S. Sensory characteristics of frankfurters as affected by salt, fat, soy protein, and carrageenan. J. Food Sci. 1995;60:48–54. [Google Scholar]

- 36.Moon S. S., Kim Y. T., Jin S. K., Kim I. S. Effects of sodium chloride, potassium chloride, potassium lactate and calcium ascorbate on the physic-chemical properties and sensory characteristics of sodium-reduced pork patties. Korean J. Food Sci. An. 2008;28:567–573. [Google Scholar]

- 37.Nishinari K., Fang Y., Guo S., Phillips G. O. Soy protein: A review on composition, aggregation and emulsification. Food Hydrocolloid. 2014;39:301–318. [Google Scholar]

- 38.Pietrasik Z., Duda Z. Effects of fat content and soy protein/carragenan mix on the quality characteristics of comminuted, scalded sausages. Meat Sci. 2000;56:181–188. doi: 10.1016/s0309-1740(00)00038-3. [DOI] [PubMed] [Google Scholar]

- 39.Schuh V., Allard K., Herrmann K., Gibis M., Kohlus R., Weiss J. Impact of carboxymethyl cellulose (CMC) and microcrystalline cellulose (MCC) on functional characteristics of emulsified sausages. Meat Sci. 2013;93:240–247. doi: 10.1016/j.meatsci.2012.08.025. [DOI] [PubMed] [Google Scholar]

- 40.Shand P. J. Textural, water holding, and sensory properties of low-fat pork bologna with normal or waxy starch hull-less barley. J. Food Sci. 2000;65:101–107. [Google Scholar]

- 41.Smith D. M. Meat proteins: functional properties comminuted meat products. Food Technol. 1988;42:116–121. [Google Scholar]

- 42.Swift C. E., Sulzbacher W. L. Comminuted meat emulsion: Factors affecting meat proteins as emulsion stabilizers. Food Technol. 1963;17:106. [Google Scholar]

- 43.Tobin B. D., O'Sullivan M. G., Hamill R. M., Kerry J. P. Effect of varying salt and fat levels on the sensory and physiochemical quality of frankfurters. Meat Sci. 2012;92:659–666. doi: 10.1016/j.meatsci.2012.06.017. [DOI] [PubMed] [Google Scholar]

- 44.Turgut H., Varol M., Uygun M., Er R. Studies on determining of the emulsion capacity of beef, buffalo, lamb and goat meats between different oil and fats. TUBITAK Marmara Scientific and Industrial Research Ins. Press; Gebze, Turkey: 1981. [Google Scholar]

- 45.Turhan S., Sagir I., Ustun N. S. Utilization of hazelnut pellicle in low-fat beef burgers. Meat Sci. 2005;71:312–316. doi: 10.1016/j.meatsci.2005.03.027. [DOI] [PubMed] [Google Scholar]

- 46.Vural H., Javidipour I. Replacement of beef fat in frankfurters by interesterified palm, cottonseed, and olive oils. Eur. Food Res. Technol. 2002;214:465–468. [Google Scholar]

- 47.Wang S. F., Smith D. M. Poultry muscle proteins and heat-induced gelation. Poultry Sci. Rev. 1994;5:145–167. [Google Scholar]

- 48.Youssef M. K., Barbut S., Smith A. Effects of pre-emulsifying fat/oil on meat batter stability, texture and microstructure. Int. J. Food Sci. Tech. 2011;46:1216–1224. [Google Scholar]

- 49.Zayas J. F. Structural and water binding properties of meat emulsions prepared with emulsified and unemulsified fat. J. Food Sci. 1985;50:689–692. [Google Scholar]