Abstract

Supramolecular hydrogels have the advantages of stimuli responsiveness and self-healing compared to covalently crosslinked hydrogels. However, the existing supramolecular hydrogels are usually poor in mechanical properties especially in extensibility. In addition, these supramolecular hydrogels need a long self-healing time and have low self-healing efficiency. In this manuscript, we report a novel strategy to develop highly extensible and fast self-healing supramolecular hydrogels by using pre-coordinated mussel-inspired catechol-Fe3+ complexes as dynamic crosslinkers. The hydrogel can be fabricated and cast into various shapes by one-step photo-crosslinking. Thus fabricated hydrogels can be stretched beyond 10 times their original lengths, and the high extensibility can completely recover within a very short time (less than 20 minutes) even after the hydrogels are entirely cut apart. Utilizing the dynamic nature of supramolecular hydrogels, we can realize different mechanical behaviors including strength, extensibility and recoverability by varying the loading conditions. In addition, the hydrogels respond to multiple stimuli including mechanical force, temperature and certain chemicals because of the dynamic catechol-Fe3+ bond.

INTRODUCTION

Hydrogels are extensively used as delivery vehicles for therapeutic drugs, scaffolds for tissue engineering and coatings for functional devices.1–4 Essentially, hydrogels are three-dimensional networks of hydrophilic polymers, which are usually created through the formation of covalent bonds between the polymer chains.5 Most of the covalent hydrogels are stable and exhibit robust mechanical properties due to the stability of covalent bonds. However, these hydrogels have limitations. For example, they are not able to self-heal after damage, have low responsiveness to external stimuli, and can’t be remolded after being fabricated. Compared to covalent bonds, supramolecular interactions are reversible and can respond to a variety of stimuli including pH change, temperature and external force, imparting dynamic features and self-healing capacity to such hydrogels.6–11 A wide variety of supramolecular chemistries have been used for hydrogel formation in the past decades including hydrogen bonding12, host-guest interaction13–17, electrostatic interaction7, 18 and metal-ligand coordination19–22. Compared to covalent hydrogels, a significant shortcoming that hinders the applications of current supramolecular hydrogels is their poor mechanical properties, which is primarily caused by the low stability of supramolecular interactions. One approach to build strong hydrogel network is to using multivalent interactions. Recently, hydrogels based on multiple ionic interactions between telechelic positively charged polymers and negatively charged nano-clays are reported to exhibit high elastic modulus.18 Oppositely charged triblock copolymers are also reported to form high modulus hydrogels, where the ionic blocks self-organize into nano-sized domains due to electrostatic interactions.7 Other strategies to fabricate stable and stiff supramolecular hydrogels include introducing reinforcing nanoparticles23 and combining multiple non-covalent interactions12. Even with the improved stiffness, supramolecular hydrogels still under-perform in extensibility.

In general, supramolecular hydrogels can self-heal after damage due to the reversible association of the supramolecular interactions. It remains a daunting challenge to achieve fast and efficient healing of these hydrogels.24, 25 For example, through rationally designing the polymer network, supramolecular hydrogels based on host-guest interactions can realize complete recovery of the mechanical strength.25 However, the time needed for the healing process is very long, typically tens of hours.

We hypothesized that a key factor for a highly extensible and fast self-healable hydrogel is a reversible interaction that is stable yet re-associate rapidly. Among the known reversible interactions, the mussel-inspired catechol-Fe3+ complexes possess some of the highest association constants (Ka ~ 1037–1040) and the rupture force of a single metal-catechol bond is even comparable to that of a covalent bond (0.8nN vs. 2.0nN).26 In addition, the complexes can rapidly re-associate after the rupture of the coordination bonds. Coordination between Fe3+ and catechol ligand was found to play a significant role in the self-healing property of the cuticle of mussel byssal threads.27–31 Only very recently, researchers began to incorporate the mussel-inspired chemistry in synthetic materials to utilize the re-association capacity of metal-catechol interactions.20, 21, 32 A hydrogel was synthesized by conjugating the catechol group to multi-functional polymers and crosslinking the catechol-bearing polymers with Fe3+ in a way that mimics the natural process for byssal thread assembly.20, 33, 34 This mussel-inspired hydrogel exhibits self-healing property. However, it still underperforms in extensibility and elasticity and cannot be fabricated in a large scale. The used pH-jump method involves mixing the precursor solution with an alkaline solution, and therefore results in extremely fast gelation and significant inhomogeneity in the resulting hydrogels. As the polymer network in the mixing-induced hydrogel is highly heterogeneous, the loosely cross-linked regions tend to develop into catastrophic cracks under a tensile force, and thus drastically reducing mechanical strength and extensibility of such hydrogels.

In this work, we report a novel strategy to develop stimuli-responsive supramolecular hydrogels with high extensibility and fast self-healing capacity by using photo-polymerizable, pre-coordinated catechol-Fe3+ (PCCI) complexes as the multi-functional crosslinkers and acrylamide (AAM) as the monomer. The pre-coordination of the metal-ligand complexes before the gelation is intended to maximize the dynamic bond formation efficiency, circumvent the uncontrollable metal-catechol association kinetics, and therefore minimize the heterogeneity of the resulting hydrogel. Excitingly, the photo-induced radical polymerization used in our hydrogel system gives rise to excellent homogeneity in microstructure due to the pre-formed coordination bonds, which we hypothesized to enhance the mechanical properties of the novel hydrogels. The hydrogels as prepared (containing FeCl3 content as low as 0.038 wt%) can be stretched beyond 10 times their original lengths without rupture, which surpasses many covalent hydrogels. The hydrogels also exhibit fast self-healing property: upon damage the high extensibility of the hydrogels can be completely recovered within 20 minutes by simply rejoining the broken pieces, even after the hydrogels are entirely cut apart.

EXPERIMENTAL SECTION

Materials

All the chemicals used in the experiments were purchased from Sigma-Aldrich unless stated otherwise. 40 wt% acrylamide stock solution, 1.9 wt% FeCl3 solution, 0.5M Tris buffer (pH 8) and 0.1M borate buffer (pH 10.2) were prepared and stored at 4°C in a refrigerator until use.

Synthesis of DMA Monomers and LAP Photo-initiator

DMA (dopamine methacrylamide) was synthesized according to a published method.35 10 g of sodium borate and 4 g of sodium bicarbonate were dissolved in 100 ml of DI water. After bubbled with nitrogen for 20 minutes, 5 g dopamine hydrochloride was added to the solution. Then 4.7 ml of methacrylate anhydride in 25 ml of THF was added drop wise. The reaction was carried out at room temperature overnight with nitrogen bubbling. The reaction mixture was washed with 50 ml ethyl acetate, followed by adjusting the pH to 2 with 4M HCl solution. 50 ml ethyl acetate was used to extract the product from the aqueous solution 3 times. The combined organic layers were dried under anhydrous magnesium sulfate and concentrated to about 25 ml. 250 ml hexane was slowly added to the solution under stirring and the suspension was held at 4°C in a refrigerator overnight. The precipitate was filtered and dried in vacuum for 1 day. 1H-NMR spectroscopy (400 MHz, DMSO-d6): 6.64–6.57 (m, 2H), 6.42 (d, 1H), 5.61 (s, 1H), 5.30 (s, 1H), 3.21 (m, 2H), 2.55 (t, 2H), 1.84 (s, 3H).

The photo-initiator, lithium acylphosphinate (LAP), was synthesized using the method introduced by Majima et al.36, 37 3.2 g (0.018 mol) of 2, 4, 6-trimethylbenzoyl chloride was added drop-wise to an equimolar amount of continuously stirred dimethyl phenylphosphonite (3.0 g) under nitrogen protection. After 18 h of reaction, lithium bromide (6.1 g) dissolved in 100 mL of 2-butanone was added to the reaction mixture and the mixture was then heated to 50°C. After 10 min, the mixture was cooled to ambient temperature and left for 4 hours before filtration. The filtrate was washed 3 times with 2-butanone and dried in vacuum overnight. 1H NMR spectroscopy (400 MHz, D2O): 7.57 (m, 2H), 7.42 (m, 1H), 7.33 (m, 2H), 6.74 (s, 2H), 2.09 (s, 3H), 1.88 (s, 6H).

Preparation of Hydrogels

Detailed procedure for the synthesis of dopamine methacrylate and LAP can be found in Supporting Information. Hydrogels were synthesized using a one-step photo-polymerization method in the presence of a photo-initiator. To prepare the precursor solution, 8.75 ml acrylamide stock solution (40 wt%) and 14.5 ml borate buffer (0.1M, pH10.2) were added into separate glass vials. Then 125 mg LAP photo-initiator was dissolved in the borate buffer. These solutions were then bubbled with nitrogen for 10 minutes to eliminate the dissolved oxygen. 44 mg DMA monomer, pre-dissolved in dimethyl sulfoxide (DMSO), was subsequently added into the acrylamide solution, followed by the addition of 500 μl FeCl3 solution (1.9 wt%). A dark green color immediately developed after the addition of FeCl3 solution. Then the borate buffer was poured into the green solution, changing the color to dark red. The mixed solution was again bubbled with nitrogen for 10 minutes before cross-linking. The oxygen-free solution was injected into a Petri dish (100×15 mm) and irradiated with ultraviolet light (8 mW/cm2, wave length 365 nm) for 1 hour to ensure complete gelation. For bis-complex crosslinked hydrogel, 0.5M Tris buffer (pH 8) was used instead of borate buffer.

Absorbance Spectrophotometry

The coordination between catechol and Fe3+ at pH 8 and 10 was monitored on a UV-visible light spectrophotometer (U-2910, HITACHI). The dopamine methacrylate-FeCl3 solution was prepared according to the same method as preparing hydrogel precursor solution except that no acrylamide was added. The final concentration of dopamine methacrylate was 4 mM for both conditions (pH 8 and pH 10).

Rheological Testing

The rheological tests of the hydrogels were performed on an HR-2 Discovery Hybrid rheometer (TA Instruments, United States). Parallel plate with 20 mm diameter was used for all the tests. The gap distance between the plates was 1 mm. A constant strain of 1% was applied for the frequency spectrum measurement. For measurements other than frequency spectrum, a constant 1.59 Hz was used. For the temperature stability test, the modulus during the heating process was measured with a heating rate of 10°C/min from 25°C to 80°C.

Mechanical Test

All the tensile stress-strain measurements were performed on an MTS Synergie 200 mechanical tester (MTS Systems Corporation, USA). All samples were cut into rectangular sheets (32×22×3 mm3). At least 3 specimens were tested for each sample. The loading rate of the tensile test was 100 mm/min with a gauge length of 10 mm. For self-healing test, the specimens were cut apart right in the middle and rejoined immediately with modest compression.

Remoldable Behavior of the Hydrogel

PDMS molds were fabricated by mixing the two components in a 10:1 ratio and curing at 70°C for 5 hours. Differently shaped molds were created by putting a triangle, hexagonal or flower-shaped metal pieces before the curing step. To reshape the hydrogel, a disc-shaped hydrogel was compressed into the PDMS molds with glass slides and the compression was maintained for 20 minutes.

Hydrogel dissolution in EDTA solution

Hydrogels prepared following the above procedures were cut into round discs with a diameter of 8 mm. 10 ml EDTA solutions with varying concentrations (0 mM, 10 mM, and 100 mM) were added into separate vials. The hydrogel discs were placed in the vials with tweezers and then the vials were sealed. The experiments were performed under room temperature.

RESULTS

Hydrogel formation via pre-coordinated metal-ligand interactions

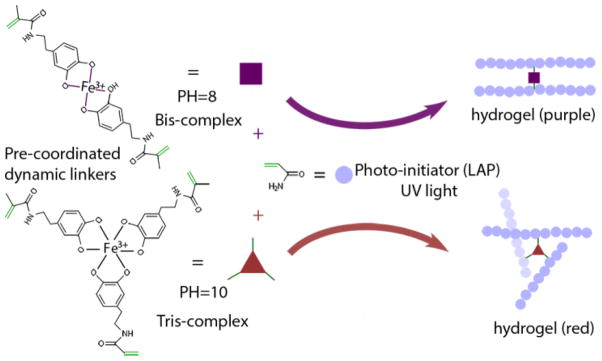

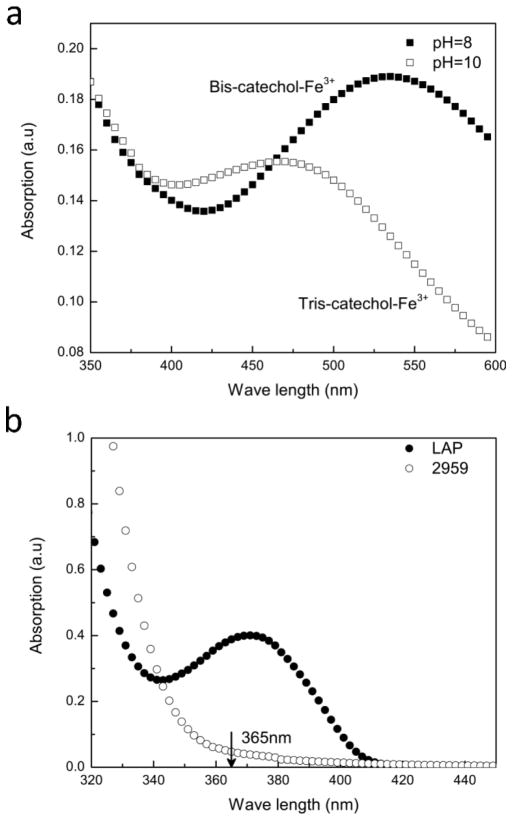

The monomer bearing a catechol group (dopamine methacrylamide, DMA) was synthesized according to the method of Messersmith et al.35 In our new approach (Scheme 1), DMA and FeCl3 solution with molar ratios of 2:1 and 3:1 were first mixed, followed by adjusting the pH to 8 and 10 using respective buffers. The instant formation of coordinated bis- and tris- catechol-Fe3+ complexes was evidenced by the color change and ultraviolet-visible light absorption spectrum (Figure 1a). The absorption peaks at 467 nm and 535 nm indicate the coordination bonding between catechol ligand and Fe3+ in ratios of 3:1 and 2:1 respectively. The pH-dependent coordination behavior between DMA and Fe3+ resembled that between polymer-conjugated catechol and Fe3+ as reported by others.20 Although borate in the buffer might form complexes with catechol groups, the coordination between catechol and Fe3+ possesses a significantly higher association constant (Ka~1040 vs. Ka~104), which explains the prevalence of the catechol-Fe3+ complexes in the solution. 20 The exact influence of buffer on the coordination behavior and performance of the hydrogel will be elucidated in future studies.

Scheme 1.

Photo-polymerized hydrogels using pre-coordinated catechol-Fe3+ complexes as dynamic crosslinkers.

Figure 1.

UV-Vis absorbance of DMA-Fe3+ solution and the photo initiators. (a) Absorption peaks at 467nm and 535nm indicate the formation of tris- (open squares) and bis- catechol-Fe3+ (solid squares) complexes respectively. (b) UV-Vis absorbance of LAP and I2959. Compared to I2959 (open circles), LAP (solid circles) absorbs significant higher amount of light at 365nm.

In the coordinated form, these complexes can act as robust multi-functional linkers for hydrogel formation. The PCCI solution containing 14 wt% of acrylamide was irradiated with ultra-violet (UV) light (8w/cm2, wavelength 365nm) for 1 hour to induce the radical polymerization in the presence of photo-initiator LAP, which was selected due to its exceptional efficiency and high water solubility compared to the commercially available initiators such as IRGACURE 2959.36, 37 As a photo-initiator, LAP absorbed a large quantity of UV light at long wavelength band (Figure 1b). Thus, compared to IRGACURE 2959, LAP can be readily excited by a long wavelength UV light lamp (wave length 365 nm). The choice of LAP as our initiator was proven to be essential for the complete gelation, as the bis- and tris- catechol-Fe3+ complexes severely interfere the initiator’s absorbance of UV light (Figure 1) and thus undermine the efficiency of the initiation process. We also tried the redox system APS/TEMED to initiate the polymerization. However, this initiator system tended to oxidize the catechol group and disrupted the coordinated complexes.

It was found that even very low concentration of PCCI complexes (molar ratio 0.0006 to acrylamide, FeCl3 0.019 wt%, pH10) was sufficient to induce the gelation. Hydrogels were fabricated using either tris- or bis- complexes (Figure S1). However, the tris-complex containing hydrogel exhibited better mechanical properties due to the higher stability and was used for the subsequent studies. To demonstrate the versatility of the pre-coordinated linker strategy, we also fabricated PCCI-linked thermo-responsive poly(N-isopropyl acrylamide) hydrogel, which exhibited a pronounced volume change in response to temperature change (Supplemental Figure S2).

As a control, we prepared catechol-Fe3+ cross-linked hydrogel by mixing the solution of AAM-DMA copolymer with Fe3+, followed by changing the pH with borate buffer (Figure S3). The copolymer solution displayed a very high viscosity, preventing its adequate reaction with the Fe3+ solution. The inadequate reaction lead to the microstructural heterogeneity of the resulting hydrogel even with vigorous stirring. A possible explanation could be that the local presentation of high concentration of Fe3+ accelerates the covalent crosslinking between the catechol groups, which hinders the homogenization.33 The subsequent addition of borate buffer instantly changed the color from green to red, indicating the transition from coordinated mono-complex to tris-complex. However, the hydrogel prepared with this method exhibited pronounced heterogeneity, making the gel too fragile to be mechanically tested. Actually in all previous publications on catechol-Fe3+ based hydrogels prepared using the pH jump method, no tensile results were reported due to their fragility.20,21,32

To further characterize the structural homogeneity, we also investigated the microstructure of hydrogels prepared using the two different methods with optical microscopy. The hydrogel prepared with our pre-coordination method exhibited excellent homogeneity throughout (Figure S4a, S4c, S4e), as evidenced by the uniform color distribution at the macro and micro scales. Not surprisingly, the hydrogel prepared using the pH jump method exhibited a large degree of heterogeneity and a large number of defects (Figure S4b, S4d, and S4f).

Mechanical behavior of pre-coordinated metal-ligand hydrogels

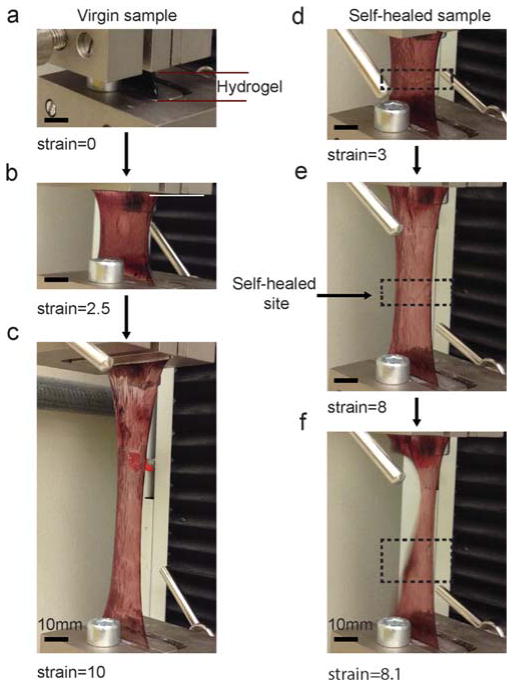

To investigate the extensibility and self-healing capacity of the PCCI cross-linked hydrogels, we performed tensile test on a polyacrylamide hydrogel containing an FeCl3 concentration of 0.038 wt% (catechol-Fe3+ ratio 3:1, pH10), which is denoted as 1xFe hydrogel from here on. 1xFe hydrogel with defined dimensionality (32 × 10 × 3 mm3) was subjected to tensile testing using an MTS Synergie 200 mechanical tester. The loading rate was 100 mm/min unless specified otherwise. Upon stretching, a hydrogel sheet underwent a continuous extension and the elongation at rupture was more than 10 times its original length (Figure 2a–c). We next cut a piece of the hydrogel apart, immediately rejoined the fresh interfaces and allow them to self-heal for 20 minutes. The involvement of fresh surfaces is crucial for good adhesion because just bringing the surfaces of two old hydrogels together for 20 minutes leads to very limited adhesion. Tensile testing showed that the healed hydrogel still displayed a fracture elongation as high as 8 times the original length. Although a trace of the self-healed scar was evident, the new rupture occurred at a location away from the self-healed site (Figure 2d–f), implying that the mechanical property of the gel was fully recuperated within 20 minutes after cutting.

Figure 2.

High extensibility and fast self-healing property of the hydrogel prepared using the pre-coordination method. (a–c) Tensile test of the as-prepared hydrogel sheet. A strain at break of 1000% was achieved in a tensile test. (d–f) Tensile test of the self-healed hydrogel sheet. The hydrogel sheet was cut apart and rejoined for self-healing for 20 minutes before the test. A maximum strain of 800% was achieved before the rupture. Note that the rupture occured not at the self-healed site, indicating the hydrogel completely self-healed within 20 minutes. The hydrogel (1xFe) used in the test was prepared with 14 wt% acrylamide, 0.176% dopamine methacrylamide, 0.038% FeCl3 and 0.5% photo-initiator (LAP).

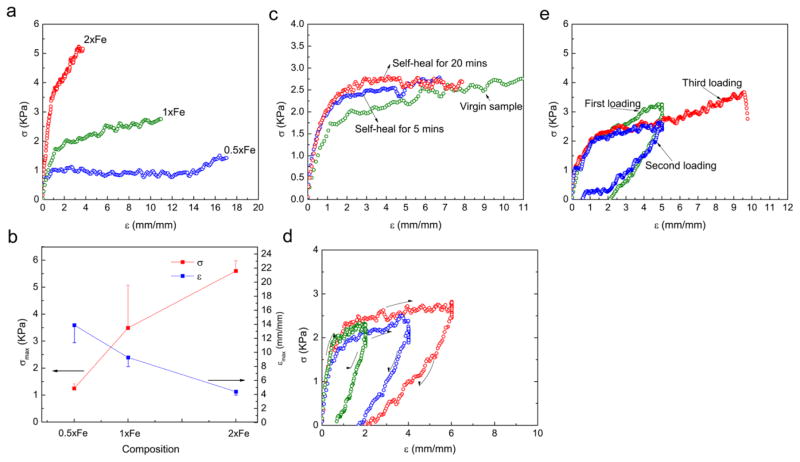

Tensile strength increased with increasing catechol-Fe3+ content, while the elongation at break decreased with increasing catechol-Fe3+ content (Figure 3a&b). The self-healing of 1xFe hydrogel was evaluated at two time points (Figure 3c). After the fresh cut surfaces were rejoined for 5 minutes, the maximum strain of the healed hydrogel reached 670%, while an increase of the healing time to 20 minutes further improved the healing and increased the maximum strain to 800% (Figure 3c). Furthermore, the self-healed sample demonstrated a similar stress-strain curve to that of the virgin sample.

Figure 3.

Composition dependent, self-healing and self-recovery properties of the hydrogels. (a) The tensile stress-strain curve of the hydrogel is dependent on the concentration of catechol-Fe3+ complexes. (b) The maximum stress and rupture strain are dependent on the concentration of the complexes. Higher concentration of the complexes results in higher mechanical strength and lower rupture strain. (c) A self-healed sample exhibits similar stress-strain behavior to that of the virgin sample. (d) Different residual strains were observed for different samples that were first stretched to 2, 4 and 6 times their original lengths, but all became negligible (less than 10%) after a short recovering time of 5 minutes. (e) Repeated loading to the same sample revealed the full recovery of the mechanical properties after a 20-minute recovery time. Error bars: SD, n=3.

Most physical hydrogels deform permanently upon external loading because such reversible interactions are low in stability and often unable to bear the load. To investigate the hydrogel’s capability of recovering from the strain, we performed a cyclic tensile test and examined the residual strain after the release of the load. Different hydrogel samples were first stretched to 2, 4 and 6 times their original lengths and then the load was immediately released. Different residual strains were observed for these samples (Figure 3d). However, after a short recovering time (less than 5 minutes), negligible amount of strain (less than 10%) was retained, indicating the hydrogel was not a viscous fluid and its shape was recoverable under these deformation conditions. The hydrogel’s resistance to fatigue was tested with repeated loading and unloading. 20 minutes after the first loading, a second loading was applied to the same specimen (Figure 3e). Approximately the same elastic modulus and stress were observed for the first and second loadings. After another 20 minutes, a third loading was applied and the sample was stretched to rupture. Again the same elastic modulus and stress were observed. The strain at rupture reached 950%, showing no statistical difference from the virgin sample. The high recovery capacity is likely due to the significant stability of the catechol-Fe3+ complexes.

Viscoelastic properties and re-shapeability of pre-coordinated metal-ligand hydrogels

The mechanical properties of the hydrogel were found to be strongly dependent on the deformation rates of the test (Figure 4a). The elastic modulus and tensile strength of the 1xFe hydrogel increased dramatically with increasing strain rate. Increasing the loading rate from 25 to 400 mm/min results in a nearly 7-fold increase in tensile strength, while the strain at rupture decreased from ~1600% to ~500% (Figure 4b). Such strong dependence of the mechanical properties on loading rate is not characteristic of static covalent hydrogels and suggests the important role of the dynamic coordination bonds.

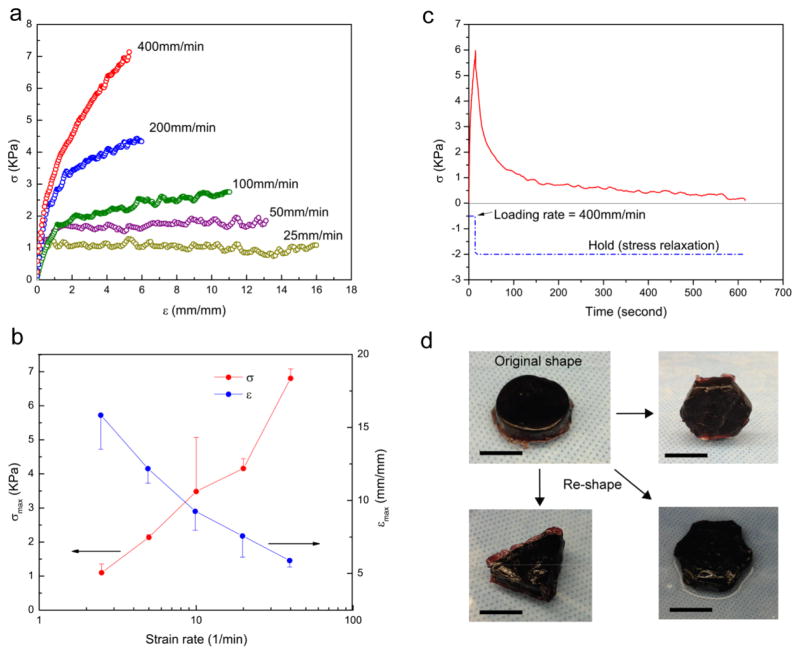

Figure 4.

The viscoelasticity and remoldable behaviors of the hydrogels (1xFe). (a) Tensile stress-strain curves of the hydrogels under different deformation rates from 25 to 400 mm/min. (b) Dependence of the tensile strength (maximum stress) and rupture strain on deformation rate. Increasing deformation rate results in higher strength and lower rupture strain (Error bars: SD, n=3). (c) Stress relaxation behavior of the hydrogel. (d) Re-moldable behavior of the hydrogel. A hydrogel disc is reshaped into triangle, hexagonal and flower-like shapes after being compressed into different PDMS molds (Scale bars: 10mm).

The strong loading-rate dependence of the deformation behavior also implies that PCCI crosslinks can rearrange in a time-dependent fashion. Therefore, the stress of the PCCI crosslinked hydrogels is likely also strongly correlated with the holding time of a fixed large strain in a stress relaxation experiment. By holding the pre-strain at a large scale (strain = 500%), we measured the decreasing stress with the increasing holding time. The result showed that the stress in the hydrogel was quickly decreased from 6.1 KPa to nearly zero within just 10 minutes (Figure 4c). Covalently crosslinked polyacrylamide hydrogels were also shown to undergo a stress relaxation caused by the disentanglement of the polymer chains, but the extent of stress relaxation was from less than 10% up to 50% due to the constraint of the covalent links. 38 The catechol-Fe3+ complex based hydrogel displayed a stress relaxation up to almost 100%, indicating the importable role of the reconfigurable dynamic crosslinks. Interestingly, the dynamic crosslinks make the PCCI crosslinked hydrogels re-shapeable after it is cast in a mold. A PCCI crosslinked hydrogel disc could be remolded into triangle, hexagonal, and flower-like shapes after being compressed into different molds for a period of 20 minutes (Figure 4d). In contrast, the remoldable behavior is absent in static covalent hydrogels and has important applications because the shape of a hydrogel in many cases needs to be altered to fit a new shape. For example, an implantable tissue substitute has to fit well to the size and shape of the tissue defect, where using re-shapeable materials is advantageous.

The recovery testing (Figure 3d) and repeated loading (Figure 3e) experiments validated the hydrogel’s elastic recovering capacity and favorable fatigue resistance. The stress relaxation and remolding experiments (Figures 4c & 4d) revealed that a large residual strain persisted after the load had been removed. To understand the relationship between the plastic deformation and loading condition, we measured the residual strain after deformation under different conditions, including high loading rate, low loading rate and stress relaxation (holding a fixed strain for a period of time). For all the measurements, the hydrogel was stretched to 5 times the original length, and the residual strain was examined 20 minutes after the unloading (supplemental Figure S5a). At high loading rates (200 and 100 mm/min) the residual strains were found to be less than 10%, corroborating well with the recovery experiment that was carried out at 100 mm/min. Reducing the loading rate to 10 mm/min dramatically increased the residual strain to 91%. After stress relaxation (pre-stretching the hydrogel sample at a rate of 400 mm/min to 5 times the original length, followed by holding this strain for 10 minutes to allow the release of the internal stress), the residual strain reached as high as 152%. The high residual strain after stress relaxation process corroborated with the re-shapeable behavior, where the hydrogel was compressed into a new mold and maintained there for a long-enough period of time, resulting in a permanent shape change. Since the loading time is inversely proportional to the loading rate when the total strain is fixed, the correlation between the residual strain and the loading time was plotted, revealing that the residual strain increased with increasing loading time (supplemental Figure S5b).

Rheological properties of pre-coordinated metal-ligand hydrogels

To further characterize the dynamic mechanical behavior of the hydrogels, we performed rheological tests to the 1xFe hydrogel under varied frequencies, strains and temperatures. Due to the reversible association between catechol ligands and Fe3+, the dynamic moduli of the hydrogel were sensitive to the test frequency (Figure 5a). At very low test frequencies, the loss modulus was slightly higher than the elastic modulus, indicating that the hydrogel displayed primarily a viscous fluid-like characteristic (Figure 5b). A sol to gel transition occurred at a frequency of 0.016Hz, and the elastic behavior became dominant after the transition point. Overall, the elastic modulus increased dramatically with the increase of test frequency from 0.01Hz to 100Hz, which corroborate with the tensile testing results under various strain rates (Figure 4a). Hydrogels with different concentrations of pre-coordinated complexes (Figure S6 for 0.5xFe hydrogel and Figure S7 for 2xFe hydrogel) exhibited a similar frequency dependent behavior, although the sol-gel transition point moved to a higher frequency for the 0.5xFe hydrogel and to a lower frequency for the 2xFe hydrogel. Control experiments were carried out on the non-crosslinked polyacrylamide solution and covalently-crosslinked polyacrylamide hydrogel (Figure S8 and Figure S9). The storage modulus of the non-crosslinked polyacrylamide was lower than the loss modulus in the full frequency range, indicating that without crosslinking the polymer displayed a pure liquid behavior. On the other hand, the covalent polyacrylamide hydrogel exhibited frequency-independent elastic modulus and the loss modulus was lower than the elastic modulus at all frequencies.

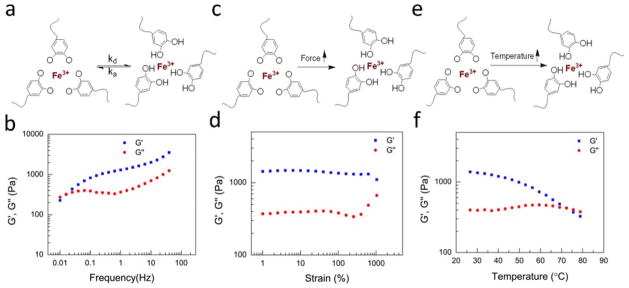

Figure 5.

The rheological measurements of the hydrogel (1xFe). (a) Reversible association and disassociation between catechol groups and Fe3+. (b) Dynamic moduli of the hydrogel under varied frequency. (c) The coordinated complexes tend to disassociate under a large strain. (d) Dynamic moduli of the hydrogel under increasing strains. (e) The coordinated complex tends to disassociate at a high temperature. (f) Dynamic moduli of the hydrogel under heating.

When strain is increased, the tendency of disassociation of the catechol-Fe3+ coordination bond is intuitively expected to increase (Figure 5c), which was tested by examining how the modulus change with increasing strain levels. In Figure 5d, the hydrogel was subjected to an increasing shear strain from 0.1% to 1000%. Interestingly, the elastic modulus kept steady even when the strain reached 500%, indicating that the catechol-Fe3+ coordination bond is very stable and the hydrogel is highly homogeneous. With further increased strains, the elastic modulus began to decrease, indicating the softening of the hydrogel. However, yielding behavior was not observed even when the strain was nearly 1000%, corroborating the tensile mechanical testing results that the hydrogel could withstand a very large deformation (10 times the original length) before break.

The strength of most dynamic bonds, including the coordination bonds, is influenced by temperature, which renders the hydrogel thermo-responsive (Figure 5e). In Figure 5f, we investigated the rheological properties of the pre-coordinated hydrogels under a wide temperature range from 25°C to 80°C. During a continuous heating process, the elastic modulus of the hydrogel gradually decreased, while the loss modulus gradually increased. A gel-sol transition occurred at 73°C, above which the hydrogel melted. This result demonstrates that the hydrogel responds to temperature change.

Hydrogel dissolution in EDTA solution

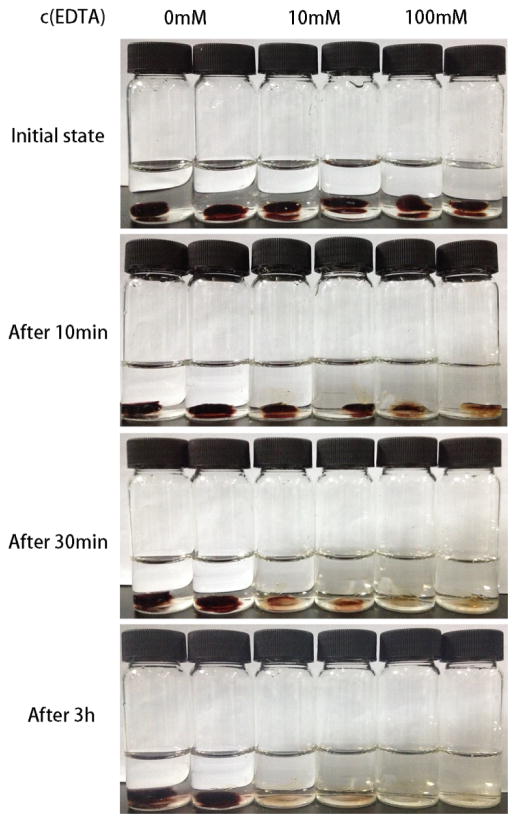

Catechol-Fe3+ complexes can disassociate in the presence of ethylene diamine tetraacetic acid (EDTA), a strong chelating agent for metallic ions including Fe3+.20, 33 Thus EDTA can be used as a chemical stimulus to trigger the dissolution of the hydrogel. We investigated the response of the pre-coordinated hydrogel to EDTA by monitoring the hydrogel change in EDTA solutions (Figure 6). The prepared hydrogel samples were placed in vials with varying concentrations of EDTA, from 0 mM to 10 mM and 100 mM. After only 10 minutes the color of the hydrogel in 100 mM EDTA started to fade from the outer surface of the sample, indicating the disassociation of the catechol-Fe3+ complexes. The hydrogel in 10 mM EDTA showed a less degree of color change. The hydrogel in pure water remained intact. Similar trend was observed after incubating the hydrogel for 30 minutes. After 3 hours, hydrogels in both 10 mM and 100 mM EDTA were completely dissolved, while the hydrogel in pure water maintained the original color and shape. The results verified the EDTA responsiveness of the hydrogels.

Figure 6.

Dissolution of the pre-coordinated metal-catechol hydrogel (1xFe) in EDTA solution. The dissolution of the hydrogel is investigated in an aqueous solution with varying EDTA concentrations (0 mM, 10 mM and 100 mM) over time (at 10 minutes, 30 minutes and 3 hours).

DISCUSSION

Taken together, the results validate our hypothesis that stimuli-responsive supramolecular hydrogels with high extensibility and fast self-healing can be fabricated using polymerizable pre-coordinated catchol-Fe3+ as crosslinkers, due to the highly stable yet reversible feature of the pre-coordinated crosslinkers and the controlled photo-polymerization. The distinctly different mechanical behaviors between our hydrogels and other catechol-Fe3+ based hydrogels demonstrate that the pre-coordination strategy significantly enhances the extensibility and strength of the materials. Structural heterogeneity has been recognized as an important cause of low mechanical properties of hydrogels. Thus, to fabricate hydrogels with homogeneous microstructure is an efficient approach to improve mechanical properties. Our group has reported a method to fabricate ionic alginate hydrogels with improved uniformity and mechanical properties by controlling the gelation kinetics.39 Similar to the alginate hydrogels, mixing-induced catechol-Fe3+ based hydrogels are highly heterogeneous in structure due to the extremely rapid association kinetics of the metal-ligand complexes. In a heterogeneous hydrogel, the regions of low crosslinking density act as structural defects, leading to substantially reduced mechanical properties. To prevent the rapid crosslinking and improve the uniformity of the hydrogels, we developed a one-step photo-crosslinking method with pre-coordinated catechol-metal complexes as the dynamic linkers. This approach simultaneously improved the uniformity and coordination efficiency, synergistically resulting in the remarkable mechanical properties of the hydrogels.

The experimental results (Figure 4) also reveal that the mechanical properties of the pre-coordinated hydrogels (strength, extensibility and recoverability) strongly depend on the deformation conditions: the hydrogels exhibit higher stiffness, better recoverability and less extensibility under fast loading, compared to those under slow loading conditions. The strong strain-rate dependency likely originates from the unique properties of the dynamic catechol-Fe3+ complexes. From a microscopic view, under fast loading the polyacrylamide chains in the network are stretched elastically, while the majority of the crosslinkers are still intact due to their exceptional resistance to rupture. Thus the deformation can be readily recovered after removing the load. However, under slow loading conditions, the coordinated complexes are dynamic, enabling the complexes to disassociate and re-associate under external forces with a sufficiently long time period. As a result, low stiffness, permanent deformation and shape change are observed. Here the PCCI complexes act as the sacrificial bonds to enhance the extensibility of the hydrogel. At the same time, numerous new catechol-Fe3+ complexes form at new locations. The relocation of the complexes accommodates the changes in size and shape of the hydrogel.

Another remarkable feature of the pre-coordinated hydrogels is that they can heal the damages autonomously in very short time even after being completely cut apart. Our results show that the high extensibility of the hydrogel can be fully recovered within 20 minutes. We hypothesize that the extraordinary self-healing capacity stems from the rapid re-association kinetics of the coordination bonds between catechol groups and Fe3+. Although certain supramolecular hydrogels are mechanically stable and self-healable, the time for the self-healing to occur is usually from hours to days.25 A possible reason for the slow self-healing is that the supramolecular units in those hydrogels (such as host-guest and cooperative electrostatic interactions) re-organize slowly after being broken by external forces. To the contrary, the catechol-Fe3+ complexes associate rapidly, as evidenced by the instant color change of the solution after mixing the two components. Previous reports on the mixing-induced catechol-Fe3+ hydrogels also confirm the rapid coordination kinetics, as the gelation occurs immediately after mixing the multi-functional polymers with Fe3+.20, 21, 33 In the pre-coordinated hydrogels, the coordination bonds at the fracture surface are broken upon cutting, leaving un-coordinated catechol groups and Fe3+. When the interfaces are rejoined, the catechol group and Fe3+ rapidly re-associate to effectively heal the hydrogel pieces.

CONCLUSION

In summary, we developed stimuli-responsive supramolecular hydrogels with high extensibility and fast self-healing capacity based on a novel strategy that uses pre-coordinated catechol-Fe3+ complexes as the dynamic crosslinkers. The hydrogels with excellent homogeneity can be fabricated and cast into various shapes by polymerizing the monomers in the presence of a highly efficient photo-initiator. Depending on the composition and deformation rate, the hydrogels can be stretched beyond 10 times their original lengths. Moreover, the high extensibility is completely recovered within a very short time period even after the hydrogel is entirely cut apart and rejoined together. The hydrogels contain very low concentrations of catechol monomer and Fe3+. The strategy can potentially be utilized to develop other polymer gels using different monomers. In addition, the re-shapeable property of the hydrogel is appealing in many applications where the alteration of hydrogel shape is required. This work demonstrates an excellent example of combining nature-inspired chemistry with a smart engineering design for novel hydrogel development.

Supplementary Material

Acknowledgments

This study was carried out in the Polymeric Biomaterials and Tissue Engineering Laboratory at the University of Michigan. The authors gratefully acknowledge the financial support from the NIH (NIDCR DE022327 and DE015384: PXM) and DOD (W81XWH-12-2-0008: PXM). SH acknowledges the partial financial support of a scholarship from China Scholarship Council.

Footnotes

Notes

The authors declare no competing financial interests.

Supporting Information. Photos of hydrogels prepared at different pH, photos of a thermosensitive hydrogel, table of concentrations of the reagents used for hydrogel synthesis, preparation of mixing-induced hydrogel, residual strains of the hydrogel deformed under different strain rates and rheological data of hydrogels with different F+3 contents (2xFe and 0.5xFe). This material is available free of charge via the Internet at http://pubs.acs.org.

References

- 1.Hoffman AS. Hydrogels for biomedical applications. Adv Drug Delivery Rev. 2002;54:3–12. doi: 10.1016/s0169-409x(01)00239-3. [DOI] [PubMed] [Google Scholar]

- 2.Lutolf MP, Hubbell JA. Synthetic biomaterials as instructive extracellular microenvironments for morphogenesis in tissue engineering. Nat Biotechnol. 2005;23:47–55. doi: 10.1038/nbt1055. [DOI] [PubMed] [Google Scholar]

- 3.Peppas NA, Hilt JZ, Khademhosseini A, Langer R. Hydrogels in biology and medicine: From molecular principles to bionanotechnology. Adv Mater. 2006;18:1345–1360. [Google Scholar]

- 4.Zhang L, Cao ZQ, Bai T, Carr L, Ella-Menye JR, Irvin C, Ratner BD, Jiang SY. Zwitterionic hydrogels implanted in mice resist the foreign-body reaction. Nat Biotechnol. 2013;31:553. doi: 10.1038/nbt.2580. [DOI] [PubMed] [Google Scholar]

- 5.Hennink WE, van Nostrum CF. Novel crosslinking methods to design hydrogels. Adv Drug Delivery Rev. 2002;54:13–36. doi: 10.1016/s0169-409x(01)00240-x. [DOI] [PubMed] [Google Scholar]

- 6.Stuart MAC, Huck WTS, Genzer J, Muller M, Ober C, Stamm M, Sukhorukov GB, Szleifer I, Tsukruk VV, Urban M, Winnik F, Zauscher S, Luzinov I, Minko S. Emerging applications of stimuli-responsive polymer materials. Nat Mater. 2010;9:101–113. doi: 10.1038/nmat2614. [DOI] [PubMed] [Google Scholar]

- 7.Hunt JN, Feldman KE, Lynd NA, Deek J, Campos LM, Spruell JM, Hernandez BM, Kramer EJ, Hawker CJ. Tunable, High Modulus Hydrogels Driven by Ionic Coacervation. Adv Mater. 2011;23:2327. doi: 10.1002/adma.201004230. [DOI] [PubMed] [Google Scholar]

- 8.Steed JW. Supramolecular gel chemistry: developments over the last decade. Chem Commun. 2011;47:1379–1383. doi: 10.1039/c0cc03293j. [DOI] [PubMed] [Google Scholar]

- 9.Aida T, Meijer EW, Stupp SI. Functional Supramolecular Polymers. Science. 2012;335:813–817. doi: 10.1126/science.1205962. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Appel EA, del Barrio J, Loh XJ, Scherman OA. Supramolecular polymeric hydrogels. Chem Soc Rev. 2012;41:6195–6214. doi: 10.1039/c2cs35264h. [DOI] [PubMed] [Google Scholar]

- 11.Yan XZ, Wang F, Zheng B, Huang FH. Stimuli-responsive supramolecular polymeric materials. Chem Soc Rev. 2012;41:6042–6065. doi: 10.1039/c2cs35091b. [DOI] [PubMed] [Google Scholar]

- 12.Dankers PYW, Hermans TM, Baughman TW, Kamikawa Y, Kieltyka RE, Bastings MMC, Janssen HM, Sommerdijk NAJM, Larsen A, van Luyn MJA, Bosman AW, Popa ER, Fytas G, Meijer EW. Hierarchical Formation of Supramolecular Transient Networks in Water: A Modular Injectable Delivery System. Adv Mater. 2012;24:2703–2709. doi: 10.1002/adma.201104072. [DOI] [PubMed] [Google Scholar]

- 13.Li J, Li X, Ni XP, Wang X, Li HZ, Leong KW. Self-assembled supramolecular hydrogels formed by biodegradable PEO-PHB-PEO triblock copolymers and alpha-cyclodextrin for controlled drug delivery. Biomaterials. 2006;27:4132–4140. doi: 10.1016/j.biomaterials.2006.03.025. [DOI] [PubMed] [Google Scholar]

- 14.Appel EA, Biedermann F, Rauwald U, Jones ST, Zayed JM, Scherman OA. Supramolecular Cross-Linked Networks via Host-Guest Complexation with Cucurbit[8]uril. J Am Chem Soc. 2010;132:14251–14260. doi: 10.1021/ja106362w. [DOI] [PubMed] [Google Scholar]

- 15.Chen Y, Pang XH, Dong CM. Dual Stimuli-Responsive Supramolecular Polypeptide-Based Hydrogel and Reverse Micellar Hydrogel Mediated by Host-Guest Chemistry. Adv Funct Mater. 2010;20:579–586. [Google Scholar]

- 16.Yan XZ, Xu DH, Chi XD, Chen JZ, Dong SY, Ding X, Yu YH, Huang FH. A Multiresponsive, Shape-Persistent, and Elastic Supramolecular Polymer Network Gel Constructed by Orthogonal Self-Assembly. Adv Mater. 2012;24:362. doi: 10.1002/adma.201103220. [DOI] [PubMed] [Google Scholar]

- 17.Jia YG, Zhu XX. Self-Healing Supramolecular Hydrogel Made of Polymers Bearing Cholic Acid and beta-Cyclodextrin Pendants. Chem Mater. 2015;27:387–393. [Google Scholar]

- 18.Wang Q, Mynar JL, Yoshida M, Lee E, Lee M, Okuro K, Kinbara K, Aida T. High-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature. 2010;463:339–343. doi: 10.1038/nature08693. [DOI] [PubMed] [Google Scholar]

- 19.Weng WG, Beck JB, Jamieson AM, Rowan SJ. Understanding the mechanism of gelation and stimuli-responsive nature of a class of metallo-supramolecular gels. J Am Chem Soc. 2006;128:11663–11672. doi: 10.1021/ja063408q. [DOI] [PubMed] [Google Scholar]

- 20.Holten-Andersen N, Harrington MJ, Birkedal H, Lee BP, Messersmith PB, Lee KYC, Waite JH. pH-induced metal-ligand cross-links inspired by mussel yield self-healing polymer networks with near-covalent elastic moduli. Proc Natl Acad Sci. 2011;108:2651–2655. doi: 10.1073/pnas.1015862108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Ceylan H, Urel M, Erkal TS, Tekinay AB, Dana A, Guler MO. Mussel Inspired Dynamic Cross-Linking of Self-Healing Peptide Nanofiber Network. Adv Funct Mater. 2013;23:2081–2090. [Google Scholar]

- 22.Park JP, Song IT, Lee J, Ryu JH, Lee Y, Lee H. Vanadyl-Catecholamine Hydrogels Inspired by Ascidians and Mussels. Chem Mater. 2015;27:105–111. [Google Scholar]

- 23.McKee JR, Appel EA, Seitsonen J, Kontturi E, Scherman OA, Ikkala O. Healable, Stable and Stiff Hydrogels: Combining Conflicting Properties Using Dynamic and Selective Three-Component Recognition with Reinforcing Cellulose Nanorods. Adv Funct Mater. 2014;24:2706–2713. [Google Scholar]

- 24.Phadke A, Zhang C, Arman B, Hsu CC, Mashelkar RA, Lele AK, Tauber MJ, Arya G, Varghese S. Rapid self-healing hydrogels. Proc Natl Acad Sci. 2012;109:4383–4388. doi: 10.1073/pnas.1201122109. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Kakuta T, Takashima Y, Nakahata M, Otsubo M, Yamaguchi H, Harada A. Preorganized Hydrogel: Self-Healing Properties of Supramolecular Hydrogels Formed by Polymerization of Host-Guest-Monomers that Contain Cyclodextrins and Hydrophobic Guest Groups. Adv Mater. 2013;25:2849–2853. doi: 10.1002/adma.201205321. [DOI] [PubMed] [Google Scholar]

- 26.Lee H, Scherer NF, Messersmith PB. Single-molecule mechanics of mussel adhesion. Proc Natl Acad Sci. 2006;103:12999–13003. doi: 10.1073/pnas.0605552103. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Taylor SW, Luther GW, Waite JH. Polarographic and Spectrophotometric Investigation of Iron(Iii) Complexation to 3,4-Dihydroxyphenylalanine-Containing Peptides and Proteins from Mytilus-Edulis. Inorg Chem. 1994;33:5819–5824. [Google Scholar]

- 28.Holm RH, Kennepohl P, Solomon EI. Structural and Functional Aspects of Metal Sites in Biology. Chem Rev. 1996;96:2239–2314. doi: 10.1021/cr9500390. [DOI] [PubMed] [Google Scholar]

- 29.Taylor SW, Chase DB, Emptage MH, Nelson MJ, Waite JH. Ferric Ion Complexes of a DOPA-Containing Adhesive Protein from Mytilus edulis. Inorg Chem. 1996;35:7572–7577. [Google Scholar]

- 30.Holten-Andersen N, Fantner GE, Hohlbauch S, Waite JH, Zok FW. Protective coatings on extensible biofibres. Nat Mater. 2007;6:669–672. doi: 10.1038/nmat1956. [DOI] [PubMed] [Google Scholar]

- 31.Harrington MJ, Masic A, Holten-Andersen N, Waite JH, Fratzl P. Iron-Clad Fibers: A Metal-Based Biological Strategy for Hard Flexible Coatings. Science. 2010;328:216–220. doi: 10.1126/science.1181044. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Krogsgaard M, Behrens MA, Pedersen JS, Birkedal H. Self-Healing Mussel-Inspired Multi-pH-Responsive Hydrogels. Biomacromolecules. 2013;14:297–301. doi: 10.1021/bm301844u. [DOI] [PubMed] [Google Scholar]

- 33.Barrett DG, Fullenkamp DE, He LH, Holten-Andersen N, Lee KYC, Messersmith PB. pH-Based Regulation of Hydrogel Mechanical Properties Through Mussel-Inspired Chemistry and Processing. Adv Funct Mater. 2013;23:1111–1119. doi: 10.1002/adfm.201201922. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Lee BP, Konst S. Novel Hydrogel Actuator Inspired by Reversible Mussel Adhesive Protein Chemistry. Adv Mater. 2014;26:3415–3419. doi: 10.1002/adma.201306137. [DOI] [PubMed] [Google Scholar]

- 35.Lee H, Lee BP, Messersmith PB. A reversible wet/dry adhesive inspired by mussels and geckos. Nature. 2007;448:338–U4. doi: 10.1038/nature05968. [DOI] [PubMed] [Google Scholar]

- 36.Majima T, Schnabel W, Weber W. Phenyl-2,4,6-trimethylbenzoylphosphinates as water-soluble photoinitiators. Generation and reactivity of O=Ṗ(C6H5)(O−) radical anions. Die Makromolekulare Chemie. 1991;192:2307–2315. [Google Scholar]

- 37.Fairbanks BD, Schwartz MP, Bowman CN, Anseth KS. Photoinitiated polymerization of PEG-diacrylate with lithium phenyl-2,4,6-trimethylbenzoylphosphinate: polymerization rate and cyto-compatibility. Biomaterials. 2009;30:6702–6707. doi: 10.1016/j.biomaterials.2009.08.055. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Lopatin VV, Askadskii AA, Peregudov AS, Vasil’ev VG. Structure and relaxation properties of medical-purposed polyacrylamide gels. J Appl Polym Sci. 2005;96:1043–1058. [Google Scholar]

- 39.Kuo CK, Ma PX. Ionically crosslinked alginate hydrogels as scaffolds for tissue engineering: Part 1. Structure, gelation rate and mechanical properties. Biomaterials. 2001;22:511–521. doi: 10.1016/s0142-9612(00)00201-5. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.