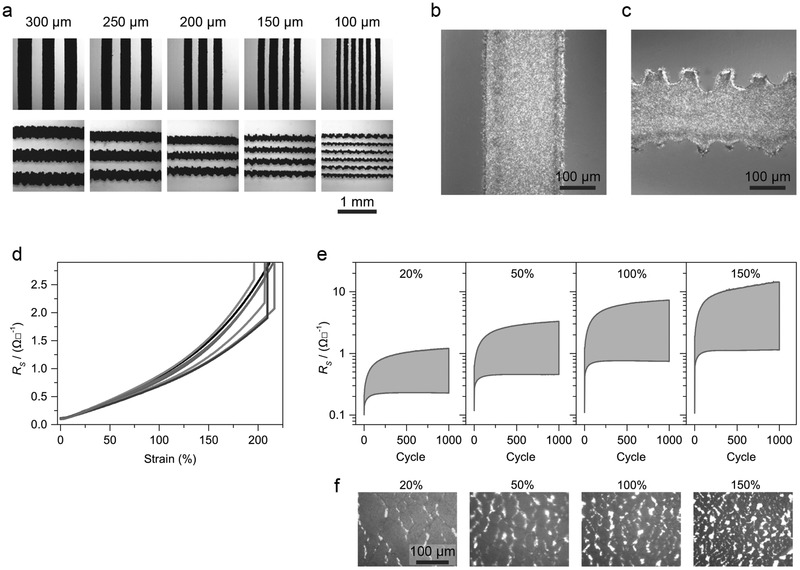

Figure 2.

AgNW conductor pattern quality and performance. a) The images show transferred AgNW conductor lines of different dimension and orientation. Linewidths down to 100 μm can be achieved for lines in the print direction, although the actual line width and spacing can vary quite a bit. For lines perpendicular to the print direction, the lowest feasible dimension is 150 μm. b) The edges of the vertical lines are smooth with little variation. c) The edges of the perpendicular lines are uneven with a typical roughness in the 40 μm range, although variations up to 70 μm can be observed. d) Seven samples with AgNW tracks of 500 μm width and 20 mm length were stretched until mechanical failure. The sheet resistance remained below 1 Ω sq−1 even at 100 % strain. The samples mechanically broke at around 200 % strain. e) For samples that were cycled to 20 %, 50 %, 100 %, and 150 % strain 1000 times, the sheet resistance initially increased rapidly but later stabilized. f) Bright field images of stretched samples that have been cycled 1000 times. The amount of internal fractures within the AgNW films increase with strain.