Abstract

Aims

To evaluate the field inactivation of Bacillus anthracis Sterne spores with methyl bromide (MB) using commercial fumigation techniques.

Methods and Results

Eighty‐seven wood and 87 glass coupons each containing ca. 1 × 106 B. anthracis Sterne spores, were placed in 22 locations inside a 1444 m3 conference building. Four additional 12‐coupon sets (six wood, six glass) were removed from the building at 16, 24, 32 and 40 h during fumigation. The building was sealed under two tarpaulins and fumigated with MB at ≥225 g m−3 mean concentration for 48 h at 28°C and 83% RH. All B. anthracis spores fumigated for more than 16 h were inactivated. A single wood coupon from the 16‐h set yielded ca. 2 × 103 CFU. No damage to the building or its contents was observed.

Conclusions

MB fumigation is a rapid, economical and effective whole‐structure decontamination method for B. anthracis spores.

Significance and Impact of the Study

MB fumigation offers a method of whole‐structure B. anthracis decontamination without removal of materials, damage to sensitive electronics, costly indoor retrofitting.

Keywords: antibacterial, commercial fumigation, non‐corrosive, sensitive materials, sporicide

Introduction

As part of its mission, the U.S. Environmental Protection Agency (USEPA) regulates chemicals used for microbial decontamination (http://www.epa.gov/pesticides/antimicrobials/). When Bacillus anthracis Ames spores were detected in the US mail stream in late 2001 (‘Amerithrax’ event), the USEPA was charged with the selection and implementation of antimicrobials for remediation of contaminated structures and materials. The weaponized nature of the B. anthracis Ames formulation (Matsumoto 2003) made fumigation the method of choice (Canter 2005) because gases could diffuse to all spaces infiltrated by these buoyant spores. For several years postrelease, the USEPA oversaw the fumigation of various tainted buildings using chlorine dioxide (CD) (Wood and Martin 2009) and vaporized hydrogen peroxide (VHP) (Canter et al. 2005). Ethylene oxide and formaldehyde (sublimated from paraformaldehyde) were each used once in small volume enclosures (Canter et al. 2009; Schmitt and Zacchia 2012). Some gases such as chlorine dioxide are reactive and/or incompatible with sensitive materials and surfaces in which spores could disperse, reducing their overall utility in structural remediations (Buhr et al. 2012a).

Although methyl bromide (MB) is a USEPA registered pesticide, its label makes mention of microbial efficacy only for ‘some bacteria (e.g. Salmonella spp.)’ (Anon. 2005). Early on, MB was not considered for B. anthracis remediation because the available literature suggested it was not efficacious (Kolb and Schneiter 1950), and because MB was listed as a ‘class one’ stratospheric ozone depleting substance (D.A. Canter, USEPA, pers. comm.). Subsequently, however, Juergensmeyer et al. (2007) showed that MB exposure of 80 mg l−1 resulted in complete deactivation of various strains of B. anthracis, including the Ames strain, after a 48‐h fumigation (3840 g h m−3 MB) at 37°C. As a published component of the current study, Wood et al. (2015) demonstrated a ˃ 99% capture of MB that entered the carbon scrubbing system.

In addition to its efficacy (Juergensmeyer et al. 2007) and capturability (Wood et al. 2015), the advantages of MB for B. anthracis inactivation is its historic use in the pest control industry (Monro 1961), its quarantine application in fresh commodity fumigation (Anon. 2014a), its neutral effects on surfaces (Corsi et al. 2007), its gaseous stability in air (Ohr et al. 1996), and its rapid degradation in seawater (Jeffers and Wolfe 1996). In this study, we use commercial MB fumigation techniques for rapid whole‐structure inactivation of B. anthracis Sterne spores. The bulk capture of MB during the aeration phase of this study, previously reported by Wood et al. (2015), is only briefly mentioned.

Materials and methods

Building sealing and conditioning

The study building (Figs 1, 2, 3) is located at the Fort Lauderdale Research and Education Center (26·0834, −80·2412) and encompasses 1444 m3, including the exterior volume contained below the roof line. Constructed in 2005, the building is used for teaching and meeting functions and contains two large open rooms, an office, a kitchen (with refrigerator and oven), two restrooms, two utility closets, an heating, ventilating, and air conditioning (HVAC) room, and a storage/computer room. The building also contains two desktop computers, a computer router, two LED monitors and an LCD projector (Fig. 2).

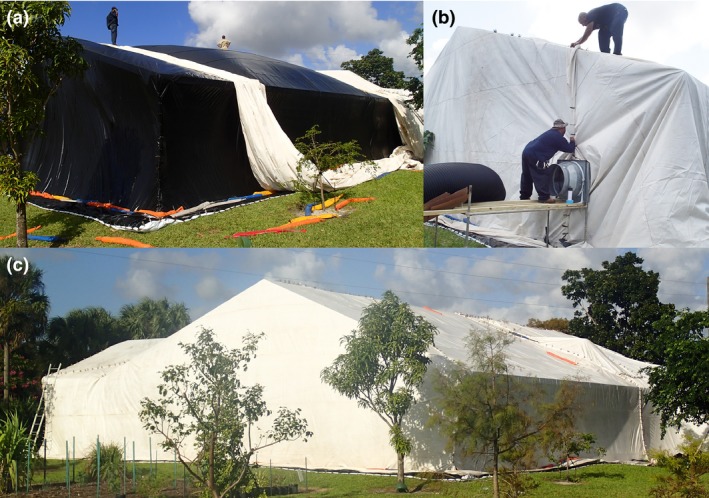

Figure 1.

(a) Inner ethylene vinyl alcohol tarp (black) with skirt around the building perimeter; (b) clamping seams of the outer vinyl tarp; (c) fully tarped building.

Figure 2.

Contents of test building. (a) Large central room; (b) projection equipment; (c) computer routing station; (d) personal computer.

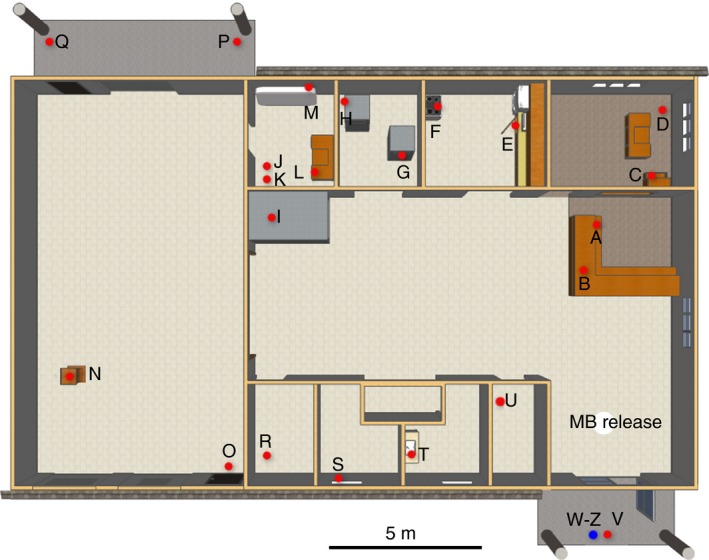

Figure 3.

Room arrangement and locations of Bacillus anthracis coupons in the fumigated building.

In preparation for sealing, fine sand was applied around the building perimeter to even and smooth the turf grass substrate. Next, a 1·8‐m‐wide tarpaulin (tarp) apron made of 6‐mil high diffusion‐resistant polyethylene vinyl alcohol (EVOH) with polyester scrim reinforcement (GeoCHEM Inc., Renton, WA) was taped (8‐cm‐wide Shurtape, Cardinal Prof. Prod., Anaheim, CA) at ground level around the building's entire perimeter. A narrow bead of silicone sealer was also applied over the edge of the tape where it adhered to the foundation. Three 25 × 32 m sections of black EVOH tarps were hoisted onto the roof and arranged (Dead Bug Edwards, Fort Lauderdale, FL) to cover the entire building. The sections were joined by overlapping and rolling adjacent edges together and binding them with plastic‐tipped, metal spring clamps. A horizontal ‘skirt’, formed from excess vertical tarp, was overlapped onto the ground apron. The skirt and apron layers were secured directly below the roof line with flexible 18‐kg sand ‘snakes’ made of tubes of tarpaulin material filled with sand and sealed. The edges of the skirt and apron were then tightly rolled and secured with clamps. To add physical strength in the case of windstorm, a second commercial fumigation tarp made of white vinyl‐coated nylon fabric (0·6 kg m−3), covered the building and was secured onto the first apron with additional overlapping sand snakes (Fig. 1a).

Two vertical tarp seams were positioned to accommodate the 0·6‐m‐ID fresh‐air inlet and exhaust ports (Fig. 1b) for a channelled aeration path. Both the inlet and the exhaust ports were sealed with metal lids during the fumigation. The ground seal was penetrated between the skirts and aprons (Fig. 3, location W–Z) to accommodate a test slide made of 10‐cm OD polyvinyl chloride (PVC) to extract test coupons during intermediate phases of the fumigation, and two 10‐cm OD PVC pipes for the MB introduction or ‘shooting’ hose (18 mm OD chemical and heat‐resistant) and seven MB monitoring lines (6·4 mm OD, nylon). The two MB shooting hoses were extended 3 metres into the building with polyethylene tubing connected by compression fittings. The hoses (one primary and one backup) were secured inside a weighted 20‐litre plastic bucket placed near the building's main entry (MB release, Fig. 3). The pipe chases and voids around the hoses and lines inside pipes were sealed with expanding polyurethane foam (Great Stuff™; Dow Chemical Co., Midland, MI). The test coupon slide was sealed to the outside with a threaded PVC cap.

The interior of the structure was fitted with seven 3000 cubic feet per minute fans, sixteen 3·7‐l capacity steam vaporizers (Walgreens Brand Model 21413ktc, Springfield, IL), and four 1500 watt radiant heaters (Delonghi, Model EW7707CM, Woodridge, NJ). The fans ran continuously during the fumigation to support homogenization of the targeted conditions, 27°C and 75% RH, based on previous experiments (JPW, unpublished data). Power for the vaporizers and heaters was controlled using extension cords routed under the tarp skirt. The building's HVAC was turned off before fumigation; however, the fan continued to operate. All cabinets, appliances, interior doors and two attic access panels were opened to further aid MB, temperature and RH equilibrium. Exterior doors and windows were opened except in the room where the scrubber duct was affixed (Fig. 3, location D) to allow for a unidirectional airflow during aeration.

Temperature and RH inside the building was monitored using a HOBO system (Model ZW‐03; Onset Computer Corporation, Bourne, MA). The system included four wireless sensor nodes spaced throughout the building and a router, which was placed on the front entryway behind the tarps. Real‐time temperature and RH data were collected and displayed on a laptop computer using hoboware pro software (Onset Computer Corporation). These data were used to determine if heaters or humidifiers needed activation. In addition to the four wireless sensors, 21 HOBO temperature and RH loggers (Model U10; Onset Computer Corporation) were placed adjacent to 21 of the 22 coupon locations inside the building (Fig. 3).

Spore coupon preparation and distribution

The B. anthracis surrogate for this study was selected from results of laboratory tests using several spore candidates: non‐virulent strains of Geobacillus stearothermophilus, B. anthracis NNR1∆1, and B. anthracis Sterne. Spores of B. anthracis Sterne 34F2, the vaccine strain (Colorado Serum Co., Denver, CO), were selected as the optimum surrogates for fully‐virulent B. anthracis Ames spores. Spore production procedures were conducted at Yakibou Labs, Inc. (Apex, NC), using proprietary methods.

Coupon substrata were selected based on laboratory screenings of glass, ceiling tile, carpet, wallboard paper, wood, and concrete. Glass (premium precleaned microscope slides, VWR International, Cat# 48300‐047, Radnor, Pennsylvania) and wood (Maple discs, 1·43 cm dia., 0·32 cm thickness, part# DIS‐050; American Woodcrafters Supply Co., Riceville, IA) were chosen because a previous study (Anon. 2014b) found these materials were most resistant to spore inactivation with MB and they represent extremes in porosity. Glass coupons (ca. 15 mm by 18 mm) were washed in alkaline detergent and rinsed until surfaces were clean, dried at 125–150°C, and sterilized by Yakibou, Inc. using a steam autoclave (1 h, 121°C, 103 kPa). Wooden coupons were sterilized using ethylene oxide.

After sterilization, test and positive‐control coupons were liquid‐inoculated using a proprietary protocol (Yakibou, Inc.) with a final spore inoculum target range of 2·0–5·0 × 106 spores as determined by enumeration of colony forming units (CFU) per volume of inoculum per coupon. The inoculum volume was identical for each coupon. Negative control coupons and field blank coupons, with uncertain sterility following packaging, remained un‐inoculated. After inoculation, coupons were allowed to dry at room temperature and packaged into Tyvek® pouches. The pouches were heat‐sealed to prevent infiltration or exfiltration of spores or particulate contaminants and labelled with an identifier unique to each product type.

Pretest and post‐test coupon spore densities were determined by aqueous extraction, 10‐fold serially‐dilution and plating onto tryptic soy agar (TSA). Following incubation at 35°C for 18–24 h, the resulting CFUs were enumerated. The CFU abundance was used to estimate the total spore abundance on the coupons. Population densities were determined in triplicate for each material type before and after the fumigation. In addition, 10 replicates of stainless steel coupons inoculated by Yakibou, Inc. at the same time as the glass and wood coupons, were analysed for population densities, before and after the fumigation. These stainless steel coupons were expected to yield more accurate and repeatable estimates of pre‐ and post‐test viable spore population densities than glass or wood (Calfee et al. 2011), as recovery of spores from stainless steel is highly efficient.

Two types of test coupons were utilized to evaluate the efficacy of the MB fumigation. These included: (i) inoculated coupons deployed throughout the building to qualitatively assess spatial efficacy over the 48‐h fumigation, and (ii) inoculated time‐series coupon sets positioned inside the PVC extraction slide for intermediate removal from the fumigated airspace. Four types of control biological indicators (BIs) were utilized during the tests: procedural blank coupons, positive‐control coupons, negative control coupons, and lab‐sterilized negative control coupons. Procedural blank coupons were not inoculated but were collocated with test coupons during the fumigation and were used to determine the extent of cross‐contamination from sample to sample during collection. Positive‐control coupons were inoculated in the same manner as test coupons, but were not exposed to MB. Positive‐control coupons travelled to the test venue, but remained in the sample shipment cooler for the duration of the study. Negative control coupons were not inoculated, but were packaged in the same manner as test coupons, travelled to the testing venue, remained in the sample shipment cooler, and were not exposed to MB.

There is a possibility that procedures required for packaging coupons into envelopes may not yield sterile coupons. Accordingly, positive growth results from these controls should not be interpreted to indicate a compromise in sample integrity through contamination. Lastly, lab‐sterilized negative control coupons, received from Yakibou, Inc., were sterilized by autoclave (1 h gravity cycle) upon arrival at the NHSRC RTP. These coupons were used to assess the handling technique of the laboratory personnel during culturing procedures. Growth from these coupons would indicate a compromise of sample integrity through contamination within the laboratory.

Four duplicate BI coupons of each type, wood and glass, along with one procedural blank of each type were positioned at 22 locations (Fig. 3) throughout the building before fumigation. Coupon locations were chosen based on spatial separation and a range of ‘sheltering’ in voids (e.g. cabinets and ducts) but still humanly accessible. These included the inside of a desk drawer (Location A), inside file cabinets (C, L), in a kitchen cabinet (E), in an oven (F), inside the HVAC return duct (G), inside a metal hurricane ‘safe room’ (I), in the attic (J), under insulation in the attic (K), on porches (P,Q,V), near a drain in a sink (R), in restrooms (S,T), and in a utility closet (U). After clearance of MB from the structure, the coupons were cold packed and transported to the NHSRC RTP for qualitative assessment of spore survival. The BI coupons were aseptically removed from their Tyvek® envelopes within a biological safety cabinet and placed into 10 ml of TSA. Culture tubes (18 mm x 150 mm sterile borosilicate glass tubes for glass coupons or 25 mm by 150 mm sterile Pyrex® tubes for wood coupons) containing broth and a BI coupon were then incubated at 35°C for 7 days. At 1, 3 and 7 days, the turbidity of the tubes was recorded. Turbid media indicated the presence of bacterial growth, and hence, incomplete decontamination.

During the fumigation, six replicates of each coupon type (wood and glass) along with two procedural blanks of each coupon type (noninoculated wood and glass coupons) were extracted from the PVC coupon slide at 16, 24, 32, and 40 h. Collocated coupons for each 8‐h batch were secured between adjacent coils of a stainless steel spring to which a wire was attached. These were retrieved by unscrewing the PVC slide cap while wearing self‐contained breathing apparatus (SCBA) and removing the spring and wire assembly. Samples were exposed to ambient air before cold‐packaging and transport to RTP NHSRC for extraction and quantification of spore survival. Using aseptic technique, the coupons were placed into 18 × 150 mm sterile borosilicate glass tubes (glass coupons) or 25 mm by 150 mm sterile Pyrex® tubes (wood coupons) each containing 10 ml phosphate buffered saline with Tween20. Each vial was then sonicated for 10 min at 42 kilohertz and 135 Watts. The tubes were then vortexed continuously for 2 min to further dislodge spores from the glass, wood, or metal coupons. Immediately before dilution or plating, each vial was vortexed again to homogenize the sample. The resulting extracts were subjected to five sequential 10‐fold serial dilutions and 0·1 ml of each dilution was inoculated onto TSA plates, spread with sterile beads, and incubated at 35 ± 2°C for 18–24 h. Following incubation, CFUs were enumerated manually.

Although B. anthracis spores remained on the test coupons and inside Tyvek® envelops until culture, sponge wipe samples were taken on structural surfaces before test coupons were deployed. Wipe tests give background contamination and offer evidence of no contamination to the environment. Wipe sampling was conducted according to CDC protocols (CDC 2012). A total of eight wipe samples were taken, four before and four after the fumigation.

MB introduction and monitoring

After sealing, conditioning and coupon placement, MB was introduced into the structure on 8 December 2013. Liquid MB (100%, Meth‐O‐Gas 100®; Great Lakes Chemical Co., West Lafayette, IN) was released from commercial 45 kg metal cylinders and converted to gas using a propane‐fired heat exchanger. The resultant 90°C MB gas entered the building through one of the shooting hoses. The certified applicator (Hammerhead Termite Control, Big Pine Key, FL) gravimetrically measured the mass of MB introduced. MB is acutely toxic to humans and has a threshold limit value of 5 ppmv. Therefore, any and all uses of MB must adhere strictly to label directions (Anon. 2005). The working concentrations of MB were logged at four locations using an RDA Fumiscope® thermal conductivity detector (Key Chemical Co., Clearwater, FL, accuracy ca. ±1 g m−3 MB) and at three locations using a manually‐controlled Fumiscope®.

Ambient air monitoring

Two hand‐held MultiRAE Plus units (RAE Systems, San Jose, CA) were used for leak detection (nonzero readings) near the tarps and the building ground seal. If readings were below 0·5 ppm MB at a 10‐m distance, two team members approached the building while continuously monitoring for MB at their breathing zones. When readings were above the 0·5 ppm action level, the team exited the area, donned SCBAs and completed the leak survey. Readings were taken around the entire perimeter, including immediately adjacent to the tarp at multiple locations. Elevated readings were reported to the tenting and fumigation contractor for potential leak mitigation.

Ambient conditions around the structure were measured with six air monitors deployed downwind of the fumigation. Each monitor contained a RAE Systems AreaRAE and a Honeywell Analytics (Morristown, NJ) ‘MDA Scientific’ single point monitor (SPM). The SPM uses cartridge and key technology. A cartridge and key specific to MB has not been developed. We were testing to see if the hydrogen bromide key and cartridge would detect MB at some level. Cartridges are known to show interference values for some compounds. Unfortunately, the test failed. Photoionization detectors and SPMs were placed at the same location and exposed to MB gas. The photoionization detectors could easily detect the MB, but an SPM with an HB key/cartridge could not detect MB.

The AreaRAE utilizes a 10·6 eV lamp and a wireless radio frequency modem. The photo‐ionization detector was calibrated to be responsive to MB using a 1.7 conversion factor (RAE Systems, 2005: http://www.raesystems.com/products/multirae-family). The AreaRAE units were calibrated with zero air and isobutylene 100 ppm (volatile organic chemical standard). Once the AreaRAE units were calibrated, a bump test was conducted with 5 ppm MB gas to ensure that the units were reading MB in the 3–5 ppm range.

Results

MB confinement

The preparation, fumigation, and aeration of the building were conducted from 6–11 December 2013. The building was completely sealed in one day. Initially, 317 kg of MB was introduced into the building over 10 h. The introduction of MB was delayed for about 8 h by two heat exchanger malfunctions. Once the MB target concentration of 212 mg l−1 was attained (Fig. 4, elapsed time 10 h) the fumigation was maintained for 48 h. The concentrations of MB in each of the seven monitoring locations were comparable and only the four continuously monitored sites are given in Fig. 4. The total time‐accumulated dosage of the fumigation was 12 425 g h m−3 MB.

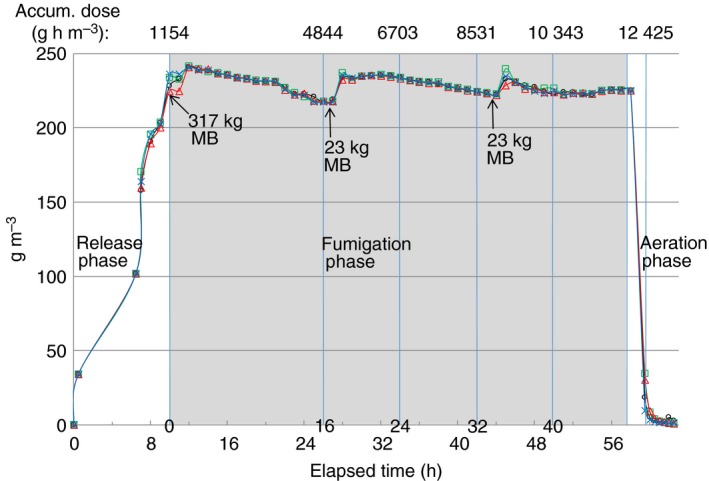

Figure 4.

Concentration (g m−3), accumulated dosage (g h m−3), and additions (kg) of methyl bromide at four data logged locations during the study fumigation. Locations (Fig. 3): N (○), D (□), K (▵) and Q (×).

To boost waning MB concentration, two 23‐kg additions of MB were introduced at 18 and 35 h after the main MB release (Fig. 4). The total quantity of MB released (363 kg) was equal to about 94 m3, or about 7% of the sealed volume. The resultant 7% ‘pressurization’ of the sealed space caused an equal volume loss of MB‐laden air through leaks mentioned below. This resulted in a loss of about 1·8 kg MB (7% of 7% = 0·5%) after the seal return to ambient pressure.

We calculate that 67 kg of MB (18·5%) leaked, permeated, or was sorbed during the fumigation [mean MB conci 241 g m−3 (317 kg MB) at equilibrium minus MB concf 225 g m−3 (296 kg MB) at aeration equals 21 kg MB, plus 46 kg MB added during fumigation]. This yielded a mean loss rate of 1·4 kg h−1 MB during the fumigation. We suspect that the primary loss of MB from the structure was caused by breaches in the adhesion of the Ethylene vinyl alcohol tarp apron to the building foundation, allowing MB to diffuse directly into the perimeter soil. This became evident after tarp removal when a zone of dead grass, which mirrored the position of the apron, was observed surrounding the building. Some ground seal leakage was mitigated with wet sand during the fumigation. Additional losses were likely due to leakage from seal penetrations (e.g., the ducting connection from the building to the scrubbers, electrical lines, conduit chases, clamped tarp seams, etc.), and slight permeation through the tarp material. Corsi et al. (2007) found that sorption and chemosorption of MB to structural surfaces are minimal. Transient sorptive losses are internal and would not contribute to external losses. The average temperature inside the building during fumigation was 27·8°C and the RH was 82·9%. These values slightly exceeded the desired target conditions of 27°C and 75% RH. At only three locations, (Fig. 3, C, D, and H) was the mean target temperature not achieved (C = 26·6, D = 26·1, and H = 26·0°C).

Ambient air monitoring

There were no sustained readings >0·5 ppm MB at any time at a 10‐m distance from the building. The concentration values at the building (one instantaneous high of 27 ppm) were obtained directly at the ground seal and do not reflect breathing zone concentrations. Breathing zone concentrations for the monitoring teams were at least an order of magnitude lower than the concentrations obtained directly at the ground seal tarp using a MultiRAE Plus extended away from body. Even when MB readings were elevated at the ground seal, there were no sustained readings >0·5 ppm in breathing zones inside the 10‐m perimeter. On occasion, elevated readings seen on the AreaRAEs were investigated with a handheld MultiRAE Plus. The elevated readings were shown to be false positives because of elevated case temperatures, vehicle emissions, and high humidity/moisture. In future studies, the AreaRAEs should be protected from sun and buffered from ambient interference as much as practical. There were no substantiated, sustained elevated levels (>0·5 ppm) of MB at any of the AreaRAE monitoring sites at any time during the fumigation.

Capture of MB emissions and aeration

Wood et al. (2015) found that capture efficiency of the activated carbon system used in this study was >99%. The concentration of MB exhausted from the structure was reduced from 41 000 to 136 ppm (atmospheric release) in 3·5 h at which time the fan for the activated carbon system was turned off (Wood et al. 2015). Eight hours later, the tarpaulins were removed and the building was aerated with all fans running and with all operable doors and windows open. The final indoor clearance below 1 ppm MB was achieved after an additional 4 h of active aeration. Doors and windows remained open an additional 24 h to ensure that all MB had desorbed from the building. A transient residual odour common to MB fumigations lingered in the house for about 4 days possibly resulting from methylation products reported by Corsi et al. (2007).

Coupon titre controls

Spore densities were enumerated from nonfumigated coupons pre‐ and postfumigation. No significant differences were detected in their population densities (Table 1) indicating that time in storage did not significantly affect the spore titre on the coupons. Recoveries from glass and stainless steel were within the targeted range (2·0 to 5·0 × 106). Recoveries from wood, however, were lower than the amount inoculated onto these coupons. This was expected, as recoveries from glass and steel are typically between 75–95% of the inoculum, while recoveries from wood have historically been between 1–25% of the inoculum (MWC pers. obs.). Glass and wood demonstrated recovery efficiencies of 91 and 44% of the stainless steel control coupons for pretest evaluations, and 88 and 18% for post‐test evaluations, each respectively. All carriers were inoculated with a population density (as determined by the coupon supplier) of 4·2 × 106 CFU per coupon. Accordingly, mean recovery efficiencies from stainless steel, glass, and wood were 52, 47 and 23% respectively. It was presumed that the lower estimates of spore population density on wood coupons were due to lower recovery efficiencies from the porous wood surfaces and not due to inactivation of spores on the surfaces.

Table 1.

Spore population densities on pre‐ and post‐test control (nonexposed) coupons

| Coupon subtrate | Pretest population | Post‐test population | n | P‐value (two tailed student's t‐test) |

|---|---|---|---|---|

| Stainless Steel | 2·2 × 106 | 2·5 × 106 | 10 pretest, 10 post‐test | 0·1297 |

| Glass | 2·0 × 106 | 2·2 × 106 | 3 pretest, 3 post‐test | 0·2499 |

| Wood | 9·6 × 105 | 4·6 × 105 | 3 pretest, 3 post‐test | 0·0659 |

Three of the four collected prefumigation sponge wipe samples showed the abundance of background organisms (non‐B. anthracis Sterne) taken from building surfaces. Similarly, three of the four postfumigation wipe samples showed background contamination after fumigation (also non‐B. anthracis Sterne organisms) which was too numerous to count. Two blank surface samples collected showed no growth upon microbiological analysis. Coupon sample collection and other postfumigation activities occurred before wipe sample collection. This may have contaminated the surfaces before wiping. The wipe samples that follow fumigation should be conducted in concert with all of the other postfumigation activities in mind. Recontamination of the building, even with organisms that do not have negative health consequences, may interfere with postfumigation sampling.

Coupon quantification, complete fumigation

None of the 87 wood or 87 glass BIs had viable spores following the fumigation. One fumigated wood coupon (Fig. 3, B) and one glass coupon (Fig. 3, R) were not analysed; the latter was missing from its envelope. At location B, only three wood coupons were inadvertently deployed. All wood and glass procedural blanks (fumigated but not inoculated,) showed no turbid media (no growth) following attempted culture. These results verify that the MB fumigation was effective throughout the entire building, as no spatial differences in BI inactivation were apparent. No growth on any of the procedural blank BIs suggests that inadvertent contamination during field or lab procedures did not occur. All 24 wood and 24 glass positive‐control coupons (inoculated, not exposed) were indeed positive for growth upon analysis. Two of the 24 negative control (not inoculated, not exposed) wood coupon BIs were positive upon analysis. None of the 24 negative control glass BIs were positive. The two growth positive (non‐B. anthracis Sterne) negative control wood BIs were not surprising, as the BI producer did not guarantee sterility of these coupons as provided. None of the laboratory negative controls were positive for growth, suggesting that inadvertent contamination of samples during lab procedures was not apparent.

Coupon quantification, temporal exposures

Analysis of the time‐series coupons showed viable spores (4967 CFU) were recovered only from one of six replicate glass coupons exposed for 16 h (4844 g h m−3 MB). This resulted in an average recovery of 828 spores across the six replicates (Table 2). The remaining 5 of 6 replicates showed zero recovered viable spores. Only one wood coupon exposed for 16 h had a single CFU detected by the 1‐ml filter‐plate analysis. Interestingly, filter‐plate analysis of the remaining 7·5 ml resulted in no growth. Log reductions for all wood coupons during the quantitative temporal assessment portion were ≥5·7. The single positive 16‐h glass coupon yielded a log reduction of 3·41, while the other 16‐h glass coupons yielded 6·3 log reductions.

Table 2.

Coupon results from the temporal assessment of methyl bromide fumigation efficacy

| Time point (h) | Location ID (Fig. 3) | Test coupons | Procedural blanks | ||

|---|---|---|---|---|---|

| Total CFU recovered | Total CFU recovered | ||||

| Wood (n = 6) | Glass (n = 6) | Wood (n = 2) | Glass (n = 2) | ||

| 16 | W | 0a | 828 ± 2027b | 0 | 0c |

| 24 | X | 0 | 0 | 0 | 0 |

| 32 | Y | 0 | 0 | 0 | 0 |

| 40 | Z | 0 | 0 | 0 | 0 |

For replicate #2 of 6), one filter‐plate sample (1 ml analysed) yielded 1 CFU. When 7·5 ml from the same sample was analysed, zero CFU were observed. No CFU were observed from the other 5 replicate wood biological indicators (BIs) at 16 h.

Viable spores recovered from 1 of 6 replicate BIs. 4967 CFU recovered from replicate #6 of 6.

Contamination by nontarget bacteria was observed on both glass procedural blanks at 16 h time point. For replicate 1, 2 and 14 CFU were observed on the 1 and 7·9 ml filter‐plates samples respectively. For replicate 2, 4 and 50 CFU were observed on the 1 ml and 7·8 ml filter‐plate samples respectively.

Contamination by nontarget bacteria was detected on both glass procedural blank coupons at the 16 h exposure point. Contamination on procedural blanks is not unexpected, as discussed before. Overall, the MB treatment was efficacious, as 46 of 48 test coupons were completely negative for growth of B. anthracis Sterne Sterne at all of the time points tested. Exposures of 16 h resulted in complete inactivation of 10 of 12 coupons, just below the 6‐log reduction efficacy criteria. These results indicate that the fumigation was efficacious (>6 LR) after 16 h and before 24 h of fumigation.

Discussion

From the 1960s to the 1990s, MB was used as a structural fumigant primarily to control drywood termites. In 1992, as an outcome of the Montreal Protocol Treaty, MB was listed as a controlled ozone depleting substance. Since then, MB production for controlled uses such as space and soil fumigation has declined to 9% of the pre‐Protocol amount. Quarantine and preshipment (QPS) uses of MB, however, are exempt from phase‐out (Anon. 2014c) because alternative treatments do not offer the efficacy, speed, and low cost (ca. $14 USD kg−1) of MB to control pests without harm to commodities, especially fresh produce. Most of the QPS fumigations in the U.S. take place at seaports and airports where selected foreign cargo is fumigated under United States Department of Agriculture, Plant Protection and Quarantine procedures and oversight (2014a). The actual port fumigations, mostly of shipping containers, are conducted by private contractors working at a designated location on port property. The logistical advantage of using MB for emergency responses lies in the fact that there are dozens of port facilities scattered around the U.S. that employ staff trained and experienced in MB fumigation. But, as with any unregistered use of a biocide, the use of MB for non‐label uses such as B. anthracis remediation requires USEPA ‘crisis exemption’ approval under Section 18 of the Federal Insecticide, Fungicide, and Rodenticide Act.

Canter (2005), Buhr et al. (2012a), and Schmitt and Zacchia (2012) provide some criteria for the selection of CD, VHP, and pCH2O for antimicrobial fumigations. These include efficacy, physical properties (e.g., diffusion/penetrability, material compatibility, byproduct formation), fumigant synthesis, toxicity, fumigant removal, cost, time, waste generation and fumigant history. In addition to these factors, temperature and humidity of the fumigated airspace may require adjustment depending on ambient conditions. Until now, MB was not considered as a viable B. anthracis fumigant because a method for ‘destroying’ MB was unavailable (Buhr et al. 2012a). In light of recent MB capture technology (Wood et al. 2015), the current study demonstrates that MB is effective as a structural decontaminant of B. anthracis spores without some of the negative factors associated with the other fumigants. Without contemplating MB, Buhr et al. (2012b) have come to the conclusion that ‘There is a need…to develop effective decontaminants for biological agents with improved materials compatibility’. Likewise, Fitch et al. (2003) report that ‘decontamination of large buildings, inaccessible spaces, and sensitive equipment remains problematic’.

The months‐long atmospheric half‐life of MB gas (Grosjean 1990) and its volatility allow MB to rapidly infiltrate all pathways at equilibrium concentration within a sealed environment. This also facilitates MB release from a single point source as was done in this study. The stability of liquid MB allows for years of storage in commercial cylinders and alleviates the complexities of on‐site fumigant synthesis. Even the use of a heat exchanger can be omitted if the liquid MB is allowed to boil/evaporate in a vessel lined with wicking material. The most important characteristic of gaseous MB is its compatibility with all known building materials, including electronics and other sensitive goods. In addition to the current findings, Scheffrahn and Weinberg (2004) showed that a 48‐h MB exposure at 312 mg l−1 (35·7°C, 75·6% RH) yielded no visible or operational damage to computers, LCD and Plasma TVs, cameras and other electronics and structural materials. MB sorption is minimal and reversible in indoor materials, and byproducts are limited to methylated C7‐C11 hydrocarbons and dimethyl disulphide (Corsi et al. 2007).

Cost, time efficiency, and waste generation detracted from the success of the Amerithrax fumigations. Schmitt and Zacchia (2012) estimated a mean cost of $1400 m−3 for fumigating just six buildings using CD, VHP and formaldehyde. This would equal almost $3M in today's dollars for remediation of the structure in this study. Canter (2005) reported that fumigation time alone exceeded 9 months and Calfee et al. (2013) noted that excessive waste from contaminated or chemically‐damaged low value materials adds much to remediation costs.

Further research is needed to reduce the overall concentration required for successful microbial fumi‐gations using MB. Increasing temperature of the target site allows for reduced MB concentrations (RHS and JPW, unpubl. obs.). The fumigant concentration and time (CT) product is fairly linear for insect pests (Monro 1961), however, a CT relationship remains unknown for using MB against B. anthracis. If a linear relationship occurs with spores, one could apply reduce MB mass by the same factor that fumigation time is increased. Finally, it is possible that, as with insects (Scheffrahn et al. 1995), carbon dioxide or another innocuous gas could act as an MB synergist during B. anthracis fumigations.

Conflict of Interest

No conflict of interest declared.

Acknowledgements

The Unites States Environmental Protection Agency was the prime project funding agency under grant GMO2413. Dynamac Corporation (Fairfax, VA) was the contracting sponsor under grant GMO747.

References

- Anonymous . (2005) Meth‐O‐Gas® Q Commodity Fumigant. Great Lakes Chemical Co., West Lafayette, IN http://www.greatlakes.com/deployedfiles/ChemturaV8/GreatLakes/Fumigants/Fumigants%20Products/GLS-Meth-O-Gas-Q.pdf

- Anonymous . (2014a) United States Department of Agriculture Treatment Manual. http://www.aphis.usda.gov/import_export/plants/manuals/ports/downloads/treatment.pdf

- Anonymous . (2014b) Methyl bromide decontamination of indoor and outdoor materials contaminated with Bacillus anthracis spores. USEPA/600/R‐14/170, 2014. http://cfpub.epa.gov/si/si_public_record_report.cfm?dirEntryId=282882

- Anonymous . (2014c) Report of the Methyl Bromide Technical Options Committee. 2014 Assessment. http://ozone.unep.org/Assessment_Panels/TEAP/Reports/MBTOC/MBTOC-Assessment Report‐2014.pdf

- Buhr, T. , Kempter, J. and Canter, D. (2012a) Biological decontamination In Handbook of Chemical and Biological Warfare Agent Decontamination eds. Lee S.M., Smith B.M. and Becker J.M. St Albans, UK: ILM Publications. [Google Scholar]

- Buhr, T.L. , Young, A.A. , Minter, Z.A. , Wells, C.M. , McPherson, D.C. , Hooban, C.L. , Johnson, C.A. , Prokop, E.J. et al (2012b) Test method development to evaluate hot, humid air decontamination of materials contaminated with Bacillus anthracis∆ Sterne and B. thuringiensis Al Hakam spores. J Appl Microbiol 113, 1037–1051. [DOI] [PubMed] [Google Scholar]

- Calfee, M.W. , Choi, Y. , Rogers, J. , Kelly, T. , Willenberg, Z. and Riggs, K. (2011) Lab‐scale assessment to support remediation of outdoor surfaces contaminated with Bacillus anthracis spores. J Bioterror Biodef 2, 1–8. [Google Scholar]

- Calfee, M.W. , Tufts, J. , Gold, K. , Mullins, M. and Shah, S. (2013) Research to advance decontamination, sampling, and analytical approaches following biological terror incidents. Biosafety 2, e130. [Google Scholar]

- Canter, D.A. (2005) Remediating anthrax‐contaminated sites: learning from the past to protect the future. Chem Health Saf 12, 13–19. [Google Scholar]

- Canter, D.A. , Gunning, D. , Rodgers, P. , O'Connor, L. , Traunero, C. and Kempter, C.J. (2005) Remediation of Bacillus anthracis contamination in the US Department of Justice mail facility. J Bioterror Biodef 3, 119–127. [DOI] [PubMed] [Google Scholar]

- Canter, D.A. , Sgroi, T.J. , O'Connor, L. and Kempter, C.J. (2009) Source reduction in an anthrax‐contaminated mail facility. J Bioterror Biodef 7, 405–412. [DOI] [PubMed] [Google Scholar]

- CDC . (2012) Surface sampling procedures for Bacillus anthracis spores from smooth, non‐porous surfaces, Revised April 26, 2012. http://www.cdc.gov/niosh/topics/emres/surface-sampling-bacillus-anthracis.html).

- Corsi, R.L. , Walker, M.B. , Liljestrand, H.M. , Hubbard, H.F. and Poppendieck, D.G. (2007) Methyl bromide as a building disinfectant: interaction with indoor materials and resulting byproduct formation. J Air Waste Manag Assoc 57, 576–585. [DOI] [PubMed] [Google Scholar]

- Fitch, J.P. , Raber, E. and Imbro, D.R. (2003) Technology challenges in responding to biological or chemical attacks in the civilian sector. Science 302, 1350–1354. [DOI] [PubMed] [Google Scholar]

- Grosjean, D. (1990) Atmospheric chemistry of toxic contaminants 1. Reaction rates and atmospheric persistence. J Air Waste Manag Assoc 40, 1397–1402. [Google Scholar]

- Jeffers, P.M. and Wolfe, N.L. (1996) On the degradation of methyl bromide in sea water. Geophys Res Lett 23, 1773–1776. [Google Scholar]

- Juergensmeyer, M.A. , Gingras, B.A. , Scheffrahn, R.H. and Weinberg, M.J. (2007) Methyl bromide fumigant lethal to Bacillus anthracis spores. J Environ Health 69, 24–26. [PubMed] [Google Scholar]

- Kolb, R.W. and Schneiter, R. (1950) The germicidal and sporicidal efficacy of methyl bromide for Bacillus anthracis . J Bacteriol 59, 401–412. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Matsumoto, G. (2003) Anthrax powder: state of the art? Science 28, 1492–1497. [DOI] [PubMed] [Google Scholar]

- Monro, H.A.U. (1961) Manual of Fumigation for Insect Control. Food and Agricultural Organization of the United Nations, Agricultural Study No. 79. [Google Scholar]

- Ohr, H.D. , Sims, J.J. , Grech, N.M. , Becker, J.O. and McGiffen, M.E. Jr (1996) Methyl iodide, an ozone‐safe alternative to methyl bromide as a soil fumigant. Plant Dis 80, 731–735. [Google Scholar]

- Scheffrahn, R.H. and Weinberg, M.J. (2004). Whole‐structure decontamination of Bacillus spores by methyl bromide fumigation. Final Report, U.S. Environmental Protection Agency, Small Business Innovation Research Phase II Topic H. Environmental Bioterrorism Detection and Decontamination Award No. 68‐D‐03‐056, 35 pp.

- Scheffrahn, R.H. , Wheeler, G.S. and Su, N.‐Y. (1995) Synergism of methyl bromide and sulfuryl fluoride toxicity against termites (Isoptera: Kalotermitidae, Rhinotermitidae) by admixture with carbon dioxide. J Econ Entomol 88, 649–653. [Google Scholar]

- Schmitt, K. and Zacchia, N.A. (2012) Total decontamination cost of the anthrax letter attacks. Biosecur Bioterror 10, 98–107. [DOI] [PubMed] [Google Scholar]

- Wood, J.P. and Martin, G.B. (2009) Development and field testing of a mobile chlorine dioxide generation system for the decontamination of buildings contaminated with Bacillus anthracis . J Haz Mat 164, 1460–1467. [DOI] [PubMed] [Google Scholar]

- Wood, J.P. , Clayton, M.J. , McArthur, T. , Serre, S.D. , Mickelsen, L. and Touati, A. (2015) Capture of methyl bromide emissions with activated carbon following the fumigation of a small building contaminated with a Bacillus anthracis spore simulant. J Air Waste Manag Assoc 65, 145–153. [DOI] [PubMed] [Google Scholar]