Abstract

Non-steroidal anti-inflammatory drugs (NSAIDs) exert their pharmacological effects by inhibiting cyclooxygenase (COX)-1 and COX-2. Though widely prescribed for pain and inflammation, these agents have limited utility in chronic diseases due to serious mechanism-based adverse events such as gastrointestinal damage. Concomitant blockade of fatty acid amide hydrolase (FAAH) enhances the therapeutic effects of the NSAIDs while attenuating their propensity to cause gastrointestinal injury. This favorable interaction is attributed to the accumulation of protective FAAH substrates, such as the endocannabinoid anandamide, and suggests that agents simultaneously targeting COX and FAAH might provide an innovative strategy to combat pain and inflammation with reduced side effects. Here, we describe the rational design and structure-active relationship (SAR) properties of the first class of potent multi-target FAAH-COX inhibitors. A focused SAR exploration around the prototype 10r (ARN2508) led to the identification of achiral (18b) as well as racemic (29a-c and 29e) analogs. Absolute configurational assignment and pharmacological evaluation of single enantiomers of 10r are also presented. (S)-(+)-10r is the first highly potent and selective chiral inhibitor of FAAH-COX with marked in vivo activity, and represents a promising lead to discover novel analgesics and anti-inflammatory drugs.

Keywords: FAAH, COX, hybrid scaffold, multitarget inhibitors, structure-activity relationship, inflammation

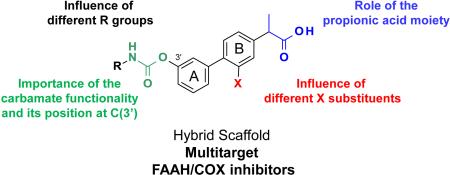

Graphical Abstract

1. Introduction

Non-steroidal anti-inflammatory drugs (NSAIDs) are widely utilized to treat pain and inflammation, [1] but their chronic use is hindered by a variety of potentially serious adverse events that include gastrointestinal (GI) mucosal lesions, bleeding and perforations. [2-5] Conventional NSAIDs inhibit the two isoforms of cyclooxygenase (COX), COX-1 and COX-2, which catalyze the first committed steps in the biosynthetic pathway that converts arachidonic acid (AA) into inflammatory prostanoids such as prostaglandin E2 (PGE2) and thromboxane A2 (TXA2). [6] The dual role of COX-1-derived PGE2 as inflammation promoter and mucosal tissue protectant explains, at least in part, why NSAIDs cause damage to the GI tract. [7-10] Efforts to overcome this problem have led to the development of selective COX-2 inhibitors, which combine a high level of anti-inflammatory efficacy with a reduced propensity to cause injury to the GI mucosa. [6] Nevertheless, the use of COX-2 inhibitors has been linked to a distinctive set of adverse cardiovascular effects. [11, 12] Thus, the need for safe and effective drugs that can be used in the treatment of chronic inflammatory disorders remains urgent.

A promising approach to meet this need is offered by targeting with a single agent more than one component of the inflammatory cascade. [13-15] Agents designed to achieve this objective include nitric oxide (NO) donors-NSAIDs, [16, 17] COX-2 inhibitors-NO-donors, [18, 19] hydrogen sulfide (H2S) donors-NSAIDs, [20-22] as well as compounds that block distinct enzymes of the AA pathway, such as COX/lipoxygenase [23, 24] and COX-2/soluble epoxy hydrolase (sEH). [25] Another potential multi-target strategy to treat inflammation is the concomitant inhibition of COX and fatty acid amide hydrolase (FAAH) [26], [27-33] a serine hydrolase that deactivates a family of analgesic and anti-inflammatory lipid amides that are produced by host-defense cells and other cells in the body. [34, 35] These lipid mediators include the endocannabinoid anandamide (arachidonoylethanolamide) – which engages cannabinoid-1 (CB1) and CB2 receptors to suppress neutrophil migration [36] and prevent immune-cell recruitment [37, 38] – as well as the endogenous peroxisome proliferator-activate receptor-α (PPAR-α) agonists, palmitoylethanolamide (PEA) and oleoylethanolamide (OEA). [39-41] In addition to opposing pain and inflammation, these FAAH substrates are also protective of the GI mucosa. [42, 43] Indeed, studies in animal pain models have shown that co-administration of FAAH and COX inhibitors results in a synergistic potentiation of analgesia along with reduced gastric damage. [44-46]

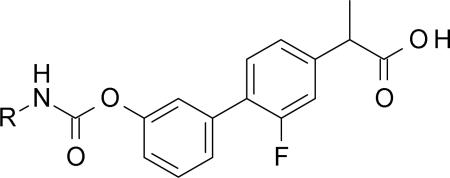

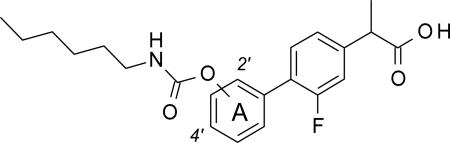

In several chronic inflammatory conditions, including inflammatory bowel disease (IBD), FAAH [47-49] and COX-2 [50] are expressed at abnormally high levels. This simultaneous up-regulation may help establish a pathological state that exacerbates inflammation by amplifying inflammatory COX-dependent signals at the expense of defensive FAAH-regulated mediators. This hypothesis predicts that drugs targeting both COX and FAAH should have substantial anti-inflammatory efficacy combined with reduced GI toxicity. In a recent study, we provided support to this hypothesis using a multi-target modulator based on the hybrid scaffold 1 (Figure 1). [51] This scaffold merges key pharmacophores of two known classes of FAAH and COX inhibitors – O-aryl carbamates [52-58] such as [3-(3-carbamoylphenyl)phenyl] N-cyclohexylcarbamate (URB597, 2) [54, 57], and 2-aryl propionic acids [6] such as flurbiprofen, 3a [59-61] – which share a biphenyl core as a common structural motif (A and B rings, Figure 1). Moreover, structure-activity relationship (SAR) studies of these scaffolds supported the hypothesis of additional elements of structural overlapping, such as the oxygenated substituents at the 3’-position of the A phenyl ring, corresponding to the carbamate functionality of 2 [53, 54, 56] and the ether moieties of 3b or 3c, [61] respectively (Figure 1).

Figure 1.

Rational design of a ‘hybrid scaffold’ for FAAH and COX inhibition.

This SAR work led to the identification of compound 10r ((±)-2-[3-fluoro-4-[3-(hexylcarbamoyloxy)phenyl]phenyl]propanoic acid, ARN2508) [51] as a potent in vivo active inhibitor of intracellular FAAH and COX activities, which exerts profound anti-inflammatory effects in mouse models of IBD without causing COX-dependent gastric toxicity. [51] In the present study, (a) we outline the in-depth SAR investigations that led to the discovery of compound 10r [51]; (b) we report an expansion of this SAR work, which culminated in the identification of several new and potent multitarget inhibitors (18b, 29a-c and 29e); and, finally (c) we describe the absolute configurational assignment and pharmacological properties of single enantiomers of 10r, identifying (S)-(+)-10r as the first chiral inhibitor of FAAH-COX with marked in vivo activity.

2. Results and discussion

2.1 Chemistry

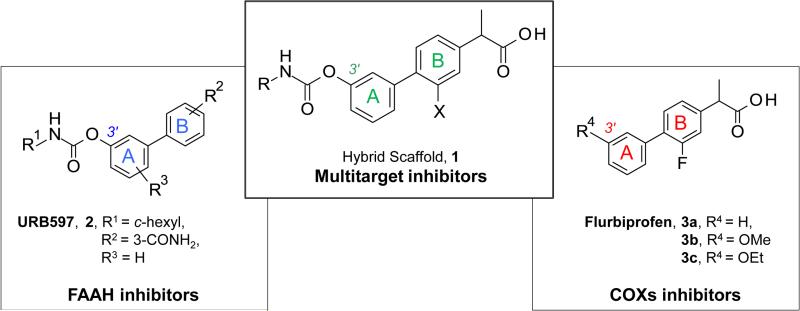

Compounds 10a-t were synthetized from the corresponding phenol 8 through a carbamoylation reaction, using commercially available isocyanates, followed by the hydrolysis of the methyl esters 9a-t, under acidic conditions (Scheme 1).

Scheme 1.

Synthesis of compounds 10a-t and 12. Reagents and conditions: (a) MeOH, conc. H2SO4, rt, 15 h, 93%; (b) HCO2NH4, 10% Pd/C, MeOH, rt, 3 h, 94%; (c) NaNO2, 3M HCl, 0 °C, 30 min, then NaI, 60 °C, 2 h, 55%; (d) (3-hydroxyphenyl)boronic acid, Pd(OAc)2, K2CO3, EGME/H2O, rt, 15 h, 84%; (e) RNCO, DMAP, MeCN, rt, 15 h, 38-99%; (f) 6M HCl, THF, rt, 2 d, 26-73%; (g) ZrCl4, NaBH4, THF, rt, 2 h, 96%; (h) n-hexyl-NCO, DMAP, MeCN, rt, 15 h, 73%.

The intermediate 8 was prepared in four steps, starting from the acid 4, obtained as previously described. [62] Compound 4 was converted to the corresponding methyl ester 5, under standard acidic conditions, to afford, after catalytic hydrogenation with ammonium formate in the presence of Pd/C, the resulting aniline 6. Compound 6 was then transformed into the corresponding diazonium salt, that was reacted in situ with NaI to obtain the phenyl iodide 7 in good yield, which was converted, under ligand less Suzuki cross coupling conditions, [63] to the biphenyl derivatives 8 and 13a-c in excellent yield (Schemes 1-3).

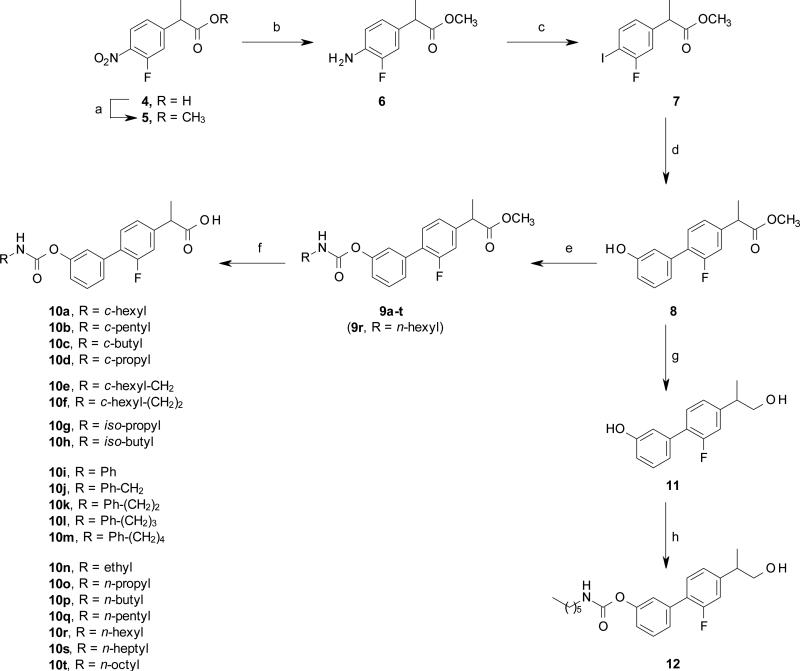

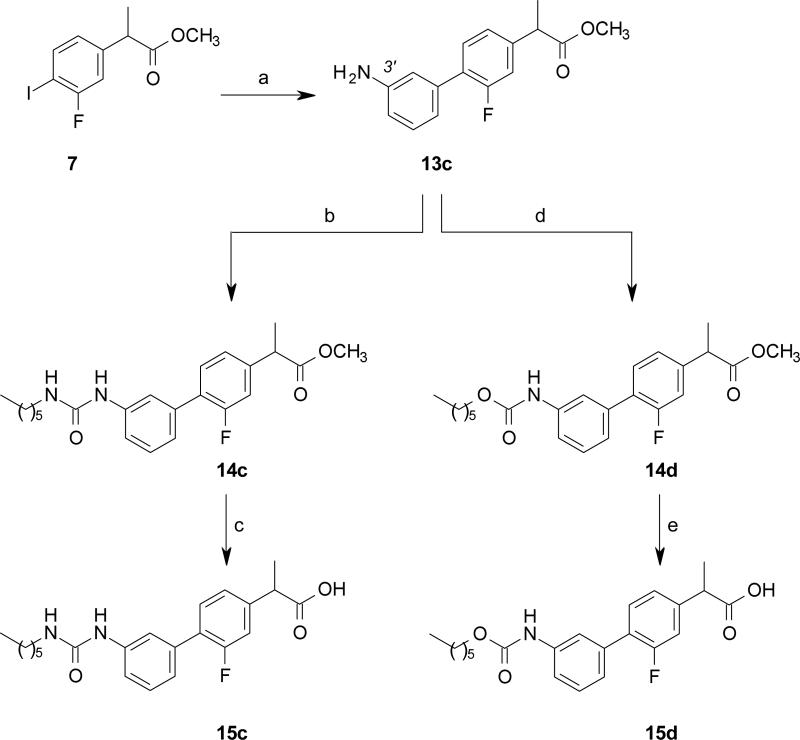

Scheme 3.

Synthesis of compounds 15c-d. Reagents and conditions: (a) (3-aminophenyl)boronic acid, Pd(OAc)2, K2CO3, EGME/H2O, rt, 15 h, 91%; (b) n-hexyl-NCO, DMAP, MeCN, rt, 15 h, 65%; (c) 6M HCl, THF, rt, 2 d, 38%; (d) triphosgene, toluene, reflux, 15 h, then n-hexanol, rt, 15 h, 82%; (e) 6M HCl, THF, rt, 2 d, 59%.

3-Hydroxypropyl derivative 12 was synthesized by reduction of the methyl ester 8 to the alcohol 11 (Scheme 1). Although lithium aluminum hydride succeeded in reducing the ester 8, a significant des-fluorinated side product was observed and separation of the two compounds was troublesome. Therefore, a milder reducing agent, such as zirconium borohydride generated in situ, was used to afford a clean conversion of 8 to 11, [64] which was then converted to 12 under standard carbamoylation reaction conditions (Scheme 1).

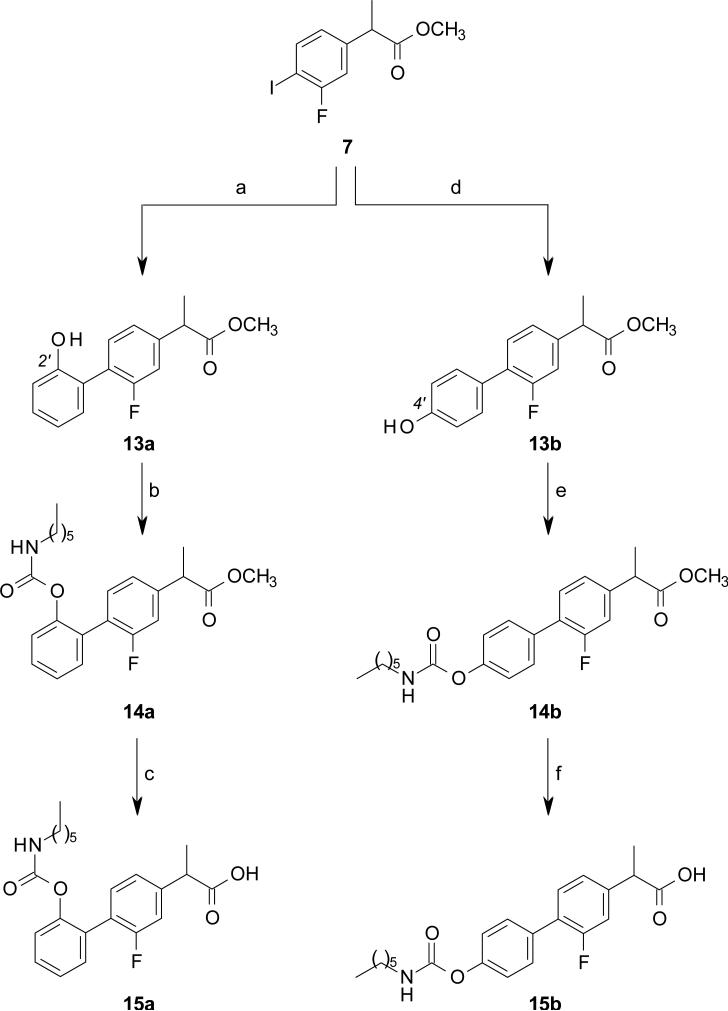

Carbamates 15a-b and urea 15c were prepared from the corresponding phenols 13a-b and aniline 13c, respectively, through a carbamoylation reaction using n-hexyl-isocyanate, followed by acidic hydrolysis of the methyl esters 14a-c (Scheme 2 and 3). The reverse carbamate 15d was prepared upon activation of the aniline 13c with triphosgene, and, then, reaction with n-hexanol, followed by acidic hydrolysis of the methyl ester 14d (Scheme 3).

Scheme 2.

Synthesis of compounds 15a-b. Reagents and conditions: (a) (2-hydroxyphenyl)boronic acid, Pd(OAc)2, K2CO3, EGME/H2O, rt, 15 h, 84%; (b) n-hexyl-NCO, DMAP, MeCN, rt, 15 h, 88%; (c) 6M HCl, THF, rt, 2 d, 90%; (d) (4-hydroxyphenyl)boronic acid, Pd(OAc)2, K2CO3, EGME/H2O, rt, 15 h, 59%; (e) n-hexyl-NCO, DMAP, MeCN, rt, 15 h, 72%; (f) 6M HCl, THF, rt, 2 d, 46%.

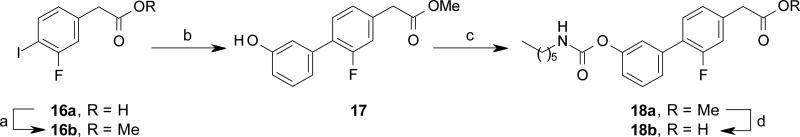

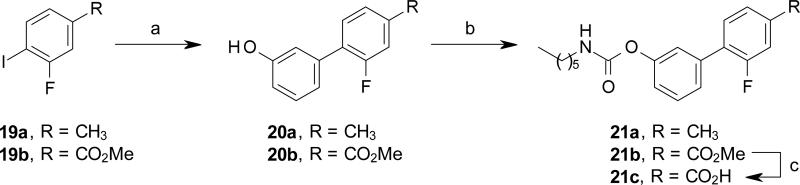

Compounds 18a and 21a-b were synthetized by reacting the phenyl iodides 16b and 19a-b, with (3-hydroxyphenyl)boronic acid under Suzuki cross coupling conditions, followed by carbamoylation reaction of phenols 17 and 20a-b under standard conditions (Scheme 4 and 5).

Scheme 4.

Synthesis of compound 18b. Reagents and conditions: (a) MeOH, conc. H2SO4, rt, 15 h, quant.; (b) (3-hydroxyphenyl)boronic acid, Pd(OAc)2, K2CO3, EGME/H2O, rt, 15 h, 71%; (c) n-hexyl-NCO, DMAP, MeCN, rt, 15 h, 64%; (d) 6M HCl, THF, rt, 2 d, 62%.

Scheme 5.

Synthesis of compound 21a and 21c. Reagents and conditions: (a) (3-hydroxyphenyl)boronic acid, Pd(OAc)2, K2CO3, EGME/H2O, rt, 15 h, 86-92%; (c) n-hexyl-NCO, DMAP, MeCN, rt, 15 h, 86%-quant.; (d) 6M HCl, THF, rt, 2 d, 34%.

Compounds 18a and 21b were then transformed into the corresponding acids 18b and 21c under standard acidic hydrolysis (Scheme 4 and 5).

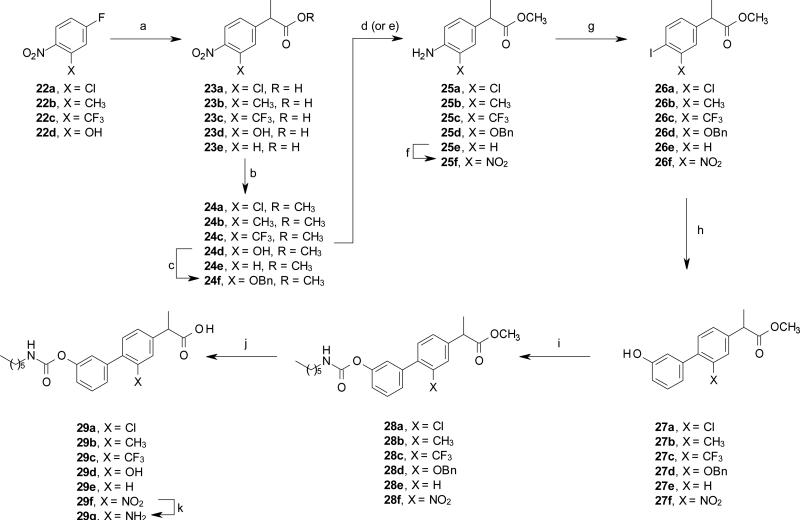

Compounds 29a-g were synthesized following the synthetic sequence described in Scheme 6. p-Nitrofluorobenzenes 22a-d were reacted with diethylmethylmalonate followed by decarboxylation to the corresponding acids 23a-d. 23a-d and the commercially available 23e were converted into methyl esters 24a-e in acidic MeOH. In addition, the phenolic intermediate 24d was directly converted into the corresponding O-Bn protected 24f, under standard reaction conditions.

Scheme 6.

Synthesis of compounds 29a-g. Reagents and conditions: (a) diethyl methylmalonate, NaOH, DMF, rt, 15 h; then AcOH, H2SO4, H2O 110 °C, 24 h, 48-87%; (b) MeOH, conc. H2SO4, rt, overnight, 81-98%; (c) BnBr, K2CO3, acetone, 60 °C, 15 h, 63%; (d) Fe, HCl, MeOH, 65 °C, 2 h, 64-94%, for 24a and 24f; (e) HCO2NH4, 10% Pd/C, MeOH, rt, 3 h, quant., for 24b-c, and 24e; (f) Ac2O, HNO3 0 °C, 2 h then H2SO4, MeOH, 65 °C, 2 h, 98%; (g) NaNO2, 3M HCl, 0 °C, 30 min, then NaI, 60 °C, 2 h, 55-72%; (h) (3-hydroxyphenyl)boronic acid, Pd(OAc)2, K2CO3, EGME/H2O, rt, 15 h, 59-84%; (i) n-hexyl-NCO, DMAP, MeCN, rt, 15 h, 89%-quant.; (j) 2M HCl, dioxane, 80 °C, 15 h, 73-95%; (k) cyclohexene, 10% Pd/C 80 °C, 2 h then 2M HCl, 55%.

Reduction of the nitro group was carried out using iron in presence of HCl for compounds 24a and 24f, and ammonium formate in the presence of Pd/C for compounds 24b-c and 24e. Compound 25f was obtained from 25e by standard nitration reaction. Diazotation/Sandmayer reaction of the anilines 25a-f gave the iodides 26a-f, which were converted to carbamates 28a-f via Suzuki and carbamoylation reactions. Compounds 28a-f were then transformed into the corresponding acids 29a-f under standard acidic hydrolysis. Finally, the aniline 29g was obtained from the nitrophenyl 29f, under standard hydrogenation conditions.

2.2. SAR exploration of the first class of potent multi-target FAAH-COX inhibitors

2.2.1 Rational drug design: merging strategy and identification of hit 10a

We started our SAR exploration with compound 10a, [51] which was designed by merging essential pharmacophores of the FAAH inhibitor, URB597, 2, and those of the NSAID, flurbiprofen, 3a (Figure 1). The inhibitory potencies of 2, 3a and 10a against rat brain FAAH, ovine testis COX-1 and human recombinant COX-2 are reported in Table 1.

Table 1.

SAR exploration on the nature of R group: cycloalkanes, small-branched alkanes and phenyls.

| ||||

|---|---|---|---|---|

| Compound | R | FAAHa,b IC50(μM)±SD | COX-1a,b IC50 (μM)±SD | COX-2a,b IC50 (μM)±SD |

| 2, URB597 | - | 0.0017±0.001 | >100 | >100 |

| 3a, flurbiprofen | - | >100 | 0.15±0.018 | 1.06±0.53 |

| 10a | c-hexyl | 8.2±2.4 | 7.9±2.1 | >100 |

| 10b | c-pentyl | 4.8±3.2 | 4.4±2.0 | > 100 |

| 10c | c-butyl | 48.7±9.0 | 0.72±0.02 | >100 |

| 10d | c-propyl | >100 | 5.4±2.9 | 74.3±6.1 |

| 10e | c-hexyl-CH2 | 0.36±0.06 | 0.60±0.04 | >100 |

| 10f | c-hexyl-(CH2)2 | 0.018±0.007 | 0.15±0.03 | 10.8±2.2 |

| 10g | iso-propyl | >100 | 3.9±2.1 | >100 |

| 10h | iso-butyl | 4.1±2.1 | 8.2±2.1 | >100 |

| 10i | Ph | 41.2±3.4 | 0.27±0.07 | 2.7±0.3 |

| 10j | Ph-CH2 | 4.18±2.8 | 1.3±0.6 | >100 |

| 10k | Ph-(CH2)2 | 0.17±0.07 | 6.3±2.2 | >100 |

| 10l | Ph-(CH2)3 | 0.09±0.01 | 0.58±0.09 | 6.2±0.3 |

| 10m | Ph-(CH2)4 | 0.027±0.010 | 3.7±2.8 | >100 |

Values are reported as mean values of ≥3 experiments performed

IC50 values were not determined for compounds showing less than 50% inhibition at concentrations of 100 μM for FAAH and COXs.

Compound 10a inhibited FAAH and COX activities with relatively weak potencies (IC50 values, in μM: FAAH = 8.2; COX-1 = 7.9; COX-2 > 100). Nevertheless, these initial results encouraged us because 10a was one of the most potent FAAH/COX-1 inhibitors previously reported. [27, 28, 30, 32, 33, 65]

We started, therefore, an SAR exploration around 10a with the objective of identifying chemical and structural determinants that might improve potency on the three targets in a balanced manner.

2.2.2. Study of the effect of the nature of R group: cycloalkanes, small-branched alkanes and phenyls

We prepared a series of analogs bearing cycloalkyl groups with different ring size at the N-terminal of the carbamate functionality (Table 1).

We observed that, while the potency against FAAH was retained with the c-pentyl analog 10b (IC50=4.8 μM), a 10-fold loss in potency occurred with the c-butyl derivative 10c (IC50=48.7 μM) and complete loss of activity (IC50>100 μM) with the c-propyl derivative 10d. With regard to COX activity, while the c-pentyl analog 10b showed a comparable potency against COX-1 (IC50=4.4 μM), the c-butyl analog 10c was 10-fold more potent than compound 10a (IC50=0.72 μM). Conversely, the c-propyl analog 10d displayed an IC50 value similar to compounds 10a and 10b against COX-1 (=5.4 μM) and was indeed the only compound in this series that showed modest activity against COX-2 (IC50=74.3 μM).

The N-terminal region of the carbamate functionality in 10a may engage in beneficial interactions with the acyl chain-binding domain of FAAH [26], [56, 57] as well as the hydrophobic channels present in COX-1 and COX-2. [6] [61] To capture such interactions, we prepared a series of analogs bearing lipophilic aliphatic and aromatic N-terminal substituents with diverse steric properties (Table 1).

The insertion of a methylene group adjacent to the c-hexyl ring of 10a - compound 10e- led to a significant increase of potency toward FAAH (23-fold) and COX-1 (10-fold), but no COX-2 inhibition (IC50>100 μM). A further homologation, compound 10f, showed a 400-fold increase in potency toward FAAH and a 50-fold increase in potency toward COX-1, compared to 10a. Interestingly, 10f also inhibited COX-2 with an IC50 of 10.8 μM.

Next, we investigated the effects of small and branched alkyl groups, the iso-propyl 10g and the iso-butyl 10h - as truncated analogs of 10a and 10e, respectively. These modifications were detrimental for FAAH and COX inhibitory activities compared to 10a and 10e, respectively.

While the replacement of the c-hexyl ring with a phenyl group (10i) was not tolerated by FAAH, in analogy to previous reports on the class of O-aryl carbamates, [56, 57] this modification led to a gain in inhibitory activity toward COX-1 and COX-2. The insertion of a methylene group adjacent to the phenyl ring of 10i - compound 10j- caused a 10-fold increase in potency toward FAAH, compared to 10i, but had almost no impact on COX-1 activity and dramatic loss on COX-2. Homologation (10k-m) resulted in a progressive enhancement of the inhibitory potency toward FAAH, but this trend was more erratic for COX-1 and COX-2: compound 10l was most active analog with IC50 = 0.58 μM and 6.2 μM against COX-1 and COX-2, respectively.

These findings might reflect differences in the depth of lipophilic pockets of FAAH and COX enzymes. [6, 26]

2.2.3. Study of the effect of the nature of the R group: linear alkanes. Identification of 10r (ARN2508)

Since the (CH2)n homologation at the N-terminal site appeared to be critical for the modulation of the biological activities at both targets, we prepared a series of carbamates bearing linear alkyl groups (alkyl = (CH3(CH2)n) with n= 1 to 7) at N- terminal region (Table 2).

Table 2.

SAR exploration on the nature of the R group: linear alkanes

| ||||

|---|---|---|---|---|

| Compound | R | FAAHa,b IC50(μM)±SD | COX-1a,b IC50 (μM)±SD | COX-2a,b IC50 (μM)±SD |

| 10n | ethyl | >100 | 2.1±0.9 | >100 |

| 10o | n-propyl | >100 | 1.65±0.06 | >100 |

| 10p | n-butyl | 7.0±1.8 | 0.26±0.07 | >100 |

| 10q | n-pentyl | 0.57±0.15 | 0.020±0.009 | 0.16±0.02 |

| 10r, ARN2508 | n-hexyl | 0.031±0.002 | 0.012±0.002 | 0.43±0.02 |

| 10s | n-heptyl | 0.011±0.003 | 0.37±0.10 | 0.32±0.005 |

| 10t | n-octyl | 0.003±0.002 | 0.99±0.07 | 28.8±8.4 |

Values are reported as mean values of ≥3 experiments performed

IC50 values were not determined for compounds showing less than 50% inhibition at concentrations of 100 μM for FAAH and COXs.

In analogy to the reported SAR results on the class of O-aryl carbamates, [56] potency toward FAAH increased with increased length of the (CH2)n chain (n = 1-7). A different trend was observed for COX-1 and COX-2, where insertion of short (CH2)n chains (n = 1-2) led to compounds (10n-o) that were weak COX-1 inhibitors and had no activity against COX-2. On the other hand, insertion of n = 3-5 (CH2)n chains (10p-r) increased the inhibitory potencies for COX-1 and COX-2 from sub-micromolar to nano-molar IC50, whereas insertion of n = 6-7 (CH2)n chains (10s-t) was detrimental.

These results are in agreement with those above reported in the homologation of the Ph(CH2)n chain series (n = 1-4, compounds 10i-m, Table 1).

From this SAR exploration, we identified 10r (ARN2508), [51] which bears a n-hexyl chain at the N-terminal site, as a potent multi-target inhibitor of FAAH, COX-1 and COX-2 (IC50: FAAH = 31 nM; COX-1 = 12 nM; COX-2 = 430 nM) (Table 2). In addition to its high balanced potency, the highest reported thus far, [27, 28, 30, 32, 33, 65] we found that 10r displays no off-target activities on a panel of >90 biologically relevant targets, and effectively engages its intended targets after oral administration in mice. [51]

These results encouraged us to initiate a more focused SAR exploration to define the effect of additional chemical and structural modifications in various regions of 10r scaffold.

2.2.4. Focused SAR exploration around 10r (ARN2508) and identification of 18b, 29a-c, e and (S)-(+)-10r

In particular, we focused our interest on the role and position of carbamate group in the A phenyl ring (Table 3 and Table 4), as well as the role of the propionic acid functionality and the fluorine atom in the B phenyl ring (Table 5 and Table 6).

Table 3.

Effect of the position of the carbamate functionality on the A phenyl ring.

| ||||

|---|---|---|---|---|

| Compound | position | FAAHa,b IC50 (μM) ±SD | COX-1a,b IC50 (μM) ±SD | COX-2a,b IC50 (μM) ±SD |

| 15a | C(2’) | 2.2±0.6 | 0.72±0.04 | >100 |

| 15b | C(4’) | 0.068±0.012 | >100 | >100 |

Values are reported as mean values of ≥3 experiments performed

IC50 values were not determined for compounds showing less than 50% inhibition at concentrations of 100 μM for FAAH and COXs.

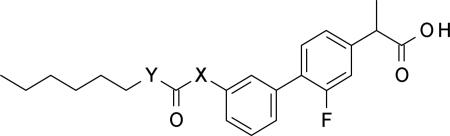

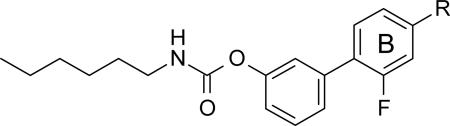

Table 4.

Carbamate replacement: urea and reversed carbamate derivatives

| |||||

|---|---|---|---|---|---|

| Compound | Y | X | FAAHa IC50 (μM) ±SD | COX-1a IC50 (μM) ±SD | COX-2a IC50 (μM) ±SD |

| 15c | NH | NH | 88.4±2.3 | 0.014±0.003 | 0.56±0.12 |

| 15d | O | NH | 14.9±1.6 | 0.03±0.01 | 0.17±0.01 |

Values are reported as mean values of ≥3 experiments performed.

Table 5.

SAR exploration on the R group: role of the propionic acid functionality on the B phenyl ring

| ||||

|---|---|---|---|---|

| Compound | R | FAAHa,b IC50 (μM) ±SD | COX-1a,b IC50 (μM) ±SD | COX-2a,b IC50 (μM) ±SD |

| 9r | CH(CH3)CO2CH3 | 0.052±0.010 | >100 | >100 |

| 12 | CH(CH3)CH2OH | 0.003±0.002 | 1.1±0.3 | >100 |

| 18b | CH2CO2H | 0.063±0.010 | 2.1±0.1 | 0.24±0.04 |

| 21a | CH3 | 0.026±0.09 | >100 | >100 |

| 21c | CO2H | 0.085±0.006 | >100 | >100 |

Values are reported as mean values of ≥3 experiments performed

IC50 values were not determined for compounds showing less than 50% inhibition at concentrations of 100 μM for FAAH and COXs.

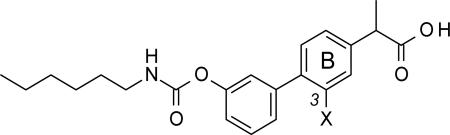

Table 6.

SAR exploration on the role of the X substituent on the B phenyl ring

| ||||

|---|---|---|---|---|

| Compound | X | FAAHa IC50(μM)±SD | COX-1a IC50 (μM)±SD | COX-2a IC50 (μM)±SD |

| 29a | Cl | 0.023±0.008 | 0.009±0.001 | 0.73±0.21 |

| 29b | CH3 | 0.010±0.001 | 0.011±0.001 | 1.40±0.31 |

| 29c | CF3 | 0.005± 0.001 | 0.01±0.003 | 0.2±0.08 |

| 29d | OH | 0.035±0.010 | 0.65±0.07 | 13.0 ±2.1 |

| 29e | H | 0.003±0.001 | 0.054±0.011 | 0.69±0.02 |

| 29f | NO2 | 0.009±0.002 | 0.13±0.03 | 0.930±0.15 |

| 29g | NH2 | 0.049±0.023 | 0.22±0.09 | 12.1±0.6 |

Values are reported as mean values of ≥3 experiments performed.

2.2.4.1. Role and position of carbamate group in the A phenyl ring

We first investigated the effect of the position of the carbamate group in the A phenyl ring, which indeed appeared to play an important role in the inhibition of both FAAH and COX (Table 3). In agreement with the rational design of our hybrid scaffold 1 (Figure 1), the C(2’)-derivative 15a (ortho derivative) showed a 70-fold decrease in potency toward FAAH, a 60-fold decrease in potency toward COX-1, and a complete loss of activity toward COX-2, when compared to the C(3’)-isomer 10r (meta derivative) (Table 3).

On the other hand, the C(4’)-derivative 15b (para derivative) exhibited a slight loss of potency toward FAAH compared to 10r, but both COX inhibitions were completely suppressed (Table 3). These results support the hypothesis that the bent shape of the O-biphenyl moieties, which is known to better fit the FAAH enzyme surface, [53] is also important in the recognition by COX-1 and COX-2, possibly through a better superimposition to the conformations adopted by the fatty acyl chain of the natural substrate/product (the first two cis-double bonds of AA) when bound to COX-1 [66] and COX-2 [67].

Next, we replaced the carbamate moiety with alternative functional groups, such as urea (15c) [51] and reversed carbamate (15d) [51] (Table 4).

As expected from the rational design of our class of multitarget inhibitors, 15c and 15d showed a significant decrease in potency toward FAAH, whilst retaining COX-1 and COX-2 inhibitory activities compared to 10r.

These results support the hypothesis that the mechanism of action of this class of compounds is similar to the one reported for the O-aryl carbamates (acylation of FAAH Ser 241) [57] and that COX inhibition does not rely on any irreversible binding mode at the expense of the carbamate group of 10r. Reported dialysis experiments on 10r are in agreement with this mechanistic speculation. [51]

2.2.4.2. Role of the propionic acid functionality in the B phenyl ring

We then turned our attention to the role of the propionic acid in the B phenyl ring (Table 5). Replacing the propionic acid group of 10r with several substituents had only a minor impact on the potency toward FAAH, compared to the effect observed on COX activities. In fact, methyl ester 9r retained FAAH inhibitory activity, compared to 10r, but completely lost activity toward both COX-1 and COX-2. Replacement of the carboxylic acid of 10r with the corresponding primary alcohol 12 resulted in a 10-fold improvement in potency toward FAAH (IC50=3 nM), a 100-fold loss in potency toward COX-1 (IC50=1.1 μM) and in a complete loss of activity toward COX-2.

On the other hand, the removal of the α-methyl group, as in the achiral des-methylated derivative 18b, caused a 2-fold decrease of the potency toward FAAH, compared to 10r (IC50 = 63 nM and 31 nM, respectively), and a 180-fold reduction of potency toward COX-1 (IC50 = 2.1 μM and 12 nM, respectively). The activity against COX-2 was slightly improved (IC50 = 0.24 μM and 0.43 μM respectively). The methyl analog 21a [51] was active against FAAH in the same potency range of 10r (IC50 = 26 nM and 31 nM, respectively), while a completely loss of activity against COX enzymes was observed. A similar result was obtained with the carboxylic analog 21c, which also showed a 3-fold reduction in potency toward FAAH, compared to 10r (IC50 = 85 nM and 31 nM, respectively).

We conclude that FAAH tolerates substituents with different steric and electronic properties at the 4-position of the B phenyl ring, while COX-1 and COX-2 display a stringent requirement for a propionic or acetic acid groups in the same position.

2.2.4.3. Role of the fluorine atom in the B phenyl ring

To complete the SAR exploration of the B phenyl ring, we evaluated the effect of substituents with different electronic and steric properties, alternative to the fluorine atom (Table 6).

Substituting the fluorine with chlorine was tolerated: indeed, 29a was virtually equipotent against FAAH and COX-1, and marginally less potent on COX-2, compared to 10r. The same trend was observed with the methyl derivative 29b, which was slightly more potent than 10r against FAAH and equally potent on COX-1, but less active against COX-2. The CF3 derivative 29c showed a 6-fold and 2-fold increase in potency toward FAAH and COX-2, respectively, and was as potent as 10r on COX-1.

Removal of the fluorine atom (29e) resulted in a 10-fold increase in potency toward FAAH, compared to 10r, and a slight decrease in activity for COX-1 and COX-2.

Compounds 29d and 29g, which bear −OH or −NH2 groups, respectively, inhibited FAAH with potencies similar to that of 10r, whereas a clear loss in potency for both COX-1 and COX-2 was observed. On the other hand, the NO2 derivative 29f had higher potency toward FAAH but loss lower potency toward both COX-1 and COX-2. We interpret these results to suggest that the electronic and steric properties of the substituents in the 3-position of the B phenyl ring affect FAAH recognition only slightly, whereas these same substituents influence COX-1 and COX-2 more markedly, with lipophilic groups being better tolerated than polar or H-bond donator groups.

2.2.4.4. Stereochemical and pharmacological studies of 10r enantiomers

Finally, we subjected the best studied member of this class of inhibitors, the racemic compound 10r, [51] to chiral HPLC separation and tested each of its enantiomers – (−)-10r (first eluted) and (+)-10r (second eluted) – for the ability to inhibit FAAH, COX-1 and COX-2 (Table 7). FAAH showed no preference for either enantiomer, with each being more active than the racemate 10r. By contrast, in analogy to prior studies on different classes of FAAH/COX inhibitors, [30, 33] substantial differences were observed on COX-1 and COX-2. Compound (+)-10r was highly potent on both COX-1 (IC50=0.29 nM) and COX-2 (IC50=50 nM), whereas (−)-10r was weakly active on either target.

Table 7.

Evaluation of the enantiomers of 10r

| Compound | r-FAAHa IC50(μM) ±SD | COX-1a IC50 (μM) ±SD | COX-2a IC50 (μM) ±SD |

|---|---|---|---|

| (±)-10r | 0.031±0.002 | 0.012±0.002 | 0.43±0.02 |

| (−)-10rb | 0.0099±0.002 | 4.0±1.3 | 22.8±8.7 |

| (+)-10rc | 0.0094±0.0003 | 0.00029±0.00004 | 0.050±0.012 |

Values are reported as mean values of ≥3 experiments performed

(R)- configurated enantiomer of 10r (see Supporting Information for details)

(S)-configurated enantiomer of 10r (see Supporting Information for details).

We completed our exploration on the two enantiomers of 10r by assigning their absolute stereo-configurations. As reported in Supporting Information (Scheme S1), a stereochemical correlation study allowed us unambiguously to assign the absolute stereochemistry of (−)-10r and (+)-10r to the (R)- and (S)- configurations, respectively. These results are in agreement with earlier reports showing that the (S)-enantiomer is responsible for the COX-inhibiting activity of aryl-propionic acid derivatives such as flurbiprofen. [29, 31, 33, 59]

2.2.4.5. In vivo experiments on (S)-(+)-10r

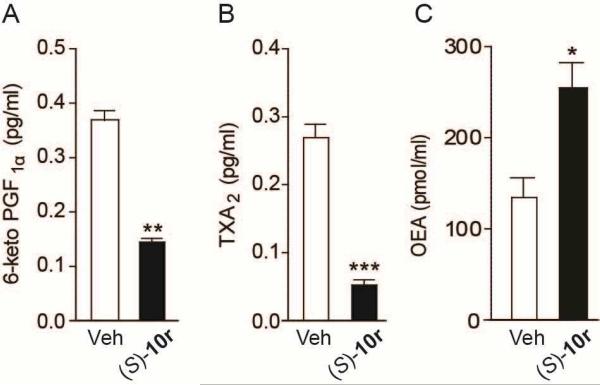

Finally, pharmacological experiments indicate that compound (S)-(+)-10r strongly engages its intended molecular targets in live mice. Intravenous administration of (S)-(+)-10r (1 mg/kg) lowered the concentrations of two COX products in circulation, prostacyclin and TXA2, as assessed surveying the stable metabolites, 6-keto-PGF1α and TXB2 (Figure 2A and 2B). Moreover, (S)-(+)-10r increased plasma levels of the FAAH substrate, OEA (Figure 2C). In addition, (S)-(+)-10r demonstrated no off-target activities on a panel of >90 biologically relevant receptors, enzymes [including N-acylethanolamine amide hydrolase (NAAA), which is the primary enzyme involved in the deactivation of PEA and OEA in innate immune cells] and ion channels (Table S1). Further pharmacological studies on the (R)- and (S)- series of this class of inhibitors will be reported in due course.

Figure 2.

Plasma levels of COX metabolites and FAAH substrate after intravenous administration of (S)-(+)-10r (1 mg/kg): 6-keto-PGF1α (A) TXA2 (B) and OEA (C). Results are expressed as mean ± s.e.m. of 6 independent determinations. *P<0.05, **P<0.01 and ***P<0.001 compared to vehicle mice, two-tailed Student's t test.

3. Conclusions

The present study outlines key SAR properties of a novel class of dual inhibitors of intracellular FAAH and COX activities, which are based on the hybrid scaffold 1. Several chemical variations of this scaffold were considered, which involved the carbamate moiety at the 3’-position of the A phenyl ring, the R groups, and the propionic acid moiety and fluorine atom in the B phenyl ring. Introduction of different alkyl and aromatic groups in the N-terminal region of the carbamate functionality improved inhibitory potency toward both FAAH and COX. A more focused exploration around the potent, selective and orally available racemic inhibitor 10r [51] led to the identification of novel potent analogs, 29a-c, and e. Because of the problems associated with the development of racemic compounds, we extended our studies and identified two additional molecules, the achiral compound 18b and the enantiomer (S)-(+)-10r, which also display high inhibitory potency for FAAH/COX-1/COX-2.

The in vivo activity of (S)-(+)-10r suggests that this agent may be used to probe the therapeutic utility of simultaneous FAAH-COX inhibition, especially in pathologies in which these enzymes are abnormally expressed.

4. Experimental part

4.1. Synthesis

Solvents and reagents were obtained from commercial suppliers and were used without further purification. URB597 was prepared following a reported procedure. [54] Flurbiprofen was purchased from Sigma-Aldrich (Milan, Italy). Melting points were determined on a Büchi M-560 capillary melting point apparatus and are uncorrected. Automated column chromatography purifications were done using a Teledyne ISCO apparatus (CombiFlash® Rf) with pre-packed silica gel columns of different sizes (from 4 g until 120 g). Mixtures of increasing polarity of Cy and EtOAc or DCM and MeOH were used as eluents. Preparative TLC analyses were performed using Macherey-Nagel pre-coated 0.05 mm TLC plates (SIL G-50 UV254). 1H and 13C-NMR experiments were run on a Bruker Avance III 400 system (400.13 MHz for 1H, and 100.62 MHz for 13C), equipped with a BBI probe and Z-gradient coil. 19F-NMR experiments were run on a Bruker Avance III 600 system (546.6 MHz for 19F), equipped with a 5 mm CryoProbe QCI 1H/19F–13C/15N–D quadruple resonance and a Z-gradient coil. Spectra were acquired at 300 K, using deuterated dimethylsulfoxide (DMSO-d6) or deuterated chloroform (CDCl3) as solvents. Chemical shifts for 1H and 13C spectra were recorded in parts per million using the residual non-deuterated solvent as the internal standard (for DMSO-d6: 2.50 ppm, 1H; 39.52 ppm, 13C; for CDCl3: 7.26 ppm, 1H and 77.16 ppm, 13C). Data are reported as follows: chemical shift (ppm), multiplicity (indicated as: bs, broad signal; s, singlet; d, doublet; t, triplet; q, quartet; p, quintet, sx, sextet; m, multiplet and combinations thereof), coupling constants (J) in Hertz (Hz) and integrated intensity. UPLC/MS analyses were run on a Waters ACQUITY UPLC/MS system consisting of a SQD (Single Quadropole Detector) Mass Spectrometer equipped with an Electrospray Ionization interface and a Photodiode Array Detector. PDA range was 210-400 nm. Analyses were performed on an ACQUITY UPLC BEH C18 column (50×2.1 mmID, particle size 1.7 μm) with a VanGuard BEH C18 pre-column (5×2.1 mmID, particle size 1.7 μm). Mobile phase was either 10 mM NH4OAc in H2O at pH 5 adjusted with AcOH (A) and 10 mM NH4OAc in MeCN-H2O (95:5) at pH 5 (B). Electrospray ionization in positive and negative mode was applied. Analyses were performed with method A or B. Method A for compounds 10a-t, 15a-d, 18b, 21c and 29b-g: Gradient: 5 to 95% B over 3 min. Flow rate 0.5 mL/min. Temperature 40 °C. Method B for compounds 9r, 12, 21a and 29a: Gradient: 50 to 100% B over 3 min. Flow rate 0.5 mL/min. Temperature 40 °C. Purifications by preparative HPLC/MS were run on a Waters Autopurification system consisting of a 3100 Single Quadropole Mass Spectrometer equipped with an Electrospray Ionization interface and a 2998 Photodiode Array Detector. HPLC system included a 2747 Sample Manager, 2545 Binary Gradient Module, System Fluidic Organizer and 515 HPLC Pump. PDA range was 210-400 nm. Purifications were performed on a XBridgeTM Prep C18 OBD column (100× 19 mmID, particle size 5 μm) with a XBridgeTM Prep C18 (10× 19 mmID, particle size 5 μm) Guard Cartridge. Mobile phase was 10 mM NH4OAc in H2O at pH 5 adjusted with AcOH (A) and 10 mM NH4OAc in MeCN-H2O (95:5) at pH 5 (B). Electrospray ionization in positive and negative mode was used. Analyses by chiral HPLC were run on a Waters Alliance HPLC instrument consisting of an e2695 Separation Module and a 2998 Photodiode Array Detector. PDA range was 210-400 nm. Analyses were performed isocratic on a Daicel ChiralPak AD column (250×4.6 mmID, particle size 10 μm). Mobile phase was 0.1 % TFA Heptane/2-Propanol (75:25). Separations of 10r by preparative chiral HPLC were run on a Waters Alliance HPLC instrument consisting of a 1525 Binary HPLC Pump, Waters Fraction Collector III and a 2998 Photodiode Array Detector. UV detection was at 240 nm. Purifications were performed isocratic on a Daicel ChiralPak AD column (250 × 10mmID, particle size 10 μm). Mobile phase was 0.1 % TFA Heptane/2-Propanol (75: 25). Optical rotations were measured on a Rudolf Research Analytical Autopol II Automatic polarimeter using a sodium lamp (589 nm) as the light source; concentrations expressed in g/100 mL using CHCl3 as a solvent and a 1 dm cell. Accurate mass measurement was performed on a Synapt G2 Quadrupole-ToF Instrument (Waters, USA), equipped with an ESI ion source; compounds were diluted to 50 μM in H2O/MeCN and analyzed. Leucine Enkephalin (2 ng/mL) was used as lock mass reference compound for spectra calibration. All final compounds displayed ≥ 95% purity as determined by NMR and UPLC/MS analysis.

All the analytical data of intermediate compounds are reported in Supporting Material.

4.1.1. (±)-2-(3-fluoro-4-nitro-phenyl)propanoic acid (4)

Compound 4 was obtained as brown clear oil (4.50 g, 81 %), according to the procedure reported in the literature starting from 2,4-difluoronitrobenzene (4.77 g, 30 mmol). [62]

4.1.2. (±)-Methyl 2-(4-nitro-3-fluoro-phenyl)propanoate (5)

To a solution of 4 (4.50 g, 21.11 mmol) in MeOH (40 mL), concentrated H2SO4 (0.1 mL) was added and the resulting solution was stirred at rt overnight. After solvent evaporation, the crude oil was diluted with Et2O (15 mL) and filtered through a pad of SiO2 to afford 5 as orange-brown oil (4.45 g, 93%).

4.1.3. (±)-Methyl 2-(4-amino-3-fluoro-phenyl)propanoate (6)

To a solution of 5 (12.60 g, 55.46 mmol) in MeOH (222 mL) was added 10% Pd/C (2.35 g, 2.22 mmol) followed by addition of HCO2NH4 (20.98 g, 332.8 mmol). The solution was stirred at rt for 3 h, then, filtered through a pad of Celite and the filtrate was concentrated under reduced pressure. The residue was dissolved in EtOAc and filtered through a pad of SiO2 to afford 6 as an orange oil (10.33 g, 94%).

4.1.4. (±)-Methyl 2-(3-fluoro-4-iodo-phenyl)propanoate (7)

A solution of NaNO2 (0.70 g, 10.21 mmol) in H2O (1.5 mL) was added slowly to a solution of 6 (1.75 g, 9.76 mmol) in a 3N HCl solution (29 mL) at 0 °C. After 30 min, NaI (1.54 g, 10.25 mmol) was added at 0 °C under stirring. The resulting mixture was slowly warmed to rt in 5 min, and then heated at 60 °C for 3 h. After cooling down to rt, the mixture was extracted with Et2O and the organic phase was then washed with a 1M solution of Na2SO3 (15 mL) and dried over Na2SO4. The residue was dissolved in EtOAc (50 mL), treated with activated carbon and then filtered through a pad of Celite. The filtrate was concentrated under reduced pressure and the yellow oil was purified by column chromatography (Cy: EtOAc, 95:5) to give 7 as a pale yellow oil (1.70 g, 55%).

4.1.5. General procedure for Suzuki cross coupling reaction (Procedure A, 8, 13a-c, 17, 20a, b, 27a-f)

To a solution of the corresponding boronic acid (1.2 mmol) in EGME/H2O (3:1, 0.25 M) were added Pd(OAc)2 (0.05 mmol) and K2CO3 (1.2 mmol), followed by the addition of the corresponding phenyl iodide (1.0 mmol). The dark reaction mixture was stirred at rt for 15 h, then diluted with EtOAc (40 mL) and filtered through a pad of Celite. The resulting filtrate was washed with H2O (20 mL) and a 1M solution of Na2SO3 (20 mL). After separation, the organic phase was dried over Na2SO4 and concentrated under reduced pressure. The residues were purified by column chromatography (Cy/EtOAc).

4.1.5.1. (±)-Methyl 2-[3-fluoro-4-(3-hydroxyphenyl)phenyl]propanoate (8)

Compound 8 was prepared according to general procedure A using 7 (3.27 g, 10.61 mmol) and 3-hydroxyphenylboronic acid (1.76 g, 12.74 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 8 as a colorless oil (2.46 g, 84%).

4.1.5.2. (±)-Methyl 2-[3-fluoro-4-(2-hydroxyphenyl)phenyl]propanoate (13a)

Compound 13a was prepared according to general method A using 7 (0.31 g, 1 mmol) and 2-hydroxyphenylboronic acid (0.17 g, 1.2 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 13a as a white oil (230 mg, 84%).

4.1.5.3. (±)-Methyl 2-[3-fluoro-4-(4-hydroxyphenyl)phenyl]propanoate (13b)

Compound 13b was prepared according to general procedure A using 7 (0.31 g, 1 mmol) and 4-hydroxyphenylboronic acid (0.17 g, 1.2 mmol). The crude was purified by column chromatography (Cy/EtOAc, 95: 5) to afford 13b as a white solid (173 mg, 59%).

4.1.5.4. (±)-Methyl 2-[4-(3-aminophenyl)-3-fluoro-phenyl]propanoate (13c)

Compound 13c was prepared according to general procedure A using 7 (0.92 g, 3 mmol) and (3-aminophenyl)boronic acid monohydrate (0.56 g, 3.6 mmol). The crude was purified by column chromatography (Cy/EtOAc, 8: 2) to afford 13c as a yellow oil (750 mg, 91%).

4.1.5.5. Methyl 2-[3-fluoro-4-(3-hydroxyphenyl)phenyl]acetate (17)

Compound 17 was prepared according to general procedure A using 16b (1.00 g, 3.50 mmol) and 3-hydroxyphenylboronic acid (0.58 g, 4.20 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 19a as white solid (0.65 g, 71%).

4.1.5.6. 3-(2-fluoro-4-methyl-phenyl)phenol (20a)

Compound 20a was prepared according to general procedure A using aryl iodide 19a (236 g, 1 mmol) and 3-hydroxyphenylboronic acid (0.17 g, 1.2 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 20a as a colorless oil (187 mg, 92 %).

4.1.5.7. Methyl 3-fluoro-4-(3-hydroxyphenyl)benzoate (20b)

Compound 20b was prepared according to general procedure A using aryl iodide 19b (1 g, 3.57 mmol) and 3-hydroxyphenylboronic acid (0.59 g, 4.29 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 20b as a white solid (0.84 g, 86 %).

4.1.5.8. (±)-Methyl 2-[3-chloro-4-(3-hydroxyphenyl)phenyl]propanoate (27a)

Compound 27a was prepared according to general procedure A using 26a (2.74 g, 8.44 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to give 27a as a white solid (1.57 g, 64%).

4.1.5.9. (±)-Methyl 2-[4-(3-hydroxyphenyl)-3-methyl-phenyl]propanoate (27b)

Compound 27b was prepared according to general procedure A using 26b (1.14 g, 3.75 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to give 27b as a colorless oil (0.72 g, 71%).

4.1.5.10. (±)-Methyl 2-[4-(3-hydroxyphenyl)-3-(trifluoromethyl)phenyl]propanoate (27c)

Compound 27c was prepared according to general procedure A using 26c (1.07 g, 3 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to give 27c as a white solid (0.78 g, 80%).

4.1.5.11. (±)-Methyl 2-[3-benzyloxy-4-(3-hydroxyphenyl)phenyl]propanoate (27d)

Compound 27d was prepared according to general procedure A using 26d (1.00 g, 2.52 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to give 27d as a clear oil (0.58 g, 63%).

4.1.5.12 (±)-Methyl 2-[4-(3-hydroxyphenyl)phenyl]propanoate (27e)

Compound 27e was prepared according to general procedure A using 26e (1.45 g, 5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 8: 2) to afford 27e as a white oil (760 mg, 59%).

4.1.5.13 (±)-Methyl 2-[4-(3-hydroxyphenyl)-3-nitro-phenyl]propanoate (27f)

Compound 27f was prepared according to general procedure A using 26f (1.76 g, 5.25 mmol). The crude was purified by column chromatography (Cy/EtOAc, 8 : 2) to give 27f as a yellow solid (1.1 g, 74%).

4.1.6. General procedure for carbamoylation reaction (Procedure B, 9a-t, 12, 14a-c, 18a, 28af)

To a solution of the corresponding phenol or aniline (1 mmol) in MeCN (0.5 M) was added DMAP (0.1 mmol) and the corresponding isocyanate (3.0 mmol). The resulting solution was stirred at rt for 15 h then the solvent was concentrated under reduced pressure. The residues were purified by column chromatography (Cy/EtOAc or DCM/MeOH).

4.1.6.1. (±)-Methyl 2-[4-[3-(cyclohexylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9a)

Compound 9a was prepared according to general procedure B using 8 (274 mg, 1 mmol) and c-hexyl isocyanate (376 mg, 3 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9a as a white solid (261 mg, 65%).

4.1.6.2. (±)-Methyl 2-[4-[3-(cyclopentylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9b)

Compound 9b was prepared according to general procedure B using 8 (274 mg, 1 mmol) and c-pentyl isocianate (333 mg, 3 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9b as a white solid (235 mg, 61%).

4.1.6.3. (±)-Methyl 2-[4-[3-(cyclobutylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9c)

Compound 9c was prepared according to general procedure B using 8 (274 mg, 1 mmol) and c-butyl isocyanate (291 mg, 3 mmol). The crude colorless oil of 9c was used in the next step without further purification.

4.1.6.4. (±)-Methyl 2-[4-[3-(cyclopropylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9d)

Compound 9d prepared according to general procedure B using 8 (274 mg, 1 mmol) and c-propyl isocyanate (250 mg, 3 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9d as a white solid (59 mg, 38%).

4.1.6.5. (±)-Methyl 2-[4-[3-(cyclohexylmethylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9e)

Compound 9e was prepared according to general procedure B using 8 (137 mg, 0.50 mmol) and c-hexyl methyl isocyanate (209 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9e as a white solid (165 mg, 80%).

4.1.6.6. (±)-Methyl 2-[4-[3-(2-cyclohexylethylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9f)

Compound 9f was prepared according to general procedure B using 8 (137 mg, 0.50 mmol) and c-hexyl ethyl isocyanate (230 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9f as a white solid (179 mg, 84%).

4.1.6.7. (±)-Methyl 2-[3-fluoro-4-[3-(isopropylcarbamoyloxy)phenyl]phenyl]propanoate (9g)

Compound 9g was prepared according to general procedure B using 8 (157 mg, 0.57 mmol) and isopropyl isocyanate (145 mg, 1.71 mmol). The crude was purified by column chromatography (Cy/EtOAc, 8: 2) to afford 9g as a white solid (159 mg, 77%).

4.1.6.8. (±)-Methyl 2-[3-fluoro-4-[3-(isobutylcarbamoyloxy)phenyl]phenyl]propanoate (9h)

Compound 9h was prepared according to general procedure B using 8 (129 mg, 0.47 mmol) and isobutyl isocyanate (140 mg, 1.41 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9h as a white solid (138 mg, 78%).

4.1.6.9. (±)-Methyl 2-[3-fluoro-4-[3-(phenylcarbamoyloxy)phenyl]phenyl]propanoate (9i)

Compound 9i was prepared according to general procedure B using 8 (137 mg, 0.5 mmol) and phenyl isocyanate (179 mg, 3 mmol) to afford 9i as a colorless oil (161 mg, 82%).

4.1.6.10. (±)-Methyl 2-[4-[3-(benzylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9j)

Compound 9j was prepared according to general procedure B using 8 (137 mg, 0.5 mmol) and benzylisocyanate (199 mg, 1.5 mmol) to afford 9j as a colorless oil which was used in the next step without further purification.

4.1.6.11. (±)-Methyl 2-[3-fluoro-4-[3-(phenethylcarbamoyloxy)phenyl]phenyl]propanoate (9k)

Compound 9k was prepared according to general procedure B using 8 (137 mg, 0.5 mmol) and phenylethyl isocyanate (221 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9k as a white solid (165 mg, 71%).

4.1.6.12. (±)-Methyl 2-[3-fluoro-4-[3-(3-phenylpropylcarbamoyloxy)phenyl]phenyl]propanoate (9l)

Compound 9l was prepared according to general procedure B using 8 (137 mg, 0.5 mmol) and phenylpropyl isocyanate (241 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9l as a white solid (174 mg, 79%).

4.1.6.13. (±)-Methyl 2-[3-fluoro-4-[3-(4-phenylbutylcarbamoyloxy)phenyl]phenyl]propanoate (9m)

Compound 9m was prepared according to general procedure B using 8 (121 mg, 0.44 mmol) and phenylbutyl isocyanate (231 mg, 1.32 mmol). The crude was purified by column chromatography (Cy/EtOAc, 8: 2) to afford 9m as a white solid (171 mg, 86%).

4.1.6.14. (±)-Methyl 2-[4-[3-(ethylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9n)

Compound 9n was prepared according to general procedure B using 8 (185 mg, 0.68 mmol) and ethyl isocyanate (145 mg, 2.04 mmol). The crude was purified by column chromatography (Cy/EtOAc, 8: 2) to afford 9n as a white solid (176 mg, 75%).

4.1.6.15. (±)-Methyl 2-[3-fluoro-4-[3-(propylcarbamoyloxy)phenyl]phenyl]propanoate (9o)

Compound 9o was prepared according to general procedure B using 8 (137 mg, 0.50 mmol) and n-propyl isocyanate (128 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9o as a white solid (87 mg, 48%).

4.1.6.16. (±)-Methyl 2-[4-[3-(butylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoate (9p)

Compound 9p was prepared according to general procedure B using 8 (137 mg, 0.50 mmol) and n-butyl isocyanate (149 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9p as a white solid (135 mg, 72%).

4.1.6.17. (±)-Methyl 2-[3-fluoro-4-[3-(pentylcarbamoyloxy)phenyl]phenyl]propanoate (9q)

Compound 9q was prepared according to general procedure B using 8 (128 mg, 0.47 mmol) and n-pentyl isocyanate (159 mg, 1.41 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1), the title compound to afford 9q as a white solid (158 mg, 87%).

4.1.6.18. (±)-Methyl 2-[3-fluoro-4-[3-(hexylcarbamoyloxy)phenyl]phenyl]propanoate (9r)

Compound 9r was prepared according to general procedure B using 8 (137 mg, 0.5 mmol) and n hexyl isocyanate (191 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9r as a white solid (170 mg, 85%). Mp: 89-91 °C. 1H NMR (400 MHz, DMSO-d6) δ 7.77 (t, J = 5.6 Hz, 1H, NH), 7.50 (t, J = 8.2 Hz, 1H, H-5), 7.47 (t, J = 7.9 Hz, 1H, h-11), 7.37 (d, J = 7.2 Hz, 1H, H-10), 7.24 (m, 3H, H-2 H-6 H-8), 7.13 (dd, J = 8.0, 1.4 Hz, 1H, H-12), 3.91 (q, J = 7.1 Hz, 1H, CH), 3.62 (s, 3H, OCH3), 3.06 (q, J = 6.7 Hz, 2H, R-H-1’), 1.48 (p, J = 6.22 Hz, 2H, R-H-2’), 1.43 (d, J = 7.2 Hz, 3H, CH3), 1.28 (m, 6H, R-H-3’ R-H-4’ R-H-5’), 0.87 (t, J = 6.9 Hz, 3H, R-H-6’). 13C NMR (101 MHz, DMSO-d6) δ 173.74 (COOH), 158.82 (d, J = 246.7 Hz, C-3), 154.17 (C-9), 151.21 (HNCOO), 142.75 (d, J = 7.8 Hz, C-7), 135.82 (C-1), 130.76 (d, J = 3.5 Hz, C-5), 129.42 (C-11), 125.98 (d, J = 13.0 Hz, C-4), 125.20 (C-10), 124.02 (C-6), 121.86 (C-8), 121.20 (C-12), 115.20 (d, J = 23.4 Hz, C-2), 51.95 (OCH3), 43.77 (CH), 40.45 (R-C-1’), 30.91 (R-C-4’), 29.12 (R-C-2’), 25.88 (R-C-3’), 22.02 (R-C-5’), 18.28 (CH3), 13.87 (R-C-6’). 19F NMR (564 MHz, DMSO-d6): δ 117.0. UPLC/MS analysis: Rt 2.00 min. MS (ES) C23H28FNO4 requires: 401, found 402 [M+H]+. HRMS C23H29NO4F [M+H]+: calculated 402.2081 measured 402.2087 Δppm 1.5.

4.1.6.19 (±)-Methyl 2-[3-fluoro-4-[3-(heptylcarbamoyloxy)phenyl]phenyl]propanoate (9s)

Compound 9s was prepared according to general procedure B using 8 (137 mg, 0.50 mmol) and n-heptyl isocyanate (212 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9s as a white solid (171 mg, 82%).

4.1.6.20. (±)-Methyl 2-[3-fluoro-4-[3-(octylcarbamoyloxy)phenyl]phenyl]propanoate (9t)

Compound 9t was prepared according to general procedure B using 8 (109 mg, 0.40 mmol) and n-octyl isocyanate (186 mg, 1.2 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 9t as a white solid (171 mg, 99%).

4.1.6.21. (±)-[3-[2-fluoro-4-(2-hydroxy-1-methyl-ethyl)phenyl]phenyl] N-hexylcarbamate (12)

Compound 12 was prepared according to general procedure B using 11 (123 mg, 0.50 mmol) and n-hexyl isocyanate (127 mg, 1 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 12 as a colorless oil (137 mg, 73%). Mp: 59-60 °C. 1H NMR (400 MHz, DMSO-d6) δ 7.77 (t, J = 5.7 Hz, 1H, NH), 7.46 (t, J = 7.7 Hz, 1H, H-5), 7.44 (t, J = 8.5 Hz, 1H, H-11), 7.36 (m, 1H, H-10), 7.23 (m, 1H, H-8), 7.17 (m, 2H, H-2 H-6), 7.12 (ddd, J = 8.1, 2.3, 1.1 Hz, 1H, H-12), 4.69 (t, J = 5.2 Hz, 1H, OH), 3.51 (m, 2H, CH2), 3.06 (q, J = 6.8 Hz, 2H, R-H-1’), 2.87 (h, J = 6.8 Hz, 1H, CH), 1.46 (h, J = 7.1 Hz, 2H, R-H-2’), 1.29 (m, 6H, R-H-3’ R-H-4’ R-H-5’), 1.21 (d, J = 7.0 Hz, 3H, CH3), 0.87 (t, J = 6.7 Hz, 3H, R-H-6’). 13C NMR (101 MHz, DMSO-d6) δ 158.8 (d, J = 246.0 Hz, C-3), 154.1 (C-9), 151.1 (HNCOO), 147.7 (d, J = 7.3 Hz, C-7), 136.2 (C-1), 130.1 (d, J = 2.4 Hz, C-5), 129.3 (C-11), 125.1 (C-10), 124.8 (d, J = 12.7 Hz, C-4), 124.0 (C-6), 121.7 (C-8), 120.9 (C-12), 114.9 (d, J = 22.4 Hz, C-2), 66.5 (CH2), 41.4 (CH), 40.4 (R-C-1’), 30.9 (R-C-4’), 29.1 (R-C-2’), 25.8 (R-C-3’), 22.0 (R-C-5’), 17.7 (CH3), 13.8 (R-C-6’). 19F NMR (564 MHz, DMSO-d6): δ 118.0. UPLC/MS analysis: Rt 2.60 min. MS (ES) C22H28FNO3 requires 373, found 374 [M+H]+. HRMS C22H29NO3F [M+H]+: calculated 374.2131 measured 374.2149 Δppm 4.8.

4.1.6.22. (±)-Methyl 2-[3-fluoro-4-[2-(hexylcarbamoyloxy)phenyl]phenyl]propanoate (14a)

Compound 14a was prepared according to general procedure B using 13a (137 mg, 0.5 mmol) and n-hexyl isocyanate (191 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 14a as a white oil (178 mg, 88%).

4.1.6.23. (±)-Methyl 2-[3-fluoro-4-[4-(hexylcarbamoyloxy)phenyl]phenyl]propanoate (14b)

Compound 14b was prepared according to general procedure B using 13b (137 mg, 0.5 mmol) and n-hexyl isocyanate (191 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 14b as a white solid (146 mg, 72%).

4.1.6.24. (±)-Methyl 2-[3-fluoro-4-[3-(hexylcarbamoylamino)phenyl]phenyl]propanoate (14c)

Compound 14c was prepared according to general procedure B using 13c (153 mg, 0.56 mmol) and n-hexyl isocyanate (214 mg, 1.7 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 14c as a white solid (146 mg, 65%).

4.1.6.25. Methyl 2-[3-fluoro-4-[3-(hexylcarbamoyloxy)phenyl]phenyl]acetate (18a)

Compound 18a was prepared according to general procedure B using 17 (130 mg, 0.50 mmol) and n-hexyl isocyanate (191 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 18a as a white solid (123 mg, 64%).

4.1.6.26. [3-(2-fluoro-4-methyl-phenyl)phenyl] N-hexylcarbamate (21a)

Compound 21a was prepared according to general procedure B using 20a (101 mg, 0.50 mmol) and n-hexyl isocyanate (191 mg, 1.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 20a as a white solid (142 mg, 86%). Mp: 56-57 °C. 1H NMR (400 MHz, DMSO-d6) δ 7.76 (t, J = 5.7 Hz, 1H, NH), 7.45 (t, J = 7.9 Hz, 1H, H-5), 7.41 (t, J = 8.0, 1H, H-11), 7.35 (d, J = 6.8 Hz, 1H, H-10), 7.22 (m, 1H, H-8), 7.12 (m, 3H, H-2 H-6 H-11 ), 3.06 (q, J = 6.8 Hz, 2H, R-H-1’), 2.36 (s, 3H, CH3), 1.47 (p, J = 6.9 Hz, 2H, R-H-2’), 1.28 (m, 6H, H-3’ H-4’ H-5’), 0.87 (t, J = 6.8 Hz, 3H, H-6’). 13C NMR (101 MHz, DMSO-d6) δ 158.8 (d, J = 247.0 Hz, C-3), 154.2 (C-9), 151.1 (HNCOO), 140.0 (d, J = 8.3 Hz, C-7), 136.2 (C-1), 130.2 (d, J = 3.6 Hz, C-5), 129.3 (C-11), 125.5 (C-10), 125.1 (C-6), 124.3 (d, J = 12.9 Hz, C-4), 121.7 (C-8), 120.9 (C-12), 116.4 (d, J = 22.3 Hz, C-2), 40.4 (R-C-1’), 30.9 (R-C-4’), 29.1 (R-C-2’), 25.8 (R-C-3’), 22.0 (RC-5’), 20.4 (CH3), 13.8 (R-C-6’). 19F NMR (564 MHz, DMSO-d6): δ 118.0. UPLC/MS analysis: Rt 2.17 min. MS (ES) C20H24FNO2 requires 329, found 330 [M+H]+. HRMS C20H25NO2F [M+H]+: calculated 330.1869 measured 330.189 Δppm 6.4.

4.1.6.27. Methyl 3-fluoro-4-[3-(hexylcarbamoyloxy)phenyl]benzoate (21b)

Compound 21b was prepared according to general procedure B using 20b (0.84 g, 3.41 mmol) and n-hexyl isocyanate (1.30 g, 10.23 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 21b as a white solid (1.27 g, quant.).

4.1.6.28 (±)-Methyl 2-[3-chloro-4-[3-(hexylcarbamoyloxy)phenyl]phenyl]propanoate (28a)

Compound 28a was prepared according to general procedure B using 27a (1.57 g, 5.40 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to give 28a as a colorless oil (2.12 g, 94%).

4.1.6.29 (±)-Methyl 2-[4-[3-(hexylcarbamoyloxy)phenyl]-3-methyl-phenyl]propanoate (28b)

Compound 28b was prepared according to general procedure B using 27b (0.72 g, 2.66 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to give 28b a white solid (0.94 g, 89%).

4.1.6.30 (±)-Methyl 2-[4-[3-(hexylcarbamoyloxy)phenyl]-3-(trifluoromethyl)phenyl]propanoate (28c)

Compound 28c was prepared according to general procedure B using 27c (0.78 g, 2.41 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to give 28c as a white solid (1.02 g, 94%).

4.1.6.31 (±)-Methyl 2-[3-benzyloxy-4-[3-(hexylcarbamoyloxy)phenyl]phenyl]propanoate (28d)

Compound 28d was prepared according to general procedure B using 27d (1.00 g, 2.52 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to obtain 28d as a clear oil (0.72 g,quant.).

4.1.6.32 (±)-Methyl 2-[4-[3-(hexylcarbamoyloxy)phenyl]phenyl]propanoate (28e)

Compound 28e was prepared according to general procedure B using 27e (128 mg, 0.5 mmol). The crude was purified by column chromatography (Cy/EtOAc, 9: 1) to afford 28e as a white solid (123 mg, 64%).

4.1.6.33 (±)-Methyl 2-[4-[3-(hexylcarbamoyloxy)phenyl]-3-nitro-phenyl]propanoate (28f)

Compound 28f was prepared according to general procedure B using 27f (0.85 g, 2.82 mmol). The crude was purified by column chromatography (Cy/EtOAc 9 : 1) to give 28f as a yellow oil (1.17 g, 97%).

4.1.7. General procedure for methyl ester hydrolysis (Procedure C, 10a-t, 15a-d, 18b, 21c, 29a-f)

To a solution of the corresponding methyl ester (1.0 mmol) in THF (0.1 M) was added 6M HCl (5 mL) and the mixture was stirred at rt until the disappearance of the starting material was noted by UPLC-MS analysis. H2O (10 mL) was added and the suspension was extracted with EtOAc (20 mL). After evaporation, the organic phase was dried over Na2SO4 and concentrated under reduced pressure. The residues were purified by crystallization (Et2O/Cy, Et2O/ pentane, TBME), preparative TLC (Cy/EtOAc) or preparative HPLC.

4.1.7.1. (±)-2-[4-[3-(cyclohexylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10a)

Compound 10a was prepared according to general procedure C using 9a (261 mg, 0.65 mmol). The crude was purified by preparative HPLC to afford 10a as a white solid (65 mg, 26%). Mp: 152-153 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.45 (s, 1H, COOH), 7.73 (d, J =7.8, 1H, NH), 7.50 (t, J =8.3, 1H, H-5), 7.47 (t, J =7.9, 1H, H-11), 7.37 (d, J = 7.7, 1H, H-10), 7.24 (m, 3H, H-2 H-6 H-8), 7.14 (d, J =8.0, 1H, H-12), 3.78 (q, J =7.1, 1H, CH), 3.33 (m, 1H, R-H-1’), 1.84 (m, 2H, R-H-2’), 1.71 (m, 2H, R-H-3’), 1.56 (m, 1H, R-H-4’), 1.41 (d, J =7.1, 3H, CH3), 1.23 (m, 5H, R-H-2’ R-H-3’, R-H-4’). 13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.7 (d, J = 246.1 Hz, C-3), 153.3 (C-9), 151.2 (HNCOO), 143.4 (d, J = 8.0 Hz, C-7), 135.9 (C-1), 130.6 (C-5), 129.4 (C-11), 125.7 (d, J = 13.0 Hz, C-4), 125.1 (C-10), 124.0 (C-6), 121.8 (C-8), 121.1 (C-12), 115.1 (d, J = 23.2 Hz, C-2), 49.7 (R-C-1’), 44.0 (CH), 32.4 (R-C-2’), 25.1 (R-C-4’), 24.5 (R-C-3’), 18.2 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.41 min. MS (ES) C22H24FNO4 requires 385, found 386 [M+H]+. HRMS C22H25NO4F [M+H]+: calculated 386.1768 measured 386.1781 Δppm 3.4.

4.1.7.2. (±)-2-[4-[3-(cyclopentylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10b)

Compound 10b was prepared according to general procedure C using 9b (235 mg, 0.61 mmol). The crude was purified by crystallization from TBME to afford 10b as a white solid (95 mg, 42%). Mp: 151-152°C. 1H NMR (400 MHz, DMSO-d6) δ 12.47 (s, 1H, COOH), 7.81 (d, J =7.2, 1H, NH), 7.50 (t, J =8.3, 1H, H-5), 7.47 (t, J =7.9, 1H, H-11), 7.37 (d, J =7.5, 1H, H-10), 7.23 (m, 3H, H-2 H-6 H-8), 7.14 (dd, J =7.9, 2.3, 1H, H-12), 3.85 (h, J =6.6, 1H, R-H-1’), 3.78 (q, J =7.1, 1H, CH), 1.83 (m, 2H, R-H-2’), 1.67 (m, 2H, R-H-3’), 1.50 (m, 4H, R-H-2’ R-H-3’), 1.41 (d, J =7.1, 3H, CH3). 13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.7 (d, J = 247.4 Hz, C-3), 153.6 (C-9), 151.1 (HNCOO), 143.4 (d, J = 7.8 Hz, C-7), 135.9 (C-1), 130.6 (C-5), 129.4 (C-11), 125.7 (d, J = 13.0 Hz, C-4), 125.1 (C-10), 124.0 (C-6), 121.8 (C-8), 121.2 (C-12), 115.1 (d, J = 23.2 Hz, C-2), 52.3(R-C-1’), 44.0 (CH), 32.1 (R-C-2’), 23.2 (R-C-3’), 18.2 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.41 min. MS (ES) C21H22FNO4 requires 371, found 372 [M+H]+. HRMS C21H23NO4F [M+H]+: calculated 372.1611 measured 372.1603 Δppm −2.1.

4.1.7.3. (±)-2-[4-[3-(cyclobutylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10c)

Compound 10c was prepared according to general procedure C using 9c. The crude was purified by preparative HPLC to afford 10c as a white solid (66 mg, 37% over 2 steps). Mp: 140-141°C. 1H NMR (400 MHz, DMSO-d6) δ 12.47 (s, 1H, COOH), 8.10 (d, J =7.9, 1H, NH), 7.49 (t, J =8.3, 1H, H-5), 7.46 (t, J =7.9, 1H, H-11), 7.38 (d, J =7.0, 1H, H-10), 7.23 (m, 3H, H-2 H-6 H-8), 7.13 (m, 1H, H-12), 4.02 (h, J =8.2, 1H, R-H-1’), 3.78 (q, J =7.1, 1H, CH), 2.18 (m, 2H, R-H-2’), 1.98 (m, 2H, R-H-2’), 1.61 (m, 2H, R-H-3’), 1.41 (d, J =7.1, 3H). 13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.7 (d, J = 246.2 Hz, C-3), 152.9 (C-9), 151.0 (HNCOO), 143.43 (d, J = 7.7 Hz, C-7), 135.9 (C-1), 130.6 (d, J = 2.9 Hz, C-5), 129.4 (C-11), 125.7 (d, J = 12.7 Hz, C-4), 125.2 (C-10), 124.0 (C-6), 121.9 (C-8), 121.2 (C-12), 115.1 (d, J = 23.3 Hz, C-2), 45.7 (R-C-1’), 44.0 (CH), 30.1 (R-C-2’), 18.2 (CH3), 14.3 (R-C-3’). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.17 min. MS (ES) C20H20FNO4 requires 357, found 358 [M+H]+. HRMS C20H21NO4F [M+H]+: calculated 358.1455 measured 358.1452 Δppm −0.8.

4.1.7.4. (±)-2-[4-[3-(cyclopropylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10d)

Compound 10d was prepared according to general procedure C using 9d (59 mg, 0.17 mmol). The crude was purified by preparative HPLC to afford 10d as a white solid (35 mg, 60%). Mp: 117-188 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.48 (s, 1H, COOH), 7.97 (d, J =2.3, 1H, NH), 7.50 (t, J =8.4, 1H, H-5), 7.47 (t, J =7.9, 1H, H-11), 7.38 (d, J =7.5, 1H, H-10), 7.23 (m, 3H, H-2 H-6 H-8), 7.14 (d, J = 7.9, 1H, H-12), 3.78 (q, J = 7.1, 1H, CH), 2.57 (m, 1H, R-H-1’), 1.41 (d, J = 7.1, 3H, CH3), 0.64 (m, 2H, R-H-2’), 0.50 (m, 2H, R-H-2’). 13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.7 (d, J = 246.5 Hz, C-3), 154.8 (C-9), 151.0 (HNCOO), 143.4 (d, J = 7.9 Hz, C-7), 135.9 (C-1), 130.6 (d, J = 2.2 Hz, C-5), 129.4 (C-11), 125.7 (d, J = 13.1 Hz, C-4), 125.2 (C-10), 124.0 (C-6), 121.8 (C-8), 121.2 (C-12), 115.1 (d, J = 23.0 Hz, C-2), 44.0 (CH), 23.0 (R-C-1’), 18.2 (CH3), 5.7 (R-C-2’). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 1.96 min. MS (ES) C19H18FNO4 requires 343, found 344 [M+H]+. HRMS C19H19NO4F [M+H]+: calculated 344.1298 measured 344.1298 Δppm 0.

4.1.7.5. (±)-2-[4-[3-(cyclohexylmethylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10e)

Compound 10e was prepared according to general procedure C using 9e (157 mg, 0.38 mmol). The crude was purified by crystallization from pentane/Et2O to afford 10e as a white solid (93 mg, 61%). Mp: 142-143 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.46 (s, 1H, COOH), 7.79 (t, J = 5.9 Hz, 1H, NH), 7.50 (t, J = 8.1, 1H, H-5), 7.47 (t, J = 7.9, 1H, H-11), 7.37 (d, J = 7.6 Hz, 1H, H-10), 7.24 (m, 3H, H-2 H-6 H.8), 7.13 (dd, J = 7.6, 1.8 Hz, 1H, H-12), 3.78 (q, J = 7.1 Hz, 1H, CH), 2.92 (t, J = 6.3 Hz, 2H, R-H-1’), 1.67 (m, 5H, R-H-3’ R-H-4’ R-H-5’), 1.46 (m, 1H, R-H-2’), 1.41 (d, J = 7.1 Hz, 3H, CH3), 1.18 (m, 3H, R-H-4’ R-H-5’), 0.90 (m, 2H, R-H-3’).13C NMR (101 MHz, DMSO-d6) δ 175.2 (COOH), 159.2 (d, J = 246.4 Hz, C-3), 154.8 (C-9), 151.7 (HNCOO), 143.9 (d, J = 7.6 Hz, C-7), 136.4 (C-1), 131.1 (d, J = 3.7 Hz, C-5), 129.9 (C-11), 126.2 (d, J = 13.0 Hz, C-4), 125.6 (C-10), 124.5 (d, J = 2.9 Hz, C-6), 122.3 (d, J = 3.0 Hz, C-8), 121.6 (C-12), 115.6 (d, J = 23.3 Hz, C-2), 47.2 (R-C-1’), 44.5 (CH), 38.1 (R-C-2’), 30.7 (R-C-3’), 26.5 (R-C-5’), 25.8 (R-C-4’), 18.7 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.57 min. MS (ES) C23H26FNO4 requires 399, found 400 [M+H]+. HRMS C23H27NO4F [M+H]+: calculated 400.1924 measured 400.193 Δppm 1.5.

4.1.7.6. (±)-2-[4-[3-(2-cyclohexylethylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10f)

Compound 10f was prepared according to general procedure C using 9f (149 mg, 0.35 mmol). The crude was purified by crystallization from pentane/Et2O to afford 10f as a white solid (98 mg, 68%). Mp: 118-119 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.07 (s, 1H, COOH), 7.74 (t, J = 5.6 Hz, 1H, NH), 7.48 (m, 2H, H-5), 7.37 (d, J = 7.0 Hz, 1H, H-11), 7.23 (m, 3H, H-2 H-6 H-8), 7.13 (dd, J = 7.7, 1.8 Hz, 1H, H-12), 3.78 (q, J = 7.1 Hz, 1H, CH), 3.09 (q, J = 6.7 Hz, 2H, R-H-1’), 1.66 (m, 5H, R-H-5’ R-H-4’ R-H-6’), 1.41 (d, J = 7.1 Hz, 3H, CH3), 1.34 (m, 3H, R-H-2’ R-H-3’), 1.19 (m, 3H, R-H-5’ R-H-6’), 0.88 (m, 2H, R-H-4’). 13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.7 (d, J = 246.5 Hz, C-3), 154.1 (C-9), 151.2 (HNCOO), 143.4 (d, J = 7.8 Hz, C-7)), 135.9 (C-1), 130.6 (d, J = 3.5 Hz, C-5), 129.4 (C-11), 125.7 (d, J = 13.1 Hz, C-4), 125.1 (C-10), 124.0 (d, J = 3.1 Hz, C-6), 121.8 (C-8), 121.1 (C-12), 115.1 (d, J = 23.1 Hz, C-2), 44.0 (CH), 38.2 (R-C-1’), 36.6 (R-C-2’), 34.4 (R-C-4’), 26.0 (R-C-6’), 25.7 (R-C-5’), 18.2 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.69 min. MS (ES) C24H28FNO4 requires 413, found 414 [M+H]+. HRMS C24H29NO4F [M+H]+: calculated 414.2081 measured 414.2096 Δppm 3.6.

4.1.7.7. (±)-2-[3-fluoro-4-[3-(isopropylcarbamoyloxy)phenyl]phenyl]propanoic acid (10g)

Compound 10g was prepared according to general procedure C using 9g (159 mg, 0.44 mmol). The crude was purified by crystallization from pentane/Et2O to afford 10g as a white solid (65 mg, 43%). Mp: 131-132 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.43 (s, 1H, COOH), 7.73 (d, J = 7.6 Hz, 1H, NH), 7.51 (t, J = 8.1 Hz, 1H, H-5), 7.48 (t, J = 7.9 Hz, 1H, H-11), 7.39 (d, J = 7.5 Hz, 1H, H-10), 7.25 (m, 3H, H-2 H-6 H-8), 7.15 (d, J = 7.9 Hz, 1H, H-12), 3.79 (q, J = 7.1 Hz, 1H, CH), 3.67 (m, J = 6.9 Hz, 1H, R-H-1’), 1.42 (d, J = 7.1 Hz, 3H, CH3), 1.15 (d, J = 6.5 Hz, 6H, R-H-2’). 13C NMR (101 MHz, DMSO-d6) δ 175.3 (COOH), 159.2 (d, J = 246.5 Hz, C-3), 153.7 (C-9), 151.6 (HNCOO), 143.9 (d, J = 8.0 Hz, C-7), 136.4 (C-1), 131.1 (d, J = 3.7 Hz, C-5), 129.8 (C-11), 126.2 (d, J = 13.1 Hz, C-4), 125.6 (C-10), 124.5 (d, J = 3.2 Hz, C-6), 122.3 (C-8), 121.7 (C-12), 115.6 (d, J = 23.1 Hz, C-2), 44.5 (CH), 43.1 (R-C-1’), 22.8 (R-C-2’), 18.7 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.09 min. MS (ES) C19H20FNO4 requires 345, found 346 [M+H]+. HRMS C19H21NO4F [M+H]+: calculated 346.1455 measured 346.1458 Δppm 0.9.

4.1.7.8. (±)-2-[3-fluoro-4-[3-(isobutylcarbamoyloxy)phenyl]phenyl]propanoic acid (10h)

Compound 10h was prepared according to general procedure C using 9h (138 mg, 0.38 mmol). The crude was purified by crystallization from pentane/Et2O to afford 10h as a white solid (57 mg, 42%). Mp: 128-130 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.45 (s, 1H, COOH), 7.84 (t, J = 5.9 Hz, 1H, NH), 7.51 (t, J = 8.1 Hz, 1H, H-5), 7.48 (t, J = 7.9 Hz, 1H, H-11), 7.39 (d, J = 7.7 Hz, 1H, H-10), 7.25 (m, 3H, H-2 H-6 H-8), 7.15 (dd, J = 8.0, 1.5 Hz, 1H, H-12), 3.79 (q, J = 7.1 Hz, 1H, CH), 2.91 (t, J = 6.4 Hz, 2H, R-H-1’), 1.76 (hept, J = 6.7 Hz, 1H, R-H-2’), 1.42 (d, J = 7.1 Hz, 3H, CH3), 0.90 (d, J = 6.7 Hz, 6H, R-H-3’). 13C NMR (101 MHz, DMSO-d6) δ 175.2 (COOH), 159.2 (d, J = 246.3 Hz, C-3), 154.9 (C-9), 151.7 (HNCOO), 143.9 (d, J = 7.7 Hz, C-7), 136.4 (C-1), 131.1 (d, J = 3.5 Hz, C-5), 129.9 (C-11), 126.2 (d, J = 13.1 Hz, C-4), 125.6 (C-10), 124.5 (d, J = 3.1 Hz, C-6), 122.3 (d, J = 2.9 Hz, C-8), 121.6 (C-12), 115.6 (d, J = 23.1 Hz, C-2), 48.5 (R-C-1’), 44.5 (CH), 28.7 (R-C-2’), 20.4 (R-C-3’), 18.7 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.24 min. MS (ES) C20H22FNO4 requires 359, found 360 [M+H]+. HRMS C20H23NO4F [M+H]+: calculated 360.1611 measured 360.1631 Δppm 5.6.

4.1.7.9. (±)-2-[3-fluoro-4-[3-(phenylcarbamoyloxy)phenyl]phenyl]propanoic acid (10i)

Compound 10i was prepared according to general procedure C using 9i (87 mg). The crude was purified by preparative HPLC to afford 10i as a white solid (31 mg, 37%). Mp: 145-146 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.48 (s, 1H, COOH), 10.26 (s, 1H, NH), 7.53 (m, 4H, H-5 H-11 R- Ph-3’), 7.45 (d, J = 6.8 Hz, 1H, H-12), 7.40 (s, 1H, H-8), 7.33 (t, J = 7.9 Hz, 2H, R-Ph-2’), 7.26 (m, 3H, H-2 H-6 H-10), 7.05 (t, J = 7.4 Hz, 1H, R- Ph-4’), 3.78 (q, J = 7.1 Hz, 1H, CH), 1.41 (d, J = 7.1 Hz, 3H, CH3). 13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.8 (d, J = 246.5 Hz, C-3), 151.5 (C-9), 150.5 (HNCOO), 143.5 (d, J = 8.0 Hz, C-7), 138.5 (R-Ph-1’), 136.1 (C-1), 130.6 (d, J = 2.9 Hz, C-5), 129.6 (C-11), 128.8 (R-Ph-3’), 125.7 (C-10), 125.6 (d, J = 13.1 Hz, C-4), 124.0 (C-6), 122.9 (R-Ph-4’), 122.0 (C-8), 121.3 (C-12), 118.4 (R-Ph-2’), 115.2 (d, J = 23.3 Hz, C-2), 44.1, 18.2. 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.05 min. MS (ES) C22H18FNO4 requires 379, found 380 [M+H]+. HRMS C22H19NO4F [M+H]+: calculated 380.1298 measured 380.1296 Δppm −0.5.

4.1.7.10. (±)-2-[4-[3-(benzylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10j)

Compound 10j was prepared according to general procedure C using 9j. The crude was purified by preparative HPLC to afford 10j as a white solid (69 mg, 35% over 2 steps). Mp: 120-122 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.47 (s, 1H, COOH), 8.36 (t, J =6.1, 1H, NH), 7.49 (m, 2H H-5 H-11), 7.36 (m, 5H, H-10 R-Ph-2’ R- Ph-3’), 7.27 (m, 2H, H-8 R-Ph-4’), 7.23 (m, 2H, H-2 H-6), 7.17 (dd, J =7.8, 1.7, 1H, H-12), 4.29 (d, J =6.1, 2H, R-H-1’), 3.78 (q, J =7.1, 1H, CH), 1.41 (d, J =7.1, 3H, CH3). 13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.7 (d, J = 246.3 Hz, C-3), 154.5 (C-9), 151.1 (HNCOO), 143.4 (d, J = 7.6 Hz, C-7), 139.1 (R-Ph-1), 135.9 (C-1), 130.6 (d, J = 2.8 Hz, C-5), 129.4 (C-11), 128.3 (R-Ph-3), 127.1 (R-Ph-2), 126.9 (R-Ph-4), 125.7 (d, J = 12.9 Hz, C-4), 125.3 (C-10), 124.0 (C-6), 121.8 (C-8), 121.2 (C-12), 115.1 (d, J = 23.2 Hz, C-2), 44.1 (CH), 44.0 (R-C-1’), 18.2 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.27 min. MS (ES) C23H20FNO4 requires 393, found 394 [M+H]+. HRMS C23H21NO4F [M+H]+: calculated 394.1455 measured 394.1462 Δppm 1.8.

4.1.7.11. (±)-2-[3-fluoro-4-[3-(phenethylcarbamoyloxy)phenyl]phenyl]propanoic acid (10k)

Compound 10k was prepared according to general procedure C using 9k. The crude was purified by crystallization from Et2O/ pentane to afford 10k as a white solid (58 mg, 41%). Mp: 104°C. 1H NMR (400 MHz, DMSO-d6) δ 12.45 (s, 1H, COOH), 7.88 (t, J = 5.6 Hz, 1H, NH), 7.51 (t, J = 8.0 Hz, 1H, H-5), 7.48 (t, J = 7.9 1H, H-11), 7.37 (m, 1H, R-Ph-4), 7.31 (m, 2H, R-Ph-3), 7.23 (m, 6H, H-10 H-2 H-6 H-8 R- Ph-2), 7.11 (dd, J = 7.7, 1.7 Hz, 1H, H-12), 3.78 (q, J = 7.1 Hz, 1H, CH), 3.31 (q, J = 7.7 Hz, 2H, R-H-1’), 2.80 (t, J = 7.4 Hz, 2H, R-H-2’), 1.41 (d, J = 7.1 Hz, 3H, CH3).13C NMR (101 MHz, DMSO-d6) δ 175.2 (COOH), 159.2 (d, J = 245.8 Hz, C-3), 154.6 (C-9), 151.1 (HNCOO), 143.9 (d, J = 7.7 Hz, C-7), 139.5 (R-Ph-1), 136.4 (C-1), 131.1 (d, J = 3.4 Hz, C-5), 129.9 (C-11), 129.1 (R-Ph-2), 128.8 (R-Ph-3), 126.6 (R-Ph-4), 126.2 (d, J = 13.0 Hz, C-4), 125.7 (C-10), 124.5 (d, J = 2.8 Hz, C-6), 122.3 (d, J = 2.6 Hz, C-8), 121.6 (C-12), 115.6 (d, J = 23.1 Hz, C-2), 44.5 (CH), 42.5 (R-C-1’), 35.6 (R-C-2’), 18.7 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.37 min. MS (ES) C24H22FNO4 requires 407, found 408 [M+H]+. HRMS C24H23NO4F [M+H]+: calculated 408.1611 measured 408.1626 Δppm 3.7.

4.1.7.12. (±)-2-[3-fluoro-4-[3-(3-phenylpropylcarbamoyloxy)phenyl]phenyl]propanoic acid (10l)

Compound 10l was prepared according to general procedure C using 9l (174 mg, 0.40 mmol). The crude was purified by preparative TLC (Cy/EtOAc, 5: 5) to afford 10l as a white solid (44 mg, 26%). Mp: 82-83 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.47 (s, 1H, COOH), 7.87 (t, J = 5.53 Hz, 1H, NH), 7.51 (t, J = 8.04 Hz, 1H, H-5), 7.48 (t, J = 8.20 Hz, 1H, H-11), 7.38 (d, J = 7.2 Hz, 1H, R- Ph-4), 7.22 (m, 9H, H-2 H-6 H-8 H-10 H-12 R- Ph-2 R- Ph-3), 3.78 (q, J = 6.5 Hz, 1H, CH), 3.09 (q, J = 6.3 Hz, 2H, R-H-1’), 2.63 (t, J = 7.3 Hz, 2H, R-H-2’), 1.78 (p, J = 6.7 Hz, 2H, R-H-3’), 1.41 (d, J = 6.9 Hz, 3H, CH3). 13C NMR (101 MHz, DMSO-d6) δ 175.2 (COOH), 159.2 (d, J = 246.1 Hz, C-3), 154.7 (C-9), 151.6 (HNCOO), 143.9 (d, J = 8.1 Hz, C-7), 142.0 (R-Ph-1), 136.4 (C-1), 131.1 (d, J = 3.3 Hz, C-5), 129.9 (C-11), 128.8 (R-Ph-3), 128.7 (RPh-2), 126.2 (R-Ph-4), 125.7 (d, J = 3.5 Hz, C-4), 124.6 (C-10) 124.5 (C-6), 122.3 (C-8), 121.70 (C-12), 115.6 (d, J = 23.5 Hz, C-2), 44.5 (CH), 40.5 (R-C-1’), 32.8 (R-C-3’), 31.4 (R-C-2’), 18.7 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.46 min. MS (ES) C25H24FNO4 requires 421, found 422 [M+H]+ . HRMS C25H25NO4F [M+H]+: calculated 422.1768 measured 422.1776 Δppm 1.9.

4.1.7.13. (±)-2-[3-fluoro-4-[3-(4-phenylbutylcarbamoyloxy)phenyl]phenyl]propanoic acid (10m)

Compound 10m was prepared according to general procedure C using 9m (171 mg, 0.38 mmol). The crude was purified by preparative TLC (Cy/EtOAc, 5: 5) to afford 10m as a white solid (70 mg, 43%). Mp: 101-102°C. 1H NMR (400 MHz, DMSO-d6) δ 12.47 (s, 1H, COOH), 7.80 (t, J = 5.7 Hz, 1H, NH), 7.47 (m, 2H, H-5 H-8), 7.37 (d, J = 7.3 Hz, 1H, R- Ph-4), 7.19 (m, 9H, H-2 H-6 H-8 H-10 H-12 R- Ph-2 R- Ph-3), 3.78 (q, J = 7.1 Hz, 1H, CH), 3.10 (q, J = 6.6 Hz, 2H, R-H-1’), 2.60 (t, J = 7.5 Hz, 2H, R-H-4’), 1.60 (q, J = 7.9 Hz, 2H, R-H-3’), 1.50 (q, J = 7.2 Hz, 2H, R-H-2’), 1.41 (d, J = 7.1 Hz, 3H, CH3). 13C NMR (101 MHz, DMSO-d6) δ 175.2 (COOH), 159.2 (d, J = 246.3 Hz, C-3), 154.7 (C-9), 151.6 (HNCOO), 143.9 (d, J = 7.5 Hz, C-7), 142.5 (R-Ph-1), 136.4 (C-1), 131.0 (d, J = 3.6 Hz, C-5), 129.9 (C-11), 128.7 (R-Ph-3), 128.6 (RPh-2), 126.1 (R-Ph-4), 125.7 (d, J = 2.4 Hz, C-4), 124.6 (C-10) 124.5 (C-6), 122.3 (d, J = 3.1 Hz, C-8), 121.6 (C-12), 115.6 (d, J = 23.2 Hz, C-2), 44.5 (CH), 40.7 (R-C-1’), 35.2 (R-C-4’), 29.3 (R-C-2’), 28.7 (R-C-3’), 18.7 (CH3). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.59 min. MS (ES) C26H26FNO4 requires 435, found 436 [M+H]+. HRMS C26H27NO4F [M+H]+: calculated 436.1924 measured 436.1936 Δppm 2.8.

4.1.7.14. (±)-2-[4-[3-(ethylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10n)

Compound 10n was prepared according to general procedure C using 8 (104 mg, 0.30 mmol). The crude was purified by crystallization from Et2O/ pentane to afford 10n as a white solid (37 mg, 37%). Mp: 93-94 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.48 (s, 1H, COOH), 7.79 (t, J = 5.5 Hz, 1H, NH), 7.51 (t, J = 8.3 Hz, 1H, H-5), 7.48 (t, J = 7.9 Hz, 1H, H-11), 7.39 (d, J = 7.5 Hz, 1H, H-10), 7.25 (m, 3H, H-2 H-6 H-8), 7.15 (d, J = 7.9 Hz, 1H, H-12), 3.79 (q, J = 7.1 Hz, 1H, CH), 3.12 (p, J = 7.1 Hz, 2H, R-H-1’), 1.42 (d, J = 7.1 Hz, 3H, CH3), 1.10 (t, J = 7.2 Hz, 3H, R-H-2’). 13C NMR (101 MHz, DMSO-d6) δ 175.3 (COOH), 159.2 (d, J = 245.9 Hz, C-3), 154.5 (C-9), 151.6 (HNCOO), 143.9 (d, J = 7.6 Hz, C-7), 136.4 (C-1), 131.1 (d, J = 3.6 Hz, C-5), 129.9 (C-11), 126.2 (d, J = 13.0 Hz, C-4), 125.7 (C-10), 124.5 (d, J = 3.0 Hz, C-6), 122.3 (d, J = 3.1 Hz, C-8), 121.7 (C-C-12), 115.6 (d, J = 23.4 Hz, C-2), 44.5 (CH), 35.7 (R-C-1’), 18.7 (CH3), 15.3 (R-C-2’). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 1.95 min. MS (ES) C18H18FNO4 requires 331, found 332 [M+H]+. HRMS C18H19NO4F [M+H]+: calculated 332.1298 measured 332.1304 Δppm 1.8.

4.1.7.15. (±)-2-[3-fluoro-4-[3-(propylcarbamoyloxy)phenyl]phenyl]propanoic acid (10o)

Compound 10o was prepared according to general procedure C using 8 (87 mg, 0.24 mmol). The crude was purified by preparative TLC (Cy/EtOAc, 5: 5) to afford 10o as a white solid (57 mg, 68%). Mp: 113-114 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.47 (s, 1H), 7.79 (t, J = 5.7 Hz, 1H), 7.50 (t, J = 8.3 Hz, 1H), 7.47 (t, J = 7.9 Hz, 1H), 7.37 (d, J = 6.9 Hz, 1H), 7.24 (ddt, J = 9.9, 3.9, 1.7 Hz, 3H), 7.14 (ddd, J = 8.2, 2.4, 1.1 Hz, 1H), 3.78 (q, J = 7.1Hz, 1H), 3.03 (td, J = 7.1, 5.9 Hz, 2H), 1.49 (h, J = 7.3 Hz, 2H), 1.41 (d, J = 7.2 Hz, 3H), 0.89 (t, J = 7.4 Hz, 3H).13C NMR (101 MHz, DMSO-d6) δ 174.7 (COOH), 158.7 (d, J = 246.5 Hz, C-3), 154.2 (C-9), 151.2 (HNCOO), 143.4 (d, J = 7.8 Hz, C-7), 135.9 (C-1), 130.6 (C-5), 129.4 (C-11), 125.7 (d, J = 12.9 Hz, C-4), 125.1 (C-10), 124.0 (C-6), 121.8 (C-8), 121.1 (C-12), 115.1 (d, J = 23.2 Hz, C-2), 44.0 (CH), 42.2 (R-C-1’), 22.4 (R-C-2’), 18.2 (CH3), 11.2 (R-C-3’). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.10 min. MS (ES) C19H20FNO4 requires 345, found 346 [M+H]+. HRMS C19H21NO4F [M+H]+: calculated 346.1455 measured 346.1459 Δppm 1.2.

4.1.7.16. (±)-2-[4-[3-(butylcarbamoyloxy)phenyl]-3-fluoro-phenyl]propanoic acid (10p)

Compound 10p was prepared according to general procedure C using 9p (135 mg, 0.36 mmol). The crude was purified by crystallization from Cy/Et2O to afford 10p as a white solid (75 mg, 58%). Mp: 110-111 °C. 1H NMR (400 MHz, DMSO-d6) δ 12.48 (s, 1H, COOH), 7.79 (t, J = 5.7 Hz, 1H, NH), 7.50 (t, J = 8.3 Hz, 1H, H-5), 7.47 (t, J = 7.9 Hz, 1H, H-11), 7.37 (d, J = 7.0 Hz, 1H, H-10), 7.23 (m, 3H, H-2 H-6 H-8), 7.13 (ddd, J = 8.1, 2.4, 1.0 Hz, 1H, H-12), 3.78 (q, J = 7.1 Hz, 1H, CH), 3.06 (q, J = 6.8 Hz, 2H, R-H-1’), 1.46 (p, J = 6.9 Hz, 2H, R-H-2’), 1.40 (d, J = 7.2 Hz, 3H, CH3), 1.32 (h, J = 7.1 Hz, 2H, R-H-3’), 0.89 (t, J = 7.3 Hz, 3H, R-H-4’). 13C NMR (101 MHz, DMSO-d6) δ 174.8 (COOH), 158.8 (d, J = 246.0 Hz, C-3), 154.2 (C-9), 151.2 (HNCOO), 143.4 (d, J = 8.0 Hz, C-7), 135.9 (C-1), 130.6 (d, J = 2.9 Hz, C-5), 129.4 (C-11), 125.7 (d, J = 12.8 Hz, C-4), 125.2 (C-10), 124.0 (C-6), 121.8 (C-8), 121.2 (C-12), 115.2 (d, J = 23.3 Hz, C-2), 44.1 (CH), 40.1 (R-C-1’), 31.3 (R-C-2’), 19.4 (R-C-3’), 18.2 (CH3), 13.6 (R-C-4’). 19F NMR (564 MHz, DMSO-d6): δ 117.3. UPLC/MS analysis: Rt 2.25 min. MS (ES) C20H22FNO4 requires 359, found 360 [M+H]+. HRMS C20H23NO4F [M+H]+ : calculated 360.1611 measured 360.1615 Δppm 1.1.

4.1.7.17. (±)-2-[3-fluoro-4-[3-(pentylcarbamoyloxy)phenyl]phenyl]propanoic acid (10q)