Abstract

The German organic chemist Johann Peter Griess (1829–88), who first developed the diazotization of aryl amines (the key reaction in the synthesis of the azo dyes), and a major figure in the formation of the modern dye industry, worked for more than a quarter of a century at the brewery of Samuel Allsopp and Sons in Burton upon Trent, which, owing to the presence of several notable figures and an increase in the scientific approach to brewing, became a significant centre of scientific enquiry in the 1870s and 1880s. Unlike the other Burton brewing chemists, Griess paralleled his work at the brewery with significant contributions to the chemistry of synthetic dyes, managing to keep the two activities separate—to the extent that some of his inventions in dye chemistry were filed as patents on behalf of the German dye company BASF, without the involvement of Allsopp's. This seemingly unlikely situation can be explained partly by the very different attitudes to patent protection in Britain and in Germany combined with an apparent indifference to the significant business opportunity that the presence of a leading dye chemist presented to Allsopp's. Although his work for the brewery remained largely proprietary, Griess's discoveries in dye chemistry were exploited by the German dye industry, which quickly outpaced its British counterpart. One less well-known connection between brewing and synthetic dyes, and one that may further explain Allsopp's attitude, is the use of synthetic dyes in identifying microorganisms—the perennial preoccupation of brewers seeking to maintain yield and quality. Developments of Griess's original work continue to be applied to many areas of science and technology.

Keywords: Johann Peter Griess; Samuel Allsopp and Sons Brewery, Burton upon Trent, diazotization; azo dyes; Griess reaction

Bei einer Wanderung durch die weit ausgedehnten Werkstätten der tinctoriellen Industrie tönt wieder und wieder der Name Peter Griess uns volltönend entgegen.

(As one wanders through the expansive workshop of the dye industry, Peter Griess's name resounds again and again.)

A. W. von Hofmann

Introduction

The German-born but Burton-based brewing chemist Johann Peter Griess1 stands out from his brewing chemist colleagues not only because of the impact of his work in much wider fields of activity but also because of the unusual manner in which he operated. Griess, after whom the diazotization of aniline (aminobenzene) and other aryl amines is named, had a career spanning both brewing and synthetic dyes but he seems to have kept these two activities almost entirely separate for a quarter of a century and, moreover, behaved quite differently in each domain. Given Griess's eminence as a chemist, it is scarcely credible that his employer, the brewery of Samuel Allsopp and Sons in Burton upon Trent, was unaware of his activities in synthetic dyes.2 How the situation arose in which Allsopp's not only failed to exploit the presence of a founder of the modern dye industry in their midst, but also permitted him to develop new synthetic dyes, will be examined in terms of the very different attitudes prevalent among industrialists in the two countries. At least one of these dyes was patented by BASF in 1879, highlighting the distinct cultures relating to patents and the attitudes of British brewers, particularly Allsopp's. Although the synthetic dye industry was initially dwarfed by brewing, this situation was soon to be reversed, largely as the result of the expansion of German synthetic dye companies. This is often presented as a consequence of British ineptitude and German technical and business acumen, combined with a superior patent system. Such accounts conceal a more nuanced and complex relationship.3 Allsopp's attitude, however, may also be explained by an interest in new synthetic dyes as a means of staining and differentiating microorganisms in brewing. The use of the microscope in brewing was under way by 1870. Griess applied it to the examination of microbiological samples from brewing, and, with the use of chemical stains, to improve the visibility of microorganisms. Allsopp's did not take the opportunity to diversify into the synthetic dye industry. Nevertheless, the consequences of Griess's work in dyes were and continue to be extensive, influencing research and technology in many fields.

A scientific approach to brewing

One less appreciated consequence of the rapidly increasing industrial population and of the drive for increased profits of the mid-eighteenth century was the practice of adulterating food and drink. In common with the providers of many foodstuffs of the period, the brewers of beer had access to a variety of potential additives, some of which are recognized today as toxins. In beer, additives could range from inorganic salts such as ferrous sulphate to organic compounds.4 One celebrated case involved the oral accusation by Anselme Payen, a distinguished French chemist,5 that brewers of pale ale had used strychnine (see Appendix) to impart a bitter taste, and this episode perhaps highlights how industry had come ‘to perceive chemical science as an ally in pollution disputes’.6 A thorough investigation was undertaken by external scientists, including one of the leading figures in chemistry, A. W. von Hofmann (1818–92).7 The investigation was centred on two major breweries, Bass, Ratcliff and Gretton, and Allsopp's, located in the principal brewing centre of Britain, Burton upon Trent. The brewers were fully exonerated.8

Burton had risen to brewing pre-eminence through a combination of possessing an Abbey, enjoying good communications and having water with a mineral content very well suited to brewing drawn from the underlying gypsum. The town began brewing beer in the eleventh century. The activity grew progressively and by the eighteenth century exports to the Baltic, including Russia and Poland, represented a significant business. After a severe economic downturn during and after the Napoleonic Wars, brewing in Burton was reinvigorated by the arrival of the Derby and Birmingham Railway in 1839, permitting more effective export of beer. In 1860 Allsopp's opened their new Burton Brewery, with the largest capacity in Britain. To provide an idea of the scale of the operations in Burton during this period, it has been estimated that in 1888, brewing involved 31 companies, employed 8000 workers and exported about three million barrels of beer per annum.9

Despite the natural advantages bestowed on Burton by geology and geography, the development of brewing also relied on the application of scientific methods. There had been a long association between brewers and scientists,10 among them James Prescott Joule (1818–89),11 who went on to establish the equivalence of heat with mechanical work. The association involved technological exchange between the two fields, such as the development of accurate thermometers to help make the brewing process more reproducible, which also provided valuable service in scientific investigations.12 Such technological innovations, combined with a change in demand from the heavier porter to the lighter and more bitter Burton-brewed India pale ales (IPAs), with their increased hop content and longer storage times, by the 1880s had helped transform brewing in Burton from an essentially seasonal occupation to an all-year-round activity.13 Anderson points out that chemists were of increasing importance to breweries at this time:

The significant export trade in India Pale Ale … for the breweries could get drawback of duty on exported beer and needed someone technically skilled to carry out the distillations and weighings required to determine original gravities and thus substantiate a claim. Also the delicacy of IPA made it much harder to produce than dark rough beers like porter and a chemist was seen as useful.14

In addition to Griess, chemists based in Burton working principally for the breweries included Horace Tabberer Brown (1848–1925),15 Adrian John Brown (1852–1919)16 and Cornelius O'Sullivan (1841–1907).17 The first two were born in the town, and all four were Fellows of the Royal Society. They were prime movers in the formation of a group known as the Bacterium Club (1876), which perhaps highlights the relevance of microbiology not only to the brewing industry18 but also to Griess. From this group the Laboratory Club was formed in 1886 and, in 1890, the Institute of Brewing (today the Institute of Brewing and Distilling).19 This concentration of scientific knowledge and endeavour made Burton, briefly during the 1870s and 1880s, a major centre of scientific enquiry.20

Johann Peter Griess

Johann Peter Griess was originally from a land-owning family in Hesse-Cassel. He showed little enthusiasm for the pastoral life intended for him by his father and, after a brief spell in the Hessian cavalry, attended the universities of Jena (1851) and Marburg (1852), where he worked during the period 1856–58 under the influential Hermann Kolbe (1818–84).21 Among his many technical contributions, Kolbe had shown experimentally that compounds such as acetic acid, previously associated only with living organisms, could be made by chemical processes, thereby disproving vitalism. Griess had been the subject of several disciplinary proceedings during his student days, including imprisonment in the Karzer, a designated detention room common among German universities of the time; at one point he had had to sell off the family farm to pay his debts. Nevertheless, in about 1856 he managed to obtain a position at the coal tar factory of Oehler at Offenbach am Main, where aniline (the industrially important precursor of many chemicals) was produced. After a fire in 1857, which devastated the factory, he returned to Marburg to work again with Kolbe and it was during this period (ca. 1858) that he developed the diazotization reaction that eventually spawned the azo dye industry.22 It has been suggested that the importance of this process was not immediately grasped by Griess and that it was the enthusiastic support of Hofmann that proved decisive.23 Nevertheless, largely as a result of this breakthrough, Griess was invited to work with Hofmann at the Royal College of Chemistry in London. It was on the recommendation of H. Böttinger,24 the chief chemist at Allsopp's in Burton, who had helped to organize the independent scientific examination into claims of adulteration mentioned above, that Griess was recruited in 1862.25 Griess would remain at Allsopp's until his death in 1888.

Relatively little has been written concerning Griess, beyond reworkings of the biographical details provided by Bopp, Hofmann and Fischer soon after Griess's death26 and subsequent technical summaries of the diazotization reaction in the dye industry.27 More specifically, there has been little examination of his working practices and of contemporary attitudes. Ray Anderson is unique in beginning to examine the motivations behind Griess's recruitment to Allsopp's and in assessing Griess's attitude to his duties. He proposes a degree of benevolence on the part of Allsopp's, suggesting that credibility may have been gained through the presence of Griess at the brewery.28 Below we further examine Griess's dual role as British brewing chemist and researcher into azo dyes for German industry, within the scientific, industrial and national context of his day. The complex working relationship that Griess had with the brewing industry, which allowed research work on potential industrial dyes to proceed alongside his duties monitoring the brewing process, as well as Griess's attitude to his roles, will be explored.

Griess's diazotization reaction and the azo dyes

Griess had been working for his mentor, Kolbe, attempting to make derivatives of picramic acid. At Kolbe's suggestion, Griess applied warm aqueous nitrous acid, considering it likely that the addition of a hydroxyl group, analogous to that observed with aminobenzoic acid, might result. After modifications to the reaction conditions, in which Griess instead employed a cold ethanolic solution (to which he later attributed his successful recovery of the products) of nitrous acid, a derivative with unexpected properties was formed. Griess demonstrated that this reaction was generally applicable to aryl amines (see Appendix) and named the products diazonium salts (figure 1a), thinking incorrectly that two nitrogen atoms (di-azo) had replaced two hydrogen atoms.29

Figure 1.

The diazotization process. (a) The reaction of aniline (or other aryl amine) with nitrous acid to form a diazonium salt. (b) Subsequent reaction of the diazonium salt with a wide variety of aromatic derivatives, including amines and phenols, to produce stable azo colours. (c) The simple azo colour chrysoidin G (chrysoidine), marketed as a dye for wool, cotton, leather and silk. (Copyright © 2015 E. and A. Yates.)

After the production of diazonium salts, the diazotization reaction opens up a convenient route to the azo dyes (figure 1b), their variety of colours arising from the extensive system of conjugated bonds and the influence of the substituents on this system. Their derivatives also possess improved properties, one of the most important allowing the possibility of direct dyeing, dispensing with a mordant, which was typically a substance such as a metal oxide used in the dyeing process to help fix the dye to the cloth. The first two diazo compounds, prepared by C. A. Martius30 and Hermann Caro31 in 1863–64, both of which were formed from reactions of the diazonium salt and an aromatic amine, were aniline yellow and Manchester (or Bismarck) brown, the latter being the first marketed azo colour.32 Some of these, although not ultimately suitable for use in dyeing on an industrial scale, went on to find scientific application as microbiological stains and, later, as stains for both DNA33 and cellulose.34

An example of Griess's own work in developing azo dyes further is evident in the patent (US213563) entitled ‘Improvement in Colouring Matters’.35 This application related to the production of ‘Anisol-Crimson’, intended to replace the red dye cochineal, which had previously been produced from insects, and extended the scope of the reaction of diazonium salts beyond aromatic amines to include phenolic compounds. Without suggesting that industrial diversification was necessarily feasible at Allsopp's, given modern preoccupations with intellectual property rights and the assumption that an employer has a major interest in any invention of an employee that might be exploited for financial gain, it may seem surprising that Griess was named as the inventor, while the original assignee of the patent was not Allsopp's, but rather Badische Anilin- und Soda-Fabrik of Baden, Germany, better known today as BASF. However, the patent system of the day was very different from its present form, and undergoing rapid change. Moreover, the attitude towards patenting in Britain and Germany, as well as the patent systems in the two countries, were quite distinct, as explored below.

Brewing and synthetic dyes

This period, in which the application of science to brewing flourished, followed a history of brewing ventures of more dubious repute, such as those undertaken by George Adolphus Wigney (1789–1872),36 among others. Wigney, described by James Sumner as a ‘philosophically minded gentleman-proprietor’,37 is also something of a rarity in that he was a brewer who wrote down his procedures, sometimes reporting alarming results. By 1838, the Brighton-based brewer felt sufficiently confident to publish an encyclopaedia of brewing, reporting that his endeavours had not always worked out for the best:

Burnt down a malthouse by snapping porter malt on an improper kiln; killed a horse by feeding him on the half burnt barley and bean malt; by leaving on the cover of the manhole to wooden wort back over copper, while running off boiling wort into hop back, created a vacuum in the copper, and the pressure of the atmosphere broke the bottom of the back asunder, and forced it into the copper with a tremendous explosion.38

Industrialized commercial operations at breweries such as Allsopp's could ill afford destruction (or the possibility of destruction) on this scale. Although employing leading industrial chemists of the day did largely minimize this risk, it nevertheless remains a curious anomaly that Griess maintained his interest in the chemistry of dyes while working for Allsopp's. Christine Macleod has argued that, earlier in the century, innovators were often seen as ‘the comrade-in-arms of the pickpocket and fraudster’,39 but a change was under way. The Patent Law Amendment Act of 1852 had made the patent system ‘more transparent and accessible to inventors’,40 and innovators such as Griess were increasingly regarded as not only models of good character but also estimable and authoritative.41

Given Griess's high profile, many awards and high rate of publication, it cannot be sustained that Allsopp's were unaware of Griess's activities outside of brewing. Furthermore, letters between Griess and Caro establish that, alongside his role of monitoring the brewing process, the firm provided him with a private laboratory in which he could pursue his research interests.42

For most of Griess's brewing career, the brewery was managed by Henry Allsopp (1811–87).43 It may be that Allsopp was too heavily involved in running his large brewing business, and also in politics—he became the Member of Parliament for East Worcestershire in 1874 (where he remained until 1880, when he was elevated to the peerage)—to consider embarking on what would have been an entirely new industrial venture in commercial synthetic dyes. In any case, at least initially, the brewery business outstripped synthetic dyes by a considerable margin.44 Another factor may have been the different attitudes towards staff recruitment for businesses in the two countries. Although Burton Breweries employed trained chemists on their technical staff,45 German dye companies were much more likely to appoint technically qualified chemists to senior management roles alongside more traditional businessmen. In Britain, although supportive of technological innovation, businesses were usually managed without the involvement of technically qualified staff at board level.46

There was little immediately obvious technical connection between brewing and dyes, although the use of stains to improve the visibility of microbiological samples followed quickly after its introduction for the same purpose in histology during the 1870s. Controlling and predicting the behaviour of microorganisms was a continual concern for the brewing industry, and failure to do so effectively could drastically affect the quality of the final product. The formation of the Bacterium Club by Griess and his fellow brewing chemists attests to their preoccupation with microbiological identification. Cohn asserts47 that the systematic study of bacteria began after 1870 and staining was originally employed to improve visibility as had earlier been done in histology, while its use in brewing followed very shortly thereafter. Griess photographed yeast and an unknown contaminating microorganism in spoilt beer in 1885.48 Thus, Griess's presence in Burton, with H. T. Brown, who was applying microscopy to brewing by 1870,49 together with the earlier association of the microscopist William Barwell Turner (1845–1917)50 with Allsopp's, place all the ingredients for the application of new synthetic dyes for the improved identification of microbes in Burton, although no direct evidence of their use for this purpose has been found. The use of dyes to identify species or classes of bacteria was also developed during this period by the Danish bacteriologist Hans Gram (1853–1938) in 1882, who published his results in 1884.51

According to Paisley52 the first definite use of a microscope by a Burton brewery had been by Brown at Worthington and Co., but not until the mid 1880s were they known to have been in use at Allsopp's, where Peter Griess's assistant was observing microbiological specimens. However, Turner, a microscopist of note, had been trained in brewing at Allsopp's, leaving in 1866. Since Pasteur's work on fermentation in the 1860s and 1870s, it had been appreciated that microbiology was important in the brewing process even if, for beer, practical measures to ensure sterile conditions rarely achieved their aim. Later in his career, Turner was known to possess slides of microbial species relevant to brewing in his collection, and we are left to speculate whether Turner influenced Griess (and Allsopp's) to the extent that Allsopp's tolerated Griess's research in synthetic dye chemistry and further development by synthetic dye companies as long as potentially useful stains were retained for use in brewing analysis. The explanation of why Allsopp's, which—though undoubtedly interested in adopting scientific approaches in their brewing business—elected to employ a chemist of Griess's calibre, perhaps lay initially in their need to maintain a highly respectable operation following exoneration of the Burton brewers after the strychnine allegations mentioned above.

In a letter written to Rudolf Schmitt (1830–98)53 in Dresden, Griess offers a description of how he managed to balance his responsibilities:

What would you say if you were in my place? To live in a foreign country in little sympathy with its aims and aspirations, always preoccupied with beer in a town which has little to offer. You must remember that I have almost to steal time for my research work and have no assistant.54

This letter also offers an insight into the practical difficulties of Griess's undertaking, as well as providing more evidence that Griess's brewing chemistry laboratories in Burton must have been used for research other than that directly related to the work of Allsopp's. Anderson comments:

he [Griess] is credited with having published over 140 papers in his lifetime. But, all except one of these papers were on what we may loosely describe as organic synthesis with no connection to brewing. The only brewing paper he published, towards the end of his life, was on the detection of choline in hops.55

And he concludes:

Allsopp's must have been benevolent employers to allow such latitude towards Griess in carrying out his private researches. Perhaps it was Griess's great prestige as chemist, which he lent to the Company, which encouraged them in this. When beer production increased, however, demands on him by the brewery became greater. This, and the fact that he never really settled into the English way of life, undoubtedly led to considerable dissatisfaction on his part in later years.56

Attitudes to secrecy and patents

The apparent paradox in the relationship between brewers and scientists of the period has been noted by James Sumner.57 Whereas the former plied their trade and rarely committed their work to paper, the latter recorded their results but usually had little involvement in brewing. However, the association between the two interests had been a long one.58 A degree of guardedness was perhaps understandable in a business such as brewing, which had both to support innovation to remain competitive, and to avoid making such radical changes to its product as to risk alienating its customers or losing their confidence. This contrasts strongly with the attitude of the successful German synthetic dye companies, who sought to protect innovative processes with patents59 under the newly formed German patent system and, in many respects, were expanding into entirely new product areas.60 The distinct attitudes to intellectual property in the UK and Germany have their origins in the contrasting development and role of patents in the two countries.61

In Britain, patent legislation had originated in the Statute of Monopolies of 1624, which required that a patentee must be a ‘true and first inventor’.62 This clearly created problems for patents to be filed when research and development had been accumulative and collaborative, such as in the brewing industry. Indeed, not all industries were subject to such priority contests. The situation was improved by the Patent Law Amendment Act of 1852, and further balance was applied by Joseph Chamberlain's British Patent Legislation Act of 1883. This legislation protected inventors’ interests without creating monopolies, while enabling effective recourse to litigation where necessary. The inventors, or

Technoscientific practitioners … participated in two spheres. Within the market economy, they pursued patent rights and copyright, trying to acquire financial rewards through proprietary claims on their creative ideas. Their professional activities were also conducted within an intersecting economy of credit, seeking recognition from institutions such as the Royal Society.63

Their objectives were ‘not only to secure financial gains, but to forge authority and credibility’.64 This description of ‘technoscientific practitioner’ fits Griess perfectly.

In Germany, only recently unified from many smaller states, a nationwide patent system was introduced in 1877 and served to protect industrial processes, although initially it was beset with speculative patents.65 Crucially though, in Germany, patents were subjected to examination, providing a much stronger tool for the protection of activities such as industrial dye manufacture, as well as facilitating mutually beneficial licensing. The strength and suitability of the German patent system, combined with the preponderance of high-quality scientific institutes that had originated in the individual states before unification, enabled Germany to provide key skilled staff and made her much better prepared to exploit industrial dyes.66

The structure of the diazonium salts and their development

One consequence of the culture of patenting in the dye industry was that much development of azo dyes was undertaken despite the precise structure of the compounds formed by the diazotization reaction remaining contentious. Originally, Griess had considered the most likely structure to involve the replacement of two hydrogen atoms by two nitrogen atoms. In 1863 Griess had suggested a structure for the diazonium salt of benzene in which both nitrogens were bonded to the benzene ring as well as to each other, which was followed by a suggestion by F. A. Kekulé in 1866 that only one of the two nitrogen atoms was linked to the benzene ring. The structure that acknowledged the salt nature of the diazonium group was proposed by C. W. Blomstrand in 1869 and was generally accepted by 1895, although debate persisted for some years.67 Interest in using Griess's method was considerable, and his former mentor, Hofmann, and colleague, Caro, were notable in continuing to produce new dyes, leading to arguments of priority, which also highlighted the contrasting needs of an open patent system and secrecy mentioned above. Later, soluble sulphonic acid derivatives of azo dyes were produced by F. Z. Roussin (1876), especially orange dyes, but they were not patented, seemingly under the mistaken belief that rivals would find it difficult to replicate the synthesis, an error that was soon exposed.68 A key breakthrough that was made by P. Bottiger in 1884 allowing direct dyeing was the patented synthesis of Congo red azo dye. Another surprising event to modern eyes is that Bottiger sold his patent to AGFA (Aktiengesellschaft für Anilinfabrikation) despite working for a rival firm, Bayer,69 which had initially shown little interest. A complex and highly lucrative industry sprang from these early findings, which was exploited by AGFA after the marketing of Congo red at the 1884 West Africa Conference in Berlin, held to mark the formation of the Congo Free State and from which the appellation Congo originates.70

A sizeable proportion of chemists employed in the UK dye industry were German or had been trained in Germany, and their motivation for coming to the UK may in part have been due to the repressive nature of the regimes at that time in their homelands or to the increase in status and opportunity offered by British industrial companies.71 These chemists included A. W. Hofmann, H. Caro, I. Levinstein (1845–1916), C. A. Martius (1838–1920) and A. Leonhardt (1827–99), most of whom returned to Germany. Griess's experience with dyes was called upon widely; for example he met H. Caro and O. N. Witt (1853–1915)72 in London in 1876 to discuss the dye chrysoidin G (figure 1c). He was also on good terms with other renowned chemists of his day, including H. E. Armstrong FRS73 and, because Griess was considered the foremost authority on azo dyes at that time, was called as an expert witness in the legal case of Caro v. Levinstein, a protracted legal wrangle over the patent for the manufacture of a red colour.74 This, and subsequent legal disputes concerning priority, would have important implications in the development of the modern patenting system in Europe75 through licensing, the formation of cartels and, eventually, the reform of the entire system.76

The British dye industry, despite its early advances under W. Perkin (1838–1907),77 soon became uncompetitive with relatively weak patent protection compared with that in Germany. In contrast, this highly competitive situation resulted in efficient and well-protected companies such as BASF and AGFA quickly dominating the market. Nevertheless, there was considerable collaboration between German and British chemists in the dye industry. Griess was unusual among dye chemists in also being a brewing chemist, and unusual by Sumner's assessment78 in that he was responsible for brewing and he published his scientific works.

The demise of Peter Griess and the continuing impact of Griess's work on dyes

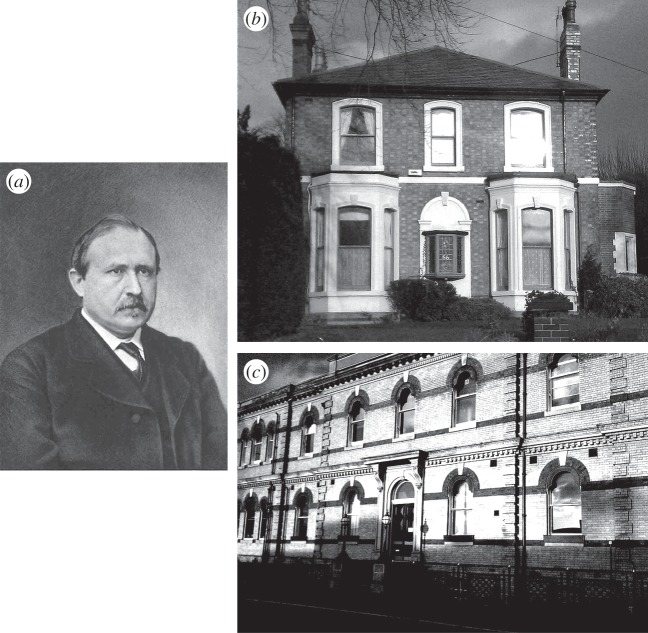

Griess (figure 2a) worked at Allsopp's (figure 2b, c) for more than a quarter of a century, dying suddenly on 30 August 1888 while on holiday in Bournemouth.79 Despite his early financial problems, Griess apparently managed his later business affairs with considerable success, presumably benefiting from both a respectable salary from Allsopp's and perhaps some share of profits accruing from BASF, with whom he first had a contract in 1876.80 In letters to Caro, who worked for BASF, he mentions many occasions on which BASF was approached as his first choice with his new synthetic dyes and, for benzidine-based dyes, expresses regret that the company did not choose to take up the offer.81 BASF even went as far as to offer Griess a job in 1883, which he eventually declined,82 fearing that, as he aged, his levels of energy would not be sufficient for the task. He had had an earlier working relationship with the Stuttgart-based company Siegle, which had merged with BASF in 187383; BASF continued to develop dyestuffs made out of picramic acid and phenols. Griess also supported BASF as a consultant for trials in questions of patents in Great Britain. However, on one occasion, his frustration is evident with the company, and Caro sympathizes over the length of time that BASF took to reach a decision on some of his new dyes.84 For the benzidine dyes, Griess eventually formed an agreement with other companies,85 but laments with Caro that BASF could have provided better terms.

Figure 2.

Griess and his Burton environment. (a) Johann Peter Griess (1829–88).105 (b) The house in Burton upon Trent where Griess and his family lived according to the 1881 census. (Copyright © 2015 E. and A. Yates.) (c) The former offices of Allsopp and Sons, Burton upon Trent. (Copyright © 2015 E. and A. Yates.)

Probate records show that Griess left an estate of just over £10 000, a considerable sum,86 contrasting his earlier parsimonious condition.87 Griess had been involved in an unusual way of working. This considerable workload, in addition to his increasing importance at Allsopp's, was effectively ‘outsourcing’, a century before it became a recognized practice.

Although the industrial and scientific application of azo dyes has been, and remains significant, their environmental impact has been more mixed. Azo dyes break down into diazo compounds, aromatic amines and phenols, some of which are toxic to aquatic life and may be carcinogenic. However, the reaction of nitrite ions added to sulphanilic acid forms the diazo compound, which can be reacted with a naphthalene derivative bearing an amine group to generate a useful coloured indicator. This variant of Griess's original work forms the basis of detection of nitrite ions, for example in the environmental testing of water quality,88 or to detect bacterial infection.89 Since the discovery of the l-arginine/nitric oxide pathway (see Appendix) in 1987,90 many assays based on this principle have been developed for use in a range of biomedical investigations. The reaction also formed the basis of a test for nitrate-containing explosives, although this last application has been largely discontinued.

The azo dyes are still used widely in dyeing fabric and leather goods,91 as well as more restrictedly in food but, unfortunately, are largely resistant to breakdown in the environment once they have been disposed of. Some progress has been made in the use of microbes to assist in degradation,92 and the possibility of dyeing silk by introducing the dye directly into the larvae of the silk worm Bombyx mori, to avoid waste dye altogether, has recently been reported.93 Aromatic amines, formed by the breakdown of some azo dyes, have been implicated in bladder cancer,94 and the EU directive 2002/61/EC of July 2002 recommended a ban on those azo dyes whose degradation products included a specified list of 22 aromatic amines.

Although Congo red is no longer employed as a dye, owing to its toxicity and propensity to run, its descendants are still widely used. Subsequent scientific developments of azo dyes led to the familiar pH indicator methyl orange, and Congo red found new applications including as a stain in the investigation of the virulent Shigella flexneri bacterium.95 They have also been used to identify amyloid fibres,96 implicated in neurodegenerative disorders such as Alzheimer's and Parkinson's diseases. It seems likely that a degree of inspired guesswork played a part in Griess's altering the conditions under which he used nitrous acid as a reactant. In the event, the products of his treatment of aryl amines turned out to be much more useful than the intended reaction and have continued to be developed in diverse applications beyond the dye industry, including nanotechnology,97 diazotype copying,98 and liquid crystal displays.99

Conclusion

Griess performed two roles while at Allsopp's in Burton, keeping them separate. Furthermore, he behaved in quite distinct ways in each domain: first, as the British brewing chemist with a traditional predilection for secrecy, and second, as the German industrial chemist, openly patenting dyes for BASF. The particular attitudes of the industries in the two countries played an important part. These attitudes arose from distinct patent cultures, which were themselves a reflection of the two nations’ very different political and industrial developments. The eventual resolution of these disputes over priority between dye firms in Britain and Germany was to have significant effects on the formation of the modern patent system in Europe. Whereas Allsopp's was initially happy to employ a reputable chemist in Griess to lend credibility to their business after a series of damaging incidents, Allsopp's seemingly relaxed attitude may have been encouraged increasingly by the potential use of new synthetic dyes in determining microbial growth during brewing, a major challenge that could, if not well controlled, devastate beer production.

Griess spent his working life handling aldehyde-containing sugar solutions in his brewing capacity, and amine-containing dyes in his role as a dye expert. Had he mixed these two substances earlier than he did,100 he might also have discovered reactions between the aldehyde group (of sugars) and amines and hence beaten Hugo Schiff (1834–1915),101 another expatriate German chemist, to the discovery of the reaction reported in 1864 that now bears Schiff's name.102 There is also a hint of irony, in view of the difficulties that persist in safely disposing of some azo dyes, that a variant of Griess's method continues to be used to detect pollutants in water for environmental monitoring purposes.103

Griess and some of his contemporaries offer us an insight into the methods of a different type of scientific practitioner from any that had preceded them. In the investigation recorded here, the duality of this role has been placed in the context of the brewing industry in Burton upon Trent, which offers us a perhaps surprising picture of a relatively small industrial town that employed key personnel and sustained a thriving intellectual environment. The brewing industry itself deployed considerable rigour in maintaining status and reputation, as well as consistency and efficiency in production, which were all key considerations in bringing Griess to Burton. This context might well merit further study, as might the technical links between the brewing and dye industries and the international nature of the professional relationships that existed at the time. Perhaps the last words, however, should go to Griess himself. The typescript of a talk given by M. L. Taylor at Allsopp's brewery (by then Ind Coope and Allsopp Ltd) in 1950 describes another discovery made under somewhat unexpected circumstances, further highlighting the sometimes serendipitous nature of scientific discovery. Taylor quotes Griess in conversation recalling how, when working on ‘nitrate of diazobenzol’,

I wanted quiet, so was at work one Sunday morning. I suppose I accidentally pressed a few crystals, so they blew up, and threw me to the floor. ‘What did you do next?’ asked a friend, to which Griess replied, ‘It was clear that I had done enough, so I went off to lunch.’104

Acknowledgements

We are indebted to Katherine Harrington of the Royal Society for assistance with archival material pertaining to Griess, to Dr Isabella Blank of the Unternehmensarkiv at BASF, Ludwigshaven, Germany, for providing details of letters (in German) between Griess and Caro, and also to Dr Anne Herrmann of the University of Liverpool for assistance clarifying their content.

Notes

Biography. By contemporaries covering Griess's early life, education and contributions to organic chemistry, which form the major sources: A. Bopp, A. W. Hofmann and E. Fischer, ‘Zur Erinnerung an Peter Griess’, Ber. Dt. Chem. Ges. 24, 1007–1078 (1891). A review of Griess’ early life with technical details of the development of azo-dyes: F. A. Mason, ‘Johann Peter Griess 1828–1888’, J. Soc. Dyers Col. 46, 33–39 (1930). A series of contemporaneous, general summaries of Griess's life and work: V. Heines, ‘Peter Griess—discoverer of diazo compounds’, J. Chem. Educ. 35, 187–191 (1958); W. H. Cliffe, ‘Johann Peter Griess’, Chem. Ind. (May), 616–621 (1958); R. Wizinger-Aust, ‘Peter Griess und seine Zeit’, Angew. Chem. 70, 199–204 (1958). A general biography (in two parts) that provides historical context for Griess's early life, containing little technical material: E. R. Ward, ‘Peter Griess and the Burton Breweries’, J. R. Inst. Chem. 82, 384–389 and 458–463 (1958). Document containing details of Griess's estate at his death: Principal Probate Registry, Calendar of the Grants of Probate and Letters of Administration made in the Probate Registries of the High Court of Justice in England. R. G. Anderson, ‘Yeast and the Victorian brewers: incidents and personalities in the search for true ferment’, J. Inst. Brew. 95, 337–345 (1989), at p. 340. The work of Anderson, although not concentrating on Griess, begins to examine the motivations of Allsopp's in hiring a foreign chemist of renown. Griess was elected (as Peter Griess) a Fellow of the Royal Society in 1868. The certificate can be found in the repository of the Royal Society Archives (GB 117 Certificates of Election and Candidature (p. 133), ref EC/1963/13). In the 1881 census Griess is described as a ‘Scientific Chemist’ and, although having his place of birth stated as Germany, his name in both cases has been anglicized from Johann Peter Griess to John Peter Griess. In his publications he is known as Peter Griess. Unusually, there is no record of an obituary in the archives of the Royal Society under any of these names, despite a request for one from the Assistant Secretary of the Royal Society, Herbert Rix, to H. E. Armstrong on 10 April 1889 (GB 117 New Letter Book vol. 3 (p. 115), ref NLB/3/203). Letters between H. E. Armstrong and F. K. Beilstein in St Petersburg in 1895 (see note 73 below, letter 71) request that Griess's last papers be published, which Beilstein states are in Armstrong's possession. Armstrong does not seem to have done so.

C. Schuster, Wissenshaft und Technik (BASF Shriftenreihe des Unternehmensarchivs der BASF Aktiengesellschaft, Ludwigshafen, 1976), pp. 77–85. Letters between Griess and Heinrich Caro summarized (in ch. 6, pp. 75–94) in German.

A. S. Travis, ‘Heinrich Caro and Ivan Levinstein: uniting colours of Ludwigshafen and Lancashire’ in The chemical industry in Europe 1850–1914: industrial growth, pollution and professionalization (ed. E. Homburg, A. S. Travis and H. G. Schroter), pp. 261–281 (Springer Science and Business Media, Dordrecht, 1998), at p. 272.

A. S. Wohl, Public health in Victorian Britain (Harvard University Press, Cambridge, MA, 1983), p. 53.

O. Davies, Murder, magic, madness: the Victorian trials of Dove and the wizard (Routledge, London, 2014), p. 95.

S. Wilmot, ‘Pollution and public concern: the response to the chemical industry in Britain to emerging environmental issues 1860–1901’ in The chemical industry in Europe 1850–1914: industrial growth, pollution and professionalization (ed. E. Homburg, A. S. Travis and H. G. Schroter), pp. 261–281 (Springer Science and Business Media, Dordrecht, 1998), p. 147.

C. M. Jackson, ‘Re-examining the research school: August Wilhelm Hofmann and the re-creation of a Liebigian research school in London’, Hist. Sci. 44, 281–319 (2006).

A. W. Hofmann and T. Graham, ‘Upon the Alleged Adulteration of Pale Ale by Strychnine’, Edin. New Phil. J. 53, 266–274 (1852).

C. C. Owen, ‘The history of brewing in Burton upon Trent’, J. Inst. Brew. 93, 37–41 (1987).

J. Sumner, Brewing science, technology and print, 1700–1880. Science and culture in the 19th century (Pickering & Chatto, London, 2013), pp. 1–320.

Hofmann and Graham, op. cit. (note 8), p. 158.

H. O. Sibum, ‘Reworking the mechanical value of heat: instruments of precision and gestures of accuracy in early Victorian England’, Stud. Hist. Phil. Sci. 26, 73–106 (1995).

Hofmann and Graham, op. cit. (note 8).

R. G. Anderson, ‘The sword and the armour: science and practice in the brewing industry 1837–1914’, Brew. Hist. 123, 74–75 (2006).

J. L. Baker, ‘Obituary notice’, Biochem. J. 19, 165–167 (1925).

A. Harden, ‘Obituary notice’, Biochem. J. 14, 1–3 (1920).

H. E. Armstrong, ‘The tragedy of starch. Cornelius O'Sullivan, 1841–1907’, J. Inst. Brew. (June), 223–225 (1934).

H. T. Brown, ‘Reminiscences of fifty years’ experience of the application of scientific method to brewing practice’, J. Inst. Brew. 22, 267–354 (1916).

C. G. Matthews, ‘Meeting of the Burton on Trent section, held at the Queen's Hotel, Burton on Trent. Wed. April 18th 1923’, J. Inst. Brew. 29, 598–611 (1923).

Ward, op. cit. (note 1).

A. J. Rocke, The quiet revolution: Hermann Kolbe and the science of organic chemistry (University of California Press, Berkeley, CA, 1993).

Bopp et al., op. cit. (note 1).

H. Van den Belt and A. Rip, ‘The Nelson–Winter–Dosi model and synthetic dye chemistry’, in The social construction of technological systems: new directions in the sociology and history of technology (ed. W. E. Bijker, T. P. Hughes and T. Pinch), pp. 135–158 (MIT Press, Cambridge, MA, 1987), at pp. 148–149.

R. G. Anderson, ‘Yeast and the Victorian brewers: incidents and personalities in the search for true ferment’, J. Inst. Brew. 95, 337–345 (1989), at p. 340.

M. L. Taylor, ‘A short history of Ind Coope and Allsopps Ltd’, Staffordshire Libraries Archive, Reference SB 705 TAY (1950). This is an unpaginated transcript of a talk given in the brewery's Guildhall on 23 October 1950.

Bopp et al., op. cit. (note 1).

K. H. Saunders, The aromatic diazo-compounds and their technical applications, 2nd edn (Edward Arnold, London, 1949), ch. 1.

Hofmann, op. cit. (note 1), p. 342.

C. Rheinhardt and A. S. Travis, Heinrich Caro and the creation of modern chemical industry (Kluwer Academic Publishing, Dordrecht, 2000), pp. 177–218.

Ibid.

Ibid.

P. Ball, Bright Earth. The invention of colour (Vintage, London, 2001), p. 250.

Y. H. Chi, J. Zhuang, Q. B. Xue and K. A. Li, ‘Study on the chemical reaction of DNA with Congo red’, Guang. Pu. Xue. Guang. Pu. Fen. Xi 26, 97–101 (2006).

J. H. Carder, ‘Detection and quantitation of cellulose by Congo red staining of substrates in a cup-plate diffusion assay’, Anal. Biochem. 153, 75–79 (1986).

‘Improvement in Colouring Matters’, United States Patent Office Letters Patent No. 213, 563, filed February 12, 1879.

Sumner, op. cit. (note 10), p. 167.

Ibid., p. 6.

George Adolphus Wigney, An Elementary Dictionary, or Cyclopaediae for the use of Maltsters, Brewers, Distillers, Rectifiers, Vinegar Manufacturers and Others (R. Sickelmore for the author, Brighton, 1838), p. iv.

C. Macleod, Heroes of innovation; technology, liberalism and British identity 1759–1914 (Cambridge University Press, 2007), p. 8.

Ibid.

Ibid., pp. 8–9.

Schuster, op. cit. (note 2), p. 77.

L. Richmond and A. Turton, The brewing industry; a guide to historical records (Manchester University Press 1990), p. 44.

Ward, op. cit. (note 1), p. 461.

Royal Commission on Scientific Instruction 1, 1872 C 536.

J. P. Murmann, Knowledge and competitive advantage (Cambridge University Press, New York, 2003), pp. 176–177.

H. J. Cohn, ‘The history of staining: the development of bacterial staining methods’, Stain Technol. 5, 39–48 (1930).

Anderson, op. cit. (note 24), p. 343.

Brown, op. cit. (note 18).

W. B. Turner (1845–1917) was a noted naturalist who became president of the Leeds Naturalists’ Club in 1881. A collection of his notes on the Desmidiaceae (one of the four classes of green algae) reside in the Brotherton Library at the University of Leeds (see http://www.microscopy-uk.org.uk/mag/artsep11/pp-beer.doc and http://library.leeds.ac.uk/special-collections-explore/6289).

H. C. Gram, ‘Über die isolierte Färbung der Schizomyceten in Schnitt und Trockenpraeparaten’, Fortschr. Med. 2, 185–189 (1884).

P. B. Paisley, ‘More than a microbiologist: remarks on the life and work of William Barwell Turner (see http://www.microscopy-uk.org.uk/mag/artsep11/pp-beer.doc).

V. Wehefritz, Bibliography on the history of chemistry and chemical technology. Seventeenth to nineteenth century (K. G. Saur, Munich, 1994), p. 1444.

R. G. Anderson ‘The pattern of brewing research: a personal view of the history of brewing chemistry in the British Isles’, J. Inst. Brew. 98, 85–109 (1992), at p. 92.

Anderson, op. cit. (note 24), p. 342.

Ibid.

Sumner, op. cit. (note 10), p. 5.

Murmann, op. cit. (note 46), p. 91.

W. Abelhauser, W. v. Hippel, J. A. Johnson and R. G. Stokes, German industry and global enterprise. BASF: the history of a company (Cambridge University Press, New York, 2004), pp. 79–81.

P. J. T. Morris and A. S. Travis, ‘A history of the international dyestuff industry’, Am. Dyestuff Rep. no. 81 (1992).

Murmann, op. cit. (note 46), p. 91.

S. Arapostathis and G. Gooday, Patently contestable: electrical technologies and inventor ideas on trial in Britain (MIT Press, Cambridge, MA, 2013), p. xii.

Sumner, op. cit. (note 10), p. 6.

Ibid.

Travis, op. cit. (note 3), pp. 261–280.

Murmann, op. cit. (note 46), p. 91.

J. C. Cain, ‘The constitution of the diazo compounds’, J. Chem. Soc. Trans. 91, 1049–1056 (1907).

Rheinhardt and Travis, op. cit. (note 29).

Travis, op. cit. (note 3).

D. P. Steensma, ‘“Congo” red’, Arch. Path. Lab. Med. 125, 250–252 (2001).

Schuster, op. cit. (note 2). Both Griess and his friend and colleague Caro lacked a doctoral degree, which may have hindered their ability to work in academic research in Germany (p. 75), although they were both awarded honorary degrees in 1877 (p. 84).

Murmann, op. cit. (note 46).

Collected papers, H. E. Armstrong, Imperial College Records and Archives, items 191 and 192, p. 22.

Travis, op. cit. (note 3).

Ibid.; Murmann, op. cit. (note 46).

Travis, op. cit. (note 3), p. 262.

R. Brightman, ‘Perkin and the dyestuff industry in Britain’, Nature 177, 808–856 (1956).

Sumner, op. cit. (note 10).

‘The Late Dr. Griess.

‘We feel sure that all who had the pleasure of an acquaintance with the late Dr. Griess will sincerely regret his sudden decease when in apparently good health, and but little over the prime of life. The doctor and his family of four children left Burton for a holiday at Bournemouth a fortnight before his decease. He was then to all appearances in his usual health and spirits, and up to the night before his death there was no apparent charge [sic]. On Wednesday night he retired to rest with one of his sons, and on Thursday morning was found dead, having quietly passed away in the night. The news of his decease caused a feeling of deep sadness among a large circle of friends in Burton, who had learned to love the quiet, gentle habits of the doctor. On Monday the remains of the deceased were brought to Burton, and were met at the Railway Station, at half-past one, by the relatives of his late wife and other friends, who assembled at Messrs. Allsopp and Sons’ offices, and followed to the cemetery, where the body was consigned to the tomb of his late father-in-law Dr. Mason.’ Burton News and Standard, 6 September 1888.

Schuster, op. cit. (note 2), p. 89.

Ibid., p. 93.

Ibid., p. 93.

Ibid., p. 84.

Ibid., p. 89.

Ibid., pp. 92–93.

Principal Probate Registry, op. cit. (note 1), dated 29 October 1888.

Ward, op. cit. (note 1), p. 462.

K. Grasshoff, M. Ehrhardt and K. Kremling, Methods of sea water analysis I (Verlag Chemie, New York, 1983), pp. 177–185.

D. Tsikas, ‘Analysis of nitrite and nitrate in biological fluids by assays based on the Griess reaction: appraisal of the Griess reaction in the l-arginine/nitric oxide area of research’, J. Chromatogr. B. Anal. Technol. Biomed Life Sci. 851, 51–70 (2007).

M. W. Radomski, R. M. Palmer and S. Moncada, ‘Comparative pharmacology of endothelium-derived relaxing factor, nitric oxide and prostacyclin in platelets’, Br. J. Pharmacol. 92, 181–187 (1987).

A. Bafana, S. S. Devi and T. Chakrabarti, ‘Azo dyes, past, present and the future’, Environ. Rev. 19, 350–371 (2011).

R. Khan and U. C. Banerjee, ‘Decolorization of azo dyes by immobilized bacteria’, in Biodegradation of azo dyes (Handbook of environmental chemistry, vol. 9) (ed. H. A. Erkurt), pp. 73–84 (Springer, New York, 2010), at pp. 78–81.

A. Pandey, P. Singh and L. Lyengar, ‘Bacterial decolorization and degradation of azo dyes’, Int. Biodeterior. Biodegr. 59, 73–84 (2007); A. Nisal and 11 others, ‘Uptake of azo dyes into silk glands for production of colored silk cocoons using a green feeding approach’, ACS Sustain. Chem. Engng 2, 312–317 (2014).

E. K. Weisburger, ‘Cancer-causing chemicals’, in Cancer: the outlaw cell (ed. R. E. LaFond), pp. 73–86 (American Chemical Society, Washington DC, 1988).

F. Qadri, S. A. Hossian, I. Ciznar, K. Haider, A. Ljungh, T. Wadstrom and D. A. Sack, ‘Congo Red binding and salt aggregation as indicators of virulence in Shigella species’, J. Clin. Microbiol. 26, 1343–1348 (1988).

E. P. Benditt, N. Eriksen and C. Berglund, ‘Congo Red dichroism with dispersed amyloid fibrils, an extrinsic Cotton effect’, Proc. Natl Acad. Sci. USA 66, 1044–1051 (1970).

A. Gizzatov, A. Dimiev, Y. Mackeyev, J. M. Tour and L. J. Wilson, ‘Highly water soluble multi-layer graphene nanoribbons and related honey-comb carbon nanostructures’, Chem. Commun. 48, 5602–5604 (2012).

H.-D. Jakubke and H. Jeschkeit (eds), Concise encyclopedia of chemistry (tr. rev. M. Eagleson) (Walter de Gruyter, Berlin, 1994).

V. Chigrinov, E. Prudnikova, V. Kozenkov and H. Kwot, ‘Synthesis and properties of azo dyes aligning layers for liquid crystal cells’, Liq. Cryst. 29, 1321–1327 (2002).

P. Griess, ‘Über die Einwirkung aromatischer Diamine auf Zuckerarten’, Ber. Dt. Chem. Ges. 20, 281–282 (1887).

T. T. Tidwell, ‘Hugo (Ugo) Schiff, Schiff bases, and a century of beta-lactam synthesis’, Angew. Chem. Int. Edn 46, 2–7 (2007).

H. Schiff, ‘Mittheilungen aus dem Universitätslaboratorium in Pisa: eine neue Reihe organischer Basen’, Justus Liebigs Annln Chem. 131, 118–119 (1864).

Grasshoff et al., op. cit. (note 88).

Taylor, op. cit. (note 25).

A. Bopp, A. W. Hofmann and E. Fischer, ‘Zur Erinnerung an Peter Griess’, Ber. Dt. Chem. Ges. 24, 1007–1078 (1891).

Appendix. Glossary of chemical terms

The prototype molecule of six-membered carbon rings in which each carbon atom is bonded to its two adjacent carbon atoms and one hydrogen is benzene, a type of unsaturated compound because not all the chemical bonds are engaged in bonding other atoms (the arrangement of the bonds is also termed a conjugated system). The general classification ‘aryl’ and description ‘aromatic’ is also given to such groups. Strychnine is a toxic alkaloid used as a pesticide with a bitter taste, whose structure was not established until 1946. The l-arginine/NO pathway is a biosynthetic pathway involving conversion by the enzyme nitric oxide synthase of the amino acid l-arginine into nitric oxide (NO), an important signalling molecule with many roles, including blood pressure regulation and wound repair.