Abstract

Aim of the Study:

To evaluate and compare the linear dimensional changes of the three representative polyvinyl siloxane (PVS) impression materials and to compare the accuracy of single mix with double mix impression technique.

Methodology:

A study mold was prepared according to revised American Dental Association specification number 19 for nonaqueous elastic dental impression materials. Three PVS impression materials selected were Elite-HD, Imprint™ II Garant, Aquasil Ultra Heavy. Two impression techniques used were single mix and double mix impression technique. A total of 60 specimens were made and after 24 h the specimens were measured using profile projector.

Statistical Analysis:

The data were analyzed using one-way analyses of variance analysis and significant differences were separated using Student's Newman–Keul's test.

Results:

When all the three study group impression materials were compared for double mix technique, the statistically significant difference was found only between Imprint™ II Garantand Elite-HD (P < 0.05). Similarly, using single mix technique, statistically significant difference were found between Elite-HD and Imprint™ II Garant (P < 0.05) and also between Aquasil Ultra Heavy and Elite-HD (P < 0.05). When the linear dimensional accuracy of all three impression material in double mix impression technique and single mix impression technique were compared with the control group, Imprint™ II Garant showed the values more nearing to the values of master die, followed by Aquasil Ultra Heavy and Elite-HD respectively.

Conclusion:

Among the impression materials Imprint™ II Garant showed least dimensional change. Among the impression techniques, double mix impression technique showed the better results.

Key Words: Dimensional accuracy, double mix impression technique, impression materials, polyvinyl siloxane, single mix impression technique

INTRODUCTION

Dental impression materials are used to register the form and relation of the teeth and the surrounding oral tissues. Accuracy and dimensional stability of impression materials have been the traditional goals of researchers and clinicians.[1] The most popular elastomer used in the dental practice today is the polyvinyl siloxane (PVS). PVS impression materials have low dimensional change, low creep, and relatively short setting time, have moderate to high tear resistance.[2] As there are no by-products to the polymerization reaction, impressions are dimensionally stable and can be poured at the convenience of the operator.[3,4] Addition silicones are available in four consistencies of viscosities like low, medium, heavy and putty. Making an impression represents a crucial step in processing and fitting dental prosthesis. The various impression techniques used for making an impression are: (1) Putty wash single step, (2) putty wash two-step, (3) single mix and (4) multiple mix techniques. In spite of best available impression materials and advanced impression techniques, we still come across inaccuracy of fit of a dental prosthesis, which may be either due to the inaccuracy of impressions or dimensional changes of impression.[1] Hence, this study is undertaken to compare the dimensional accuracy of three brands of PVS impression materials and to evaluate the most accurate impression technique.

METHODOLOGY

Impression materials used in the study

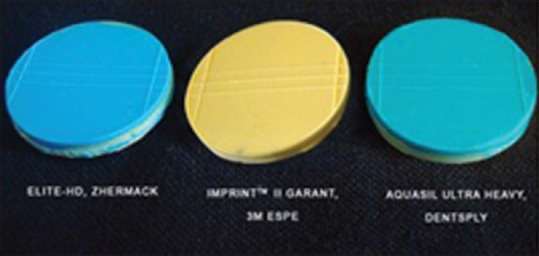

-

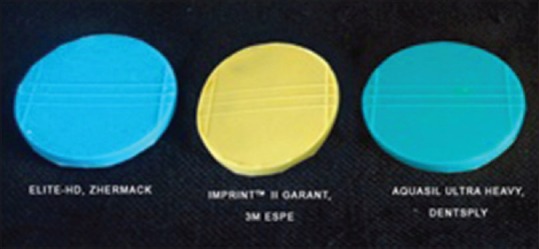

Elite-HD, (Zhermack, Italy) hydrophilic vinyl polysiloxane [Figure 1]

- Heavy body – Lot number 64747

- Light body – Lot number 69125.

-

Imprint™ II Garant (3M ESPE, Germany) vinyl polysiloxane: [Figure 1]

- Heavy body – Lot number 20030127

- Light body – Lot number 20041215.

-

Aquasil ultra heavy, (Dentsply/Caulk, USA) hydrophilic addition reaction silicone: [Figure 1]

- Heavy body – Lot number 071012

- Light body – Lot number 100608.

Figure 1.

Impression materials used in the study

For the purpose of the study, the impression specimens have been divided into three main groups

Group I: Consists of specimens made using, Elite-HD impression material

Group II: Consists of specimens made using Imprint™ II Garant impression material

Group III: Consists of specimens made using Aquasil Ultra Heavy impression material.

Method of impression making

Two different impression techniques utilized in this study were subgrouped as follows:

Method A – Double mix impression technique

Method B – Single mix impression technique.

Steps followed for the study

Study mold fabrication

Manipulation of selected study materials

Recovery of test specimens

Measuring of test specimens for dimensional accuracy.

Study mold fabrication

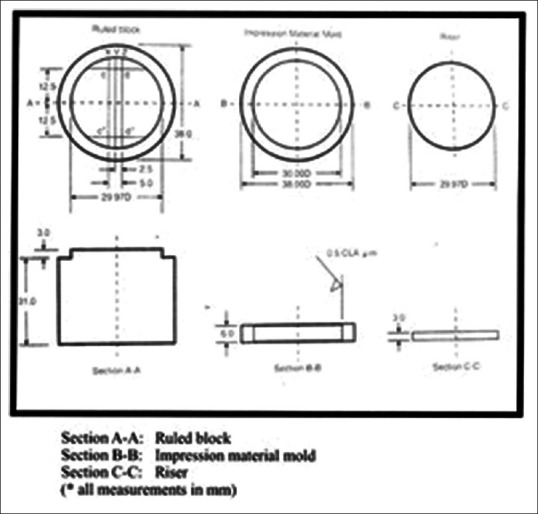

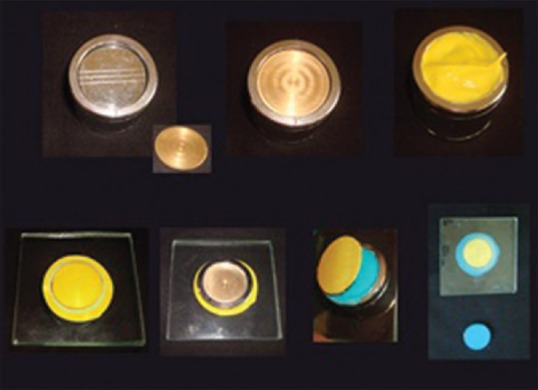

For the study, stainless steel molds were custom fabricated according to revised American Dental Association (ADA) specification number 19, which is used for testing nonaqueous elastic dental impression materials [Figures 2 and 3].[2] A brass metal plate of thickness 1.5 mm and diameter of 29.9 mm was also made to be used as a spacer to create uniform space for light bodied wash impression material for the specimens made using method A.

Figure 2.

Schematic diagram showing American Dental Association specification number 19 detail reproduction block

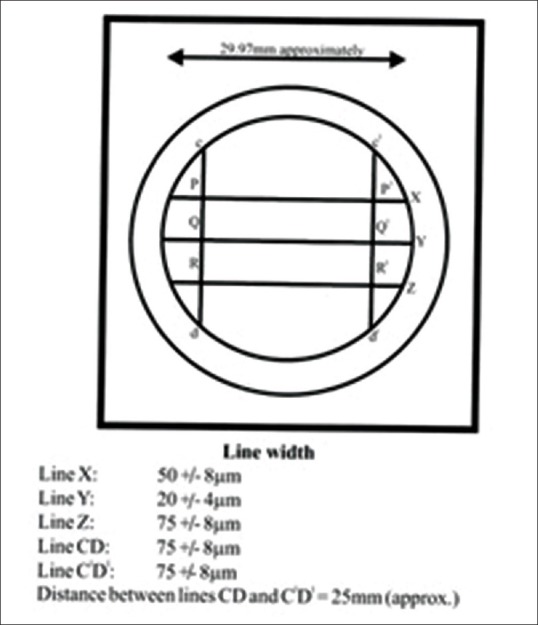

Figure 3.

Schematic diagram showing ruled surface of the die

Manipulation of selected study materials

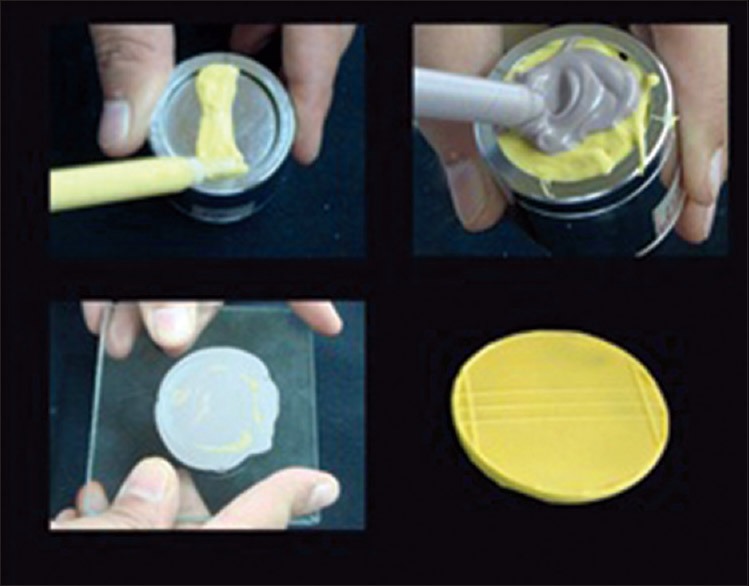

Procedure for making specimens for all three study group materials using method A

Impression of the die was made using an automixing impression gun of 3M ESPE. Brass metal plate of thickness 1.5 mm and diameter of 29.9 mm (to create uniform space for light body material) was placed in the mold. Heavy body impression material was loaded on the metal plate. Flat glass plate (of weight 67 g) was placed on top of the mold to keep the impression material within the mold and to apply sufficient force. Allow the heavy-bodied material to harden. Then brass metal plate was taken out and light bodied wash impression material was applied to the die space created by 1.5 mm thickness metal plate [Figures 4 and 5]. Care was taken to ensure that the tip was in contact with the lined areas of the metal die and then the impression material was pushed ahead of syringe tip. A polyethylene sheet followed by a flat glass plate was placed on top of the mold.

Figure 4.

Procedure for making double mix impression technique

Figure 5.

Close-up view of each impression material specimens made using double mix impression technique

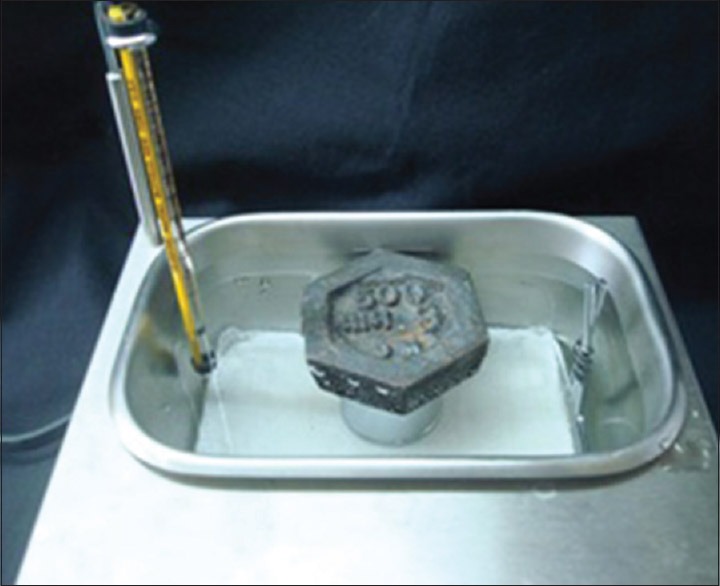

The assembly was immediately transferred to the thermostatically controlled water bath [Figure 6]. 500 g weight was placed on top of the flat glass plate to ensure that the die did not move and to maintain adequate pressure to record the detail production of the scribed lines of the mold. The water bath was temperature maintained at 32 ± 2°C to simulate oral conditions in accordance with ADA specification number 19 [Figures 7–9].

Figure 6.

Thermostatically controlled water bath with test assembly

Figure 7.

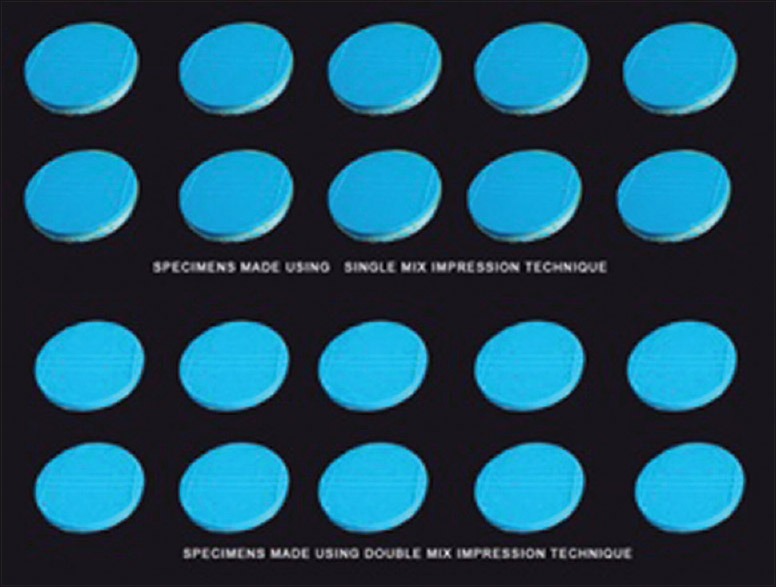

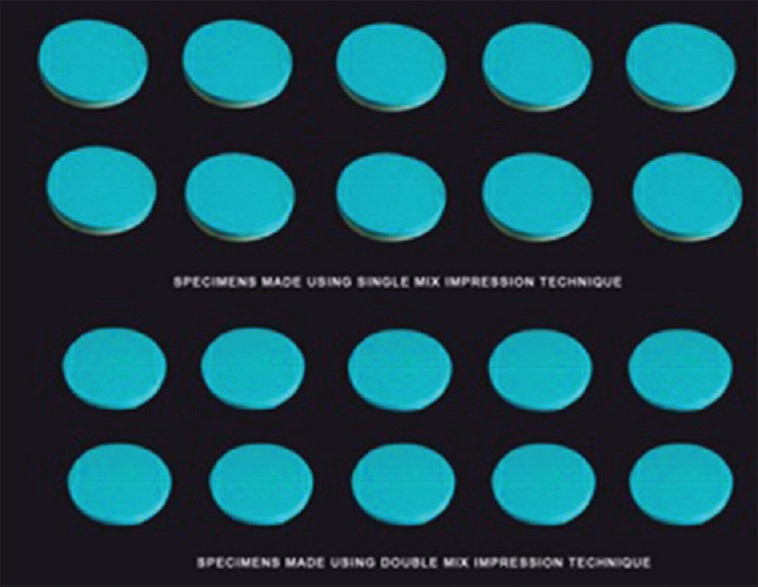

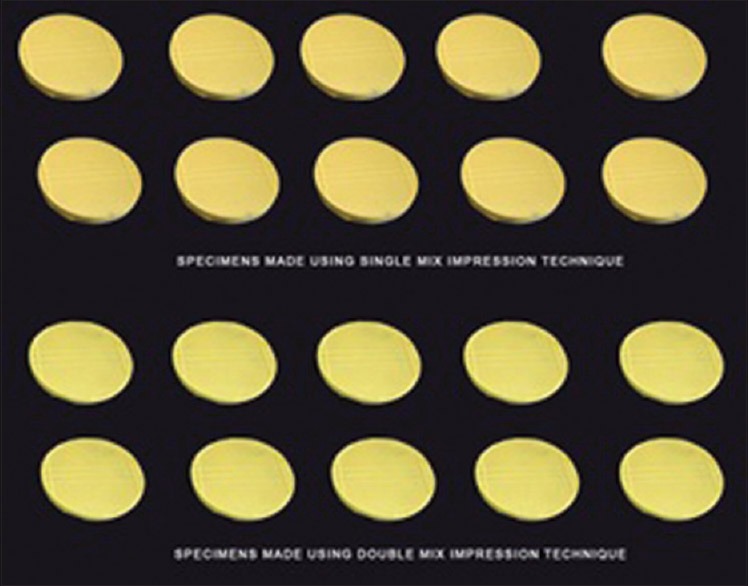

Specimens of impressions of Group – I impression material (Elite-HD, Zhermack)

Figure 9.

Specimens of impressions of Group – III impression material (Aquasil Ultra Heavy, Dentsply)

Figure 8.

Specimens of impressions of Group – II impression material (ImprintTM II Garant, 3M ESPE)

Procedure for making specimens for all three study group materials using method B

The heavy bodied impression material and the light bodied impression material was loaded separately into a fine tipped impression syringe. Light bodied material was applied to lined areas of the die and then heavy bodied impression material was loaded. A polyethylene sheet followed by a flat glass plate (of weight 67 g) was placed on top of the mold to keep the impression material within the mold and to apply sufficient force [Figures 10 and 11].

Figure 10.

Procedure for making single mix impression technique

Figure 11.

Close-up view of each impression material specimens made using single mix impression technique

The assembly was immediately transferred to the thermostatically controlled water bath. 500 g weight was placed on top of the flat glass plate to ensure that the die did not move and to maintain adequate pressure to record the detail production of the scribed lines of the mold. The water bath was temperature maintained at 32 ± 2°C to simulate oral conditions in accordance with ADA specification number 19.

Recovery of test specimens

The entire assembly that is, the die, polyethylene sheet, flat glass plate and weight were removed from the water bath after 13 min. The impressions were allowed to set for 5 min longer than the manufacturers recommended minimal removal time, as indicated in ADA specification Number 19 for lab testing. The mould and raiser were then separated, and the impression was retrieved. All the specimens were numbered group wise for measuring dimensional accuracy [Figures 7–9].

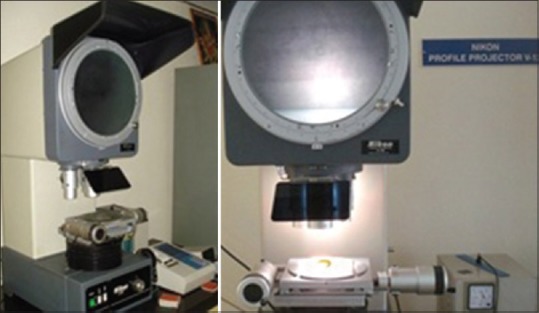

Measuring of test specimens for dimensional accuracy

Dimensional accuracy was evaluated 24 h after making of impression. The length of the line “Y” between cross points “Q” and “Q1” of each impression sample was measured [Figures 12]. This measurement was made thrice for each sample using profile projector to the nearest of 0.001 mm at ×10 magnification. All the readings thus obtained were tabulated and subjected to statistical analysis.

Figure 12.

Nikon profile projector V12, Japan, for measuring the specimen dimensions, and the specimen on the projector table

Statistical analysis

The data obtained were analyzed using one-way analyses of variance at 1% confidence level with impression materials. Significant differences were calculated using Student's Newman–Keul's test.

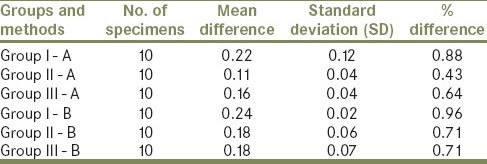

RESULTS

Table 1 shows the descriptive statistics for all the three study groups. The table shows the mean difference value obtained for each study group by subtracting the overall mean of each group with that of the overall mean of the control group. The table also shows the standard deviation of all three study group impression materials.

Table 1.

The descriptive statistics of mean difference, standard deviation (in mm) and percent difference of three study groups for single mix impression technique and double mix impression technique

When the linear dimensional accuracy of all three impression material in double mix and single mix impression technique were compared with the control group that is, with the metal die, Imprint™ II Garant showed the value more nearing to the values of the metal, which demonstrates least dimensional changes followed by Aquasil Ultra Heavy and Elite-HD.

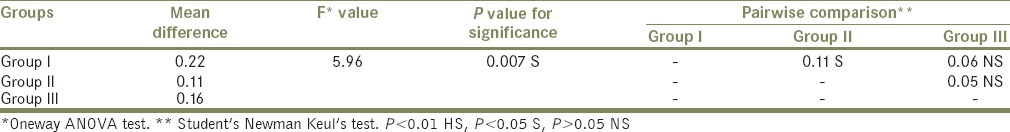

Table 2 shows the intergroup comparison between all the three study group impression materials using double mix impression technique, Imprint™ II Garant was more accurate, followed by Aquasil Ultra Heavy and Elite-HD.

Table 2.

Intergroup comparison between three study groups in Double Mix Technique (all values are in mm)

Table 3 shows the intergroup comparison of all the three study group impression materials using single mix impression technique. The mean values obtained for:

Table 3.

Comparison between all three study groups in Single Mix Technique (all values are in mm)

Elite-HD and Imprint™ II Garant reveals a statistically significant difference (P < 0.05) of 0.06 mm.

Elite-HD and Aquasil ultra heavy show statistically significant (P < 0.05) difference between the specimens to the value of 0.06 mm.

Imprint™ II Garant and Aquasil ultra heavy show the difference between them was 0.0008 mm, which was not statistically significant.

Thus, both group II that is, Imprint™ II Garant and group III that is, Aquasil ultra heavy were more accurate with similar mean difference value of 0.18 mm followed by group I that is, Elite-HD with the value of 0.28 mm.

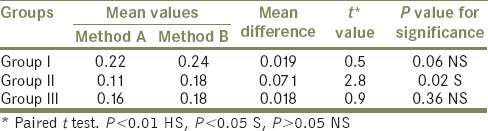

Table 4 shows the intragroup comparison between double mix and single mix impression techniques in all the three study groups with mean difference of double mix technique and single mix technique, “t” value and “P” value of significant. Only group II that is, Imprint™ II Garant showed significant difference with P < 0.05, which was significant and both group III and group I that is, Elite-HD did not show any significant difference.

Table 4.

Comparison of dimensional accuracy between Double Mix Technique and Single Mix Technique within the three study groups:

DISCUSSION

Impressions must be stable enough to produce accurate casts over extended periods of time as many dentists do not pour the impressions immediately. Hence, there is a need for more stable impression material. The accuracy of the impression may be affected due to several factors such as impression materials, impression techniques, impression trays, shrinkage due to polymerization reactions, etc.

Several studies have been conducted in the past and few authors have reported that the accuracy of addition silicone was affected rather by type of materials than the technique while others have stated that accuracy may be controlled more with technique than by the material itself.[5,6,7,8]

In a study was carried out to measure the dimensional changes in three silicone impression materials (Xantopren-H, President and Fulldent) using single mix and double mix techniques and concluded that Xantopren-H had more accurate dimensions and single mix gave more accurate casts.[9]

Another study comparing the dimensional accuracy of monophase, one-step and two-step putty/light-body, and a novel two-step injection impression technique using silicone impression materials it was concluded that two-step putty/light-body and two-step injection techniques were the most dimensionally accurate impression methods in terms of resultant casts.[10]

Since many studies showed conflicting results, it was felt necessary to compare the accuracy of double mix impression technique with the single mix impression technique using most commonly used brands of VPS impression materials.

The present study result coincides with the finding of other studies: Lacy et al. have made a quantitative comparison of the accuracy and dimensional stability of representative products in each class of polyether, polysulfides and PVS. Results showed that PVSs are the most stable of elastomers.[3]

However, in the present study, slight differences in accuracy were noted among all brands of products measured and no single product seemed to noticeably outperform the others; all appeared to be comparable with the reported values for addition silicones, and were considered to be within clinically acceptable limits for accuracy. It was found that both in single mix and double mix technique; the least dimensional change was exhibited by Imprint™ II Garant which was followed by Aquasil Ultra Heavy, and Elite-HD.

There are other studies which contradict the findings of the present study conducted by Hassan to measure the dimensional changes in three silicone impression materials (Xantopren-H, President and Fulldent) using single mix and double mix techniques and concluded that Xantopren-H had more accurate dimensions and single mix gave more accurate casts.[9] And also with the study conducted by Lepe et al. where they compared the accuracy of a one-step versus two-step putty wash impression technique using five addition silicone impression materials and found that the one-step impression technique was more accurate than the two-step impression technique.[11]

The present study is in accordance with the study carried out b by Caputi and Varvara, to compare the dimensional accuracy of a monophase, one-step and two-step putty/light-body, and a novel two-step injection impression technique using silicone impression materials in which it was concluded that two-step putty/light-body and two-step injection techniques were the most dimensionally accurate impression methods in terms of resultant casts.[10]

The difference in the single mix and double mix in accuracy and elasticity may be attributed to the rate of polymerization: Faster polymerization will prohibit the penetration of the free radicals. The light body component occupies a minute volume, so its effect on the resultant deformation will be slight.[9]

Vinyl polysiloxane impression materials are available in all viscosities: Light, medium, heavy, and putty. Studies have shown that higher filler loading may increase the accuracy[1] and higher the viscosity, less the constriction.[12] And low viscosity material showed the greatest changes due to their lower filler content.[13]

With the above discussion, following interpretations can be made for the present study. Since all the procedures were standardized and all groups received the same control treatments, the difference in dimensional accuracy among the test groups were assumed to be attributed to brand differences.

If an accurate impression material, good impression protocol and controlled conditions that approximate clinical situation such as oral temperatures are used, double mix impression technique was found to be better than the single mix impression technique. However, the dimensional change demonstrated was well within ADA standards.

CONCLUSION

Within the limitations of this in vitro study, the following conclusions can be drawn:

When the linear dimensional accuracy of all three impression material in double mix impression technique and single mix impression technique were compared Imprint™ II Garant showed the values more nearing to the values of master die followed by Aquasil Ultra Heavy and Elite-HD respectively. However, the dimensional changes for all the three impression materials were well within the standards of maximal shrinkage value for type I, II, III according to ADA specification number 19

Among the impression techniques, the double mix impression technique showed the better results compared with single mix impression technique.

Footnotes

Source of Support: Nil

Conflict of Interest: None.

REFERENCES

- 1.Wadhwani CP, Johnson GH, Lepe X, Raigrodski AJ. Accuracy of newly formulated fast-setting elastomeric impression materials. J Prosthet Dent. 2005;93:530–9. doi: 10.1016/j.prosdent.2005.03.007. [DOI] [PubMed] [Google Scholar]

- 2.Ciesco JN, Malone WF, Sandrik JL, Mazur B. Comparison of elastomeric impression materials used in fixed prosthodontics. J Prosthet Dent. 1981;45:89–94. doi: 10.1016/0022-3913(81)90018-4. [DOI] [PubMed] [Google Scholar]

- 3.Lacy AM, Fukui H, Bellman T, Jendresen MD. Time-dependent accuracy of elastomer impression materials. Part II: Polyether, polysulfides, and polyvinylsiloxane. J Prosthet Dent. 1981;45:329–33. doi: 10.1016/0022-3913(81)90400-5. [DOI] [PubMed] [Google Scholar]

- 4.Boksman L. Eliminating variables in impression-taking. Ont Dent. 2005 Dec;:22–5. [Google Scholar]

- 5.Johnson GH, Craig RG. Accuracy of four types of rubber impression materials compared with time of pour and a repeat pour of models. J Prosthet Dent. 1985;53:484–90. doi: 10.1016/0022-3913(85)90630-4. [DOI] [PubMed] [Google Scholar]

- 6.Hung SH, Purk JH, Tira DE, Eick JD. Accuracy of one-step versus two-step putty wash addition silicone impression technique. J Prosthet Dent. 1992;67:583–9. doi: 10.1016/0022-3913(92)90151-y. [DOI] [PubMed] [Google Scholar]

- 7.Habib AN, Shehata MT. The effect of the type and technique used for impression making on the accuracy of elastomeric impression materials. Egypt Dent J. 1995;41:1409–16. [PubMed] [Google Scholar]

- 8.Wöstmann B, Rehmann P, Balkenhol M. Influence of impression technique and material on the accuracy of multiple implant impressions. Int J Prosthodont. 2008;21:299–301. [PubMed] [Google Scholar]

- 9.Hassan AK. Dimensional accuracy of 3 silicone dental impression materials. East Mediterr Health J. 2006;12:632–6. [PubMed] [Google Scholar]

- 10.Caputi S, Varvara G. Dimensional accuracy of resultant casts made by a monophase, one-step and two-step, and a novel two-step putty/light-body impression technique: An in vitro study. J Prosthet Dent. 2008;99:274–81. doi: 10.1016/S0022-3913(08)60061-X. [DOI] [PubMed] [Google Scholar]

- 11.Lepe X, Johnson GH, Berg JC, Aw TC. Effect of mixing technique on surface characteristics of impression materials. J Prosthet Dent. 1998;79:495–502. doi: 10.1016/s0022-3913(98)70168-4. [DOI] [PubMed] [Google Scholar]

- 12.Fano V, Gennari PU, Ortalli I. Dimensional stability of silicone-based impression materials. Dent Mater. 1992;8:105–9. doi: 10.1016/0109-5641(92)90064-j. [DOI] [PubMed] [Google Scholar]

- 13.Mandikos MN. Polyvinyl siloxane impression materials: An update on clinical use. Aust Dent J. 1998;43:428–34. doi: 10.1111/j.1834-7819.1998.tb00204.x. [DOI] [PubMed] [Google Scholar]