Abstract

One form of waterproof, breathable apparel is manufactured from polytetrafluoroethylene (PTFE) membrane laminated fabric, using a specific process to seal seams that have been sewn with traditional techniques. The sealing process involves applying waterproof tape to the seam by feeding the seam through two rollers while applying hot air (600°C). This study addressed the potential for exposure to particulate matter from this sealing process, by characterizing airborne particles in a facility that produces over 1,000 lightweight PTFE rain jackets per day. Aerosol concentrations throughout the facility were mapped, breathing zone concentrations were measured, and hoods used to ventilate the seam sealing operation were evaluated. The geometric mean (GM) particle number concentrations were substantially greater in the sewing and sealing areas (67,000 and 188,000 particles cm−3) compared to that measured in the office area (12,100 particles cm−3). Respirable mass concentrations were negligible throughout the facility (GM=0.002 mg m−3 in the sewing and sealing areas). The particles exiting the final discharge of the facility's ventilation system were dominated by nanoparticles (number median diameter = 25 nm; geometric standard deviation of 1.39). The breathing zone particle number concentrations of the workers who sealed the sewn seams were highly variable and significantly greater when sealing seams than when conducting other tasks (p<0.0001). The sealing workers’ breathing zone concentrations ranged from 147,000 particles cm−3 to 798,000 particles cm−3, and their seam responsibility significantly influenced their breathing zone concentrations (p=0.03). The finding that particle number concentrations were approximately equal outside the hood and inside the local exhaust duct indicated poor effectiveness of the canopy hoods used to ventilate sealing operations.

Keywords: Nanoparticles, Apparel Workers, Aerosol Mapping, Occupational Exposure, Polytetrafluoroethylene

INTRODUCTION

Waterproof, breathable apparel, which is impermeable to liquids but allows vapor such as perspiration to pass through,(1) is commonly produced from polytetrafluoroethylene (PTFE) membrane laminated material.(2) This type of apparel is used by a variety of professions, such as gowns for surgeons and nurses, foul weather survival clothing for military personnel, or protective gear for firefighters.(2)

Depending on the fabric used to make apparel, workers may have a wide variety of exposures (e.g., cotton dust,(3) latex,(4) formaldehyde(5)). The PTFE fabric and processes used to produce waterproof, breathable apparel may cause specific and unique particulate hazards. In the manufacturing process, pieces of fabric are joined using traditional sewing techniques. Then sealing tape, also containing PTFE, is applied to ensure that the sewn seam is waterproof.(6) During the traditional sewing of the PTFE fabric there is a low potential for airborne particle production. However, during the sealing of the sewn seams, there is a possibility of exposure to incidental nanoparticles. The sealing process involves feeding the apparel through two rollers that compress the sealing tape onto the seam while hot air (600 °C) is blown onto the sealing tape. Places where two seams overlap are reheated by placing the overlapping section between two heated plates to ensure they do not leak.

Toxicological studies in rodents have found exposure to nanoparticles of PTFE to be toxic(7) and that PTFE nanoparticles had greater pulmonary toxicity than larger particles of PTFE.(8) In humans, very high exposure to PTFE nanoparticles has led to cases of polymer fume fever(9, 10) and in extreme exposure, pulmonary edema, with one case resulting in death.(11)

The purpose of this work was to characterize airborne particle concentrations in a facility that makes two styles of light-weight, waterproof, breathable rain jackets made of PTFE fabric, at a production rate of 1,000 jackets per day. Aerosol concentrations throughout the facility were mapped, breathing zone concentrations were measured, and the hoods used to ventilate the sealing operation were evaluated. In addition worker characteristics that may have had a potential association with breathing zone concentrations were identified.

METHODS

Facility

The facility was divided into three main areas (FIGURE 1): office area, sewing area, and sealing area. The office area housed management, administration, and engineering staff and was physically partitioned from the other areas. Jobs performed in the sewing and sealing areas to create a rain jacket included: 1) traditional sewing of cut pieces of fabric (sewing area); 2) sealing of sewn seams (sealing area); 3) quality control (sealing area) 4) reheating overlapping seams (sealing area); and 5) bundling jackets for shipping (sewing area.) In the sealing area there were 41 sealing stations (work stations to seal seams) and 20 overlap stations (work stations where overlapping sealed seams are reheated).

FIGURE 1.

Layout of the facility showing three major areas: office area; sewing area; and sealing area.

As depicted in Figure 2, each sealing station was fitted with a local exhaust ventilation hood intended to remove contaminants that were generated by the sealing process. The hood consisted of a transparent canopy (the hood manufacturer requested to remain anonymous) with a design airflow of 11.3 m3 min−1 (400 ft3 min−1). The hood had sloping front and back sides and a flat top (FIGURE 2B). The hood was positioned approximately 20 cm over the work table and was held by a support on the right side. The sealing workers viewed their work through a window on the front of the hood. The hood was connected to a ventilation duct (diameter = 15.2 cm; 6 in.) on the right front corner. The duct opening was positioned away from the sealing tape rollers to avoid cooling of the hot air required to produce a high-quality seal. The hood contained gaps where the sealing tape holder extended up through the hood top. The hood (68 cm by 53 cm) covered only a portion of the entire work table (100 cm by 66 cm).

FIGURE 2.

Schematic diagram of sealing station, showing the local exhaust ventilation hood: (A) front view; and (B) side view.

Aerosol Mapping

On a morning when 15 workers were actively sealing seams, particle number and respirable mass concentrations were mapped at multiple locations in the sewing and sealing areas and at one location in the office area. As described by Peters et al.,(12) two real-time aerosol instruments were placed on a mobile sampling cart–condensation particle counter (CPC) (Model 3007, TSI Incorporated, Shoreview, MN) and an optical particle counter (OPC) (PDM-1108, Grimm, Ainring, Germany)–and measurements were taken at 34 locations throughout the sewing and sealing areas. At each location over a period of one minute, the CPC was used to measure the number concentration of particles between 10 nm to 1 μm in diameter, and the OPC was used to measure the number concentrations of particles between 0.3 μm to 20 μm in diameter in 15 size channels. These data were then used to estimate nanoparticle number and respirable mass concentrations.(12)

Initial number concentrations measured with the CPC were found to exceed the maximum concentration range for the instrument. Therefore to dilute the particle concentration, a filter (6702-7500 Whatman Inc. Kent, United Kingdom) with a 0.16 cm (1/16 in.) hole drilled into its end cap was connected to the inlet of the CPC as described by Peters et al.(12) In the office area, one-minute mean particle number concentrations were measured using the CPC with (W) the filter present and without (WO) the filter present in the following configuration: WO-W-WO-W-WO-W. The dilution factor was then estimated by dividing the mean number concentration measured without the filter by that measured with the filter. Mapping software (Surfer, Golden Sofware, Golden, CO) was used to perform Kriging—a geostatistical method that produce regularly spaced data from irregularly spaced data—of the particle number concentrations measured at the 34 locations. The regularly-spaced data was then used to construct a map of the facility with contours of equal particle number concentration. Respirable mass concentrations were summarized in tabular format.

Breathing Zone Concentrations

Number concentrations were measured in the breathing zone of nine sealing workers. A 0.64 cm inner diameter electrically conductive tube was used to transport air from outside of the exhaust hood, directly above the window, to a CPC (Model 3007, TSI Incorporated, Shoreview, MN) that was set up to log concentrations once per second. The inlet of the transport tube was positioned in the breathing zone of the sealing workers when they were sealing seams.(13) Although a representation of personal exposure, this measurement is not a true personal sample because the inlet of the transport tube was affixed to the window of the canopy hood on the workstation instead of on the sealing worker. Aerosol entering the CPC was diluted as described above for the aerosol mapping.

Measurement duration for each worker varied from 9 to 26 minutes to cover all of the tasks that composed the job of sealing seams. Sealing seams involved four tasks. First, the sealing worker collected a bundle of jackets from a storage shelf in the sewing area and brought it back to their sealing station. The sealing worker then filled out paperwork associated with the bundle. Next, the worker sealed a number of seams on each jacket. Each jacket required the sealing of over 20 seams, but each worker was assigned only a specific set up seams to seal on the jacket. Multiple workers had similar seam responsibilities. When finished, the jackets were re-bundled and placed on a different shelf in the sewing area for the next sealing worker to collect. One jacket from every third bundle was taken to a quality control station by the sealing worker.

Sealing worker tasks and characteristics were video recorded to allow identification and coding of tasks and characteristics that may have influenced breathing zone concentrations. The task information from the video included the specific time when a worker was sealing seams and when they conducted other tasks (e.g., paperwork). Percent time sealing seams versus conducting other tasks was calculated and each worker was placed in one of three groups: greater than 70% time, 61 to 69% time and less than 60% time. The characteristic information from the video included the worker's seam responsibility, jacket style, and worker movement while feeding material into the rollers. Worker movement (determined by personal preference) was categorized as either a smooth, fluid motion or a choppy motion, quickly and repeatedly moving the material slightly up and down.

The video was also used to place sealing workers into one of four seam responsibility groups, based on seam length, position, and number of seams. The groups were:

“long” - two long seams (the length of the jacket) with or without two additional short seams (less than one fourth the length of the jacket);

“middle” - 10 or more long (at least one half the length of the jacket) and short (less than one fourth the length of the jacket) seams located in the middle of the jacket;

“short” - four or fewer short seams (less than one fourth the length of the jacket); and

“mixture” - five long (length of the jacket) and short (less than one forth the length of the jacket) seams throughout the jacket.

Evaluation of Hood Used to Capture Particles at Sealing Stations

The effectiveness of the hood used to capture particles was evaluated at three sealing stations. At each station, the airflow was measured 80 cm downstream of the hood-duct connection by Pitot tube traverse using a Series 400 Air Velocity Meter (Dwyer Instruments, Inc., Michigan City, IN).

Particle number concentrations were measured simultaneously in the breathing zone of the sealing worker and inside the exhaust duct immediately downstream of the hoods. Breathing zone concentrations were measured with one CPC as described above, and a second CPC was used to measure in-duct concentrations. A 0.64 cm conductive tube, with the opening placed in the center of the duct, was used to transport aerosol to the second CPC. The aerosols entering both instruments were diluted as described above. Both CPCs were set up to record concentrations once per second and the measurement duration for each station varied from 28 to 38 minutes. Hood concentration reduction factor was estimated as the GM number concentration measured in the duct divided by the sum of that measured in the duct and in the breathing zone times 100%.

The number concentration by size of the airborne particles was measured at the final discharge of the facility's local exhaust ventilation system. An electrically conductive tube with a 0.64 cm inner diameter was used to transport the aerosol to a 20 L holding chamber from the final discharge duct. A scanning mobility particle sizer (SMPS) (SMPS+C model 5.4, Grimm, Ainring, Germany) was used to measure the particle size distribution of aerosol in the holding chamber. The holding chamber dampened fluctuations in aerosol concentration that would otherwise have rendered the size distribution measured with the SMPS invalid.

Statistical Analyses

The number concentrations measured in the workers’ breathing zones and in the local exhaust ducts were log-transformed. A linear mixed-effects model was fit to determine if there was a statistically significant difference in the breathing zone concentrations when the sealing workers sealed seams compared to when they conducted other tasks (e.g. paperwork). The model was also used to determine if the sealing workers’ breathing zone concentrations were equal across workers. A linear mixed-effects model was used to account for the aforementioned fixed affects as well as random within subject variability. Many variance/covariance structures were tested to specify the within-subject correlation in the model and compound symmetry was chosen because had the lowest Akaike information criterion (AIC) value. A post-hoc Tukey-Kramer multiple comparison test identified which workers’ breathing zone concentrations were statistically different. The geometric mean (GM) and geometric standard deviation (GSD) of the particle number concentrations for each worker was determined.

Statistical analyses were conducted on the GM particle number concentration for each worker to determine which worker characteristics of seam responsibility, movement, and jacket style significantly influenced breathing zone concentrations. One-way Analysis of Variance (ANOVA) was used to test whether breathing zone concentrations were equal across the four seam responsibility groups with a post hoc Duncan's multiple comparisons test to identify which groups had different concentrations. Independent sample t-tests were used to determine if worker movement or jacket style were associated with breathing zone concentrations. A one-way ANOVA was used to determine if GM breathing zone number concentration was equal across the three groups of percent time sealing seams versus conducting other tasks. Statistical significance for all tests was evaluated at the 95% confidence level. Analyses were carried out using the statistical software SAS version 9.2.

RESULTS

Aerosol Mapping

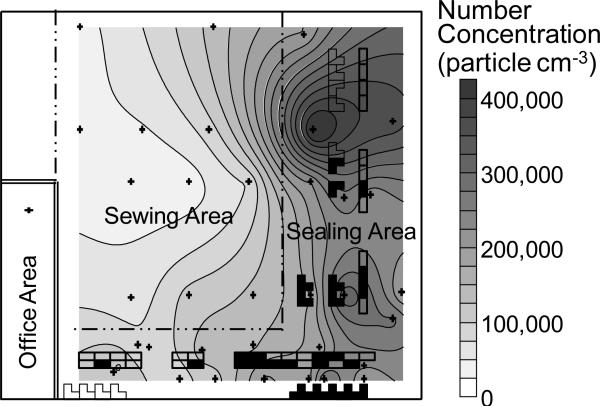

Particle number concentrations were greater in the sealing area than in the sewing area (Figure 3; Table I). The GM of the particle number concentrations in the sewing area (67,000 particles cm−3) was over three times greater than that in the office area (12,100 particles cm−3). The GM of the particle number concentrations in the sealing area (188,000 particles cm−3) was more than a magnitude greater than the office area. Respirable mass concentrations in the sewing and sealing areas ranged from 0.001-0.007 mg m−3 with the GM concentration (0.002 mg m−3) in the sealing area slightly greater than that in the sewing area (0.001 mg m−3).

FIGURE 3.

Map of particle number concentrations in the sewing and sealing areas. Crosses indicate sample locations, and shaded work stations indicate stations that were in use during mapping.

Table I.

Particle number and respirable mass concentrations found during aerosol mapping by area

| Particle Number Concentrations | ||||

|---|---|---|---|---|

| Area | n | GM (particles cm−3) | Range (particles cm−3) | GSD |

| Office | 101 | 12,100 | 11,600-12,500 | 1.02 |

| Sewing | 11 | 67,000 | 39,000-136,000 | 1.63 |

| Sealing | 23 | 188,000 | 78,000-445,000 | 1.59 |

| Respirable Mass Concentrations | ||||

|---|---|---|---|---|

| Area | n | GM (mg m−3) | Range (mg m−3) | GSD |

| Sewing | 11 | 0.001 | 0.001-0.002 | 1.36 |

| Sealing | 23 | 0.002 | 0.001-0.007 | 1.5 |

Breathing Zone Concentrations

The GM of particle number concentrations measured in the breathing zone of the sealing workers ranged from 147,000 particles cm−3 to 798,000 particles cm−3 (Table II). The concentrations were highly variable with GSDs ranging from 1.16 to 2.27. The GM concentrations were not equal across workers (p<0.0001). Thus, the sealing workers were not a homogeneous exposure group with respect to breathing zone number concentration. Five breathing zone concentration groups were found to be statistically significantly different. Breathing zone number concentrations were significantly different (p<0.0001) when the workers were sealing seams (GM = 394,000 particles cm−3, GSD = 2.18) compared to when they were conducting other tasks (GM = 266,000 particles cm−3, GSD = 1.77).

Table II.

Breathing zone number concentrations by worker

| Worker | Number of 1- Second Measurements | GM (particles cm−3) | GSD | Duncan Grouping Levels* |

|---|---|---|---|---|

| 1 | 1312 | 240,000 | 1.79 | A |

| 2 | 1464 | 248,000 | 1.16 | B |

| 3 | 1275 | 250,000 | 1.21 | B |

| 4 | 1211 | 291,000 | 1.48 | C |

| 5 | 1316 | 321,000 | 1.96 | C |

| 6 | 1599 | 798,000 | 2.27 | D |

| 7 | 865 | 591,000 | 1.75 | D |

| 8 | 485 | 147,000 | 1.75 | E |

| 9 | 592 | 603,000 | 2.10 | D |

Means with the same letter are not statistically different.

The results from the analysis of tasks and characteristics are summarized in Table III and Table IV. The GM number concentrations of the four seam responsibility groups ranged from 192,000 particles cm−3 (“short” group) to 688,000 particles cm−3 (“middle” group) and the GM concentrations were not equal across seam responsibility groups (p = 0.03; Table III). The GM concentration of the “middle” group was significantly greater than that of the “short” and “mixture” groups. The GM concentration of the “long” group was not statistically different from that of any other group. The GM concentrations of the three percentage time sealing seams versus conducting other task groups were also not statistically different (p = 0.22; Table IV). The GM concentrations were not statistically significantly different for workers using different movements (p = 0.82) or sealing seams on different jacket styles (p = 0.36).

Table III.

Breathing zone number concentrations by seam responsibility

| Group | Worker ID | GM (particles cm−3) | GSD | Duncan Grouping Levels* |

|---|---|---|---|---|

| Long | 4, 5, 9 | 383,000 | 1.48 | A, B |

| Middle | 6, 7 | 688,000 | 1.24 | A |

| Short | 2, 8 | 192,000 | 1.44 | B |

| Mixture | 1, 3, | 245,000 | 1.03 | B |

Means with the same letter are not statistically different.

Table IV.

Breathing zone number concentrations by percent time sealing seams versus conducting other tasks

| Group | Worker ID | GM (particles cm−3) | GSD | Duncan Grouping Levels* |

|---|---|---|---|---|

| Greater than 70% | 1, 6, 7 | 484,000 | 1.87 | A |

| 61% to 69% | 3, 5, 9 | 364,000 | 1.57 | A |

| Less than 60% | 4, 2, 8 | 220,000 | 1.42 | A |

Means with the same letter are not statistically different.

FIGURE 4 shows breathing zone particle number concentrations as a worker transitioned from lunch break to the beginning of the afternoon shift. Breathing zone concentrations were relatively low and constant during the end of the lunch break (GM = 117,000 particles cm−3, GSD = 1.21) but increased dramatically and became more variable when the afternoon shift began (GM = 240,000 particles cm−3, GSD = 1.79). Breathing zone concentrations during lunch break did not reach levels of the office area due to other sealing workers working through the lunch break.

FIGURE 4.

Particle number concentrations measured in the breathing zone of a sealing worker during the transition from lunch break to the afternoon shift.

Evaluation of Hood Used to Capture Particles at Sealing Stations

Particle number concentrations measured in the breathing zone and inside the exhaust ducts of the local exhaust ventilation system are shown in Table V. Although some of the particles were captured the concentration reduction factor of the hood was 56% or less. Airflow through the local exhaust ventilation system ranged from 11.5-12.3 m3 min−1 (405-436 ft3 min−1) and met vendor specifications.

Table V.

Breathing zone and in-duct particle number concentrations

| Station | Number of Measurements | Air Flow (m3 min−1) | Breathing Zone | In-Duct | Conc Reduction Factor (%) | ||

|---|---|---|---|---|---|---|---|

| GM (particles cm−3) | GSD | GM (particles cm−3) | GSD | ||||

| 1 | 2440 | 12.3 | 6.03 × 105 | 2.60 | 7.75 × 105 | 2.57 | 56 |

| 2 | 1761 | 11.5 | 2.57 × 106 | 2.44 | 1.45 × 106 | 1.90 | 36 |

| 3 | 2318 | 12.3 | 3.77 × 105 | 1.41 | 2.31 × 105 | 3.30 | 38 |

The particle number concentration by size of the aerosol captured by the local exhaust ventilation measured at the final discharge of the system (FIGURE 5) was composed almost entirely of nanoparticles. The size distribution had a number median diameter of 25 nm with GSD of 1.39.

FIGURE 5.

Particle number concentration by size measured at the final discharge of the local exhaust ventilation system.

DISCUSSION

Nanoparticle number concentrations were elevated in a facility that produces apparel composed of PTFE fabric. The airborne particles were dominated by nanoparticles (NMD = 25 nm, GSD = 1.39) with the greatest concentrations observed in the breathing zone of sealing workers (GM ranged from 147,000 to 798,000 particles cm−3). Number concentrations in both sealing and sewing areas were very high compared to those found in the office area. There are no regulatory standards for particle number concentration. However, number concentrations found at this facility were similar to or greater than those observed in heavy industrial settings, such as an automotive foundry(14) and plants where smelting and grinding occurred.(15) Actual breathing zone concentrations may in fact be greater than measured because, even with the filter to dilute the particle number concentrations, the CPC readings were at times above the upper limit of the CPC (100,000 particles cm −3). At concentrations above the upper limit coincidence may cause the CPC to underestimate the particle concentration.(16)

In contrast, particle mass concentrations were low throughout the facility (GM < 0.020 mg m−3). These values are substantially lower than the OSHA permissible exposure limit for particles not otherwise regulated with time-weighted average exposure limit of 15 mg m−3 for respirable mass concentration. This finding is expected given that the aerosol was composed almost entirely of nanoparticles that contribute little to mass concentration despite their high number concentrations.

The source of the nanoparticles is attributed to the hot process of sealing seams. Breathing zone number concentrations were significantly greater when the sealing workers were sealing seams compared to when they were conducting other tasks. They also increased dramatically at the start of a work shift (FIGURE 4). The single mode observed in the particle size distribution (FIGURE 5) is typical of a single aerosol source, and the aerosol mapping provided further evidence that the source was located within the sewing and sealing areas. Lastly, the fact that breathing zone number concentrations were substantially greater than those observed during aerosol mapping was consistent with the heated sealing process being the dominate aerosol source.

The canopy hoods of the local exhaust ventilation system do not adequately capture the nanoparticles generated by the sealing process. Breathing zone concentrations were very high for all sealing workers. The concentration reduction factor was poor and ranged from 36% to 56%.

Certain characteristics of canopy hoods combined with their application for sealing may explain the poor capture efficiencies. First, canopy hoods function best when they are used to control hot contaminates which have thermal buoyancy to aid in their collection.(17) Although sealing involves high heat, nanoparticles may have been created and then trapped underneath the jacket during sealing. Those particles would then tend to mix with cool air and would no longer be carried by thermal buoyancy up into the hood. Second, canopy hoods are known to produce a limited capture zone even with a high exhaust airflow rate.(17) When removing the jacket from underneath the hood, the worker may have released the nanoparticles that were trapped under the jacket outside the canopy hood's capture zone. Lastly, capture efficiency of a canopy hood is diminished by objects located below the hood(18) and sealing required the workers’ arms and the jacket to be below the hood. The importance of the combination of canopy hood characteristics is illustrated by the association among seam responsibilities and breathing zone concentrations. The breathing zone concentrations for the “short” or “mixture” groups were lower than those in the “middle” group (Table III). Workers in “short” or “mixture” groups had at least one seam that ended at a jacket edge, so they lifted the jacket when it was still underneath the hood before starting another seam. With this lifting action, nanoparticles would have a fair likelihood of capture. In contrast the “middle” group was responsible for a combination of more than ten long and short seams located in the middle of the jacket. The location of those seams required the worker to slide and drape the jacket over the work table as they moved from seam to seam. Sliding the jacket may have drawn the nanoparticles outside the canopy hood's capture zone.

A redesigned hood may improve nanoparticle capture and reduce the number concentrations in the breathing zone. However, a new design must balance the need to provide sufficient workspace to access all seams of a jacket, maintain the temperature at the seam to create a high quality seal, and adequately capture the nanoparticles. Although providing adequate workspace and proper sealing temperature, the current design does not have appropriate concentration reduction factor. A hood with a partial enclosure may address these competing issues more effectively than a canopy hood, but may also reduce the workspace to an unacceptable size. Further work under controlled laboratory conditions is needed to evaluate the effectiveness of different hood designs.

There are several issues that may limit the applicability of our findings. The measurements for this study were taken at one facility and may not be representative of other facilities that seal sewn seams. Aerosol mapping was conducted during one morning only and consequently may not be representative of different days or times of day. The particle size distribution measured in the exhaust air was assumed to represent the particulate inside the facility. This assumption enabled measurement despite constraints of sampling with the SMPS (requires stable aerosol concentrations over ~6 min sampling time) near aerosol sources with highly fluctuating generation rates (i.e., seam sealing). It is possible that larger particles within the facility were not captured or conveyed through the ductwork, thereby biasing the measured distribution to smaller sizes. However, the results of aerosol mapping (Table I; high number concentrations and low mass concentrations) are consistent with the fact that the aerosol burden within the facility is dominated by nanoparticles and with the particle size distribution measured in the exhaust air.

Breathing zone concentrations were not measured when workers were away from their work station conducting tasks other than sealing because the tube was affixed to the canopy hood. However, these tasks (picking up and dropping off bundles of jackets) took the worker away from the measurement location for a short time (<10%) compared to the tasks that were conducted at the work station (filling out paperwork and sealing seams). Particle mapping results suggest that these tasks were conducted in areas of the facility where particle concentrations were likely to be substantially lower than at the workstation. Thus, particle number concentrations for these tasks were likely overestimated. Despite this fact, breathing zone concentrations during seam sealing were found to be significantly and substantially greater than those observed during other tasks. Sampling was conducted in this way because of the limitation that there were no direct-read instruments to measure personal exposure to nanoparticles at the time of this work.

The characteristics of time sealing seams, movement of sealing worker, and style of jacket sealed were tested using a small sample of the sealing workers and may be significant when tested with a larger sample size. The analysis of particle composition was outside the scope of this work and should be a focus of future work.

CONCLUSIONS

Nanoparticle number concentrations were identified to be very high in a facility that produces apparel composed of PTFE fabric. The greatest concentrations were found in the breathing zone of workers responsible for sealing sewn seams. These nanoparticles were identified to be incidental to the hot process of sealing seams. Canopy hoods used to ventilate the sealing workstations were found to have poor concentration reduction factor. Several limitations of canopy hoods when applied to this particular application may explain this poor concentration reduction factor.

RECOMMENDATIONS

Determination of the composition of the particles in the facility was outside the scope of this work. However, it is an important subject of future work.

A redesigned hood is likely to improve nanoparticle capture and reduce the number concentrations in the breathing zone. A hood with a partial enclosure may reconcile the need to provide sufficient workspace, obtain high concentration reduction factor, and to maintain adequate temperature of sealing. Further work under controlled laboratory conditions are needed to develop different hood designs and evaluate their effectiveness.

ACKNOWLEDGEMENTS

Funding for this project was provided by NIOSH (K01OH009255). The authors would like to thank Adele Bonney for her review and comments.

REFERENCES

- 1.Holmes DA. Handbook of Technical Textiles. Woodhead Publishing Limited; 2000. [Google Scholar]

- 2.Mukhopadhyay A, Midha VK. A Review on Designing the Waterproof Breathable Fabrics Part II: Construction and Suitability of Breathable Fabrics for Different Uses. Journal of Industrial Textiles. 2008;38:17–41. [Google Scholar]

- 3.LeVan TD, Koh WP, Lee HP, Koh D, Yu MC, London SJ. Vapor, dust, and smoke exposure in relation to adult-onset asthma and chronic respiratory symptoms, The Singapore Chinese Health Study. Am J Epidemiol. 2006;163:1118–1128. doi: 10.1093/aje/kwj144. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Weytjens K, Labrecque M, Malo JL, Cartier A. Asthma to latex in a seamstress. Allergy. 1999;54:290–291. doi: 10.1034/j.1398-9995.1999.00000.x. [DOI] [PubMed] [Google Scholar]

- 5.Pinkerton LE, Hein MJ, Stayner LT. Mortality among a cohort of garment workers exposed to formaldehyde: an update. Br Med J. 2004;61:193–200. doi: 10.1136/oem.2003.007476. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Jeong WY, An SK. Mechanical properties of breathable waterproof fabrics with seaming and sealing processes. Fibers and Polymers. 2004;5:316–320. [Google Scholar]

- 7.Oberdorster G, Celein RM, Ferin J, Weiss B. Association of particulate air pollution and acute mortality: involvement of ultrafine particles? Inhal Toxicol. 1995;7:111–124. doi: 10.3109/08958379509014275. [DOI] [PubMed] [Google Scholar]

- 8.Johnston CJ, Finkelstein JN, Mercer P, Corson N, Gelein R, Oberdörster G. Pulmonary effects induced by ultrafine PTFE particles. Toxicol Appl Pharmacol . 2000;168:208–215. doi: 10.1006/taap.2000.9037. [DOI] [PubMed] [Google Scholar]

- 9.Harris DK. Polymer-fume fever. Lancet. 1951;2:1008–1011. doi: 10.1016/s0140-6736(51)93401-0. [DOI] [PubMed] [Google Scholar]

- 10.Lewis CE, R Kerby G. An epidemic of polymer-fume fever. JAMA. 1965;191:375–378. doi: 10.1001/jama.1965.03080050021005. [DOI] [PubMed] [Google Scholar]

- 11.Tsai P, Guo Y, Chen J, Shieh H. An integrated approach to initiative preventive strategies for workers exposed to teflon pyrolytic gases in a plastic industry. Journal of Occupational Health. 2000;42:297–303. [Google Scholar]

- 12.Peters TM, Heitbrink WA, Evans DE, Slavin TJ, Maynard AD. The mapping of fine and ultrafine particle concentrations in an engine machining and assembly facility. Ann Occup Hyg. 2006;50:249–257. doi: 10.1093/annhyg/mei061. [DOI] [PubMed] [Google Scholar]

- 13.DiNardi SR. The Occupational Environment: Its Evaluation, Control and Management. American Industrial Hygiene Association; Fairfax, Virginia: 2003. [Google Scholar]

- 14.Evans DE, Heitbrink WA, Slavin TJ, Peters TM. Ultrafine and respirable particles in an automotive grey iron foundry. Ann Occup Hyg. 2007;52:9–21. doi: 10.1093/annhyg/mem056. [DOI] [PubMed] [Google Scholar]

- 15.Elihn K, Berg P. Ultrafine Particle Characteristics in Seven Industrial Plants. Ann Occup Hyg. 2009;53:475–484. doi: 10.1093/annhyg/mep033. [DOI] [PubMed] [Google Scholar]

- 16.Hämeri K, Koponen IK, Aalto PP, Kulmala M. The particle detection efficiency of the TSI-3007 condensation particle counter. J Aerosol Sci. 2002;33:1463–1469. [Google Scholar]

- 17.McDermott HJ. Handbook of Ventilation for Contaminant Control. American Conference of Governmental Industrial Hygienists; Cincinnati, Ohio: 2001. [Google Scholar]

- 18.Goodfellow HD, Bender M. Design considerations for fume hoods for process plants. Am Ind Hyg Assoc J. 1980;41:473–484. doi: 10.1080/15298668091425103. [DOI] [PubMed] [Google Scholar]