Abstract

We evaluated the robust, lightweight DiSCmini (DM) aerosol monitor for its ability to measure the concentration and mean diameter of submicrometer aerosols. Tests were conducted with monodispersed and polydispersed aerosols composed of two particle types (sodium chloride, NaCl, and spark generated metal particles, which simulate particles found in welding fume) at three different steady-state concentration ranges (Low, <103; Medium, 103–104; and High, >104 particles/cm3). Particle number concentration, lung deposited surface area (LDSA) concentration, and mean size measured with the DM were compared to those measured with reference instruments, a scanning mobility particle sizer (SMPS) and a handheld condensation particle counter (CPC). Particle number concentrations measured with the DM were within 21% of those measured by reference instruments for polydisperse aerosols. Poorer agreement was observed for monodispersed aerosols (±35% for most tests and +130% for 300-nm NaCl). LDSA concentrations measured by the DM were 96% to 155% of those estimated with the SMPS. The geometric mean diameters measured with the DM were within 30% of those measured with the SMPS for monodispersed aerosols and within 25% for polydispersed aerosols (except for the case when the aerosol contained a substantial number of particles larger than 300 nm). The accuracy of the DM is reasonable for particles smaller than 300 nm but caution should be exercised when particles larger than 300 nm are present.

Keywords: DiSCmini, CPC, SMPS, Welding fume, Nanoparticles

INTRODUCTION

Worker exposure to submicrometer aerosols is a major concern in many occupations and particularly so in welding. Welding fume typically consists of high concentrations of metal particles smaller than 300 nm,(1) which have been referred to as very fine particles.(2) The small particle size and presence of metals such as manganese, chromium, and cadmium contribute to the toxicity of welding fume as reviewed by Antonini.(3) Welding fume exposures have been associated with a variety of adverse health effects, including adverse pulmonary responses,(4) impaired neurological function,(5) lung cancer,(6) and cardiovascular disease.(7)

Personal monitoring with a direct-reading instrument (DRI) can be useful in associating high exposures to a contaminant with a particular task. A worker’s time weighted average exposure may then be lowered by modifying the behavior of the worker, implementing engineering controls, or requiring personal protective equipment for high-exposure tasks. Photometers have previously been used to perform task-based exposure monitoring, such as in the assessment of personal exposure to dust among swine barn workers.(8) More recently, photometers have been recommended for use in identifying sources of nanomaterials in production facilities,(9) and to monitor personal exposures to carbon nanotube-containing composite material from surface grinding.(10) Photometers are, however, limited to measuring the mass concentration of particles larger than 300 nm. Consequently, they are inadequate for use in personal monitoring of the very fine particles that typically dominate welding fume exposures.

A variety of instruments may be used to measure the number concentration and size of very fine particles (examples provided in TABLE I). Traditionally, the size distribution of submicrometer aerosols has been measured with a scanning mobility particle sizer (SMPS), which electrically classifies particles by size and then counts them using condensation followed by optical detection.(11) The SMPS has excellent size resolution, but takes several minutes for a single measurement. Further, the SMPS is a bulky and expensive instrument, making it impractical for field use and limited to area rather than personal monitoring. Condensation particle counters (CPCs) are commercially available in a small, light, portable format, referred to as ‘handheld’. Handheld CPCs can be used to rapidly (one-sec time resolution) measure total particle number concentration for submicrometer aerosols. The TSI 3007 handheld CPC has been used to monitor particle concentrations in a variety of workplaces.(10,12) However, handheld CPCs provide no indication of particle size and are subject to counting errors when multiple particles are coincident in the optical detection region, which is common for high concentrations.(13) Moreover, their large size and the fact that they must remain level to prevent working fluid from entering the optical circuitry presents a challenge for use in personal exposure monitoring applications.

TABLE I.

Manufacturer reported capabilities for each instrument used.

| Company Model | Grimm SMPS 5.402 |

TSI CPC 3007 |

Matter Aerosol DiSCmini 1.1 |

|---|---|---|---|

| Measurement principal | Electrical Size Separation & Condensation with Optical Detection | Condensation with Optical Detection | Diffusion Charging with Electrical Detection |

| Size range (nm) | 11–1083 | 10–1000 | 10–300 |

| Concentration range (particles/cm3) | 0–107 | 0–105 | 20nm: 103–106 100nm: 5×102–5×105 |

| Sampling flow rate (L/min) | 0.3 | 0.7 | 1.0 |

| Weight (kg) | DMA: 7.8 CPC: 11.5 Total: 19.3 |

1.7 | 0.7 |

| Limitations | Large, bulky size & slow measurement time | Too large for personal monitoring | Less accurate than laboratory-grade instruments (±30%) |

| Cost (USD) | $60,000 | $8,500 | $15,000 |

Fierz et al.(14) introduced a new type of device for measuring the size distribution of submicrometer aerosols called the electrical diffusion battery. This bench-top-sized electrical diffusion battery used a positive corona discharge to charge particles entering the instrument. The charged particles then passed through an induction stage (or ion filter), a series of four diffusion stages—each consisting of a stack of metal screens—and a high efficiency particulate air (HEPA) filter. The diffusion stages and the HEPA filter were each connected to an electrometer, which measured the charge of depositing particles. The smallest particles deposited on the screens in the first diffusion stage, whereas larger particles penetrated to subsequent diffusion stages or to the HEPA filter. The size distribution of the aerosol was then estimated from the electrical signals from the electrometers. Later, Fierz et al.(15) introduced a smaller, ‘backpack’ version of this device. In this work, they suggested that only two or three stages were needed to achieve 10–20% agreement with the SMPS for number counting and sizing. In another effort, Fierz et al.(16) described the diffusion size classifier (DiSC), which was again a backpack-sized instrument identical to the electrical diffusion battery but with only one diffusion stage. Bau et al.(17) evaluated the DiSC, which they refer to as a commercial product sold as the meDiSC by Matter Engineering, Switzerland. They found that the number concentration measured by the meDiSC differed from a reference CPC by greater than 30% for certain types of particles.

Further development by Fierz and colleagues resulted in miniature versions of the DiSC. Fierz et al.(18) described an instrument that they refer to as the ‘miniature DiSC’ in the text but show as the ‘miniDiSC’ in a figure of the manuscript. The miniDiSC was a compact, rapidly responding, and robust miniature diffusion size classifier that was sold through the University of Applied Sciences Northwestern Switzerland. They recommended that the miniDiSC be used for aerosols with a mean diameter near 100 nm, concentration range of 103–106 particles/cm3 and geometric standard deviation (σg) of about 1.7. The miniDiSC has been used to assess exposures to nanoparticles in nanomaterial facilities with simulated accident situations(19) and to ultrafine particles in ambient air.(20) For NaCl, oil [DEHS, Bis(2-ethylhexyl) sebecate], and soot aerosols, Fierz et al.(18) reported that number concentrations measured with the miniDiSC were within ±30% of those measured with a CPC and an SMPS. Asbach et al.(21) observed similar results for aerosols containing mostly particles smaller than 300 nm. Fierz et al.(18) identified that the miniDiSC underestimates particle size for narrowly distributed aerosols (σg < 1.5) and overestimates particle size for widely distributed aerosols (σg > 2.1).

The DiSCmini (DM; V1.1, Matter Aerosol, Switzerland) is a commercialized version of the miniDiSC.(22) We have been unable to identify any literature on the performance of this version of the instrument. Moreover, performance of the miniDiSC has not been evaluated for occupationally-relevant nanoparticles, such as metallic particles common to welding fume.

Thus, the primary objective of the current study was to evaluate the performance of the DM particularly for very fine metal aerosols, like those typical of welding fume. We compared the measurements made with the DM to those made with a handheld CPC (3007, TSI, MN, US) and the SMPS (Model 5.4, Grimm, Germany). Performance was evaluated in terms of lung deposited surface area concentration, number concentration, and sizing for monodispersed and polydispersed salt and metal aerosols.

METHODS

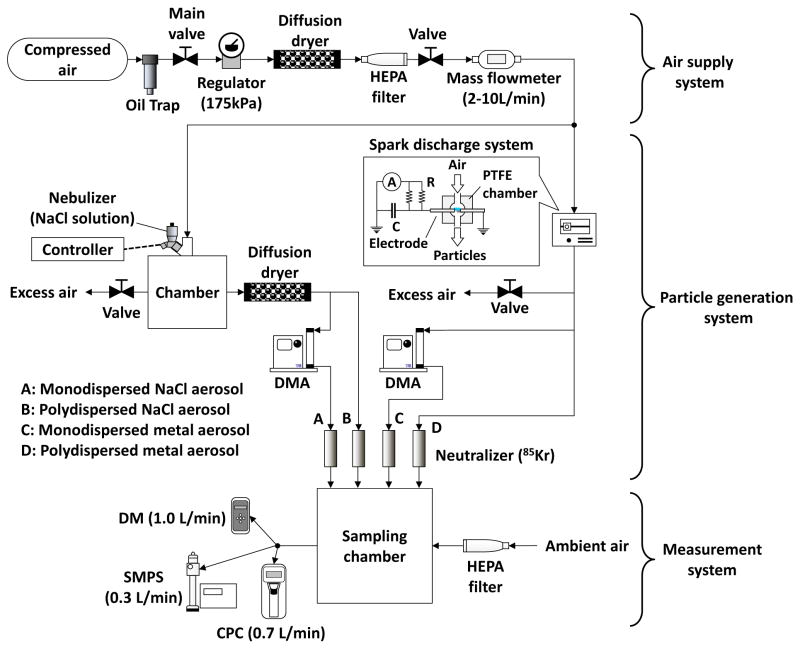

Shown in FIGURE 1, the experimental setup consisted of an air supply system, an aerosol generation system, and a measurement system. The air supply system was composed of an oil trap, a diffusion dryer, and a HEPA filter to remove oil-contaminants, humidity and particles, respectively. The dry, clean air, controlled by a needle valve and monitored with a mass flowmeter (4146, TSI, MN, US), was delivered to the test aerosol generation system. A nebulizer (Model Aeroneb Solo System, Aerogen, Galway, Ireland) was used to produce polydispersed NaCl-water droplets. The droplets were passed through a diffusion dryer to dry them. The nebulizer was turned on and off (1 Hz frequency and 10% duty cycle) to reduce the aerosol generation rate. A spark discharge system was used to generate polydispersed metal aerosols to simulate a welding fume. A spark discharge was formed in an air environment between two identical welding electrodes (Hard Surfacing Stick Electrodes, Overlay, Hobart, US).(23) The electrical circuit included a resistance of 0.5 MΩ (two 1 MΩ resistors arranged in parallel), a capacitance of 10 nF, a loading current of 1 mA, and an applied voltage of 5 kV.

FIGURE 1.

Experimental setup

Monodispersed test aerosols were produced by passing the NaCl or metal aerosols through a neutralizer (3077A, TSI, Shoreview, MN, US), then through a differential mobility analyzer (DMA; 3081, TSI, Shoreview, MN, USA). NaCl aerosols were classified to sizes of 30 nm, 100 nm, and 300 nm, and metal aerosols were classified to sizes of 30 nm and 100 nm. A second neutralizer (3054, TSI, MN, US) was used to discharge the classified aerosol. Both mono- and polydispersed aerosols were controlled in three different steady-state concentration levels: low: under 103; medium: 103–104; and high: over 104 particles/cm3.

Test aerosols were passed into a sampling chamber (4 L volume). The SMPS (0.3 L/min), CPC (0.7 L/min), and DM (1 L/min) were used to monitor the particle concentration and particle size distribution in the chamber (specifications for instruments provided in TABLE I). Additional room air was allowed to pass through a HEPA filter to maintain ambient static pressure in the sampling chamber. The temperature and relative humidity of room air were 22.5±3°C and 25±5%, respectively.

For each test aerosol and concentration level, the SMPS was used to measure particle number concentration by size over three sequential six-minute sampling periods. The DM and CPC were set up to log measurements every second. The software from the SMPS manufacturer was used to obtain the total number concentration and GMD of the aerosol for each sampling period. For polydispersed aerosols only, SMPS-estimated alveolar lung deposited surface area concentration was calculated as:

| (1) |

where CSMPS is the number concentration, dSMPS is the midpoint diameter, and DAL is the alveolar deposition in the human respiratory tract for each channel (i) of the SMPS. This equation assumes that particles are spherical. DAL was computed using equation 11.4 of Hinds.(24) The data from the DM corresponding to each of the three SMPS sampling periods was averaged to obtain three measurements of alveolar lung deposited surface area concentration, total number concentration, and GMD. The data from the CPC was processed similarly to obtain three measurements of particle number concentration.

The total number concentrations measured with the DM and CPC were compared to the reference number concentration from SMPS. The number concentration ratio (rn) was defined as follows,

| (2) |

where CDM, CCPC and CSMPS are the total number concentration measured with the DM, CPC and SMPS, respectively. The lung deposited surface area concentration ratio (rLDSA) was defined as:

| (3) |

where LDSADM and LDSASMPS are the alveolar lung deposition surface area concentration measured with the DM and SMPS, respectively.

The particle size measured with the DM and SMPS measurements were compared in two ways. First, a two-tailed, independent t-test was performed to test the hypothesis that the GMD measured by the DM was equal to that measured by the SMPS. Second, the ratio of particle size measured by the two instruments (rs) was calculated as:

| (4) |

where dDM and dSMPS are the GMD measured with the DM and SMPS, respectively.

RESULTS AND DISCUSSION

Monodispersed Aerosols

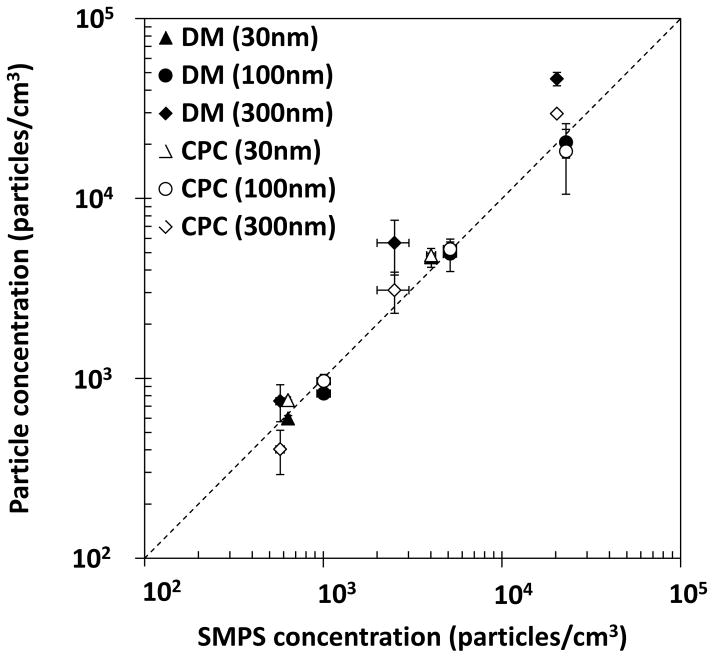

Scatter plots of the total number concentration measured with the DM and CPC compared to that measured with the SMPS are provided for tests conducted with monodispersed NaCl aerosols in FIGURE 2 and metal aerosols in FIGURE 3. Number concentration ratios are provided in TABLE II, and results of sizing comparisons are provided in TABLE III.

FIGURE 2.

Total number concentration measured by the DM and CPC compared to that measured by SMPS for monodispersed NaCl aerosols

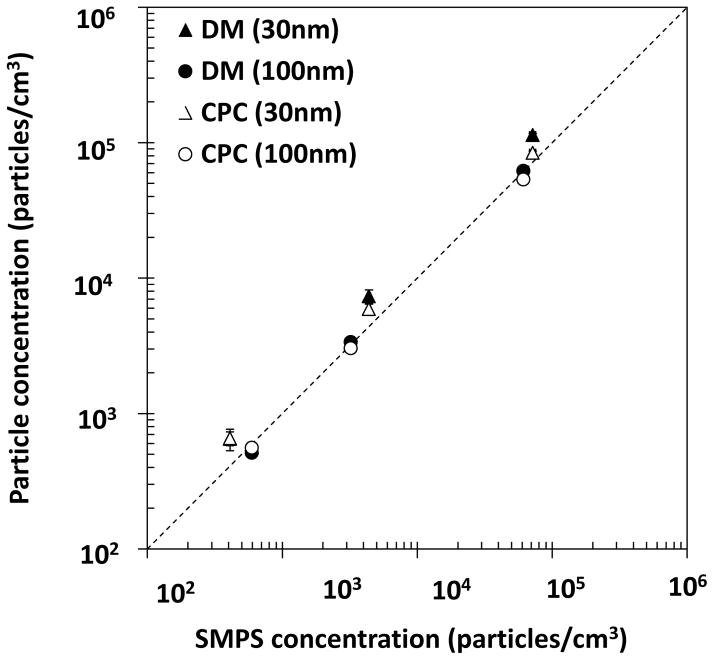

FIGURE 3.

Total number concentration measured by the DM and CPC compared to that measured by SMPS for monodispersed metal aerosols

TABLE II.

Ratios of particle concentration for tests with monodispersed aerosols.

| Test Aerosol Composition | dDMA | Concentration Range* | rn,SMPS = CDM/CSMPS | rn, CPC = CDM/CCPC |

|---|---|---|---|---|

| NaCl | 30 | L | 0.93 | 0.78 |

| M | 1.17 | 0.98 | ||

| H | - | - | ||

| 100 | L | 0.81 | 0.85 | |

| M | 0.96 | 0.94 | ||

| H | 0.89 | 1.13 | ||

| 300 | L | 1.30 | 1.86 | |

| M | 2.26 | 1.84 | ||

| H | 2.27 | 1.55 | ||

| Metal | 30 | L | 1.58 | 0.99 |

| M | 1.67 | 1.19 | ||

| H | 1.58 | 1.35 | ||

| 100 | L | 0.86 | 0.91 | |

| M | 1.05 | 1.12 | ||

| H | 1.01 | 1.16 |

Concentration ranges are: low (L, <103 particles/cm3), medium (M, 103–104 particles/cm3), and high (H, >104 particles/cm3)

TABLE III.

Summary of particle size measured by the DiSCmini (DM) and the SMPS reference instrument for tests with monodispersed aerosols.

| Test Aerosol Composition | dDMA | Concentration Range* | DM | SMPS | Size Ratio (rs) | P-value** | |

|---|---|---|---|---|---|---|---|

| Avg. Geo. Mean Dia. (Std. Dev.) nm | Avg. Geo. Mean Dia. (Std. Dev.) nm | Avg. Geo. Std. Dev. | |||||

| NaCl | 30 | L | 29 (3.8) | 31 (0.44) | 1.4 | 0.94 | 0.33 |

| M | 46 (1.6) | 36 (0.51) | 1.6 | 1.28 | <0.01 | ||

| H | - | - | - | - | - | ||

| 100 | L | 105 (1.7) | 107 (0.67) | 1.3 | 0.98 | 0.10 | |

| M | 112 (2.3) | 114 (4.22) | 1.3 | 0.98 | 0.63 | ||

| H | 118 (2.2) | 118 (1.46) | 1.4 | 1.00 | 0.78 | ||

| 300 | L | 256 (4.0) | 199 (17.2) | 2.0 | 1.28 | 0.01 | |

| M | 232 (16.0) | 272 (1.07) | 1.4 | 0.85 | 0.01 | ||

| H | 263 (11.7) | 258 (1.60) | 1.6 | 1.02 | 0.50 | ||

| Metal | 30 | L | 38 (1.8) | 40 (1.67) | 1.9 | 0.95 | 0.28 |

| M | 24 (0.9) | 31 (0.10) | 1.3 | 0.76 | <0.01 | ||

| H | 21 (0.0) | 30 (0.06) | 1.2 | 0.71 | <0.01 | ||

| 100 | L | 79 (1.2) | 73 (2.32) | 1.9 | 1.08 | 0.02 | |

| M | 76 (0.4) | 92 (0.65) | 1.3 | 0.83 | <0.01 | ||

| H | 79 (0.5) | 94 (0.44) | 1.2 | 0.84 | <0.01 | ||

Concentration ranges are: low (L, <103 particles/cm3), medium (M, 103–104 particles/cm3), and high (H, >104 particles/cm3)

bold indicates p-value <0.05

In most monodispersed tests, the particle number concentrations measured with the DM compared favorably to those measured with the SMPS and CPC. Number concentrations measured by the DM were within 35% of those measured with the CPC (rn,CPC: 0.78 to 1.35), except for 300-nm NaCl aerosols. Concentration ratios for the SMPS were also near unity (rn,SMPS: 0.81 to 1.17), with the exception of the 300-nm NaCl and 30-nm metal aerosols. A summary of the linear equations and R2 information for monodispersed particle number concentration tests is provided in supplementary information (TABLE S1). R2 values indicate an excellent fit for the linear models. The R2 was 1 for both the DM and CPC in the case of the monodispersed 30-nm NaCl aerosols.

A measurement deviation of 35% is not unexpected given the manufacturer-reported accuracy of ±20% for the CPC and ±30% accuracy for the DM. These favorable results were found for monodispersed aerosols (σg) despite the fact that in calculating the number concentration with the DM, the geometric standard deviation (σg) assumed within the software of the DM is 1.7.(22) These results are consistent with those of Fierz et al.(18), who observed that particle number concentrations measured with the miniDiSC were comparable to those made with a CPC regardless of the shape of the aerosol for 70-nm particles.

However, there were some notable deviations with number concentrations measured with the DM that were greater than ±35% different from those measured with the SMPS or CPC. For tests conducted with 30-nm, monodispersed metal aerosols (FIGURE 3; TABLE II), number concentrations measured with the DM were substantially higher than those measured with the SMPS (rn,SMPS ranged from 1.58 to 1.67). These results were considerably different than those for 30-nm NaCl aerosols (rn for both instruments ranged from 0.78 to 1.17). This discrepancy may relate to the fractal nature of the welding fume aerosol. However, number concentration ratios were near unity for the 100-nm metal aerosol (rn,SMPS ranged from 0.86 to 1.05), which were likely to be more fractal in nature than the smaller aerosol. Also, Asbach et al.(21) observed that the number counting accuracy of the miniDiSC was impacted to a minor extent by the morphology of soot aerosols. Interestingly, the ratios for the 30-nm metal aerosols for the CPC (rn,CPC ranged from 0.99 to 1.35) were nearer to unity than for the SMPS. A rationale for these differences is unknown.

For 300-nm NaCl aerosols, number concentration ratios were substantially greater than unity for both the SMPS (rn,SMPS ranged from 1.30 to 2.27) and the CPC (rn,CPC ranged from 1.55 to 1.86). A value of 1.7 for σg is used by the software internal to the DM used to compute particle number concentration. This assumption becomes increasingly problematical for monodispersed aerosols with a mean diameter larger than 100 nm, which are capable of carrying more charges. Similarly, Bau et al.(17) observed discrepancies of ±74% in particle number concentrations measured with the meDiSC compared to those measured with the CPC.

A summary of particle size measured with the DM compared to that measured with the SMPS for monodispersed aerosols is provided in TABLE III. In general, the GMDs measured with the DM compared favorably with those measured with the SMPS, with rs values ranging from 0.71 to 1.28. In many cases, however, the average GMD reported by the DM was statistically not equal to that reported by the SMPS (see p-values <0.05 in TABLE III). This finding relates to the fact that sizing each instrument was highly repeatable, resulting in low standard deviations observed for a given GMD measurement. For NaCl aerosols, the GMDs measured with the DM were significantly and substantially different for the medium concentration of 30-nm particles (rs = 1.28; p < 0.01) and for 300-nm particles at low (rs = 1.28; p = 0.01) and medium concentrations (rs = 0.85; p = 0.01). For monodipsersed metal aerosols, significant and substantial differences in the GMD measured with the DM and the SMPS occurred for the medium (rs = 0.76; p < 0.01) and high concentrations (rs = 0.71; p < 0.01).

Our results conflict somewhat with those of other researchers. Compared to the particle size measured with an SMPS, Fierz et al.(18) observed that the size measured with a miniDiSC was 18% smaller for an aerosol with a σg of 1.1. Bau et al.(17) observed that the meDiSC undersized monodispersed carbon and calcium carbonate particles larger than 300 nm. In contrast, we observed positive and negative deviations in sizing for monodispersed aerosols and therefore attribute these deviations to random error.

We observed notable deviations in the GMDs measured with the DM and SMPS from the particle size selected with the DMA (TABLE III). GMDs measured by both instruments were within ±10 nm for a DMA setting of 30 nm, except for the DM at medium concentration of NaCl particles (GMD = 46 nm). For 100-nm tests, GMDs were consistently larger than the DMA setting for NaCl aerosols (105 nm to 118 nm) but smaller than the DMA setting for metal aerosols (73 nm to 94 nm). For 300-nm NaCl tests, measured GMDs were smaller than the DMA setting. The reason for these deviations is not known. However, this issue should not adversely affect the ability to evaluate the DM in this work.

Polydispersed Aerosols

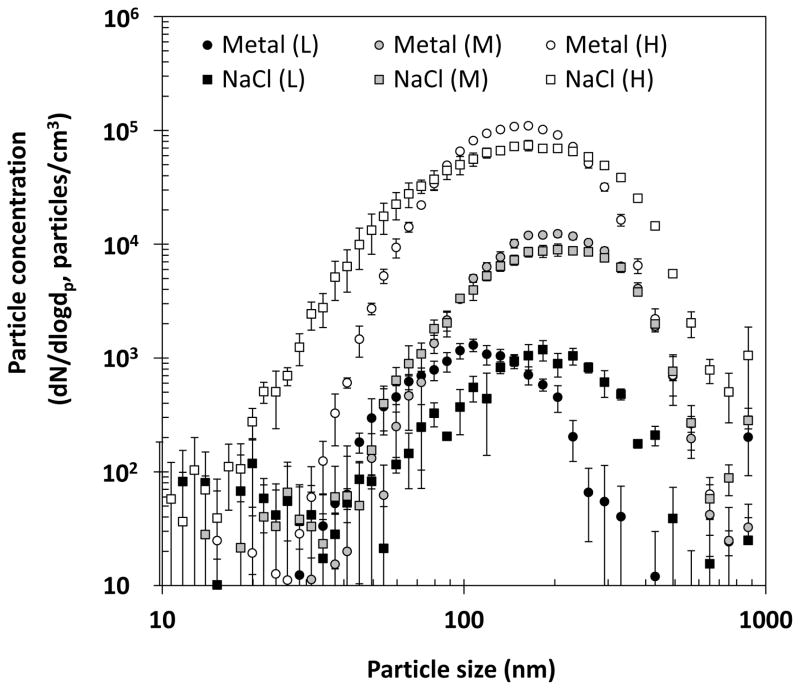

Size distributions of polydispersed NaCl and metal test aerosols are shown in FIGURE 4. For NaCl aerosols, the GMD ranged from approximately 150–190 nm, and the σg ranged from 1.6–1.9. For metal aerosols, the GMD ranged from approximately 100–190 nm, and the σg ranged from 1.5–2.3 (see TABLE S2 in supplementary for details). The size distribution of the metal aerosols in this study was similar to that of a field study analyzing welding aerosols.(25,26) Zimmer(25) analyzed welding particles using transmission electron microscopy and the particles formed during welding ranged in size from 50–300 nm. Stephenson et al.(26) reported that welding produced an approximately lognormal particle mode with a 120-nm count median and a σg of 2.07.

FIGURE 4.

Size distributions of polydispersed test aerosols

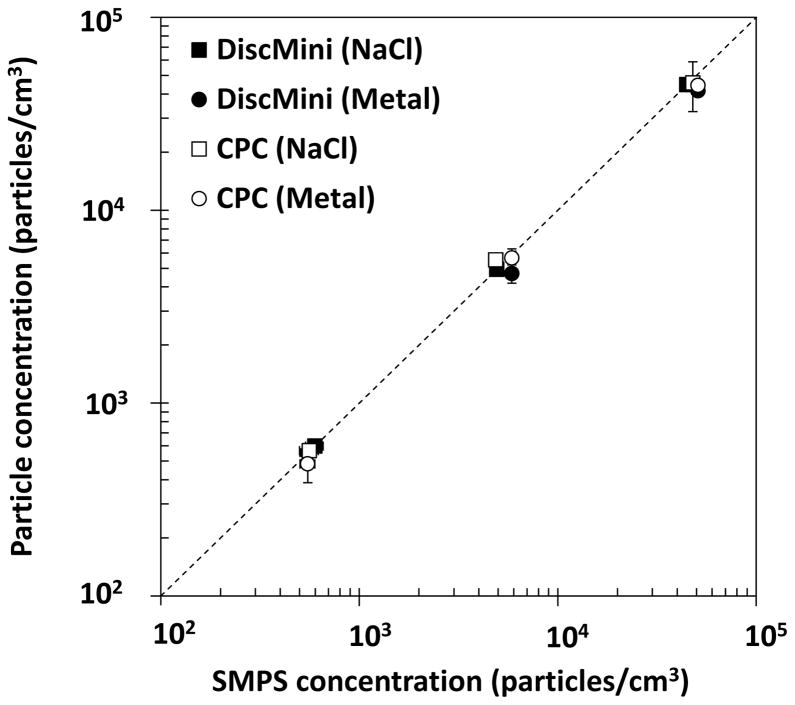

The total number concentration measured with the DM and CPC compared to that measured with the SMPS for polydispersed NaCl and metal aerosols is shown in FIGURE 5. A summary of particle number and LDSA concentration ratios is provided in TABLE IV.

FIGURE 5.

Total number concentration measured by the DM and CPC compared to that measured by SMPS for polydispersed NaCl and metal aerosols

TABLE IV.

Ratios of particle concentration for tests with polydispersed aerosols.

| Test Aerosol Composition | Concentration Range* | rn,SMPS = CDM/CSMPS | rn,CPC = CDM/CCPC | rLDSA = LDSADM/LDSASMPS |

|---|---|---|---|---|

| NaCl | L | 1.07 | 1.06 | 1.08 |

| M | 1.01 | 1.00 | 1.40 | |

| H | 0.93 | 0.98 | 1.55 | |

| Metal | L | 1.00 | 1.12 | 1.01 |

| M | 0.79 | 0.82 | 0.96 | |

| H | 0.82 | 0.94 | 1.10 |

Concentration ranges are: low (L, <103 particles/cm3), medium (M, 103–104 particles/cm3), and high (H, >104 particles/cm3)

For polydispersed NaCl or metal aerosols, the number concentration measured with the DM was within 21% of that measured by the SMPS or CPC (FIGURE 5; TABLE IV). The rn,SMPS values ranged from 0.79 to 1.07, and rn,CPC values ranged from 0.82 to 1.12. A summary of the linear equations and R2 information for polydispersed particle number concentration tests was documented in the supplementary materials (TABLE S1). Similar to the results of monodispersed particle tests, R2 values indicated a highly linear relationship among the number concentrations measured by the DM and the SMPS, as well as the CPC and the SMPS.

The finding that the DM measure of particle number concentration are accurate compared to reference instruments was expected. The polydispersed aerosols tested in this study (GMD from 150–190 nm, and σg from 1.6–1.9) were near optimal for the DM. Similar results were obtained by Fierz et al.(18) and Asbach et al.(21) for polydispersed aerosols that have GMD near 100 nm. However, Asbach et al.(21) observed that number concentrations measured by the DM were low compared to those measured by reference instruments for polydisperse aerosols with a substantial number of particles larger than 300 nm.

The ratio of LDSA concentrations ranged from 0.96 to 1.55. The finding that the DM slightly overestimates LDSA concentrations is counter to that described by Asbach et al.,(21) who observed that LDSA concentations from the miniDiSC were slightly underestimated compared to those estimated from a fast scan particle sizer.

A summary of the particle size measurements for polydispersed NaCl and metal aerosols is shown in TABLE IV. The GMD measured with the DM was equal to or larger than that measured with the SMPS with rs values ranging from 1.00 to 1.81. There were significant differences between the GMD from the DM and the SMPS in all tests (p-value > 0.05), except for the metal particle test in the low concentration range (p-value = 0.98). This difference was substantial for the tests conducted with a high concentration of NaCl particles (rs = 1.81) but less so for other tests (rs < 1.25).

The reason why the rs values observed for the high concentration of NaCl particles were much higher than those observed in other tests is unclear. A possible explanation is that large particles can carry more charges, which may cause the DM-measured particle size to be overestimated. As Fierz et al.(18) recommended, the DM should be used for aerosols with a mean diameter near 100 nm. For particles larger than 300 nm, uncertainty with the DM can be increased and affect the size measurement capabilities. As shown in FIGURE 4, the test aerosols in this case included more particles larger than 300 nm compared to other test aerosols. Asbach et al.(21) identified similar performance for the miniDiSC with reported mean size matching reference instruments well when aerosols were dominated by particles within the 10 nm to 300 nm size range. They found that the GMD from the miniDiSC was overestimated compared to that measured by the fast mobility particle sizer.

CONCLUSIONS

In this study, the measurement capabilities of the DM were compared to those of a handheld CPC and an SMPS for submicrometer NaCl and metal aerosols. In the case of the monodispersed aerosols, the particle number concentration measured with the DM were within 35% of those measured with the CPC and SMPS with some exceptions. The greatest deviation was observed for aerosols composed of 300-nm NaCl particles, where the DM measured particle concentrations were approximately two times those of the SMPS. The mean particle size measured with the DM was within 30% of that measured with the SMPS. For polydispersed particles, the number concentration was within 21% of those measured with the CPC and the SMPS for NaCl and metal aerosols.

The results from this study verify that the DM can be useful to measure metal aerosols, such as welding fume, for personal task-based exposure monitoring, as well as many other occupational settings where very fine particles of interest are present. While further studies are needed to improve understanding of the DM, this work highlights the rapid response time and similarity of measurements to more common instruments, the CPC and SMPS.

Supplementary Material

TABLE V.

Summary of particle size measured by the DiSCmini (DM) and the SMPS reference instrument for tests with polydisperse aerosols.

| Test Aerosol Composition | Concentration Range* | DM | SMPS | Size Ratio (rs) | P-value** | |

|---|---|---|---|---|---|---|

| Avg. Geo. Mean Dia. (Std. Dev.) nm | Avg. Geo. Mean Dia. (Std. Dev.) nm | Avg. Geo. Std. Dev. | ||||

| NaCl | L | 181 (10.3) | 157 (8.5) | 1.9 | 1.15 | 0.04 |

| M | 240 (2.2) | 192 (2.1) | 1.6 | 1.25 | <0.01 | |

| H | 277 (9.1) | 153 (7.9) | 1.8 | 1.81 | <0.01 | |

| Metal | L | 107 (2.7) | 107 (2.6) | 1.6 | 1.00 | 0.98 |

| M | 240 (2.2) | 194 (4.2) | 1.5 | 1.24 | <0.01 | |

| H | 176 (3.9) | 150 (2.3) | 2.3 | 1.17 | <0.01 | |

Concentration ranges are: low (L, <103 particles/cm3), medium (M, 103–104 particles/cm3), and high (H, >104 particles/cm3)

bold indicates p-value <0.05

Acknowledgments

This work was funded by the Centers for Disease Control / National Institute of Occupational Safety and Health (NIOSH) Education and Research Training grant T42OH008491 and grant U60-0H009762 from NIOSH.

Footnotes

The contents of this paper are solely the responsibility of the authors and do not necessarily represent the official views of the NIOSH.

References

- 1.Jenkins N, Eagar T. Chemical analysis of welding fume particles. Welding J. 2005;84(6):87. [Google Scholar]

- 2.Heitbrink WA, Evans DE, Peters TM, Slavin TJ. Characterization and mapping of very fine particles in an engine machining and assembly facility. J Occup Environ Hyg. 2007;4(5):341–351. doi: 10.1080/15459620701290081. [DOI] [PubMed] [Google Scholar]

- 3.Antonini JM. Health effects of welding. CRC Critical Reviews in Toxicology. 2003;33(1):61–103. doi: 10.1080/713611032. [DOI] [PubMed] [Google Scholar]

- 4.Antonini JM, Taylor MD, Zimmer AT, Roberts JR. Pulmonary responses to welding fumes: role of metal constituents. Journal of Toxicology and Environmental Health, Part A. 2004;67(3):233–249. doi: 10.1080/15287390490266909. [DOI] [PubMed] [Google Scholar]

- 5.Flynn MR, Susi P. Neurological risks associated with manganese exposure from welding operations-A literature review. International journal of hygiene and environmental health. 2009;212(5):459–469. doi: 10.1016/j.ijheh.2008.12.003. [DOI] [PubMed] [Google Scholar]

- 6.Moulin JJ. A meta-analysis of epidemiologic studies of lung cancer in welders. Scandinavian journal of work, environment & health. 1997;23(2):104–113. doi: 10.5271/sjweh.187. [DOI] [PubMed] [Google Scholar]

- 7.Ibfelt E, Bonde JP, Hansen J. Exposure to metal welding fume particles and risk for cardiovascular disease in Denmark: a prospective cohort study. Occupational and Environmental Medicine. 2010;67(11):772–777. doi: 10.1136/oem.2009.051086. [DOI] [PubMed] [Google Scholar]

- 8.O’Shaughnessy PT, Donham KJ, Peters TM, Taylor C, Altmaier R, Kelly KM. A task-specific assessment of swine worker exposure to airborne dust. Journal of Occupational and Environmental Hygiene. 2009;7(1):7–13. doi: 10.1080/15459620903327970. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Ramachandran G, Ostraat M, Evans DE, Methner MM, O’Shaughnessy P, D’Arcy J, Geraci CL, Stevenson E, Maynard A, Rickabaugh K. A Strategy for Assessing Workplace Exposures to Nanomaterials. Journal of Occupational and Environmental Hygiene. 2011;8(11):673–685. doi: 10.1080/15459624.2011.623223. [DOI] [PubMed] [Google Scholar]

- 10.Methner M, Crawford C, Geraci C. Evaluation of the Potential Airborne Release of Carbon Nanofibers During the Preparation, Grinding, and Cutting of Epoxy-Based Nanocomposite Material. Journal of Occupational and Environmental Hygiene. 2012;9(5):308–318. doi: 10.1080/15459624.2012.670790. [DOI] [PubMed] [Google Scholar]

- 11.Wang SC, Flagan RC. Scanning electrical mobility spectrometer. Aerosol Science and Technology. 1990;13(2):230–240. [Google Scholar]

- 12.Peters TM, Heitbrink WA, Evans DE, Slavin TJ, Maynard AD. The mapping of fine and ultrafine particle concentrations in an engine machining and assembly facility. Annals of Occupational Hygiene. 2006;50(3):249–257. doi: 10.1093/annhyg/mei061. [DOI] [PubMed] [Google Scholar]; Curwin B, Bertke S. Exposure Characterization of Metal Oxide Nanoparticles in the Workplace. Journal of Occupational and Environmental Hygiene. 2011;8(10):580–587. doi: 10.1080/15459624.2011.613348. [DOI] [PubMed] [Google Scholar]

- 13.Park J, Ramachandran G, Raynor P, Kim S. Estimation of surface area concentration of workplace incidental nanoparticles based on number and mass concentrations. Journal of Nanoparticle Research. 2011:1–15. [Google Scholar]

- 14.Fierz M, Scherrer L, Burtscher H. Real-time measurement of aerosol size distributions with an electrical diffusion battery. Journal of Aerosol Science. 2002;33(7):1049. [Google Scholar]

- 15.Fierz M, Weimer S, Burtscher H. Design and performance of an optimized electrical diffusion battery. Journal of Aerosol Science. 2009;40(2):152–163. [Google Scholar]

- 16.Fierz M, Burtscher H, Steigmeier P, Kasper M. Field Measurement of Particle Size and Number Concentration with the Diffusion Size Classifier, DiSC, Pub 2008-01-1179. SAE SP. 2008;2150:119. [Google Scholar]

- 17.Bau S, Jacoby J, Witschger O. Evaluation of the diffusion size classifier (meDiSC) for the real-time measurement of particle size and number concentration of nanoaerosols in the range 20–700 nm. J Environ Monit. 2012;14(3):1014–1023. doi: 10.1039/c2em10619a. [DOI] [PubMed] [Google Scholar]

- 18.Fierz M, Houle C, Steigmeier P, Burtscher H. Design, calibration, and field performance of a miniature diffusion size classifier. Aerosol Science and Technology. 2011;45(1):1–10. [Google Scholar]

- 19.Walser T, Hellweg S, Juraske R, Luechinger NA, Wang J, Fierz M. Exposure to engineered nanoparticles: Model and measurements for accident situations in laboratories. Science of The Total Environment. 2012 doi: 10.1016/j.scitotenv.2012.01.038. [DOI] [PubMed] [Google Scholar]

- 20.Burtscher H, Schüepp K. The occurrence of ultrafine particles in the specific environment of children. Paediatric Respiratory Reviews. 2012;13(2):89–94. doi: 10.1016/j.prrv.2011.07.004. [DOI] [PubMed] [Google Scholar]

- 21.Asbach C, Kaminski H, Von Barany D, Kuhlbusch TAJ, Monz C, Dziurowitz N, Pelzer J, Vossen K, Berlin K, Dietrich S, Gotz U, Kiesling HJ, Schierl R, Dahmann D. Comparability of Portable Nanoparticle Exposure Monitors⇓. Annals of Occupational Hygiene. 2012;56(5):606–621. doi: 10.1093/annhyg/mes033. [DOI] [PubMed] [Google Scholar]

- 22.Aerosol Matter. DiSCmini Diffusion Size Classifier Miniature Instruction Manual, Rev 1.00. 2011 [Google Scholar]

- 23.Byeon JH, Park JH, Hwang J. Spark generation of monometallic and bimetallic aerosol nanoparticles. Journal of Aerosol Science. 2008;39(10):888–896. [Google Scholar]

- 24.Hinds WC. Aerosol technology: properties, behavior, and measurement of airborne particles. 2 John Wiley & Sons, Inc; New York: 1999. [Google Scholar]

- 25.Zimmer AT. The influence of metallurgy on the formation of welding aerosols. J Environ Monit. 2002;4:628–632. doi: 10.1039/b202337g. [DOI] [PubMed] [Google Scholar]

- 26.Stephenson D, Seshadri G, Veranth JM. Workplace exposure to submicron particle mass and number concentrations from manual arc welding of carbon steel. AIHA Journal. 2003;64(4):516–521. doi: 10.1202/394.1. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.