Abstract

Fluidic devices that employ nanoscale structures (<100 nm in one or two dimensions, slits or channels, respectively) are generating great interest due to the unique properties afforded by this size domain compared to their micro-scale counterparts. Examples of interesting nanoscale phenomena include the ability to preconcentrate ionic species at extremely high levels due to ion selective migration, unique molecular separation modalities, confined environments to allow biopolymer stretching and elongation and solid-phase bioreactions that are not constrained by mass transport artifacts. Indeed, many examples in the literature have demonstrated these unique opportunities, although predominately using glass, fused silica or silicon as the substrate material. Polymer microfluidics has established itself as an alternative to glass, fused silica, or silicon-based fluidic devices. The primary advantages arising from the use of polymers are the diverse fabrication protocols that can be used to produce the desired structures, the extensive array of physiochemical properties associated with different polymeric materials, and the simple and robust modification strategies that can be employed to alter the substrate's surface chemistry. However, while the strengths of polymer microfluidics is currently being realized, the evolution of polymer-based nanofluidics has only recently been reported. In this critical review, the opportunities afforded by polymer-based nanofluidics will be discussed using both elastomeric and thermoplastic materials. In particular, various fabrication modalities will be discussed along with the nanometre size domains that they can achieve for both elastomer and thermoplastic materials. Different polymer substrates that can be used for nanofluidics will be presented along with comparisons to inorganic nanodevices and the consequences of material differences on the fabrication and operation of nanofluidic devices (257 references).

1. Introduction

There have been a number of reviews focused on the fabrication of nanoslits (nanoslits are defined here as conduits that have one dimension below 100 nm) and/or nanochannels (nanochannels are defined as conduits with two dimensions below 100 nm) and their applications resulting primarily from unique phenomena that occur in nano-confined environments but do not exist in micro-scale environments.1–4 Indeed, a recent issue appearing in Chemical Society Reviews (2010, Vol. 39, Issue 3) dealt specifically with reviewing basic phenomena unique to nano-confined environments, such as ion transport,5 nanofluidic diodes,6 concentration polarization,7,8 capillarity9 and voltage responsive structures.10 In addition, many applications of nanofluidic systems were reviewed such as DNA manipulations and mapping,11,12 tether forces in DNA electrophoresis13 and chemical analyses.14,15 In many of these applications, phenomena that occur in nano-confined environments are necessary to realize the intended goal of the application. For example, in micro-scale environments, double-stranded DNA (dsDNA) exists as a randomly coiled structure whereas in nanoenvironments, the dsDNA will stretch to near its full contour length allowing the ability to either size the dsDNA molecule directly or observe enzymatic cutting of the DNA to identify certain sequence locations, such as restriction sites.16 In terms of DNA sequencing, translocation of single-stranded DNA through nanochannels with dimensions below its persistence length will provide an effective means to read the primary structure of DNAs directly using an electrical readout modality.17

The major focus of most reviews as well as the predominate literature dealing with nanofluidics has been directed toward devices that use glass, fused silica or silicon (Si) as the substrate material due to their established surface chemistry, excellent optical properties, and well-entrenched fabrication technologies. In addition, these brittle materials (i.e., high Young's modulus) tend to maintain their form factors during thermal and/or pressure processing used for assembling devices to enclose the fluidic structures. Fabricating nanofluidic structures in these materials typically requires a lithography step in which a resist is patterned with nanofeatures using an electron beam (electron beam lithography, EBL) or nanoimprint lithography (NIL) followed by wet/dry etching or direct writing into the substrate using a focused ion beam (FIB). The shortcoming of these nanofabrication strategies is that they require extensive device processing steps, therefore making it difficult to realize the generation of low-cost devices conducive to mass production. The replication of these devices could potentially expand the user-base in performing nanofluidic experiments or transitioning this exciting technology into important application areas, such as in vitro diagnostics.

Polymers provide an attractive alternative to glass-based materials for nanofluidics due to their diverse range of physiochemical properties (see Section 1.1), low material cost, a variety of surface modification protocols that can be used (see Section 1.2) and a number of fabrication techniques that can be employed to make the prerequisite structures (see Sections 2 and 3). The fabrication modalities include such techniques as hot embossing, which have been well demonstrated in the area of microfluidics that can produce devices in a high production mode and at low-cost.18,19

In this critical review, we will provide an overview of the emerging area of polymer-based nanofluidics using both elastomeric and thermoplastic polymers. We will cover different fabrication techniques that can be used to produce nanofluidic devices in polymers, fluidic transport phenomena in polymeric materials and finally, some compelling applications where polymer-based nanofluidics have been or potentially could be employed. As a final note, there has been a wealth of literature focused on the fabrication and applications of nuclear-tracked polymer-membrane nano-conduits. We have classified these as vertical devices, in which the nanofluidic via is oriented orthogonal to the plane of the substrate. We will not include a description of these devices in this review. However, the reader is referred to several reviews dealing with this type of devices.4,20,21 Instead, we will focus on horizontal devices, in which the nanofluidic via is oriented parallel to the substrate's surface.

1.1 General properties of polymers

There are two general categories of polymeric materials that have been used in nanofluidic applications: (1) elastomers and (2) thermoplastics. Elastomers are amorphous polymers with a low to moderate number of cross-links between polymer chains. While the low Young's modulus ensures large deformation upon application of an external load, covalent cross-links help elastomers return to their original shape upon release of the load. On the other hand, thermoplastics are usually linear or branched polymers with higher molecular weights and Young's moduli. Polydimethylsiloxane, PDMS, is a good example of an elastomeric material, while examples of thermoplastics are poly(methyl methacrylate), PMMA; polycarbonate, PC; and cyclo-olefin-copolymer, COC. Some of the physiochemical properties of common polymers used for nanofluidics are shown in Table 1. For comparison purposes, we have also included the physiochemical properties of glass (Table 1). As can be seen, polymers have a diverse range of properties that are critical not only in terms of their mechanical properties associated with the ability to fabricate nanostructures (glass transition temperature, Tg; melting temperature, Tm; coefficient of thermal expansion, CTE) using injection molding or hot embossing, but also their operational characteristics in terms of nanofluidics (optical transmissivity and refractive index). The major differences between most polymers and glass is the substantially lower Tg and Tm of polymers, providing the ability to use nanoreplication to directly produce the prerequisite structures and also assemble devices, where the assembly consists of enclosing the fluidic network using for example thermal fusion bonding with a temperature close to the material's Tg.22,23 Another sharp contrast between polymers and glass is the lower Young's modulus of polymers, which in the case of thermoplastics is about one order of magnitude smaller, but in the case of elastomers this can be as much as 6 orders of magnitude smaller. This value can be critical, because lower Young's moduli can result in nanostructure collapse during thermal/pressure operation of the finished device or during assembly (see Sections 2.2.1, 2.2.6, and 2.3.4).

Table 1.

Common polymers and their physiochemical properties and comparison to glass

| Material | Acronym | Tg/°C | Tm/°C | CTE (α) ppm °C–1 | Refractive index | Young's modulus/GPa | Optical transmissivity |

|

|---|---|---|---|---|---|---|---|---|

| UV | Vis | |||||||

| Polystyrene | PS | 92–100 | 240–260 | 10–150 | 1.55–1.59 | 3.3–3.5 | Poor | Excellent |

| Polycarbonate | PC | 145–148 | 260–270 | 60–70 | 1.584 | 2.0–2.4 | Poor | Excellent |

| Poly(methyl methacrylate) | PMMA | 100–122 | 250–260 | 70–150 | 1.492 | 1.8–3.1 | Good | Excellent |

| Cyclic olefin co(polymer) | COC | 70–155 | 190–320 | 60–80 | 1.53 | 2.6–3.2 | Excellent | Excellent |

| Poly(ethylene terephthalate) | PET | 69–78 | 248–260 | 48–78 | 1.575 | 2.0–2.7 | Good | Good |

| Polypropylene | PP | –20 | 160 | 18–185 | 1.49 | 1.5–2.0 | Fair | Good |

| Poly(dimethylsiloxane) | PDMS | –125 | –55 | 67.3 | 1.40 | 0.36–0.87 × 10–3 | Excellent | Excellent |

| Glass (Soda lime) | G | 520–600 | 1040 | 9 | 1.52 | 50–90 | Good | Excellent |

CTE—Coefficient of thermal expansion (linear).

1.2 Surface modification of polymers

Another interesting property of polymers is their diverse chemistries, which is determined by the monomer units comprising the polymer chains. For example, PMMA possesses functional groups on its backbone consisting of methyl esters while for PC, these functional groups are carbonates. In the case of glass materials, the functional groups are primarily silanols. As such, a diverse range of surface modification chemistries can be used for polymers to generate functional surfaces appropriate for the intended application,18,19,24 which can consist of the surface immobilization of biological agents for recognition (nucleic acid probes, antibodies, etc.),25–32 formation of biocompatible surfaces (i.e., surface wettability),33–37 immobilization of catalytic enzymes for solid-phase bioreactors,38,39 or solid-phase molecular extractions.40–42 In addition, simple surface modification protocols can be used to generate functional groups through the use of ultraviolet (UV)-activation,43–45 plasma oxidation,46–51 reactive ion beams,52 microwave-oven generated plasmas,53 atom-transfer radical polymerizations,54 and layer-by-layer techniques.55–58 In the case of glass-based materials, the major surface modification protocol takes advantage of the silanol groups and attaches chemical moieties to this surface through siloxane-based chemistry, which in many cases requires a cross linking agent, such as aminopropyltriethoxy silane (APTES). Unfortunately, this chemistry is susceptible to hydrolytic cleavage at extreme pH values. In contrast, polymer surface chemistries can utilize not only siloxane linkages, but also imine or amide-based linkages as examples.

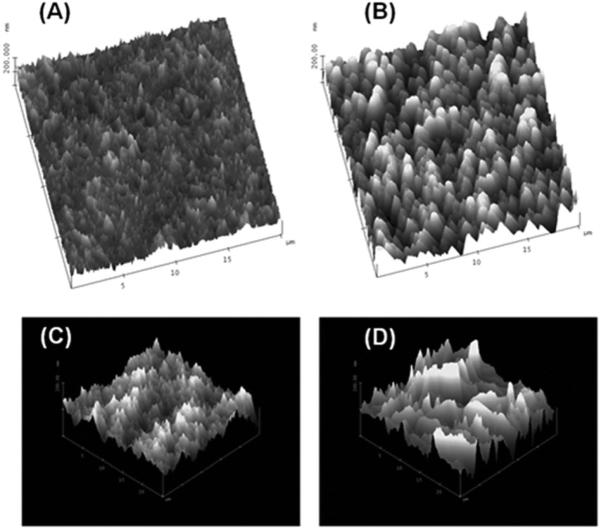

Common modification protocols employed for polymer surfaces use UV or plasma oxidation of the material, which generates a host of oxygen-containing species, such as alcohols and different carbonyls (aldehydes, ketones and carboxylic acids).43 In fact, in some cases UV/plasma modification protocols are used to assist in the assembly of the nanofluidic device by lowering the Tg of the exposed material, which permits low-temperature thermal fusion bonding of a cover plate to the substrate minimizing nanostructure deformation.1,59–61 Unfortunately, some of these modification processes can also alter the surface morphology. For example, Fig. 1 shows tapping mode AFM images of PMMA surfaces treated with either UV radiation or an oxygen plasma.49,62 In both cases, the root-mean-square (RMS) roughness was found to increase when the material was treated with plasma or UV light. The treated material was found to have an approximately 10 nm increase in its RMS roughness compared to the native material. Therefore, if the substrate containing the nanostructures must be treated with either a plasma or UV light to assist in assembly or to generate surface functional scaffolds for further elaboration, the dose must be carefully controlled to minimize nano-scale roughness increases that can affect the operational characteristics of the nanofluidic device.62 In the case of glass-like structures, the use of plasmas or UV light is not necessary to generate an activate surface to allow for functionalization and as such, the surface roughness is basically a function of the starting material.

Fig. 1.

Tapping mode AFM images of PMMA that has been treated with either UV radiation or an oxygen plasma showing the effects of the treatment on the surface roughness. (A) Native PMMA with an RMS roughness of 18 nm. (B) The same PMMA surface as in (A), but treated with UV radiation for 30 s; RMS roughness was found to be 27.5 nm. (C) Another PMMA surface (native) interrogated using tapping mode AFM with an RMS roughness of 16.7 nm. (D) Same PMMA surface as in (C), but plasma treated at 500 mW for 2 min and possessing an RMS roughness of 28.6 nm. The micrographs were reproduced with permission from Wei et al. (2005)62 and Xu et al. (2007).49

2. Fabrication of nanochannels and nanoslits in polymers

The production of nanoslits and/or nanochannels in polymer materials, whether it be elastomers such as PDMS or the more brittle materials such as thermoplastics, can utilize a variety of fabrication modalities, including those that are typically employed for the fabrication of nanostructures in glass, fused silica, or Si. A summary of the various fabrication techniques that have been used to produce nanostructures in polymers is shown in Table 2. There are several important distinctions that can be noted from this table as opposed to the fabrication of glass, Si or fused silica-based nanofluidic devices: (1) in some cases, one can produce microchannels in the substrate and then apply a stress to the material to generate the desired nanostructures. (2) Instead of direct writing the nanostructures into a substrate, the demanding steps of nanostructure production using EBL or FIB can be undertaken on a master or stamp, which is then used to produce final parts in the desired polymer; this is basically a nanoreplication or nanomolding process. The primary advantage of the processing strategies depicted in Table 2 is that nanofluidic devices can be produced in a high volume and at low-cost as opposed to direct write fabrication methods typically used for glass-like nanofluidic devices. In this section, we will introduce the concept of nanomolding and then discuss the various techniques used to fabricate nanoslits and/or nanochannels in elastomers, primarily PDMS, and then various thermoplastics.

Table 2.

Nanochannels/nanoslits fabricated in various polymeric materials along with the characteristic geometry of the structures and their reported application

| Material | Dimension (nm, width × depth) | Fabrication method | Application | Reference |

|---|---|---|---|---|

| PDMS | 690 × 80 | Crack-induced tunable | λDNA stretching | Huh et al. (2007)165 |

| PDMS | 7 × 103 nm2 (area) | Tunnel cracking | Nanoparticle trapping | Mills et al. (2010)166 |

| PDMS | 1470 × 275 | Wrinkle induced by oxygen plasma | Protein preconcentration | Seok et al. (2008)257 |

| PDMS | 100, 500 (depth) | Deformation of thin PDMS | DNA stretching | Park et al. (2009)171 |

| PDMS | 200 × 60 | Collapse of micron-scale PDMS microchannels. Glass/PDMS bonding substrate | DNA elongation and surface enhanced Raman detection of nucleic acids | Park et al. (2009)172 |

| PDMS | 400 × 20 | Nanochannels cracked from PS petri-dish induced by ethanol | Ion selective enrichment | Xu et al. (2010)37 |

| PMMA | 200 × 2000 | Proton beam writing, thermal fusion bonding | NA | Shao et al. (2006)188 |

| SU-8, SiO2 layer | 250 × 250 | EBL and NIL, thermal fusion bonding | DNA stretching | Thamdrup et al. (2008)159 |

| PMMA, COC, PC | 3000/7000 × 100 | Nanomolding replication, NIL, oxygen plasma treatment with thermal fusion bonding | λDNA transport dynamics and DNA mobilities | Chantiwas et al. (2010)59 |

| PMMA | 300 × 500, 300 × 140 and 75 × 120 | Imprinting nanostructure from Si etched into PMMA thin film | DNA stretching | Guo (2004)134 |

| PMMA | 10 000 × 80 | Si molding with thermal fusion bonding | NA | Abgrall et al. (2007)191 |

| PC | 100-900 wide, 200 nm wire | Hot embossing of silica nanowire molding with PC substrate, PDMS for cover plate bonded material | NA | Zhang et al. (2008)194 |

| PMMA | 185 × 85 | Replication of polymer stamp and polymer nanofluidic channels by NIL using polymer stamp | NA | Wu et al. (2010)196 |

| PI (Polyimide) | 2000-30 000 wide, 100 and 500 nm deep | Spin coat PI onto Si wafer and deposition of Al as sacrificial layer; etch Al, deposit another layer of PI and remove patterned Al | EOF measurements | Eijkel et al. (2004)203 |

2.1 Introduction to nanomolding

The deformability of polymers, especially at elevated temperatures, has made these materials to be routinely used for molding of microscale components in industrial production processes for decades.63 Various molding tools have been developed, which can be used for hot embossing, injection molding, compression molding, thermal forming, casting etc. However, only recently has molding demonstrated its capability for producing nano-scale patterns.64,65 After the pioneering work on nanoimprint lithography (NIL) by Chou et al. demonstrating patterns of 25 nm diameter holes in a PMMA film and the subsequent fabrication of metal pillars by metal deposition and lift-off,64,65 considerable efforts have been devoted to overcome many challenges associated with NIL. Such efforts include understanding fundamentals related to the process, such as polymer flow behavior during molding and stress and deformation of molded polymers during demolding,66–83 developing optimal materials applicable to the NIL process,84–95 overcoming the overlay issue,96–104 fabricating reliable stamps with sub-100 nm features,105–122 and improving anti-stick coatings.123–129 NIL has become very successful in patterning structures to sub-10 nm scales,64,130–132 with the ultimate resolution seemingly determined by the minimum feature size associated with the molding tool.133 This is the driving force behind the growing efforts of using NIL to produce nanofluidic devices because it can potentially produce multi-scale structures in a relatively high production mode over large areas and do so at low-cost. Readers who are interested in the NIL technology are referred to recent reviews and books.134–139 Here, we will briefly give some insights of NIL, which are needed in order to apply this technology to the fabrication of nano-based fluidic structures in polymers.

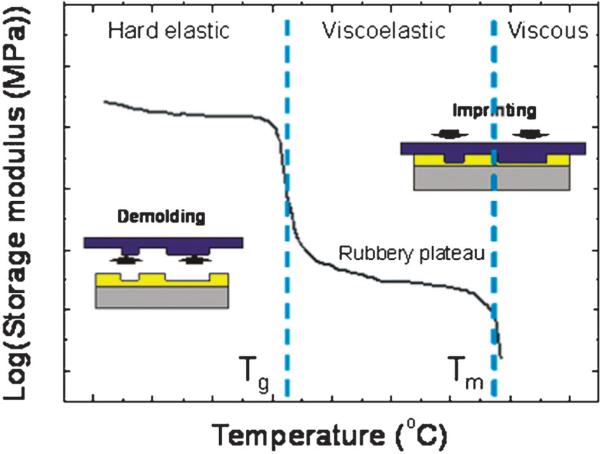

NIL or hot embossing utilizes the rapid change in viscosity (or modulus) of a polymer around its Tg. Fig. 2 shows the typical behavior of the storage modulus versus temperature for thermoplastics. The conventional NIL process starts with heating a polymer substrate above its Tg. Then, a hard stamp or molding tool with the desired nanostructures on its surface is pressed into the softened substrate, which forces the resist to flow into the cavities of the stamp structures. After conformal molding, the stamp/substrate assembly is cooled below the substrate's Tg and the stamp is released from the molded substrate. The term “nanoimprint lithography” is considered a special subset of “hot embossing” to indicate the formation of nanostructures. However, for many cases, the two terms are used without distinction.

Fig. 2.

Typical behavior of the storage modulus for thermoplastic polymers that is dependent on the temperature. Tg and Tm represent the glass transition temperature and melting temperature, respectively. NIL or hot embossing is usually performed above the Tg either in the viscoelastic or viscous state while demolding is done in the hard glassy state below the Tg.

The flow behavior of a polymer at a molding temperature, usually 50–70 °C higher than its Tg, is determined by the interplay of thermal and mechanical properties of the polymer substrate, wettability of the polymer on the stamp surface and the geometries of the stamp structures. Basically, polymers suitable for NIL are those which allow for sufficient flow for conformal molding at the process temperature and pressure while during demolding, a high modulus is desired to ensure that the deformed polymer patterns sustain detachment of the stamp without damage. Stamp geometry (i.e. distribution of stamp cavities and protrusions on a stamp surface) also has a significant role in polymer filling during NIL, and thus should be carefully considered in the design of the stamp and process parameters.68,71,78–80,137 A general rule on polymer filling is, the shorter the transport distance of the polymer, the faster the filling of stamp cavities under identical imprinting conditions. As an example, large, isolated recessed features surrounded by a large unstructured area requires a long time for complete filling. Also, when patterns with different sizes and densities are present on a single stamp, there is a local variation of stamp sinking velocities resulting in local bending of the stamp during NIL, and thus surface curvature in the imprinted polymer substrate.137 The polymer or substrate properties can also affect molding fidelity, such as its molecular weight.

While fast molding is important to improve the yield of the process, the process step that determines the success of imprinting high aspect ratio structures is demolding, a process to separate the molding tool from the patterned material. Most structural damage of the imprinted patterns occur at this step. Demolding is a process that involves overcoming all levels of chemical and mechanical interactions between the stamp and the substrate formed by the process history and properties of materials involved. Such interactions include thermal stress generated due to mismatches of thermal expansion in the tool/substrate during the cooling step, adhesion at the tool/substrate interface and friction occurring at sidewalls of the tool/substrate interface during demolding. Demolding failure will occur when stress at the tool/substrate interface becomes larger than the yield strength (σY) of the substrate. Demolding is usually performed at an elevated temperature but still in the glassy state below the Tg of the polymer. Low temperature demolding requires large demolding forces because thermal stress generated during cooling is proportional to ΔT, which is equal to T − Tg. On the other hand, at high demolding temperatures, the molded polymer structures are susceptible to deformation during demolding. For PMMA with a Tg ≈ 105 °C, an optimal demolding temperature has been reported to be around 70 °C, as determined by demolding force measurements and verified by finite element simulations.140 Efforts to improve demolding processes have been mainly devoted to decreasing the tool/substrate interface energy by: (1) modification of the surface properties for tools by applying an anti-adhesive coating;86,92,94,124,125 and (2) development of new imprint substrates with anti-adhesive properties.92,141–143 When the molding tool is made of either silicon or silicon oxide, a coating with fluorinated silane molecules has proven to be an excellent solution to improve the anti-adhesion properties of the tool's surface due to their low surface energy and stability of the bonding. Fluorinated silanes with different carbon chain lengths and silane head groups are readily available. The silane chemistry can be applied to other tool materials, such as nickel, by introducing a very thin intermediate layer (~ 10 nm) of silicon dioxide by sputtering prior to the silane coating.124 Fluorinated diamond-like carbon (DLC) coatings have also been employed as a release layer due to its low reactivity to polymer chains.144–147

Studies on stress and deformation behavior during demolding provides strategies to improve the demolding process.140,148–152 For example, high stress concentration usually occurring in the outer most structures indicates that important active structures can be protected during demolding if auxiliary structures are designed and added around the active structures. Also, slightly tapered or rounded stamp structures have been found to significantly help reduce demolding force.

As discussed, the stress generated during molding due to the contact between two dissimilar materials, such as the tool and polymer substrate, inevitably produces undesirable deformation in the molded patterns like warping and a non-uniform residual layer in addition to incomplete filling and ripping of structures. Such deformation in the molded polymer substrate can be tolerated for micro-scale components. However, when nanopatterns are present, particularly when a low number of nanopatterns are surrounded by large micropatterns as is the case for many nanofluidic devices, the deformation is not tolerable, making it difficult to achieve good sealing in the subsequent assembly process. Excessive surface roughness on the stamp surface and inclusion of contamination during the process are also detrimental to nanofluidic structures. For these reasons, most nanofluidic structures fabricated via NIL have been formed in a thin layer of thermoplastic polymer spin-coated onto a hard substrate or in an underlying Si or quartz substrate via pattern transfer.153–159

2.2 Elastomeric materials

Elastomers, although widely used for microchannel fabrication,47,160 have generally been considered problematic as nanochannels or nanoslits because of their deformability and tendency to collapse. Recently, there have been efforts aimed to overcome or even take advantage of the deformable nature of elastomers to form functional nanochannels and nanoslits. Various categories of nanochannel fabrication have been developed using the elastomer PDMS that we will describe here. We note that there are also a number of nanopores161 embedded in PDMS structures that have been reported in the literature. In this review, we will not describe such structures.

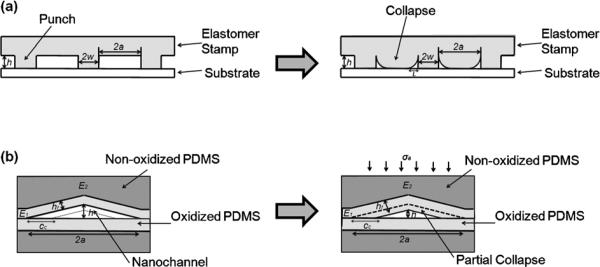

2.2.1 Collapse of elastomers with low Young's modulus

The multiple orders of magnitude lower Young's modulus compared to glass and Si is a major challenge for construction of nanochannels using elastomers (Table 1). Unwanted elastomer collapse often occurs (Fig. 3) and has traditionally been pointed out as a problem. One of the early studies related to elastomer collapse mechanisms used a PDMS stamp with a Young's modulus of less than 1 MPa.162 The authors analyzed various types of stamp deformations such as roof collapse, lateral collapse, smooth surface asperities, punch buckling and explained the stability criteria in terms of stamp features and Young's modulus. Here, “punch” refers to the pillars of material between void spaces that function to suspend the stamp structure. Focusing on the adhesion between a PDMS stamp and a substrate, Huang et al. and Zhou et al. reported the mechanism of “roof collapse” and derived a scaling law to prevent unwanted roof collapse (Fig. 3a).163,164 Taking the modulus mismatch between the PDMS stamp and the substrate, the investigators showed that the normalized work of adhesion, and geometrical features, w/a, were important in determining roof collapse. Here, E denotes the Young's modulus of PDMS, E′=4/3E and denotes the plane-strain modulus, γW is the work of adhesion between the stamp and the substrate, 2a is the punch spacing, hP is the punch height and 2w is the punch width. This analysis results in three regimes of roof collapse: no collapse (weak adhesion), meta-stable collapse, and stable collapse (strong adhesion).

Fig. 3.

Schematic showing the collapse of elastomeric channels; (a) roof collapse (b) collapse of crack induced-triangular nanochannels.

Channel collapse can be useful when controlled. Huh et al. analyzed triangular nanoslits and determined the normalized closure distance, cc/a, (Fig. 3b) as a function of, E2h2/γα, E1/E2, and σa/E2, where E1 denotes the plane-strain modulus of the oxidized layer, E2 is Young's modulus of unoxidized PDMS, γ is the surface energy of the nanochannels, cc is closure distance, σa is the remote applied compressive stress, h is height, hf is the thickness of the oxidized layer and 2a is the base length of the cross section.165 These material properties of elastomeric triangular nanoslits allow size-adjustable channel collapse upon application of an external force, however, these inhibit spontaneous channel collapse. This notable characteristic not only applies to crack-induced PDMS nanostructures but can also be generalized to many elastomeric nanoslits and nanochannels. An interesting aspect of triangular nanochannels is that they can partially collapse to different degrees of closure depending on the material property as well as external forces applied. In comparison, roof collapse of rectangular nanochannels is typically an all or nothing phenomenon; either the roof adheres to the bottom of the substrate and collapses or the roof does not adhere to the bottom of the substrate and is suspended.

2.2.2 Tunable PDMS crack-induced nanochannels/nanoslits

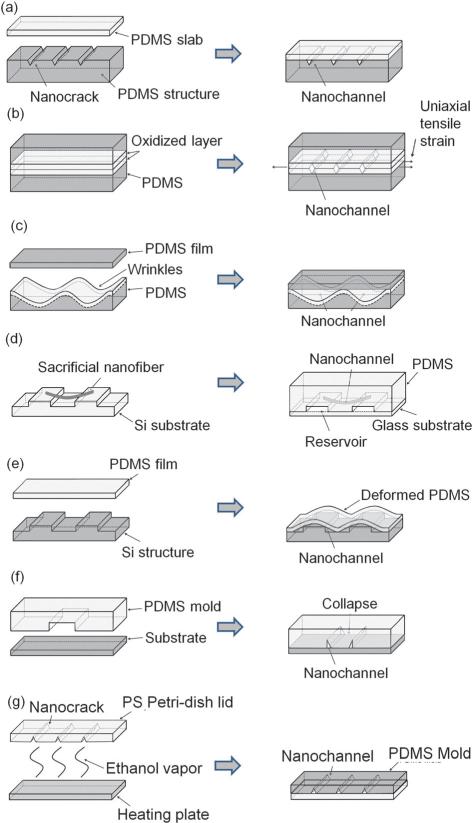

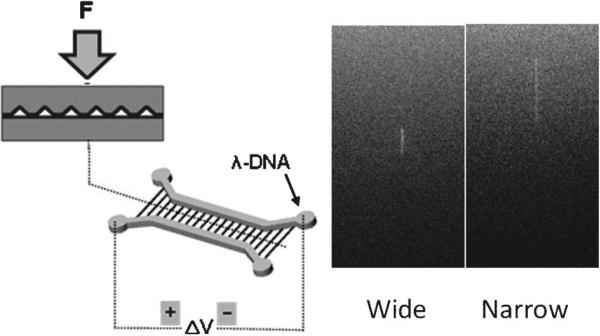

One of the early sub-100 nm nanofluidic structures made with PDMS were triangular cross-section nanoslits generated by fracture of surface oxidized PDMS structures (see Fig. 4a).165 Surface oxidation of PDMS, for example using a plasma etcher, increases the modulus of the surface PDMS layer generating a modulus mismatch between the surface and the bulk polymer. This material property mismatch provides the foundation for crack formation on the PDMS surface. Thus, an array of parallel cracks was created on the plasma-oxidized PDMS layer by an applied uniaxial tensile strain. The pattern of cracks can then be transferred to UV-curable epoxy, which can be used as a master mold. A separate PDMS structure was made from this epoxy mold and sealed with a flat PDMS slab using plasma oxidization. A key requirement for this process was to find mechanical properties of materials that avoided spontaneous nanostructure collapse, but maintained sufficient elasticity to allow for reduction of the nanoslit cross-section upon application of an external force to reversibly convert it into a nanochannel (Fig. 3b and Section 2.2.1). Sealed crack features formed triangular normally-open nanoslits with widths of ~690 nm and heights of ~80 nm. Closure into nanochannels and re-opening back to the larger cross-section nanoslit structures was reversibly controlled by application and removal of pressure on the device. These deformable nanoslit/nanochannel structures have been used for reversible capture of nanoparticles by nanochannel closure induced by application of an external force and subsequent release of the nanoparticles upon removal of the external force.165,166 The method has also been demonstrated for nanoscale polymer synthesis, particle sieving and reversible stretching and unstretching of single DNA molecules.165

Fig. 4.

Schemes for nanoslit and nanochannel fabrication in PDMS. Fabrication of crack-induced (a) normally-open nanochannels; (b) normally-closed nanochannels. (c) Fabrication of nanochannels using wrinkles made by surface buckling. (d) Nanochannel fabrication using sacrificial electrospun nanofibers. (e) Fabrication of nanochannels by deformation of a thin layer of PDMS over nanotopography. (f) Nanochannel fabrication by collapse of micron-scale PDMS microchannels. (g) Nanochannel fabrication with PS Petri-dish cracking.

Recently, Mills et al. published a variation to this concept of fracture-based nanofabrication by utilizing tunnel cracking rather than surface cracking (see Fig. 4b).166 This fabrication method is based on crack formation in oxidized PDMS, however, does not require transfer of structures to an intermediate epoxy mold. This is because rather than generating crack features on a surface, then sealing the features against another slab of PDMS to create a closed channel structure, bonding of two PDMS structures is performed first followed by formation of tunneling cracks. In this procedure, a thin flat PDMS membrane and a thicker PDMS slab that contained two microchannel structures were plasma-oxidized and bonded to each other. Subsequently, a uniaxial force was applied to the bonded structure to generate cracks that tunnelled through the brittle layer at the bonding interface. The ordered array of cracks that tunnel through the brittle bonded interface generated size-adjustable diamond-shaped cross-section channels. The cross-sectional dimensions of these conduits could be reversibly adjusted by the amount of external strain applied, where increased stretching leads to larger cross-sectional areas. Optical imaging, electrical resistance measurements and nanoparticle trapping experiments showed that the cross-sectional areas of these channels can be modulated from being completely closed when no strain was applied to having micron-scale cross-sectional dimensions when extensively stretched. Compared to the normally-open triangular nanoslits described previously that required application of external forces to narrow them down to nanochannels, these tunneling crack nanochannels have the advantage that they are normally-closed. This feature eliminates unwanted PDMS collapse as well as clogging problems because nanochannels can be widened when desired by stretching the device.

2.2.3 Wrinkle-induced nanoslit fabrication

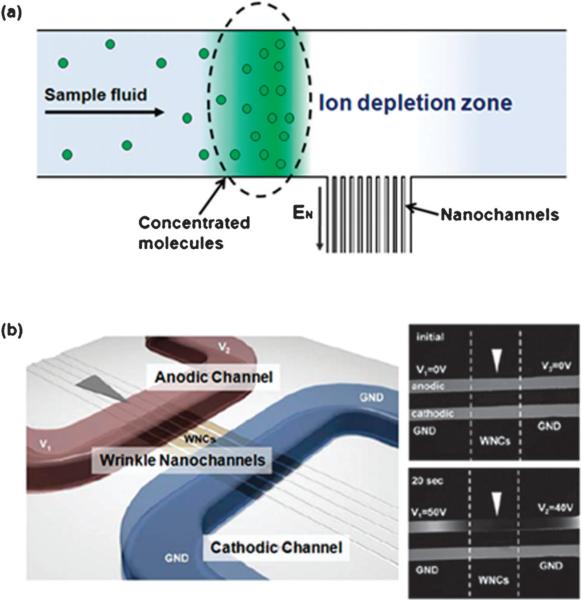

Due to surface stiffness changes and the need to release strain, sinusoidal wrinkle patterns were generated when a sheet of stretched PDMS was exposed to an oxygen plasma167 or UV/ozone (UVO) and then relaxed.168 The height and the width of the sinusoidal wrinkle patterns were governed by wave amplitude and wave length. The wave length of the formed structures was dependent on the ratio of elastic moduli of the film and the substrate. Because the thickness of the brittle layer can be regulated by the duration of oxidation treatment, wave length can also be controlled by different plasma/UVO exposure times. The amplitude of the wrinkle structures could be modulated based on the applied strain. This surface buckling phenomena has been used to fabricate nanoslits by Chung et al. (see Fig. 4c).169 PDMS membranes were stretched and exposed to oxygen plasma. Wrinkled PDMS membranes were created when the strain was slowly released. Nanoslit structures referred to by the authors as wrinkle nanochannels (WNC) resulted by bonding the wrinkled PDMS membranes with another oxidized PDMS layer, which contained microfluidic structures. This wrinkle-induced nanoslit fabrication technique has merits of enabling adjustment of the size of the nanoslits formed by controlling the wave length and wave height through fabrication parameters, such as the amount of surface oxidation and the degree of strain. The size of wrinkle-induced nanoslits ranges from tens of nanometres to 2500 nm in width and from tens of nanometres to approximately 500 nm in height.

2.2.4 Sacrificial electrospun nanofibers

Electrospinning produces nanofibers derived from polymer solutions. With an adequate applied electrical field, a droplet of polymer solution at an electrified tip is charged and stretched because of electrostatic repulsion. The droplet generates a “Taylor Cone” from which an electrified liquid jet erupts. The jet dries during flight as it heads towards a grounded substrate resulting in nanofibers. Based on this technique, Bellan et al. built sub-micron channels in PDMS using water-dissolvable electrospun nanofibers as sacrificial structures (see Fig. 4d).170 A PDMS mixture was poured onto a pre-featured silicon substrate with water dissolvable polyethylene oxide (PEO) nanofibers and cured at room temperature overnight. A low curing temperature was used to prevent premature melting of the PEO. After the PDMS structure cured, it was peeled off of the substrate and the PDMS slab soaked in water to dissolve PEO fibers in the PDMS slab. Sub-micron sized channels were left in place of the PEO nanofibers. The channel fabrication was completed by bonding it to a glass substrate using plasma oxidation. Features transferred to the PDMS from the Si substrate served as reservoirs. The measured average diameter of the resulting channels was 455 ± 16 nm and reflected the original structure of the electrospun nanofibers.

2.2.5 PDMS film deformation

Park et al. demonstrated a nanochannel fabrication method using deformation of a thin PDMS film (Fig. 4e).171 Triangular nanochannels were formed between a PDMS film and the sides of a structure fabricated by reactive ion etching (RIE). Specifically, Si structures were prepared using a thin Cr layer pattern followed by RIE with CF4 gas. Control of the etching time was critical to determine the final height of the structures. After additional steps to make inlet and outlet structures, the fabricated features were sealed to a thin PDMS film by plasma oxidation. Because the thin PDMS film was deformable, the shape of the film conformed to the structure and nano-sized gaps between the structure and the film were generated. In this way, nanochannels were formed without the need of EBL or FIB milling.

2.2.6 “Roof collapse” PDMS nanochannels

In general, nanoslit and nanochannel fabrication with compliant PDMS is challenging because of structural collapse (e.g. Fig. 3a). However, Park et al. described a nanoslit fabrication technique that actually took advantage of this mechanism (see Fig. 4f).172 Nanospatial gaps were formed at corners of microfluidic channels through “roof collapse”. The types of submicron channels and slits formed by collapse of microchannels of a given material stiffness were dependent on the geometry of the microchannel. In the work by Park et al., stable high-yield submicron channel and slit formation occurred for a starting microchannel width (a) to height (h) ratio of a/h2 ≈ 0.2. For the preparation of the initial microfluidic channel master, precise photolithographic methods were used that incorporated thin photoresist layers or metal deposition. The nanoscale height precision was important because the thickness of the channel master determined the size of the resulting nanoslits and channels. Once a precise master mold was made, PDMS replicas were produced from the master and bonded to a substrate by plasma oxidization. Roof collapse occurred spontaneously to generate nanoslits and channels at the microchannel corners. The advantage of this fabrication method was that nanoslits of arbitrary shapes, not just straight line patterns, could be made. The range of sizes of the nanoslits and submicron channels reported was 60–1000 nm in height.

2.3 Thermoplastic materials

Any nanofabrication technique that has demonstrated the capability for fabricating nanochannel/nanoslit structures in thermoplastics can be used for the fabrication of nanofluidic devices. However, for fluidic applications there are additional constrains in the selection of the appropriate fabrication method. These constraints arise mainly from the requirement of forming enclosed channels and deformability issues associated with thermoplastics. For example, to bond a cover plate made of the same polymer material as that of the substrate, the surface of the substrate involved in the bonding will result in a reduction of nanochannel depth in the enclosed device. Thus, nanochannels with low aspect ratios and rounded cross-sectional profiles may not be suitable for nanofluidic applications. Also, nanochannel/nanoslit-based fluidic devices usually consist of mixed-scale structures containing an array of nanochannels and micro-scale channels as well as large reservoirs serving as the inlets and outlets for reagents. Therefore, the nanofabrication technique should allow for either hierarchical or parallel combinations with various micromachining techniques. In this regard, the overlay accuracy between nanochannels and the microfluidic network must be considered. In this section, we will limit our discussion to those fabrication techniques employed in the fabrication of enclosed nanochannel/nanoslit fluidic devices in thermoplastics.

2.3.1 Beam-based nanolithographic methods

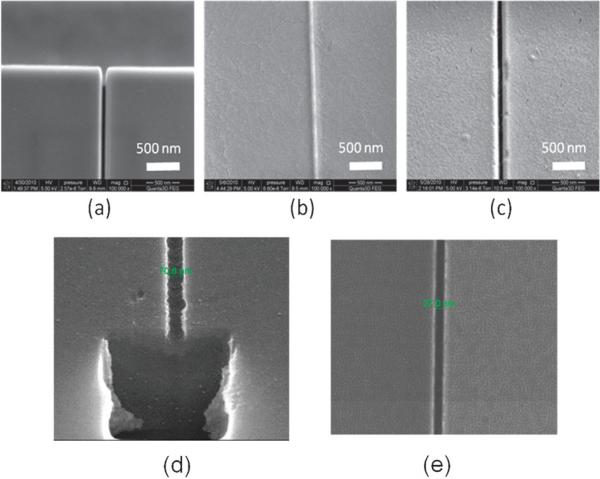

Energetic beam-based nanolithography methods, represented by EBL and FIB milling, are the most common techniques for patterning nano-scale features with arbitrary designs.173–181 In EBL, patterns are directly defined by scanning focused electron beams onto a thin resist layer, which creates a latent image by chemical development. FIB milling makes use of Ga+ ions to physically remove materials with a spatial resolution of 20–30 nm. Despite their intensive use in nanoelectronics, these techniques have seldom been used to create nanochannels directly into polymer substrates, which is most likely due to the difficulties associated with the formation of well-defined nanochannel patterns and enclosed fluidic devices following the patterning process. Sub-100 nm patterns formed by EBL usually have low aspect ratios and Gaussian sidewall profiles and this makes the subsequent bonding/assembly process difficult. FIB milling directly into polymers for nanostructure fabrication is still at a very early stage of development due to:182,183 (1) chemical changes induced in the polymer after direct milling arising from interactions with the impinging high energy ions; (2) charge build-up due to the insulating nature of the polymers; and (3) localized heating due to the low thermal conductivity of the material. Therefore, rather than direct patterning into polymer substrates, EBL and FIB have been used as a means of defining nanostructures in a thin resist layer, which are then transferred to an underlying hard substrate, such as Si or quartz-based nanofluidic chips,154,184 or for imprint stamps containing nanofluidic structures.159,185

As opposed to EBL, proton beam writing can create straight-walled, high aspect ratio nanostructures because a proton is more massive than an electron and, therefore, deviates much less as it penetrates matter.186,187 Shao et al. demonstrated the fabrication of enclosed nanochannels with 200 nm wide and 2 μm deep structures in a thick PMMA resist layer spin-coated onto a Kapton film using proton beam writing coupled with thermal fusion bonding (see Fig. 5).188 The use of the flexible Kapton film as a substrate for the nanofluidic chips promoted uniformity of contact pressure over large areas during thermal bonding. Proton beam writing has the potential for rapid and cheap prototyping of 3D micro/nanostructures for research and development purposes and also for the fabrication of high resolution 3D stamps for hot embossing.106

Fig. 5.

(a) PMMA enclosed nanochannels fabricated using proton beam writing coupled with thermal bonding, and (b) high magnification view of one of the buried channels. The channels are 200 nm wide and 2 μm deep. The proton beam was a 2 MeV energy beam that consisted of a 200 × 300 nm2 spot size and was scanned over a 2 μm thick layer of PMMA layer spin coated onto a 50 μm Kapton film. Reprinted with permission from Shao et al. (2006).188

Femtosecond laser beams have also been reported in fabricating channels with sub-micrometre cross sections. Yamasaki et al. demonstrated the fabrication of sub-micron channels in PMMA films in a single processing step, where a femtosecond pulsed laser beam was scanned in a 3D pattern within a 100 mm thick PMMA film.189 Both axial lengths of an elliptical cross section close to 200 nm were achieved with a pulse energy of 8 nJ. Channels formed in the PMMA had walls of densified material relocated from the channels’ core so that the etch resistance near channel walls was larger than that of the bulk PMMA. Combined with selective etching, this method offered the ability to produce polymer nanotubes. Because enclosed nanochannels were formed in a single processing step, bonding a cover plate was not required, which reduced device assembly steps and minimized nanostructure deformation induced by the bonding process. However, the minimum width in this patterning process was limited to a few hundred nanometres.

2.3.2 Nanoimprint lithography (NIL)/hot embossing

As noted previously, the strong drive of molding technology for producing nanofluidic devices is due to its ability to mass produce parts at low-cost and the diversity of materials that can be chosen as substrates for molding. In this section, we will review some of the work that has been directed toward producing polymer-based nanofluidic devices using NIL as the fabrication protocol.

In work by Abad et al.,153 an array of nanochannels were first produced by nanoimprinting into a thermoplastic polymer resist layer, which were then subsequently transferred to the underlying Si substrate using RIE. Then, the microfluidic structures were added by additional photolithography and RIE steps. Similar approaches have been considered by other groups to produce hierarchical nanofluidic structures.154,156–158

Imprinting entire fluidic structures in a single step requires fabrication of imprint stamps with multi-scale structures using various micro- and nanofabrication techniques.155,159 Thamdrup et al. demonstrated the production of a nanochannel chip by means of single step imprinting with a stamp having both nanometre and micrometre protrusions.159 The protrusions in the stamp were hierarchically fabricated in a SiO2 layer via EBL and photolithographically in a sol–gel resist, which were then transferred to an SU-8 layer via imprinting. Then, a simple thermal polymer fusion bonding process was used to seal the imprinted fluidic structures.

Chantiwas et al. demonstrated the use of sequential imprinting processes to produce nanoslit-based fluidic devices in different polymer substrates (PMMA, COC, and PC) used for DNA stretching.59 After formation of the microfluidic vias using hot embossing with a metal molding tool, nanoimprinting followed in order to produce an array of nanoslits in pre-patterned substrates. Critical in this method was preventing the undesired deformation of the pre-patterned microfluidic vias by the second nanoimprinting step. For that, a significantly lower temperature (110, 130, and 147 °C for PMMA, COC and PC, respectively) was used for the nanoimprinting step compared to that used for hot embossing to prepare the microstructures (160, 175, and 190 °C for PMMA, COC and PC, respectively). The authors also showed production of the entire fluidic devices by single step imprinting using a PDMS stamp. The fabricated nanoslit chips were enclosed with a thin polymer plate bonded to the molded polymer substrate via thermal fusion bonding.

Guo et al. have shown that nanoimprinting can be used to enclose nanochannel networks.190 Their method utilized incomplete filling of molding tools usually occurring when the thickness of a resist layer is much lower than the height of a template. The PMMA nanochannels were made by NIL, in which a Si or glass template was fabricated using NIL structuring of a resist, standard metal deposition, liftoff and dry etching of the substrate to form nanopatterns. They demonstrated that the height of enclosed nanochannels could be controlled by the initial thickness of the PMMA layer and the depth of the nanochannel template.

As noted previously, most nanochannels fabricated with NIL have been formed in a thin resist layer coated on a hard substrate, such as Si or quartz, with the patterns subsequently transferred via RIE into a hard substrate; little has been done to form fluidic nanostructures in the bulk polymer directly. Abgrall et al. employed hot embossing with two levels of applied force (2 kN and 7 kN) into 1 mm thick PMMA cast sheets with a Si mold fabricated using photolithography and RIE.191 The chip was then sealed using thermal fusion bonding. They demonstrated an array of enclosed nanoslits with a width of 10 μm and a depth of 80 nm. The critical dimensions (width-to-depth) of nanoslits that could be sustained without collapse were determined by considering the competition between van der Waals forces and the stiffness of the material.191,192 In the work from Studer et al., nanochannels in polymer substrates were formed by hot embossing of PMMA pellets between a Si mold and a dummy Si wafer followed by thermal fusion bonding with another polymer sheet for enclosing the fluidic network.193

Silica nanowires have also been used as templates for the fabrication of isolated nanochannels by placing them between a glass wafer and a PC substrate.194 The silica nanowires were made by tapering single-mode optical fibers to the desired diameter in an alcohol flame. The wires could be positioned on the glass plate using the probe tip of a scanning tunneling microscope. Following hot embossing, which embedded the wire into the PC, the silica nanowires could be removed from the substrate by etching in hydrofluoric acid. The PC channels were subsequently enclosed using a PDMS cover plate, which also contained microchannels. Channels with widths down to 100 nm could be formed using this technique with lengths up to several millimetres. However, this method could not produce vertical sidewalls and was limited to the formation of simple fluidic architectures (i.e., straight channels).

Direct nanoimprinting into polymer substrates using a Si, quartz, or metal stamp can lead to rather severe, undesired deformation of channels and the entire chip can show warping and/or local substrate bending, making it difficult to generate a tight seal between the fluidic substrate and cover plate.190,195 The stamp lifetime is also an issue because the expensive nanostructured molding tool can be damaged due to high stress generated during the imprinting process. In addition, differences in the thermal expansion coefficients between the polymer substrate and the nanoimprinting tool can lead to replication errors.

In an effort to reduce undesired deformation and stress in molded patterns as well as the imprint tool, Wu et al. utilized an imprint tool made of a UV curable polymer on a glass substrate to directly nanoimprint structures into a PMMA substrate.196 The Si master, fabricated by a combination of two sets of photolithography/RIE and FIB milling, consisted of an array of nanochannels, micro-scale channels and reservoirs for inlet and outlet of reagents. The microchannels possessed a depth of 10 mm with a gradient interface as the inlet to the nanochannels where the microchannel depth was reduced to 500 nm. The Si master, with the same polarity as the final fluidic structures, was first replicated into a UV curable polymer coated onto a glass substrate using UV NIL. The pattern in the UV curable polymer layer was then used as a stamp to imprint structures into PMMA substrates. Fig. 6a–c shows SEMs of a Si master, polymer imprinting stamp, and imprinted PMMA using the polymer stamp, which showed good replication fidelity. Also shown in Fig. 6(d) and (e) are nanochannels produced in quartz prepared via direct writing into the substrate using a Ga+ ion beam (FIB milling). From a dimensional perspective, both direct FIB milling and NIL can produce nanochannels with the designed dimensions. In these examples, topographical features on the channel floor could not be interrogated. One subtle issue that can arise using direct FIB milling is ion implantation within the substrate being milled, which would not be present for the polymer channels fabricated via NIL even though the Si master was prepared via FIB milling. Polymer stamps significantly improved the demolding step during the imprinting process in two ways: (1) thermal stress generated during the cooling step was significantly reduced due to the similar thermal expansion coefficients of the stamp and substrate. (2) Force of adhesion at the stamp/substrate interface, which depends on Young's modulus of the stamp and substrate, was reduced due to a lower Young's modulus of the polymer stamp. The stamp structures were deformed by the application of high pressure during the nanoimprinting process with a polymer stamp of low Young's modulus. Therefore, it was necessary to find an optimal resist composition, which provided both good demolding characteristics and replication fidelity. Additionally, polymer stamps could be repeatedly produced by replication from the original Si master, significantly increasing the lifetime of the expensive Si master patterned via EBL, FIB or proton beam writing. Finally, the stamps could be used to produce the desired patterns in a vast array of materials, provided the selected material had a lower Tg than that of the stamp.

Fig. 6.

SEMs of a 60 nm channel produced in (a) a Si master, (b) UV curable polymer stamp replicated from the Si master, and (c) imprinted PMMA produced using the polymer stamp shown in (b). The nanochannel shown in (a) was made by FIB milling using a Ga+ ion beam into a Si 〈100〉 substrate. A monolayer of 1H, 1H, 2H, 2H-perfluoro-decyltrichlorosilane was coated onto the patterned substrate. To create the polymer stamp, a UV-curable polymeric blend containing 69 wt% tripropylene glycol diacrylate (TPGDA) as the base, 29 wt% trimethylol-propane triacrylate as the crosslinking agent, and 2 wt% Irgacure 651 as the photo-initiator were used. The Si master was coated with the UV resin by dispensing with a pipette. Then, a COC substrate (COC-TOPAS 6017, TOPAS Advanced Polymers, Florence, KY) was placed on the UV resin-coated stamp and was gently pressed in order to ensure complete filling of the resin into the master cavities. This was followed by UV exposure for 20 s to allow for curing. The UV lamp used for curing had an intensity of 1.8 W cm −2. The patterned UV-curable resin was then used as a stamp to hot impress into a 3 mm-thick PMMA sheet. The imprinting was carried out at 130 °C and 20 bars for 5 min using an NIL machine (Obducat nanoimprint system), with an applied pressure to the stamp and substrate using compressed air, ensuring pressure uniformity over the entire imprint area. The pressure was added after a 30 s preheating at the desired molding temperature and was kept constant during the imprinting process until cooled to 70 °C. After the stamp and substrate were cooled to room temperature, the PMMA replica was removed from the UV-resin stamp. (d), (e) SEMs showing 71 nm and 27 nm channels, respectively, fabricated directly in a quartz substrate using FIB milling (Ga+ ion beam). In all cases, the channels shown were not sealed with a cover plate. For (d), the FIB was used to cut a cross-section from the substrate following nanochannel patterning to inspect the topology of the channel. In all cases, the aspect ratio of the channels shown in this figure were ~1 (aspect ratio = channel depth/channel width).

Nanotransfer printing,197,198 a technique of transferring a nanostructured layer from a mold into another substrate by stamping, has been demonstrated as a useful process to fabricate enclosed nano-scale polymer channels. In the process developed by Dumond et al.,195 a thin PMMA film cast on a Si grating mold was subsequently embossed with a second grating mold. The PMMA film with patterns on both sides was then stamped into a Si or indium substrate, which transferred the structured film from the second grating mold into the substrate due to surface energy contrast at the two interfaces. The substrate used for the stamp acted as a cover plate for enclosing the nanochannels, and thus no additional bonding process was required. The use of a substrate of the same polymer material as the transferred film in order to produce all polymer-based nanofluidic chips would potentially be feasible.

2.3.3 Miscellaneous methods

Several groups have reported the creation of nanoscale depressions in a thin film of thermoplastic using atomic force microscopy (AFM) nanolithography.199–202 As an example, Tsai et al. employed AFM nanolithography with high aspect ratio Si tips to fabricate nanochannels in PMMA with a width of 80 nm and a depth of 30 nm for the fabrication of glucose biosensors.201 However, the serial process with small scan velocities of 1–10 μm s−1 limits the throughput of this process to generate nanostructures over large areas. The maximum channel length that could be produced without break or stitching was also limited by the range of the AFM scanner motion, which was 10–100 μm. Moreover, the nanochannels produced by AFM nanolithography usually possess low aspect ratios and have V-shapes, conforming to the shape of the AFM tips. Also, the material removed by the AFM tip piles up surrounding the indentation, which makes it difficult to form enclosed nanochannels in the subsequent bonding process.

A number of methods, which do not require the use of nano-scale writing tools or a stamp (or mold) with nano-scale patterns have also been developed. Eijkel et al. developed a simple method using spin-coating and sacrificial layer etching to fabricate all-polyimide nanoslits.203 After patterning an aluminium sacrificial layer with micropatterns on the first polyimide film using photolithography and an aluminium etchant, the authors spin-coated a second layer of polyimide on top of the aluminium and first polyimide layer. The thickness of the sputtered aluminium sacrificial layer determined the height of the final nanoslits. The formation of enclosed nanoslits was achieved by etching the sacrificial aluminium layer. The sacrificial layer etching process took about 20 h and was limited by diffusion of both the Al etchant and removed Al in the enclosed nanoslits. This limitation in the sacrificial layer etching process made it difficult to use this method for the fabrication of nanochannels.

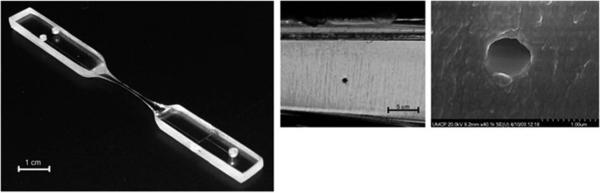

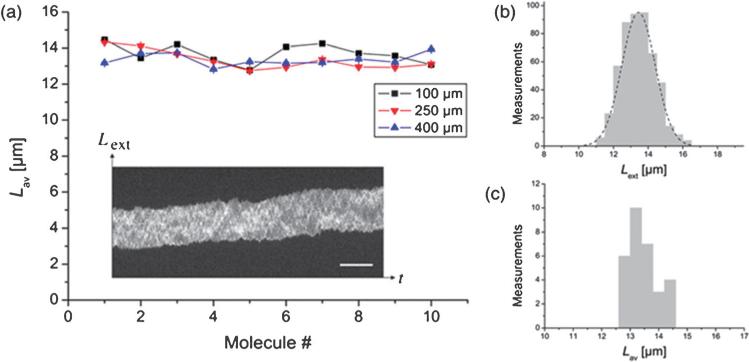

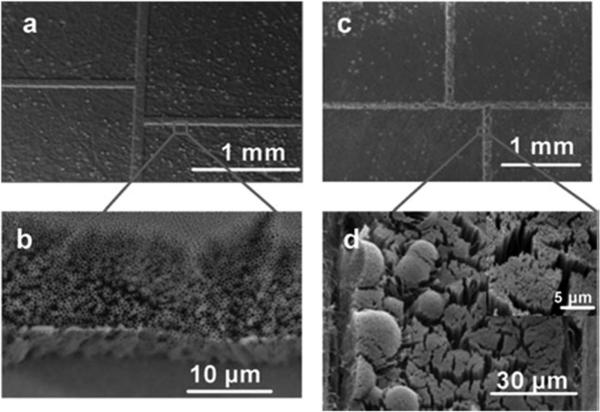

Sivanesan et al. demonstrated a simple method for fabricating nano-scale channels based on thermomechanical deformation of rigid polymer substrates, mimicking the draw process in the fabrication of silica capillaries.204 In their work, PC preforms containing microchannels with cross-sectional dimensions on the order of tens of micrometres were controllably deformed by applying a uniaxial tensile force at the Tg of PC (~ 150 °C). This reduced the channel cross section through the Poisson effect. Arrays of parallel nanochannels with critical dimensions down to 400 nm were demonstrated. Fig. 7 shows a fabricated nanofluidic chip made by the mechanical deformation of thermoplastic polymers and electron micrographs showing a single nanochannel. Factors determining the size and shape of the final nanochannels included the pull distance, temperature distribution and location of the original microchannel within the preform. Also, the maximum reduction in channel width and height was found near the edge and center of the preform, respectively. Despite its simplicity and reproducibility, the thermomechanical process is limited to applications where straight channels or an array of nanochannels with equal lengths are required.

Fig. 7.

(a) Typical fabricated nanofluidic chip via thermomechanical deformation of a thermoplastic, in this case PC. (b) Far-field and (c) high magnification electron micrographs showing a single nanochannel with a circular cross section of 700 nm in diameter. PC pre-forms, consisting of microchannels, were placed between two Ni–Cr resistive radiant heaters and heated above the Tg of the polymer; linear motors were used to pull the microchannel to the desired nm diameter. This technique could be used to form nanochannels with diameters up to 400 nm. Reprinted with permission from Sivanesan et al. (2005).204

The ability to make Si nanoimprinting stamps with high aspect ratios without requiring EBL or FIB was recently demonstrated.205 In this process strategy, Si 〈100〉 stamps were fabricated using KOH anisotropic etching of Si and the local oxidation of Si. The Si nanoimprinting stamps were coated with 1H, 1H, 2H, 2H-perfluorodecyltrichlorosilane and the imprinting was performed using PMMA substrates. Channels with depths of 1.1 μm and widths of 200 nm were formed (aspect ratio = 1 : 5.5) with the minimum width reported to be 100 nm. The fluidic channels were enclosed using a solvent-assisted method; the substrate was exposed to methanol or toluene vapor, which caused melting of only the top portion of the high aspect ratio structures basically sealing the nanochannel.

Self-organization of materials is a powerful tool to produce nanoscale structures in a cost effective manner, requiring no nanolithographic tools. Faruqui and Sharma demonstrated a simple nanofabrication technique to obtain an array of nanochannels based on stress-induced cracking of thin film microstructures at sharp edges.206 PMMA micro-scale stripes of triangular cross-section were first produced using incomplete filling and extended annealing. When the triangular gratings were further annealed, cleavage was observed starting on the pointed tips of the triangular stripes in order to relieve the stresses locally built up at the tips. Fabrication of 100 nm wide and 120 nm deep fine nanochannels has been demonstrated with this method. Fabrication routes based on dewetting of polymer films on nonwetting substrates207 and di-block copolymers in combination with external fields and chemical steps208–211 have also been developed to produce highly aligned polymer nanochannels. However, these routes are still premature to be used for the fabrication of enclosed nanochannel-based fluidic chips due to difficulties in integrating hierarchical multi-scale structures.

Xu et al. developed a lithography-free nanochannel fabrication technique where cracks are induced by swelling a polymer layer on the surface of polystyrene (PS) petri-dish lids (see Fig. 4g).212 In this procedure, PS petri-dishes filled with an ethanol solution were heated. The heated ethanol stream absorbs on the inner surface of the petri-dish lid, swelling thin layers of the inner PS petri-dish surface. Simultaneously, the process generates a temperature gradient (80 °C to 25 °C) between the inner and the outer surface of the PS petri-dish lid. Upon cooling, the released ethanol from the inner petri-dish lid surface resulted in shrinking of the surface thin film. Due to the anisotropy of PS chains within the petri-dishes, release of stress was biased in terms of direction and induces parallel cracks that were evenly spaced on the surface. The crack array features on the PS petri-dish could be replicated into a polymer mold and further transferred into PDMS. Nanochannel dimensions could be adjusted by choice of temperature, solvent type, solvent volume, heating duration of the original PS cracking step and was affected by the degree of swelling and temperature gradients. Use of ethanol and 80 °C heating were ideal conditions for mild PS swelling and regular crack pattern formation. This fabrication method was related to the cracking fabrication by PDMS stretching except that the surface thin film was strained without direct application of external mechanical forces.

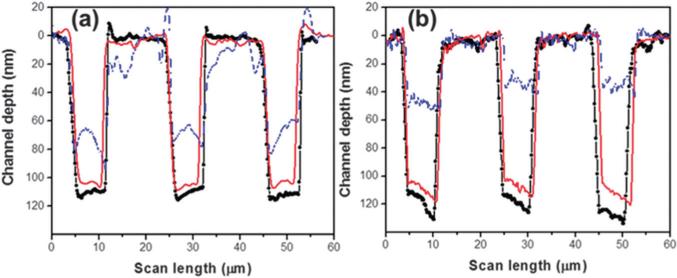

2.3.4 Thermoplastic nanofluidic device assembly

Thermal fusion bonding is a common technique used to enclose polymer-based fluidic devices and is accomplished by carefully controlling the time, temperature and pressure used for bonding a patterned polymer substrate to its cover plate. For microfluidic channels, direct thermal fusion bonding is carried out by heating both the substrate and cover plate to a temperature near or above the Tg of the specific material while applying a pressure to increase fusion contact force.61 However, this process can be challenging for enclosing fluidic devices containing nanostructures due to slight bulk polymer flow, which can cause significant nanostructure deformation. Abgrall et al. and Chantiwas et al. achieved assembly of thermoplastic nanoslits (80 nm and 100 nm deep nanoslits, respectively) by utilizing a protocol employing thermal fusion bonding at a temperature lower than the Tg of the material by using oxygen plasma treatment of both the cover plate and substrate prior to chip assembly.59,191 Fig. 8 shows the metrology of (a) PMMA and (b) COC nanoslits (see Fig. 8 for chip assembly conditions) assembled at different temperatures. Reduction in the depth of the nanoslits (red traces) when plasma oxidized and fusion bonded at a temperature below the bulk Tg of the material compared to the slits without chip assembly (black traces), which were found to be 6% for PMMA and 9% for COC, respectively. However, thermal fusion bonding close to the bulk Tg of the material (107 °C for PMMA and 130 °C for COC) collapsed the nanoslits by 40% and 60% for PMMA and COC, respectively.

Fig. 8.

AFM profiles measured for (a) PMMA and (b) COC nanoslits (7 μm wide, ~100 nm deep, 12 μm pitch) before and after different cover plate assembly protocols. The blue-dash line represents the slit depth following thermal fusion bonding at 107 °C for PMMA and at 130 °C for COC slits; red-solid line is the depth of the slits following thermal fusion bonding at 87 °C and 115 °C of an oxygen plasma treated substrate and cover plate for PMMA and COC, respectively; and the black-circle line is the nanoslits following molding, but not subjected to thermal fusion bonding. Reprinted with permission from Chantiwas et al. (2010).59

However, thermoplastic structure deformation via thermal fusion bonding can be used for tailoring the geometrical properties of polymer structures. Wang et al. presented an approach coined ‘pressed self-perfection by liquefaction (SPEL)’ to control trench, line and hole dimensions.213 By pressing a guiding plate with a smooth surface on top of patterned structures on a substrate, the structure spacing and hole diameter decreased using SPEL. By applying a temperature of 65 °C for 20 min, the grating spacing was reduced from 120 nm to 12 nm using an applied temperature of 100 °C for 0.5 min. The Tg of the material used for these nanostructures was 55 °C.

3. Transport phenomena in polymer nanochannels and nanoslits

There have been several comprehensive reviews on nanofluidic transport phenomena.1,2,209,210 The major differences that exist between microfluidics and nanofluidics result from electro-kinetic transport mechanisms. The electrical double layer can occupy a large amount of the cross-sectional area of the fluidic via or in some cases, even overlap if the channel dimensions are comparable to the double layer thickness. Therefore, the electrical double layer is critical in determining the characteristics of nanofluidics compared to microfluidics and this is where polymer nanofluidics can be uniquely distinguished from glass or fused silica nanofluidics due to differences in the zeta potential between glass and many polymers. In this section, we summarize nanofluidic principles based on electro-kinetic and hydrodynamic transport phenomena and compare and contrast polymer and glass-based nanofluidics with respect to these transport phenomena. For a more extensive review of transport phenomena in nano-confined environments, the reader can refer to the references listed above.

3.1 The electrical double layer and electrokinetic transport in nano-confined environments

Electrokinetics is a commonly used transport mechanism in nanofluidics due to the fact that significantly smaller pressure drops occur compared to hydrodynamic driven transport and the ability to directionally drive the flow without the need for valves. Electrokinetic transport is typically produced from both the electrophoretic mobility of the molecule being driven through the nanochannel or nanoslit and the bulk electroosmotic flow. Electroosmotic flows (EOF) are highly dependent on the surface charge of the material and this is where polymers distinguish themselves from glass or fused silica-based substrates; the surface charge for polymers can be highly variable and depends on the substrate material as well as the nature in which it was treated. In most cases, the EOF in polymer-based devices is smaller compared to glass.19,214

The surface charge density (σs) is described by σs = Σiqi/A where qi is the net charge of the ion and is given by qi = zie, where zi is the valency of the ion, e is the electron charge, and A is the surface area. Surface charges also result in an electrostatic force, which can play a significant role in the interactions between the transported molecules and surfaces, especially in the case of nanofluidics.

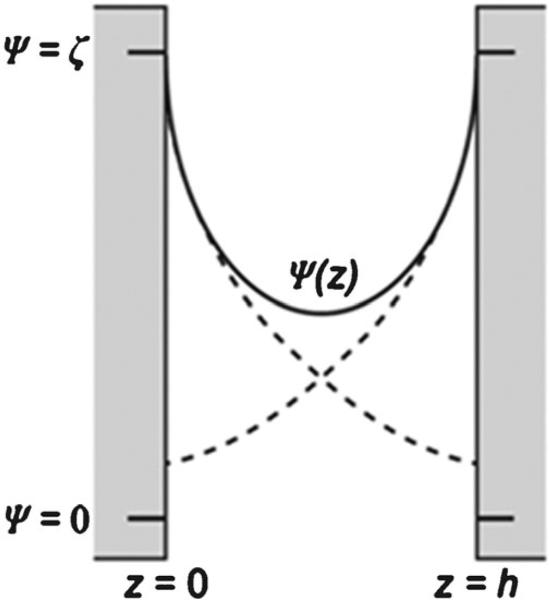

Here we describe the formation of the electrical double layer (EDL) and how it relates to the surface charge density when different materials are used. The EDL is composed of the Stern layer and the diffuse layer and occurs at the solid–liquid interface. The potential distribution of the charged interface in the EDL (ψ) is expressed by the Poisson–Boltzmann equation, , where κ is the Debye–Hückel parameter and z is the surface normal direction. The Debye length, λD = κ−1, describes the length where the potential has dropped to e−1 of the original potential. By assuming a symmetrical zi : zi electrolyte with concentration Ci at 25 °C, the Debye length (m) can be given as , where the ionic strength is . For Is = 10−2 M, λD = 3.04 nm, while for Is = 10−4 M, λD = 30.4nm.

For nanochannels as opposed to microchannels, λD/h (h is the width and/or height of the nanochannel or nanoslit) is close to unity (dashed line, Fig. 9), which can have a pronounced effect on the EOF and follows the electric potential ψ(z) profile and will not produce the common plug flow profile associated with electrokinetics in microchannels. At low ionic strength, the electroosmotic velocity (νeo) is dependent on the electric potential distribution ψ(z) as expressed in the equation , where EV is the applied electric field, ε is the relative dielectric permittivity, ε0 is the vacuum permittivity, η is the dynamic viscosity of the electrolyte and ζ is zeta potential, which is the electric potential at the interface of the Stern and diffuse layers. Based on this equation, if one compares νeo at a certain z-position between polymers and glass nanochannels, it can be assumed that νeo will be lower in polymers because ζ of polymers is typically lower than glass.215,216

Fig. 9.

Schematic representation of the potential distribution in a nanochannel with height h in direction z when the EDLs overlap (solid line), compared to the EDL potentials if the opposite wall is not present (dashed line). Reproduced with permission from Schoch et al. (2006).217

The zeta potential is related to the diffuse layer charge density and can be determined through the electroosmotic mobility,209,212 and can be changed either using different materials, such as glass or polymers, or by surface treatment of the material, for example through chemical reactions or photochemically-induced surface reactions.215,217 Kirby and Hasselbrink recently reviewed zeta potentials for different materials, such as Si, glass and fused silica and included information on a variety of polymers, for example PDMS, PC, PMMA, polyethylene terephthalate, polyethylene, polystyrene and polyvinyl chloride.216 Chai et al. reported on zeta potentials of PMMA modified using an oxygen plasma.218 Oxygen plasma modification is often used for polymer microfluidics and recently, nanofluidics. For example, Abgrall et al. reported the use of oxygen plasma treatment for nanoslit preparation in PMMA191 and Chantiwas et al. utilized oxygen plasma treatment for different thermoplastic nanoslits (PMMA, PC and COC) for chip assembly.59 Chai et al. found that ζ depends on the surface charge density and double layer thickness of different electrolyte solutions.218

Table 3 presents ζ and the corresponding interfacial charge density of untreated and 50 s plasma-treated PMMA in different solutions. Plasma-treated PMMA has higher values of ζ and the corresponding interfacial charge density (σ) for all solutions. Increases in ζ of modified PMMA surfaces in water could be due to the generation of charge states arising from plasma treatment or the ionization or dissociation of new functional groups (e.g. the dissociation of surface carboxylic acid groups).218 Effects of oxygen plasma treatment on the EDL and ζ is a complicated process, however, oxygen plasma treatment does lead to a more negatively charged surface. The authors also reported that the EDL contribution to the solid–liquid interfacial tension was negligible.218 Measurement of ζ for COC compared to glass substrates was reported.219 By considering hydrophilic/hydrophobic differences between COC and glass substrates and using time-resolved electro-kinetic measurements, ζ of silica was −25.7 mV with a value of −14.1 mV for COC using a 10 mM phosphate buffer (pH 7).

Table 3.

Experimental values of ζ and σ for untreated and 50 s oxygen plasma treated PMMA in different electrolyte solutions. Data taken with permission from Chai et al. (2004)218

| Sample | Solution | ζ/mV | σ/μC cm–2 |

|---|---|---|---|

| No treatment | Water | –35.9 | –0.0089 |

| 0.1 mM KCl | –13.4 | –0.031 | |

| 1 mM KCl | –7.5 | –0.055 | |

| 50 s treatment | Water | –82.5 | –0.028 |

| 0.1 mM KCl | –48.5 | –0.130 | |

| 1 mM KCl | –20.9 | –0.157 |

The EDL overlap can also induce concentration polarization effects near the end of a nanochannel. Concentration polarization involves two basic phenomena—ionic depletion and ionic enrichment. Application of an applied voltage, in which the EDLs overlap, results in the selective passage of counter-ions through nanochannels with the migration of co-ions toward the anode. As a result, the concentration of counter-ions decreases near the anodic side of the nanochannel to maintain electroneutrality generating an ion depletion region. The electrical conductivity in the ion depletion region becomes very low; thus, a high electric field is formed near the anodic side of a nanochannel. This electric field induces an excess flux of counter-ions through the nanochannels forming an enrichment effect on the cathodic side. Finally, ionic depletion and enrichment regions are formed at both ends of the nanochannel when a voltage is applied across the channel.

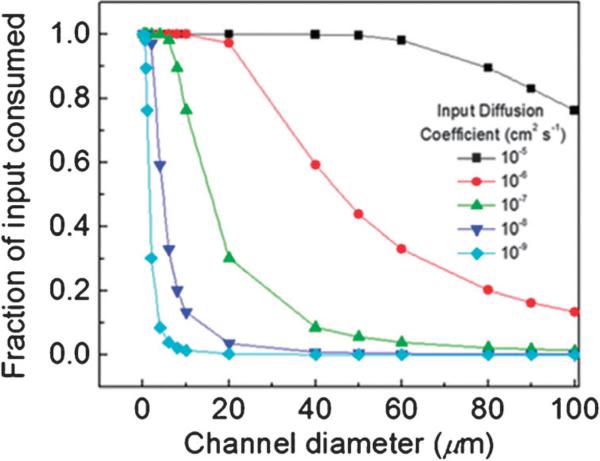

3.2 Hydrodynamic flow in polymer nanochannels

There are basically two different modalities to induce flow in nanochannels hydrodynamically: (1) the use of capillary pressure, which is based on the surface tension forces between the liquid and the surface; and (2) hydrostatic pressure, which requires the use of an external source to force the fluid through the nanochannel or nanoslit. The capillary or Laplace pressure (ΔPL) can be calculated using the equation, ΔPL = 2γ(cos θC)/r, where r is the capillary radius, θC is the water contact angle and γ is the surface tension of the liquid in air (for water, γ = 0:0073N/m). As can be seen from this equation, the capillary pressure is dependent on the water contact angle of the substrate material comprising the nanochannel. For example, the water contact angle of glass, PMMA, PC, COC and PDMS are 36°, 67°, 82°, 92°, and 110°, respectively. For a 50 nm channel (aspect ratio ~1) and water filling this channel, the capillary pressure would be approximately 23.4 atm, 11.3 atm, 4.0 atm, −1.2 atm, and −9.8 atm for glass, PMMA, PC, COC and PDMS, respectively. As can be seen, the capillary pressure actually drives the fluid from the channel and towards the inlet for PDMS and COC substrates due to their hydrophobic nature (i.e., water contact angle >90°) as opposed to glass, which draws the fluid into the channel strongly. However, oxygen plasma treatment can introduce many different oxygen-containing moieties onto the polymer substrate material, and thus lower its water contact angle. For example, COC treated with an oxygen-plasma will produce a surface with a water contact angle of ~23°, which will reverse the direction of the capillary pressure and draw water into the channel.

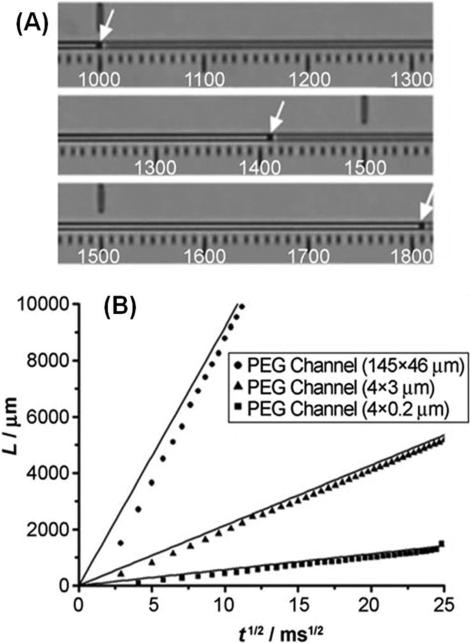

The liquid position in the channels was modeled using , where L is the liquid front position, Cg is the shape factor of the channel/slit, η is the solution viscosity, t is time, and R is the hydraulic radius, which is equal to the ratio of the cross-sectional area to the wetted perimeter. Recently, capillary flow in poly(ethylene glycol), PEG, and PDMS nanoslits has been measured. Average flow velocities for 3 mm long rectangle channels were reported as 1.5 × 105, 1.2 × 104, and 6.0 × 102 μm s−1 for PEG channels corresponding to hydraulic radii (R) of 34.92, 1.71 and 0.19 μm, respectively. The water flow velocity was measured in PEG nanoslits with dimensions of 4 × 0.2 μm2, 4 × 3 μm2 and 145 × 46 μm2 (width × height) corresponding to R values of 0.19, 1.71 and 34.92 μm, respectively. In the case of PDMS nanoslits, water did not enter the nanoslit with dimensions of 4 × 0.2 μm2 (R = 0.19 μm) due to a high flow resistance because of the large water contact angle of PDMS and partial collapse of the nanoslit arising from the low Young's modulus of PDMS. In Fig. 10 is shown a plot of L versus t1/2 values, which followed that predicted by the equation for Poiseuille flow.220

Fig. 10.

Capillary flow in PEG microchannels and a PEG nanoslit. (A) Optical micrograph showing the movement of water through a PEG channel via capillary pressure. (B) A plot of the water front position, L, versus t1/2. As can be seen from the data, for the 4 μm × 200 nm nanoslit, the experimental data followed that predicated by Poiseuille flow, even for small rectangular channels (R = 0.19 μm). For these PEG rectangular slits, the water contact angle was found to be 53°. Reproduced with permission from Jeong et al. (2007).220

For hydrostatic pressure driven flow, an external source is used to actively pump the fluid through the nanochannel with the flow rate determined by the equation , where k is the permeability, ΔPE is the pressure drop along the nanochannel, of which the length and the cross-sectional area are l and A, respectively. There are two challenges with driving fluids hydrodynamically through nanochannels or nanoslits, the high pressure drop that is associated with the small cross sections of these conduits and also, the capillary back pressure that can be generated for channels with contact angles >90°.