Abstract

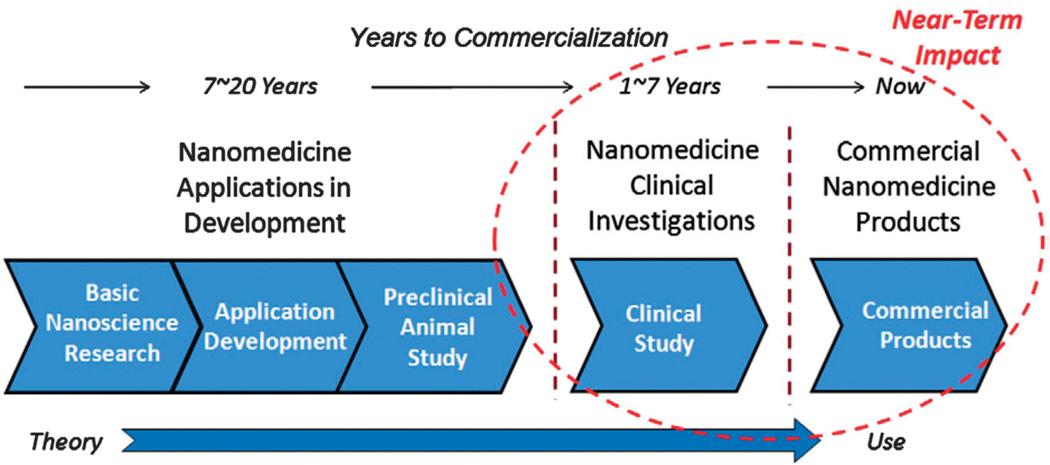

New achievements in the realm of nanoscience and innovative techniques of nanomedicine have moved micro/nanoparticles (MNPs) to the point of becoming actually useful for practical applications in the near future. Various differences between the extracellular and intracellular environments of cancerous and normal cells and the particular characteristics of tumors such as physicochemical properties, neovasculature, elasticity, surface electrical charge, and pH have motivated the design and fabrication of inventive “smart” MNPs for stimulus-responsive controlled drug release. These novel MNPs can be tailored to be responsive to pH variations, redox potential, enzymatic activation, thermal gradients, magnetic fields, light, and ultrasound (US), or can even be responsive to dual or multi-combinations of different stimuli. This unparalleled capability has increased their importance as site-specific controlled drug delivery systems (DDSs) and has encouraged their rapid development in recent years. An in-depth understanding of the underlying mechanisms of these DDS approaches is expected to further contribute to this groundbreaking field of nanomedicine. Smart nanocarriers in the form of MNPs that can be triggered by internal or external stimulus are summarized and discussed in the present review, including pH-sensitive peptides and polymers, redox-responsive micelles and nanogels, thermo- or magnetic-responsive nanoparticles (NPs), mechanical- or electrical-responsive MNPs, light or ultrasound-sensitive particles, and multi-responsive MNPs including dual stimuli-sensitive nanosheets of graphene. This review highlights the recent advances of smart MNPs categorized according to their activation stimulus (physical, chemical, or biological) and looks forward to future pharmaceutical applications.

1 Introduction

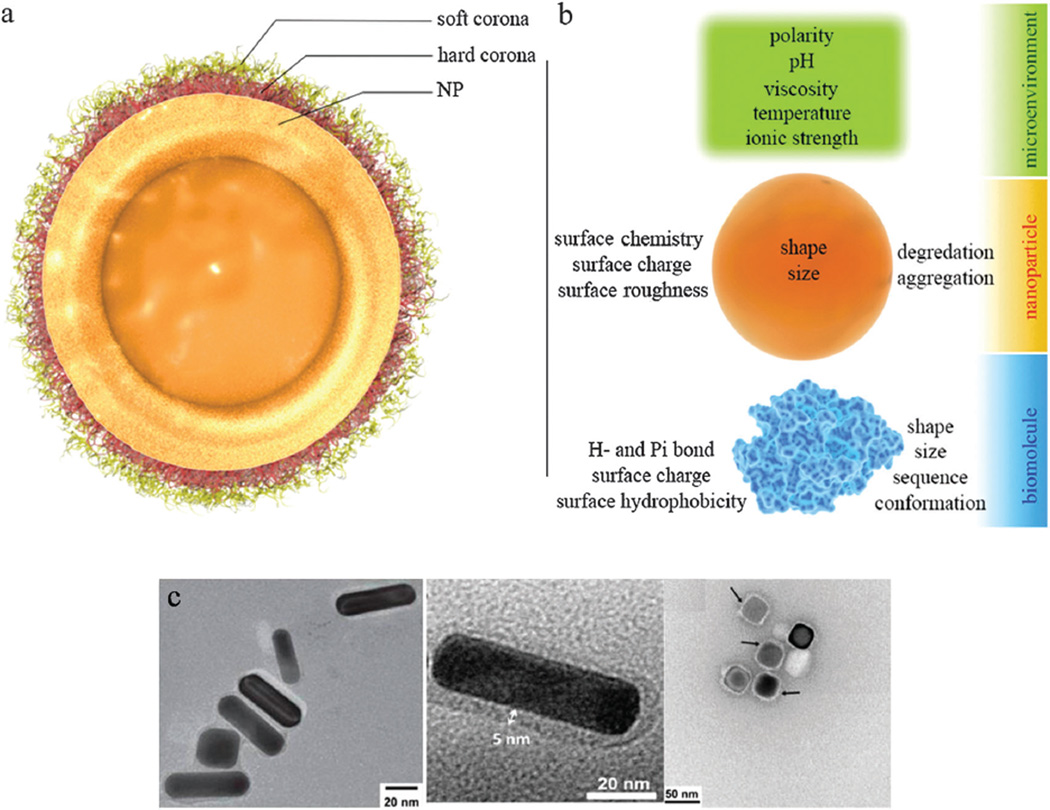

Breakthroughs in nanotechnology have had an important influence on many different industries, especially materials science, biotechnology, and pharmacotherapy. Different nanocarriers such as liposomes, polymers, micelles, and carbon-based nanomaterials are increasingly being used for medical purposes,1–6 such as the delivery of macromolecules (drugs and genes) as therapeutic agents. It is undoubtedly a challenging issue, since the required drug delivery system (DDS) is expected to be both site-specific and time-release controlled. Controlled release of drugs can be triggered by various external or internal stimuli of heat, solvent polarity, ionic strength, action of biomolecules, or the effects of electric/magnetic fields or light, as illustrated in Fig. 1. While temperature can be either an internal or external stimulus, pH, redox, and enzyme activity are known as internal stimuli, and on the other hand, light, magnetic fields, and US are recognized as external stimuli.7–9 Robust and efficient nano-carriers that can respond to changes in their ambient environmental parameters are of particular importance for drug and gene delivery purposes. The term “smart” has been applied to micro/nanoparticles (MNPs) that can react in a predictable and specific way to external/internal stimuli. This property of such carriers to undergo controlled-release of the loaded drugs results in overall mitigation of their side-effects and increases their treatment efficacy. Well-designed smart-MNPs might even be responsive to multiple combinations of different stimuli to further improve their specificity for targeted and controlled drug delivery.10 There exists a similarity between the main action algorithm of multi-responsive smart MNPs and the computer logic gates; an exciting issue to be discussed further.

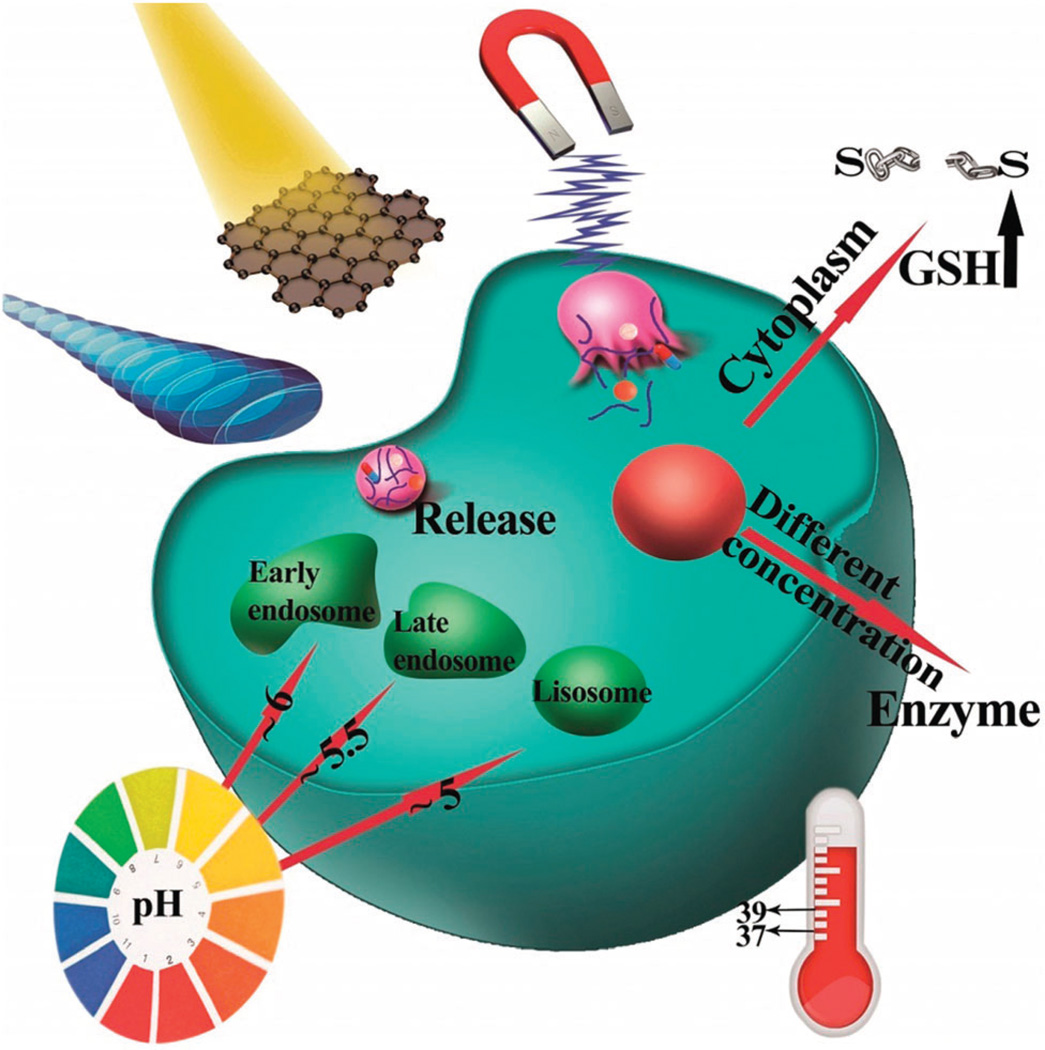

Fig. 1.

Different physical and chemical stimuli exploited for triggering smart MNPs in controlled release of drugs, namely, magnetic induction, light irradiation, US agitation, temperature difference, enzyme activation, redox potential, or pH difference.

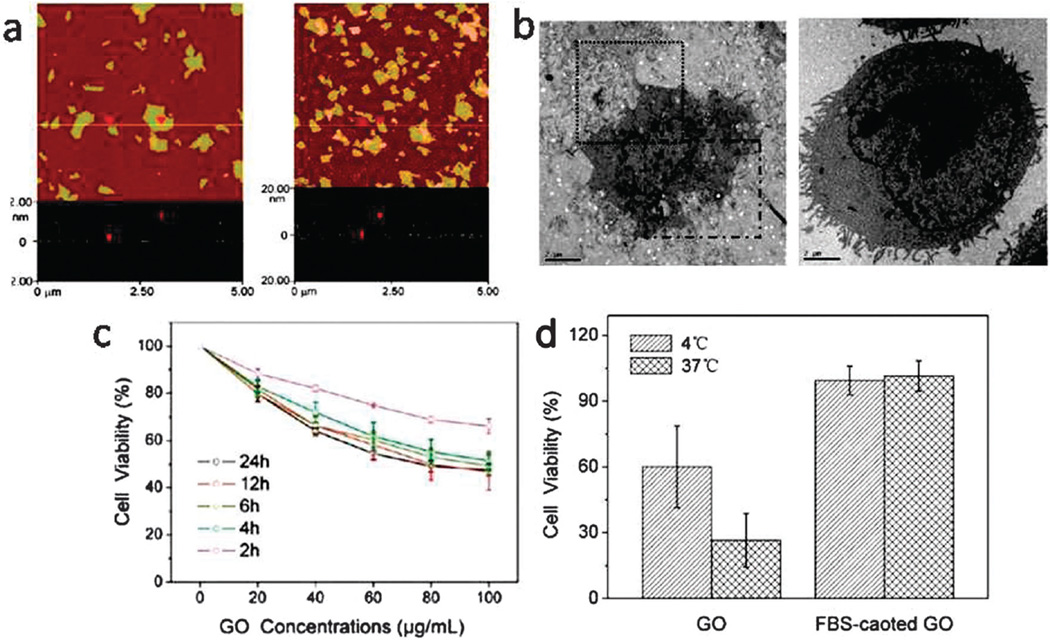

The emergence of novel nanomaterials from the flourishing field of nanoscience has given a boost to research in many areas of technology.11,12 Smart nanostructures have been intensively investigated during the last decade, and their unique and intriguing properties have given hope for the design of more efficient drug delivery vehicles. MNPs can play a crucial role as DDSs as their size (and hence their physical, chemical, and electrical properties) can be tuned and they can be easily functionalized and used in non-toxic concentrations for selective or passive drug delivery. Smart MNPs are considered to be promising agents for targeted delivery of drugs, particularly water-insoluble compounds, and can also be helpful in the field of dual-function cancer diagnosis and treatment systems (theranostics).13 They can escape the reticuloendothelial system and even have the potential to cross the blood–brain barrier (BBB)14 and the blood–testicle barrier (BTB). Their functionalization is a relatively easy process and appropriate functionalization can enable imaging and real-time monitoring of drug delivery to tumors. Although the protein corona-induced screening of MNPs has an important role in mitigation of their cytotoxicity, protein attachment can also reduce the efficiency of targeted MNPs due to covering-up or shielding of active targeting ligands.15 Different organic and inorganic MNPs have been utilized in DDSs. As a particular example, nanosheets of graphene (the first class of two-dimensional crystals16) discovered only a few years ago, have made a tremendous impact on all areas of applied science ranging from nanoelectronics,17 gas sensors,18 and biosensors19 to composites20–23 and somewhat surprisingly, to nanomedicine.24–28 In the field of stimuli-triggered DDSs, intense investigation is being focused on graphene,29 as it is relatively biocompatible30 and can be functionalized easily.31 Thanks to its theoretically-calculated outstanding specific surface area of 2630 m2 g−1,32,33 a single sheet of graphene oxide (GO) can be loaded with drugs to more than two times its own weight. The superior electrical34 and thermal35 conductivity of the graphene nanosheets, the high absorbance of near-infrared (NIR) radiation,36 and most importantly, its nontoxicity at low concentrations37,38 has motivated many investigators to prepare this nanomaterial (micrometer-sized sheets with a thickness of only one nanometer) in a stimuli-responsive form.39,40

The uptake of very small particles by cells is critically dependent on the particle size, which can range from only a few nanometers up to a few microns. For example, although there is no consensus on the optimum size of the particles used for vaccine delivery (according to a review elsewhere41), it is reasonably believed that NPs, particularly, those with diameters less than 100 nm, are better candidates for targeted-delivery purposes due to their good stability in blood circulation, their ability to pass thorough capillaries, their efficiency in permeating biological barriers,42 and even their ability to accumulate in cells without being recognized by efflux pumps such as P-glycoprotein.43 However, due to the fact that the volume of the particles diminishes by three orders of magnitude when the diameter is shortened by a factor of ten, care must be taken that the loading capacity or “cargo space” is large enough to carry the desired drug payload.44

The increasing prevalence of various types of cancer is becoming a serious global health concern as it is the second most common cause of death after cardiovascular diseases. Treatment of cancer is feasible in many cases and can even result in its complete eradication provided it is diagnosed early. However, even though there are innovative attempts in the realm of nanotechnology to achieve detection of cancer at the single-cell level,45 in most cases, due to the low detection limit of the available technologies,46,47 cancer is often not detected until many different parts of the body have been affected. The undesired side-effects of anti-cancer drugs may severely limit their use, since these cytotoxic compounds unfavorably affect the normal proliferating cells at the same time as they kills the cancerous cells, since both have active DNA replication and cell cycle progression. Likewise in radiotherapy, surrounding normal tissue can be damaged by the radiation beam, although improvements are being pursued through emerging approaches of hadron therapy and promising techniques of modern nanomedicine.

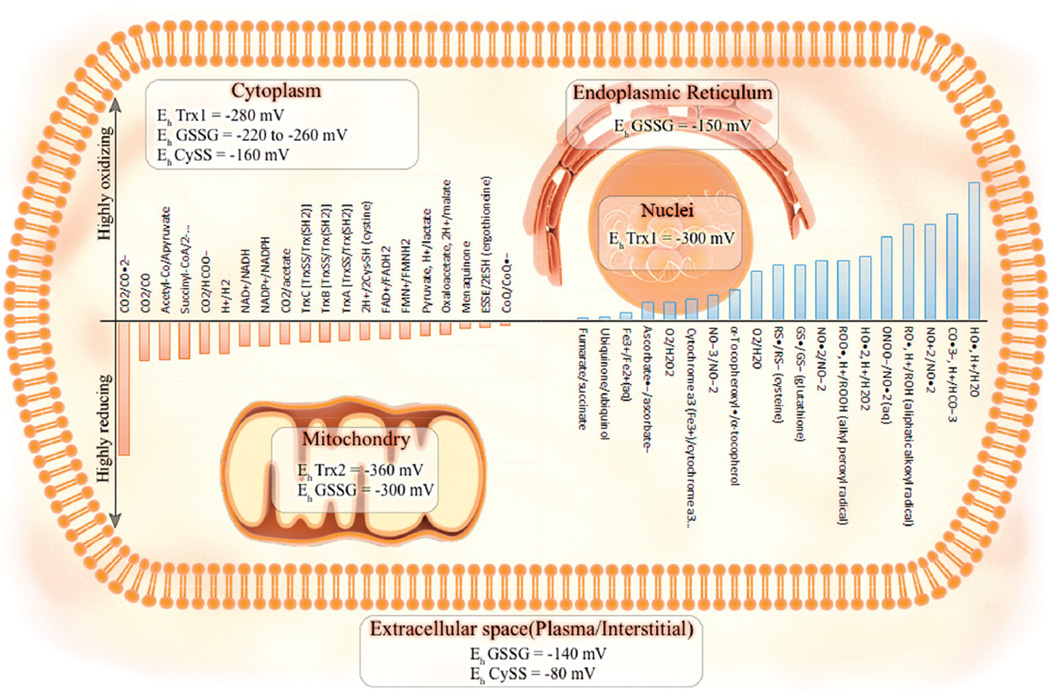

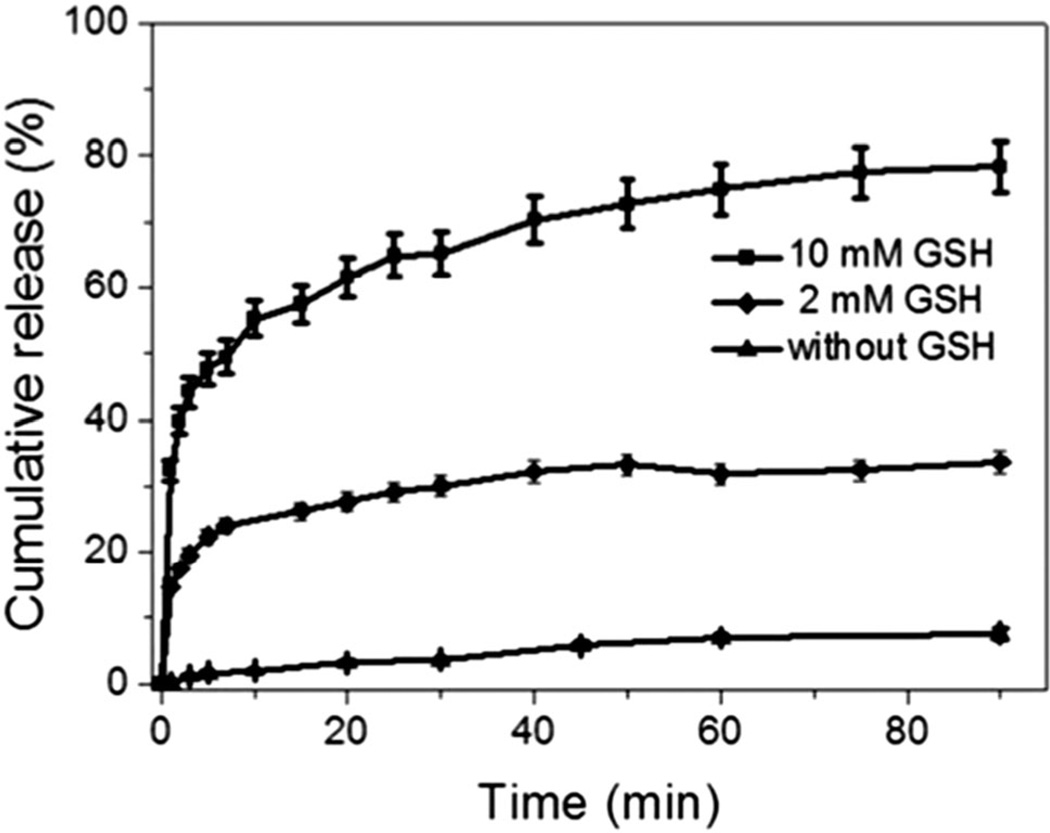

Pathological lesions within normal tissue, such as tumors and abnormal cancerous cells, can be discriminated from their normal counterparts due to the unique pathophysiology of tumors, and the peculiarities of malignant and transformed cells.48 Cancerous cells have been reported to differ from normal cells in their morphology, elasticity, and permeability. They often express different glycans compared with their normal counterparts.49 Intracellular glutathione (GSH) levels50 and the concentration of some enzymes51 within tumors can be more than two orders of magnitude higher in comparison with the extracellular levels. Interestingly, it has been reported that the extracellular pH in solid tumors tends to be significantly more acidic (~6.5) than the pH of blood (7.4).52 Controlled drug delivery is not only advantageous in suppressing the side-effects of the toxic drugs by passive or active targeting of the diseased tissue, but also by overcoming the drawbacks of insoluble anti-cancer drugs like the widely-studied doxorubicin (DOX).

The state-of-the-art developments of micro/nanostructures used in smart drug/gene delivery systems are summarized in the present review. A comprehensive perspective is presented for the first time classifying their responsiveness to different stimuli, either physical (temperature, magnetic force, electricity, light irradiation, mechanical agitation, or ultrasound), chemical (pH or redox), or biological factors (specific biomolecules or enzymes). We also discuss the corresponding nanotoxicity of these nanocarriers, their fate and pathology in biological systems, and the cell vision effect resulting from the protein corona formation. Furthermore, a brief background discussion of each category and its corresponding mechanism of action are covered in this compendium and the latest progress and current challenges are highlighted.

2 Different stimuli-responsive MNPs

2.1 Physical stimuli-responsive MNPs

2.1.1 Thermo-responsive MNPs

Temperature is among the most often investigated stimuli to control the release of drugs from stimuli-responsive DDSs with spatiotemporal control. The hyperthermic nature of most inflamed pathological sites and tumours can act as an internal stimulus. Applying external temperature changes can also activate thermo-responsive MNPs to provide an attractive option for stimulus-responsive DDSs as they can rapidly response to temperature changes. Another important advantage of these DDSs is that they can be formulated as injectable fluids so that no surgical operation is needed for implantation in the diseased tissue.53 The ideal smart DDSs should retain their load at inappropriate times and place and release the drug inside with controlled kinetics in the target tissues such as tumors.

One of the most well-known materials which have been applied in DDSs are temperature-sensitive polymers that can switch their structure from a shrunken form to a swollen form (or vice versa) in response to a change in temperature. In fact, since there is a change in solubility with temperature, the significant properties of these polymers lead to release of the encapsulated drug. They are characterized by an upper critical solution temperature (UCST) or a lower critical solution temperature (LCST). By changing the temperature around the UCST or LCST, a phase transition leading to swelling or shrinking occurs. Fig. 2 illustrates this concept. Drugs can be easily loaded into LCST polymers at room temperature, and then delivered to the target tissue where they are released.54–57

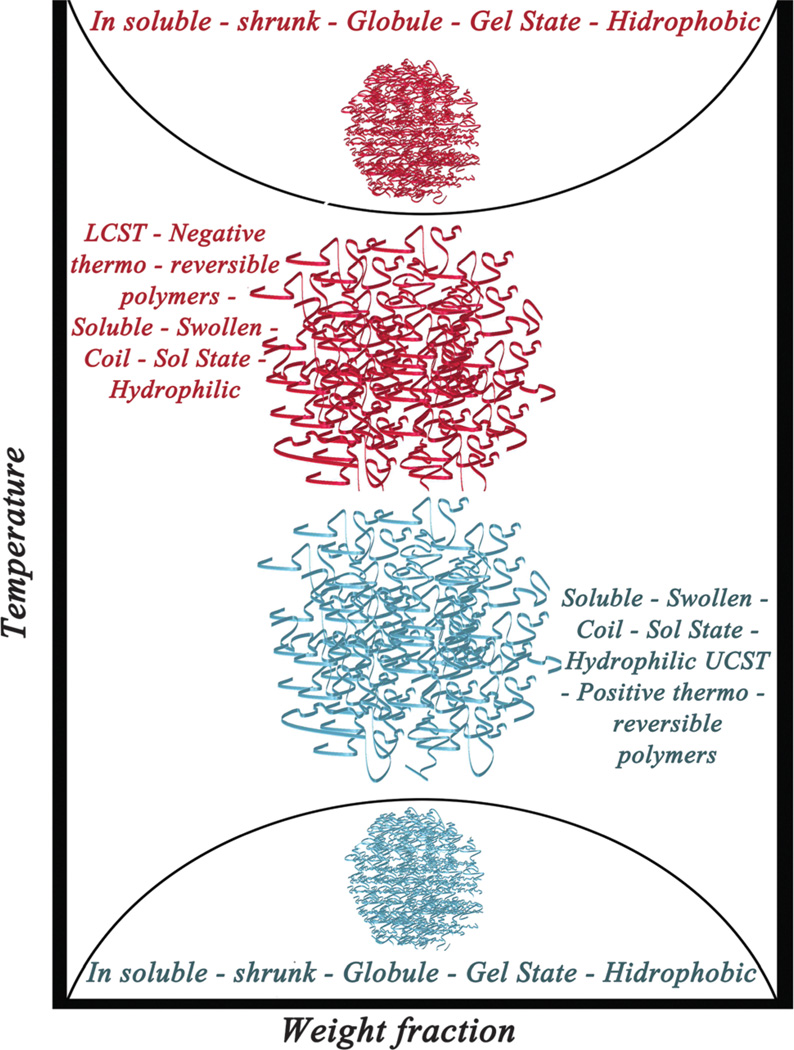

Fig. 2.

Schematic representation of LCST and UCST concepts and their properties.

PNIPAAm and its derivatives have attracted the most attention as thermo-negative hydrogel-based DDSs, since their corresponding LCST is about 32 °C, which is close to the physiological temperature of the human body.58–60 Also, by coupling other polymers, peptides, liposomes and proteins to PNIPAAm, its properties can be optimized in order to get improved targeting and drug release.8,61 For example, in a semi-interpenetrating polymer network with increased LCST and improved swelling ratio synthesized by Fu et al.62 through a free radical polymerization method, the LCST of the modified PNIPAAm increased from 32 °C to 41 °C when AAm content exceeded 5.5% and the hydrophilic nature of AAm could form bonds with PNIPAAm.

Nanovalves have been used by researchers in order to control drug release and the opening of gates that control the mesopores of mesoporous silica nanoparticles (MSNs) and can be made to be sensitive to light, pH or temperature.63 Thermo-responsive polymers can be used as an “on-off switch”. For example, Okahata et al.64 first used a nylon capsule (membrane) and attached N-isopropylacrylamide (NIPAAm) to the surface of the membrane. They showed that, at temperatures above 35 °C when shrinkage and collapse of NIPAAm occurred, the nanovalve closed and drug release was reduced, whereas at a temperature below the LCST (35 °C), the valve opened and increased the drug release due to swelling of the polymer (Fig. 3a). Lue et al.65,66 used a different technique involving the use of a NIPAAm and acrylic acid (AAc) copolymer as “brush hydrogels” that were grafted on the surface of a porous polycarbonate support, and showed that by increasing the temperature above the LCST, the NIPAAm-co-AAc brush underwent shrinkage resulting in increased release of the drug through the pores, while by decreasing the temperature below the LCST, the drug delivery route was blocked due to swelling of the brushes (Fig. 3b).

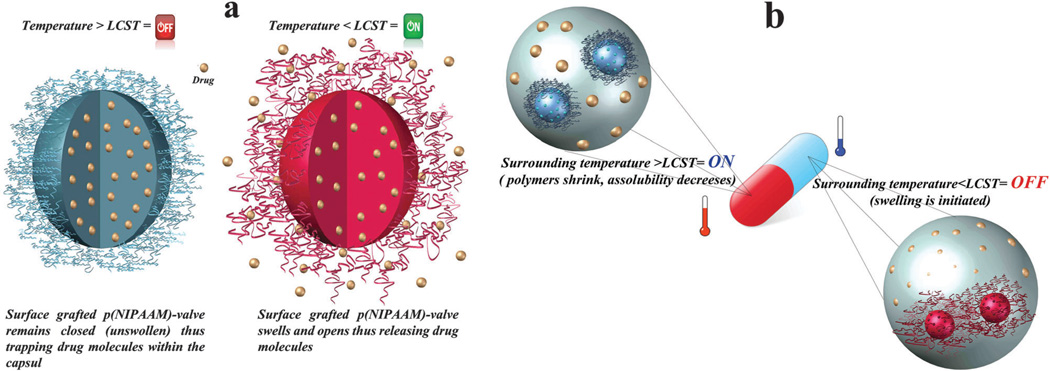

Fig. 3.

Schematic illustration of on-off switch/membrane. (a) Drug release in temperature below LCST. (b) Drug release in temperature above LCST.

The insolubility of hydrophobic drugs and anticancer agents in water (e.g., the anticancer drug Deguelin), limits their application in drug delivery.67 To overcome this problem, core–shell thermo-responsive DDSs can be used, which often consist of a hydrophobic core such as polystyrene (PS) acting as a reservoir for the loaded drug, together with a temperature-sensitive shell of a hydrogel such as PNIPAAm,68–70 Yan-Ling Luo et al.71 prepared a four-armed star multiblock copolymer with the hydrophobic HTPB acting as the central block with the thermo-sensitive PNIPAAm arranged as arms. The average hydrodynamic diameter of the micelles was under 150 nm. The micelles showed a temperature-dependent size change, with a LCST of about 33–35 °C. Water insoluble CPT was loaded into the micelles as an anticancer drug which showed strong antitumor properties.71,72

Azobenzene can be attached to temperature-sensitive polymers because of its transition from trans to cis (or cis to trans) by ultraviolet (UV) or visible light irradiation. In this manner, the LCST of temperature-sensitive polymers such as PNIPAAm can be controlled by the amount of azobenzene. For example, reversible alteration of LCST could be achieved through E-to-Z photoisomerization in azobenzene-conjugated PNIPAAm.73 A linear increase in the LCST point (up to 10 °C) upon irradiation was also claimed and attributed to a decrease in the molecular weight of the employed PNIPAAm. In another study, chemotherapy and hyperthermia were concurrently applied by Kim et al.74 activating a core–shell system to improve the effectiveness of gemcitabine for pancreatic cancer. They used super paramagnetic iron oxide NPs with 7 nm diameter which formed a cluster with a core diameter of 60 nm encapsulated in a porous silica shell. The surface of the shell was modified by conjugation to polyvinylpyrrolidone in order to allow grafting of hydroxypropyl cellulose as a thermo-sensitive polymer. By this design gemcitabine release (chemotherapy), magnetic heating and magnetic resonance imaging (MRI) could be accomplished concurrently. They suggested that concurrent chemohyperthermia could improve tumor cell death compared to chemotherapy or hyperthermia alone.

Although PNIPAAm is a well-known candidate for temperature-sensitive DDSs, it is not degradable in the body, so polymers such as polyethylene glycol (PEG) which have better biocompatibility can be an alternative to PNIPAAm.75 Na et al.76 synthesized biodegradable temperature-responsive poly(l-lactic acid)/poly(ethylene glycol) NPs for DOX controlled release. They showed by increasing the temperature, the release of DOX increased and the temperature sensitivity depended on the poly(l-lactide) (PLLA) polymer chain length. Polysaccharides such as alginate, hyaluronic acid (HA), dextran, chitosan, and carrageenan which have no significant toxicity, good biodegradability, biocompatibility, and are natural materials with antibacterial and mucoadhesive properties which can be used in drug delivery, cell encapsulation and injectable matrices for tissue engineering.77–80 For example, Daniel-da-Silva et al.78 synthesized K-carrageenan polysaccharide thermo-sensitive nanogels. Methylene blue was used as a model drug loaded at temperatures between 25–45 °C in phosphate buffered saline (PBS), and it was shown that both encapsulation efficiency and loading capacity doubled when the K-carrageenan increased from 1% to 4%. This behavior was attributed to the interaction between the sulfate group from K-carrageenan and cationic methylene blue. They also reported an increase in methylene blue release when the temperature increased from 25 °C to 37 and 45 °C, as the nanogel swelled. Similarly, poly(methyl vinyl ether), poly(N-vinyl caprolactam, poly(N-ethyloxazoline), poly-(N-vinylalkylamides), PEG, poly(ethylene oxide)–poly(propylene oxide), PAAc and PAAm or their copolymers have been studied and tested in this regard.81–88

Temperature-sensitive liposomes (TSL) can be nanocarriers for DDSs and exhibit a phase transition after a change in temperature. Liposomes formed from lipid bilayers, in addition to reducing drug side-effects and limiting toxicity, can decrease the drug uptake in non-diseased tissues. “ThermoDox” is a liposome-based drug produced by Celsion American Corporation, which received FDA approval to conduct a phase III clinical trial for hepatocellular carcinoma and a phase II clinical trial for breast cancer. ThermoDox gives an increase between 25 and 5 times in drug release in comparison with IV DOX and standard liposomal DOX, respectively, in tumors. In order to provide the external temperature stimulus, heat is often induced by radiofrequency thermal ablation (RFA), microwave hyperthermia and high intensity focused ultrasound (HIFU) for activating TSL. Chen et al.89 encapsulated DOX and incorporated ammonium bicarbonate into the TSL membrane. When the temperature was increased to 40 °C, the ammonium bicarbonate decomposed releasing carbon dioxide that disrupted the liposome bilayers. Then DOX was then delivered to the diseased tissue through the pores generated in the liposomes. TSL nanocarriers have the potential to be tuned and modified by attaching polymers or molecular ligands for specific targeting to receptors. In a study, Ta et al.90 fabricated a TSL using PNIPAAm-co-PAAc in order to release DOX in solid tumors. Here, PNIPAAm acted as a temperature-sensitive component inducing enhanced drug release above 40 °C. Temperature-sensitive nanovalves can be used in liposomes. For example, Al-Ahmady and coworkers91 inserted a leucine peptide zipper into the liposome membrane and when the temperature increased to 43 °C, the zipper opened and DOX was released. However, DOX can cause toxic effects toward healthy tissue in case of its sudden release at 42 °C. To overcome this drawback and in order to render the liposome thermo-sensitive and decrease toxicity, Elk et al.92 conjugated N-(2-hydroxypropyl)methacrylamide mono/dilactate to the liposome surface with different molecular weights and used HIFU as a thermo-generator. They could control DOX release over 10 min at 42 °C using this hyperthermia technique. They also concluded that the temperature required for efficient DOX release had a reverse relation with the polymer molecular weight.

“Smart nanobombs” are another class of temperature-sensitive DDSs showing a reversible phase transition, and which swell from the nanoscale to the microscale when the temperature decreases. This reduction in temperature is similar to “cold shock” or “cryotherapy”. For example, Lee et al.93 fabricated a super-expandable Pluronic/PEI nanogel with 150 nm diameter at 37 °C, which was taken up by diseased cells by an endocytic mechanism. After cell uptake, the temperature was decreased to 20 °C and the nanogel underwent a phase transition with dramatic swelling and its size increased by 800-fold to 1.4 µm. This size increase generated a large internal hydrostatic pressure within the cells and the physical force induced the breakdown of the intracellular endosomal compartments and “blew up” the tumor cells generating necrotic cell death (Fig. 4). Furthermore drugs such as DOX could be loaded in the nanogel and released inside tumor cells.

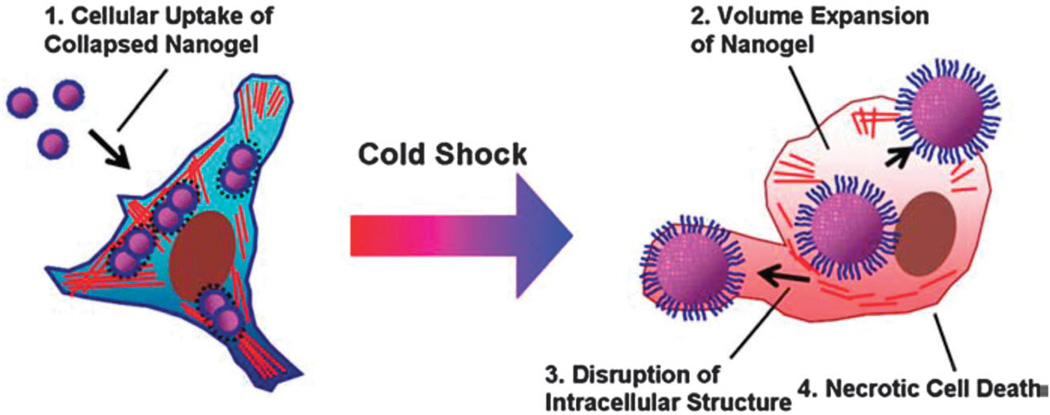

Fig. 4.

Schematic illustration of intracellular explosion of volume-transition nanogels (Nanobomb) (reproduced from ref. 93. Copyright 2009 with permission from Elsevier).

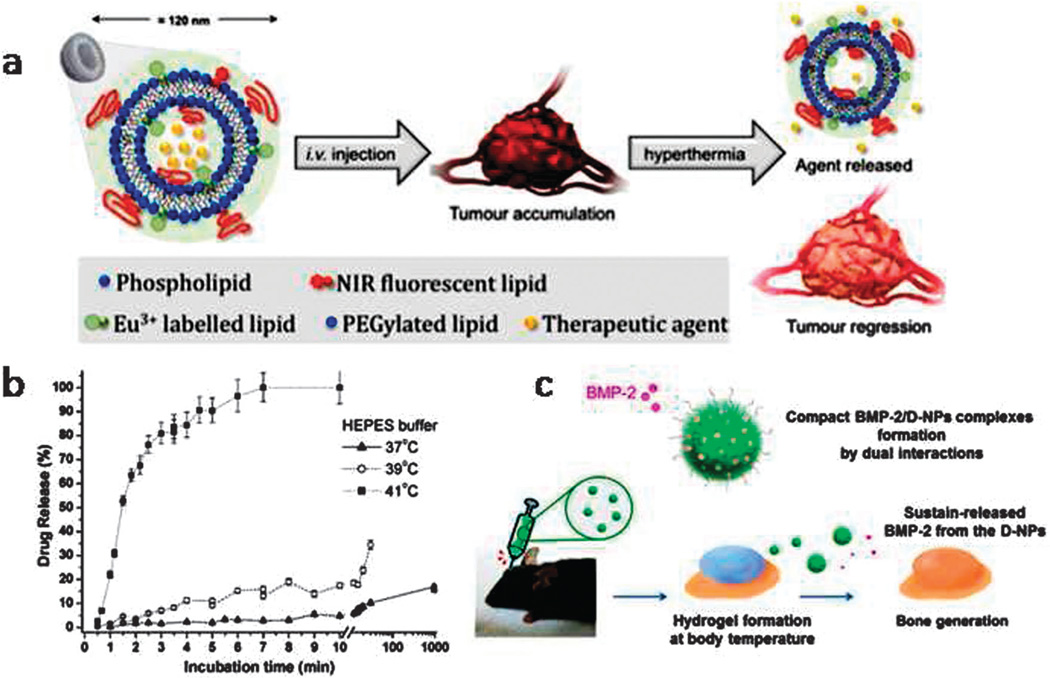

Smart stimuli-responsive nanocarriers with the highest sensitivity to minimal changes of body temperature (such as tumors) are required in the near future. In recent studies thermo-sensitive DDSs have been used for: co-delivery of drugs and genes,94 induced therapeutic angiogenesis in peripheral vascular disease,95 allowed ophthalmic drug delivery with enhanced corneal permeation and retention capacity,96 produced a new intelligent dermatological formulation,97 allowed mucoadhesive-thermogel-based vaginal delivery,98 protein delivery in tissue engineering99 and for bone regeneration.100 Other applications have been reported in cutaneous protein delivery,101 delivery to the uterus for efficacious therapy of uterine diseases (e.g. bovine reproductive disorders),102 therapy of inflammatory bowel disease with enhanced colonic retention of drugs,103 real-time image-guided theranostic drug delivery in cancer chemotherapy,104 efficient mild hyperthermia with increased tumor retention and high specificity toward cancer and angiogenic cells,105 and treatment of hypoxic hepatocellular carcinoma.106 Fig. 5 illustrates studies focused on bone regeneration and image-guided theranostic drug delivery by Seo et al.100 and Rosca et al.,104 respectively.

Fig. 5.

(a) Schematic of image-guided thermo-sensitive liposome (ITSL) injection and their accumulation in the tumor followed by agent release by hyperthermia and consequent tumor regression, (b) topotecan release from ITSL at different incubation temperatures, (c) schematic of dualacting hydrophobic and anionic charged nanocomplex hydrogel carriers for localized release of BMP-2 leading to bone generation (a and b reprinted with permission from ref. 100. Copyright 2015 “American Chemical Society”, and c reproduced from ref. 104. Copyright 2015 “Elsevier”).

Thermo-responsive polymers have also been used for delivery of genes and nucleic acids.107–109 Similar to the case of drug delivery, PNIPAAm has often been used as the temperature-sensitive component in temperature-responsive polymers for nucleic acid delivery.55,110 At a temperature above the LCST, the complexes between the polymer and the DNA become more densely bound, because the PNIPAAm shrinks due to rapid dehydration. As a result, the complexes can better protect the DNA from enzymatic degradation in environments such as the endosomes. By decreasing the temperature below the LCST, hydration occurs and increases the water solubility of PNIPAAm, that in turn makes the complexes less compact and finally results in facilitation of DNA release from polymer/DNA complexes.111,112

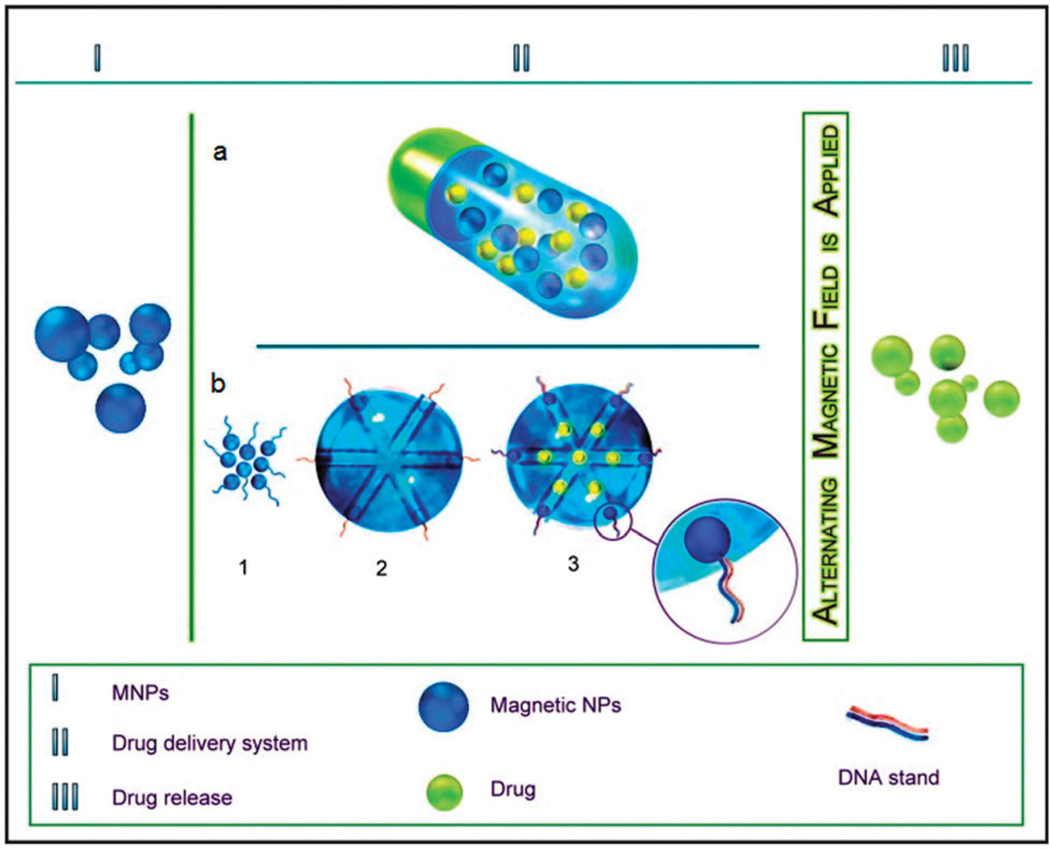

2.1.2 Magnetic-responsive MNPs

The force of magnetism is considered as one of the best options for an external stimulus as it scarcely has any physical interaction with the body, in comparison to other stimuli such as light irradiation, US or electrical fields. Also, magnetic-responsive materials can provide a real-time response to a brief triggering impulse.113 Engineered magnetic NPs (MagNPs) can be functionalized and magnetically driven and controlled, and hence magnetic field-responsive particles are being studied as useful vehicles in drug delivery114 and biomedical targeting.115 These engineered MNPs can also be triggered by external stimuli such as alternating magnetic field (AMF) for targeted and controlled drug-release. In 1960, Freeman et al.116 first conceived the idea of using magnetic fields as an external trigger to release drugs. Single domain MNPs with intrinsic superparamagnetic features above their blocking temperature, TB, are promising candidates for biomedical purposes, as compared to ferromagnetic particles, because they display no dipolar attraction in the presence of magnetic fields, have good colloidal stability, and homogenous dispersion within a polymeric matrix.117

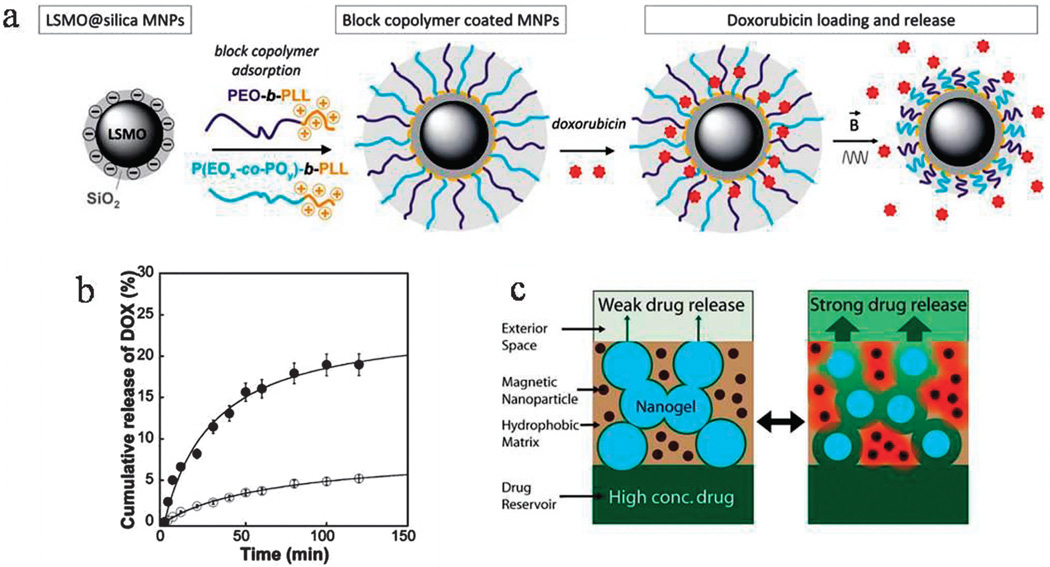

The unique ability of MNPs to generate heat under the influence of external high-frequency AMF is called magnetic hyperthermia. MNPs (with superparamagnetic behavior) exposed to a strong magnetic field can withstand internal stresses caused by the fluctuating distortions induced by magnetic forces (via alternating current (AC) or direct current (DC)). It is considered that the heat generated by MNPs in an AMF is due to two mechanisms of intrinsic rotational motion (Brownian) and extrinsic motion (Neel); i.e. thermal rotation of the particle’s magnetic moment and relaxation via diffusion. This inductive hyperthermia depends on several factors including the saturation magnetization and the hysteresis coercivity, both of which are related to the size of the MNPs. Magnetic fields can be used for applications including controlled/local drug release, guidance, targeting, imaging (MRI and fluorescence) as well as hyperthermal therapy.113 For example, polymeric NPs can undergo thermodynamic phase/conformational transitions depending on their LCST/UCST followed by swelling/shrinkage as described above. This phenomenon can be induced by magnetic heating with potential for drug-release e.g. via structural disruption of the NP or by a “pumping effect” (i.e. squeezing the drugs out from the NPs).113,118,119 It is worth noting that MagNPs can be trapped inside polymer particles e.g. hydrogels with a second polymer chain either as a random copolymer or semi/fully-interpenetrated network, by adsorption of the chains to the surface of MNPs.117 An external magnetic field can also enhance cellular uptake of NPs.119 Louguet et al.118 developed silica-coated MagNPs functionalized with thermo-sensitive block copolymer brushes with an LCST transition. Application of an AC-magnetic field induced heat generation by the magnetic core and enhancement of the triggered release of the drug (DOX) due to conformational changes occurring in the brushes (Fig. 6a and b). Nanoporous membranes prepared as electrically conductive flexible electrodes can act as a magnetically-triggered smart-nanocarrier with tunable drug-release profiles. These can include reversible, burst, stepwise, sustained and slow-release profiles depending on the mode of magnetic triggering. They show zero drug release in the absence of a magnetic field (see Fig. 6c).120 A hybrid nanocarrier composed of iron oxide nanocubes (cubic-IONPs) (with semi-superparamagnetic/semi-ferromagnetic behavior) encapsulated by a thermo-sensitive polymeric shell with a LCST phase transition at 37 °C showed minimal drug release below 37 °C but a consistent on-demand release due to heat generation under an AMF.121

Fig. 6.

(a) Design of a hybrid silica-coated copolymer functionalized magnetic NP followed by the release of DOX via application of an AMF inducing the LCST transition, (b) cumulative release profile of DOX from the nanocarrier, (c) weak and strong drug release (an ON/OFF reversible switch) from a nanoporous membrane comprised of thermo-sensitive nanogels and superparamagnetic MNPs, before and after AMF trigger (a and b reproduced from ref. 118 with permission from the Royal Society of Chemistry; c reprinted with permission from ref. 120. Copyright 2011 American Chemical Society).

Magnetic hyperthermia can also be controlled by adjusting the field strength. Incorporation of micro- and nano-scale metal NPs into the hydrogel matrix has led to the introduction of magnetic hybrid hydrogels as a group of novel materials with unique properties that are of great importance in controlled drug delivery.122 Super paramagnetic iron oxide (SPIO) NPs, functionalized with FA and β-cyclodextrin (β-CD), were reported to generate heat in the presence of an AMF.123 These MNPs showed a specific absorption rate of 132 W g−1 at 230 KHz and 100 Oe where drug release from the CD has been triggered by induced heating. Giani et al.124 cross-linked CoFe2O4 NPs into a carboxymethylcellulose polymer to fabricate hybrid hydrogels. The MagNPs were functionalized with (3-aminopropyl)-trimethoxysilane (APTMS) in order to introduce NH2 groups onto their surface. The preliminary results showed controlled drug-release from the matrix under the influence of AMF. Hyperthermia has been considered to be a promising way to treat cancer for some years, based on the assumption that cancer cells are more affected by heat than the surrounding normal cells.125 Many studies have utilized hyperthermia for clinical use, the results of which have shown tumor regression after application of a magnetic field to solid tumors that had been directly-injected with MNPs.126 In a study by Brulé et al.127 MNPs and DOX were incorporated inside alginate microbeads for dual hyperthermia and drug release. Human breast cancer MCF-7 cells were exposed to 37 °C for 2 hours with or without an AMF (frequency 700 kHz, amplitude 10 mTesla, 45 °C). DOX release was higher at 43 and 50 °C in comparison to temperatures of 20 and 37 °C. No DOX was detected at 4 °C, indicating that drug release was controlled by increased temperature.

Polymersomes have been used for magnetic field-triggered drug delivery.128 In a recent study, it was shown that polymersomes could entrap up to 6% (w/w) of DOX along with 30% (w/w) of ultra-SPION; γ-Fe2O3. When internalized by HeLa cells and subsequently triggered by a high frequency AC magnetic field (14 mT at 750 kHz), an 18% greater cytotoxicity was observed along with increased DOX release. Another important advantage of polymersomes over other delivery systems is the capacity to carry a larger drug load, for instance polymersomes could accommodate up to 12% DOX LC coupled with 50% LC USPIONPs, compared with only 2.4% DOX LC by other systems.129,130 The efficacy of a lipid–polymer hybrid NP system with improved drug release kinetics containing Fe3O4 magnetic beads providing site-specific release of CPT to treat breast cancer of MT2 mouse was evaluated by an external radio frequency (RF) magnetic fields.131

The guidance and triggering abilities of magnetic-responsive materials are superior to those of temperature and pH triggers113 and they are effective over a distance as large as a few centimetres.117 Extracorporeal magnetic guidance can serve to overcome several limitations of DDSs such as natural physiological barriers and lack of specificity to the targeted cells/tissue because spatial/magnetic fields can be spatially focused. For example to overcome high blood flow in arteries or capillaries after an intravenous injection of nanocarriers, powerful magnets can be placed at the desired sites.117 Image-guided drug delivery is an important component of the magnetic responsive DDS approach. Singh et al.132 fabricated magnetic carbon nanotubes (CNTs) ensheathed with surface-layered MSNs (the MNPs were located inside the multiwalled CNTs) for drug delivery accompanied by MR imaging. MSNs were chosen for their enhanced loading of bioactive molecules such as the protein cytochrome C, the drug gentamicin, and the nucleic acid siRNA within the mesopores. Along with high loading-capacity, the cellular uptake was also increased via application of magnetic fields, and negligible cytotoxicity was observed.

Magnetofection or magnetically-aided transfection is another way for controlled gene delivery. By linking MNPs with viral vectors, Mah et al.133 first reported magnetofection in 2009. A novel magnetite-silica nanocomposite (Fe3O4-SBA-15) was surface-coated with short chain PEI–DNA complexes for the strategic purpose of gene delivery and transfection. Surprisingly, this composite led to 15% higher transfection after applying an external magnetic field.134 Furthermore, MSNs can be utilized to entrap nucleotides in their pores while also being functionalized to form a magnetic field-responsive delivery system as was reported by Lu et al.135 Ruiz-Hernandez et al.136 devised stimulus-responsive MNPs in which ‘caps’ were formed from iron oxide NPs (IONPs) entrapping drug molecules/genes within the porous matrix. The caps were conjugated with one strand of DNA and the complementary strand was conjugated to the mesoporous silica membrane. Hence, the structures could maintain their closed conformation due to the double-helix DNA binding, so under normal conditions no drugs/genes were released. When exposed to an AMF, their temperature was locally raised, the DNA was dehybridized and the entrapped molecules were released from the matrix. This stimuli-responsive delivery mechanism works like an ‘on-off’ switch and aids in controlled drug release (Fig. 7).

Fig. 7.

(a) Alginate-microbead system loaded with MNPs (nanoheaters) and DOX for drug delivery using thermotherapy, (b) magnetically triggered release using reversible magnetic nanogates based on DNA hybridization/dehybridization.

Polymer nanoassemblies made up of biocompatible block copolymers can also be made to be responsive to magnetic fields.137–139 In an innovative approach, where drug molecules (DOX) and IONPs were loaded into block polymer self-assembled nanoassemblies (SNAs) or cross-linked analogues (CNAs) with 100 nm diameter, DOX release was detected at 40–42 °C after the temperature was raised by inductive heating using AMF. It was also observed that CNAs released DOX at a faster rate than SNAs.140 While many research groups have used direct intra-tumoral injection claiming it has low systemic toxicity and permits a higher tumor load of MNPs, the inability of this route to allow MNPs to reach small metastatic cancers, the poor distribution within inhomogeneous tumors, and its relatively invasive approach, make the intravenous approach much more preferable.141 In a study by Huang et al.142 using an intravenous injection, the tumor to non-tumor ratio was >16 where they employed a concentration of 1.9 mg Fe g−1 in a mouse model of subcutaneous squamous cell carcinoma. Their approach was validated as the surrounding normal tissues were completely left intact after a two-minute exposure to AMF (38 kA m−1) at 980 kHz during which the target tumor tissue was heated to 60 °C. In a study by Silva et al.,143 antibiotics were loaded into a nanostructure composed of Fe3O4 NPs with a TiO2-co-pectin shell then were released slowly by application of a remote magnetic field.

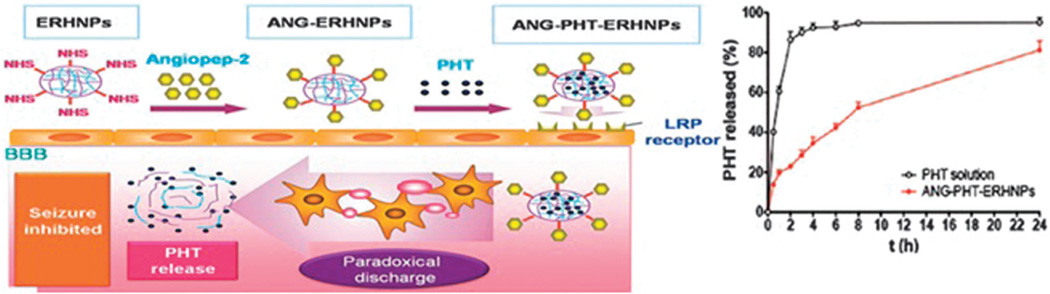

2.1.3 Electrical-responsive MNPs

Electrically-triggered DDSs can be utilized for sustained, pulsed, or on-demand drug release via the application of external electric fields. Electro-responsive drug release can be performed with various platforms including electro-responsive nanostructures, electro-responsive compound-loaded nanostructures, and the combination of electroresponsive materials with other stimuli-responsive vehicles such as temperature or magnetic. The introduction of polyelectrolytes containing large numbers of ionizable groups confers responsiveness to an electrical stimulus through shrinking or swelling of the polymers.144,145 For instance, Ying et al. developed electro-responsive hydrogel NPs for targeted delivery of an antiepileptic drug (Phenytoin sodium, Fig. 8). An increased degree of ionization in the structure was achieved under the influence of an electric field due to the presence of the polyelectrolyte poly(sodium 4-vinylbenzene sulfonate) (PSS). The swelling ratio and the particle size could be tuned via the external electric field. In this study in vitro triggering and increased drug release with potential application in epilepsy treatment was shown.146

Fig. 8.

Schematic representation of electro-responsive hydrogel NPs containing PSS, with in vitro favorable sustained release (inset); reproduced from ref. 146. Copyright 2014 with permission from John Wiley & Sons, Inc.

In another example a GO-conducting polymer [poly(pyrrole) (PPy)] nanocomposite film with favorable electrical properties, linear drug release profile, and a good level of temporal control of dexamethasone release in response to electrical magnitudes was developed.147 Electroresponsive scaffolds have also been developed for on-demand and pulsatile drug delivery.148,149 These were composed of a hybrid between graphene and poly-(methylacrylic acid) (PMAA)–(MWNT) hydrogels with electroresponsive properties. The drawbacks of traditional electroresponsive DDSs such as an increase in temperature due to resistive heating after exposure to an electric field, and poor reproducibility of the drug release between the ON/OFF stimuli, were overcome by using the heat-dissipating and good electrical properties of graphene. Other applications of electrically-triggered smart nanostructures include the externally controlled on-demand release of an anti-HIV drug by CoFe2O4@BaTiO3 magneto-electric NPs,150 a polymer–MWCNT network in an electro-sensitive transdermal DDS,151 and PPy-loaded PLGA–PEG–PLGA NPs152 with on-demand drug delivery. These all possess excellent spatio-temporal control of dosage, and have potential clinical applications in multiple diseases. Apart from the above-mentioned advantages of electro-responsive DDSs, there are some limitations such as cell damage and poor tissue penetration, which should be considered in future investigations.

2.1.4 Light-responsive MNPs

Light irradiation can be used to stimulate or trigger drug release. Absorbance of photon energy by materials depends on the corresponding energy band-gap of the electron in the highest occupied molecular orbital. Light absorbing materials have a broad range of practical applications like shielding against UV irradiation in sunlight, generation of electrical power from solar radiation, and acting as optical contrast agents and fluorescent reporter molecules. Among the several stimuli exploited in smart DDSs, light irradiation has attracted a significant amount of attention due to the ease of precisely tuning its intensity, the ability to control the exposure duration and tissue location (via the selection of appropriate beam parameters), and the fact that photo-regulated activation is perceived as non-invasive. Ultraviolet (10–400 nm), visible, or near infrared (IR) regions (650–900 nm) of the light spectrum can be used to trigger drug or gene release from appropriately designed nanocarriers. Although the higher energy per photon of UV light enables it to ionize and cleave covalent bonds with energies of the order of 100 kcal mol−1, the potential hazards of far-UV (wavelengths shorter than 200 nm) to tissues and the possible photodestruction of active molecules makes these wavelengths unsuitable for therapeutic purposes. However the application of continuous wave (CW) long-UV lasers (wavelengths of 200–400 nm) can leave both drugs and tissues intact.153 UV irradiation is much more cytotoxic than the other regions of the light spectrum and its inability to penetrate deeply into the tissue due to its absorption by endogenous chromophores (such as oxy- and deoxy-hemoglobin, lipids, and water) is considered as another disadvantage. Thus, wavelengths below 650 nm are considered to be only suitable to trigger drug release for topical treatment of pathological states affecting the skin and mucosa.153 Supramolecular assemblies designed to use visible light are relatively rare.154

NIR has better transmission through tissue due to its lower absorption and scattering in tissue (penetrating into the body about 10 cm) because hemoglobin, water, and lipids barely absorb it, and causes less damage to cells than visible light, due to its lower energy per photon.155 To solve the problem of low energy of NIR photons, some organic chromophores capable of simultaneously absorbing two photons of low-energy have been studied.156

Diverse MNPs have been exploited for the fabrication of light-sensitive DDSs including carbon dots with strong fluorescent emission,157 polymeric hydrogels exhibiting a hydration/dehydration transition mechanism,158 gold NPs for photogenerated localized heating,159 core-shell particles,160 and MSNs possessing high surface area, good targeting ability and controlled drug-release especially toward tumor cells.135,161

In general, light-responsive NPs have found a wide range of applications. The most commonly studied types are micelles and liposomes.162 Although light-responsive MNPs can be made of different materials, all of them have a chromophore in their architecture to harvest the light. Chromophores are therefore the key component of light-sensitive NPs163 which may rely on photo-isomerization (a conformational change of a double bond that is restricted in rotation usually accompanied by a change in the hydrophilic/hydrophobic balance of the photo-excitable molecules), photo-induced cleavage of bonds, photo-oxidation (generation of singlet oxygen or other reactive oxygen species (ROS)), and reversible photo-cross-linking.164

Photo-cleavage reactions occur in o-nitrobenzyl165,166 and coumarin167,168 containing molecules. In this regard, Dong et al.169 designed an s-(o-nitrobenzyl)-l-cysteine N-carboxyanhydride monomer and synthesized a novel block copolymer derivative for controlled release of DOX via photo-cleavage in the core of the NPs. In another work, Zhao et al.156 synthesized a novel block copolymer containing a coumarin chromophore [7-(diethylamino)coumarin-4-yl]methyl methacrylate that was disrupted by both UVA (365 nm) and by 2-photon NIR (794 nm) absorption. A Ti:sapphire laser, generating 80 fs pulses at 794 nm with a repetition rate of 1 kHz and energy per pulse about 300 mJ was able to photocleave coumarin and release encapsulated nile red from the hydrophobic core of the micelle into a water-based solution.

Photo-induced rearrangements of components of micelles are rare. The most common chromophore exploited in these types of light-sensitive micelles is 2-diazo-1,2-naphthoquinone (DNQ).170 This hydrophobic molecule changes into hydrophilic 3-indene carboxylic acid through a Wolf rearrangement reaction.171 DNQ has been widely used in many nanocarriers in order to deliver different cargos. For example Wang and coworkers synthesized a triple-stimulus responsive copolymer consisting of DNQ as a chromophore which was modulated by pH, light, and temperature.172

Another common type of chromophore employed in light-responsive NPs is azobenzene and its derivatives. These molecules such as azobenzenes, spirooxazines, and spiropyrans are organic photochromic compounds that are used to disrupt NPs due to their ability to undergo reversible isomerization in response to UV.173 Son et al.174 used a synthetic photoresponsive molecule to induce destabilization of polymeric micelles of hyperbranched polyglycerols into individual chains by UV irradiation. In other words, they employed the solubility-switching (from hydrophobic to hydrophilic) characteristic of the molecule to release cargo inside the micelles.

MSNs can contain drugs that are retained in the pores by different capping agents.175 Cargo molecules are released only in the presence of an external stimulus like UV light or visible-light that induces destruction of capping agents. To this end, a supramolecular assembly was used to deliver cargo molecules from a MSN-based structure upon irradiation of visible-light.176 Sulforhodamine 101 was loaded inside the mesopores of mercaptopropyl (MP)-MSN and entrapped by mercaptopropyl-coordinated Ru(bpy)(2)(PPh(3))-moieties.

Photo-isomerization induced by upconversion luminescence (UCL) is another mechanism used for drug release activated via low intensity (e.g. 0.35 W cm−2) light irradiation and with features such as minimal damage to biological sites (considering that the maximum permissible light intensity for skin exposure is 0.726 W cm−2). For example, upconverting NPs (UCNPs) doped with lanthanide ions have been used to convert NIR irradiation to UV/visible light. After the upconversion emission another photosensitive material absorbs the upconverted light producing photoreactions which induce drug-release mechanisms e.g. through degradation of polymeric NPs.177–179

Recently, the assembly/disassembly of NPs through light-triggered reversion of surface charge has been used as an efficient drug release mechanism. For example, colloidosome microcapsules fabricated via the electrostatic assembly of organosilica NPs with oppositely charged surfaces were exposed to light irradiation (365 nm). This induced electrostatic interactions leading to surface charge reversion or “flipping” by which the positive charges turned to negative and thus the repulsive forces between negative charges disassembled the colloidosomes and resulted in drug release.180

An important photo-activated mechanism is two-photon NIR-triggered drug release, in which simultaneous two-photon absorption induces chemical reactions. However the low efficiency of energy absorption by chromophores using this mechanism can reduce its efficiency.181 Furthermore, this mechanism has several advantages such as high three dimensional spatial resolution due to the required tight focus of the laser, low scattering losses, deep penetration in tissues,182 insignificant premature drug release,33 and significant cytotoxic effects by generation of toxic ROC.183,184 In this approach, two-photon fluorophores and photosensitizers are doped or covalently bound to a nanostructure such as MSN based nanovalves. Thereafter, by two-photon NIR irradiation, the fluorophores with high two-photon cross-section and having maximum emission capability through mechanisms e.g. Forster resonance energy transfer (FRET) isomerize the photosensitizers (e.g. azobenzene) located on the fluorophores in the nanostructure. Thus, the drug release process is activated.77,185

The photo-reduction of metal-based prodrugs (e.g. Pt) is another novel technique to induce drug release in reductive milieus such as cancerous sites. Herein, via photo-irradiation, a non-toxic inactive prodrug (e.g. a metal complex containing Pt(IV)) changes to the active cytotoxic form (e.g. a complex with toxic Pt(II)).186,187 Photo-triggers such as UV light,188 visible light189 and NIR irradiation67 have been reported to induce photo-reductive activated prodrug release with advantages such as enhanced specific cytotoxicity against cancer cells, induction of apoptosis, in vivo bioavailability, maximal light penetration, significant inhibition of tumor growth as well as simultaneous imaging capability.

Several efforts have been conducted to develop photolabile protecting groups as a component of nanocarriers which can encapsulate drug molecules and sequester them. Thereafter, these protecting groups can be eliminated by light irradiation, hence the protected drug molecules are uncaged and delivered to a targeted biological site where they can bind to cell receptors.190 Photolabile protecting groups (i.e. photo-uncaging groups) can be employed in different nanostructures such as liposomes, peptides, and lipidic NPs for delivery of biomolecules including antimicrobial peptides, nucleic acids, and anti-tumor agents.190–192

In photothermal therapy by DDSs, the light absorbed by a nanomaterial is converted to localized heat via plasmonic mechanisms (i.e. collective oscillation of free electrons in the conduction band leading to light scattering due to localized surface plasmon resonance (LSPR))193 which can induce enhanced detrimental effects on bacterial cells,194 tumor cells and tissues.195,196 LSPR enhanced heating can be effective although conventional hyperthermia (41–44 °C) has adverse effects such as protein unfolding, and DNA denaturation.197 In photo-triggered thermal activated drug release, low power densities e.g. 0.20 W cm−2 (Ag–Au shell–core),160 0.6 W cm−2 (reduced GO),198 and 1–2 W cm−2 (gold nanocage–CNT hybrid)199 have been reported that do not damage tissue. Photo-triggered thermal systems have also led to a type of photochemotherapy with advantages including on-demand drug release, destruction of tumor cells either in light treated or light-shielded areas (the latter one due to heat-generated diffusing in the tissue), with a light-dosage dependent response.200 Novel hollow plasmonic nanocrystals made from caged gold nanorods (CGNRs) were fabricated by Xiong et al.201 They showed broad-band dipolar surface plasmon resonances to NIR, obtained via tuning their length and thickness. The strong plasmon coupling between the surrounding gold nanocages and the internal gold nanorods could potentially intensify the efficiency of the photothermal effect thus providing a multifunctional theranostic CGNR-based nanoconstruct for cancer treatment (Fig. 9).

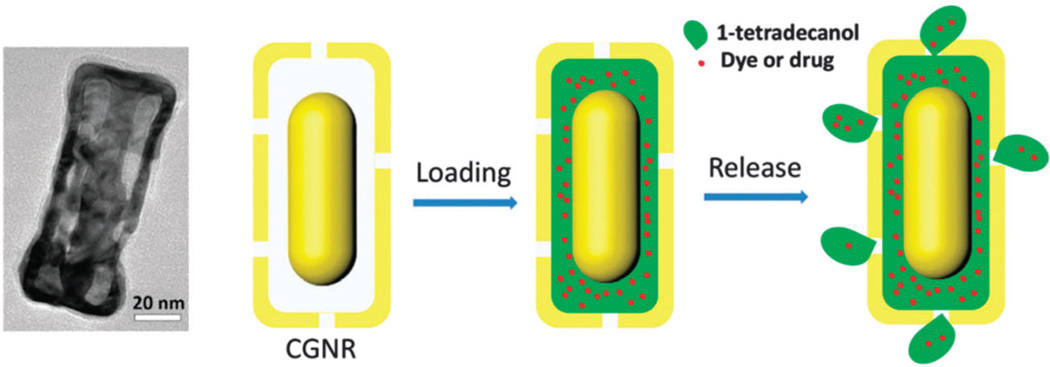

Fig. 9.

TEM images of CGNR and the schematic mechanism of 1-tetradecanol and dye/drug loading and release, reproduced from ref. 201 Copyright 2014 with permission from “Royal society of Chemistry”.

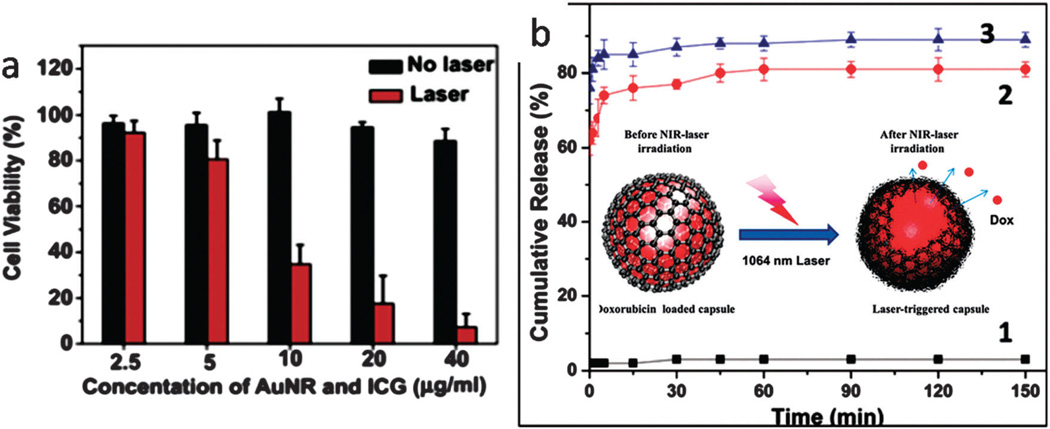

Furthermore, photothermal therapy that is combined with photodynamic therapy (i.e. generation of ROS such as singlet oxygen and free radicals) has shown high cytotoxic efficacies and enhanced damage to tumors45 but can have disadvantageous features such as low ROS production, a tendency toward self destruction, inadequate selectivity, and meager water-solubility.202 A NIR-activated aptamer-silver-gold shell-core nanocarrier showed insignificant destructive effects against normal cells along with highly sensitive detection of various cancer cells at low concentration.160 Another system based on chitosan nanospheres showed a synergistic photothermal effect (due to hyperthermia from gold nanorods) and photodynamic effect (due to ROS production by indocynine green (ICG)) against cancer tissues as well as localized accumulation in these sites. Fig. 10a shows the significantly reduced cell viability after NIR-irradiation.203 Fig. 10b illustrates how a DOX loaded GO–poly(allylamine hydrochloride) (PAH) composite capsule was fabricated. Here, NIR irradiation ruptured the capsules and drugs were released.204 Chang et al. studied drugs encapsulated inside Au-nanorods capped by oligonucleotides. NIR was utilized in their attempt to produce photothermal conversion of Au nanorods and subsequently dehybridization of their light-sensitive gate of duplex DNA.205

Fig. 10.

(a) Cell viability evaluation of cancer cells before and after NIR irradiation using an ICG-Au–chitosan based nanocarrier, reproduced from ref. 203. Copyright 2013, with permission from Elsevier, (b) cumulative release curves before NIR-irradiation (curve 1) and after NIR irradiation (curve 2 and 3) and the schematic of drug release process (inset image), reproduced from ref. 204 with permission from “the Royal Society of Chemistry”.

Another light-sensitive drug release mechanism, known as photochemical internalization (PCI), has recently been used to treat cancer in both animals and patients.206 In PCI, which was first reported in 1999,207 photosensitizing compounds are localized in intracellular endocytic membranes and are then excited by light, producing ROS, whereupon cargo inside the endosomal vesicles is released after disruption of the membranes. This route is often utilized in releasing macromolecules (such as ribosome inactivating proteins or nucleic acid therapeutics) that have been taken up into cells by endocytosis, but need to get out of endosomes to reach the nucleus or the ribosomes to have their best effect.207,208 Oliveira et al.209 utilized this method to silence epidermal growth factor receptors by siRNA. They concluded that endosomal escape was a limiting step for the efficiency of siRNA silencing. In addition they found that lipid-based carriers of nucleic acids had an increased efficacy in PCI. The location of some photosensitizing compounds inside the cytoplasmic membrane is one of the main problems in PCI as photoactivation would be detrimental to the cells.31 It could be suggested that a pH-sensitive linker between the photosensitizing compound and the drug-bearing MNP may be engineered so that the release of drug/gene happens only within either/both lysosomes or/and endosomes. Consequently, only the membrane of these two organelles would be destroyed after light irradiation and release of the loaded material occurring in the cytoplasm.

2.1.5 Mechanical-responsive MNPs

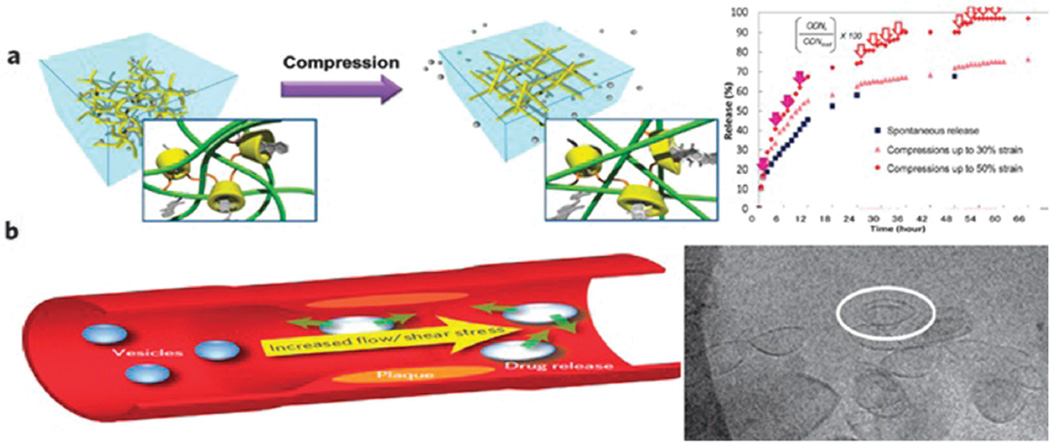

Mechano-responsive nanostructures are another approach to smart DDSs for which only a few studies have so far been reported. Generally this concept is based on the assembly and disassembly of mechano-responsive molecules/structures with applied pressure or other physical stimuli with the aim of changing the overall volume.145 This approach proposes a biomimetic and simple mechanism for controlled DDS compared to other external stimuli-based systems.210 For example cyclodextrin (CyD) inclusion complexes can be affected by pressure, and the destabilization of the inclusion complex in CyD–alginate (AL) hydrogels by mechanical compression was reported for the purpose of patient-controlled release of ondansetron (ODN) (Fig. 11a).211 Accelerated drug release occurred when the inclusion ability of the β-CyD was reduced by applying pressure to an implantable gel thus forming an on-demand strategy for the treatment of severe nausea caused by chemotherapy.

Fig. 11.

(a) Concept of controlled release of ODN from a pressure-sensitive hydrogel. The inset shows accelerated release in response to mechanical compression, (b) endogenous shear stress as a drug releasing stimulus, mechanoresponsive lenticular vesicles 100 nm (inset); (a) reproduced from ref. 211. Copyright 2013 with permission from the Royal Society of Chemistry, (b) reproduced from ref. 213. Copyright 2012 with permission from Nature publishing group.

Shear stress is a less often discussed mechanical stimulus that can be used in the design of smart DDSs. Shear stress is higher in narrowed segments of arteries compared to healthy arterial segments. This difference could be a better physical/mechanical signal to trigger drug release in arteries in comparison with other biological or chemical stimuli.212 Cardiovascular diseases such as stenosis and atherosclerosis could be promising applications of these endogenous mechano-stimuli-responsive systems. For example a study prepared lenticular liposomes that were stable under static conditions but unstable in the elevated shear stress of atherosclerosis.213 The lenticular morphology led to preferential rupture along the equator of the nanostructures followed by increased release of drugs in the areas of high shear stress (Fig. 11b).

Another study developed microscale aggregates of NPs that were broken up into their individual nanoscale components under high local shear stress, for treatment of thrombosis.214 Rapid clot dissolution, lower required doses, restoration of normal flow dynamics, minimized side-effects with maximized drug efficacy were all obtained after in vivo administration.

2.1.6 Ultrasound-responsive MNPs

Ultrasound (US) is one of the external stimuli that can induce mechanical or thermal stimulation. US is of great importance in modern medicine and has a role in many medical applications such as diagnosis (at low frequencies for imaging) and treatment (at high frequencies for the removal of masses such as tumors). In the design of US responsive nano-carriers, three main properties are required; reliable and stable drug encapsulation before delivering the applied US waves to the tissue, efficient drug release owing in response to particular US waves, and the capability of monitoring drug release for imaging and therapeutic purposes. The biomedical range of US waves varies from 0.1 to 50 MHz, although the minimal required frequency is 1 MHz in deep therapy and imaging.4,5,8,215

US not only can trigger the release of drugs from carriers, but can also increase the permeability of biological barriers (cell membranes, blood brain barrier, etc.) by the formation of cavitation bubbles and increased temperature resulting in enhanced drug diffusion.216 Insonated medium can cause unidirectional flow in an aquatic medium, which can affect the tissue structures. Furthermore these waves produce an oscillating pressure between the two layers of biological membranes and create pores in them, thus enhancing the permeability of cell membranes. The effects of US for transdermal drug delivery were widely discussed in a review by Azagury et al.217 The absorption coefficients of US vary among the different body parts and tissues. Some tissues such as bones have much higher coefficients compared to soft tissues, but studies have revealed that the threshold of US pressure and frequency as well as the burst length can influence this tissue disruption and control brain damage when US is applied to the head.218

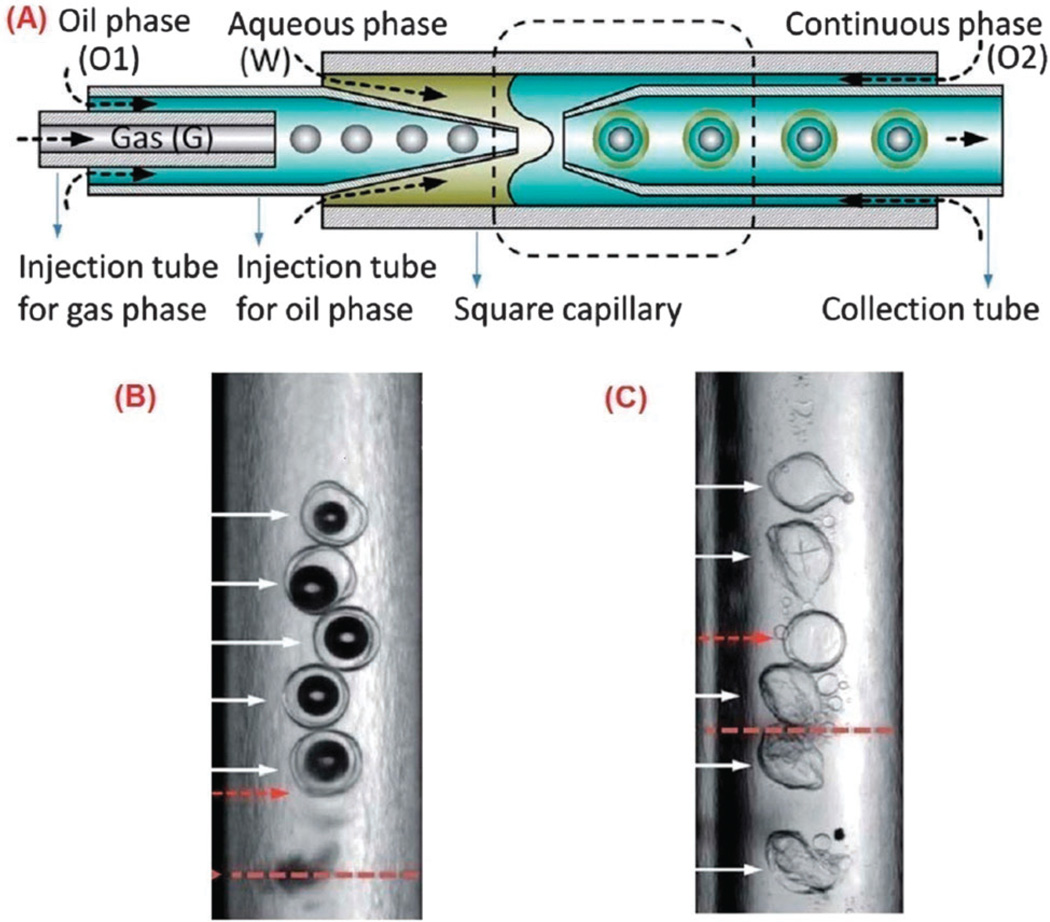

The most suitable structure for US responsive drug-carriers is microbubbles (not nanobubbles) consisting of a gas core such as perfluorocarbons, nitrogen or air, surrounded by a shell of lipids, polymers and proteins such as albumin. The radius of the microbubbles needs to be in a particular range and the number of sites at which microbubbles interact with the vasculature, must be maximized by considering the saturation level. The bubbles are typically on the micron scale (1–10 micrometers) and do not leave the circulation after injection unless they are phagocytosed. Their activation by US also causes physiological changes that enhance drug penetration into the cells.218,219 Optimizing the gas-core is a good strategy to enhance US responsivity of the core–shell nanocarriers, even in more complicated structures in which several liquid and elastic layers surround a gas-core. Each layer of this type of carrier could possess different hydrophobic and hydrophilic properties and could incorporate different types of active cargo molecules. Microfluidic technology provides a good method to produce a gas-core triple emulsion with a gas-in-oil-in-water-in-oil (G/O1/W/O2) structure as shown in Fig. 12. In this study, Chen et al. demonstrated the importance of the gas-core in US responsivity by comparing the effect of US triggering on double oil–water–oil (O/W/O) emulsion structures without the gas-core and the triple G/O/W/O emulsion. The O/W/O emulsions only slightly vibrated without a major response to US waves, whereas the G/O/W/O emulsions disintegrated and their cargo was released220 (Fig. 12B and C). Moreover the materials comprising the core and shell govern the interaction of the immune system with the microbubbles. Soft-shell microbubbles have a thin layer of phospholipid or protein which provides higher sensitivity to the US waves. On the other hand hard-shell microbubbles contain entangled or cross-linked polymers that have higher stability and lower US response.478,480,481

Fig. 12.

Production of US responsive gas-core triple emulsion nanocarrier. (A) Schematic of microfluidic apparatus for the fabrication of the triple emulsion. Dashed lines show the encapsulation of gas in oil and aqueous phases by microcapillary needle. Active cargo might be present in either the oil or the water and then the outer layer of oil surrounds the whole drop. (B) The double emulsion O/W/O drops do not respond to US waves (C) The gas-core triple emulsion disintegrates by US trigger. Arrows show the direction of US waves. Reproduced from ref. 220 with permission from the Royal Society of Chemistry.

The two principal advantages of US, namely energy focusing and good effective depth, make US an attractive route for gene delivery. Many commercial US contrast agents are available such as SonoVue, Optison and Levovist which can be used to monitor the delivery of therapeutic genes by low intensity US. The low intensity of the US prevents the harmful effects on tissues and organs. After the carrier has reached the targeted tissue, high intensity US is applied that causes cavitation in the microbubble gas core and release of the attached DNA to the targeted cells.221–225

He et al.226 used US-mediated collapse of microbubbles to deliver siRNA to enhance therapy against yolk sac carcinoma in vitro. They suggested that owing to the negative charge of DNA, cationic lipid microbubbles would be suitable candidates for gene delivery. Unger et al.216 showed the capability of US to increase gene expression and transfection efficiency using cationic liposomes into cells.227 Lawrie et al.228 reported that US could enhance vascular gene delivery used for a cardiovascular application such as prevention of restenosis. Kuo et al.229 showed that poly-l-lysine (PLL) and polyethylenimine (PEI) both protected nucleic acids from 20 KHz US waves, better than PEG. Hou et al.230 transfected the gene for inducible Smad 7 by US-triggered microbubbles in order to block TGFβ and decrease renal fibrosis in chronic kidney disease. Moreover, nanoscale bubbles also can be designed for targeted drug delivery. For example, Zhang et al.231 combined poly lactic-co-glycolic acid (PLGA) nanobubbles with monoclonal anti-HLA antibody to generate a carrier for targeted delivery to cancer, and enhanced high-intensity focused US ablation of tumors, and Chen et al.232 used US-triggered nano/microbubbles to transfect a model gene (luciferase) into periodontal tissue and observed high gene expression localized in the muscle cells of gingival tissues.

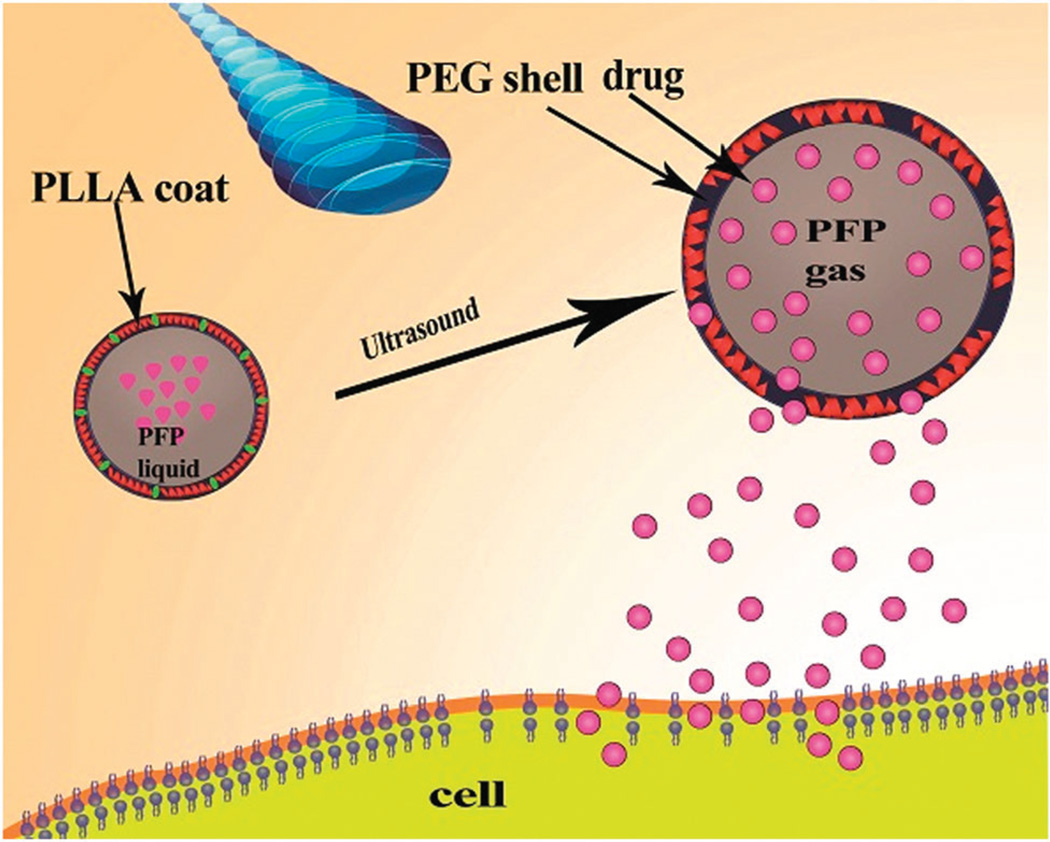

Different structures have been used to deliver drugs and release them by US stimulation. Naked DNA and free drugs can enter into the cell through endocytosis after application of US without using nano/microbubbles and the percentage of Ca2+ has a central role in this phenomenon. Ca2+ increases inside the cell by cell membrane disruption, although the amount of unspecific delivery will also significantly increase which is more important in the case of gene delivery.233 Micelles with 10–100 nm diameter have been used for the delivery of hydrophobic drugs. They self-assemble from amphiphilic polymers in aqueous solution and under the influence of US they release their cargo. The highest drug release occurred at 20 KHz although a low frequency of 20–90 KHz was also effective for drug release from micelles. Rapoport et al.234 generated US-responsive micelles by composing PEG–PLLA poly(ethylene oxide)-co-poly(l-lactide) or PEC-microbubble PCL poly(ethylene oxide-co-polycaprolactone) (PEO-co-PCL). They introduced a core containing 1% PFP (perfluoropentane) that was coated by PEG–PLLA. The resulting microbubbles had a maximum diameter of 500–700 µm and possessed the ability to deliver paclitaxel (PTX) to A2780 ovarian carcinoma or MDA MB 231 breast cancer cells exposed to unfocused 1 MHz US for 1 min. Fig. 13 depicts this mechanism.

Fig. 13.

US-induced phase change particles to facilitate drug release from bubbles.

Husseini et al.235 studied the factors that triggered drug release, and highlighted the role of cavitation as the single most important factor in drug delivery. The size and material properties of bubbles along with the US amplitude directly influenced the type of cavitation (the formation of gas filled cavities such as bubbles when exposed to an oscillating pressure). The mechanical index (MI) of cavitation, in tissue without micro-bubbles, should be less than 1.9, whereas in the presence of micro-bubbles it is reduced to less than 0.8. Increased cell uptake of drugs was proposed as the second reason since the cell membrane can be temporarily permeabilized by the cavitation-induced shock wave. Geer et al.236 designed a liposomal microbubble for increasing cytotoxicity of cancer drugs even at very low doses. Nonlinear reflection of US with low acoustic pressure led to particle destruction in addition to the increased membrane permeability.

The energy of the acoustic waves, when they pass through cells and tissues, is transformed into heat, and therefore applying a focused US beam can generate local tissue heating which can be monitored by different thermometric devices. US also led to the cavitation of the NPs and the destruction of nearby cancer cell membranes, therefore increasing drug uptake. In 2013 Rapoport et al.237 loaded PTX into NPs (nano-emulsions) with 200–300 nm diameter for the treatment of pancreatic cancer activated by FUS (focused US). Here, US delivery (pressure ≥ 1 MPA), 6 h after injection of the NPs, enhanced tumor regression. In addition US can improve the contractile strength of the myocardium. In a study Spivak et al.238 utilized US-mediated sonoporation to increase the uptake of 30 nm AuNPs conjugated with Simdax (a calcium sensitizer) in a rat model of heart failure. The strong anti-oxidant property of AuNPs was observed, and the Simdax was released under US beams.

Rather than the usual advantages of liposomes such as being a stable carrier for lipophilic and hydrophobic compounds, the US beams applied for liposomal drug release should be strong enough to disrupt the liposomal structure and low frequency beams have better efficiency. Furthermore, the combination of US with hyperthermia can also enhance drug release. Smet et al.239 used HIFU mediated drug delivery under MR image guidance. They used temperature responsive liposomes (TSLs) co-encapsulating DOX and an MR contrast agent (250 mM [Gd(HPDO3A)(H2O)]) and showed release of DOX while no leakage of the MRI contrast agent was reported over 1 h at 37 °C. Owing to many simultaneous processes occurring in vivo, identifying the dominant mechanism of action is difficult, US-responsive lipid nano-carriers still have good potential for treatment of cancers.240–242 Xie et al.243 utilized a lipid-encapsulated formulation (MRX 802) with 1 µm diameter that included platelet targeted ligands such as the peptide (cyclo-CRGDWPC)-OH) and targeted glycoprotein 2b/3a receptor. In pigs afflicted with acute left anterior descending thrombotic occlusions, a low-MI (mechanical index) US pulse sequence was utilized to guide the delivery of high-MI (1.9 MI) US and image the myocardium. They observed epicardial recanalization, myocardial blood flow and infarct size were significantly improved by US induced cavitation of MBs.

Di et al.244 described a three-dimensional cohesive gel-like nano-network formed from PGLA through electrostatic interaction between positively-charged (chitosan) and negatively-charged (alginate) NPs. This nano-network could be loaded with insulin, subcutaneously injected into diabetic mice, whereupon the insulin was released in a controlled fashion by US-induced shock waves causing cavitation (frequency: 950 kHz, pulse duration: 20 µs, output power: 4.31 W, administration time: 30 s).

Although sometimes the size of microbubbles is too large to reach the targeted tissues outside the vasculature, they can be combined with other NPs such as liposomes and micelles. This strategy can enhance drug loading capacity, increase the systemic targeting capability and increase the vascular permeability of microbubbles. For example, Burke et al.245 showed that the delivery of PLGA NPs containing 5FU was improved by covalently linking them to US-activated microbubbles. After intravenous injection into Rag-1 knockout mice with C6 gliomas, mice were exposed to pulsed 1 MHz US giving a 67% reduction in tumor volume at 7 days. Improved drug delivery to PC3 prostate cancer xenografts and the subsequent controlled release were shown using air-containing microbubbles consisting of poly-(butylcyanoacrylate) (PBCA) loaded with the model drug Nile red after exposure to 300 kHz or 5 MHz US.246

2.2 Chemical stimuli-responsive MNPs

2.2.1 pH-Responsive MNPs

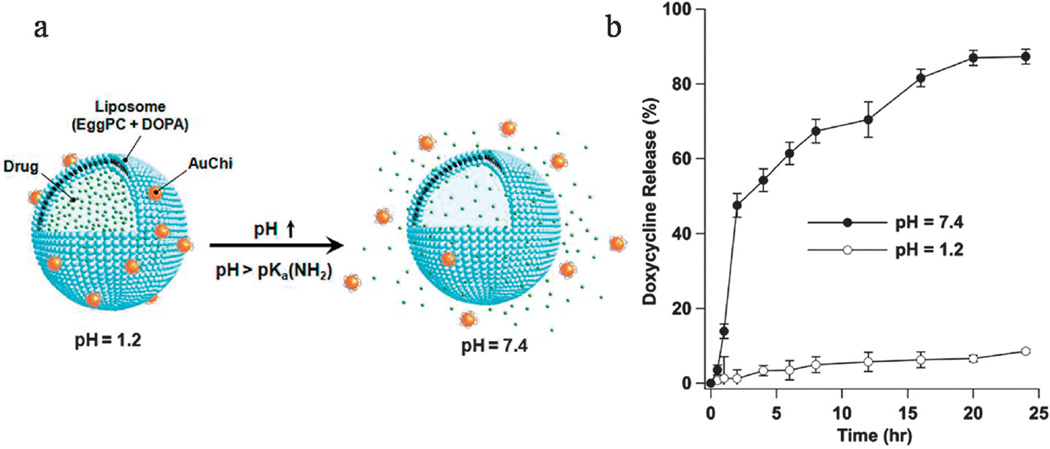

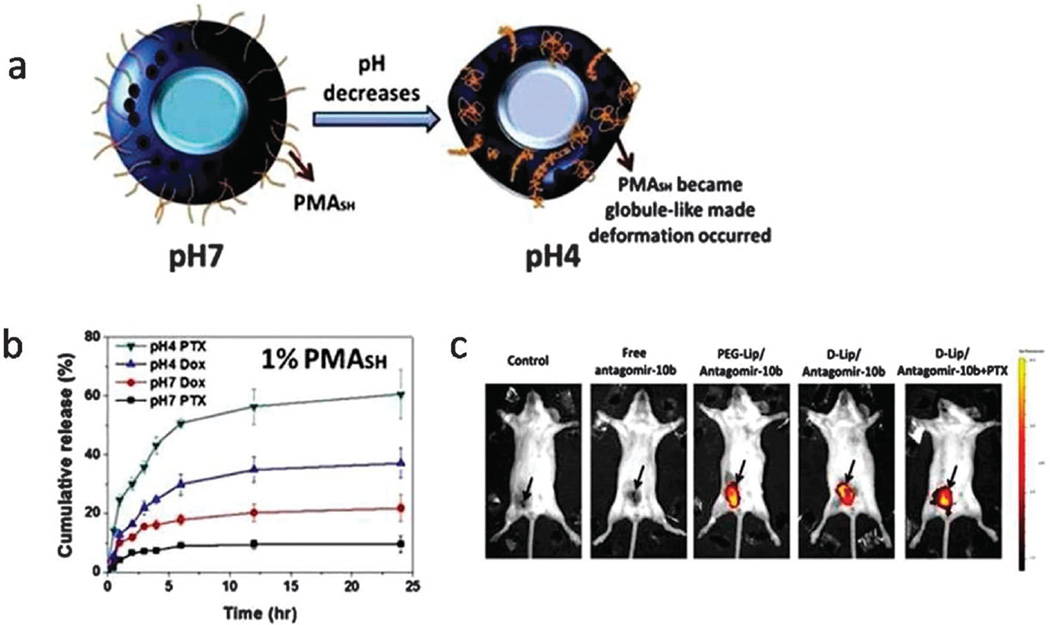

It is well-known that significant pH gradients exist within body (especially the gastrointestinal tract (GI) tract) and also considerable pH differences exist among healthy and pH values vary among the lysosomes (4.5–5), endosomes (5.5–6), Golgi apparatus (6.4), and cytosol (7.4). pH alterations can be induced by the growth of microorganisms (directly or through induction of the release of host enzymes),247 there is an acidic milieu in healing wounds and an alkaline milieu in non-healing wounds.248 Most importantly there is a lower pH profile in tumors than in corresponding normal tissues (i.e. 7.4). This occurs due to the rapid proliferation of cancerous cells outrunning the blood supply, and causing inadequate supplies of oxygen and nutrients, and the thus the formation of lactic acid produced by glycolysis rather than oxidative phosphorylation in normal cells. This phenomenon is known as the Warburg effect. These widely varying pH conditions in diverse biological systems have motivated the design of pH-responsive DDSs.52,249

pH-Responsive nanomaterials have demonstrated a variety of applications including pH-sensors,250 theranostic applications,251,252 controllable switches, controlled-release surfaces, controllable wettability, and cell-recognition devices.,253 Novel pH-responsive nanocarriers of biphasic colloidal particles and “Janus particles”254 have been recently developed with advanced features enabling them to undergo morphological alterations upon pH changes, a new concept of great importance in the design of pH-sensitive DDSs.

There have been abundant advances in smart DDS based on pH-responsiveness of nanosystems in the past few years that have resulted in remarkable breakthroughs in diagnosis and therapy of a range of diseases and disorders such as malignancies and infections. They have shown enhanced antitumor efficacy and reduction of the toxicity of chemotherapy,255 delivery of nucleic acids, proteins, peptides, etc.256 pH-Responsive DDSs can significantly enhance oral bioavailability of anticancer drugs, producing efficient inhibition of tumor growth, reduction of systemic toxicity257 as well as improving selectivity to tumor cells while only giving extremely low cytotoxicity toward normal cells.258

The pH-sensitive nanomaterials that have been used in DDSs can be classified into organic, inorganic and hybrids259 and their methods of synthesis, properties and applications have been recently reviewed.260 The design of pH-responsive nanocarriers requires a good comprehension of their features and mechanisms. For example, the degradation of the spacers conjugating the drug to the polymeric NP at the low environmental pH of tumors or in endosomes/lysosome,261 the protonation of moieties (e.g. carboxylic groups or titratable amines) attached to the surface of the polymeric micellar particles and subsequent structural changes,262 the cleavage of dendrimer particles induced by sensitivity of its hydrophobic groups to acidic conditions,263 and utilizing acid-labile zwitterionic peptide–lipid derivatives in lipidic nanocarriers255 are several examples of pH-dependent mechanisms that can be used for smart drug-delivery. However, the concept of the instability of different pH-responsive nanocarriers in biological media is mostly based on ionizable pH-sensitive groups present in polymeric and peptide NPs, and on acid-labile chemical bonds; both topics are discussed below.

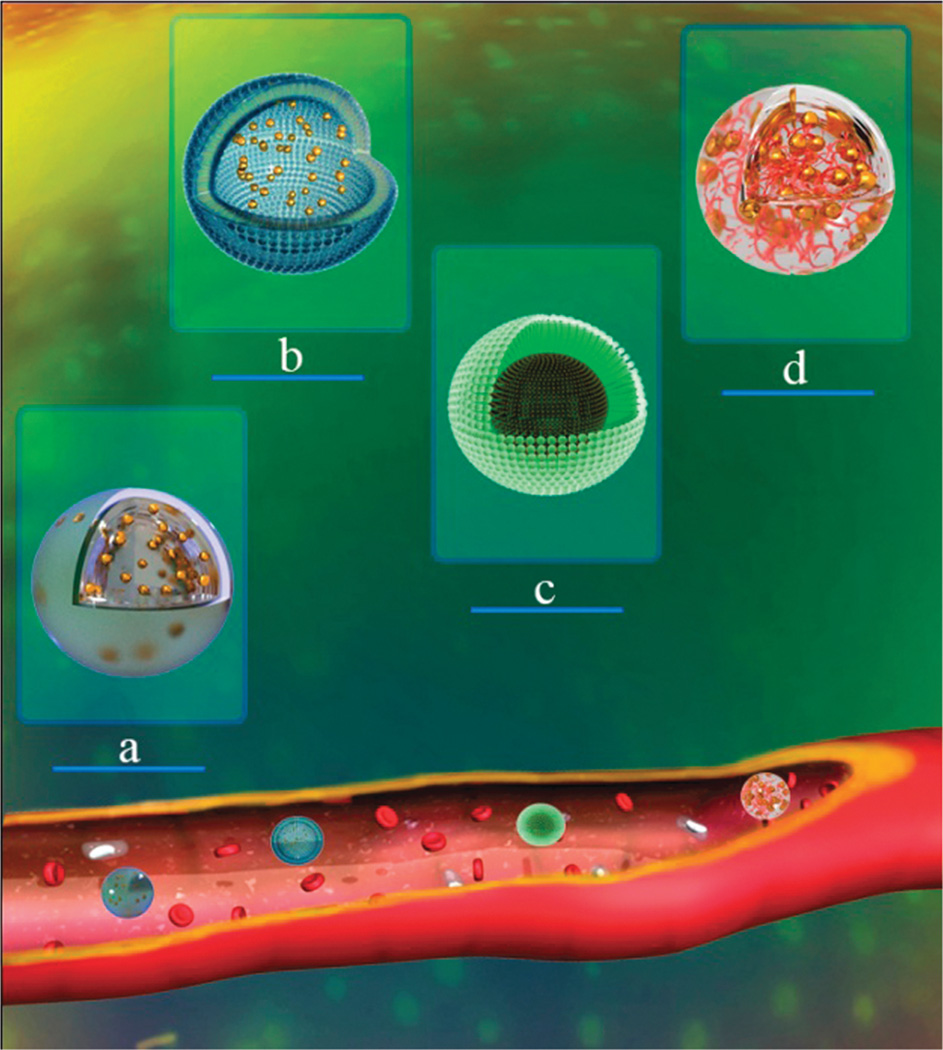

Ionizable chemical groups (e.g. amines, carboxylic acid) including weakly acidic groups (proton donor) or weakly basic groups (proton acceptor) are used in anionic and cationic pH-sensitive polymers, respectively.264,265 These pH-triggered delivery systems show advantageous features such as enhanced cellular uptake, high efficiency of drug or gene (e.g. plasmid DNA (pDNA), and small interfering RNA (siRNA)) delivery, facilitated endosomal membrane rupture induced by the proton sponge effect (i.e. endosomal destabilization by osmotic swelling), surface charge reversion of nanocarriers and deshielding in the low extracellular pH of the tumor environment.266–271 The pH-sensitivity of chitosan derivatives and chitosan-based NPs make them good candidates for pH-responsive oral drug delivery272–274 with properties such as drug release in the intestinal environment (pH 6.8),275 delivery of macromolecules, drugs, and gene (non-viral) delivery,276–278 apoptotic effects produced in tumor cells,279 low cytotoxicity, and increased gene transfection and expression in cancer cells.278 Various chitosan-based nanoassemblies are illustrated in Fig. 14.

Fig. 14.

Chitosan-based nanoassemblies applied in biomedicine. (a) Nano-spheres, (b) vesicles, (c) micelles, and (d) nanogels.

Peptides have been considered as efficient and safe nanocarriers for non-viral delivery of genes to cells,280 as compared to viral gene delivery systems, although the structure has been inspired by these viral vectors. Peptide vectors have advantageous features such as the ability to penetrate the cell membrane, endosomal fusion (in low pH of endosome), and nuclear delivery.281,282 Moreover they avoid the side-effects seen with viral vectors such as inflammation, sustained immune response, and development of cancer and even death.283–285 In addition, multiple repeats of peptide motifs such as glutamic acid–alanine–leucine–alanine (a 30 amino acid) (GALA), shorter version of GALA (shGALA), lysine–alanine–leucine–alanine (KALA) and a 16-amino-acid peptide (RALA) peptides have also been utilized as efficient gene delivery platforms with advantages such as increased interactions with cellular lipid bilayers (especially at lower pH), a long blood circulation time, efficient tumor growth inhibition, improved gene expression, reduced cytotoxicity, increased binding ability to DNA, improved cell-internalization, ability to carry both hydrophilic and hydrophobic molecules with a broad size range (e.g. small molecules, viruses, antibodies, plasmids, proteins), pH-sensitivity to regions of the gastrointestinal tract and good oral delivery.280,286–289 Such gene delivery platforms can be also envisioned for clinical applications.280

Among pH-sensitive moieties, the acid-labile linkers responding to only slight pH changes can provide new classes of highly sensitive pH-responsive MNPs. Acid-labile covalent linkages can be rapidly hydrolyzed in acidic environments such as tumor tissues and several cellular compartments including lysosomes (pH ~ 4.5–5.0), early endosomes (pH ~ 6.0–6.5) and late endosomes (pH 5.0–6.0).290 Polymers containing these cleavable linkers (e.g. acetal/ketal, hydrazine, imine groups etc.) are stable at physiological pH, while drug release occurs due to hydrolysis of the linker bonds in response to the decrease in pH. Cleavable linkages can either be placed in the backbone of the polymer or in the side chains.290,291

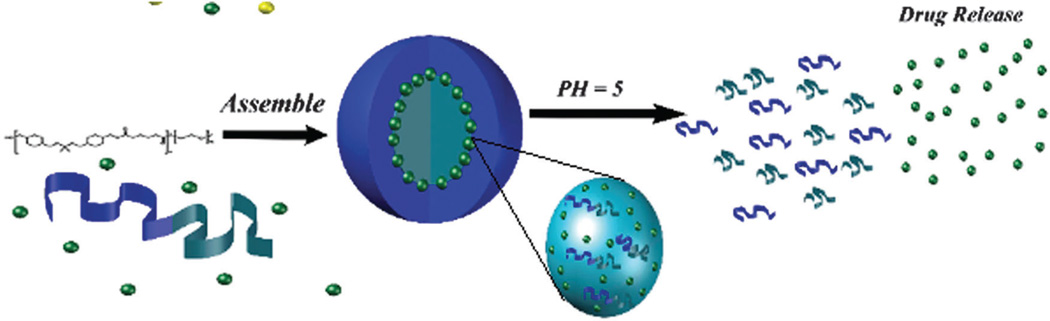

Acid-labile linkages in nanostructures (e.g. polymers) have shown noticeable advantages in gene delivery including biocompatibility, biodegradability, highly efficient delivery, efficient serum-resistant gene transport, low cytotoxicity.292–294 pH-Responsive micelles with an acid-labile ketal linkage in the hydrophobic backbone were dissociated at an acidic pH and thus their anticancer cargo was released. Fig. 15 illustrates the assembly and release of drug from micelles.295

Fig. 15.

Schematic illustration of the assembly and drug release from a micelle encapsulating hydrophobic drugs.

pH-Sensitive micellar structures have other favourable features including multi-functionality, good stability at physiological pH (7.4), partial hydrolysis at the extracellular pH of solid tumors and complete hydrolysis at the lower endosomal pH, a positively charged surface at tumor pH, improved cellular uptake through surface ionization and electrostatic interaction with cell membranes, good endosomal dissociation of micelles, and endosomal membrane disruption leading to enhanced intracellular delivery via the endocytic pathway.296

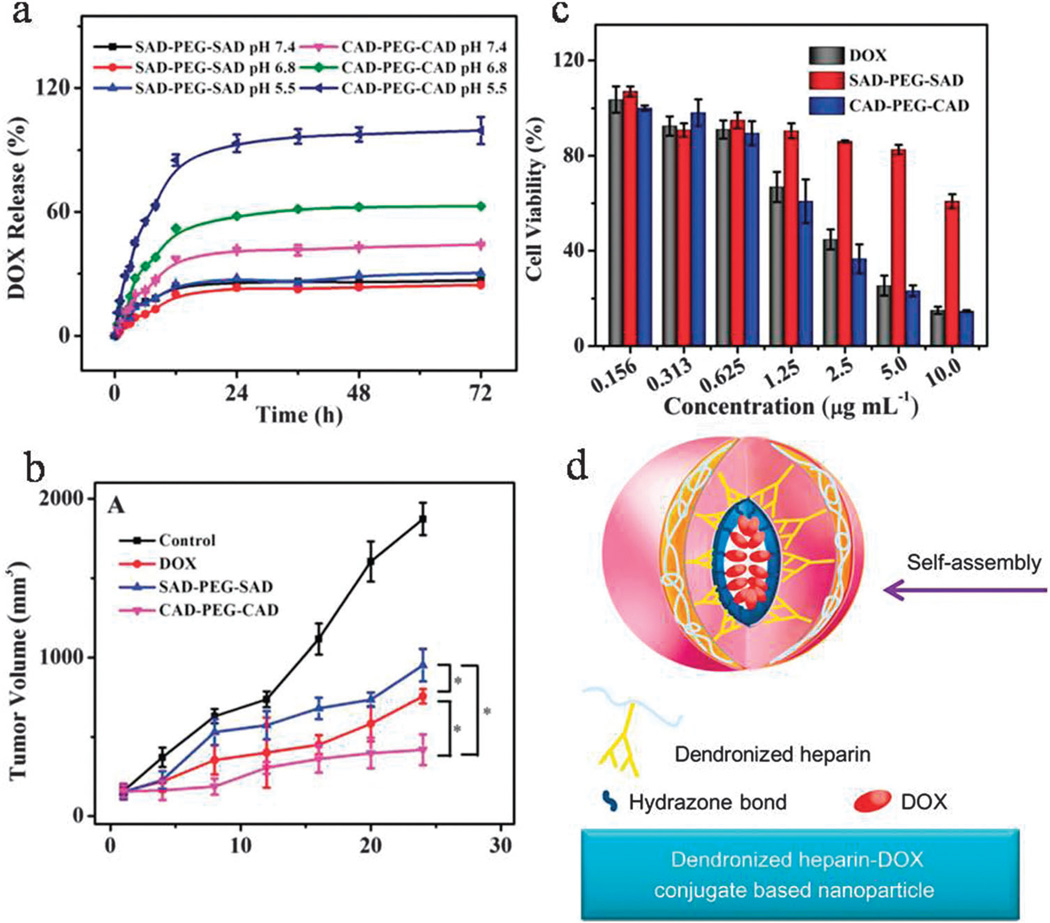

Acid-labile hydrazone bonds can be utilized in pH-responsive DDSs for cancer treatment.297–302 pH-Responsive nanosystems containing hydrazone bonds such as polyurethane (PU) have shown diverse advantages including multi-functionality, biocompatibility, biodegradability of the carriers, anticancer drug release in response to the acidic intracellular environment, ability to be loaded with lipophilic agents in physiological conditions,303 controlled stepwise drug release, and nontoxicity.304 Micelles containing hydrazone bonds have also been developed, especially for cancer therapy305 with advantages such as more rapid drug release at acidic pH,306 and delivery of hydrophobic drugs with no need for conjugation sites.307 Furthermore, the use of nanosystems containing pH-sensitive hydrazone bonds enables co-delivery of drugs such as DOX together with siRNA to tumor cells.298,302 Fig. 16d illustrates a self-assembled dendronized NP containing heparin conjugated to DOX using an acid-labile hydrazone linkage and a negatively charged surface. This NP showed more rapid drug release at pH 5.0 than at pH 7.4 followed by significant killing of 4T1 cancer cells by apoptosis, an antiangiogenesis effect in a breast cancer model with insignificant side-effects.308

Fig. 16.

(a) DOX release from SAD–PEG–SA and CAD–PEG–CAD at pH 5.5, 6.8 and 7.4 at 37 °C, (b) cytotoxic effects and (c) tumor volume evaluation, for free DOX, SAD–PEG–SA and CAD–PEG–CAD, (d) dendronized heparin–DOX based NPs with hydrazone bonds. (a–c reproduced from ref. 313. Copyright 2013 with permission from “John Wiley & Sons, Inc.”, and reproduced from ref. 308. Copyright 2013 with permission from “Elsevier”).

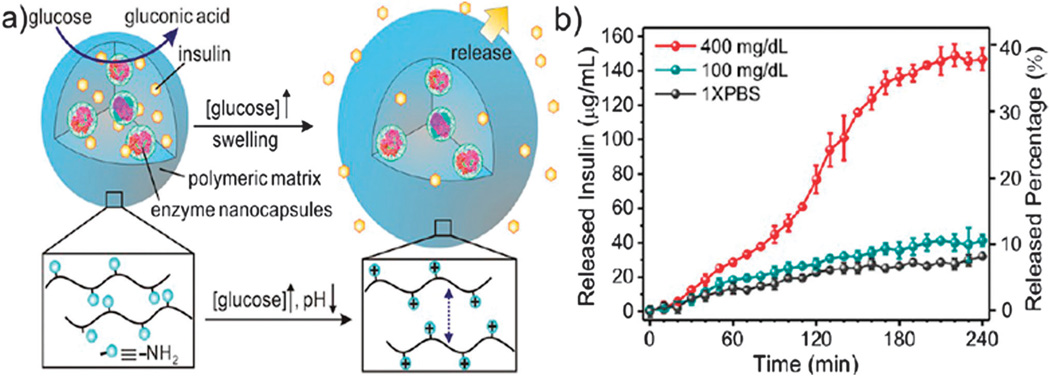

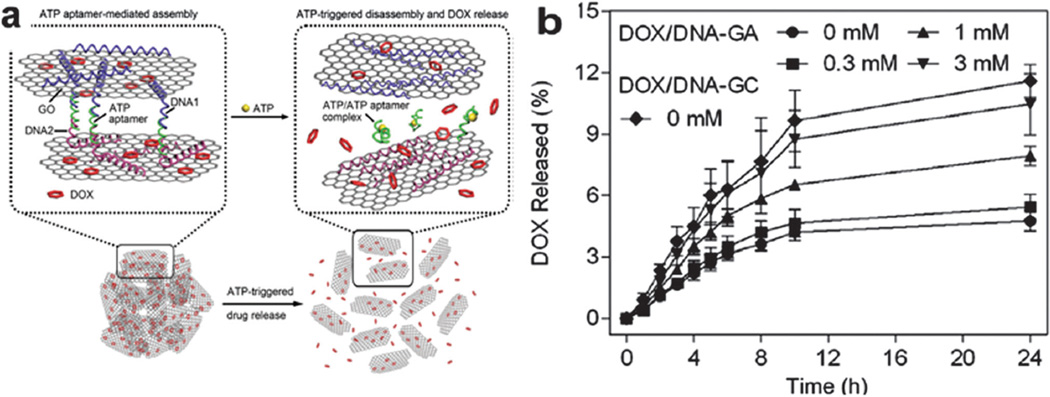

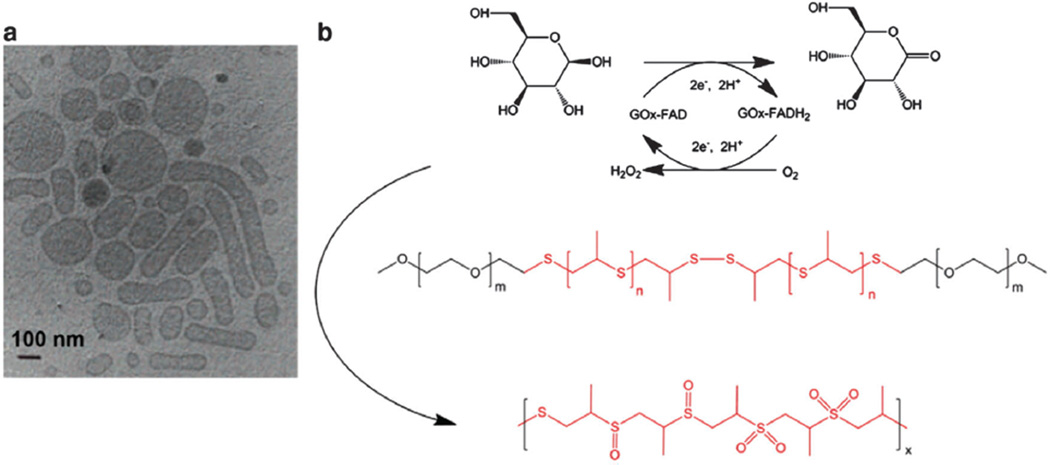

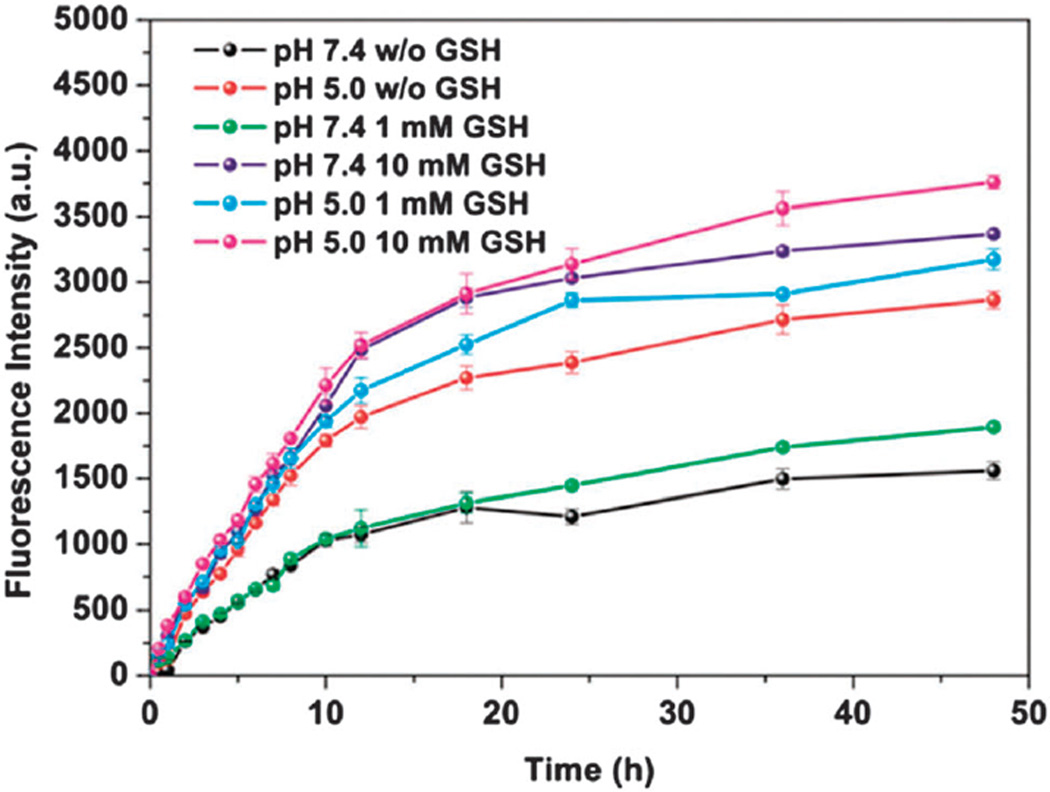

The deep penetration of anticancer drugs (especially those loaded into nanocarriers) into the tumor tissue is a challenging issue. The size and the surface charge of the nanocarriers are the key parameters determining penetration, but the drug release in response to slight pH-changes will lead to better tissue penetration and cellular uptake in cancer cells.309 Smart pH-triggered nanocarriers including micelles with hydrazone bonds310 and liposomes311 have shown good cytotoxic effects and high tumor targeting capability.