Abstract

Objectives

Dust mass concentrations, temperatures, and carbon dioxide concentrations were mapped in a modern, 1048-pen swine gestation barn in winter, spring, and summer.

Methods

In each season, two technicians measured respirable mass concentrations with an aerosol photometer and temperatures and carbon dioxide concentrations with an indoor air quality monitor at 60 positions in the barn. Stationary photometers were also deployed to measure mass concentrations during mapping at five fixed locations.

Results

In winter when building ventilation rates were low (center–barn mean air velocity = 0.34 m s−1, 68 fpm) to conserve heat within the barn, mass and carbon dioxide concentrations were highest (mass geometric mean, GM = 0.50mg m−3; CO2 GM = 2060 ppm) and fairly uniform over space (mass geometric standard deviation, GSD = 1.48; CO2 GSD = 1.24). Concentrations were lowest in summer (mass GM = 0.13mg m−3; CO2 GM = 610 ppm) when ventilation rates were high (center–barn mean air velocity = 0.99 m s−1, 196 fpm) to provide cooling. Spatial gradients were greatest in spring (mass GSD = 2.11; CO2 GSD = 1.50) with low concentrations observed near the building intake, increasing to higher concentrations at the building exhaust.

Conclusions

Mass concentrations obtained in mapping were generally consistent with those obtained from stationary monitors. A moderately strong linear relationship (R2 = 0.60) was observed between the log of photometer-measured mass concentration and the log of carbon dioxide concentration, suggesting that carbon dioxide may be an inexpensive alternative to assessing air quality in a swine barn. These results indicate that ventilation can effectively reduce contaminant levels in addition to controlling temperature.

Keywords: aerosol mapping, agricultural exposures, particulate matter, swine barn, ventilation

Introduction

Compared to workers in other occupational settings, those in the swine industry experience an increased prevalence of adverse pulmonary health effects, including bronchial inflammation (Larsson et al., 1994; Pedersen et al., 1996), acute reductions in pulmonary function (Donham et al., 1995), chronic reductions in pulmonary function (Iversen and Dahl, 2000), and bronchial hyperresponsiveness (Vogelzang et al., 2000). Increasing respiratory symptoms have been related to more hours working per day inside swine barns (Radon et al., 2002) and higher exposures to dust and ammonia (Donham et al., 1995). Donham et al. (1995) recommended that exposures inside swine confinement buildings be maintained to keep personal exposures below 2.8mg m−3 total dust averaged over an 8-h shift. Based on this and recent research adjusting for different sampling techniques as discussed by O’Shaughnessy et al. (2010), adverse health effects in swine barns should be minimized if 8-h time-weighted average (TWA) inhalable dust exposures are maintained at less than 3mg m−3.

Swine production has increasingly shifted to large, corporate operations over the past 30 years, relying on large confinement buildings that can contain >1000 hogs with automated and integrated ventilation, feed, and waste management systems. Ventilation systems, however, are designed to maintain temperatures adequate for animal production, not to control contaminant concentrations (Hellickson and Walker, 1983; Hinz and Linke, 1998). When temperatures outdoors are cool, these barns are typically closed with only minimal exhaust ventilation rates provided from small wall fans or under-floor manure pit fans to minimize heating costs.

As a consequence, contaminant dust exposures commonly exceed 3mg m−3. O’Shaughnessy et al. (2010) measured personal inhalable dust exposures in a modern 3500-pen, swine facility with five tunnel-ventilated buildings, which were each devoted to a specific swine life cycle (1 nursery, 1 for young gilts, 1 for breeding, 2 for gestation). Personal exposures were associated with work tasks but less so than with season, exceeding 3mg m–3 inhalable dust 8 of 11 times in winter when building ventilation rates were low and 3 of 23 times in other seasons. Jerez (2007) observed similar seasonal trends in a single 2300-swine building with nursery through finishing activities. Hinz and Linke (1998) also found inhalable dust concentrations to commonly exceed recommended levels in a 450-pen, finishing barn with large open pens and roof ventilation, although they observed no significant seasonal differences.

Less is known about the spatial distribution of dust concentrations in swine barns, although knowledge of this type is critical in developing effective control strategies. In a 180-pen swine barn, Barber et al. (1991) found that dust concentrations varied to a greater extent temporally (day-to-day) than spatially (horizontal and vertical gradients). In contrast, using a novel multi-point total suspended particulate filter sampler in a mechanically ventilated swine barn comprised of two 11-pen rooms, each housing 72 swine, Wang et al. (2002) found considerable vertical and horizontal spatial variation in dust concentrations, which they related to clean air distribution. Jerez (2007) used this multi-point sampler to measure concentrations in 50 locations in a large, modern swine barn (2300 swine in 40 pens at various stages of production from weaning to finishing). Jarez observed similar concentrations at 0.8 m and 1.6 m vertically. Higher and more spatially uniform dust concentrations were observed along the length of the building in winter than in summer. In summer, concentrations were lowest near the building intake but then rapidly increased as air moved through the building to the exhaust fans, reaching concentrations roughly half of those observed in winter.

Aerosol mapping has been used with direct-reading instruments to measure the spatial distribution of contaminants in workplaces other than agriculture. In aerosol mapping, particle concentrations measured by one or more technicians as they walk through a workplace are plotted using mapping software. Particle number and mass concentration maps have been constructed to determine particle sources in various workplaces: apparel production facilities (Vosburgh et al., 2011); restaurant kitchens (Park et al., 2010); and engine manufacturing facilities (Peters et al., 2006). Compared to filter sampling, mapping with direct-reading instruments provides rapid feedback on the environment and enables a higher number of measurements to be obtained in a shorter time period. Mapping is, however, subject to error when contaminant sources vary substantially during the collection of data for a single map (Koehler and Volckens, 2011).

The primary objective of this work was to use aerosol mapping to determine the spatial variability of dust concentrations by season in a modern, tunnel-ventilated swine barn used exclusively for gestation. Stationary monitoring with direct-reading instruments was used as a potentially less labor-intensive alternative to mapping. A secondary objective was to determine if carbon dioxide concentrations can be used as a surrogate for dust concentrations in this environment. Knowledge of the spatial variability in dust concentrations and how it relates to ventilation parameters is important to the development of cost-effective control strategies to protect worker health.

Methods

Study site

This study was conducted at a gestation/farrowing facility in the midwestern USA that was built within the past 7 years. This facility was the site of a companion study on the determinants of personal exposures to inhalable dust (O’Shaughnessy et al., 2010), and was typical of those used in modern swine production in USA. The facility consisted of five 23 m × 96 m buildings that were connected by enclosed walkways. These buildings were configured as follows: 1 building held ~450 gilts (young females); 3 buildings (1 for breeding and 2 for gestation) were set up with 1048 pens per building; 1 building was set up for farrowing piglets, containing six 15 m × 21 m rooms with 48 stalls in each.

All measurements in this study were conducted in a gestation building, shown schematically in Fig. 1. The building used tunnel ventilation powered by 1 small exhaust fan and 12 large exhaust fans at the smaller wall at one end of the building. Ventilation rate was temperature controlled with more fans turned on during hotter temperatures. The intake of the building was covered with a fiberboard material that was wetted on warm days to provide evaporative cooling. Nine aisles along the axis of airflow provided access to the front and rear of the 1048 pens, one pen for each sow. Sows were positioned in a 1-m-high pen so that they faced towards a common feeder. The ceiling was 2.3 m above concrete slatted floors with shallow pits 0.6 m beneath. These pits were drained to exterior lagoons at 20–25-day intervals. The enclosed walkways that connect this building to other buildings in the facility extend from the central walkway.

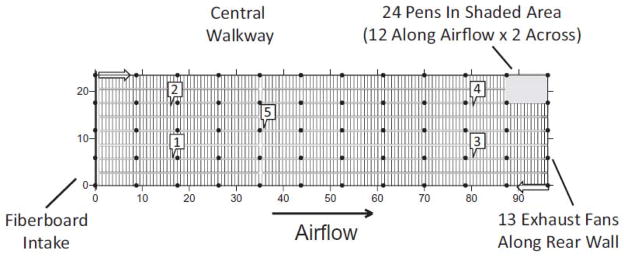

Fig. 1.

Schematic diagram of the swine gestation barn. Each vertical rectangle indicates a pen for one sow for a total capacity of 1048 sows. Measurement locations used during mapping are indicated with a black dot, and stationary locations are indicated with a numbered call-out box. The open arrow indicates technician starting point and direction of travel during mapping. Numbers along the perimeter of the building indicate distance in meters.

Mapping procedures

Particle mass concentrations, temperatures, and carbon dioxide concentrations were mapped in winter, spring, and summer. Particle mass concentrations were measured with a photometer (Model pDR-1200, Thermo-Electron Corp., Waltham, MA) set up to log every 10 s. A sampling pump (Model 224-PCXR4, SKC Inc., Eighty Four, PA) was used to pull air into the photometer at an airflow rate of 1.5L min−1. All photometers were calibrated to provide a zero response with a filter on the inlet and a span value of 1mg m−3 when exposed to Arizona road dust in laboratory tests. Preliminary side-by-side comparisons in this facility (n = 6; 2 each in winter, spring, and summer seasons; center–barn position, see Supplementary data available at Annals of Occupational Hygiene online) were conducted to determine that mass concentrations measured with the photometer were 3.55 times lower than those measured with inhalable samplers (IOM, SKC Inc., Eighty Four, PA). Thus, all photometer readings were increased by this factor to estimate inhalable mass concentrations. Temperature and carbon dioxide concentrations were measured with an indoor air quality monitor (Q-Trak, Model 7575, TSI Inc, Shoreview, MN). The indoor air quality monitors were calibrated by the manufacturer prior to sampling.

In each season, all instruments were collocated in the center of the building and warmed up for 15min with the photometer operated with a filter on the inlet and for another 5min without the filter on the inlet. The photometers were rezeroed if the output deviated by greater than ± 0.010mg m−3 when the filter was on the inlet. Adjustments to our data were made if these collocated measurements deviated by greater than ±10%. Slight adjustments were needed for two stationary photometer measurements in winter only.

Two technicians measured mass concentrations, temperature, and carbon dioxide concentrations in two passes at each of 60 positions in the building (12 positions along 5 aisle ways, with aisles oriented in the main direction of air movement; black, filled dots in Fig. 1). The technicians started at opposite corners of the building, walking to a new location along the long aisles. At each position, the technician initiated a 2-min sample collection (12, 10-s measurements) with the indoor air quality monitor. After completing data collection for the first pass (all 60 positions), the process was repeated with the technicians following the reverse path. Direct-reading instruments were held at breathing zone height (~1.3 m from the floor) during the measurements. Mapping data collection was initiated between 8 AM and 10 AM, and took approximately 2.5h per day to complete. The total number of 10-sec samples collected during one pass was 720 (60 positions × 12 samples per position) for a total of 1440 samples collected for two passes.

Mapping software (Surfer Version 8, Golden Software, Golden, CO) was used to construct maps of mass concentrations, temperatures, and carbon dioxide concentrations for each season. A Kriging method with zero-order polynomial drift was first used to convert measured data into a uniform dense grid (100 by 25) for each parameter and season. The software was then used to display the uniformly gridded data in maps. In winter and spring, both technicians collected data twice at each position. These data were averaged to obtain a single combined map. In summer, data from one of the indoor air quality monitors was compromised. Thus, the summer maps represent the measurements made at 60 positions by one technician.

Stationary monitoring

At five locations identified in Fig. 1, photometers (Model pDR-1200, Thermo-Electron Corp., Waltham, MA) were set up to log mass concentration every 10 s. These monitors were prepared for sampling in the same manner as described above and were mounted on vertical poles 1.5 m from the slatted floor. Air velocity was measured at a fixed location (identified as Location 3 in Fig. 1) 1.5 m above the floor with a hot wire anemometer (Velocicalc, Model 9565, TSI Inc., Shoreview, MN). Stationary monitors were deployed prior to initiating mapping and were removed after mapping was complete. Data analyzed from stationary mapping were matched in time to the entire mobile sampling period for the mapping data. Approximately 900 total stationary measurements (1 measurement per 10 s × 2.5h) were made at each position.

Data analysis

All mass concentration, carbon dioxide concentration, and temperature data were log transformed. For each season and each parameter, the geometric mean (GM) and geometric standard deviation (GSD) were calculated for all raw data obtained through mapping and by location for stationary sampling. In all cases, we rejected the the null hypothesis that there was no difference between the distribution of the data (normal or log transformed) by season using the Anderson–Darling normality test. However compared to the normal data, the log-transformed data provided a better fit to the normal distribution when viewed on a probability plot.

One-way ANOVA of the samples taken at each position was performed to test the hypothesis that GM mass concentrations, GM temperatures, or GM carbon dioxide concentrations were different from each other by season. A separate one-way ANOVA was performed to test the hypothesis that the GM of each of these parameters was different by location of the five stationary samplers. Tukey’s multiple comparison test was used to determine which GMs were significantly different. A P value less than 0.05 was considered statistically significant.

Mass concentrations obtained from mapping were compared to those from stationary monitoring as a potentially less labor-intensive alternative to mapping. For each season, the mass concentration associated with the 84th percentile of observations, C84%, was calculated as the GM multiplied by the GSD for data obtained from mapping, the central stationary monitor only, and all stationary monitors. The percentage difference in GM and C84% mass concentrations obtained with stationary and mobile monitoring was calculated using data from all stationary monitors. These values were also calculated using data from the central stationary monitor only.

Linear regression was used to develop a model to predict photometer-measured mass concentrations from carbon dioxide concentrations. All statistical analyses were carried out with statistical software (Release 16, Minitab, State College, PA).

Results

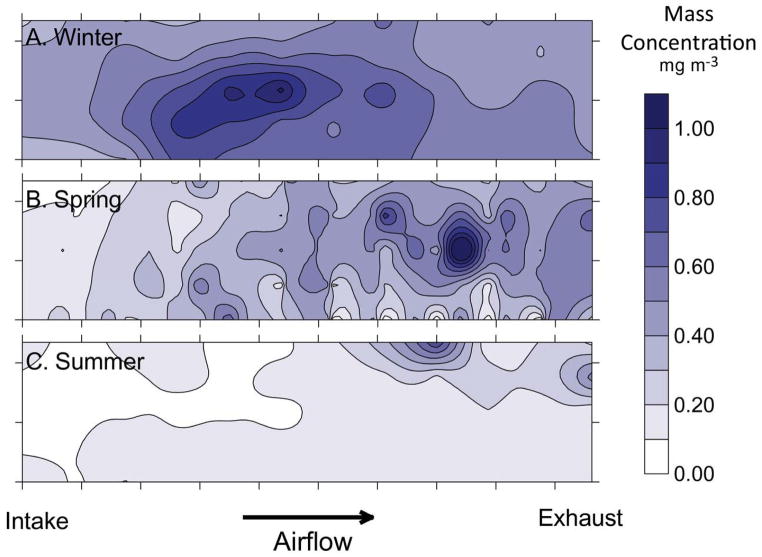

Maps of mass concentrations, temperatures, and carbon dioxide concentrations from mobile monitoring are shown in Figs. 2 through 4, respectively. These data are summarized in Table 1 along with outdoor temperatures (mean = 2.8°C in winter, 7.2°C in spring, and 26°C in summer) and indoor air velocity (mean = 0.36 m s−1 in winter, 1.25 m s−1 in spring, and 0.99 m s−1 in summer). As shown in Fig. 2, the highest mass concentrations were observed in the center of the barn in winter, whereas they were observed away from the intake in spring and summer. Mass concentrations were statistically higher in winter (GM = 0.50mg m−3; Tukey group A) than in spring (GM = 0.30mg m−3; Tukey group B) or in summer (GM = 0.13mg m−3; Tukey group C; P < 0.001; Table 1). Mass concentrations were more uniform in winter (GSD = 1.48) and in summer (GSD = 1.65) compared to those in spring (GSD = 2.11; Table 1).

Fig. 2.

Mass concentration measured during mobile monitoring in the barn in A) winter; B) spring; and C) summer.

Fig. 4.

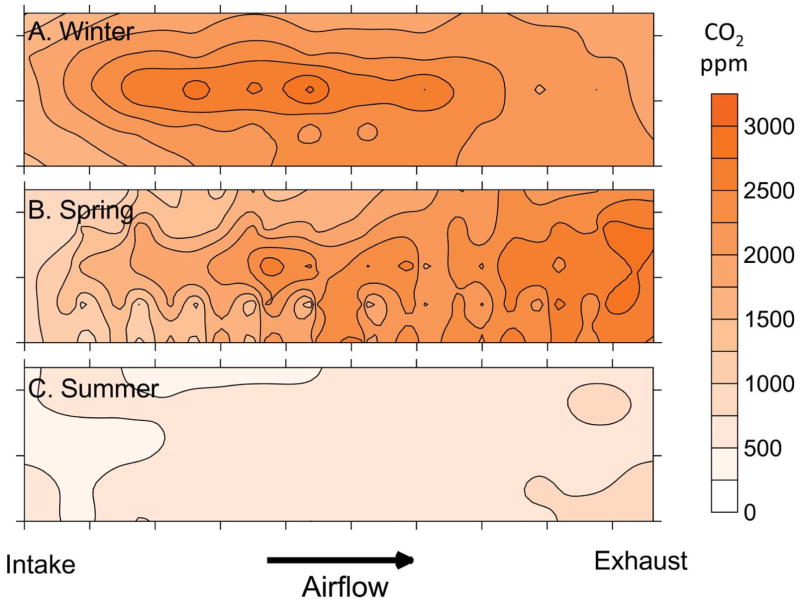

Carbon dioxide measured during mobile monitoring in the barn in A) winter; B) spring; and C) summer.

Table 1.

Summary of measurements from mobile monitoring by season. Letter indicates grouping results from Tukey’s multiple comparison test (A is highest value; C is lowest value).

| Season | Outdoor Temperature °C Mean | Velocity m s−1 Mean (SD) | n | Mass Concentration mg m−3 GM (GSD) | Temperature °CGM (GSD) | CO2ppm GM (GSD) |

|---|---|---|---|---|---|---|

| Winter | 2.8 | 0.36 (0.05) | 1440 | 0.50 (1.48) A | 19.9 (1.06) B | 2060 (1.24) A |

| Spring | 7.2 | 1.25 (0.11) | 1440 | 0.30 (2.11) B | 18.7 (1.25) C | 1760 (1.50) B |

| Summer | 26 | 0.99 (0.04) | 720 | 0.13 (1.65) C | 29.2 (1.02) A | 610 (1.22) C |

Outdoor temperatures obtained from local airport. Velocities obtained from a stationary position near exhaust (position identified as Location 3 in Fig. 1). Sample size (n) reflects the number of 10-s measurements made of each parameter (i.e., mass concentration, temperature, and CO2 concentration).

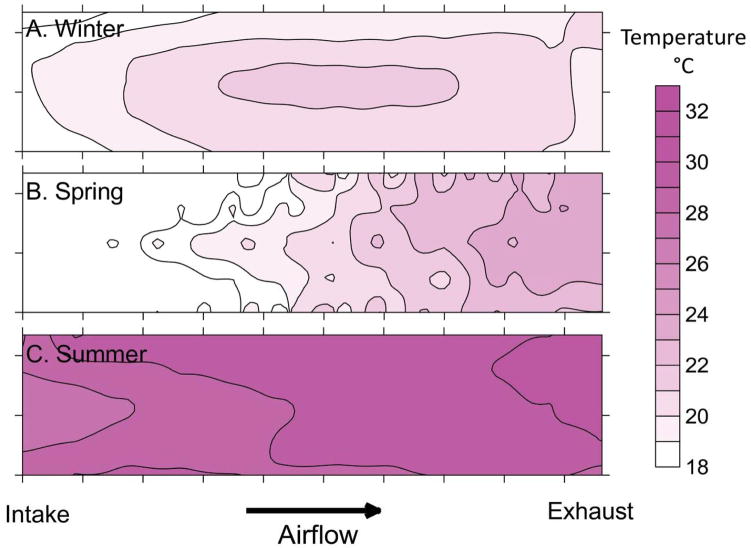

The maps of temperatures were substantially different by season (Fig. 3). In winter, temperatures were fairly uniform, ranging from 17°C near the intake and outer wall to 22°C in the center of the barn. In contrast, a marked temperature gradient was observed in spring with the lowest temperatures (10°C to 18°C) in roughly one-third of the barn at the intake rising to higher than 22°C near the exhaust fans. In summer, temperatures were highly uniform with a range from 27°C to 31°C. The highest temperatures were observed in summer (GM = 29.2°C), which were substantially and statistically higher than those observed in winter (GM = 19.9°C; P <0.001) or spring (GM = 18.7°C; P <0.001; Table 1).

Fig. 3.

Temperature measured during mobile monitoring in the barn in A) winter; B) spring; and C) summer.

The maps of carbon dioxide concentrations (Fig. 4) exhibit patterns similar to those of mass concentrations (Fig. 2). In winter, carbon dioxide concentrations ranged from 1200 ppm to 3090 ppm with the highest concentrations observed in the center of the barn. In spring, carbon dioxide concentrations increased from approximately 700 ppm near the intake to higher than 2500 ppm near the barn exhaust fans. Carbon dioxide concentrations in winter (GM = 2060 ppm) were substantially and statistically higher than those in spring (GM = 1760 ppm) or summer (GM = 607 ppm; P < 0.001).

Mass concentrations measured at stationary locations are summarized in Table 2. For all seasons, the overall GM concentrations observed with stationary monitors (Table 2) were slightly lower than those observed in mapping (Table 1). GMs of mass concentrations by stationary monitor location were statistically different in all seasons (P < 0.001) with concentrations measured near the intake consistently lower than those observed at the exhaust end of the building. GSDs of mass concentrations were lower in winter (GSD all locations = 1.57) than those observed in other seasons (GSD all locations, spring = 1.99; GSD all locations, summer = 2.50). In all cases within a given season, GSDs were highest at locations near the intake.

Table 2.

Summary of mass concentrations measured with stationary samplers. Letter indicates grouping results from Tukey’s multiple comparison test. Approximately 900 measurements were made at each location.

| Mass Concentration, mg m−3, GM (GSD) | ||||

|---|---|---|---|---|

| Season | Intake | Center | Exhaust | Overall |

| Winter | 0.32 (1.47)D | 0.72 (1.37)A | 0.60 (1.24)B | 0.44 (1.57) |

| 0.32 (1.41)D | 0.40 (1.28)C | |||

| Spring | 0.16 (1.78)C | 0.28 (1.50)B | 0.50 (1.31)A | 0.27 (1.99) |

| 0.15 (1.78)C | 0.49 (1.36)A | |||

| Summer | 0.10 (1.21)A | 0.09 (1.27)B | 0.08 (1.43)C | 0.07 (2.50) |

| 0.01 (2.25)D | 0.11 (1.34)A | |||

A summary of the percentage difference in mass concentration measurements made with stationary samplers compared to those from mapping is presented in Table 3. In winter, the GM and C84% mass concentrations obtained with all stationary monitors were lower (GM, −12%; C84%, −7%) than those obtained through mapping, whereas they were higher (GM, 42%; C84%, 31%) when data from the central monitor only was used. In spring and summer, GM and C84% mass concentrations obtained with stationary monitors (all monitors or central only monitor) were lower than those obtained through mapping, ranging from −7% to −47%.

Table 3.

Percentage difference in mass concentrations from stationary monitors relative to those from mobile monitoring. The mass concentration associated with the 84th percentile of observations, C84%, was calculated as GM*GSD.

| Season | Data Source | Mass Concentration, mg m−3 | Percentage Difference, % | ||

|---|---|---|---|---|---|

| GM (GSD) | C 84% | GM | C 84% | ||

| Winter | Map | 0.50 (1.48) | 0.74 | — | — |

| Stationary All | 0.44 (1.57) | 0.69 | 12 | 7 | |

| Stationary Central Only 0.71 (1.37) | 0.97 | 42 | 31 | ||

| Spring | Map | 0.30 (2.11) | 0.63 | — | — |

| Stationary All | 0.27 (1.99) | 0.54 | 10 | 15 | |

| Stationary Central Only 0.28 (1.50) | 0.42 | 7 | 34 | ||

| Summer | Map | 0.13 (1.65) | 0.21 | — | — |

| Stationary All | 0.07 (2.50) | 0.18 | 46 | 18 | |

| Stationary Central Only 0.09 (1.27) | 0.11 | 31 | 47 | ||

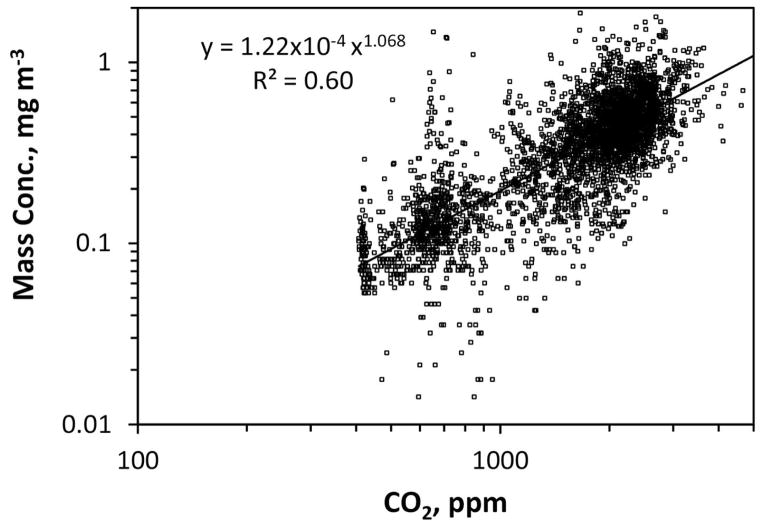

Linear regression was conducted to evaluate the use of carbon dioxide concentrations to predict mass concentrations. Different forms of the regression were modeled with and without the dependent and independent variables log transformed. As shown in Fig. 5, the strongest relationship (R2 = 0.60) was observed when both variables were log transformed to yield the following power–law relationship:

where C m is the inhalable mass concentration estimated from photometer data and Cco2 is the carbon dioxide concentration from the indoor air quality monitor. Eighty percent of the measurements of mass concentration were within ±50% of the predicted values.

Fig. 5.

Linear relationship observed between the log of mass concentrations measured with the photometer and the log of carbon dioxide concentrations measured with the indoor air quality monitor.

Discussion

The spatial distribution of mass concentrations, temperatures, and carbon dioxide concentrations differed substantially by season in a large, modern swine gestation barn. These gradients can generally be described by building ventilation that is used to maintain building temperatures within a range where swine productivity is maximized. However, the distributions of contaminants also have important implications for controlling contaminants in swine barns to protect worker health.

In winter, only the single, small exhaust fan was used infrequently to conserve heat within the barn, providing only minimal ventilation. Despite cool outdoor temperatures (mean outdoor temperature = 2.8°C), this practice effectively maintained temperatures within a narrow range inside the barn (17°C to 22°C; Fig. 3, winter). However, low ventilation rates allowed mass and carbon dioxide concentrations to build up and become higher throughout the barn (mass, Fig. 2A; and CO2, Fig. 4A) than in other seasons. Slight spatial gradients in mass concentrations, temperatures, and carbon dioxide concentrations can be observed in winter maps with the highest values observed in the center, left side of the building and lowest values were observed near the intake, exhaust, and right wall. These gradients are consistent with channeling clean, cool, fresh air moving at a low airflow from the intake along the right wall and then to the exhaust fan. Such channeling is likely to occur with the low ventilation rate produced with the single, small exhaust fan, which would have insufficient pressure drop to pull air through the fiberboard intake and through the building in plug flow from the intake to the exhaust.

In spring, outdoor temperatures (mean temperature = 7.2°C) triggered on three large exhaust fans in addition to the small fan, which produced substantial gradients in all maps. Mass (Fig. 2B) and carbon dioxide concentrations (Fig. 4B) were lowest in the one-third of the building nearest to the intake, where the cold air from outside was first drawn in (Fig. 3B). This air became more contaminated and hotter as it moved through the barn. These gradients are consistent with plug airflow moving through the barn imparted and maintained by the pressure drop as the air moves through the intake at substantially higher ventilation rates than those in winter.

Finally in summer, all 13 exhaust fans were operating to produce a high ventilation airflow rate. Temperatures were fairly uniform within the building with a slight increase from the intake (~27°C) to the exhaust of the building (~30°C) and reflected warmer conditions outdoors (mean outdoor temperature = 26°C). Compared to other seasons, the large volume of fresh air diluted mass and carbon dioxide to low and fairly uniform concentrations inside the building. An exception was the higher mass concentration, comparable to those observed in winter, in the right, exhaust-end of the building (Fig. 2B). These higher mass concentrations may be transient in nature from increased local swine activity or feeding. However, they follow the general trend that contaminants should increase if clean air moves through the facility in relatively plug flow.

This work and that of others show that dust concentrations are highest in large, tunnel-ventilated swine barns when outdoor temperatures are low. The spatial gradients in mass concentration by season observed in our work are consistent with those of Jerez (Jerez, 2007), who mapped total suspended mass concentrations in a modern swine building of mixed use and roughly double the capacity of the current study. Similar to our work, Jarez observed mass concentrations to be higher and more uniform in winter than in summer. She also observed concentrations to be lowest at the intake and highest near the exhaust in summer. Jerez did not measure concentrations in spring when we observed the highest spatial variability in mass concentrations, temperatures, and carbon dioxide concentrations.

In contrast to our study, Jarez observed higher mass concentrations near the end wall intake than near the exhaust fans in winter. Unlike the barn in this study, that studied by Jarez was designed to allow fresh air to enter through baffled ceiling inlets in addition to the end wall intake. Consequently, in winter when ventilation rates were low, fresh air may have preferentially entered the barn and diluted mass concentrations nearer to the fans. The ratio of mass concentrations in summer to those in winter was substantially greater in the Jarez study (~50%) than observed in this study (~25%). Although possibly related to many factors (e.g., barn size, ventilation rates, feeding methods, and animal activity), this difference is consistent with increased dust resuspension from higher swine activity in the large pens (40 swine per pen) used in the building studied by Jerez compared to our study (one swine per pen).

The finding that mass concentrations were highest in winter and lowest in summer is consistent with personal inhalable exposures measured in the same facility (O’Shaughnessy et al., 2010). In the previous study, personal IOM-measured inhalable mass exposures were observed as follows: winter GM = 3.8mg m−3, GSD = 1.91; spring GM = 2.5mg m−3, GSD = 1.56; summer GM = 0.83mg m−3, GSD = 1.91. However, these personal inhalable exposures were substantially greater than the mass concentrations obtained in this study during mapping. The ratios of GM concentrations measured with inhalable samplers in the O’Shaughnessy study to those measured in this study during mapping were 7.6 in winter, 8.3 in spring, and 6.4 in summer. This discrepancy may be due to the fact that workers interact with the animals, increasing their activity and dust resuspension, which causes personal exposures to be higher than area measurements like those conducted in this study.

The fact that mass concentrations measured at stationary locations (Table 2) were consistent with the results from mapping (Fig. 2) helps to show that mapping can be used to investigate spatial and temporal patterns in this type of environment. Stationary monitoring and mapping yielded similar spatial patterns with generally the lowest concentrations near the intake and highest concentrations near the exhaust. They also yielded similar rank ordering of concentrations by season with highest concentrations in winter and lowest in spring.

Information provided in Table 3 may be useful in making decisions regarding the ventilation system. Currently, fans are activated exclusively with temperature sensors that indicate when thermal loads will adversely affect the gestating sows. Use of contaminant sensors, such as those for particulates, to activate fans may help growers reduce contaminant exposures to workers and their sows. The set of five stationary samplers underestimated the mapped concentrations for particulates for every condition (Table 3). Although the mapping data has unresolved temporal bias and the stationary samplers have spatial bias, the relative agreement in rank order indicate that each one provides a reasonable representation of concentrations throughout this barn. However, designing a control system using a safety factor of two (to accommodate the 50% between-method uncertainty) is reasonable. Using this same table, however, we see that the single central position overestimated mapping concentrations in winter (42%) and underestimated mapping concentrations in spring and summer. This result indicates that a single dust sensor to characterize the air quality within a large barn may be insufficient to estimate whole-barn concentrations or to make decisions to actuate a ventilation system to control dust concentrations. As summarized in Table 3, GM and C84% mass concentrations measured with stationary samplers were within ± 50% of those obtained through mapping.

This result is important because it suggests that there were no large temporal shifts in mass concentrations during mapping events, although maps were constructed from 2-min monitoring in each location. Thus, mapping in this environment is a reasonable way to obtain greater spatial information with fewer instruments than is possible with stationary monitoring, despite the fact that mass concentrations can change temporally during mapping. In this work, the issue of temporal changes was partially resolved by averaging the measurements obtained by two technicians who took measurements at the same location at different times, although averaging was not possible for the summer data.

The use of mapping with multiple instruments allowed us to rapidly measure mass concentrations simultaneously with indoor air quality variables (temperatures and CO2 concentrations). The addition of these indoor air quality variables is useful in relating contaminant concentrations (e.g., dust) to building ventilation. The addition of carbon dioxide is particularly useful when studying an environment with large animals in a densely packed environment. The fact that carbon dioxide is emitted from swine as a byproduct of respiration helped to clearly identify that mass concentrations in this facility were related to the presence of swine.

Carbon dioxide concentrations may be a reasonable surrogate for mass concentrations measured with a photometer in a swine barn. A moderately strong linear relationship (R2 = 0.60) was observed between the log of mass concentrations measured with the photometer and the log of carbon dioxide concentrations measured with the indoor air quality monitor. Carbon dioxide monitors are relatively inexpensive compared to photometers and, consequently, may represent an attractive solution for monitoring indoor air quality in the swine barn setting. They may also prove more robust than photometers or ammonia monitors. The response of photometers and ammonia monitors has been shown to drift over time when applied to swine barns (O’Shaughnessy et al., 2002).

We provide evidence that dust concentrations in swine barns are dictated to a great extent by ventilation rates. Ventilation in these buildings, however, is controlled exclusively to maintain temperatures within certain bounds. An alternative strategy may be to use carbon dioxide monitors and thermometers to trigger on ventilation to control both contaminants and temperature in a swine barn. This approach would potentially require substantial heating of intake air, which may be prohibitively expensive unless air from within the building is cleaned and recirculated. Such approaches are used commonly in factories but have not been applied to swine barns. Lowering contaminant concentrations in swine barns may benefit worker health and improve swine heard health. Our work may also help identify where contaminant monitors should be placed within the building. Positioning a contaminant monitor near the intake would likely be inappropriate because contaminant levels would be consistently underestimated compared to the mean concentration. A position in the center of the barn or near the exhaust would better represent contaminant levels in the barn, although a central monitor would likely bias estimates high compared to the mean concentration in winter (Table 3). Further work along these lines could include integration of other variables, such as outdoor air temperature, along with carbon dioxide as predictors of contaminant concentrations. Further work would also be needed to evaluate the robustness of carbon dioxide monitors in swine barns.

This work is limited in that measurements were made in only one type of swine building used for gestation with one kind of ventilation. Inhalable mass concentration with IOM samplers at stationary locations were not performed although they would have been useful to help evaluate the accuracy of mapping and stationary measurements. The fact that one mapping event was compromised in summer reduces our estimates of spatial variability for that season. However, lower spatial variability is expected when ventilation rates are high as they commonly are in the summer when temperatures are high. We did not measure total flow through the building or ammonia, which is another contaminant of concern from a health outcomes standpoint. However, the fact that our results match well with those of others who have studied dust concentrations in modern barns provides evidence of generalizability of our results.

Although outside the scope of the current study, further analysis of the data collected in this study can be conducted to inform methods used to estimate exposures with data from direct-reading instruments. We have used the maps in Figs. 2 through 4 to provide for visualization of concentrations. However, our data could be used to investigate the uncertainty associated with the various ways to produce maps to inform best practices for future work. Given that we have both stationary and mapping measurements, it could also be used to evaluate the impact of temporal variation in the data on estimates made from mapping.

Conclusion

Dust mass concentrations, temperatures, and carbon dioxide concentrations were mapped in a modern, 1048-pen swine gestation barn in winter, spring, and summer. Mass and carbon dioxide concentrations were highest winter and fairly uniform when building ventilation rates were low (0.34 m s−1 ave) to conserve heat within the building. Concentrations were lowest in summer when ventilation rates were high to provide cooling (1 m s−1 ave). These results show that ventilation can effectively reduce contaminant levels. Mass concentrations obtained in mapping were generally consistent with those obtained from stationary monitors. A moderately strong linear relationship (R2 = 0.60) was observed between the log of photometer-measured mass concentration and the log of carbon dioxide concentration, suggesting that carbon dioxide may be an inexpensive alternative to assessing air quality in a swine barn. These results show that ventilation can effectively reduce contaminant levels in addition to controlling temperature.

Supplementary Material

Acknowledgments

FUNDING

This work was supported by the National Institute for Occupational Safety and Health through funds supplied to the Great Plains Center for Agricultural Health (U50 OH007548-06).

References

- Barber E, Dawson J, Battams V, Nicol R. Spatial variability of airborne and settled dust in a piggery. J Agr Eng Res. 1991;50:107–127. [Google Scholar]

- Donham KJ, Reynolds SJ, Whitten P, Merchant JA, Burmeister L, Popendorf WJ. Respiratory dysfunction in swine production facility workers: dose–response relationships of environmental exposures and pulmonary function. Am J Ind Med; 1995;27(3):405–418. doi: 10.1002/ajim.4700270309. [DOI] [PubMed] [Google Scholar]

- Ventilation of agricultural structures. American Society of Agricultural Engineers; St Joseph, MI: 1983. p. 372. [Google Scholar]

- Hinz T, Linke S. A comprehensive experimental study of aerial pollutants in and emissions from livestock buildings. Part 2: Results. J Agr Eng Res; 1998;70(1):119–129. [Google Scholar]

- Iversen M, Dahl R. Working in swine-confinement buildings causes an accelerated decline in FEV1: A 7-yr follow-up of Danish farmers. Eur Respir J; 2000;16(3):404–408. doi: 10.1034/j.1399-3003.2000.016003404.x. [DOI] [PubMed] [Google Scholar]

- Jerez SB. PhD. University of Illinois; Urbana-Champaign: 2007. Airborne pollutant spatial distribution, emission, and ventilation effectiveness for mechanically ventilated livestock buildings. [Google Scholar]

- Koehler KA, Volckens J. Prospects and pitfalls of occupational hazard mapping: “between these lines there be dragons”. Ann Occup Hyg. 2011;55(8):829–840. doi: 10.1093/annhyg/mer063. [DOI] [PubMed] [Google Scholar]

- Larsson KA, Eklund AG, Hansson LO, Isaksson BM, Malmberg PO. Swine dust causes intense airways inflammation in healthy subjects. Am J Resp Crit Care Med. 1994;150(4):973. doi: 10.1164/ajrccm.150.4.7921472. [DOI] [PubMed] [Google Scholar]

- O’Shaughnessy P, Achutan C, Karsten A. Temporal variation of indoor air quality in an enclosed swine confinement building. J Agric Safety Health; 2002;8(4):349–364. doi: 10.13031/2013.10217. [DOI] [PubMed] [Google Scholar]

- O’Shaughnessy PT, Donham KJ, Peters TM, Taylor C, Altmaier R, Kelly KM. A task-specific assessment of Swine worker exposure to airborne dust. J Occup Environ Hyg; 2010;7(1):7–13. doi: 10.1080/15459620903327970. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Park JY, Ramachandran G, Raynor PC, Olson GM., Jr Determination of particle concentration rankings by spatial mapping of particle surface area, number, and mass concentrations in a restaurant and a die casting plant. J Occup Environ Hyg. 2010;7(8):466. doi: 10.1080/15459624.2010.485263. [DOI] [PubMed] [Google Scholar]

- Pedersen B, Iversen M, Bundgaard Larsen B, Dahl R. Pig farmers have signs of bronchial inflammation and increased numbers of lymphocytes and neutrophils in BAL fluid. Euro Resp J. 1996;9(3):524. [PubMed] [Google Scholar]

- Peters TM, Heitbrink WA, Evans DE, Slavin TJ, Maynard AD. The mapping of fine and ultrafine particle concentrations in an engine machining and assembly facility. Ann Occup Hyg; 2006;50(3):249–257. doi: 10.1093/annhyg/mei061. [DOI] [PubMed] [Google Scholar]

- Vogelzang PFJ, van der Gulden JWJ, Folgering H, Heederik D, Tielen MJM, van Schayck CP. Longitudinal changes in bronchial responsiveness associated with swine confinement dust exposure*. Chest. 2000;117(5):1488. doi: 10.1378/chest.117.5.1488. [DOI] [PubMed] [Google Scholar]

- Vosburgh DJH, Boysen DA, Oleson JJ, Peters TM. Airborne nanoparticle concentrations in the manufacturing of polytetrafluoroethylene (PTFE) apparel. J Occup Environ Hyg. 2011;8(3):139–146. doi: 10.1080/15459624.2011.554317. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang X, Zhang Y, Riskowski G, Ellis M. Measure ment and analysis of dust spatial distribution in a mechanically ventilated pig building. Biosyst Eng. 2002;81:225–236. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.