Abstract

The increasing use of robots in performing tasks alongside or together with human coworkers raises novel occupational safety and health issues. The new 21st century workplace will be one in which occupational robotics plays an increasing role. This paper describes the increasing complexity of robots and proposes a number of recommendations for the practice of safe occupational robotics.

Keywords: service robots, industrial robots, collaborative robots, occupational safety, risk mitigation, risk assessment, workplace, workers

INTRODUCTION

Robots are used in increasing numbers in the workplace and in society in general. As their capabilities increase, there is interest in ensuring that the rise of robots will not spell “doom for humanity”.(1) However, a more immediate and pressing need is to ensure that the increasing deployment of robot workers does not bring new risks for human workers. This is further emphasized by continuing headlines about workers injured or killed by robots.(2) In his 1942 story “Runaround,” Isaac Asimov set out three laws of robotics. The three laws were quoted as being from the “Handbook of Robotics, 56th Edition, 2058 A.D.”(3) Of importance for occupational safety is the first law, “a robot may not injure a human being or, through inaction, allow a human being to come to harm.” How well is Asimov’s first law of robotics being applied as robots take on more tasks in the 21st century workplace?

The term “robot” first appeared in a science fiction play “R.U.R.” by Karel Čapek in 1920.(4) The word “robot” has a common root in Slavic languages. It originates from an Old Church Slavonic word, “rabota,” which means “servitude”,(5) and now means “work” in many modern Slavic languages. In the play, this term refers to artificial “people” who were created to perform work for humans. Today, the term robot is generally used to describe a machine which is programmable by computer algorithms to perform simple and complex tasks, and, in some cases, is capable of modifying tasks in response to changes in the robot’s external environment. This latter capability distinguishes robots from automated machines.

The complexity of tasks performed by robots, and the degree of their autonomy and self-learning capabilities, have been steadily increasing since the creation of the first industrial robot in 1937.(6) Presently, there are three categories of robots: (1) industrial robots; (2) professional and personal service robots; and (3) collaborative robots. A new, and largely experimental category of robot workers is emerging, called managerial robots.

The initial wave of industrial robots were introduced in the 1970s when they began to be used in the manufacturing sector for assembling automobiles. The second robot wave took off at the turn of the 21st century with the introduction of service robots. It was facilitated by the increasing autonomy and sensory capabilities of robots coupled with decreasing cost and size of microprocessor controllers, which led to the development of mobile robots capable of autonomous operation in unfamiliar environments such as disaster zones (“drones”). With the availability of relatively inexpensive collaborative robots capable of working in direct contact with people, we are now entering the third robot wave where robotic workers operate alongside human workers and symbiotic workers, i.e., human workers equipped with performance-enhancing robotic devices such as robotic exoskeletons and other capacity-enhancing prostheses.

As more robots, especially those who are mobile, come into direct contact with workers, concerns about the safety profile of the worker-robot interaction space has increased. Historically, human workers are the first to experience the adverse effects of any new technology. In addition, the duration of human workers’ exposure to new technologies is often greater than is that in the general population. In this paper, we describe approaches and recommendations to ensuring human worker safety in the new 21st century workplace where both human and robot workers can be found.

DISCUSSION

Industrial Robots

The International Organization for Standardization (ISO) defines industrial robot as “an automatically controlled, reprogrammable, multipurpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications”.(7) Industrial robots are characterized by high strength, endurance and precision and are widely used for welding, painting, assembling, moving, and testing.

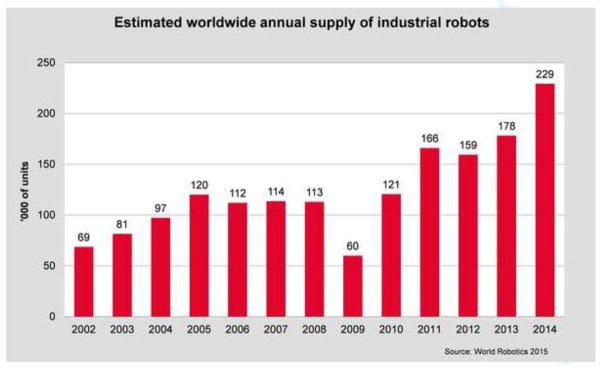

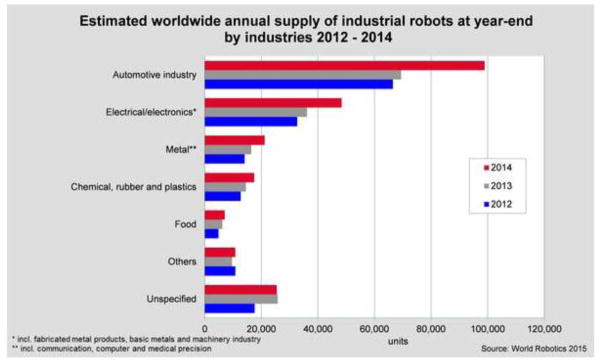

The International Federation of Robotics (IFR) publishes statistics of robot installation around the world.(8) According to IFR, industrial robot sales increased by 29% to 229,261 units in 2014 compared to 2013 and the average robot sales increase between 2010 and 2014 was 17% per year (see Figure 1). Sales of industrial robots to the automotive and the electrical/electronics industry contributed most to the growth in 2014 (see Figure 2). China leads the robot market with a share of 25% of the total supply in 2014. About 70% of the total robot sales in 2014 were in China, Japan, the United States, the Republic of Korea and Germany.(8)

FIGURE 1.

Annual sales of industrial robots.(8) (Reproduced with permission from IFR.)

FIGURE 2.

Sales of industrial robots by industries.(8) (Reproduced with permission from IFR.)

Most of industrial robots are unaware of their surroundings, therefore, they can be dangerous to people. Industrial robots can pose several types of hazards based on their origin: (1) mechanical hazards such as those arising from unintended and unexpected movements or release of tools; (2) electrical hazards such as contacts with live parts or connections or exposure to arc flash; (3) thermal hazards such as those associated with hot surfaces or exposure to extreme temperatures; 4) noise hazards; and (5) other hazards such as vibration, radiation, and chemicals.(9)

There are two main categories of worker injuries from working around industrial robots—those due to engineering errors and human errors. Engineering errors include errors in the robot’s mechanics (e.g., loose connections across parts, faulty electronics), errors made by the controller (e.g., programming bugs, faulty algorithm). As a consequence, robots might, for example, fail to stop, or a robot arm might achieve high, uncontrolled speed, abrupt motion or acceleration.(10) Human sources of injuries such as errors in programming, interfacing peripheral equipment, connecting input/output sensors, can all result in unpredicted movement or action by the robot which can result in personnel injury or equipment breakage. Human errors in judgment result frequently from incorrectly activating the teach pendant or control panel. The greatest human judgment error results from becoming so familiar with the robot’s redundant motions that personnel are too trusting in assuming the nature of these motions and place themselves in hazardous positions while programming or performing maintenance within the robot’s work zone.(11)

There are few reports detailing incidents involving robots. A widely cited 1987 report analyzed 32 reported cases of robot incidents.(12) Reported findings indicate that line workers (23 cases) are at greatest risk, followed by maintenance workers (6 cases) and programmers (3 cases). Pinch-point injuries accounted for 56% of all injury events, while impact injuries accounted for 44%. Most injuries were caused by poor workplace design (20 of 32 injury events) and human error (13 of 32 injury events).

The main approach to the industrial robot safety is maintenance of a safe distance between human workers and operating robots through the creation of “guarded areas.” Worker entrance into the safe guarded area would require a shutdown of the robot. Shutdown of one robot for safety reasons, in an assembly line of robots, can impair productivity and may be a disincentive to achieving the highest level of safety for the human worker.

More detailed recommendations regarding the design of industrial robotic systems, the training of workers, and their supervision can be found in the NIOSH publication, “Preventing the Injury of Workers by Robots.”(13) For the design of industrial robotic systems, NIOSH recommended that robotic systems include: (1) physical barriers that incorporate gates with electrical interlocks and backup sensors stopping robots when the gate is open; (2) barriers between robotic equipment and any freestanding objects to eliminate pinch points; (3) adequate clearance distances around all moving components of the robot; (4) remote diagnostic equipment; (5) adequate illumination around the robot working area; and (6) clearly visible marks on working surfaces or floors that indicate the zones of maximum robot movement. Safety training and refresher courses specific to the particular robot in question should be provided to human workers who will be programming, operating, or maintaining robot workers. Supervisors should ensure that workers do not enter the operational area of a robot without first putting the robot on “hold,” in a “power down” condition, or at a reduced operating speed mode, and ensure that workers doing automated tasks are closely supervised (e.g., video monitored).

There are several reasons why human workers enter robot worker operating areas such as to set up a job, to re-program the robot, to inspect the robot operational system, or for routine maintenance. The injuries which have occurred to human workers have happened most frequently when corrective maintenance was being done. NIOSH technical report, “Safe Maintenance Guidelines for Robotic Workstations,” describes approaches for preventing injury due to unexpected or unintended robot motion to workers whose job is to correct problems with the normal operation of robotized industrial systems.(14) One recommended systematic approach to selecting safeguards and setting safety procedures is the Structured Analysis and Design Technique (SADT). This is a general problem-solving tool relying on a box-and-arrow diagramming methodology for organizing and analysis of complex problems. In SADT the analysis of any robot worker problem, such as achieving the goal of robot maintenance intervention without human worker injury, is carried out according to a descending, modular, hierarchic, and structured logic. SADT models include both objects (documents, products, information, and data) and activities (performed by people, machines, or programs).

The American National Standards Institute (ANSI) and the U.S.-based Robotics Industry Association (RIA) published the first robotic safety standard for industrial robots in 1986 as ANSI/RIA R15.06 “American National Standard for Industrial Robots and Robot Systems – Safety requirements”(15) Major international standards for robots are developed by the ISO Technical Committee (TC) 184 (Automation systems and integration) Sub-Committee (SC) 2 on Robots and robotic devices. Under this subcommittee, three working groups (WG) develop standards on the safety of robots: (1) Working Group 3 (WG3), Industrial Safety; (2) Working Group 7 (WG7), Personal Care Robot Safety; and (3) Joint Working Group 9 (JWG9), Safety for Medical Devices using Robotic Technology.

Sub-Committee 2 has published a standard (in two parts) dealing with the safety of industrial robots: (1) ISO 10218-1:2011 “Safety requirements for industrial robots -- Part 1: Robots;”(9) and (2) ISO 10218-2:2011 “Safety requirements for industrial robots -- Part 2: Robot systems and integration.”(16) These standards originate from a standard developed by RIA and published in 1999 by ANSI as ANSI/RIA R15.06 “Safety of Robots, Integration of Robots, Robot Systems, Robot Cells.”(17) The ANSI/RIA R15.06 was updated in 2012 as “Industrial Robots and Robot Systems- Safety Requirements” to include robot collaboration (see discussion in chapter Collaborative Robots).(18)

Despite improvements in the safety of industrial robots, injuries and fatalities caused by industrial robots still occur. Most recently, a German newspaper (Hessische/Niedersächsische Allgemeine, HNA) reported that a worker, an employee of a third-party contractor, was killed while installing an industrial robot at a Volkswagen assembly line on June 30, 2015 in Baunatal, Germany.(19) The robot gripped and pressed him up against a metal plate, crushing his chest. Despite efforts to revive him, the worker later died at a hospital.(2) It is unclear whether this fatality was caused by engineering error or human error. This case and others of workplace incidents involving industrial robots suggest that additional redundancies in the safety mechanisms of industrial robots may be warranted.

Professional (and Personal) Service Robots

The ISO defines a service robot as one that performs useful tasks for humans or equipment excluding industrial automation applications. Professional service robots are further differentiated as a service robot used for commercial tasks, usually operated by a properly trained operator,(7) while personal service robots are used for non-commercial tasks. Similar to industrial robots, professional service robots manipulate and navigate their physical environments. However, unlike industrial robots, professional service robots operate mostly outside industrial settings in unstructured and highly unpredictable environments without people such as disaster areas or with people present such as hospitals. Professional service robots introduced in the initial wave are also commonly referred to as “drones.”

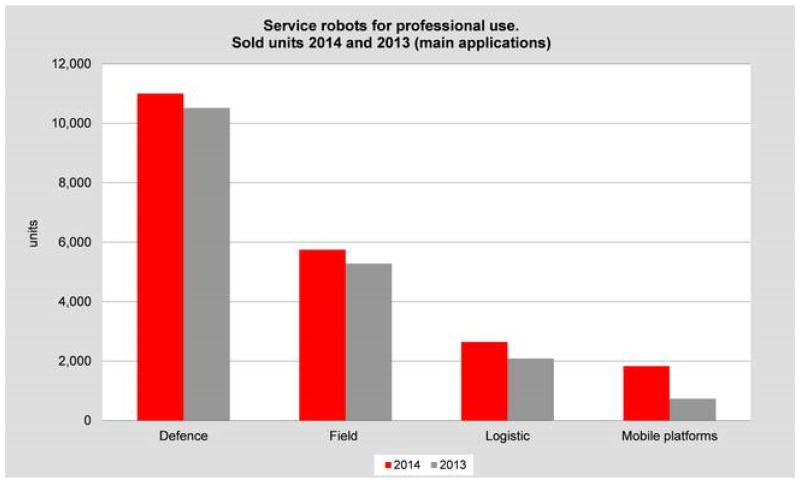

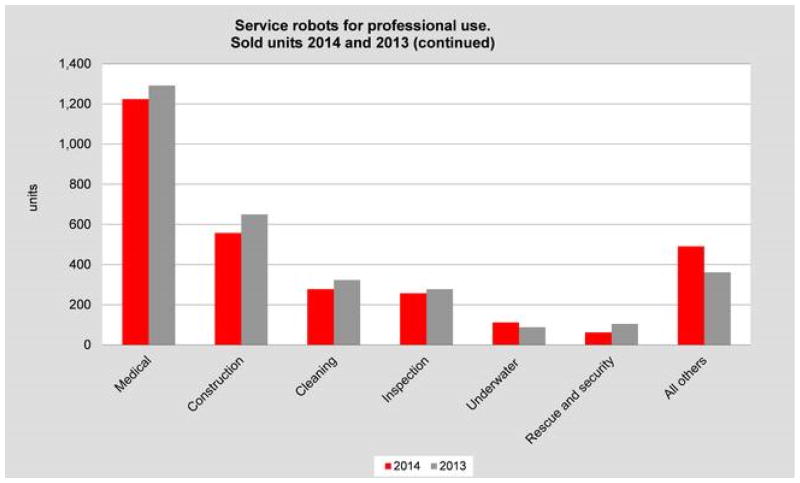

According to the IFR, from 1998 to 2014 about 172,000 service robots for professional use were sold.(20) In 2014 the total number of professional service robots increased by 11.5% to 24,207 compared to 2013, demonstrating the accelerating rate of increase in professional service robot sales. However, just a few main application areas make up most of the sales volume. With about 11,000 units, service robots in defense applications accounted for 45% of the total number of service robots for professional use sold in 2014. Other professional service robots by application areas include agriculture/field (24%), logistic systems (11%), medical/healthcare (5%), and mobile platforms (7%) (Figures 3 and 4).

FIGURE 3.

Sales of professional service robots in 2013 and 2014.(20) (Reproduced with permission from IFR.)

FIGURE 4.

Professional service robots in 2013 and 2014.(20) (Reproduced with permission from IFR.)

Physical proximity between professional service robots and human workers are much more common than between industrial robots and workers since they often share the same workspace. Therefore, worker isolation from the professional service robot is no longer an option as the main safety approach. Furthermore, more complex environments in which professional service robots must operate dictate much higher degree of autonomy and mobility afforded to professional service robots. This autonomous and mobile behavior can result in dangerous situations for workers. Therefore robot designers must consider physical, social and ethical implications of such autonomy.(21) For example, people seem to perceive autonomous robots, especially those with “humanoid” features, differently than they do with most other computer technologies. People tend to “over-attribute” to such robots more human-like qualities and capabilities than they actually have(22) and commonly give them human-type names.(23)

Professional service robots such as tele-operated robots commonly interact unidirectionally with their human operators. In this mode of interaction, the operator controls the robot which sends back information about its environment and its task.(24) For such professional service robots their interaction with workers is very limited and inactivation of robot for servicing can be used to minimize risks during maintenance. Most of professional and personal service robots operating autonomously are equipped with collision detection and avoidance systems,(25) which reduce the possibility of a harmful physical contact during unplanned encounters with human workers. Other approaches to minimizing risks of service robots are reducing their weight, size and operating speeds and forces. However, these approaches cannot completely eliminate collisions and other methods for improving safety are necessary.(26) In addition to engineering and human sources of injuries, adverse environmental factors such as extreme temperature, poor sensing in difficult weather or lightning conditions can lead to incorrect response by service robots and can be a source of injury.(10) Yet, despite the proliferation of safety concerns involving service robot workers in the same workplace as human workers, no international standards have been developed to address human worker safety in maintaining or operating professional and personal service robots.

Collaborative Robots

The ISO has defined a collaborative robot as “a robot designed for direct interaction with a human”.(7) Depending on the application area, collaborative robots could be any of the three types of robots described previously, industrial, professional, or personal service robot. For example, the ISO Draft Technical Specification (DTS) 15066 “Safety requirements for industrial robots -- Collaborative operation” defines industrial collaborative robots as operating within a defined collaborative workspace, where the collaborative workspace is defined as a workspace within a safeguarded space where the robot and a human worker can perform tasks simultaneously during production operation.

Collaborative robots strive to combine the dexterity, flexibility and problem-solving skills of human workers with the strength, endurance and precision of a mechanical robots. In 2007, Pilz GmbH & Company launched a multi-camera computer system that monitors the area surrounding robots and adjusts their behavior accordingly. The system, called SafetyEYE, allows a robot to perform tasks without sectioning off the entire area from human workers. Thus, this system allows robots to perform their tasks collaboratively with human workers in the same workspace. A robot equipped with such a system can move around freely, but can slow its movements if a worker approaches or, if the robot gets too close to the human worker, stop altogether without disrupting activities of the entire workspace.(27)

In 2009, Universal Robots of Denmark launched the UR5 collaborative robot, initially available on the Danish and German markets only.(28) In 2011, a first humanoid collaborative robot, R2B, was launched into space to work alongside astronauts and cosmonauts on board of the International Space Station.(29) By 2012, several car manufactures deployed collaborative robots on their assembly lines. For example, in December 2012, German carmaker BMW introduced a slow-moving collaborative robot in its factory in Spartanburg, South Carolina, which co-operates along with a human worker to insulate and water-seal vehicle doors.(27) The robot spreads out and glues down material that is held in place by the human worker’s more agile fingers.

A new field of collaborative robotics is managerial robotics. Instead of being relegated to mundane, repetitive, and precise job tasks, researchers are increasingly wondering if robots with their perfect memories, internet connectivity and high-powered computers for data analysis can also keep “a perfect record of project progress, provide real-time scheduling and decision support, and hold perfect recall (and remind others) of complex policies and procedures, all while communicating with people in a natural, social way.”(30) Researchers have shown that correlations between autonomy and sociality for collaborative robots could lead to robots succeeding in particular management roles.(31)

Since robots are working alongside human workers, isolation as a safety measure is no longer an option, and other safety approaches must be developed and implemented (e.g., proximity sensors, appropriate materials, software tools, and similar controls).(10) Workspace sharing without any resultant harm to human workers (and to robot itself) has been the goal of research in the domain of physical and cognitive human robot interactions. The research on physical safety of human and robot workers in the collaborative space falls into three categories:(32) (1) interaction safety assessment and the quantitative description of the human-robot safety concept;(33) (2) interaction safety through design, such as lightweight manipulators, passive compliant systems, safe actuators, and passive robotic systems; and (3) interaction safety through planning and control such as navigation and collision avoidance in an environment shared by human and robot through proactive safety systems and control of the stiffness/pliability to reduce the impact force during collisions.(34)

Cognitive interactions between a robot and a human worker can lead to mental health risks for the human worker. As the definition implies, collaborative robots interact bi-directionally with their human collaborators. In this new mode of interaction, the information exchange between human workers and robots flows in both directions and is on an equal level of importance with regard to work processes for both workers—human and robot.

In this new workplace, the design of robots should ensure that the motions of the robot are predictable to human and do not cause any unpleasant reactions like fear, shock, or surprise. The ability to read human emotions is a capability which would not only improve the functionality of collaborative robots, but also improve their safety profile. Several methods are being investigated such as behavior pattern recognition, on-skin sensors or other similar methods that would enhance the ability of a robot to “read” human emotion.(35)

Another example of novel approaches to improve the emotional safety profile of collaborative robots is the ability of certain models of collaborative robots “to act like a human worker.” For example, the robot could have an “eye” looking in the direction of the human worker and be able to react to the human worker’s facial expressions indicating danger, distress or fear. Though such capabilities also bring new safety issues with them, e.g., human workers might unintentionally attribute non-existent “reasoning” or “recognition” capabilities to robots.(36)

These enhanced capabilities are being developed in the area of collaborative “humanoid” robots. Humanoid robots, by virtue of their appearance and behavior, appeal to people differently than other robots.(37) A 2004 study of cognitive interactions suggests that humanoid robots may be appropriate for settings in which people have to delegate responsibility to robots or when the task is too demanding for a human worker to do.(38) Machine-like robots, as opposed to humanoid robots, however, may be more appropriate when robots are expected to be unreliable, are less well-equipped for the task than people are, or in other situations in which personal responsibility should be emphasized.

As workplace risks are addressed proactively,(39) international safety standards for collaborative robots are being developed in parallel with their rapid introduction into the workplace. Specifically, while the published ISO 10218 provides some specific guidelines for collaborative robots, ISO TC 184 SC 2 is also developing the 15066 standard on collaborative operation as a Technical Specification (TS), which is one level below an International Standard (IS). This is a reflection of the nascent nature of collaborative robots in the workplace, as more application knowledge is needed before publishing this standard as an IS. Some of the issues being standardized in this TS include guidance on the maximum force with which a robot worker may strike a human worker (“power and force limiting“), and guidance on “speed and separation monitoring,” which allows for correlation in real-time of increasing danger in robot actions with decreasing distance between people and the robot.(40) The latter issue was not covered in another standard developed by ISO, TC 184 SC 2 and published in 2014, ISO 13482 “Robots and robotic devices -- Safety requirements for personal care robots.”(41)

Personal care robots is an example of collaborative robots as they are designed for direct human-robot physical contact. This ISO standard distinguishes three types of personal care robots: mobile servant robot, physical assistant robot (exoskeleton robots), and person carrier robot. These robots typically perform tasks to improve the quality of life of intended users, regardless of age or capability. The ISO standard describes hazards associated with the use of each of these three robot types, and provides requirements to eliminate, or reduce, the risks associated with these hazards to an acceptable level. Thus, ISO 13482:2014 does not include workplace safety considerations for personal care robots used in home settings, such as their maintenance or interaction of personal care robots with home healthcare workers.(41)

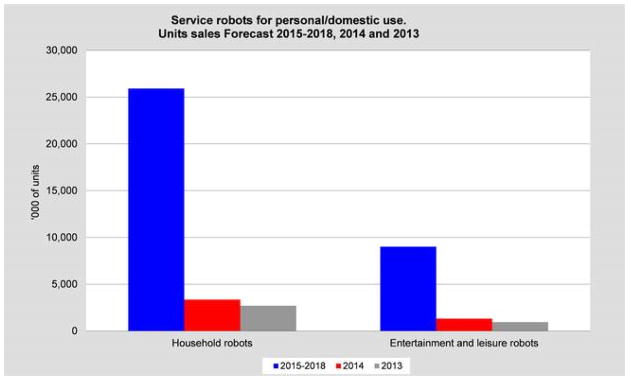

The IFR estimated that about 4.7 million personal service robots were sold in 2014 that is 28% more than in 2013 (see Figure 5). Two major application areas of personal service robots include household robots (e.g. vacuum and floor cleaning and lawn-mowing) and entertainment and leisure robots (e.g. toys and hobby systems).(20)

FIGURE 5.

Personal service robots in 2013, 2014 and 2015–2018.(20) (Reproduced with permission from IFR.)

The IFR projected that sales of personal service robots would reach 35 million units in the 2015–2018 period, while 152,400 units of professional service robots would be installed in the same period.(20) New applications for service robots in the workplace are increasing. For example, there is an emerging use of exoskeleton robots to increase the strength and endurance of human workers.(42,43) With this dramatic increase in the number of service robots, their interaction with workers will also increase exponentially. Therefore, it is necessary to address the safety of these workers now before millions of potentially unsafe robot workers enter the 21st century workplace.

Occupational Robotics as a New Field in Occupational Safety and Health

Recent progress in mechanization modeling and algorithm computerization has resulted in the availability of affordable, dependable and functional robots for an increasing number of tasks both at home and in the workplace. Economic forces dictate the constant drive to increase productivity and reduce the costs of products and services.(44) These forces are leading to the replacement of human workers with robot workers as the costs of the latter fall below the costs of the former.(45) Replacing human workers with robots in hazardous operations can lead to improvements in workplace safety.(46) For example, if robots are able to replace human workers in the poultry processing facilities, the high incidence of musculoskeletal disorders and traumatic injuries to human workers could be reduced.(47) In addition, robots could be deployed to respond to extremely hazardous disaster areas, such as nuclear disaster sites, which would eliminate serious human worker exposures.(48) Further, in countries where the workforce is aging, such as Japan, the increasing use of robots for many work tasks is already occurring.(49) However positive these new uses may be for robots, there is also a host of concerns about the rise of robot workers, ranging from the increasing unemployment of human workers(45) to the destruction of human civilization by self-aware robots.(50) Arguments have been made that the present day technological revolution will not create enough jobs to substitute for the lost ones and the society is entering the new age of global unemployment.(45,51) Just as the first wave of robots eliminated many of blue collar jobs, the third wave of robots, collaborative robots, is predicted to eliminate many of white collar jobs. For example, a new start-up, Steel Collar Associates, based in Holland, Michigan, distributes Motoman dual-arm robots as “contract employees.” More creative jobs such as scientists, journalists, medical doctors and computer programmers are being replaced by robots due to the increasing sophistication of artificial intelligence through algorithm development. In addition to managerial robots, robots are beginning to take care of themselves and to replicate themselves.(52,53) Thus, the fear is that advanced robotics will result in fewer job options being available.(54)

The introduction of collaborative robots in the 21st century workplace are creating three different types of workers: (1) human workers; (2) robot workers; and (3) symbiotic workers, i.e., human workers equipped with performance-enhancing robotic devices such as robotic prostheses and exoskeletons. The increased complexity that is emerging in the 21st century with regard to the traditional occupational safety and health concept of “worker” requires the occupational safety and health community to broaden the traditional scope of risk management. Similar to another emerging technology, nanotechnology, any discussion of the emerging field of occupational robotics should include a discussion of the methods needed to do robotic hazard assessment and risk management, as well as managing the ethical issues impacting a workplace where human workers may be in the minority.(55)

The ethics of occupational robotics will be complex and there are already those who believe robots should be designed as “transparent artificial beings” which are able to “communicate with us about what they know, how they know it, and what they want”.(36) It may not be too early for occupational robotics to consider questions such as: (1) “How should a robot algorithm be structured to address the trade-off between the small probability of injury to a human versus the near-certainty of a large productivity cost?” (2) “Should such trade-offs be the subject of national safety and health standards?” Predictions have been made that robots equipped with advanced artificial intelligence will someday be capable of self-awareness. Science-fiction novels and movies have included self-aware robots. The most famous of these was the HAL 9000, a Heuristically programmed ALgorithmic computer Series, which was a sentient computer in the movie, “2001: A Space Odyssey.”(56) Even though no self-aware robots are on the market yet, it may not be too early for occupational safety and health professionals to begin a dialogue about the safety of these robots and the challenges they present to human workers.

CONCLUSIONS

The on-going introduction of advanced industrial, professional service and collaborative robots working alongside of human workers requires occupational safety and health professionals to take a proactive approach to the assessment and management of the risk profile of occupational robotics. Proactive risk management approaches developed for other emerging technologies such as nanotechnology could be applied to occupational robotic safety and health. The elements of a proactive approach include: (1) qualitative risk assessment; (2) the ability to adapt strategies and refine requirements; (3) an appropriate level of precaution; (4) global applicability; (5) the ability to elicit voluntary cooperation by companies; and (6) stakeholder involvement.(39) Similar to nanotechnology, international consensus standards might be useful to protect human workers through three major mechanisms: (1) nationalizing international consensus standards; (2) using the employer’s general duty to provide work free of recognized hazards; and (3) adopting international standards as voluntary guidance by government.(57) As with other emerging technologies, the proactive approach for occupational robotics provides an opportunity to address occupational safety and health at the earliest or design stage.(58)

To ensure that human workers are protected, the following measures are recommended for occupational robotics: (1) occupational safety and health professionals should be directly involved in the development of international standards aimed at ensuring safety of workplaces with human and robot workers; (2) workplace safety standards for maintenance, operation, and interaction with human workers, of professional, personal service and collaborative (including managerial) robots should be developed; (3) proactive approaches for establishing risk profiles of robotic workplaces should be developed; and (4) redundant safety measures should be developed and operationalized to protect human workers while performing maintenance tasks on robot workers. These measures, and others suggested by experts, should be examined now before millions of potentially unsafe robots enter the 21st century workplace.

In the Čapek’s play, robots rose up and demanded rights equal to those of the humans.(4) When humans refused to recognize robots as equal, they ended up being exterminated by robots. As we approach the increasing sophistication of artificial intelligent robots which have acquired self-awareness, calls have been made to start thinking about the threat of self-aware robots to humanity. Some scholars suggest that robots with artificial intelligence should be treated like people and given human rights including rights to life and safety.(59) Will the society grant intelligent robots worker protection rights? Time will tell. But, in the meantime, the time is now to take steps to ensure that everything is being done to make certain that human workers are fully protected against robots with increasing capabilities to create workplace risks.

Footnotes

Disclaimer: The findings and conclusions in this report are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health, the Centers for Disease Control and Prevention, or the U.S. Department of Health and Human Services.

References

- 1.Rawlinson K. Microsoft’s Bill Gates insists AI is a threat. [Accessed on April 28, 2015];BBC News. 2015 Jan 29; Available at http://www.bbc.com/news/31047780.

- 2.Brumfield B. Car assembly line robot kills worker in Germany. [accessed October 28, 2015];CNN. 2015 Jul 2; Available at http://www.cnn.com/2015/07/02/europe/germany-volkswagen-robot-kills-worker/

- 3.Asimov I. I, Robot. New York: Doubleday & Company; 1950. [Google Scholar]

- 4.Čapek K. In: R.U.R. (Rossum’s universal robots) Selver Paul, Playfair Nigel., translators. New York: Dover Publications; 2001. [Google Scholar]

- 5.Brugmann KA. In: Comparative Grammar of the Indo-Germanic Languages. A Concise Exposition of the History of Sanskrit, Old Iranian (Avestic and Old Persian), Old Armenian, Greek, Latin, Umbro-Samnitic, Old Irish, Gothic, Old High German, Lithuanian and Old Church Slavonic. I. Seymour Conway R, Rouse WHD, translators. II. B. Westermann & Co; New York: 1891. p. 241. Morphology (Stem-formation and inflexion) [Google Scholar]

- 6.Taylor GP. In: The Robot Gargantua. Johnson R, editor. Gargantua: Constructor Quarterly; 1995. [Google Scholar]

- 7.International Organization for Standardization (ISO) Robots and robotic devices – Vocabulary. Geneva, Switzerland: ISO; 2012. (ISO 8373:2012). [Standard] [Google Scholar]

- 8.International Federation of Robotics (IFR) [accessed October 28, 2015];World Robotics 2015 Industrial Robots. Available at http://www.ifr.org/

- 9.International Organization for Standardization (ISO) Safety requirements for industrial robots -- Part 1: Robots. Geneva, Switzerland: ISO; 2011. (ISO 10218-1:2011). [Standard] [Google Scholar]

- 10.Vasic M, Billard A. Safety Issues in Human-Robot Interactions. 2013 IEEE Int. Conf. Robotics Automation (ICRA); Karlsruhe, Germany. May 6–10, 2013; New York, N.Y: IEEE; 2013. pp. 197–204. [Google Scholar]

- 11.U.S. Occupational Safety and Health Administration (OSHA) [accessed October 28, 2015];Chapter 6 – Robotics in the workplace. Available at https://www.osha.gov/Publications/Mach_SafeGuard/chapt6.html.

- 12.Jiang BC, Gainer CA. A Cause-and-Effect Analysis of Robot Accidents. J Occ Accidents. 1987;9:27–45. [Google Scholar]

- 13.U.S. National Institute for Occupational Safety and Health (NIOSH) Preventing the injury of workers by robots. U.S. National Institute for Occupational Safety and Health; Dec, 1984. DHHS (NIOSH) Publication Number 85-103. [Google Scholar]

- 14.U.S. National Institute for Occupational Safety and Health (NIOSH) Safe maintenance guidelines for robotic workstations. U.S. National Institute for Occupational Safety and Health; Mar, 1988. DHHS (NIOSH) Publication Number 88-108. [Google Scholar]

- 15.American National Standards Institute (ANSI) American National Standard for Industrial Robots and Robot Systems – Safety requirements. New York, N.Y: ANSI; 1986. (ANSI/RIA R15.06:1986). [Standard] [Google Scholar]

- 16.International Organization for Standardization (ISO) Safety requirements for industrial robots -- Part 2: Robot systems and integration. Geneva, Switzerland: ISO; 2011. (ISO 10218-2:2011). [Standard] [Google Scholar]

- 17.American National Standards Institute (ANSI) Safety of Robots, Integration of Robots, Robot Systems, Robot Cells. New York, N.Y: ANSI; 1999. (ANSI/RIA R15.06:1999). [Standard] [Google Scholar]

- 18.American National Standards Institute (ANSI) Industrial Robots and Robot Systems-Safety Requirements. New York, N.Y: ANSI; 2012. (ANSI/RIA R15.06:2012). [Standard] [Google Scholar]

- 19.Kühling S. Unglück im VW-Werk Baunatal: Roboter tötet Arbeiter. [accessed August 5, 2015];HNA. 2015 Jul 1; Available at https://www.hna.de/kassel/kreis-kassel/baunatal-ort312516/roboter-toetet-arbeiter-vw-werk-5191637.html.

- 20.International Federation of Robotics (IFR) [accessed October 28, 2015];World Robotics 2015 Service Robots. Available at http://www.ifr.org/

- 21.Rogers E. Introduction to Human-Computer Interaction (HCI). RAS/IFRR Summer School on “Human-Robot Interaction”; Volterra, Italy. July 19–23, 2004; [accessed October 28, 2015]. Available at http://www.cas.kth.se/ras-ifrr-ss04/material/rogers-hci-intro.pdf. [Google Scholar]

- 22.Reeves N, Nass C. The Media Equation: How People Treat Computers, Television and New Media Like Real People and Places. Cambridge, Mass: Cambridge University Press; 1996. [Google Scholar]

- 23.Ramsey M. The Wall Street Journal. Apr 15, 2015. How factory workers learned to love their robot colleagues. [Google Scholar]

- 24.Thrun S. Toward a Framework for Human-Robot Interactions. Human-Computer Interaction. 2004;19(1–2):9–24. [Google Scholar]

- 25.Siegwart R, Nourbakhsh IR, Scaramuzza D. Introduction to Autonomous Mobile robots. 2. Cambridge, MA: The MIT Press; 2011. p. 472. [Google Scholar]

- 26.Zinn M, Khatib O, Roth B, Salisbury JK. Playing it safe. IEEE Robotics & Automation Magazine. 2004 Jun;:12–21. [Google Scholar]

- 27.Economist. Working with Robots: Our Friends Electric. [accessed October 28, 2015];The Economist. 2013 Sep 7; Available at http://www.economist.com/news/technology-quarterly/21584455-robotics-new-breed-robots-being-designed-collaborate-humans.

- 28.Bélanger-Barrette. Robotics’ history: from GM work floor to collaborative robots. [accessed August 5, 2015];Robotiq blog. 2015 Apr 24; Available at http://blog.robotiq.com/robotics-history-from-gm-workfloor-to-collaborative-robots.

- 29.U.S. National Aeronautics and Space Administration (NASA) [accessed August 5, 2015];Robonaut 2. Available at http://robonaut.jsc.nasa.gov/default.asp.

- 30.Young J, Cormier D. Can robots be managers, too? Harvard Business Review. 2014 Apr 2; [Google Scholar]

- 31.Gladden ME. Managerial robotics: a model of sociality and autonomy for robots managing human beings and machine. Int J Contemp Management. 2014;13(3):67–76. [Google Scholar]

- 32.Pervez A, Ryu J. Safe physical human robot interaction-past, present and future. J Mech Sci Tech. 2008;22:469–483. [Google Scholar]

- 33.Alami R, Albu-Schaeffer A, Bicchi A, Bischoff R, Chatila R, De Luca A, et al. Safe and Dependable Physical Human-Robot Interaction in Anthropic Domains: State of the Art and Challenges. Workshop on Physical Human-Robot Interaction in Anthropic Domains, IEEE/RSJ Int. Conf. on Intelligent Robots and Systems; 9–15 October; Bejing, China. New York, N.Y: IEEE; 2006. [Google Scholar]

- 34.Ribeiro L, Barata J, Barreira P. Is ambient intelligence a truly human-centric paradigm in industry? Current research and application scenario. Ent Work Inn Studies. 2009;5:25–53. [Google Scholar]

- 35.Roh E, Hwang BU, Kim D, Kim BY, Lee NE. Stretchable, Transparent, Ultrasensitive, and Patchable Strain Sensor for Human-Machine Interfaces Comprising a Nanohybrid of Carbon Nanotubes and Conductive Elastomers. ACS Nano. 2015;9(6):6252–6261. doi: 10.1021/acsnano.5b01613. [DOI] [PubMed] [Google Scholar]

- 36.Nourbakhsh IR. The Coming Robot Dystopia. [accessed July 27, 2015];Foreign Affairs. 2015 Jul-Aug;:23–28. Available at https://www.foreignaffairs.com/articles/2015-06-16/coming-robot-dystopia.

- 37.Fong T, Nourbakhsh I, Dautenhahn K. A survey of socially interactive robots. Rob Auton Sys. 2003;42(3–4):143–166. [Google Scholar]

- 38.Hinds PJ, Roberts TL, Jones H. Whose Job Is It Anyway? A Study of Human-Robot Interaction in a Collaborative Task. Human-Computer Interaction. 2004;19:151–181. [Google Scholar]

- 39.Murashov V, Howard J. Essential features for proactive risk management. Nature Nanotech. 2009;4:467–470. doi: 10.1038/nnano.2009.205. [DOI] [PubMed] [Google Scholar]

- 40.Kuhn S, Gecks T, Henrich D. Velocity control for safe robot guidance based on fused vision and force/torque data. 2006 IEEE Int. Conf. on Multisensor Fusion and Intelligent Systems; Heidelberg, Germany. September 2006; New York, N.Y: IEEE; 2006. pp. 485–492. [Google Scholar]

- 41.International Organization for Standardization (ISO) Robots and robotic devices -- Safety requirements for personal care robots. Geneva, Switzerland: ISO; 2014. (ISO 13482:2014). [Standard] [Google Scholar]

- 42.Bogue R. Robotic exoskeletons: a review of recent progress. Ind Robot: Int J. 2015;42(1):5–10. [Google Scholar]

- 43.Huen D, Liu J, Lo B. The IEEE Life Sciences Newsletter, May 2015. New York, N.Y: IEEE; 2015. [accessed August 5, 2015]. Assistive wearable robotics: healthcare’s new clothes. Available at http://www.lifesciences.ieee.org/publications/newsletter/may-2015/648-assistive-wearable-robotics-healthcare-s-new-clothes. [Google Scholar]

- 44.Graetz G, Michaels G. Robots at work (March 2015). CEPR Discussion Paper No. DP10477. [accessed October 28, 2015]; Available at http://ssrn.com/abstract=2575781.

- 45.Thompson D. A world without work. [accessed July 31, 2015];The Atlantic. 2015 Jul-Aug;:51–61. Available at http://www.theatlantic.com/magazine/archive/2015/07/world-without-work/395294/

- 46.U.S. National Institute for Occupational Safety and Health (NIOSH) NIOSH Update: NIOSH seeks proposals on robotics technologies for assisting in underground mining rescue efforts. U.S. National Institute for Occupational Safety and Health; Apr 28, 2014. [accessed August 5, 2015]. Available at http://www.cdc.gov/niosh/updates/upd-04-28-14.html. [Google Scholar]

- 47.McEachran R. Gribbot robot could take chicken deboning out of human hands. The Guardian. 2015 May 1; [Google Scholar]

- 48.Murphy RR. Disaster robotics. Cambridge, MA: The MIT Press; 2014. p. 240. [Google Scholar]

- 49.Ripley W. As Japan’s population ages, robots seen as workforce solution. [accessed August 5, 2015];CNN. 2015 Apr 25; Available at http://edition.cnn.com/2015/04/24/asia/japan-robots-work/index.html.

- 50.Future of Life Institute. [accessed October 28, 2015];Autonomous Weapons: an Open Letter from AI & Robotics Researchers. 2015 Jul 28; Available at http://futureoflife.org/AI/open_letter_autonomous_weapons.

- 51.Ford MR. Rise of the robots: technology and the threat of a jobless future. New York: Basic Books; 2015. [Google Scholar]

- 52.Zykov V, Mytilinaios E, Adams B, Lipson H. Robotics: Self-reproducing machines. Nature. 2005;435:163–164. doi: 10.1038/435163a. [DOI] [PubMed] [Google Scholar]

- 53.Ellery AA. AIAA SPACE 2015 Conference and Exposition. Reston, VA: American Institute of Aeronautics and Astronautics; 2015. Are Self-Replicating Machines Feasible? [Google Scholar]

- 54.Brynjolfsson E, McAfee A. Will humans go the way of horses? Foreign Affairs. 2015;94(4):8–14. [Google Scholar]

- 55.Schulte PA, Salamanca-Buentello F. Ethical and Scientific Issues of Nanotechnology in the Workplace. Env Health Persp. 2007;115(1):5–12. doi: 10.1289/ehp.9456. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Bostrom N. Superintelligence: Paths, Dangers, Strategies. Oxford, UK: Oxford University Press; 2014. [Google Scholar]

- 57.Murashov V, Howard J. Protecting Nanotechnology Workers While Waiting for Godot. J Occ Env Hygiene. 2013;10(8):D111–D115. doi: 10.1080/15459624.2013.803914. [DOI] [PubMed] [Google Scholar]

- 58.Schulte PA, Rinehart R, Okun A, Geraci C, Heidel DS. National Prevention through Design (PtD) Initiative. J Safety Res. 2008;39:115–121. doi: 10.1016/j.jsr.2008.02.021. [DOI] [PubMed] [Google Scholar]

- 59.Ashrafian H. Intelligent robots must uphold human rights. Nature. 2015;519:391. doi: 10.1038/519391a. [DOI] [PubMed] [Google Scholar]