Abstract

Background

Construction painters have not been studied well in terms of their hazards exposure. The objective of this study was to evaluate the exposure levels of total volatile organic compounds (TVOCs) for painters in the construction industry.

Methods

Activity-specific personal air samplings were carried out in three waterproofing activities [polyurethane (PU), asphalt, and cement mortar] and three painting activities (epoxy, oil based, and water based) by using organic-vapor-monitor passive-sampling devices. Gas chromatograph with flame ionization detector could be used for identifying and quantifying individual organic chemicals. The levels of TVOCs, by summing up 15 targeted substances, were expressed in exposure-index (EI) values.

Results

As arithmetic means in the order of concentration levels, the EIs of TVOCs in waterproofing works were 10.77, 2.42, 1.78, 1.68, 0.47, 0.07, and none detected (ND) for indoor PU-primer task, outdoor PU-primer task, outdoor PU-resin task, indoor PU-resin task, asphalt-primer task, asphalt-adhesive task, and cement-mortar task, respectively. The highest EI for painting works was 5.61 for indoor epoxy-primer task, followed by indoor epoxy-resin task (2.03), outdoor oil-based-spray-paint task (1.65), outdoor water-based-paint task (0.66), and indoor oil-based-paint task (0.15). Assuming that the operations were carried out continuously for 8 hours without breaks and by using the arithmetic means of EIs for each of the 12 tasks in this study, 58.3% (7 out of 12) exceeded the exposure limit of 100% (EI > 1.0), while 8.3% (1 out of 12) was in 50–100% of exposure limit (0.5 > EI > 1.0), and 4 tasks out of 12 were located in less than 50% of the limit range (EI < 0.5).

Conclusion

From this study, we recognized that construction painters are exposed to various solvents, including carcinogens and reproductive toxins, and the levels of TVOC concentration in many of the painting tasks exceeded the exposure limits. Construction workers need to be protected from chemical agents during their painting works by using personal protective devices and/or work practice measures. Additional studies should focus on the exposure assessment of other hazards for construction workers, in order to identify high-risk tasks and to improve hazardous work environments.

Keywords: construction painter, solvent exposure, total volatile organic compounds

1. Introduction

Solvent exposure is related to adverse disorders of the skin, lung, kidney, and nervous system [1]. Painters who are exposed to organic solvents have high rates of cancers than other workers; increased prevalence of neurotoxic effects; and elevated rates of slips, trips, and falls [2]. Construction painters are also known to suffer from respiratory symptoms and diseases [3], [4] and neurotoxic symptoms [5]. Although health effects are well reported, on-site studies for construction workers, especially construction painters, are rare in terms of personal exposure levels to hazards. The reason why only a few studies have focused on this group is that most of the construction painters are highly mobile from one site to the other, and they tend to be temporary workers, and also their work environment continuously changes at every construction site on a daily basis.

In this study, we evaluated the exposure concentrations of total volatile organic compounds (TVOCs) among construction painters to build up the chemical-job-exposure matrix. The data might be valuable for protecting construction painters from related occupational diseases by identifying high-risk tasks.

2. Materials and methods

2.1. Target works and tasks

In this study, waterproofing and painting works were monitored at eight construction workplaces, five apartment buildings, an office building, a logistics center, and a swimming pool. Twelve tasks, including seven waterproofing and five painting tasks, were evaluated in 18 sampling units. Several sampling units were included in one task. The representative job tasks for waterproofing work were polyurethane (PU)-primer task (indoor/outdoor), PU-resin task (indoor/outdoor), asphalt-primer task, asphalt-adhesive task, and cement-mortar task (Table 1). Epoxy-resin task, epoxy-primer task, oil-based-paint task (brush/spray), and water-based-paint task were the major job tasks for painting work in this study (Table 2).

Table 1.

Target-monitoring workplaces for waterproofing work

| Material | Environment | Task | Sampling unit | Building type (sampling location) | Application area (m2) | Daily used amount (kg/d) | Applied amount (kg/m2) | Applying method |

|---|---|---|---|---|---|---|---|---|

| Polyurethane | Outdoor | Polyurethane primer | PU 1 | Apartment (first floor) | 400 | 1,980 | 3.3 | Roller |

| Polyurethane resin | PU 2 | Apartment (first floor) | 600 | 1,320 | 3.3 | Roller | ||

| PU 3 | Apartment (rooftop) | 590 | 900 | 1.5 | Roller | |||

| PU 4 | Logistic center (rooftop) | 1,500 | 2,835 | 1.89 | Roller | |||

| Indoor | Polyurethane primer | PU 5∗ | Swimming pool (pool floor) | 400 | 200 | 0.5 | Roller | |

| Polyurethane resin | PU 6∗ | Swimming pool (pool floor) | 400 | 900 | 2.25 | Roller | ||

| Asphalt | Outdoor | Asphalt primer | AS 1 | Apartment (first floor) | 800 | 400 | 0.5 | Roller |

| Asphalt adhesive | AS 2 | Apartment (first floor) | 1,200 | 600 | 0.5 | Roller | ||

| Cement mortar | Indoor | Cement mortar | CM 1 | Apartment (first floor) | NA | NA | NA | Paddle |

| CM 2 | Apartment (restroom) |

NA, not available; PU, polyurethane.

PU 5 and PU 6 were identical places.

Table 2.

Target-monitoring workplaces for painting work

| Material | Environment | Task | Sampling unit | Building type (sampling location) | Application area (m2) | Daily used amount (kg/d) | Applied amount (kg/m2) | Applying method |

|---|---|---|---|---|---|---|---|---|

| Epoxy | Indoor | Epoxy primer | ER 1∗ | Apartment (underground parking lot) | 5,300 | 1,600 | 0.3 | Roller |

| ER 3∗ | Apartment (underground parking lot) | 2,000 | 540 | 0.27 | Spray | |||

| ER 5∗ | Apartment (underground parking lot) | 400 | 100 | 0.25 | Roller | |||

| Epoxy resin | ER 2∗ | Apartment (underground parking lot) | 5,300 | 1,600 | 0.3 | Roller | ||

| ER 4∗ | Apartment (underground parking lot) | 2,000 | 180 | 0.27 | Roller | |||

| ER 6∗ | Apartment (underground parking lot) | 100 | 25 | 0.25 | Roller | |||

| Oil-based paint | Indoor | Oil-based paint | OP 1 | Office building (door frame) | NA | 7 | NA | Brush |

| Outdoor | Oil-based paint | OP 2 | Logistic center (steel structure) | NA | 180 | 0.27 | Spray | |

| Water-based paint | Outdoor | Water-based paint | WP 1 | Apartment (underground parking lot) | 10,000 | 2,700 | 0.27 | Spray |

ER 1 and ER 2, ER 3 and ER 4, and ER 5 and ER 6 were identical places, each other except different application areas for ER 5 and ER 6.

2.1.1. PU-primer/resin tasks for waterproofing work

Six sampling units, four outdoor (PU 1–PU 4) and two indoor (PU 5 and PU 6) units, were selected for the PU-primer/resin tasks. Primer was applied as the first layer, followed by PU-resin coating additionally as the second outer layer. The PU primer contains 50–60% solvents, such as toluene, xylene, ethyl benzene (EB), methyl ethyl ketone (MEK), and ethyl acetate. PU resins were normally composed of the key material (about 9 kg) and the curing agent (about 24 kg), and they might be formulated just before their application. The PU key material contains 30–35% organic solvents; and the PU-resin curing agent contains 50–60% calcium carbonate, 15–25% polypropylene glycol, and 10% petroleum hydrocarbons.

2.1.2. Asphalt-primer/adhesive tasks for waterproofing work

Two outdoor sampling units (AS 1 and AS 2) were selected for the asphalt-primer and asphalt-adhesive tasks. Asphalt primer was applied on the construction surface as the first layer, and then it was additionally covered with asphalt adhesive, followed by attachment of the asphalt sheet. The asphalt sheet consisted of asphalt (60–65%), synthetic rubber (15–20%), inorganic filler (10–15%), and solvents, such as hydrocarbon mixture (5–10%). The asphalt primer and asphalt adhesive (asphalt-sheet adhesive) contained several organic solvents, but material safety data sheets (MSDSs) were not available to identify the components. Organic vapors were generated from the asphalt primer and sheet adhesive rather than the asphalt sheet itself, as the sheet was already commercially hardened before the waterproofing work.

2.1.3. Cement-mortar task for waterproofing work

One restroom of the apartment commercial building complex was selected to quantitatively measure the concentration of TVOCs during the cement-mortar waterproofing work (cement-mortar task). Liquid-water-based chemicals, which mainly consisted of a copious amount of water and a small amount of oleic acid without volatile organic compounds, were mostly used in the task.

2.1.4. Epoxy-primer/resin task for painting work

Six sampling units were selected for the epoxy-primer (ER 1, ER 3, and ER 5) and -resin tasks (ER 2, ER 4, and ER 6) in the underground parking lot of the apartment (Table 2). Epoxy coating was performed by applying a primer for good adhesion on building surfaces as the first layer, followed by the second outer epoxy-resin coating by using materials, such as resin mortar, lining material, and/or coating agent on the first primer layer. The epoxy primer usually consisted of 60–70% solvents, such as toluene, xylene, methyl isobutyl ketone (MIBK), and EB. The organic-solvent content in each epoxy resin varied according to the manufacturer, but they usually contained 20–40% solvents.

2.1.5. Oil-based-paint task for painting work

Two oil-based-paint tasks were selected. One task was oil-based brush painting of the door frame, pillar, railing, and fire hydrants at an office-building construction site (OP 1), and the other task was oil-based spray painting of the steel structure at a logistics center construction site (OP 2). The oil-based paint used for the main steel structure consisted of 30–40% organic chemical substances, such as toluene and xylene, and the oil-based paint for the frame and pillar contained 25–30% solvent chemicals. The thinner consisted of various solvents, such as toluene/xylene (41–45%), methyl acetate (21–30%), light naphtha aromatic solvent (11–20%), and alcohols, such as methanol (6–10%).

2.1.6. Water-based-paint task for painting work

One ceiling of the underground parking lot was selected to monitor the TVOC concentrations during the water-based-paint task (spraying). The water-based paint mostly consisted of water (40–50%), and it also contained limestone, calcium carbonate, and talc (1–10%). In terms of the types of paints, like water-soluble resin and water-dispersion paint, they contained some amount of solvents. According to several MSDSs provided by paint manufacturers, some water-based paints might contain approximately 20% organic solvents in order to emulsify nonwater-soluble materials, such as dyes, in the paints.

2.2. Sampling and analytical methods

For the personal air monitoring of TVOCs, 3M 3500 organic-vapor monitor (OVM) passive-sampling media (3M Co., London, Ontario, Canada) were used for each specific painting work. Fifteen organic vapors were detected by gas chromatography with flame ionization detector. The analytical instrument and conditions are shown in Table 3. Thirteen chemicals, including toluene, xylene, MEK, MIBK, benzene, EB, styrene, trichloroethylene, perchloroethylene, n-butyl acetate, iso-butyl acetate, sec-butyl acetate, and tert-butyl acetate, were selected, as the US Occupational Safety and Health Administration and/or the National Institute for Occupational Safety and Health had validated the sampling and analytical methods for passive sampling. Additionally, n-hexane and acetone were targeted because the vapors had been identified frequently in domestic work environments. The manufacturer of OVM recommended passive sampling for these two compounds. Polar chemicals, such as methanol and methyl acetate, were not included in this monitoring program, as the manufacturers did not specify them in their recommended passive-sampling methodology [6].

Table 3.

Analytical instrument and conditions

| Instrument | GC 6890 (Agilent Technologies, Wilmington, Delaware) | |

|---|---|---|

| Analytical condition | Detector | Flame ionization detector |

| Inlet | 200°C, column flow: 1 mL/min | |

| Oven | 40°C (5 min) 10°C/min to 130°C (1 min) 20°C/min to 230°C for 7 min |

|

| Detector | Temperature: 230°C H2 flow: 40 mL/min Airflow: 450 mL/min Makeup flow (N2): 29 mL/min |

|

| Column | DB-624 (60 m × 0.25 mm × 1.4 μm) DB-WAX (30 m × 0.25 mm × 1.0 μm) |

|

2.3. Statistical analysis and calculation of exposure index

Exposure index (EI) was calculated by the following equation to express the combined effects of organic compounds [7]. In the equation, Ci means the measured concentration of each organic compound, and OELi denotes the occupational exposure limit (OEL) for the chemical vapors. For defining OELs, the 2014 threshold limit values (TLVs) of the American Conference of Governmental Industrial Hygienists were applied as the reliable international workplace exposure recommendation.

Data distribution was examined for statistical normality by using Shapiro–Wilk's W test. Nonparametric tests, such as Mann–Whitney test and Kruskal–Wallis analysis, were performed to determine the concentration differences between various waterproofing and painting works by using the PASW version 18.0 (Spss Inc., Chicago, IL, USA). Using the central limit theorem, two-sample t test or analysis of variance was performed for group-mean comparisons. SigmaPlot version 13.5 (Systat Software Inc., San Jose, CA, USA) was used for constructing the figures in this study.

3. Results

3.1. Distribution of monitoring data

Most of the data were distributed log normally rather than normally. Some monitoring results, such as those for waterproofing work (all data, n = 45), indoor PU-resin task, and outdoor asphalt-adhesive task, did not match a normal or log-normal distribution, but they were quite close to log normality. As toluene was the most abundantly used chemical in the two works, it could be easily observed that the monitoring data were close to log-normality, although the statistical-distribution-test results for toluene in Table 4 showed similar trends to those in the EI data with less rigorous statistical values.

Table 4.

Distribution test results of normality/log normality for exposure index and toluene

| Work | Environment | Task | EI value data |

Toluene concentration data |

||||

|---|---|---|---|---|---|---|---|---|

|

W test (p) |

W test (p) |

|||||||

| n | Normal | Log normal | n | Normal | Log normal | |||

| Waterproofing | All data | 45 | 0.000 | 0.009 | 37 | 0.000 | 0.009 | |

| Outdoor | PU primer | 5 | 0.344∗ | 0.437∗ | 5 | 0.988∗ | 0.872∗ | |

| PU resin | 15 | 0.015 | 0.324∗ | 15 | 0.001 | 0.122∗ | ||

| Indoor | PU primer | 4 | 0.138∗ | 0.234∗ | 4 | 0.135∗ | 0.201∗ | |

| PU resin | 6 | 0.003 | 0.006 | 6 | 0.003 | 0.007 | ||

| Outdoor | Asphalt primer | 7 | 0.867∗ | 0.626∗ | 7 | 0.370∗ | 0.255∗ | |

| Asphalt adhesive | 8 | 0.002 | 0.014 | – | ND | ND | ||

| Painting | All data | 31 | 0.000 | 0.388∗ | 30 | 0.000 | 0.512∗ | |

| Indoor | Epoxy primer | 14 | 0.001 | 0.324∗ | 14 | 0.004 | 0.465∗ | |

| Epoxy resin | 13 | 0.303∗ | 0.319∗ | 13 | 0.097∗ | 0.181∗ | ||

| Indoor | Oil-based paint | 1 | – | – | – | ND | ND | |

| Outdoor | Oil-based paint | 2 | – | – | 2 | – | – | |

| Outdoor | Water-based paint | 1 | – | – | 1 | – | – | |

ND, none detected; PU, polyurethane.

Normal/log-normal distribution at 5% significant level.

3.2. Waterproofing work

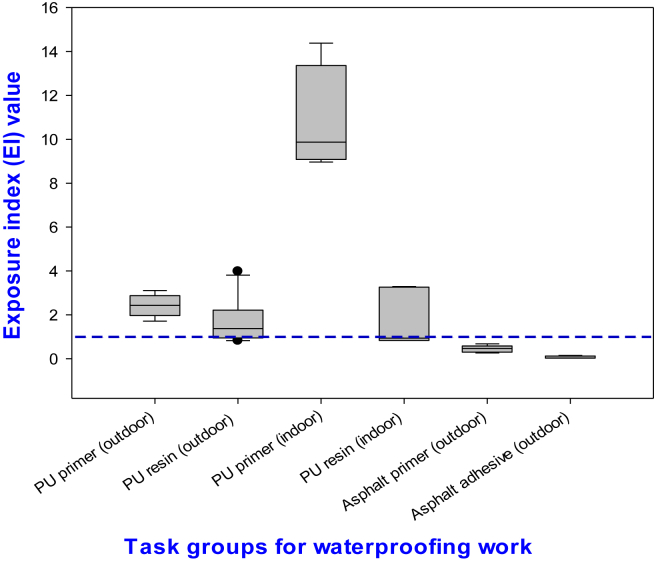

Among the 15 targeted chemicals, six vapors, including toluene (TLV = 20 ppm), xylene (TLV = 100 ppm), EB (TLV = 20 ppm), ethyl acetate (TLV = 400 ppm), MEK (TLV = 200 ppm), and n-hexane (TLV = 50 ppm), were detected during the waterproofing work. The concentration of each substance and the EI of TVOCs are shown in Table 5. The PU-primer task performed in an indoor unit (PU 5) generated the highest TVOC concentration level among the seven tasks of waterproofing work. The EI value recorded was 10.77 ± 2.47 [arithmetic mean (AM) ± standard deviation (SD)] with a geometric mean (GM) of 10.58 and a geometric standard deviation (GSD) of 1.24, respectively. This indicated that all four workers in PU 5 were enormously overexposed to organic vapors at the site, especially to toluene with AM ± SD of 213.26 ppm ± 49.40 ppm, while performing their task. In spite of a relatively large sample size (n = 10), no organic compounds were detected during the cement-mortar task, which might be commonly expected. The asphalt-primer and asphalt-adhesive tasks yielded unserious exposure levels with EI values of 0.47 ± 0.15 and 0.07 ± 0.05 as AM ± SD, respectively. Other tasks, such as PU-primer (outdoor, PU 1), PU-resin (outdoor, PU 2–4), and PU-resin (indoor, PU 6) tasks, recorded an AM ± SD of 2.42 ± 0.51 (PU 1), 1.85 ± 0.58 (PU 2), 1.01 ± 0.15 (PU 3), 2.48 ± 1.34 (PU 4), and 1.68 ± 1.23 (PU 6), respectively. Figure 1 illustrates the EI-value distribution for each task in the waterproofing work without the cement-mortar task. The data from the PU-resin tasks performed in outdoor units (PU 2–PU 4) were combined into a single bar in the figure.

Table 5.

Total-volatile-organic-compound concentrations of waterproofing work∗

| Material | Environment | Task | Sampling unit | n | Toluene (ppm) | Xylene (ppm) | Ethyl benzene (ppm) | Ethyl acetate (ppm) | MEK (ppm) | n-Hexane (ppm) | EI (exposure limit) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Threshold limit values (ACGIH), ppm | 20 | 100 | 20 | 400 | 200 | 50 | 1 | ||||

| Polyurethane | Outdoor | PU primer | PU 1 | 5 | 5 48.03 ± 10.13 47.13 (1.25) (99.07%) |

ND | 3 0.34 ± 0.25 0.24 (2.93) (0.64%) |

ND | 4 1.41 ± 1.05 0.91 (3.81) (0.29%) |

ND | 5 2.42 ± 0.51 2.38 (1.25) (100.00%) |

| PU resin | PU 2/ PU 3/ PU 4 |

15 | 15 29.68 ± 20.95 24.90 (1.78) (83.47%) |

10 4.88 ± 5.22 1.370 (8.83) (2.75%) |

10 4.85 ± 6.68 0.99 (8.87) (13.64%) |

ND | 5 0.46 ± 1.00 0.19 (3.70) (0.13%) |

ND | 15 1.78 ± 1.00 1.56 (1.67) (100.00%) |

||

| PU 2 | 5 | 5 21.40 ± 7.32 20.42 (1.41) (57.89%) |

5 10.30 ± 2.85 10.02 (1.29) (5.57%) |

5 13.51 ± 3.80 13.13 (1.30) (36.54%) |

ND | ND | ND | 5 1.85 ± 0.58 1.78 (1.35) (100.00%) |

|||

| PU 3 | 5 | 5 18.15 ± 4.08 17.73 (1.29) (89.84%) |

5 4.34 ± 4.53 3.21 (2.17) (4.30%) |

5 1.05 ± 0.64 0.91 (1.79) (5.19%) |

ND | 5 1.37 ± 1.40 1.02 (2.17) (0.68%) |

ND | 5 1.01 ± 0.15 1.00 (1.16) (100.00%) |

|||

| PU 4 | 5 | 5 49.50 ± 26.88 42.65 (1.92) (100.00%) |

ND | ND | ND | ND | ND | 5 2.48 ± 1.34 2.14 (1.91) (100.00%) |

|||

| Indoor | PU primer | PU 5 | 4 | 4 213.26 ± 49.40 209.41 (1.24) (98.99%) |

4 1.91 ± 0.29 1.90 (1.16) (0.18%) |

4 0.34 ± 0.05 0.34 (1.15) (0.16%) |

4 6.70 ± 0.39 6.69 (1.06) (0.16%) |

4 11.18 ± 1.01 11.14 (1.10) (0.52%) |

ND | 4 10.77 ± 2.47 10.58 (1.24) (100.00%) |

|

| PU resin | PU 6 | 6 | 6 28.50 ± 25.66 20.60 (2.34) (84.72%) |

6 14.62 ± 3.51 14.23 (1.29) (8.69%) |

6 2.09 ± 0.50 2.04 (1.29) (6.22%) |

3 0.67 ± 0.83 0.32 (3.74) (0.09%) |

6 0.95 ± 0.92 0.66 (2.48) (0.28%) |

ND | 6 1.68 ± 1.23 1.37 (1.97) (100.00%) |

||

| Asphalt | Outdoor | Asphalt primer | AS 1 | 7 | 7 1.11 ± 0.27 1.08 (1.34) (11.83%) |

7 4.03 ± 1.26 3.85 (1.40) (8.61%) |

7 7.36 ± 2.37 7.01 (1.41) (78.68%) |

ND | ND | 4 0.22 ± 0.18 0.13 (3.48) (0.88%) |

7 0.47 ± 0.15 0.45 (1.40) (100.00%) |

| Asphalt adhesive | AS 2 | 8 | 8 0.11 ± 0.04 0.11 (1.33) (8.44%) |

8 1.04 ± 0.51 0.95 (1.57) (14.64%) |

8 1.03 ± 0.95 0.75 (2.19) (76.92%) |

ND | ND | ND | 8 0.07 ± 0.05 0.05 (1.96) (100.00%) |

||

| Indoor | Cement mortar | CM 1 | 10 | ND | ND | ND | ND | ND | ND | ND | |

ACGIH, American Conference of Governmental Industrial Hygienists; EI, exposure index for total volatile organic compounds; MEK,methyl ethyl ketone; ND, none detected; PU, polyurethane.

Detected n; arithmetic mean ± standard deviation; geometric mean (geometric standard deviation); (% proportion to exposure index).

Fig. 1.

Exposure level for each task group in waterproofing work (horizontal broken line represents exposure limit for exposure index). PU, polyurethane.

On considering individual substances, toluene was the most abundantly used organic solvent in the PU jobs in the waterproofing work. The percent compositions of toluene for each EI value were 99.07%, 57.89%, 89.84%, 100.00%, 98.99%, and 84.72% from PU 1 to PU 6 sampling unit, respectively.

3.3. Painting work

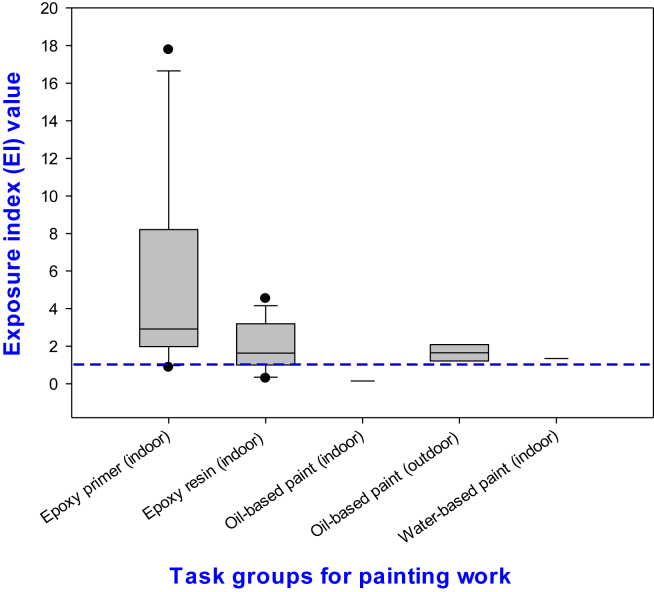

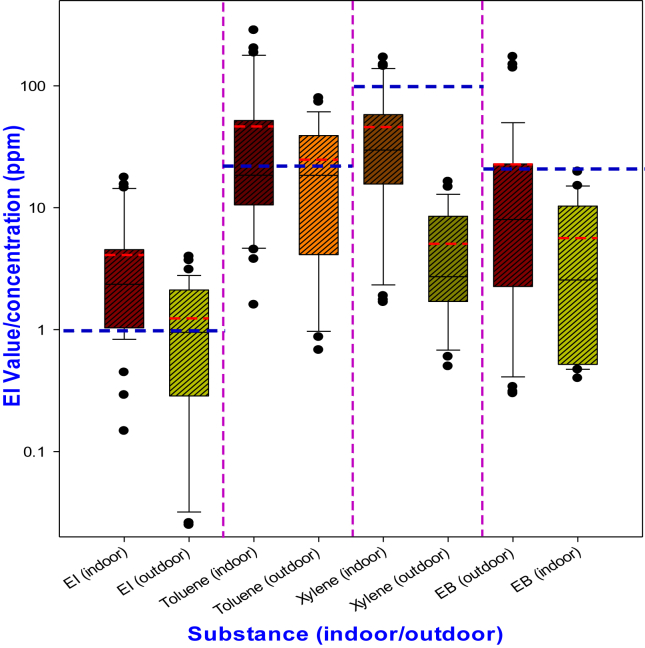

Among the five tasks, the probability of overexposure was observed during three tasks (epoxy-primer, epoxy-resin, outdoor oil-based-spray-paint tasks) of the painting work. During two tasks, including the indoor oil-based-brush-paint task (OP 1, n = 1) with an EI value of 0.15 and the water-based-paint task (WP 1) with an EI value of 0.66 (n = 1), the exposure limit (EI = 1.0) was not exceeded. The highest exposure levels as per the EI were observed during the epoxy-primer task performed in an indoor unit (ER 1) with AM ± SD of 15.97 ± 1.62. For the other sampling units, AM ± SD was 3.46 ± 1.42 for ER 3, 1.07 ± 0.21 for ER 5, 3.50 ± 0.62 for ER 2, 1.00 ± 0.76 for ER 4, 1.28 ± 0.32 for ER 6, and 1.65 ± 0.62 for OP 2. Figure 2 shows the EI-value distribution for all five tasks in the painting work.

Fig. 2.

Exposure level for each task group in painting work (horizontal broken line represents exposure limit for exposure index).

As shown in Table 6, 10 organic chemicals, including toluene, xylene, EB, MIBK (TLV = 20 ppm), styrene (TLV = 10 ppm), ethyl acetate, MEK, n-butyl acetate (TLV = 150 ppm), n-hexane, and acetone (TLV = 500 ppm), were detected among the 15 targeted substances; four more chemicals were detected compared to those detected in the waterproofing work. Among these 10 substances, toluene recorded the highest composition levels to EI values during the indoor epoxy-primer tasks, 32.72% for ER 1, 41.11% for ER 3, and 44.40% for ER 5, followed by EB and xylene for percent EI rates. During the epoxy-resin tasks (ER 2, ER 4, and ER 6), toluene, xylene, and EB showed relatively similar composition rates with slight abundance of EB. During the indoor oil-based-paint task (OP 1), styrene showed the highest rate of 42.71%. During the outdoor oil-based-paint task (OP 2) and the outdoor water-based-paint task (WP 1), EB and toluene showed the highest rate of 53.25% and 57.66%, respectively. Compared to the major solvent components, such as toluene, xylene, and EB, ethyl acetate (EA), MEK, n-butyl acetate, n-hexane, and acetone were not the important components of epoxy primer and epoxy resin. Especially, n-hexane and MEK showed impurity-level air concentrations during the two tasks. A marginal level of acetone with AM ± SD of 9.76 ppm ± 0.53 ppm (0.12% composition rate for EI) was detected. Among the 15 targeted substances, only toluene, xylene, and EB were detected in the OP 2 and WP 1 sampling units. Compared to the waterproofing work, a relatively larger variation in the solvent components was identified.

Table 6.

Total-volatile-organic-compound concentrations of painting work∗

| Material/task | Environment | Sampling unit | n | Toluene | Xylene (ppm) | Ethyl benzene (ppm) | MIBK (ppm) | Styrene (ppm) | Ethyl acetate (ppm) | MEK (ppm) | n-Butyl acetate (ppm) | n-Hexane (ppm) | Acetone (ppm) | EI (exposure limits) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Threshold limit values (ACGIH), ppm | 20 | 100 | 20 | 20 | 20 | 400 | 200 | 150 | 50 | 500 | 1 | |||

| ER 1/ ER 3/ ER 5 |

14 40.56 ± 36.80 28.31 (2.40) (36.13%) |

14 88.70 ± 50.42 73.22 (1.99) (15.80%) |

14 44.24 ± 60.41 21.57 (3.18) (39.41%) |

11 8.93 ± 11.14 2.33 (11.40) (7.95%) |

14 0.60 ± 0.45 0.42 (2.55) (0.53%) |

11 0.40 ± 0.24 0.34 (1.87) (0.02%) |

3 0.25 ± 0.31 0.15 (2.54) (0.02%) |

3 0.71 ± 1.25 0.18 (4.67) (0.05%) |

ND | 3 2.21 ± 4.09 0.37 (5.87) (0.08%) |

14 5.61 ± 5.82 3.57 (2.65) (100.00%) |

|||

| Epoxy primer | Indoor | ER 1 | 3 | 3 104.52 ± 10.97 104.15 (1.11) (32.72%) |

3 151.60 ± 17.08 150.98 (1.12) (9.49%) |

3 154.45 ± 16.74 153.86 (1.11) (48.35%) |

3 28.95 ± 1.29 28.93 (1.05) (9.06%) |

3 0.27 ± 0.05 0.26 (1.19) (0.08%) |

3 0.76 ± 0.02 0.76 (1.03) (0.01%) |

3 0.81 ± 0.04 0.81 (1.05) (0.03%) |

3 3.02 ± 0.12 3.02 (1.04) (0.13%) |

ND | 3 9.76 ± 0.53 9.75 (1.05) (0.12%) |

3 15.97 ± 1.62 15.92 (1.11) (100.00%) |

| ER 3 | 8 | 8 28.21 ± 11.82 26.28 (1.48) (41.11%) |

8 88.78 ± 35.05 83.11 (1.47) (25.87%) |

8 16.99 ± 6.21 16.08 (1.42) (24.75%) |

8 4.75 ± 2.08 4.41 (1.49) (6.92%) |

8 0.90 ± 0.35 0.85 (1.46) (1.31%) |

8 0.36 ± 0.15 0.34 (1.47) (0.03%) |

ND | ND | ND | ND | 8 3.46 ± 1.42 3.23 (1.47) (100.00%) |

||

| ER 5 | 3 | 3 9.53 ± 2.05 9.38 (1.24) (44.40%) |

3 25.58 ± 4.34 25.33 (1.19) (23.84%) |

3 6.70 ± 1.25 6.62 (1.20) (31.23%) |

ND | 3 0.11 ± 0.04 0.11 (1.42) (0.53%) |

ND | ND | ND | ND | ND | 3 1.07 ± 0.21 1.06 (1.22) (100.00%) |

||

| ER 2/ ER 4/ ER 6 |

13 12.20 ± 8.38 9.11 (2.38) (30.10%) |

13 32.32 ± 14.04 28.77 (1.74) (15.95%) |

13 18.86 ± 16.69 11.67 (3.05) (46.54%) |

13 2.63 ± 1.12 2.33 (1.77) (6.49%) |

8 0.23 ± 0.26 0.14 (2.54) (0.57%) |

7 0.34 ± 0.26 0.26 (2.14) (0.03%) |

5 0.24 ± 0.20 0.17 (2.29) (0.04%) |

5 0.91 ± 1.12 0.29 (5.34) (0.29%) |

5 0.07 ± 0.05 0.06 (1.88) (0.01%) |

ND | 13 2.03 ± 1.34 1.55 (2.31) (100.00%) |

|||

| Epoxy resin | Indoor | ER 2 | 5 | 5 20.91 ± 3.49 20.69 (1.17) (29.87%) |

5 39.96 ± 7.71 39.42 (1.20) (11.42%) |

5 38.24 ± 7.07 37.76 (1.19) (54.62%) |

5 2.44 ± 0.38 2.42 (1.16) (3.49%) |

ND | 5 0.65 ± 0.10 0.64 (1.17) (0.05%) |

5 0.47 ± 0.08 0.46 (1.19) (0.07%) |

5 2.23 ± 0.47 2.19 (1.21) (0.42%) |

5 0.12 ± 0.02 0.12 (1.15) (0.07%) |

ND | 5 3.50 ± 0.62 3.46 (1.18) (100.00%) |

| ER 4 | 5 | 5 6.51 ± 6.51 4.71 (2.38) (32.51%) |

5 27.86 ± 20.00 21.95 (2.24) (27.83%) |

5 5.17 ± 3.56 4.16 (2.15) (25.81%) |

5 2.31 ± 1.50 1.80 (2.36) (11.54%) |

5 0.46 ± 0.30 0.36 (2.38) (2.30%) |

2 0.15 ± 0.04 0.15 (1.26) (0.02%) |

ND | ND | ND | ND | 5 1.00 ± 0.76 0.79 (2.21) (100.00%) |

||

| ER 6 | 3 | 3 7.20 ± 2.10 7.00 (1.33) (28.16%) |

3 27.02 ± 5.11 26.72 (1.20) (21.14%) |

3 9.37 ± 2.17 9.22 (1.25) (36.67%) |

3 3.49 ± 1.14 3.37 (1.37) (13.64%) |

3 0.10 ± 0.02 0.10 (1.20) (0.39%) |

ND | ND | ND | ND | ND | 3 1.28 ± 0.32 1.25 (1.27) (100.00%) |

||

| Oil-based paint | Indoor | OP 1 | 1 | ND | 4.2 (28.47%) |

0.85 (28.81%) |

ND | 1.26 (42.71%) |

ND | ND | ND | ND | ND | 0.15 (100.00%) |

| Oil-based paint | Outdoor | OP 2 | 2 | 2 12.67 ± 8.21 11.26 (2.01) (38.47%) |

2 13.64 ± 3.90 13.36 (1.21) (8.29%) |

2 17.53 ± 3.37 17.37 (1.34) (53.25%) |

ND | ND | ND | ND | ND | ND | ND | 2 1.65 ± 0.62 1.59 (1.47) (100.00%) |

| Water-based paint | Outdoor | WP 1 | 1 | 15.57 (57.66%) |

29.66 (21.97%) |

5.50 (20.37%) |

ND | ND | ND | ND | ND | ND | ND | 0.66 (100.00%) |

ACGIH, American Conference of Governmental Industrial Hygienists; EI, exposure index for total volatile organic compounds; MEK, methyl ethyl ketone; MIBK, methyl isobutyl ketone; n, number of samples; ND, none detected.

Detected n; arithmetic mean ± standard deviation; geometric mean (geometric standard deviation); (% proportion to exposure index).

3.4. Waterproofing versus painting work

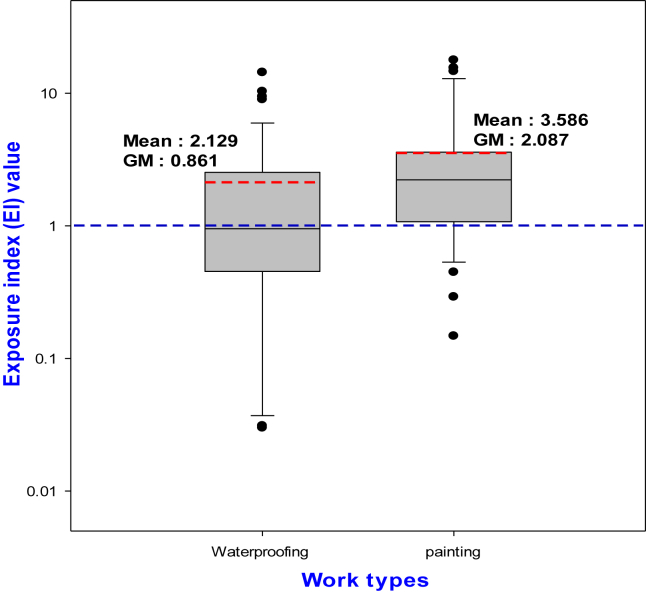

In this study, there were two groups of work: the waterproofing work and the painting work. As different materials and organic solvents were used in each work, possible differences in organic-vapor exposures between the groups of work were tested graphically and statistically (Table 7; Fig. 3).

Table 7.

Descriptive statistics for exposure index, toluene, xylene, and ethyl benzene of waterproofing work and painting work

| Material | Work group | n | AM | SD | GM | GSD | Maximum | Minimum | p |

|---|---|---|---|---|---|---|---|---|---|

| EI | Waterproofing | 45 | 2.13 | 3.00 | 0.86 | 4.94 | 14.38 | 0.03 | 0.008∗ |

| Painting | 31 | 3.59 | 4.38 | 2.09 | 2.87 | 17.77 | 0.15 | ||

| Toluene | Waterproofing | 37 | 46.41 | 64.34 | 18.29 | 5.07 | 285.50 | 0.68 | 0.671 |

| Painting | 30 | 25.58 | 29.02 | 15.97 | 2.69 | 116.53 | 1.60 | ||

| Xylene | Waterproofing | 35 | 5.84 | 5.52 | 3.54 | 2.94 | 18.73 | 0.50 | 0.000∗ |

| Painting | 31 | 55.58 | 46.42 | 39.27 | 2.45 | 170.96 | 4.20 | ||

| EB | Waterproofing | 38 | 3.89 | 4.81 | 1.77 | 3.73 | 19.68 | 0.30 | 0.000∗ |

| Painting | 31 | 29.22 | 43.59 | 14.63 | 3.39 | 173.03 | 0.85 |

AM, arithmetic mean; EB, ethyl benzene; EI, exposure index; GM, geometric mean; GSD, geometric standard deviation; SD, standard deviation.

Statistically significant at 1% significant level.

Fig. 3.

Exposure levels of exposure indexes for waterproofing work and painting work (horizontal broken line represents exposure limit for exposure index). GM, geometric mean.

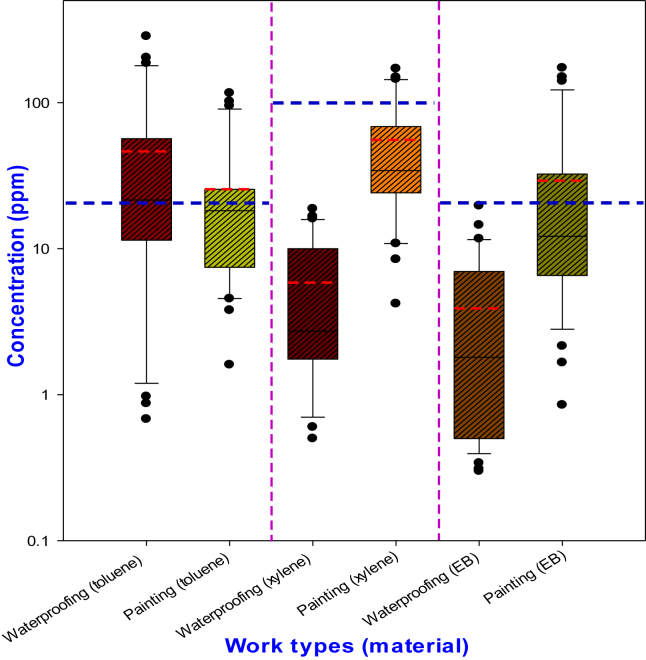

Workers engaged in the water-proofing work were exposed to a lower EI value with AM ± SD of 2.13 ± 3.00 and a GM (GSD) of 0.86 (4.94) compared to those engaged in the painting work. The EI values of AM (SD) and GM (GSD) during the painting work were 3.59 (4.38) and 2.09 (2.87), respectively. For comparison of each chemical, three major organic vapors (toluene, xylene, and EB) were selected. In the case of toluene, the waterproofing work generated higher exposure concentrations with AM ± SD of 46.41 ppm ± 64.34 ppm compared to the painting work with AM ± SD of 25.58 ppm ± 29.02 ppm. But, due to large concentration variations in the tasks, the mean values did not show any statistically significant differences with a p of 0.671 for log-transformed data by the independent t test (Table 7). In the case of xylene, painting workers were exposed to 55.58 ppm (AM), while waterproofing workers were exposed to 5.84 ppm. The AM of EB during the painting work was recorded as 29. 22 ppm, while the AM of EB during the waterproofing work was recorded as 3.89 ppm (Fig. 4).

Fig. 4.

Exposure levels of major chemicals for waterproofing work and painting work (horizontal broken line represents threshold limit value for each chemical). EB, ethyl benzene.

3.5. Comparison of primer versus resin painting concentration

There were two groups of tasks: primer painting and resin painting. The comparison of EI values and seven major organic chemicals during both tasks by nonparametric Mann–Whitney test is summarized in Table 8. All four EIs showed statistically significant differences during outdoor PU-primer task versus PU-resin task (p = 0.040), indoor PU-primer task versus PU-resin task (p = 0.011), outdoor asphalt-primer task versus asphalt-adhesive task (p = 0.001), and indoor epoxy-primer task versus epoxy-resin task (p = 0.013). The PU and epoxy primers contain 50–70% solvents, such as toluene, xylene, EB, MEK, and ethyl acetate. As the major components of organic solvents in each construction-painting material, toluene and xylene showed the maximum solvent-exposure concentration results, while EB showed mixed results.

Table 8.

The p for exposure index and major organic vapors for tasks by nonparametric tests

| Work | Environment | Task | Sampling unit | Toluene | Xylene | Ethyl benzene | MIBK | Ethyl acetate | MEK | n-Butyl acetate | p for EI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Waterproofing | Outdoor | PU primer | PU 1 | 0.021 | 0.020 | 0.228∗ | ND | ND | 0.025 | ND | 0.040 |

| PU resin | PU 2-4 | ||||||||||

| Indoor | PU primer | PU 5 | 0.011 | 0.011 | 0.011 | ND | 0.010 | 0.011 | ND | 0.011 | |

| PU resin | PU 6 | ||||||||||

| Outdoor | Asphalt primer | AS 1 | 0.001 | 0.001 | 0.001 | ND | ND | ND | ND | 0.001 | |

| Asphalt adhesive | AS 2 | ||||||||||

| Painting | Indoor | Epoxy primer | ER 1/3/5 | 0.006 | 0.003 | 0.265∗ | 0.076∗ | ND | 0.631∗ | 0.548∗ | 0.013 |

| Epoxy resin | ER 2/4/6 |

EI, exposure index; MEK, methyl ethyl ketone; MIBK, methyl isobutyl ketone; ND, none detected; PU, polyurethane.

Statistically insignificant at 5% significant level.

3.6. Comparison of indoor versus outdoor concentration

All 11 tasks (except for the indoor cement-mortar task) were divided into two other groups, which could be performed in an indoor or outdoor environment; hence, there might be different exposure profiles of volatile organic vapors. The EI value, toluene, xylene, and EB were also included in these tests. The levels of all four variables were higher during the indoor-environment task compared to the tasks performed in an outdoor environment (Table 9; Fig. 5). Except for toluene with a p of 0.081, the mean values of the variables in each environment showed statistically significant differences, and the p for EI, xylene, and EB approached zero.

Table 9.

Descriptive statistics for exposure index, toluene, xylene, and ethyl benzene of indoor and outdoor tasks

| Material | Environment | n | AM | SD | GM | GSD | Maximum | Minimum | p |

|---|---|---|---|---|---|---|---|---|---|

| EI | Indoor | 39 | 4.09 | 4.62 | 2.34 | 3.03 | 17.77 | 0.15 | 0.000∗ |

| Outdoor | 37 | 1.24 | 1.09 | 0.61 | 4.7 | 3.98 | 0.03 | ||

| Toluene | Indoor | 38 | 46.48 | 65.55 | 17.89 | 2.81 | 285.50 | 1.60 | 0.081 |

| Outdoor | 29 | 24.78 | 22.28 | 16.68 | 4.98 | 79.51 | 0.68 | ||

| Xylene | Indoor | 39 | 45.93 | 45.63 | 42.31 | 2.40 | 170.96 | 1.68 | 0.000∗ |

| Outdoor | 27 | 5.06 | 4.68 | 3.80 | 2.99 | 16.40 | 0.50 | ||

| EB | Indoor | 39 | 22.69 | 40.65 | 11.53 | 3.83 | 173.03 | 0.30 | 0.000∗ |

| Outdoor | 30 | 5.64 | 6.10 | 2.00 | 4.18 | 19.91 | 0.40 |

AM, arithmetic mean; EB, ethyl benzene; EI, exposure index; GM, geometric mean; GSD, geometric standard deviation; SD, standard deviation.

Statistically significant at 1% significant level.

Fig. 5.

Exposure levels of exposure index and major chemicals for indoor versus outdoor (horizontal broken line represents exposure limit for exposure index or threshold limit value for each chemical). EB, ethyl benzene; EI, exposure index.

4. Discussion

In this study, the common construction-painting works, including seven waterproofing tasks and five painting tasks, were evaluated. Assuming that the operations were carried out continuously for 8 hours without breaks and by using the AM of EIs for each of the 12 tasks in this study, 58.3% (7 out of 12) of the tasks overexpose the exposure limit (EI > 1.0), while 8.3% (1 out of 12) of the tasks was between 50 and 100% of the exposure limit (0.5 > EI > 1.0), and in 4 tasks out of the 12 tasks, the EI was less than 50% of the limit range (EI < 0.5). The task that generated the highest concentration levels was the indoor PU-primer task with an EI of 10.77. In a domestic research that was targeted at interior painting [8], exposure assessments were carried out for the interior painting and modification coating of the apartment. The authors reported that, in all painting workers (n = 14), the exposure exceeded the exposure limits. The AM concentrations as EI corresponding values of TVOCs for painters, painting assistants, spray painters, brush painters, and area samples after finishing the painting work were 7.97, 3.36, 11.50, 2.12, and 3.27, respectively. Riala et al [9] reported the results for the concentrations during the painting of the highway and subway steel bridges, and the level of TVOCs, such as solvent naphtha, was 670 ppm ± 138 ppm during spray painting and 11.5 ppm ± 16.2 ppm during roller and brush painting. During indoor painting, without the mechanical-ventilation system, the level of TVOCs was 235 ppm as AM during spray painting, and 194 ppm during roller and brush painting. The authors suggested that, when a job was carried out with the wind blowing in from the doors and windows, the TVOC concentration was decreased to about 38 ppm compared to that during painting in a relatively confined space.

Qian et al [10] reported the TVOC concentration during bridge painting using OVM (3M OVM 3500). They presented the results of both 58 activity-specific air samples (assessment method for performing measurements only during the operation time) and 30 daily workday air samples (assessment method for performing measurements during the day for 8 hours). In the activity-specific air samples during spray painting (n = 18), the results showed that the AM ± SD of aromatics, esters, ketones, alkanes, and TVOCs were 410.1 ppm ± 242.1 ppm, 209.0 ppm ± 300.6 ppm, 50.1 ppm ± 80.8 ppm, less than 0.3 ppm, and 669.5 ppm ± 138.3 ppm, respectively. In the activity-specific air samples during brush and roller painting (n = 39), the AM ± SD of aromatics was 6.5 ppm ± 9.3 ppm, and it was 1.0 ppm ± 2.6 ppm for esters, 0.9 ppm ± 0.4 ppm for ketones, < 0.3 ppm ± 6.9 ppm for alkanes, and 11.5 ppm ± 2.9 ppm for TVOCs. In the daily workday air samples during spray painting (n = 12), the results showed that the AM ± SD for aromatics, esters, ketones, alkanes, and TVOCs were 87.3 ppm ± 60.6 ppm, 23.7 ppm ± 35.4 ppm, 0.2 ppm ± 0.2 ppm, less than 0.4 ppm, and 112 ppm ± 43.9 ppm, respectively. In the daily workday air samples during brush and roller painting (n = 18), aromatics recorded a concentration of 1.1 ppm ± 1.2 ppm, a concentration of < 0.1 ppm for esters, 0.3 ppm ± 0.8 ppm for ketones, 1.7 ppm ± 0.9 ppm for alkanes, and 3.2 ppm ± 1.7 ppm for TVOCs. The activity-specific samples that might correspond to the real-time projected dose showed relatively high concentration levels compared to the daily workday samples that might be represented as time-weighted average. Therefore, any exposure-monitoring program for construction workers who may have irregular working schedules on a daily basis might require a more stringent work-activity analysis with several day measurements to obtain real-average daily-exposure profiles for the comparison of OELs. As a large amount of organic solvents per working time are used during spray painting, it was easily observed that large exposures could occur in the workers compared to the brushing painters.

While estimating the past exposure levels, we should consider the painting method (spray, roller, brush), painting time, and use of respiratory protective equipment. Wang et al [11] reported that the most influential environmental factors affecting TVOC concentrations were the painting method (spray, roller, brush) and painting time. In addition, spray-type painting while wearing respiratory protective equipment generates higher TVOC concentrations than roller- and brush-type painting even without wearing respiratory protective equipment. Age-specific exposure status was also found to be one of the factors affecting TVOC concentrations more significantly than the use of respiratory protective equipment. The researchers said that TVOC concentrations prior to the year 1990 were three times higher compared to the levels after the year 1990. Based on our research, the indoor-work and primer-painting task generated higher TVOCs than the outdoor and resin-painting task.

In this study, we found that many construction painters were overexposed to volatile organic solvents during their various tasks. It is well known that organic solvents, such as xylene, acetone, n-hexane, styrene, MEK, and MIBK, are harmful to the human eye, skin, respiratory tract, and central and peripheral nervous systems. Especially, toluene may cause harm to pregnant women and the embryo. EB could cause kidney damage and cochlear impairment in humans [7]. Benzene, which is a known human carcinogen, may be included unintentionally in paint thinners that mainly consist of aromatic chemicals, such as toluene and xylene. Workers who are exposed to organic-solvent chemicals cannot be easily protected by using personal protective equipment (PPE), such as air-purifying respirators. The Occupational Safety and Health Administration of the United States introduced assigned protection factor (APF) for respirators for the capabilities and limitations of PPEs. The maximum APF for air-purifying respirators is 10 for half masks, which means that workers should not use these types of respirators when air levels of organic solvents exceed 10 times the exposure limit. In the case of full facepiece masks, the APF is 50 [12]. As some painting workers in this study were exposed to solvent levels of more than 10 times the EI values, it is not recommended to use an air-purifying respirator during an extended time of work. Powered air-purifying respirators that have an APF of 50 or more for half masks and continuous-flow mode or pressure-demand/positive-pressure-mode supplied air respirators with an APF of 50 for half masks might be the possible options for the workers. Employers could introduce administrative controls by restricting the work time for 30 minutes or less on certain days when the EI values exceed 10. It is very difficult to use a local ventilation system because most of the painting works are temporary and locally sporadic.

In this study, 12 tasks of painting works including waterproofing works were monitored at eight construction workplaces. We recognized that construction painting has complex combinations of exposure profiles of organic solvents and reproductive toxins, and the TVOC concentrations during many of the painting tasks might have extensively exceeded the OEL in our study. Although the results are limited to our studied samples because the exposure levels at construction workplaces have large variations in each task, construction painters essentially need to be protected from chemical agents during their painting work. Working environmental-management practices, such as the use of respiratory protective equipment, local ventilation system, and restriction on working hours, should be considered with caution depending on the concentrations of TVOCs.

Further studies on methods to improve the hazardous working environment need to be performed. During any work-monitoring programs for construction sites, data on the detailed work status, such as real working time, chemical usage per day, specific working method, and types of PPE, should be considered to identify the real exposure status of the workers.

5. Limitations

As mentioned previously, some polar chemicals, including methanol, ethanol, and methyl acetate, were not included in this study, although they were identified in some MSDSs, such as those for oil-based paints, as active sampling methods could not be used. This might be a limitation of our study. Therefore, there was an underestimation of EI values for oil-based-paint tasks. On the other hand, as we did not calculate the time-weighted average of each task, there might have been some overestimation of workers' exposure levels. When somebody wants to use the data for any epidemiological study or for comparing with other monitoring results, care should be taken by performing time adjustment to real working time with hazardous substances for each task with task–time analysis. Also, the small sample size for the tasks might be another weakness of our study. Additional monitoring studies with a large sample size are required in order to perform risk-based analysis and management of construction painters.

Conflicts of interest

None declared.

References

- 1.Winder C., Turner P.J. Solvent exposure and related work practices amongst apprentice spray painters in automotive body repair workshops. Ann Occup Hyg. 1992;36:385–394. doi: 10.1093/annhyg/36.4.385. [DOI] [PubMed] [Google Scholar]

- 2.Wolford R. Intervention research in construction: a hypothetical case study of painters. Am J Ind Med. 1996;29:431–434. doi: 10.1002/(SICI)1097-0274(199604)29:4<431::AID-AJIM32>3.0.CO;2-0. [DOI] [PubMed] [Google Scholar]

- 3.White M.C., Baker E.L. Measurements of respiratory illness among construction painters. Br J Ind Med. 1988;45:523–531. doi: 10.1136/oem.45.8.523. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Kaukiainen A., Riala R., Martikainen R., Akila R., Reijula K., Sainio M. Solvent-related health effects among construction painters with decreasing exposure. Am J Ind Med. 2004;46:627–636. doi: 10.1002/ajim.20107. [DOI] [PubMed] [Google Scholar]

- 5.Fidler A.T., Baker E.L., Letz R.E. Neurobehavioural effects of occupational exposure to organic solvents among construction painters. Br J Ind Med. 1987;44:292–308. doi: 10.1136/oem.44.5.292. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.3M Company . 3M Occupational Health and Environmental Safety Division; St paul (MN): 2006. Technical data bulletin: Organic vapor monitor sampling and analysis guide, 3M organic vapor monitor 3500/3510 and 3M organic vapor 3520/3530. [Google Scholar]

- 7.American Conference of Governmental Industrial Hygienists (ACGIH) ACGIH; Cincinnati (OH): 2014. Threshold limit values for chemical substances and physical agents & biological exposure indices. [Google Scholar]

- 8.Choi J.W., Mun J.S., Won J.I., Park H.C. Health Hazardous Substances in Construction Work in Korea. J Korean Soc Occup Environ Hyg. 2000;10:74–92. [Google Scholar]

- 9.Riala R., Kalliokoski P., Pyy L., Wickström G. Solvent exposure in construction and maintenance painting. Scand J Work Environ Health. 1984;10:263–266. doi: 10.5271/sjweh.2332. [DOI] [PubMed] [Google Scholar]

- 10.Qian H., Fiedler N., Moore D.F., Weisel C.P. Occupational exposure to organic solvents during bridge painting. Ann Occup Hyg. 2010;54:417–426. doi: 10.1093/annhyg/meq021. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Wang S.W., Qian H., Weisel C., Nwankwo C., Fiedler N. Development of solvent exposure index for construction painters. J Occup Environ Hyg. 2011;8:375–386. doi: 10.1080/15459624.2011.583488. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Colton C.E. Respiratory protection. In: Anna D.H., editor. The occupational environment: its evaluation, control, and management. 3rd ed. American Industrial Hygiene Association; Fairfax (VA): 2011. pp. 1255–1283. [Google Scholar]