Abstract

Aim:

The aim of this study was to evaluate the surface roughness of three composites with three different polishing systems.

Materials and Methods:

Composite specimens were made from the Teflon mold with a standardized cavity size (6 mm diameter and 3 mm height). Group I — Filtek Z350XT (Nano clusters), group II — T-Econom plus (Microhybrid), group III — G-aenial Flo (True Nano). The samples were cured for 30 s from both sides with the matrices in place. The 60 samples were divided into 3 groups (N = 20), which accounted for 40 surfaces, (n = 20 × 2 = 40) in each groups. Each group were subdivided into four subgroups based on the type polishing material, subgroup A — Control, subgroup B — Astrobrush, subgroup C — Astropol, and subgroup D — Soflex spiral wheel. The samples of all groups except group A (control) were finished and polished according to the manufacture's instruction.

Results:

After polishing, the roughness (Ra) of the resin composite of all the specimens were measured using a profilometer. Soflex spiral wheel (group D) significantly had the least roughness (Ra) value as compared to the other groups.

Conclusion:

Among the three resin composites tested, G-aenial Flo exhibited least Ra value due to its reduced filler size and its uniform distribution.

Keywords: Composite resin, polishing, polishing system, Soflex, surface roughness

INTRODUCTION

The ultimate goal of using a dental restorative material is to restore the biological, functional, and aesthetic properties of healthy tooth structure. Due to increasing restorative esthetic demand of the patient and newer improvement of composite, its clinical use has expanded considerably over the years, regardless of the cavity type and location. Application of nanotechnology in composites with nanoparticles and nanoclusters have been introduced which reduces the interstitial spaces among the inorganic particles, providing better physical properties and polish maintenance, which can be seen in the surface texture. It reduces the material degradation over the years. This technology enables us to use nanocomposite in both anterior and posterior teeth.[1,2] The aesthetic and clinical properties of composite resin depend not only on their structure, but also on the finishing and polishing protocol, which are of greater importance in achieving longevity of the restoration. Surface roughness leads to adherence of bacterial plaque retention, which later evolves into periodontal disease.[3,4,5]

Various finishing and polishing systems are available on the market, including abrasive diamond tips, silicon disks, aluminum oxide discs, abrasive rubbers, and several polishing pastes containing thin abrasive particles.[6,7] There is no general consensus in the dental literature on the best methods for finishing and polishing of different composite restoration materials. Hence, the present in vitro study was undertaken to evaluate and compare the polishing ability of three different polishing devices with different composite resins.

MATERIALS AND METHODS

The commercially available composite restorative materials used in this study are as follows: Filtek Z350XT (3M ESPE, St. Paul, MN, USA, N479887) that contains a combination of a nonagglomerated/nonaggregated filler (size 4-11 μm), zirconia filler, and an aggregated zirconia/silica cluster filler (comprised of 20 nm silica and 4-11 μm zirconia particles) and T -Econom plus (Ivoclar Vivadent, Liechtenstein, L6403) that contains microhybrid particles of sizes 0.04 μm and 7 μm and G-aenial universal flo (GC Ptd, Germany, L3241) that contains 69% filler load by weight and homogenous dispersion of silinated true nano silica glass particles of 200-nm diameter.

Using Teflon mold, a total of 60 samples were prepared 6 mm in diameter and 3 mm in height. The composite material was filled in the Teflon mold with a composite filling instrument. The mold was slightly overfilled and was then covered on both sides with matrix strip (Samit products, Jhadewalan, New Delhi). Then the composite resin was sandwiched between two glass plates to extrude the excess material, and the excess material was removed.

Each side of the two-sided samples was cured with light-emitting diode (LED) unit (LEdition, Ivoclar Vivadent) for 30 s. The samples were further cured for additional 60 s from both sides with the matrices in place. Then the samples were removed from the mold and was stored in deionized water at 37°C for 24 h.

Grouping of samples

The 60 specimens were divided into 3 groups (N = 20), which accounted for 40 surfaces (N = 20 × 2 = 40) in each groups. Each group (I-III) was subdivided into four subgroups (A-D).

Finishing of samples

The samples of all groups except subgroup A (control) were finished with their respective finishing instruments according to the manufacturer's instructions. Care was taken to maintain the planar motion during the procedure.

Polishing of samples

The four subgroups of group II, group III, and group IV were polished according to the respective manufacture's instructions as follow:

Subgroup A: (control) Mylar strip was used to provide a surface finish and no polishing was carried out.

Subgroup B: Polishing was carried out using Astrobrush single step polishing system (Ivoclar vivadent, AG, Liechtenstein, lot no-RL3771).

Subgroup C: Polishing was carried out using Astropol three step polishing system (Ivoclar vivadent, AG, Liechtenstein, lot no-ML0797).

Subgroup D: Polishing was carried out using Soflex spiral wheel polishing system. (3M, ESPE, St. Paul, MN, USA, lot no-N493180).

The baseline surface roughness (Ra) values of each sample were measured using a profilometer. The Ra value (μm) reading was also recorded using a profilometer (Kosaka Lab. SE 1700) with 0.25 mm cutoff and 0.1 mm/s speed. Three measurements were made and an average was calculated. To reduce the interoperator variability, all the specimens were finished and polished by the same operator. After polishing, the smoothness of the resin composite of all the groups were again calculated and were compared within the baseline values. Data were analyzed by one-way analysis of variance (ANOVA) and Tukey's test for individual comparisons between the groups.

RESULTS

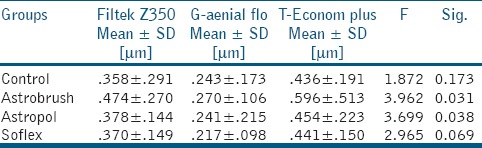

ANOVA and independent sample t-tests were carried out. In the following table, the mean values of control, Astrobrush, Astropol and Soflex for three groups are compared using ANOVA [Table 1]. It is found that the mean values of control and Soflex are the same among the three groups compared since the P values of these two parameters are greater than 0.05. The variances in Astrobrush among the groups are heterogeneous, and hence Tamhane's test has been applied. It is found from the post hoc test that the mean values of the three groups compared are different from one another. The mean value of Astrobrush is found to be very high in T -Econom plus, it is very low in G-aenial Flo, and it is in the average level in Filtek Z350.

Table 1.

Comparison between three groups, mean value (μm), and standard deviation

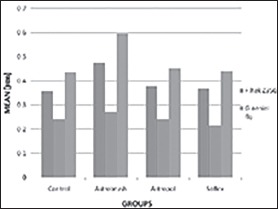

As far as Astropol is concerned, the mean values of the three groups are found to be different since the significance value of ANOVA is less than 0.05. The variances of the three groups compared are homogeneous in nature for Astropol values with G-aenieal Flo exhibiting significantly lower surface roughness value compared to T-Econom plus and filtek Z350 XT. Significant differences in the mean values of Astropol and Astrobrush are found for the three groups compared [Graph 1].

Graph 1.

Variation between three polishing systems with control

DISCUSSION

Composites have revolutionized the concept of aesthetic dentistry. It is a heterogeneous material that is composed of three major components resin matrix, filler particles, and silane-coupling agent.[8] Composite restoration can be imperceptible when its surface closely resembles the surrounding enamel surface. Polished restoration should demonstrate enamel like surface structure and gloss. The organic matrix structure and characteristic of fillers exert a direct influence on the surface roughness and staining susceptibility of composite resin. Besides the effect of composition, degree of conversion, finishing, and polishing procedures can also influence the surface quality of composite resins. Hence, the surface finish of composite resin is dependent on the microstructure and also on the finishing and polishing systems used to modify their surface.

Different finishing and polishing techniques provide different surface Ra values. The use of clear polyester strips over the last increment of material in composite resin restorations is a usual step to avoid the oxygen inhibition layer on the resin surface. However, the resulting surface is rich in organic matrix, leading to a relatively unstable surface that is rich in resin. Resin rich layer on the surface of composite resin need to be removed by polishing to avoid accelerated clinical wear.[9] However, the use of carbide burs is limited to initial contouring because of their ability to remove equal amount of adjacent enamel. According to Stoddard and Johnson et al.,[10] the effectiveness of finishing/polishing systems depends on material (filler size and content), type of abrasive used, time spent with each abrasives, strokes, amount of pressure applied, orientation of abrading surfaces and geometry (discs, cups, cones) of abrasive instruments. For years, specially designed diamonds with very fine abrasive particles size and white Arkansas stones have been used to polish resin composite restorations.[11]

The use of finishing and polishing technique is essential to improve the mechanical properties of composite resin surface. Fruits[6] have reported that three types of motion may be critical to the development of optimal surface smoothness rotary motion (circular), planar motion, or reciprocating motion. It was found that for all the possible combinations of materials and abrasive grits, the planer motion achieved the lowest Ra values. In the current study, a planar motion was used for all the polishing systems.[12]

The effectiveness of surface finishing and polishing procedures is of fundamental importance for any restoration.[12] These procedures are commonly required after the placement of direct composite resin restorations since they minimize the retention of plaque and stains and other problems resulting from the exposure of rough surfaces to the oral environment.[13] Initially, surface irregularities provide increased colonization area and good protection against detachment forces (such as chewing, oral fluids, desquamation, or oral hygiene). This provides shift to irreversible attachment and subsequent plaque growth, since its maturation depends mainly on multiplication of present bacteria. Studies have reported no appreciable difference in plaque accumulation between surfaces polished by various methods that resulted in average surface Ra values in the range of 0.7-1.4 μm.[14,15,16] The Ra value was measured in each samples after the finishing and polishing procedures following the manufacture's instruction by using a surface profilometer.

The Ra value of a specimen was defined as the arithmetic average height of roughness component irregularities from the mean line measured within the sampling length.[17] The surface roughness of the restoration will appear optically smooth when their surface Ra value is smaller than 0.1 μ.[9]

Harder filler particles are left protruding from the surface during polishing, as the softer resin matrix is referentially removed from microhybrid composites. Filler particles should be situated together as close as possible in order to protect the resin matrix from abrasives.[18] Hence, the application of nanotechnology in composite research is of great benefit in reduction of roughness.[9]

The surface roughness created by Astrobrush was statistically significant as compared to the other groups. Due to the reason that Astrobrush group does not have a separate finishing procedure before polishing which are more prone to expose the filler particles with preferential loss of the resin matrix. The surface irregularities of resin composites left by the use of tungsten carbide bur were not sufficiently removed due to the low abrasive potential of silicon carbide that is incorporated in Astrobrush (Group B).[3,9]

Though the diamond abrasives in Astropol (Group C) gave a good surface finish, they were found to be rougher than the surface finish produced by aluminum oxide incorporated in Soflex spiral wheel (Group D). This may occur due to the nondisplacement of composite filler particles by Soflex spiral wheel as compared to Astropol points that are less flexible. Aluminum oxide in Soflex spiral wheel promotes a homogenous abrasion of fillers and the resin matrix. Added to that, the Soflex wheel efficiently adapts to the surface of the composite resin.

All the finishing and polishing system seem to perform better in G-aenial Flo as compared to T - Econom plus and Filtek Z350. True nanosized particles in G-aenial Flo tend to improve the surface polish due to the reduced filler size (30 μm) and its uniform distribution. No statistically significant difference was found between the three groups as compared to the control group for G-aenial Flo.

CONCLUSION

Soflex spiral wheel had least Ra value as compared to other groups and it may be attributed to the presence aluminum oxide in Soflex spiral wheel, which promote homogenous abrasion of fillers and resin matrix. Among the three groups tested, G-aenial Flo exhibited least Ra value due to its reduced filler size and its uniform distribution.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Hervás-García A, Martínez-Lozano MA, Cabanes-Vila J, Barjau-Escribano A, Fos-Galve P. Composite resins: A review of the materials and clinical indications. Med Oral Patol Oral Cir Bucal. 2006;11:E215–20. [PubMed] [Google Scholar]

- 2.Janus J, Fauxpoint G, Arntz Y, Pelletier H, Etienne O. Surface roughness and morphology of three nanocomposites after two different polishing treatments by a multitechnique approach. Dent Mater. 2010;26:416–25. doi: 10.1016/j.dental.2009.09.014. [DOI] [PubMed] [Google Scholar]

- 3.Aykent F, Yondem I, Ozyesil AG, Gunal SK, Avunduk MC, Ozkan S. Effect of different finishing techniques for restorative materials on surface roughness and bacterial adhesion. J Prosthet Dent. 2010;103:221–7. doi: 10.1016/S0022-3913(10)60034-0. [DOI] [PubMed] [Google Scholar]

- 4.Perez Cdos R, Hirata RJ, da Silva AH, Sampaio EM, de Miranda MS. Effect of a glaze/composite sealant on the 3-D surface roughness of esthetic restorative materials. Oper Dent. 2009;34:674–80. doi: 10.2341/08-014-L. [DOI] [PubMed] [Google Scholar]

- 5.Topcu FT, Erdemir U, Sahinkesen G, Yildiz E, Uslan I, Acikel C. Evaluation of microhardness, surface roughness, and wear behavior of different types of resin composites polymerized with two different light sources. J Biomed Mater Res B Appl Biomater. 2010;92:470–8. doi: 10.1002/jbm.b.31540. [DOI] [PubMed] [Google Scholar]

- 6.Senawongse P, Pongprueksa P. Surface roughness of nanofill and nanohybrid resin composites after polishing and brushing. J Esthet Restor Dent. 2007;19:265–75. doi: 10.1111/j.1708-8240.2007.00116.x. [DOI] [PubMed] [Google Scholar]

- 7.Reis AS, Giannini M, Lovadino JR, dos Santos Dias CT. The effect of six polishing systems on the surface roughness of two packable resin-based composites. Am J Dent. 2002;15:193–7. [PubMed] [Google Scholar]

- 8.Joniot SB, Grégoire GL, Auther AM, Roques YM. Three-dimensional optical profilometry analysis of surface states obtained after finishing sequences for three composite resins. Oper Dent. 2000;25:311–5. [PubMed] [Google Scholar]

- 9.Gedik R, Hürmüzlü F, Coşkun A, Bektaş OO, Ozdemir AK. Surface roughness of new microhybrid resin-based composites. J Am Dent Assoc. 2005;136:1106–2. doi: 10.14219/jada.archive.2005.0314. [DOI] [PubMed] [Google Scholar]

- 10.Barbosa SH, Zanata RL, Navarro MF, Nunes OB. Effect of different finishing and polishing techniques on the surface roughness of microfilled, hybrid and packable composite resins. Braz Dent J. 2005;16:39–44. doi: 10.1590/s0103-64402005000100007. [DOI] [PubMed] [Google Scholar]

- 11.Gupta T, Mohan B, Lakshmi Narayanan LL. Profilometric analysis of microfilled resin using five different polishing systems. J Conserv Dent. 2002;5:110–3. [Google Scholar]

- 12.Roulet JF, Hirt T, Lutz F. Surface roughness and marginal behaviour experimental and commercial composites: An in vitro study. J Oral Rehabil. 1984;11:499–509. doi: 10.1111/j.1365-2842.1984.tb00602.x. [DOI] [PubMed] [Google Scholar]

- 13.Fruits TJ, Miranda FJ, Coury TL. Effects of equivalent abrasive grit sizes utilizing different polishing motions on selected restorative materials. Quintessence Int. 1996;27:279–85. [PubMed] [Google Scholar]

- 14.Quiroz L, Lentz DL. The effect of polishing procedures on the surface smoothness of several light-cured posterior composites. Compend Contin Educ Dent. 1986;7:676–8. [PubMed] [Google Scholar]

- 15.Weitman RT, Eames WB. Plaque accumulation on composite surfaces after various finishing procedures. J Am Dent Assoc. 1975;91:101–6. doi: 10.14219/jada.archive.1975.0294. [DOI] [PubMed] [Google Scholar]

- 16.Shintani H, Sayou J, Satou N, Hayashihara H, Inoue T. Effects of various finishing methods on staining and accumulation Streptococcus mutans HS-6 on composite resins. Dent Mater. 1985;1:225–7. doi: 10.1016/S0109-5641(85)80046-4. [DOI] [PubMed] [Google Scholar]

- 17.Setcos JC, Tarim B, Suzuki S. Surface finish produced on resin composites by new polishing systems. Quintessence Int. 1999;30:169–73. [PubMed] [Google Scholar]

- 18.Paravina RD, Roeder L, Lu H, Vogel K, Powers JM. Effect of finishing and polishing procedures on surface roughness, gloss and color of resin-based composites. Am J Dent. 2004;17:262–6. [PubMed] [Google Scholar]