Abstract

Mycotoxins, toxins produced by fungi that colonize food crops, can pose a heavy economic burden to the United States corn industry. In terms of economic burden, aflatoxins are the most problematic mycotoxins in US agriculture. Estimates of their market impacts are important in determining the benefits of implementing mitigation strategies within the US corn industry, and the value of strategies to mitigate mycotoxin problems. Additionally, climate change may cause increases in aflatoxin contamination in corn, greatly affecting the economy of the US Midwest and all sectors in the US and worldwide that rely upon its corn production. We propose two separate models for estimating the potential market loss to the corn industry from aflatoxin contamination, in the case of potential near-future climate scenarios (based on aflatoxin levels in Midwest corn in warm summers in the last decade). One model uses probability of acceptance based on operating characteristic (OC) curves for aflatoxin sampling and testing, while the other employs partial equilibrium economic analysis, assuming no Type 1 or Type 2 errors, to estimate losses due to proportions of lots above the US Food and Drug Administration (FDA) aflatoxin action levels. We estimate that aflatoxin contamination could cause losses to the corn industry ranging from $52.1 million to $1.68 billion annually in the United States, if climate change causes more regular aflatoxin contamination in the Corn Belt as was experienced in years such as 2012. The wide range represents the natural variability in aflatoxin contamination from year to year in US corn, with higher losses representative of warmer years.

Keywords: Aflatoxin, economic analysis, market loss, operating characteristic curve

Introduction

Corn trade is the largest contributor to the United States’ (US) agricultural trade balance, with the US providing over half of the total supply of corn in the world market (USDA 2014). Field corn accounts for over 87 million acres of land harvested within the US, contributes about $75 billion to the economy, and comprises 95.4% of the total US feed grain production (NASS 2013; USDA 2015). In short, corn is vitally important to the US agricultural and food economies, and ensuring a sustainable supply of quality corn is critical in the years to come; not only for the United States, but for the global food supply.

The size of the corn industry and its importance in the economy makes consideration of quality changes in light of near-future climate scenarios critical. The price received by corn growers and suppliers from food and feed companies depends on multiple factors, including the quality and safety of the grain being sold within the supply chain. It has been proposed that grain quality in the future could be affected by elevated levels of mycotoxin contamination due to a combination of climatic factors, including higher temperatures and changes in rainfall and relative humidity (Wu et al. 2011). Mycotoxin contamination can pose significant costs to the corn industry through an increased need for testing, lower prices received for contaminated loads, potential lawsuits from consumers, and decreased production in the livestock industry. The mycotoxin of greatest concern to the US corn industry is aflatoxin, as it is the most toxic and carcinogenic of the known mycotoxins and also the most heavily regulated in the US and worldwide.

Aflatoxin

Aflatoxins are produced by the fungi Aspergillus flavus and A. parasiticus, with four major congeners, AFB1, AFB2, AFG1, and AFG2 formed. A. flavus and A. parasiticus infection is associated with high humidity (moisture content exceeds 7%), warm temperatures (between 24 and 35 °C) and drought (Williams et al. 2004). Conditions of high temperature during drought stress in the field and high moisture content just prior to harvest and during storage are the primary conditions for aflatoxin production. AFB1 is a potent human liver carcinogen, and has been estimated to contribute to 25,200 to 155,000 cases of hepatocellular carcinoma each year, although the majority of these cases occur in Asia and sub-Saharan Africa (Liu & Wu 2010). Worldwide, aflatoxin exposure has also been associated with growth impairment (Gong et al. 2002, Khlangwiset et al. 2011), immune system dysfunction (Jiang et al. 2005, 2008), and acute toxicity at high doses (Lewis et al. 2005). Aflatoxin causes a range of adverse effects in animals as well, ranging from liver toxicity to growth impairment (CAST 2003, Khlangwiset et al. 2011).

The level of aflatoxin in the US food supply is generally considered to be low. However, from 2004 to 2013, there were 18 reports of food and feed recalls due to aflatoxin contamination (FDA 2014a). The majority of these recalls occurred for dog food that caused anorexia, lethargy, and bloody diarrhoea in dogs (Marroquin-Cardona et al. 2014). Moreover, near-future climate scenarios and increased corn production may exacerbate aflatoxin-related economic problems in the decades to come.

Economic impacts of mycotoxins

In the US, aflatoxin-related losses are primarily to the market rather than to animal and human health, as aflatoxin regulations are enforced at multiple levels along the corn supply chain. Action levels for aflatoxins have been set by the US Food and Drug Administration (FDA 2014b) for both human food and animal feed (Table 1). Regulation and testing in the US aids in assigning contaminated grain for use in appropriate markets, minimizing potential adverse effects to human and animal health. At grain elevators, when growers bring corn with aflatoxin contamination exceeding these action levels, their corn lots can be rejected outright or bought at a lower price. In high contamination years, grain elevators must deal with the problem of insufficient supplies of high-quality corn. Thus, the primary loss associated with mycotoxins in the US affects the farmers and grain elevators most significantly.

Table 1.

Corn discount schedule based on FDA action levels for aflatoxin

| Ranges of mycotoxins | Discount in $US | FDA standards | |

|---|---|---|---|

| Aflatoxin (AFB1+AFB2+AFG1+AFG2) | Kansas Schedule | Texas Schedule | |

| 20 ng g−1 or less | Full price | Full price | For corn products intended for humans, dairy animals, or other species not specified below, or when the intended use is not known. |

| >20-100 ng g−1 | −0.05 | −0.3 | For corn products intended for breeding beef cattle, breeding swine or mature poultry |

| >100-200 ng g−1 | −0.45 | −0.6 | For corn products intended for finishing swine (100lbs or more) |

| >200-300 ng g−1 | −0.55 | −0.9 | For corn products intended for finishing beef cattle (feedlot cattle) |

| >300-500 ng g−1 | −0.65 | −1.65 | For corn intended for non-animal uses (i.e. ethanol production) |

| >500 ng g−1 | No Sale | No Sale | Considered non-salvagable |

* Losses were also calculated base on each schedule with any lots over 200 ng g−1 receiving a No Sale designation.

Economic impacts of mycotoxins within the US are multifaceted and difficult to determine. Costs associated with such contaminants can range from control and surveillance costs to the farmers, handling and testing costs incurred by grain elevators, losses in the livestock industry from decreased efficiency/productivity, losses in the export market, and crop insurance pay-outs imposed on the government. Vardon et al. (2003) calculated potential annual losses of three mycotoxins (aflatoxin, fumonisin, and deoxynivalenol) to range between $418 million to $1.66 billion from corn, wheat, and peanuts produced in the US. Additionally, they estimated that mitigation costs and losses to livestock could include another $466 million and $6 million to the annual total, respectively.

Market losses due to aflatoxin in corn are likely to increase over the next decade, absent appropriate control strategies, due to changes in the climate (Wu et al. 2011). The optimal climate conditions for aflatoxin contamination have been studied extensively; high temperatures and drought stress directly impact both A. flavus growth and impairs healthy development of corn plants (McMillian et al 1985; Payne & Widstrom 1985; Diener et al. 1987; Payne et al. 1992; Cotty & Jaime-Garcia 2007). Controlled environment studies have provided evidence that high temperatures and low rainfall favour infection of corn by A. flavus and increased concentrations of aflatoxin, as reviewed by Wu et al. (2011). Such changes in the climate, and subsequent probability of aflatoxin contamination of corn crops in the Corn Belt states, could cause a need for increased testing frequency and standardized discount schedules imposed at grain elevators, as currently occurs in Texas and other Southern states. The impact of discount schedules in the Corn Belt on the corn industry would be potentially large losses in the total economic product, due to the sheer volume of corn produced in this part of the US.

There is currently a lack of data on mycotoxin occurrence state by state in the US and resulting financial impacts, which makes it difficult to model a comprehensive cost analysis. Additionally, modelling difficulties arise as a result of high variability, which is an inherent characteristic of mycotoxin contamination of grains. High variability is a result of the heterogeneous nature of aflatoxin contamination between grain lots and among individual kernels within a lot (Lee et al. 1980). This heterogeneity renders sampling difficult; sampling variability accounts for the majority of variance in mycotoxin analyses (Johansson et al. 2000). Aflatoxin test methods also vary in laboratory sample and test sample size, among other characteristics; this variability can be observed in the performance verified mycotoxin test kits, a service executed and maintained by the US Department of Agriculture Grain Inspection, Packers and Stockyards Administration (GIPSA 2014). Price per bushel of corn varies by location, as do discounts for grain of inferior quality. All of the difficulties described above require modelling assumptions and result in a large variance of the resulting economic impact estimate.

The aim of the current study is to estimate economic impacts of aflatoxin in US corn – both under current conditions, and conditions that could occur if the climate of the Corn Belt became similar to that observed in Texas (high temperatures and drought stress), resulting in increased regulation and testing. Thus, it was assumed that grain elevators in those states with the highest corn production would follow the same frequent testing and regulation practices that are currently applied in Texas. The potential losses are calculated using two separate methodologies: 1) accounts for variability in Type 1 (false positive) and Type 2 (false negative) errors associated with mycotoxin testing; and 2) a partial equilibrium economic analysis assuming no Type 1 or Type 2 errors. Our estimates are focused on direct losses that would be incurred by the farmers and grain elevators, and do not include estimates of losses to the livestock industry or costs incurred for mycotoxin prevention.

Materials and methods

Mycotoxin testing plan and operating characteristic (OC) curves

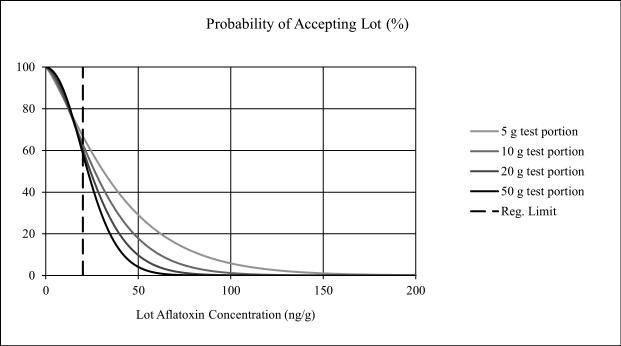

Mycotoxin sampling plans can result in two types of statistical errors: samples can falsely test over a regulatory level and be rejected (Type 1 error: a false positive) or they can falsely test under a regulatory level with a contaminated lot wrongly accepted into general commerce (Type 2 error: a false negative). These scenarios for regulatory and quality control programs are often evaluated, and costs and benefits weighed, through the use of operating characteristic curves (OC curves) (Whitaker et al. 2011). OC curves represent the likelihood of acceptance as a function of the actual level of aflatoxin in a lot, based on the variability in the sampling protocol and the actual levels and distribution of the toxin in the lot. We applied OC curves to determine the probabilities of obtaining false positives or false negatives if the rejection limit is set at 20 ng g−1 aflatoxin, the action level for corn acceptable into general commerce. To calculate these probabilities, software from the Food and Agriculture Organization of the United Nations (FAO) was utilized (FAO 2013). This type of OC curve, as described by Whitaker et al. (2011) and Brera et al. (2010), predicts the acceptance probability associated with a specific sampling procedure, accept/reject level, and specific lot mycotoxin concentrations.

The mycotoxin sampling procedure chosen for our calculations was that specified for aflatoxin quick-test test strips. These strips utilize a dip-stick detection method, are relatively inexpensive, and do not have long time requirements for returning results; making these tests attractive for use at grain elevators. For this analysis, the following variables were stipulated to produce an OC curve that was specific to aflatoxin in shelled corn commodities. Kernel count per kg was left at the software default of 3000, analytical variance type was set as “among lab”†, laboratory sample size was set at 2.5 kg, number of laboratory samples was equal to 1, test portion was 5 g, number of aliquots was equal to 1, and the accept/reject limit was 20 ng g−1.

Figure 1 shows the output OC curve obtained for the sampling protocol described above as well as curves from scenarios with changing test portion size. The test portion size was varied in an effort to examine the sensitivity of changing acceptance probabilities on the overall economic impact. The results indicated that changes in the test size portion did not significantly contribute to increases in economic loss; therefore, the OC curve calculations were conducted solely with the 5 g methodology described in the aflatoxin quick-test test strips. It is important to note that if an elevator suspects a low probability of incoming lots to be over 20 ng g−1, testing will not usually occur, as is currently usually the case in the Corn Belt.

Figure 1.

The operating characteristic curve utilized in our economic analysis was based on a lenient sampling and testing protocol that was deemed probable for real world testing practices in the US. These curves represent the differences in changing one variable (test portion size) from a VICAM AflaCheck quick test strips protocol. The 5 g test portion is the verified protocol specified by VICAM and the 5 g curve and its related probabilities were utilized in the economic analysis. The curves were generated with the FAO mycotoxin sampling tool: http://www.fstools.org/mycotoxins/.

Aflatoxin contamination levels by State

Average aflatoxin contamination levels in US produced corn were obtained for three separate states (Iowa, Illinois, and Texas) in various years. Data from Iowa was obtained through a state surveillance survey at grain elevators in the year 2012, conducted by the Iowa Department of Agriculture and Land Stewardship. These surveys used the Charm-ROSA Aflatoxin Quantitative Lateral Flow Assay (Charm Sciences, Inc., Lawrence, MA, USA). The method used 70% methanol extraction and detected and reported the sum of aflatoxins B1, B2, G1, and G2. The reported LOD is < 2 ng g−1 for aflatoxins. In 2012, climatic conditions in Iowa were favourable for some aflatoxin contamination: a situation that has occurred once or twice a decade, over the last several decades, in this state. Samples were collected from each of Iowa's 99 counties and were typically taken from scale house containers that held grain collected from probing incoming grain trucks. Aflatoxin contamination was analysed and averages calculated based on the nine Iowa crop reporting districts (Northwest, North Central, Northeast, West Central, Central, East Central, Southwest, South Central, and Southeast), with a total of 304 samples used in the analysis. While this data only covers one year of possible contamination and was not originally collected for the purpose of economic modelling, we have included the data in our analysis, because Iowa is the largest producer of corn in the US. Thus, any contamination of the state's crop would have a large impact on the economics of the US corn industry as a whole. We assumed that the distribution of test results is representative of what a grain buyer would experience.

Since 2010, the Illinois Department of Agriculture has published mycotoxin survey results every year for the grain crops produced in that state (IDA 2014). These surveys are currently conducted in Illinois as a proactive communication with feed mills, to predict years when increased testing and caution should be taken to avoid potential injury down the market chain. Although the sampling method is not described in the IDA reports, the limit of detection for aflatoxin analysis is specified at 0.5 μg g−1. Samples are collected from each of the 102 counties in Illinois, totalling over 400 samples collected and analysed per year. Illinois is one of the only states that publicly report on mycotoxin contamination in grain, making these the best available data for analysis on a state level. For our economic analysis, we have included the aflatoxin contamination levels reported for the harvest seasons of 2011, 2012, and 2013. Maps of the mycotoxin contamination data used in this economic analysis are available at the Illinois Department of Agriculture website (IDA 2014).

We obtained aflatoxin contamination data for Texas through the Texas Office of the State Chemist, and from research by Dr Thomas Isakeit at Texas A&M University. Most data came from counties within the Central, Eastern, or South eastern regions of the state. It is important to note that total number of samples analysed each year varied, but typically included over 200 samples total for the state. Analysis of samples was conducted with immunosorbent affinity chromatography for clean-up, followed by HPLC-fluorescence detection for quantification of aflatoxins; the LOD in 1 ng g−1. For our economic analysis we have included the aflatoxin contamination levels reported for the harvest seasons of 2011, 2012, and 2013. These were the best available aflatoxin data for the Southern United States.

For a comprehensive estimate of potential loss to the corn industry due to aflatoxin contamination, data for Texas, Illinois, and Iowa was assumed to represent contamination of corn crops in similar climate regions within the United States. Table 2 details the categorization of all the states within the US for aflatoxin contamination, corn production of that state, and price received per bushel that was applied to the total harvested corn for representative years for that state. While the aflatoxin levels in each state are estimated and are likely to have considerably higher variability among and even within individual states, the calculations were conducted to be as conservative as possible. For instance, 15 states were assumed to have no aflatoxin contamination within their corn, and individual production values and price received per bushel were applied in the economic loss equation for each state (Table 2). Additionally, current losses to the corn industry in the Corn Belt states were considered to be negligible due to the low mean of the distribution in Iowa, and the historic rare incidence of aflatoxin in Corn Belt states. Thus, in the current climate, the majority of aflatoxin impacts are thought to solely occur in the South and Southeast states. For Corn Belt states we utilized the distribution in Iowa from a problem year (i.e., 2012) to estimate future distributions if more problem years occurred.

Table 2.

| State | Production (1,000 Bushels) | Average Price Received $/BU | Grouping | ||||

|---|---|---|---|---|---|---|---|

| 2011 | 2012 | 2013 | 2011 | 2012 | 2013 | ||

| Alabama | 28500 | 28910 | 43660 | 6.32 | 7.18 | 4.5 | TX |

| Arizona | 6300 | 6240 | 9180 | 6.78 | 7.84 | 6.3 | TX |

| Arkansas | 73840 | 123710 | 162690 | 6.27 | 6.81 | 5.2 | TX |

| California | 27750 | 33300 | 35100 | 6.41 | 6.68 | 5.55 | Assume No AF |

| Colorado | 172900 | 134330 | 129690 | 6.15 | 6.86 | 4.65 | Assume No AF |

| Conneticut | NA | NA | NA | ||||

| Delaware | 23660 | 24030 | 28884 | 6.93 | 7.55 | 4.7 | Assume No AF |

| Florida | 3300 | 4480 | 10140 | 6.65 | 7.5 | 4.55 | TX |

| Georgia | 42660 | 55800 | 81375 | 7.3 | 7.9 | 5.35 | TX |

| Idaho | 22200 | 25650 | 21600 | 6.96 | 7.1 | 5.7 | Assume No AF |

| Illinois | 1946800 | 1286250 | 2100400 | 6.25 | 6.87 | 4.5 | IL |

| Indiana | 839500 | 596970 | 1035450 | 6.31 | 7.23 | 4.25 | IL |

| Iowa | 2356400 | 1876900 | 2161500 | 6.2 | 6.92 | 4.6 | IA |

| Kansas | 449400 | 379200 | 508000 | 6.28 | 7.04 | 4.55 | TX |

| Kentucky | 180700 | 104040 | 243100 | 6.3 | 6.96 | 4.55 | IL |

| Louisiana | 76950 | 91690 | 115910 | 6.1 | 6.9 | 5.1 | TX |

| Maine | NA | NA | NA | ||||

| Maryland | 46870 | 53070 | 66360 | 6.7 | 7.3 | 4.7 | Assume No AF |

| Massachusetts | NA | NA | NA | ||||

| Michigan | 335070 | 317870 | 348750 | 6.14 | 6.69 | 4.05 | IA |

| Minnesota | 1201200 | 1374450 | 1304000 | 6.09 | 6.67 | 4.6 | IA |

| Mississippi | 94720 | 131175 | 146080 | 6.23 | 6.94 | 5.35 | TX |

| Missouri | 349980 | 247500 | 435200 | 6.4 | 7.34 | 4.55 | IL |

| Montana | 4680 | 6600 | 8625 | 6.47 | 7.21 | 4.5 | Assume No AF |

| Nebraska | 1536000 | 1292200 | 1623500 | 6.11 | 6.85 | 4.55 | Assume No AF |

| Nevada | NA | NA | NA | ||||

| New Hampshire | NA | NA | NA | ||||

| New Jersey | 9963 | 10148 | 11120 | 6.8 | 7.4 | 4.65 | Assume No AF |

| New Mexico | 8100 | 7310 | 7410 | 6.35 | 7.3 | 5.1 | TX |

| New York | 82460 | 91120 | 95220 | 6.9 | 6.78 | 4.35 | Assume No AF |

| North Carolina | 68460 | 95940 | 123540 | 7.04 | 7.48 | 4.9 | TX |

| North Dakota | 216300 | 422120 | 396000 | 5.81 | 6.46 | 4 | Assume No AF |

| Ohio | 508760 | 448950 | 661980 | 6.44 | 7.09 | 4.3 | IL |

| Oklahoma | 17100 | 32450 | 44950 | 6.22 | 7.04 | 5.2 | TX |

| Oregon | 10965 | 10920 | 6840 | 6.95 | 6.96 | 5.6 | Assume No AF |

| Pennsylvania | 106560 | 132000 | 160230 | 7.05 | 7.21 | 4.15 | Assume No AF |

| Rhode Island | NA | NA | NA | ||||

| South Carolina | 21450 | 37820 | 43550 | 6.6 | 7.5 | 4.7 | TX |

| South Dakota | 653400 | 535300 | 808680 | 6.03 | 6.72 | 4.1 | Assume No AF |

| Tennessee | 96285 | 81600 | 127920 | 6.56 | 7.28 | 4.7 | IL |

| Texas | 136710 | 201500 | 276000 | 6.61 | 7.12 | 5.15 | TX |

| Utah | 4920 | 5678 | 5270 | 6.97 | 7.59 | 5.35 | Assume No AF |

| Vermont | NA | NA | NA | ||||

| Virginia | 40120 | 36050 | 55440 | 6.58 | 7.3 | 4.7 | IL |

| Washingon | 28125 | 24725 | 22575 | 6.22 | 6.69 | 5.5 | Assume No AF |

| West Virginia | 3534 | 4480 | 5292 | 6.5 | 7.2 | 4.7 | IL |

| Wisconsin | 517920 | 399300 | 445300 | 6.02 | 6.69 | 4.2 | IA |

| Wyoming | 9100 | 8520 | 8636 | 6.2 | 7.05 | 4.15 | Assume No AF |

*Production and average price received values are from the USDA NASS (2013, 2014). The table depicts how each state and thus the corn production for that state was classified. Based on location and climate states were classified as either being: 1) Iowa like, 2) Illinois like, 3) Texas like, or 4) not high risk for aflatoxin. Classification as either an Iowa, Illinois, or Texas like state resulted in application of those respective states probabilities of aflatoxin contamination (Figures 2-4) to their ‘like’ states.

Production and price received for individual states were obtained for 2011, 2012, and 2013 from the USDA National Agricultural Statistics Service (NASS 2014). Current discount schedules detailing price reductions based on aflatoxin contamination were obtained from Texas (Dr. Tom Isakeit, Texas A&M University) and from Kansas (Team Marketing Alliance, Moundridge, KS). These discount schedules were applied in our study to calculate the price received for harvested grain that exceeded FDA aflatoxin action levels (Table 1). We assumed that all bushels were subject to a discounted price and the Corn Belt states were assumed to have similar testing protocols and discount schedules as those currently observed in Texas. Discount schedules such as these are used in areas where aflatoxin is a persistent annual problem, but are currently rare in the Corn Belt and other corn-producing states with more moderate climates. Therefore, the following calculations with the discount schedule are indicative of losses that could occur under climate change conditions.

OC curve based calculations

The projected economic impacts to the US corn industry, under conditions requiring Texas-like testing protocols, were calculated using two separate models. The first model utilized the acceptance probabilities calculated from the OC curve to understand how aflatoxin sampling can impact the economic gains and losses based on aflatoxin contamination by climate region. The amount of corn produced in each state that would fall into a specific FDA action level range (i.e., 20 ng g−1 or less, 21-100 ng g−1, 101-200 ng g−1, and greater than 200 ng g−1) was calculated based on the percentages in those same ranges from the survey data in Iowa, Illinois, or Texas. These amounts of corn (bushels) within each range were then multiplied by the probability of rejection based on the OC curve (Figure 1) at the low and high end of the FDA action level range. These values were considered the amount of crop subject to price reduction in bushels for each state. Economic losses were then calculated as total of those bushels multiplied by the discount value applied to each range as described in the discount schedule. In this way we were able to obtain ranges of potential monetary losses for each state based on a relevant testing protocol and observed aflatoxin levels in previous years. The equation for each state's total economic loss in US dollars (USD) was as follows:

| (1) |

Where L is the total potential loss in USD; B is the amount of bushels of corn harvested; R is the ratio of corn within a specified FDA regulatory range; P is the probability of acceptance based on the OC curve; D is the discounted amount in USD; i is the state of interest; and k is the FDA action level range of interest. It is important to note that, using the OC curve method, 200 ng g−1 was the highest lot concentration for which a probability value could be predicted. Any crops exceeding the 200 ng g−1 level, which mostly occurred in Texas, were assumed to lose $0.90 per bushel on the low side and $1.65 per bushel on the high side of the range. Additionally, this calculation assumes that all corn is tested and, therefore, is subject to discounts.

Non-OC curve based calculations

The second model utilized to calculate potential economic losses was similar to the first model, but without including the probability of acceptance factor from the OC curve. This model thus, does not take into account the sampling protocol for aflatoxin. Because this model also did not lend itself to calculating ranges of losses, the total losses reported are averages for each climate region. However, ranges are represented from a lenient discount schedule (Kansas) and a highly conservative discount schedule (Texas). The subsequent calculations in this model have two assumed variables (mycotoxin level and price discount) and two specific variables (corn production and price received per bushel) for each state. The equation used for each state's total production in USD was as follows:

| (2) |

Where T is the production in USD; B the amount of bushels of corn harvested; R is the ratio of corn within a specified FDA regulatory range; M is the average price received per bushel of corn; D is the amount discounted from the base price; i is the state of interest; and k is the FDA action level range of interest. Ti was calculated for each state, at each FDA regulatory range. The economic loss for each state was thus:

| (3) |

Where L is the economic loss to the corn industry for state i and P(USDA) is total production in USD as reported by USDA NASS for state i. The sum of L for each US state reflects the potential economic loss to the US corn industry based on grain price reductions due to aflatoxin contamination in 2011, 2012, and 2013. It is important to note that in this model monetary losses were calculated for crops contaminated up to 200 ng g−1, after which they were deemed unsuitable for market and lost the whole of their value; and as high as 500 ng g−1 aflatoxin, after which they lost the whole of their value. Therefore, the economic losses we calculated account for four different scenarios in a sensitivity analysis: 1) Kansas discounts applied up to 200 ng g−1, 2) Texas discounts applied up to 200 ng g−1, 3) Kansas discounts applied up to 500 ng g−1, and 4) Texas discounts applied up to 500 ng g−1. Similar to the OC calculations, this calculation assumes that all corn is tested and, therefore, is subject to discounts.

Results

Observed levels of aflatoxin

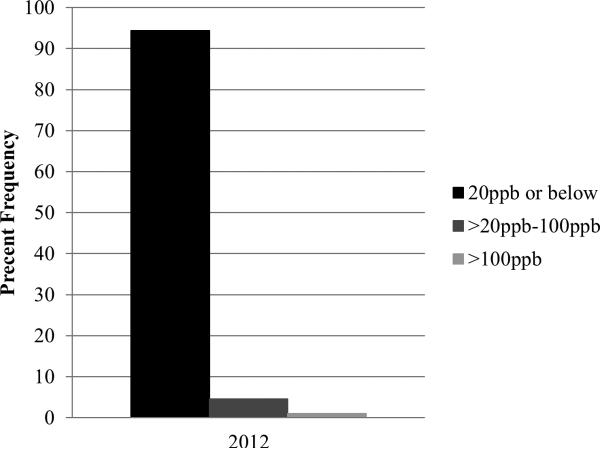

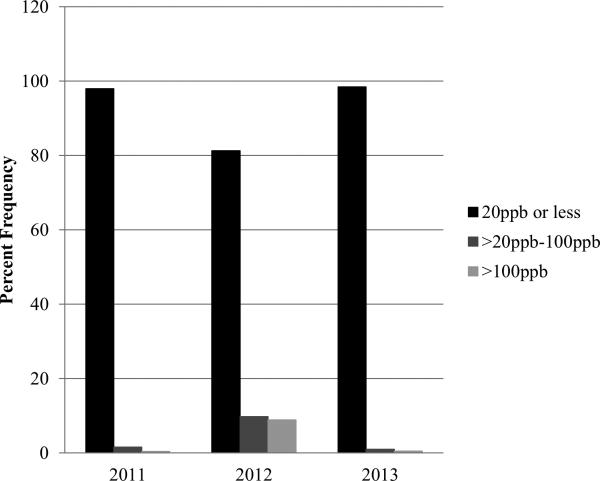

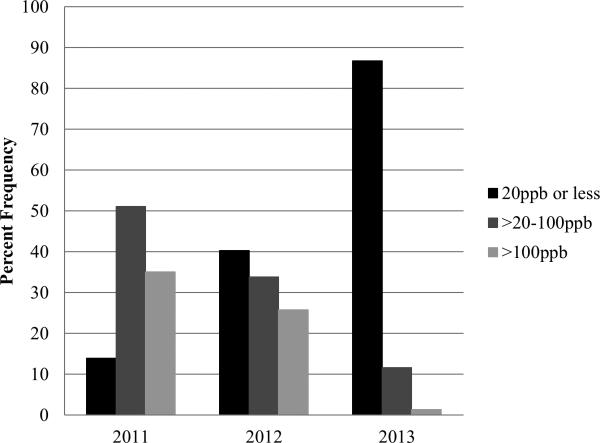

In 2012, over 94% of the corn tested in Iowa was under the 20 ng g−1 action level, demonstrating the improbability of significant aflatoxin contamination and price loss in Iowa-grown corn. The overall mean aflatoxin level in Iowa corn from 2012, a year with climate conditions favourable for A. flavus and subsequent aflatoxin contamination was 4 ng g−1. This level is well below the 20 ng g−1 action level for human foods; thus, costs to the Iowa corn industry would be negligible unless there was more frequent testing occurring as is currently seen in Texas. Figure 2 shows the frequency of corn samples falling within the ranges of FDA action levels for the state of Iowa in 2012. Based on Illinois surveys, the vast majority of corn samples in Illinois have contained less than 20 ng g−1 aflatoxin over the past three years, with the worst aflatoxin contamination occurring in 2012, as shown in Figure 3. Aflatoxin data from Texas was the most comprehensive and complete out of our three represented states. Figure 4 shows the aflatoxin contamination levels in Texas from 2011 through 2013. The frequency of aflatoxin contamination in Texas corn has been decreasing over the past three years, with over 86% of the crop in 2013 containing less than 20 ng g−1 aflatoxin.

Figure 2.

Aflatoxin levels were obtained from a surveillance survey at grain elevators by the Iowa Department of Agriculture and Land Stewardship. Averages were calculated from nine crop reporting districts within the state and a total of 304 samples were analysed during this survey. Appropriate fumonisin data for this analysis is not readily available for Iowa.

Figure 3.

Aflatoxin levels were obtained from the Illinois Department of Agriculture. Samples are representative of all the counties within Illinois and typically included over 400 analysed samples each year. Maps of the contamination occurrence are available at: http://www.agr.state.il.us/mycotoxin-survey/.

Figure 4.

Aflatoxin levels were provided by Dr. Tom Isakeit (Texas A&M University). Total number of samples analysed varied between years, but typically included over 200 samples.

Estimated potential losses to the US corn industry

The largest portion of the OC curve variability included the sample preparation variance due to the size of the test portion specified. As the size of the test portion increased, the variance of the resulting OC curve decreased. Changes in test portion and probabilities of acceptance and their corresponding economic losses were calculated for test sizes of 5, 10, 20, and 50 g (Figure 1). The contribution of different acceptance probabilities based on the changes in test size accounted for a 3% increase in loss from a test size of 5 g to 10 g, and a 4.5% increase from 5 g to 50 g. Increasing the test size from 10 g to 20 g resulted in a less than 1% increase in economic loss and the difference between 20 g to 50 g was even smaller.

Table 3 shows potential economic losses calculated from the OC curve model for 5 g test portion size (model 1). The potential range of economic losses varies from $52.1 million to $1.06 billion dollars. The year with the lowest range of potential losses was 2013; however, the crops produced in much of the Corn Belt (including Iowa) are not factored into this year, as we did not have available aflatoxin data. The highest losses due to aflatoxin contamination were observed in the sole year that Iowa and other upper Midwest states were taken into account (2012), due to the large amount of corn production in those states. The variability in the OC curve probabilities assessment creates a much larger range of potential losses in the economic analysis than the ranges described below for model 2.

Table 3.

Estimated economic losses US $million (model 1)

| US Region | 2011 | 2012 | 2013 | |||

|---|---|---|---|---|---|---|

| Low range | high range | low range | high range | low range | high range | |

| Upper Midwest | -- | -- | 40.4 | 445.4 | -- | -- |

| Ohio Valley | 30.3 | 423.9 | 170.1 | 454.1 | 18.1 | 484.1 |

| South/Southeast/Southwest | 258.4 | 377.9 | 47.2 | 132.8 | 34 | 202.8 |

| Total US losses | 288.7 | 801.8 | 257.7 | 1062.3 | 52.1 | 686.9 |

* Numbers are calculated from model 1; which accounts for probabilities of Type 1 and Type 2 errore during aflatoxin testing methods. Calculations were based on corn production in each state, average price received per bushel for each state, percentage of bushels within aflatoxin ranges specified in Table 1 (applied uniformly across states), discount applied to each aflatoxin range for the Texas discount schedule (applied uniformly across states), and the probability of acceptance for each range (based on the OC curve). The low range value is a cumulative value based on the probability of acceptance if the aflatoxin level in lots is equivalent to the lowest value within a given FDA range (Table 1) for all aflatoxin ranges. The high range value is a cumulative value based on the probability of acceptance if the aflatoxin level in lots is equivalent to the highest value within a given FDA range (Table 1) for all aflatoxin ranges.

The potential economic loss for each climate region calculated without including false positive and false negatives from aflatoxin testing methods (as described in model 2) is shown in Table 4 for 2011, 2012, and 2013. This model utilizes four different discount schedules to demonstrate how different discount schedules, which are highly likely across the country, affect the economic output. Based on this model, the potential economic loss due to aflatoxin in a susceptible year could range between $104.5 million and $1.68 billion, depending on the discount schedule. The lowest losses remain in the upper Midwest region and the Ohio valley region. The states included in the upper Midwest, did not significantly contribute to the total economic losses in the US even in 2012, a year when climate conditions heightened the risk of aflatoxin contamination in the Midwest.

Table 4.

Estimated economic losses in US $million (model 2)

| 2011 | 2012 | 2013 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| US Region | Type of discount schedule | |||||||||||

| Discard after 500 ng g−1 | Discard after 200 ng g−1 | Discard after 500 ng g−1 | Discard after 200 ng g−1 | Discard after 500 ng g−1 | Discard after 200 ng g−1 | |||||||

| Kansas | Texas | Kansas | Texas | Kansas | Texas | Kansas | Texas | Kansas | Texas | Kansas | Texas | |

| Upper Midwest | -- | -- | -- | -- | 26.8 | 78.3 | 26.8 | 78.3 | -- | -- | -- | -- |

| Ohio Valley | 140 | 151.9 | 140.1 | 151.9 | 124.5 | 248.3 | 533.8 | 630.9 | 12.8 | 27.8 | 12.8 | 27.8 |

| South/Southeast/Southwest | 317.5 | 582.5 | 1376.0 | 1531.3 | 37.4 | 94.9 | 91.8 | 142.4 | 91.7 | 138.5 | 91.7 | 138.5 |

| Total US losses | 457.5 | 734.4 | 1516.1 | 1683.2 | 188.7 | 421.5 | 652.4 | 851.6 | 104.5 | 166.3 | 104.5 | 166.3 |

* Numbers represent the cumulative losses for each region by year and discount schedule. Discard after 500 or 200 ng g−1 designates those calculations where any lots that exceeded either 500 or 200 ng g−1 were assumed to lose all of their value. Calculations were based on corn production in each state, average price received per bushel for each state, percentage of bushels within aflatoxin ranges specified in Table 1 (applied uniformly across states), and discount applied to each aflatoxin range also specified in Table 1 (applied uniformly across states). The Kansas discount schedule applied smaller discounts than Texas for each range, however elevators in Kansas did not accept lots over 200 ng g−1, where Texas elevators would go up to 500 ng g−1. Therefore, these four discount schedules represent different possibilities that could be applied within the US.

Discussion

Aflatoxin poses a complex economic problem in the US corn industry. Aflatoxin levels in corn are influenced by multiple grower and environmental variables, and can change drastically from year to year and location to location within the US. Climate plays a significant role in aflatoxin contamination in corn, with years having warm summers and drought favouring aflatoxin accumulation in corn. Thus, the South and Southeast regions within the US have historically had a higher potential for aflatoxin contamination in corn crops. As a result, corn produced in these regions is more frequently tested than in other parts of the US. The Corn Belt states, with the highest corn production, have had climates that do not favour aflatoxin contamination, and the current risk in most years does not warrant extensive testing protocols. Discarding or discounting corn does not occur on a regular basis in these states making the current economic impact due to aflatoxin in the Midwest negligible. Human exposures in the US are often thought to be negligible, and decreases in animal production are not significant enough for producers to actively consider mycotoxins a threat to profits. Currently, significant economic impacts are incurred primarily in the southern and South Eastern US due to aflatoxin contamination in corn including regulation, testing, handling, and discounted prices.

However, changes in climate are increasing the probability that a larger proportion of the US corn-growing regions may contain aflatoxin levels that approach FDA action levels. One possible result would be more widespread adoption of discount schedules (for example, in the Corn Belt states) and more rigorous testing protocols. If this were to happen, especially in the major corn-producing states, economic impacts could increase significantly. However, calculation of economic impacts is difficult to assess due to the vast variability inherent to aflatoxin contamination and the variability in how the corn industry deals with aflatoxin-contaminated grain. For instance, it is common practice within the grain industry to commingle grain lots in storage and again when the grain leaves storage; in the latter instance, the purpose being to meet contract grade specifications (e.g., moisture and foreign material). This practice naturally mixes the grain and, secondarily, tends to dilute any aflatoxin “hot spots” that may have existed within the lots, decreasing the probability of an end product containing unacceptable levels.

The lack of specific aflatoxin contamination data within the US corn crop and a lack of industry standard in testing protocols, discount schedules, and grain-handling techniques required us to make assumptions within our economic model. First, in relation to developing an OC curve, we assumed that all grain elevators utilize a rapid aflatoxin test kit that has been performance verified by the USDA GIPSA. Second, a lack of data on number of rejected lots due to aflatoxin contamination required that we apply aflatoxin levels that we obtained for three states to other states with similar climates. Third, a discount schedule from a grain elevator in Texas or Kansas was applied uniformly across all the states to examine hypothetical economic losses to aflatoxin, if climate change results in a need for increased testing in the Midwest and Ohio Valley states. Although discounts and rejections of lots vary among grain elevators, utilization of the Texas and Kansas discount schedules was the only method for applying actual dollar amounts to aflatoxin losses. Additionally, in addition to differences in discounts given for aflatoxin contaminated lots different states fully reject lots that test over different levels. Therefore, we calculated economic losses based on two different discard limits: 1) 500 ng g−1 and 2) 200 ng g−1.

Model 1 of the economic analysis included the probabilities associated with Type 1 and Type 2 errors inherent to mycotoxin testing protocols, thus accounting for the variability associated with sample preparation and testing. Results from a sensitivity analysis of test size portion on the OC curve acceptance probabilities demonstrated a small increase in economic impact with increases in size of the test portion taken for aflatoxin analysis. However, this effect appears to be minimal for test sizes above 10 g, and there was only a difference of 3% in economic loss, between the 5 g method and 10 g method. Information of this nature is important when weighing the benefits and costs of a testing methodology. For instance, utilizing a method of a 5 g sample would allow for greater flexibility of corn lots that are actually over the 20 ng g−1 regulatory limit circulation into the market; however, this method also reduces the immediate economic impacts to farmers from discounted sale prices. The results from our analysis indicate that, with increasing test sizes, the probability of false negative lots passing through inspection significantly decreases while the economic burden increases by only 3%.

Model 2 does not take into account these errors, but instead demonstrates the potential losses assuming zero variability in testing. The values of losses for each respective year represents what could have been lost to the corn industry if testing and uniform discount schedules were applied across the country. With the impacts of climate change, it is plausible to speculate that states like Iowa and Illinois will develop more stringent testing protocols and discount schedules similar to that of Texas – even if aflatoxin levels in corn are still below the strictest FDA action level of 20 ppb. The data obtained for each of the three states were not initially collected for the purpose of economic analysis, and much of the data came from corn lots that were suspected of containing aflatoxin, making the contamination data slightly skewed. Our estimates, therefore, should be considered to be representative of potential losses during years of increased probability for mycotoxin contamination and in a market where frequent testing puts all bushels at risk for discounts. A stringent discard cut-off value of 200 ng g−1 mostly affected the Southern states demonstrating those states greater likelihood of producing corn with extremely high levels of aflatoxins. However, in the instance that states in the Ohio Valley have lots over 200 ng g−1 (see Table 4, 2012) and the total value of those is discarded the economic implications can be as much as an increase of 4-fold, due to the large amount of corn production in those states.

Previous estimates put aflatoxin-associated economic losses at $47 million per year in food crops (corn and peanuts) and $225 million per year in feed crops (Vardon et al. 2003). While these previous estimates are lower than those calculated here, we assumed that all bushels were subject to a discounted price and the Corn Belt states were assumed to have similar testing protocols and discount schedules as those currently observed in Texas. If climate change incites frequent testing of corn in Corn Belt states the economic impact could reach the billion-dollar mark. Mitigation and testing strategies within the US need to be assessed to derive a comprehensive understanding of the impact of aflatoxin in the US corn supply, and to determine the cost-effective testing and mitigation strategies to implement in years when climate conditions in the Midwest increase aflatoxin probability in large volumes of the US corn supply.

Conclusions

In our economic analyses, we determined potential losses to the corn industry based on the application of price discounts to corn crops within given ranges of FDA action levels. The estimates of loss were similar between our two separate models (see Table 3 and Table 4). The first model used an OC curve that was developed with parameters of a relevant testing protocol – i.e., it would be commonly used in grain elevators - to determine the probability of acceptance of contaminated corn lots falling within given FDA action level ranges. The second model did not include the acceptance probabilities generated by the OC curve, and trended towards slightly higher economic losses than when the OC curve was factored in. This second method assumes accurate assignment of all bushels of U.S. corn to the appropriate contamination level resulting in modelling discounting of the entire U.S. grain supply. In reality, lots that have a mean concentration over the accept/reject limit have a potential to test under this limit and not be appropriately discounted. The non-OC curve model, therefore, is considered the less conservative of the two model approximations of the potential economic losses. At the high end (years with warm summers and drought), losses to the US corn industry from aflatoxin contamination could exceed $1 billion. In other years, the loss would be several tens of millions USD.

This work demonstrates how increased testing and discount schedules would drastically increase the economic burden of aflatoxin contamination. A risk assessment needs to be considered in the future, in regards to climate change impacts on aflatoxin contamination, in order to develop a testing and regulatory protocol that balances the risk for human and animal exposure with economic burden to growers.

Acknowledgments

Funding

This project was funded by the Agriculture and Food Research Initiative Competitive Grants Program under grant number [2013-68004-20359], from the USDA National Institute of Food and Agriculture; the National Institute of Environmental Health Sciences of the National Institutes of Health under grant number [T32ES007255]. We would like to acknowledge Dr. Thomas Isakeit (Texas A&M University) for sharing his data on Texas aflatoxin contamination and discount schedule.

Footnotes

The “among lab” variance depends on the mycotoxin/commodity combination under investigation in a given sampling plan and is double the “within lab” variance. For aflatoxin/shelled corn the “within lab variance is specified as (1/na)0.143C1.16 in the user guide for the FAO sampling tool (FAO 2014).

Disclosure statement

No potential conflict of interest was reported by the authors.

References

- Brera C, De Santis B, Prantera E, Debegnach F, Pannunzi E, Fasano F, Berdini C, Slate AB, Miraglia M, Whitaker TB. Effect of sample size in the evaluation of “in-field” sampling plans for aflatoxin B1 determination in corn. J Agric Food Chem. 2010;58:8481–8489. doi: 10.1021/jf1018356. [DOI] [PubMed] [Google Scholar]

- CAST . Mycotoxins. (Task force report) Council of Agriculture, Science, and Technology; Ames (IA): 2003. [Google Scholar]

- Cotty PJ, Jaime-Garcia R. Influences of climate on aflatoxin producing fungi and aflatoxin contamination. Int J Food Microbiol. 2007;119:109–115. doi: 10.1016/j.ijfoodmicro.2007.07.060. [DOI] [PubMed] [Google Scholar]

- Diener U, Cole R, Sanders T, Payne G, Lee L, Klich M. Epidemiology of aflatoxin formation by Apergillus flavus. Ann Rev Pyhtopathol. 1987;25:249–270. [Google Scholar]

- FAO . Mycotoxin sampling tool (version 1.1) [Internet]. C 2013-2014. Food and Agriculture Organization of the United Nations; Rome: 2013. [2014 Oct 26]. Available from: http://www.fstools.org/mycotoxins/ [Google Scholar]

- FAO . Mycotoxin sampling tool user guide (version 1.1) [Internet]. C2014. Food and Agriculture Organization of the United Nations; Rome: 2014. [2015 Nov 25]. Available from: http://www.fstools.org/mycotoxins/Documents/UserGuide.pdf. [Google Scholar]

- FDA . Online Archives of the US FDA recalls, market withdrawals, & safety alerts [Internet]. c2014. United States Food and Drug Administration; Silver Spring: 2014a. Available from: http://www.fda.gov/Safety/Recalls/ [Google Scholar]

- FDA . CPG Sec. 683.100 Action levels for aflatoxins in animal feeds [Internet]. c1976-2014. United States Food and Drug Administration; Silver Spring: 2014b. Available from: http://www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatoryInformati on/ChemicalContaminantsMetalsNaturalToxinsPesticides/ucm077969.htm. [Google Scholar]

- GIPSA . Mycotoxins [Internet]. c2014. United States Department of Agriculture, Grain Inspection, Packers & Stockyards Administration; Washington DC: [2014 Oct 26]. Available from: http://www.gipsa.usda.gov/fgis/standproc/mycot.html. [Google Scholar]

- Gong YY, Cardwell K, Hounsa A, Egal S, Turner PC, Hall AJ, Wild CP. Dietary aflatoxin exposure and impaired growth in young children from Benin and Togo: cross sectional study. BMJ. 2002;325:20–21. doi: 10.1136/bmj.325.7354.20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- IDA . Mycotoxin survey [Internet]. c2010-2014. Illinois Department of Agriculture; Illinois: [2014 March 24]. Available from: http://www.agr.state.il.us/mycotoxin-survey/ [Google Scholar]

- Jiang Y, Jolly PE, Ellis WO, Wang JS, Phillips TD, Williams JH. Aflatoxin B1 albumin adduct levels and cellular immune status in Ghanaians. Int Immunol. 2005;17:807–814. doi: 10.1093/intimm/dxh262. [DOI] [PubMed] [Google Scholar]

- Jiang Y, Jolly PE, Preko P, Wang JS, Ellis WO, Phillips TD, Williams JH. Aflatoxin-related immune dysfunction in health and in human immunodeficiency virus disease. Clin Dev Immunol. 2008 doi: 10.1155/2008/790309. Doi: 10.1155/2008/790309. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Johansson AS, Whitaker TB, Hagler WM, Giesbrecht FG, Young JH, Bowman DT. Testing shelled corn for aflatoxin, part I: estimation of variance components. J AOAC Int. 2000;83:1264–1269. [PubMed] [Google Scholar]

- Khlangwiset P, Shephard GS, Wu F. Aflatoxins and growth impairment: a review. Crit Rev Toxicol. 2011;41:740–755. doi: 10.3109/10408444.2011.575766. [DOI] [PubMed] [Google Scholar]

- Lee LS, Lillehouj EB, Kwolek WF. Aflatoxin distribution in individual corn kernels from intact ears. Cereal Chem. 1980;57:340–343. [Google Scholar]

- Lewis L, Onsongo M, Njapau H, Schurz-Rogers H, Luber G, Kieszak S, Nyamongo J, Backer L, Dahiye AM, Misore A, et al. Aflatoxin contamination of commercial maize products during an outbreak of acute aflatoxicosis in eastern and central Kenya. Environ Health Perspect. 2005;113:1763–1767. doi: 10.1289/ehp.7998. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu Y, Wu F. Global burden of aflatoxin-induced hepatocellular carcinoma: a risk assessment. Environ Health Perspect. 2010;118:818–824. doi: 10.1289/ehp.0901388. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mahadavi R, Nikniaz L, Arefhosseini SR, Vahed Jabbari M. Determination of aflatoxin M1 in breast mild samples in Tabriz-Iran. Matern Child Health J. 2010;14:141–145. doi: 10.1007/s10995-008-0439-9. [DOI] [PubMed] [Google Scholar]

- Marroquin-Cardona AG, Johnson NM, Phillips TD, Hayes AW. Mycotoxins in a changing global environment-a review. Food Chem Toxicol. 2014;69:220–230. doi: 10.1016/j.fct.2014.04.025. [DOI] [PubMed] [Google Scholar]

- McMillian W, Wilson D, Widstrom N. Aflatoxin contamination of preharvest corn in Georgia: a six-year study of insect damage and visible Aspergillus flavus. J Environ Quality. 1985;14:200–202. [Google Scholar]

- NASS . Online database of the National Agricultural Statistics Service [Internet]. 2013. United States Department of Agriculture; Washington DC: Available from: http://www.nass.usda.gov/Statistics_by_Subject/index.php?sector=CROPS. [Google Scholar]

- NASS . Online database of the National Agricultural Statistics Service [Internet]. 2014. United States Department of Agriculture; Washington DC: Available from: http://usda.mannlib.cornell.edu/MannUsda/viewDocumentInfo.do;jsessionid=F154BA78C7C50C021C8CA924EDB72FD5?documentID=1002. [Google Scholar]

- Payne GA, Casseel DK, Adkins CR. Reduction of aflatoxin levels in maize due to irrigation and tillage. Phytopathol. 1985;75:1283–1283. [Google Scholar]

- Payne G, Widstrom N. Aflatoxin in maize. Crit Rev Plant Sci. 1992;10:423–440. [Google Scholar]

- USDA ERS . corn trade [Internet]. c2014. United States Department of Agriculture Economic Research Service; Washington DC: [2014 Oct 26]. Available from: http://www.ers.usda.gov/topics/crops/corn/trade.aspx#.U6BWjyhXcrg. [Google Scholar]

- USDA ERS . Corn: Background [Internet]. c2015. United States Department of Agriculture Economic Research Service; Washington DC: [2015 April 23]. Available from: http://www.ers.usda.gov/topics/crops/corn/background.aspx. [Google Scholar]

- Vardon PJ, McLaughlin C, Nardinelli C. Potential economic costs of mycotoxins in the United States. Council of Agriculture, Science, and Technology; Ames(IA): 2003. Mycotoxins: Risks in plant, animal and human systems (Task force report). pp. 136–142. Chapter 10. [Google Scholar]

- Whitaker TB. Designing mycotoxin sampling plans. Springer; Dordecht: 2011. Sampling procedures to detect mycotoxins in agricultural commodities. pp. 41–47. Chapter 10. [Google Scholar]

- Williams JH, Phillips TD, Jolly PE, Stiles JK, Jolly CM, Aggarwal D. Human aflatoxicosis in developing countries: a review of toxicology, exposure, potential health consequences, and interventions. Am J Clin Nutr. 2004;80:1106–1122. doi: 10.1093/ajcn/80.5.1106. [DOI] [PubMed] [Google Scholar]

- Wu F, Bhatnagar D, Bui-Klimke T, Carbone I, Hellmich R, Munkvold G, Paul P, Payne G, Takle E. Climate change impacts on mycotoxin risk in US maize. World Mycotoxin J. 2011;4:79–93. [Google Scholar]