Abstract

We investigate the resistive switching power from unipolar resistive switching current-voltage characteristics in various binary metal oxide films sandwiched by different metal electrodes, and find a universal feature (the so-called universality) in the switching power among these devices. To experimentally derive the switching power universality, systematic measurements of the switching voltage and current are performed, and neither of these correlate with one another. As the switching resistance (R) increases, the switching power (P) decreases following a power law P ∝ R−β, regardless of the device configurations. The observed switching power universality is indicative of the existence of a commonly applicable switching mechanism. The origin of the power universality is discussed based on a metallic filament model and thermo-chemical reaction.

Though reversible resistive switching (RS) is not novel: it has been observed in various insulating oxides sandwiched by metal electrodes since the 1970s1,2,3,4,5,6,7,8,9,10,11, there is renewed interest in using the RS phenomena as an operating principle for new-functional nonvolatile memory (often referred to as ReRAM) applications. According to the way reversible RS phenomena are controlled, either by current magnitude or by voltage bias polarity, the character of RS is grouped into two categories: unipolar or bipolar. The responsible physics of the RS phenomena is diverse. Many models proposed include oxygen diffusion12, Schottky barrier behavior at the metallic contact interface13, charge trapping/de-trapping14, and the creation of crystalline defects15.

The generally accepted RS model in binary metal oxide films exhibiting unipolar RS is a filament model such that a conduction channel called a filament is formed in the insulating oxide film if a critical voltage is applied across the film. Although the filament model is widely accepted in binary metal oxide based unipolar ReRAM16,17,18, the common underlying physics of the model is not well clarified regardless of the materials used. So, the absence of quantified common features (in another word, universality) in the RS phenomena makes it difficult to accept the general applicability of the filament model. From a practical point of view, predictable universal device parameters are very useful for device and circuit engineers to understand the correlation between material, device, and circuit at the industry level (see Supplementary Information, Fig. S3) and eventually as a starting point of their advanced research19. Recently, scaling effects in RS devices have been reported20,21,22,23,24. However, discovery of additional universal behaviors in which two main parameters, switching voltage and current, are involved would certainly be useful in gaining an intuitive understanding of switching mechanisms and practical RS memory applications.

In this work, we present the RS characteristics of various binary oxides sandwiched by metal electrodes and report on the existence of universality between the switching power (P) and switching resistance regardless of the oxide materials and metal electrodes used. In order to validate the observed universality of resistive switching powers in binary metal oxide based unipolar ReRAM devices, as many binary metal oxides as possible: NiO, TiO2, Nb2O5, CaO, MgO, HfO, MnO2 and Al2O3 which show clear unipolar RS characteristics were investigated. We describe the power universality and low-resistance current-voltage (I–V) features using a general electro-thermal chemical reaction model and the filamentary resistive switching model.

Results and Discussion

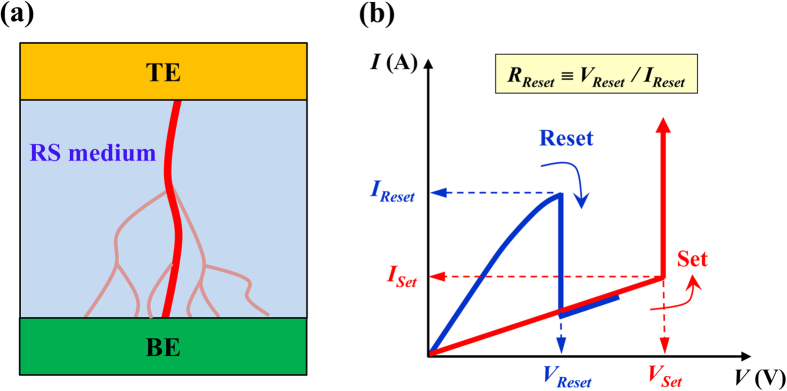

The RS memory device consisted of a highly resistive binary oxide film which is sandwiched by a top electrode (TE) and a bottom electrode (BE), as illustrated in Fig. 1(a). When a large voltage is applied to the pristine metal-dielectric insulator-metal RS device, a process called “forming” (which changes the insulating high-resistance phase into a bistable reversible switching phase between the high-resistance state (HRS) and the low-resistance state (LRS)) occurs (see Fig. 1(b)). Afterwards, by sweeping the bias voltage, an abrupt drop in the current appears at a relatively lower voltage (named the Reset voltage). Then, by re-sweeping the voltage, a similar abrupt increase in the current occurs at a higher voltage (named the Set voltage).

Figure 1. Schematic diagram for filamentary channels in a RS device and unipolar RS characteristics.

(a) Schematic of an electrode-binary oxide-electrode RS device with a tree structure of filamentary conducting channels embedded inside the RS insulating medium. (b) Typical unipolar-type resistive switching I–V characteristics of a metal-binary oxide-metal RS device. The switching resistance R is defined as the ratio of the switching voltage to the switching current.

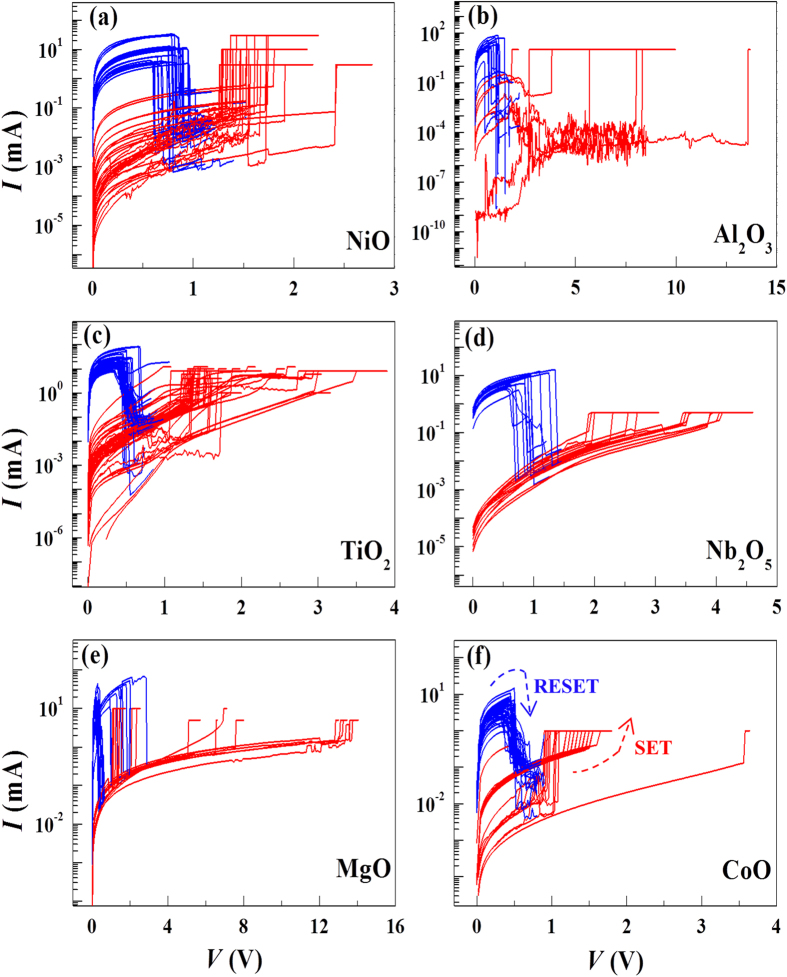

Figure 2 shows the bistable RS current-voltage (I–V) characteristics for various metal-oxide-metal ReRAM devices (See Supplementary Information, Fig. S1). For all devices, the electrical forming process occurred with a wide range of 3 V and 20 V. The observed switching I–V characteristics are typical of unipolar-type RS behavior. The temperature (T) dependence of the transport channel in the LRS is very similar to the T-dependent electrical conduction in metals, suggesting that the physical object responsible for the LRS transport is metallic25. The observed unipolar switching behavior in our binary oxide devices is well described by the metallic filament model26,27,28. The physical formation of the metallic filament in binary oxides has been directly identified by ourselves19,29,30 and other groups31,32.

Figure 2. Resistive switching I–V characteristics for various metal-oxide-metal systems.

(a) NiO, (b) Al2O3, (c) TiO2, (d) Nb2O5, (e) MgO, (f) CoO. The blue and red curves show the LRS and HRS I–V characteristics respectively. The blue and red arrows in (f) represent the Reset (LRS→HRS) and Set (HRS→LRS) processes, respectively.

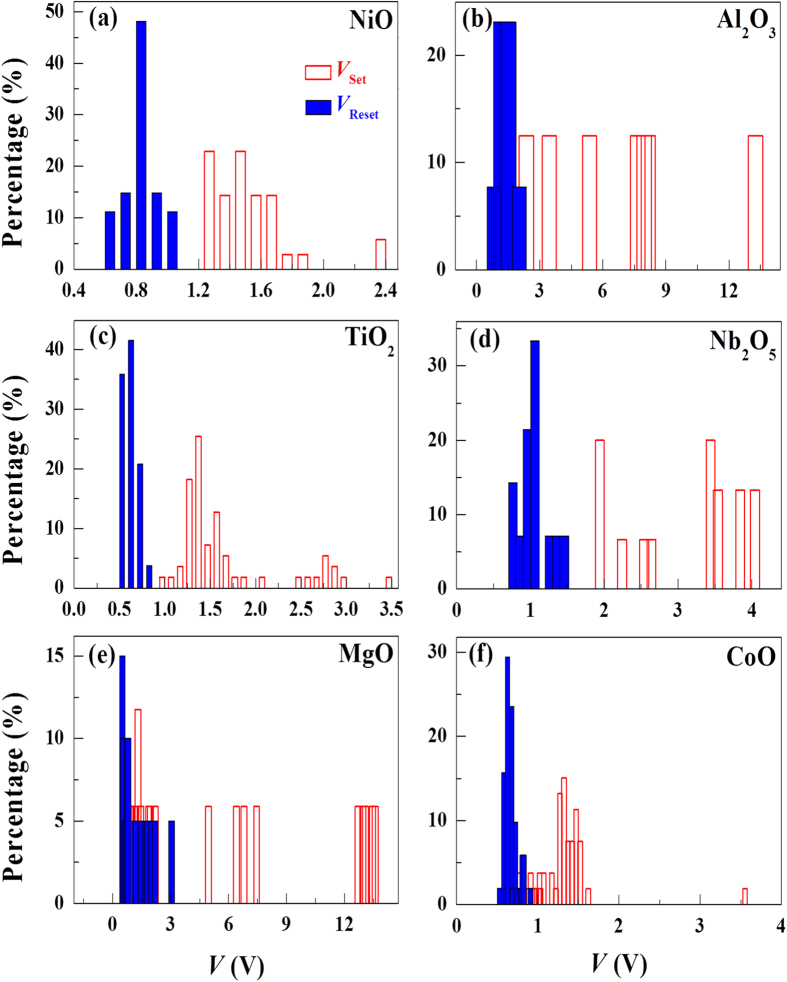

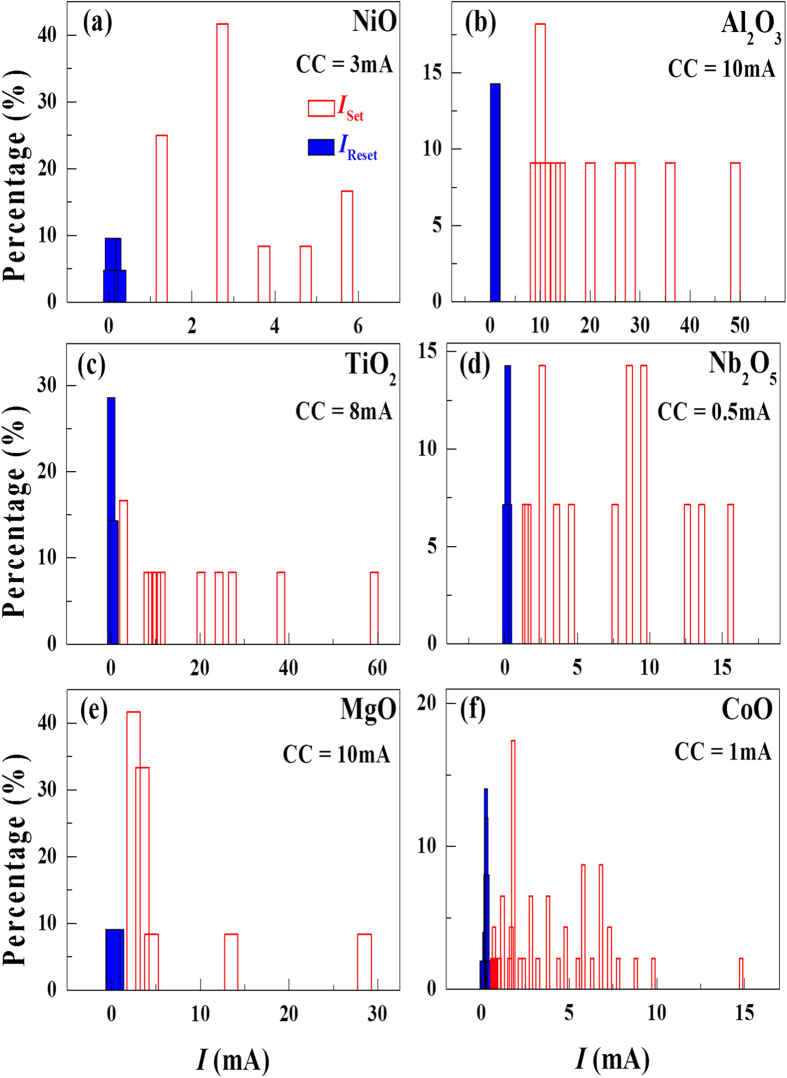

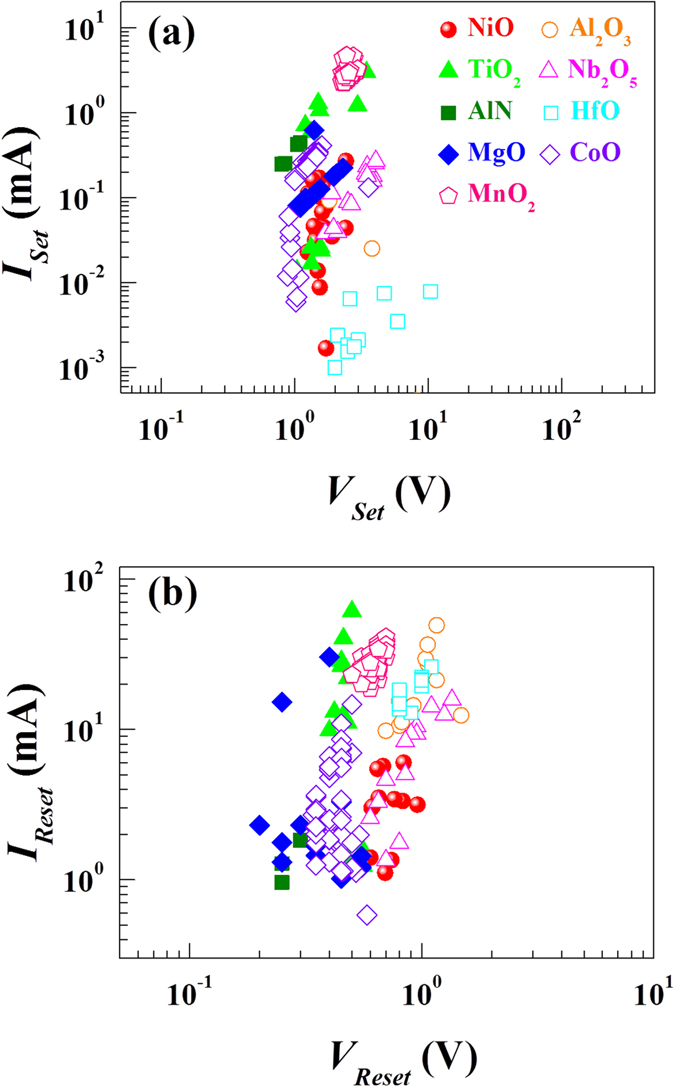

Figure 3 shows the measured switching voltages for the LRS→HRS (Reset) and HRS→LRS (Set) processes. The distribution in the switching voltage appears to be random without noticeable common trends among the devices. Similarly, the measured switching currents of each device are randomly distributed and there does not seem to be a common trend in the distribution of the currents (see Fig. 4). Furthermore, the measured switching voltage and current values do not correlate with one another, as clearly evident in the scatter plot of Fig. 5.

Figure 3. Distributions of switching voltages.

There seems to be no obvious common features in the switching voltage among devices. (a) NiO, (b) Al2O3, (c) TiO2, (d) Nb2O5, (e) MgO, (f) CoO.

Figure 4. Distributions of switching currents.

There seems to be no obvious common features in the switching voltage among devices. (a) NiO, (b) Al2O3, (c) TiO2, (d) Nb2O5, (e) MgO, (f) CoO.

Figure 5. Non-correlation between switching voltage and switching current.

Scatter plot of switching voltage versus switching current for (a) the Set (HRS→LRS) and (b) the Reset (LRS→HRS) processes. There seems to be no correlation between them.

The mechanism responsible for the LRS→HRS switching can be due to either redox-oxidation or melting (rupture) of the main filament. However, considering that the effective temperature of a metallic nano-wire for redox-oxidation (a few hundred °C) is much lower than that for melting (a few thousand °C), a thermo-chemical redox-oxidation process is more likely to be responsible for the LRS→HRS switching33. At a current large enough to initiate the thermal chemical reaction between the metallic element constituting the filament and un-bonded oxygen nearby, redox-oxidation starts and breaks the filament causing an abrupt drop in current (LRS→HRS switching)34,35. In each resistive switching cycle, a different formation of metallic (filamentary) channel structures is anticipated resulting in the fluctuation of switching voltage and current. In addition, unbroken high-resistive filaments can still remain after the Reset process contributing to the HRS current25.

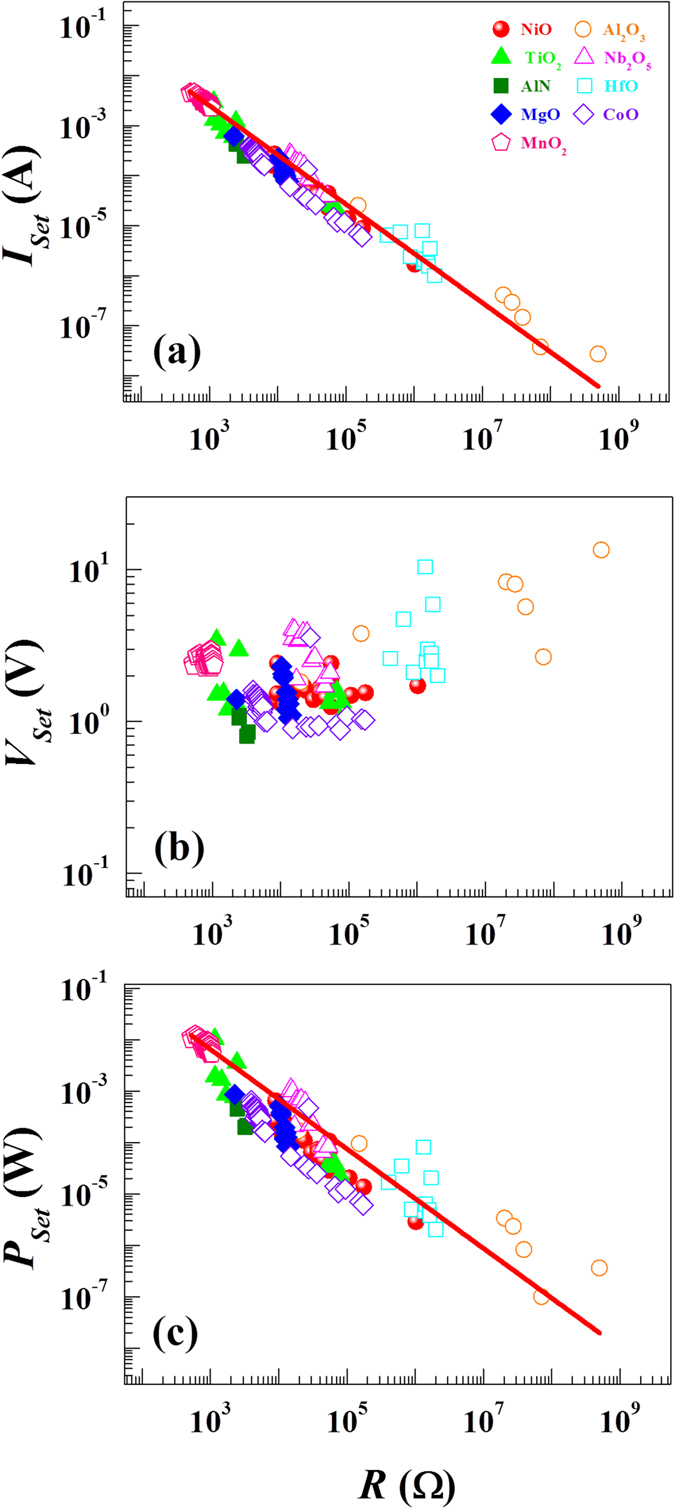

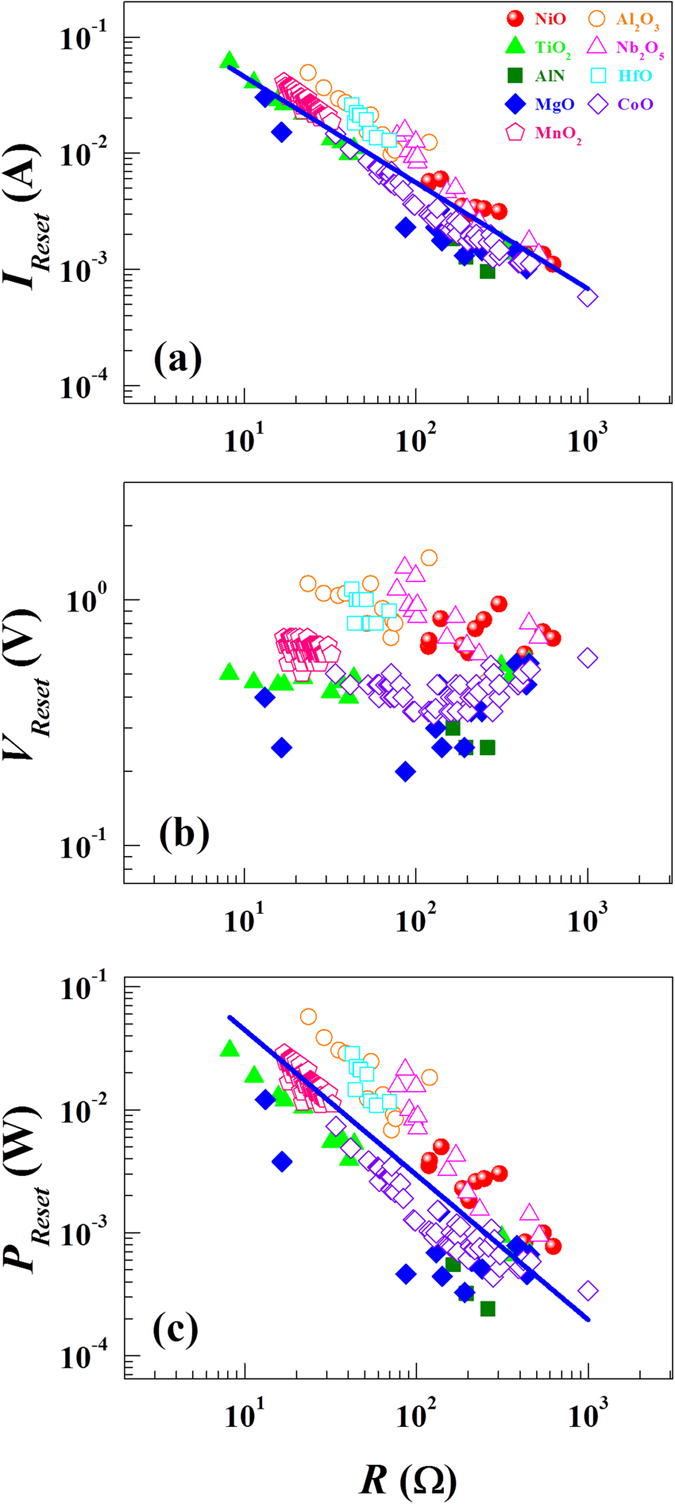

Scaling effects between switching current and switching resistance have been demonstrated for the Reset process21,22. In order to confirm the existence of such scaling effects in our RS devices, we plot both the switching current and the switching voltage as a function of switching resistance for the Set and Reset processes. The switching resistance R is defined as a ratio between switching current and switching voltage. Because the devices show a sharp transition between the LRS and the HRS, it is not difficult to extract R. For the switching current (Fig. 6a for the Set and Fig. 7a for the Reset), there exists a scaling behavior following a power-law relation (I ∝ R−γ) in our RS devices. From the least-squares curve fitting (solid lines), we find the exponent γ to be 0.99 ± 0.025 for the Set and 0.97 ± 0.038 for the Reset. The γ value of 0.97 ± 0.038 for the Reset is larger by ~25% than reported values of ~0.7 ± 0.1 in the high resistance regime21. However, in considering different ways to define the switching resistance, the γ values appear comparable. On the contrary, the switching voltage seems to have no such scaling effects (Fig. 6b for the Set and Fig. 7b for the Reset). There is no consistent trend in the switching voltage when increasing the switching resistance for individual RS devices.

Figure 6. Switching current and switching power universality for the Set process.

(a) Switching current as a function of R. (b) Switching voltage as a function of R. (c) Switching power as a function of R. While the switching current and power show a universal behavior which can be described by a power law, there seems to be no universal feature between the switching voltage and the switching resistance. The solid lines represent the fitting curves based on a power law relationship.

Figure 7. Switching current and switching power universality for the Reset process.

(a) Switching current as a function of R. (b) Switching voltage as a function of R. (c) Switching power as a function of R. While the switching current and power show a universal behavior which can be described by a power law, there seems to be no universal feature between the switching voltage and the switching resistance. The solid lines represent the fitting curves based on a power law relationship.

Figures 6c and 7c show the switching power (P) vs R, taken at the Reset and Set transitions. The switching power for the Reset (PReset) and Set (PSet) processes is defined as a product of switching current and switching voltage in each resistance state (See Supplementary Information, Fig. S2). As R increases the switching power P for both Set and Reset processes decreases with the similar empirical power-law expression: P = αR−β where α and β are constants. The solid lines represent the fitting curves. The exponent β value is found to be 0.96 ± 0.044 for Set and 1.12 ± 0.078 for Reset. Interestingly, the obtained β values are comparable (See Supplementary Information, Table S1). However, α is found to be 5.04 ± 1.49 for the Set and 0.57 ± 0.13 for the Reset. The much larger α value for the Set process means that approximately 10 times more electrical power is required for the Set process at similar R values.

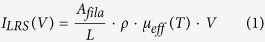

Assuming that one filament having the lowest-resistance plays a dominant role in determining the LRS I–V characteristics, the metallic ohmic-like LRS transport can be described by the conventional drift current-voltage (ILRS−V) model:

|

where Afila and L are the effective area and length of the filament respectively. Note again that Afila is not the area of the pad used. ρ and μeff represent the charge density and the effective mobility of electrons in the main low-resistance filament. Both ρ and μeff are parameters peculiar to the materials. As the current increases the effective temperature of the filament also increases. When the temperature becomes high enough to allow the thermo-chemical reaction induced rupture of the filament, the LRS→HRS transition occurs. Because smaller R values mean thicker filaments (larger Afila), PReset required for disconnecting narrower filaments is higher36. As the LRS current increases beyond a critical value, the thermo-chemical reaction starts breaking the thermo-chemically weakest part of the metallic filament. The experimentally observed power-law relation (or universality) between PReset and R is indicative that as Afila/L of a conducting filament increases linearly the required PReset increases according to the power law. Though individual RS devices have different material parameters and heat dissipation properties which affect the switching properties37,38, the experimental observations suggest that the thermal electro-chemical reaction responsible for the rupture of the filament (Reset) is related to the universality described by the power law equation of P ∝ R−β.

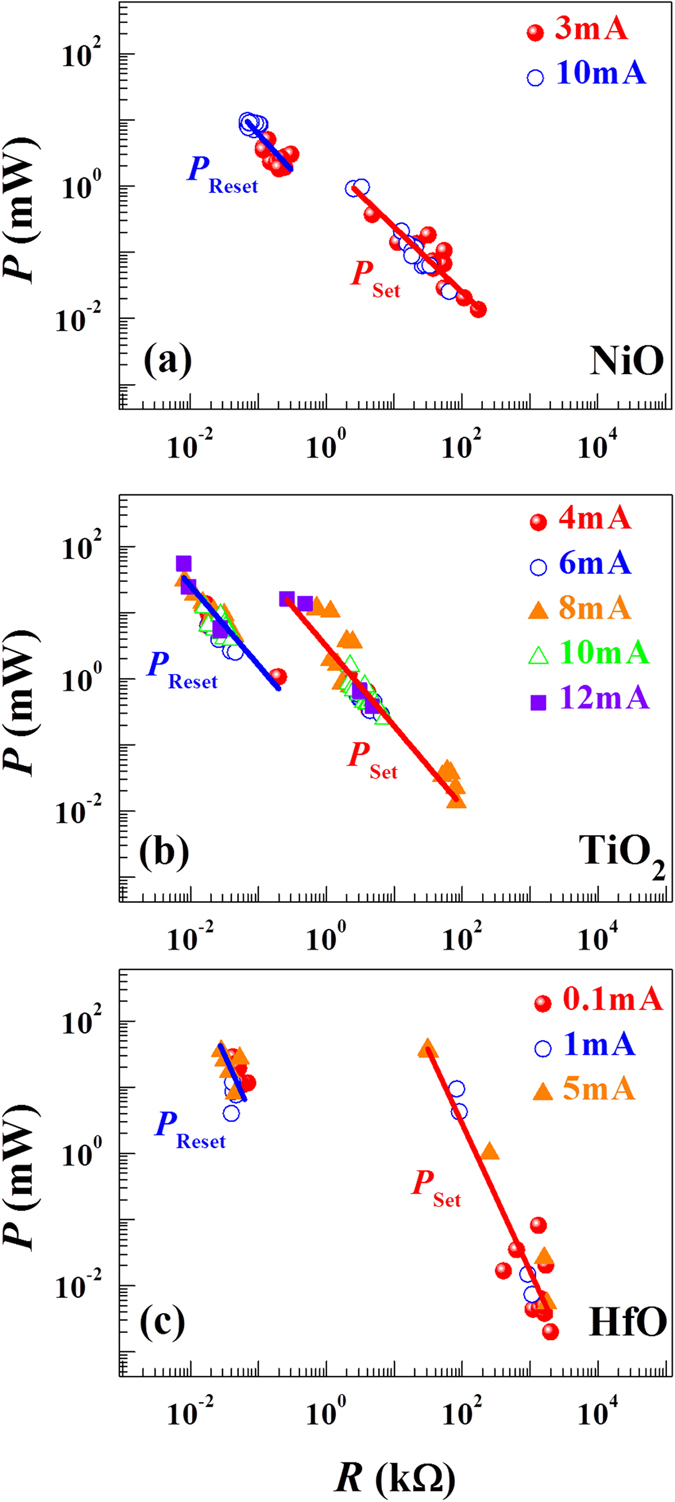

Figure 8 shows the switching power versus switching resistance data for various current compliance limit values. These NiO-, TiO2- and HfO-based RS devices shows the dependence of the LRS current on the pre-set current compliance value. As the compliance value increases, the LRS current also increases proportionately. Because the thickness of the film is fixed, the ILRS current is determined mainly by the effective area of the filament (Afila). As evident in these results, a power-law relation between R and PReset is detected validating the switching power universality and corroborating the idea that the effective area Afila of the filament plays an important role in determining the switching power for the LRS→HRS transition. A similar power universality is also observed for the Set process indicating that the nature of the filamentary conduction channels formed in the previous LRS plays a crucial role in determining the HRS→LRS transition. For the HRS→LRS transition after the forming process, the basic mechanism could be described by a thermo-chemical dielectric breakdown model39. This model suggests that the enthalpy of activation for bond breakage and local electric field plays a key role in the breakdown process. These parameters are presumably dependent on structural and electronic properties of the switching oxide medium after the forming process.

Figure 8. Switching power (P) as a function of switching resistance (R) for different current compliance values.

(a) NiO, (b) TiO2 and (c) HfO. The similar power universality is observed regardless of the applied compliance value. The solid lines represent data fitting with a power law relationship.

In addition, our experimental findings are obtained in the relatively high resistive regime (RReset > 10 Ω and RSet > 103 Ω). Thus, it would be interesting and worthwhile to elucidate whether analogous power universal behaviors in the low resistive region (where different scaling effects in the switching current are observed21 and the microscopic nature of the switching medium is expected to differ accordingly) exist.

Conclusions

In summary, we have fabricated various binary metal oxide-based RS memory devices and investigated their reversible unipolar RS characteristics. We find universality between switching power and resistance. The switching power shows a power-law decrease with increasing switching resistance. For the Reset process (LRS→HRS), this universality can be described in the framework of the conducting filament model, or vice versa, the observed power universality proves the existence of a common behavior in the filament model. For the Set process (HRS→LRS), a similar power-law relation between switching power and resistance is observed, but it is found that larger electrical power is needed, by as much as one order of magnitude at a similar switching resistance. Though the data analysis is based mainly on binary metal oxides, the overall experimental findings in this work can be further extended to other systems such as nitride films which also show unipolar RS whose origin is understood in terms of the same filament model. These experimental findings for the power universality advance the understanding of the filament model for the unipolar RS phenomena and are also useful for device and circuit engineers to perform advanced research on non-volatile RS memory devices.

Method

The experimental details of the ReRAM device structure and film growth are summarized in Table 1. The two terminal current-voltage measurements (I–V) were performed using a standard voltage source and current amplifier system (Keithley 4200 system). A bias voltage was applied to the top electrode keeping the bottom electrode to be grounded.

Table 1. Fabrication parameter values of used ReRAM devices and growth method.

| Structure | Switching film Thickness | Growth Temperature | Partial pressure or working pressure | Method |

|---|---|---|---|---|

| Pt/NiO/Pt | 300 nm | RT | Ar/O2 = 20:4, 17% | DC magnetron sputtering, ref. 40 |

| 350 nm | 250 °C | Ar/O2 = 27:3, 10% | ||

| 400 nm | RT | Ar/O2 = 27:3, 10% | ||

| Pt/TiO2/Pt | 100 nm | RT | Ar/O2 = 2:8, 80% | RF-sputtering |

| 50 nm | RT | Ar/O2 = 2:8, 80% | ||

| Pt/Nb2O5/Pt | 40 nm | 200 °C | Pulsed laser deposition, ref. 41 | |

| Al/Al2O3/Al | 100 nm | RT | Anodizing technique | |

| Pt/HfO/Ti | 10 nm | RT | Ar/O2 = 10:1.5, 2 mTorr | Inductively coupled RF-sputtering |

| Pt/MgO/CuAg/MgO/Ag | 50 nm 100 nm | RT | Ar/O2 = 10:2, 3 mTorr | RF-sputtering |

| Pt/CoO/Pt | 50 nm | RT | Ar = 15 sccm, 2 mTorr | DC magnetron sputtering, ref. 42 |

| Ti/AlN/Ti | 70 nm | RT | Ar/N2 = 10:3, 3 mTorr | RF-sputtering |

| Ti/MnO2/Pt | 80 nm | 650 °C | Ar/O2 = 5:5, 50% | RF-magnetron sputtering with Mn target |

Additional Information

How to cite this article: Kim, J. et al. Switching Power Universality in Unipolar Resistive Switching Memories. Sci. Rep. 6, 23930; doi: 10.1038/srep23930 (2016).

Supplementary Material

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (Nos 2015R1A2A2A01004782, 2015M2A2A6A02045252, 2015R1D1A1A01058851 and 2015R1D1A1A01060743) and by KIST program (2E25430).

Footnotes

Author Contributions H.I. designed this work and prepared the manuscript. The experimental and electrical measurements were carried out by J.K., K.J., Y.K., Y.J., S.C., H.W., A.I.I. and J.H. J.-K.L., S.L. and H.K. have analyzed the results and discussed the manuscript during the preparation. All authors discussed the results and implications and commented on the manuscript at all stages.

References

- Lee M.-J. et al. A fast, high-endurance and scalable non-volatile memory device made from asymmetric Ta2O5−x/TaO2−x bilayer structures. Nature Mater. 10, 625–630 (2011). [DOI] [PubMed] [Google Scholar]

- Jeong D. S., Schroeder H. & Waser R. Mechanism for bipolar switching in a Pt/TiO2/Pt resistive switching cell. Phys. Rev. B 79, 195317 (2009). [Google Scholar]

- Akinaga H. & Shima H. Resistive random access memory (ReRAM) based on metal oxides. Proceedings of the IEEE. 98, 2237–2251 (2010). [Google Scholar]

- Waser R., Dittmann R., Staikov G. & Szot K. Redox-based resistive switching memories – nanoionic mechanisms, prospects, and challenges. Adv. Mater. 21, 2632–2663 (2009). [DOI] [PubMed] [Google Scholar]

- Sawa A. Resistive switching in transition metal oxides. Mater. Today 11, 28–36 (2008). [Google Scholar]

- Kim K. M., Jeong D. S. & Hwang C. S. Nanofilamentary resistive switching in binary oxide system; a review on the present status and outlook. Nanotechnology 22, 254002 (2011). [DOI] [PubMed] [Google Scholar]

- Seo S. et al. Reproducible resistance switching in polycrystalline NiO films. Appl. Phys. Lett. 85, 5655–5657 (2004). [Google Scholar]

- Choi B. J. et al. Resistive switching mechanism of TiO2 thin films grown by atomic-layer deposition. J. Appl. Phys. 98, 033715 (2005). [Google Scholar]

- Chang W.-Y. et al. Unipolar resistive switching characteristics of ZnO thin films for nonvolatile memory applications. Appl. Phys. Lett. 92, 022110 (2008). [Google Scholar]

- Kim J. et al. Impact of graphene and single-layer BN insertion on bipolar resistive switching characteristics in tungsten oxide resistive memory. Thin Solid Films 589, 188–193 (2015). [Google Scholar]

- Jo Y. et al. Resistance switching mode transformation in SrRuO3/Cr-doped SrZrO3/Pt frameworks via a thermally activated Ti out-diffusion process. Sci. Rep. 4, 7354 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Clima S. et al. First-principles simulation of oxygen diffusion in HfOx: Role in the resistive switching mechanism. Appl. Phys. Lett. 100, 133102 (2012). [Google Scholar]

- Yang J. J. et al. Memristive switching mechanism for metal/oxide/metal nanodevices. Nat. Nanotechnol. 3, 429–433 (2008). [DOI] [PubMed] [Google Scholar]

- Sawa A., Fujii T., Kawasaki M. & Tokura Y. Hysteretic current–voltage characteristics and resistance switching at a rectifying Ti/Pr0.7Ca0.3MnO3 interface. Appl. Phys. Lett. 85, 4073–4075 (2004). [Google Scholar]

- Tsui S. et al. Field-induced resistive switching in metal-oxide interfaces. Appl. Phys. Lett. 85, 317–319 (2004). [Google Scholar]

- Russo U., Ielmini D., Cagli C. & Lacaita A. L. Filament conduction and reset mechanism in NiO-based resistive-switching memory (RRAM) devices. IEEE Trans. Electron Devices 56, 186–192 (2009). [Google Scholar]

- Kwon D.-H. et al. Atomic structure of conducting nanofilaments in TiO2 resistive switching memory. Nat. Nanotechnol. 5, 148–153 (2010). [DOI] [PubMed] [Google Scholar]

- Kim K. M. et al. Collective motion of conducting filaments in Pt/n-Type TiO2 /p-Type NiO/Pt stacked resistance switching memory. Adv. Funct. Mater. 21, 1587–1592 (2011). [Google Scholar]

- Mahapatra S. et al. Universality of NBTI–from devices to circuits and products. In 2014 IEEE International Reliability Physics Symposium (IRPS), pp. 3B.1.1-3B.1.8, Waikoloa, Hawaii, USA doi: 10.1109/IRPS.2014.6860615 (2014, June 1–5).

- Lee J. S. et al. Scaling theory for unipolar resistance switching. Phys. Rev. Lett. 105, 205701 (2010). [DOI] [PubMed] [Google Scholar]

- Lee S. B. et al. Scaling behaviors of reset voltages and currents in unipolar resistance switching. Appl. Phys. Lett. 93, 212105 (2008). [Google Scholar]

- Hwang I. et al. Effects of a load resistor on conducting filament characteristics and unipolar resistive switching behaviors in a Pt/NiO/Pt structure. IEEE Electron Dev. Lett. 33, 881–883 (2012). [Google Scholar]

- Yanagida T. et al. Scaling effect on unipolar and bipolar resistive switching of metal oxides. Sci. Rep. 3, 1657 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tanaka H., Kinoshita K., Yoshihara M. & Kishida S. Correlation between filament distribution and resistive switching properties in resistive random access memory consisting of binary transition-metal oxides. AIP Adv. 2, 022141 (2012). [Google Scholar]

- Jung K. et al. Temperature dependence of high- and low-resistance bistable states in polycrystalline NiO films. Appl. Phys. Lett. 90, 052104 (2007). [Google Scholar]

- Lee H. D., Magyari-Köpe B. & Nishi Y. Model of metallic filament formation and rupture in NiO for unipolar switching. Phys. Rev. B 81, 193202 (2010). [Google Scholar]

- Kim D. C. et al. Electrical observations of filamentary conductions for the resistive memory switching in NiO films. Appl. Phys. Lett. 88, 202102 (2006). [Google Scholar]

- Xue K.-H., Paz de Araujo C. A., Celinska J. & McWilliams C. A non-filamentary model for unipolar switching transition metal oxide resistance random access memories. J. Appl. Phys. 109, 091602 (2011). [Google Scholar]

- Inamdar A. I. et al. Memory conductance switching in a Ni–Ti–O compound thin film. Jpn. J. Appl. Phys. 51, 104102 (2012). [Google Scholar]

- Jang B. U. et al. Effects of oxygen stoichiometry on resistive switching properties in amorphous tungsten oxide films. Thin Solid Films 520, 5451–5454 (2012). [Google Scholar]

- Ielmini D. Modeling the universal set/reset characteristics of bipolar RRAM by field- and temperature-driven filament growth. IEEE Trans. Electron Devices 58, 4309–4317 (2011). [Google Scholar]

- Ielmini D., Nardi F. & Cagli C. Physical models of size-dependent nanofilament formation and rupture in NiO resistive switching memories. Nanotechnology 22, 254022 (2011). [DOI] [PubMed] [Google Scholar]

- Waser R., Menzel S. & Rana V. Recent progress in redox-based resistive switching. In 2012 IEEE International Symposium on Circuits and Systems (ISCAS), pp. 1596–1599, Seoul, South Korea. doi: 10.1109/ISCAS.2012.6271558 (2012, May 20–23).

- Ke J.-J., Liu Z.-J., Kang C.-F., Lin S.-J. & He J.-H. Surface effect on resistive switching behaviors of ZnO. Appl. Phys. Lett. 99, 192106 (2011). [Google Scholar]

- Yu. Z. & Wang Y. Unveiling switching mechanisms in RRAMs. In 2010 IEEE International Conference of Electron Devices and Solid-State Circuits (EDSSC), pp. 1–4, Hong Kong, China. doi: 10.1109/EDSSC.2010.5713731 (2010, Dec 15–17).

- Sato Y., Kinoshita K., Aoki M. & Sugiyama Y. Consideration of switching mechanism of binary metal oxide resistive junctions using a thermal reaction model. Appl. Phys. Lett. 90, 033503 (2007). [Google Scholar]

- Chang S. H. et al. Effects of heat dissipation on unipolar resistance switching in Pt/NiO/Pt capacitors. Appl. Phys. Lett. 92, 183507 (2008). [Google Scholar]

- Kim S. et al. Physical electro-thermal model of resistive switching in bi-layered resistance-change memory. Sci. Rep. 3, 1680 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- McPherson J., Kim J.-Y., Shanware A. & Mogul H. Thermochemical description of dielectric breakdown in high dielectric constant materials. Appl. Phys. Lett. 82, 2121–2123 (2003). [Google Scholar]

- Jung K. et al. Resistance switching characteristics in Li-doped NiO. J. Appl. Phys. 103, 034504 (2008). [Google Scholar]

- Jung K., Kim Y., Im H., Kim H. & Park B. Leakage transport in the high-resistance state of a resistive-switching NbOx thin film prepared by pulsed laser deposition. J. Korean Phys. Soc. 59, 2778–2781 (2011). [Google Scholar]

- Kwak J. S., Do Y. H., Bae Y. C., Im H. & Hong J. P. Reproducible unipolar resistive switching behaviors in the metal-deficient CoOx thin film. Thin Solid Films 518, 6437–6440 (2010). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.