Abstract

The discovery of 3-methoxy-9-(3′,4′,5′-trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulen-4-ol (a benzosuberene-based analogue referred to as KGP18) was originally inspired by the natural products colchicine and combretastatin A-4 (CA4). The relative structural simplicity and ease of synthesis of KGP18, coupled with its potent biological activity as an inhibitor of tubulin polymerization and its cytotoxicity (in vitro) against human cancer cell lines, has resulted in studies focused on new analogue design and synthesis. Our goal was to probe the relationship of structure to function in this class of anticancer agents. A series of twenty-two new benzosuberene-based analogues of KGP18 was designed and synthesized. These compounds vary in their methoxylation pattern and separately incorporate trifluoromethyl groups around the pendant aryl ring for the evaluation of the effect of functional group modifications on the fused six-membered aromatic ring. In addition, the 8,9-saturated congener of KGP18 has been synthesized to assess the necessity of unsaturation at the carbon atom bearing the pendant aryl ring. Six of the molecules from this benzosuberene-series of compounds were active (IC50 < 5 μM) as inhibitors of tubulin polymerization while four analogues were comparable (IC50 approximately 1 μM) in their tubulin inhibitory activity to CA4 and KGP18. The potency of a bis-trifluoromethyl analogue 74 and the unsaturated KGP18 derivative 73 as inhibitors of tubulin assembly along with their moderate cytotoxicity suggested the potential utility of these compounds as vascular disrupting agents (VDAs) to selectively target microvessels feeding tumors. Accordingly, water-soluble and DMSO-soluble phosphate prodrug salts of each were synthesized for preliminary in vivo studies to assess their potential efficacy as VDAs.

Keywords: inhibitors of tubulin polymerization, benzosuberene analogues, vascular disrupting agents, small-molecule synthesis

Graphical Abstract

1. Introduction

As solid tumors grow beyond approximately 1 mm3 in size, they require an ever larger vascular network to supply oxygen and nutrients to the cells and remove cellular waste products.1 Since the vasculature feeding tumors tends to grow rapidly to keep up with tumor expansion, it has a tendency to vary in diameter and incorporate bulges and blind ends, rendering it somewhat fragile and chaotic in character.2–4 The primitive nature of the vascular network in tumors makes it a promising target for cancer therapy.

There are two types of antivascular therapies: angiogenesis inhibiting agents (AIAs) and vascular disrupting agents (VDAs).5–7 AIAs inhibit the formation of new vasculature in developing tumors, while VDAs damage the already existing tumor vasculature.6,8–9 VDAs are further subdivided into biologics and small-molecule anticancer agents. Inhibitors of tubulin polymerization represent one class of small-molecule VDAs. These compounds disrupt the tubulin-microtubule protein system and cause structural changes to the endothelial cells lining the vasculature, in response to cell signaling events. These morphological changes eventually lead to irreversible damage to the tumor vasculature, thus starving the tumor of nutrients and oxygen, ultimately leading to tumor necrosis.10–19

One class of VDAs interact with the colchicine site on β-tubulin near the α,β-tubulin heterodimer interface. Two of the most potent colchicine site binding VDAs are the natural products combretastatin A-4 (CA4)20 and combretastatin A-1 (CA1)21 originally isolated from Combretum caffrum, the South African bushwillow tree (Fig. 1). The corresponding phosphate prodrug salts combretastatin A-4P (CA4P)22–23 and combretastatin A-1P (CA1P)15 have improved water solubility and have been extensively evaluated in both pre-clinical experiments and clinical studies in humans.24–29

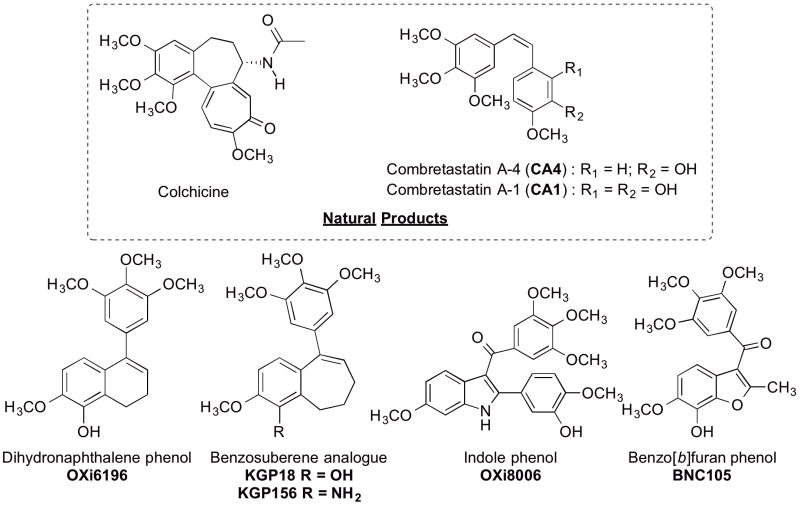

Figure 1.

Representative small-molecule inhibitors of tubulin polymerization: colchicine, combretastatins (CA4, CA1),20–21 dihydronaphthalene analogue (OXi6196),30–32 benzosuberene analogues (KGP18 and KGP156),30,33,34 indole analogue (OXi8006)35 and benzo[b]furan analogue (BNC105).36

Significant structural similarities exist among the natural products colchicine, CA4, and CA1 (Fig. 1), including a trimethoxy phenyl ring, a separate p-methoxy phenyl moiety, and bridging functionality connecting the two rings at a comparable centroid to centroid distance. The relative structural simplicity of CA4 has inspired the synthesis of a vast array of synthetic analogues and derivatives in which both aryl rings and the ethylene bridge have been structurally modified. An early initial molecular design paradigm led us to utilize clinically relevant non-steroidal, selective estrogen receptor modulators (SERMs) and related compounds as molecular templates modified to mimic colchicine and CA4.37–39 This led us to the discovery and establishment of benzo[b]thiophene,40–42 benzofuran,42–43 dihydronaphthalene, 30–32 benzosuberene,30–34 and indole-based35 analogues as potent inhibitors of tubulin polymerization (Fig. 1). Two benzosuberene analogues (referred to as KGP1830,33 and its amino congener KGP15631,34) are especially promising anticancer agents based, in part, on their pronounced cytotoxicity against human cancer cell lines and their efficacy as inhibitors of tubulin polymerization. Our previous studies in this area30,33,34 resulted in two separate synthetic strategies towards the pendant 9-aryl, fused six-seven ring system present in the benzosuberene analogues KGP18 and KGP156. These studies included a variety of functional group modifications designed to probe structural diversity as it relates to biological function. Inspired by our original work with these and related benzosuberene analogues, Maderna and colleagues at Pfizer developed a separate synthetic approach utilizing a ring-closing metathesis (RCM) reaction to form the benzosuberene molecular core and a Suzuki coupling to install the pendant aryl ring.44 They prepared and evaluated a series of structurally diverse benzosuberene analogues.45 Using KGP18 and KGP156 as models, we developed a series of analogues to analyze further functional group modifications for their effects on cytotoxicity and inhibition of tubulin polymerization.

2. Results and Discussion

2.1. Synthesis

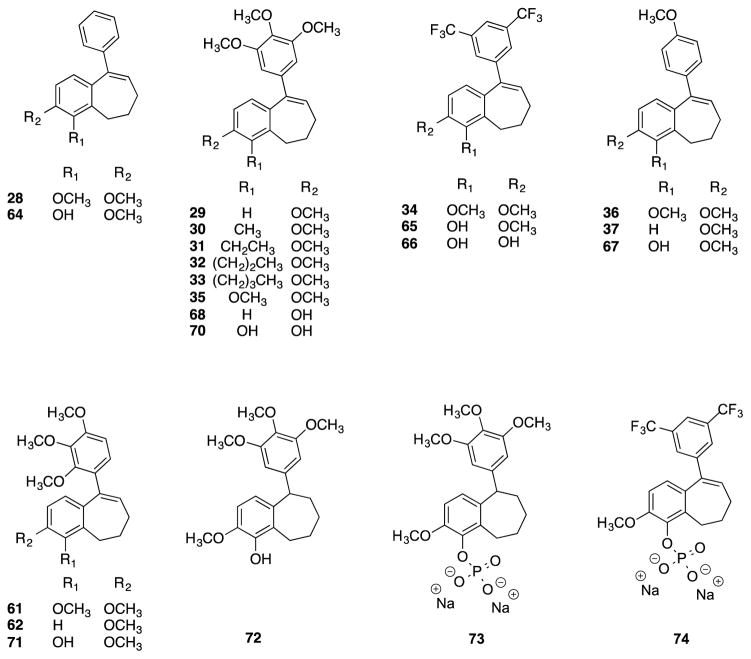

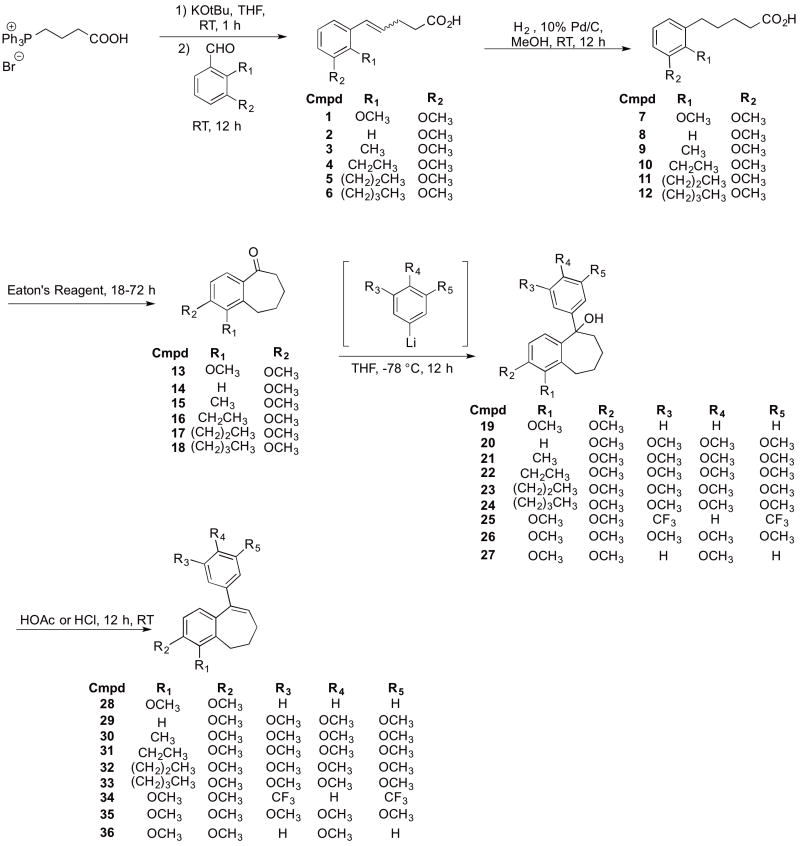

Twenty-two benzosuberene analogues (Fig. 2) were synthesized and evaluated for both their ability to inhibit tubulin polymerization and for their in vitro cytotoxicity against selected human cancer cell lines. Structural modifications to the R1 and R2 positions of the fused aryl ring as well as the pendant aryl ring were explored in order to evaluate their impact on tubulin dynamics and cytotoxicity. The synthesis of each benzosuberene analogue involved a Wittig olefination reaction followed by hydrogenation to afford carboxylic acid derivatives 7-12. An intramolecular Friedel-Crafts annulation facilitated by Eaton’s reagent (7.7 weight percent P2O5 in CH3SO3H)46–47 yielded benzosuberone analogues 13-18, which were subsequently treated with requisite aryl-lithium reagents to generate tertiary alcohols 19-27, which upon dehydration afforded the final benzosuberene analogues 28-36 (Scheme 1).

Figure 2.

Compilation of synthesized benzosuberene analogues.

Scheme 1.

Synthesis of benzosuberene analogues 28-36.

Concomitant elimination accompanied the addition of 4-methoxyphenyl lithium, which resulted in benzosuberene analogue 37 (Scheme 2).

Scheme 2.

Synthesis of benzosuberene analogue 37.

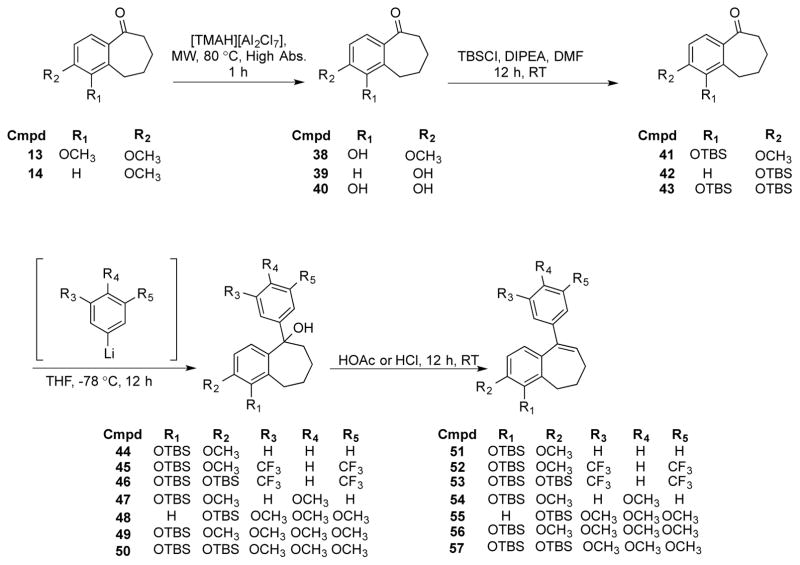

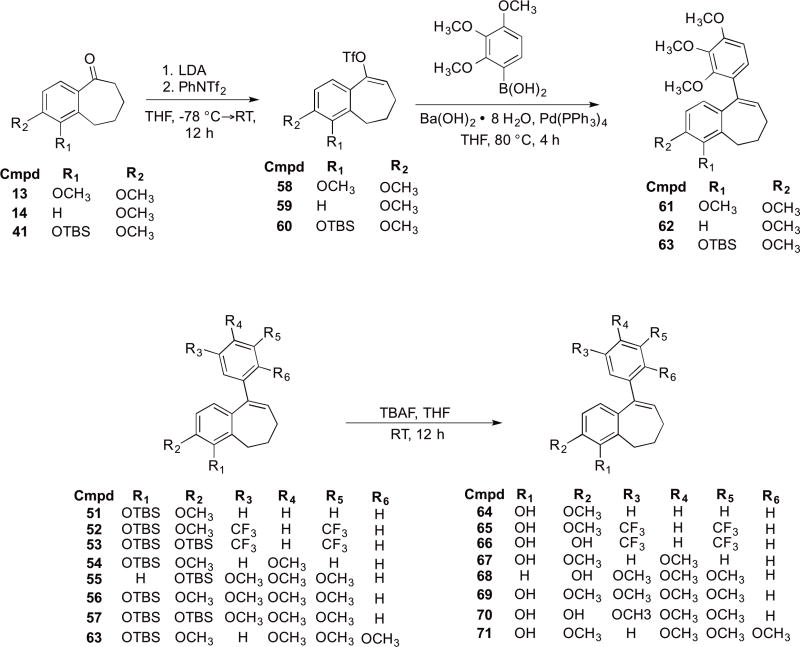

Benzosuberone analogues 13 and 14 were also subjected to a demethylation reaction using the ionic liquid [TMAH][Al2Cl7]48 to afford phenolic derivatives 38-40. We previously demonstrated the regioselective demethylation of compound 13.33,48 Protection of the phenolic moieties as their corresponding tert-butyldimethylsilyl (TBS) ethers followed by nucleophilic addition with an appropriately substituted lithiated aryl ring produced tertiary alcohols 44-50, which were subsequently dehydrated to yield TBS protected benzosuberene analogues 51-57 (Scheme 3). Removal of the TBS protecting groups upon treatment with TBAF resulted in benzosuberene analogues 64-70 (Scheme 4).

Scheme 3.

Synthesis of TBS protected analogues 51-57

Scheme 4.

Synthesis of benzosuberene analogues 61, 62, and 64-71.

In our hands, desired benzosuberene analogues 61, 62, and 71 were not accessible by the methodology involving aryl lithium addition, instead yielding recovered starting material. It is possible that competing enolate formation was faster than 1,2-carbonyl addition in these cases. Alternatively, the synthesis of analogues 61, 62, and 71 was accomplished using a Suzuki coupling to attach the pendant aryl ring, similar to the methodology of Maderna et. al.44 Vinyl triflates 58, 59, and 60 were reacted with the corresponding boronic acids to generate target benzosuberene analogues 61 and 62 and TBS protected compound 63, which, after deprotection with TBAF, afforded benzosuberene analogue 71 (Scheme 4).

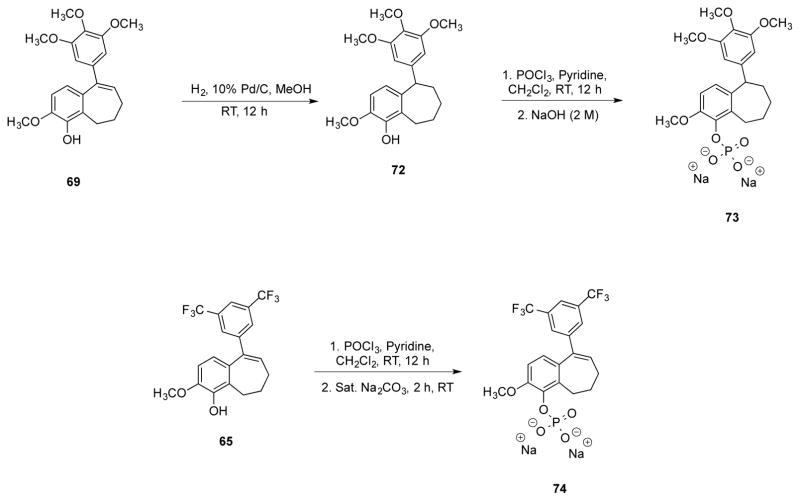

The double bond of benzosuberene 69 (KGP18) was reduced to afford benzosuberane analogue 72, which was subsequently converted to its corresponding phosphate salt 73. Benzosuberene analogue 65 was also converted to its phosphate prodrug salt 74 under analogous reaction conditions (Scheme 5).

Scheme 5.

Synthesis of reduced benzosuberane analogue 72 and phosphate salts 73 and 74.

2.2. Biological Evaluation

Each of the twenty-two analogues was evaluated biologically for its ability to inhibit tubulin polymerization (cell free assay), as well as its cytotoxicity against human cancer cell lines [SK-OV-3 (ovarian), NCI-H460 (lung), and DU-145 (prostate)]. It is important to note that these two assays, while providing complementary structure activity relationship (SAR) information, represent very different approaches to analyzing the biological activity of the target benzosuberene analogues. It is common for biologically active, small-molecule inhibitors of tubulin polymerization to demonstrate IC50 values in the low micromolar range (in this type of cell free assay) while demonstrating sub-micromolar to nanomolar GI50 values in terms of cytotoxicity against human cancer cell lines. This activity differential may be due, in part, to requisite stoichiometry differences in regard to the number of molecules of inhibitor bound to tubulin in a cell-based assay versus a pure protein assay, as well as practical assay limits (in the low micromolar range) in the pure protein assay (no cells and no additional microtubule-associated proteins). Inhibitor generated interference within the dynamic that is inherent to the tubulin-microtubule protein system in cells may influence signal transduction leading to an amplification of activity in cell-based assays.35,49 An initial structure-activity analysis for the 22 compounds for which we obtained biological data (Table 1), is perhaps best accomplished by focusing on the studies on the presumptive intracellular target, tubulin. The most extensive data were obtained for effects on tubulin assembly, in part because we have rarely observed substantial inhibition of colchicine binding (> 50%, with 5 μM inhibitor) if the assembly IC50 is > 3 μM.

Table 1.

Inhibition of tubulin polymerization, percent inhibition of colchicine binding, and cytotoxicity of the target benzosuberene analogues

| Compound | Inhibition of tubulin polymerization IC50 (μM) ± SD | % Inhibition of colchicine binding ± SD | GI50 (μM) SRB assaya | ||

|---|---|---|---|---|---|

|

| |||||

| SK-OV-3 | NCI-H460 | DU-145 | |||

| CA4 | 1.0b | 84 ± 3 (1 μM), 98 ± 0.007 (5 μM) | 0.00455 | 0.00223c | 0.00327c |

| CA4P | >40b | nr | 0.00119 | 0.00194c | 0.00323c |

| KGP18 | 1.4d | nr | 0.0000543e | 0.0000418e | 0.0000249e |

| 28 | >20 | nr | 32.7 | 37.5 | 89.3 |

| 29 | 1.0 ± 0.02 | 37 ± 5 (1 μM), 72 ± 0.8 (5 μM) | 0.0516 | 0.0527 | 0.0619 |

| 30 | 1.6 ± 0.2 | 65 ± 0.6 (5 μM) | 0.330 | 0.422 | 0.644 |

| 31 | >20 | nr | 0.568 | 0.763 | 1.51 |

| 32 | >20 | nr | 2.96 | 3.32 | 6.03 |

| 33 | >20 | nr | 11.5 | 16.1 | 12.2 |

| 34 | >20 | nr | 31.1 | 25.5 | 52.1 |

| 35 | 3.1 ± 0.03 | 30 ± 4 (5 μM), 56 ± 4 (50 μM) | 0.277 | 0.593 | 0.708 |

| 36 | >20 | nr | 20.5 | 33.4 | 48.3 |

| 37 | >20 | nr | 40.7 | 57.7 | 68.7 |

| 61 | >20 | nr | 6.96 | 10.5 | 26.2 |

| 62 | 1.2 ± 0.007 | 36 ± 5 (1 μM), 69 ± 3 (5 μM) | 0.0432 | 0.120 | 0.0562 |

| 64 | >20 | nr | 0.557 | 0.652 | 4.40 |

| 65 | 3.8 ± 0.3 | 8.5 ± 4 (5 μM), 37 ± 5 (50 μM) | 4.81 | 4.39 | 4.92 |

| 66 | >20 | nr | 16.8 | 25.0 | 21.8 |

| 67 | 7.4 ± 0.06 | nr | 18.4 | 10.6 | 8.59 |

| 68 | 2.7 ± 0.1 | 27 ± 5 (5 μM) | 0.527 | 0.647 | 1.02 |

| 70 | 7.7 ± 0.2 | nr | 0.346 | 0.691 | 1.53 |

| 71 | 11 ± 0.4 | nr | 3.53 | 4.24 | 7.54 |

| 72 | 0.70 ± 0.1 | 21 ± 0.9 (1 μM), 67 ± 0.6 (5 μM) | 0.408 | 0.141 | 0.570 |

| 73 | >20 | nr | 0.357 | 0.145 | 0.753 |

| 74 | >20 | nr | 17.2 | 16.3 | 17.5 |

Ten of the evaluated compounds were active inhibitors of tubulin polymerization (IC50 values < 20 μM). Structural variability was tolerated (in terms of retained tubulin inhibitory activity) by the incorporation of several groups (H, OCH3, CH3) at R1 while the pendant 3,4,5-trimethoxyaryl motif reminiscent of CA4 and colchicine was maintained. This mirrored our previous observations with other functional groups [OH (parent KGP18), NH2 (parent KGP156), Br, Cl) situated at R1 in this same molecular template. Replacement of the R2 methoxy group with a hydroxyl group, while either maintaining R1 = OH or modifying R1 to be a hydrogen atom, led to analogues (70 and 68, respectively) that were also active inhibitors of tubulin polymerization. Variation of the methoxylation pattern (2,3,4-trimethoxy) within the pendant aryl ring also led to active inhibitors of tubulin polymerization when R1 was H or OH (62 and 71, respectively). Replacement of the trimethoxyaryl ring with either a 3,5-bis-trifluoromethyl aryl ring or a 4-methoxyaryl ring with maintenance of R1 = OH (compounds 65 and 67, respectively) resulted in benzosuberene analogues that were still inhibitory against tubulin polymerization. Intriguingly, the double-bond reduced analogue 72 was the most active inhibitor of tubulin assembly within the entire series of benzosuberene analogues analyzed. Loss of inhibition of tubulin polymerization was observed when the trimethoxy aryl substituent was replaced with an unsubstituted phenyl ring (28 and 64). While the R1 methyl analogue 30 functioned as an inhibitor of tubulin polymerization, extension of the alkyl chain to ethyl, propyl, and butyl resulted in the loss of inhibitory activity (as observed with compounds 31, 32, and 33). While ten of the analogues inhibited tubulin assembly, only 29, 30, 62, and 72 demonstrated inhibition values (1.0 μM, 1.6 μM, 1.2 μM, and 0.70 μM, respectively) comparable to those observed with lead compounds KGP18 and CA4.

Molecular docking studies were carried out on several analogues that were active inhibitors of tubulin polymerization (compounds 29, 62 and 72), and compared to compound 33 with an IC50 > 20 μM (inactive) in this assay. Docking placed the trimethoxyphenyl ring of all three active analogues in a similar position to that of the trimethoxyphenyl moiety of N-deacetyl-N-(2-mercaptoacetyl)-colchicine in the structure co-crystallized with tubulin. In contrast, modeling placed multiple top conformations of compound 33 with its trimethoxyphenyl ring outside of this pocket (see Supplementary Data).

Among the twenty-two benzosuberene analogues investigated in this study, the most cytotoxic agents were compounds 29 and 62 (for example, GI50 = 0.0516 μM and 0.0432 μM, respectively, against the SK-OV-3 cell line). Both of these compounds bear trimethoxy aryl groups, but, unlike KGP18, they each contain a hydrogen atom at the R1 position, rather than a hydroxyl group. The cytotoxicity, inhibition of colchicine binding, and the inhibition of tubulin polymerization correlate well for these compounds. Compounds 31 and 64 were not inhibitors of tubulin polymerization (IC50 > 20 μM), but they were found to be cytotoxic (GI50 < 1 μM) against two of the three cell lines utilized in this study. Although these compounds are structurally similar to others in this library, they may have an alternate mechanism of inhibiting cell growth. We note the strong antitubulin activity of compound 72, in which the double bond in the seven-membered fused ring was reduced, although this modification appears to be associated with reduced cytotoxicity. This reduction in cytotoxicity (for compound 72) correlates with a decrease in the percent inhibition of colchicine binding (at 1 μM) relative to compounds 29 and 62, although all three compounds (29, 62, and 72) are comparable in the colchicine binding assay at 5 μM..

Two compounds, 65 and the strong tubulin inhibitor 72, were selected for conversion to prodrugs (74 and 73, respectively) by phosphorylation, in order to improve water-solubility and potentially bioavailability. As with CA4 (phosphorylated to CA4P), this synthetic transformation eliminated (IC50 > 20 μM) the ability to inhibit tubulin polymerization (cell-free assay), while the cytotoxicity was maintained presumably due to phosphatase activity present in the cell-based assay.

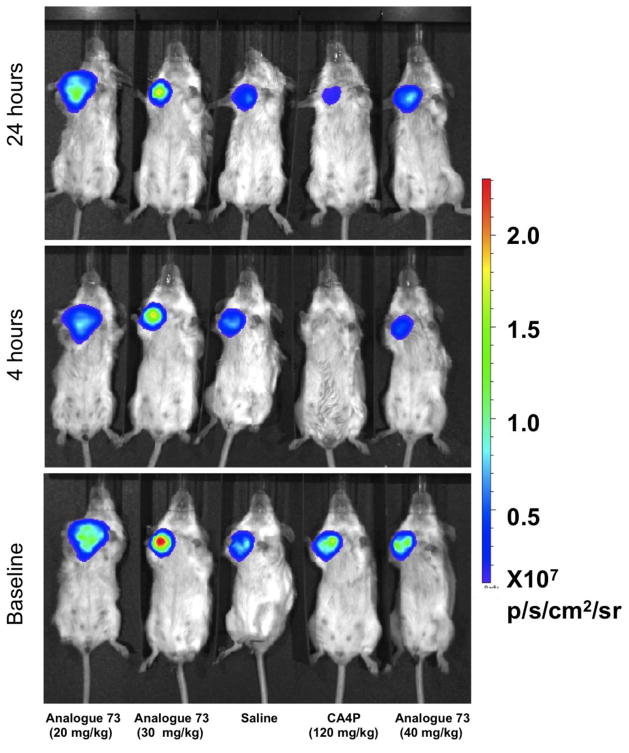

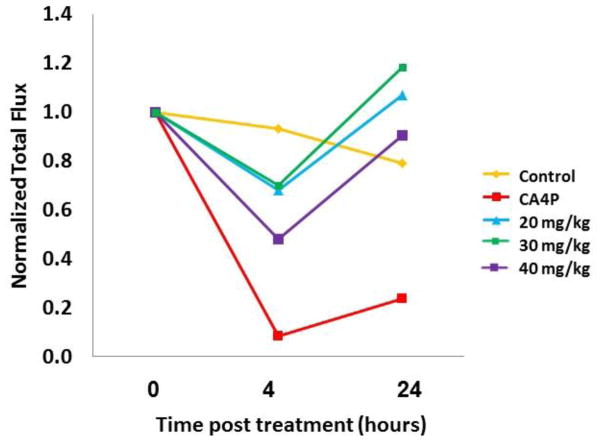

We previously demonstrated that dynamic bioluminescence imaging (BLI) provides a facile indication of vascular disruption in luciferase transfected tumors.7,51–52 Analysis is noninvasive, and each tumor acts as its own control. Specifically, the substrate luciferin normally diffuses into the blood stream following subcutaneous injection, and, when it reaches a tumor, light emission occurs. Vascular disruption impairs delivery, and reduced light emission is observed. Analogue 73 showed no obvious acute toxicity over 24 h to breast tumor bearing SCID mice following IP administration of saline solutions delivering doses up to 40 mg/kg. Doses of 20 or 30 mg/kg showed a similar modest reduction of BLI signal 4 h after administration. At 40 mg/kg there was approximately a 50% reduction of the emitted signal. In each case, the signal generally returned to its original level within 24 h. By comparison, saline controls showed a highly reproducible signal, and CA4P (a well-established VDA in clinical development) showed greater than 90% reduction at 4 h, which remained depressed (>75%, after 24 h). These data are presented in Figures 3 and 4. Patterns of light emission are presented in Figure 5. The signal intensity for saline emphasizes reproducibility of signal (hence assessment of vasculature) for repeat measurements. As reported previously, CA4P7,51–52 caused significant vascular impairment at 4 h. Compound 73 had little effect at 20 or 30 mg/kg, but caused about 50% reduction in light emission at 40 mg/kg. While these initial, preliminary studies at 20, 30, and 40 mg/kg suggested a potential VDA mechanism for analogue 73, future dose escalation studies will be necessary to establish a maximum tolerated dose (MTD) in this mouse model and to confirm the extent to which analogue 73 is capable of disrupting tumor-associated vasculature.

Figure 3.

BLI assessment of vascular disruption caused in MDA-MB-231-luc orthotopic human tumor xenografts by analogue 73. Dynamic BLI was performed at baseline (bottom row), 4 h after VDA administration (middle), and after 24 h (top), and images are shown for representative mice 17 min after administering fresh luciferin substrate on each occasion to each animal. Images show bioluminescent signal intensity overlaid on photographs of the mice. Analogue 73 was administered at 20, 30 or 40 mg/kg IP in saline, and additional mice received saline control or CA4P (120 mg/kg) for comparison. Analogue 73 caused a reduced signal at all doses at 4 h with substantial recovery by 24 h.

Figure 4.

Vascular disruption caused by analogue 73

Relative signal intensity is plotted for the mice shown in Fig. 3.

Figure 5.

Dynamic bioluminescence with respect to vascular disruption.

Graphs show evolution of light emission from individual MDA-MB-231-luc tumors following administration of luciferin substrate subcutaneously in the fore-back region of each mouse at baseline (blue) and 4 h after administration of agent (red). Analogue 73 had a modest effect at 30 mg/kg and a greater effect at 40 mg/kg. By comparison control saline showed a high degree of reproducibility and CA4P showed >90% reduction in light emission.

3. Conclusion

In summary, the results of these experiments have expanded our SAR knowledge regarding effects that modifications of the benzosuberene skeleton play in relationship to cytotoxicity and antitubulin activity. The most promising analogues evaluated in this study demonstrated inhibition of tubulin assembly comparable to CA4 and KGP18, but these compounds had reduced inhibitory effects on colchicine binding and on cell growth. Preliminary in vivo BLI evaluation of the VDA capability of benzosuberene analogue 73 against an MDA-MB-231-luc xenograft (in a SCID mouse model) showed efficacy, but, at the doses examined, the effect of 73 was less pronounced than that obtained with an established VDA (in this case, CA4P) currently in clinical development. Future studies with compound 73 and related benzosuberene analogues involving dose escalation and other tumor models to assess vascular damage appear warranted.

4. Experimental Section

4.1. Chemistry

General Materials and Methods

Tetrahydrofuran (THF), dichloromethane, ethanol, methanol, dimethylformamide (DMF), and acetonitrile were used in their anhydrous forms. Reactions were performed under nitrogen gas, unless otherwise specified. Thin-layer chromatography (TLC) plates (precoated glass plates with silica gel 60 F254, 0.25 mm thickness) were used to monitor reactions. Purification of intermediates and products was carried out with a Biotage Isolera or Teledyne Combiflash flash purification system using silica gel (200–400 mesh, 60 Å) or RP-18 pre-packed columns or manually in glass columns. Intermediates and products synthesized were characterized on the basis of their 1H NMR (500 or 300 MHz), 13C NMR (125 or 75 MHz), 19F (470 MHz) and 31P NMR (200 or 120 MHz) spectroscopic data using a Varian VNMRS 500 MHz or a Bruker DPX 300 MHz instrument. Spectra were recorded in CDCl3, D2O, (CD3)2CO, or CD3OD. All chemical shifts are expressed in ppm (δ), and peak patterns are reported as broad (br), singlet (s), doublet (d), triplet (t), quartet (q), pentet (p), sextet (sext), septet (sept), double doublet (dd), double double doublet (ddd), and multiplet (m).

Purity of the final compounds was further analyzed at 25 °C using an Agilent 1200 HPLC system with a diode-array detector (λ = 190–400 nm), a Zorbax XDB-C18 HPLC column (4.6 mm Å~ 150 mm, 5 μm), and a Zorbax reliance cartridge guard-column; Method A: solvent A, acetonitrile, solvent B, 0.1% TFA in H2O; or Method B: solvent A, acetonitrile, solvent B, H2O; gradient, 10% A/90% B to 100% A/0% B over 0 to 40 min; post-time 10 min; flow rate 1.0 mL/min; injection volume 20 μL; monitored at wavelengths of 210, 230, 254, 280, and 320 nm. Mass spectrometry was carried out under positive or negative ESI (electrospray ionization) using a Thermo Scientific LTQ OrbitrapDiscovery instrument.

4.1.1. 5-(2′,3′-Dimethoxyphenyl)pent-4-enoic acid (1).31,33

To dissolved 3-(carboxypropyl)triphenyl phosphonium bromide (13.04 g, 30.39 mmol) in THF (500 mL) was added potassium tert-butoxide (7.43 g, 66.2 mmol), and the reaction mixture was stirred at room temperature for 1 h. 2,3-Dimethoxybenzaldehyde (5.02 g, 30.1 mmol) dissolved in THF (100 mL) was added, and the mixture was stirred at room temperature for 12 h. The THF was removed under reduced pressure, and the resulting material was quenched with 2 M HCl (75 mL) and extracted with EtOAc (3 × 100 mL). The combined organic layers were evaporated under reduced pressure, and the crude reaction product was purified by flash chromatography using a pre-packed 100 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 10%A / 90%B (1 CV), 10%A / 90%B → 50%A / 50%B (10 CV), 50%A / 50%B (2 CV); flow rate: 40 mL/min; monitored at 254 and 280 nm] to afford compound 1 (5.39 g, 21.5 mmol, 72%) as a yellow oil. NMR characterization was conducted after the next step.

4.1.2. 5-(2′,3′-Dimethoxyphenyl)pentanoic acid (7).31,33,53

To dissolved carboxylic acid 1 (5.39 g, 21.5 mmol) in methanol (100 mL) was added 10% palladium on carbon (0.43 g) and hydrogen gas. The reaction mixture was stirred at room temperature for 12 h and filtered through Celite®, and the Celite® was washed with EtOAc (3 × 50 mL). The combined organic phase (MeOH and EtOAc) was evaporated under reduced pressure. The resulting organic material was purified by flash chromatography using a pre-packed 100 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 40%A / 60%B (10 CV), 40%A / 60%B (2 CV); flow rate: 40 mL/min; monitored at 254 and 280 nm] to afford carboxylic acid 7 (4.45 g, 18.7 mmol, 82%) as a colorless oil. 1H NMR (500 MHz, CDCl3) δ 11.67 (1H, s), 6.99 (1H, t, J = 8 Hz), 6.78 (2H, m), 3.86 (3H, s), 3.84 (3H, s), 2.68 (2H, t, J = 8 Hz), 2.41 (2H, t, J = 7.5 Hz), 1.70 (4H, m). 13C NMR (125 MHz, CDCl3) δ 180.2, 152.7, 147.1, 135.8, 123.8, 121.9, 110.2, 60.6, 55.6, 34.0, 30.8, 29.4, 24.5.

4.1.3. 1,2-Dimethoxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-one (13).31,33,54

To carboxylic acid 7 (3.55 g, 14.9 mmol) was added Eaton’s reagent (29 mL, 3 g per mmol of compound 7), and the reaction mixture was stirred at room temperature for 12 h. It was then poured over ice and neutralized with sodium bicarbonate. The reaction mixture was extracted with EtOAc (3 × 50 mL), and the combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The reaction product was purified by flash chromatography using a pre-packed 100 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 40%A / 60%B (10 CV), 40%A / 60%B (2 CV); flow rate: 40 mL/min; monitored at 254 and 280 nm] to afford benzosuberone 13 (2.43 g, 11.0 mmol, 74%) as a light yellow solid. 1H NMR (500 MHz, CDCl3) δ 7.33 (1H, d, J = 8.5 Hz), 6.67 (1H, d, J = 9 Hz), 3.72 (3H, s), 3.62 (3H, s), 2.83 (2H, t, J = 6 Hz), 2.50 (2H, t, J = 6 Hz), 1.66 (2H, p, J = 6.5 Hz), 1.59 (2H, p, J = 6.5 Hz). 13C NMR (125 MHz, CDCl3) δ 204.2, 155.9, 145.8, 135.5, 132.6, 125.2, 109.6, 60.8, 55.6, 40.4, 24.7, 23.0, 20.7.

4.1.4. [TMAH][Al2Cl7]48

To dry dichloromethane (150 mL) was added AlCl3 (19.84 g, 149.1 mmol), and the mixture was stirred and cooled to 0 °C. Trimethylamine hydrochloride (7.11 g, 74.5 mmol) was added, and the reaction mixture was allowed to stir for 2 h at room temperature. The resulting liquid was stored at room temperature under nitrogen.

4.1.5. 1-Hydroxy-2-dimethoxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-one (38).31,33,55

To benzosuberone 13 (1.01 g, 4.54 mmol) in a 20 mL microwave vial was added [TMAH][Al2Cl7] (18.3 mL, 9.08 mmol), and the mixture was subjected to microwave irradiation for 1 h at 80 °C on high absorbance. The solution was then poured into water (50 mL) and extracted with EtOAc (3 x 25 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 50 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford benzosuberone 38 (0.61 g, 3.0 mmol, 65%) as a yellow oil. 1H NMR (500 MHz, CDCl3) δ 7.24 (1H, d, J = 8.5 Hz), 6.67 (1H, d, J = 9 Hz), 6.26 (1H, s), 3.78 (3H, s), 2.93 (2H, t, J = 5.5 Hz), 2.61 (2H, t, J = 6.5 Hz), 1.71 (4H, m). 13C NMR (125 MHz, CDCl3) δ 205.0, 149.5, 142.5, 133.0, 127.8, 120.7, 107.9, 55.9, 40.6, 24.4, 23.0, 21.2.

4.1.6. 1-((tert-Butyldimethylsilyl)oxy)-2-dimethoxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-one (41).31,33

Benzosuberone 38 (2.16 g, 10.5 mmol) was dissolved in dimethylformamide (50 mL). TBSCl (3.16 g, 21.0 mmol) and DIPEA (5.50 mL, 31.6 mmol) were added, and the solution was stirred for 12 h at room temperature. The reaction mixture was washed with water and extracted with EtOAc (5 x 30 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 100 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 2%A / 98%B (1 CV), 2%A / 98%B → 20%A / 80%B (10 CV), 20%A / 80%B (2 CV); flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford TBS protected analogue 41 (2.37 g, 7.38 mmol, 71%) as a white solid. 1H NMR (500 MHz, CDCl3) δ 7.23 (1H, d, J = 8.5 Hz), 6.62 (1H, d, J = 9 Hz), 3.67 (3H, s), 2.88 (2H, t, J = 5.5 Hz), 2.53 (2H, t, J = 5.5 Hz), 1.64 (4H, m), 0.89 (9H, s), 0.06 (6H, s). 13C NMR (125 MHz, CDCl3) δ 204.3, 152.9, 141.6, 132.9, 132.7, 122.2, 108.6, 54.6, 40.5, 26.0, 24.6, 23.8, 21.1, 18.8, −4.0.

4.1.7. 4-((tert-Butyldimethylsilyl)oxy)-3-methoxy-6,7-dihydro-5H-benzo[7]annulen-9-yl trifluoromethanesulfonate (60)

To an oven-dried flask, diisopropylamine (0.18 mL, 1.3 mmol) dissolved in THF (50 mL) was added and cooled to −78 °C, and n-BuLi (0.51 mL, 1.3 mmol) was added. The reaction mixture was stirred for 15 min. TBS protected 41 (0.37 g, 1.2 mmol) dissolved in THF (10 mL) was added dropwise, and the reaction mixture was stirred for 2 h at −78 °C. N-Phenyl-bis(trifluoromethanesulfonimide) (0.45 g, 1.3 mmol) dissolved in THF (10 mL) was then added dropwise, and the reaction mixture was stirred for 12 h while warming from −78 °C to room temperature. After 12 h, the THF was evaporated under reduced pressure, and the resulting solid was washed with water (50 mL) and extracted with EtOAc (3 x 50 mL). The organic layer was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 2%A / 98%B (1 CV), 2%A / 98%B → 20%A / 80%B (10 CV), 20%A / 80%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford triflate 60 (0.17 g, 0.38 mmol, 33%) as a yellow oil. 1H NMR (500 MHz, CDCl3) δ 7.10 (1H, d, J = 8.5 Hz), 6.79 (1H, d, J = 8.5 Hz), 6.09 (1H, t, J = 6.5 Hz), 3.82 (3H, s), 2.88 (2H, t, J = 6 Hz), 2.15 (2H, q, J = 6.5 Hz), 2.03 (2H, p, J = 6.5 Hz), 1.03 (9H, s), 0.20 (6H, s). 13C NMR (125 MHz, CDCl3) δ 150.8. 146.5, 132.9, 130.9, 129.9, 126.0, 120.9, 119.7, 108.8, 54.7. 30.5, 26.0, 25.0, 24.5, 18.9, 4.0.

4.1.8. tert-Butyl((3-methoxy-9-(2′,3′,4′-trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulen-4-yl)oxy)dimethylsilane (63)

Triflate 60 (0.17 g, 0.38 mmol) was dissolved in THF (25 mL) and 2,3,4-trimethoxyphenyl boronic acid (0.09 g, 0.41 mmol), barium hydroxide octahydrate (0.18 g, 0.57 mmol), and tetrakis(triphenylphosphine)palladium(0) (0.013 g, 0.011 mmol) were added to the solution and refluxed at 80 °C for 2 h. The solution was then filtered through Celite®, and the Celite® was washed with dichloromethane. The organic solution (dichloromethane and THF) was evaporated under reduced pressure. The crude reaction product was purified using flash chromatography using a pre-packed 10 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 2%A / 98%B (1 CV), 2%A / 98%B → 20%A / 80%B (10 CV), 20%A / 80%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford benzosuberene 63 (0.07 g, 0.15 mmol, 41%) as a yellow oil. 1H NMR (500 MHz, CDCl3) δ 6.91 (1H, d, J = 8.5 Hz), 6.64 (1H, d, J = 8.5 Hz), 6.60 (1H, d, J = 8 Hz), 6.44 (1H, d, J = 8 Hz), 6.10 (1H, t, J = 7 Hz), 3.87 (3H, s), 3.83 (3H, s), 3.76 (3H, s), 3.38 (3H, s), 2.89 (2H, t, J = 6.5 Hz), 2.12 (2H, p, J = 7 Hz), 1.95 (2H, q, J = 7 Hz), 1.05 (9H, s), 0.22 (6H, s). 13C NMR (125 MHz, CDCl3) δ 153.0, 151.7, 148.5, 142.4, 140.3, 135.8, 132.5, 131.1, 128.2, 124.9, 120.7, 108.0, 106.6, 105.2, 60.6, 60.4, 55.9, 54.6, 33.8, 26.2, 25.5, 24.2, 19.0, −3.9.

4.1.9. 3-Methoxy-9-(2′,3, ′4′-trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulen-4-ol (71)

TBS-protected benzosuberene 63 (0.068 g, 0.146 mmol) was dissolved in THF (5 mL), and tetrabutylammonium fluoride (0.18 mL, 0.18 mmol) was added. The reaction was stirred at room temperature for 12 h, washed with water, extracted with EtOAc (3 x 25 mL), dried over sodium sulfate, and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 10 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford benzosuberene analogue 71 (0.053 g, 0.15 mmol, 96%) as a white solid. 1H NMR (500 MHz, CDCl3) δ 6.91 (1H, d, J = 8.5 Hz), 6.63 (1H, d, J = 8.5 Hz), 6.61 (1H, d, J = 8.5 Hz), 6.37 (1H, d, J = 8.5 Hz), 6.10 (1H, t, J = 7 Hz), 5.71 (1H, s) 3.87 (3H, s), 3.85 (3H, s), 3.82 (3H, s), 3.42 (3H, s), 2.87 (2H, t, J = 7 Hz), 2.15 (2H, p, J = 7 Hz), 1.96 (2H, q, J = 7 Hz). 13C NMR (125 MHz, CDCl3) δ 153.0, 151.8, 144.7, 142.39, 142.36, 140.0, 136.2, 131.0, 128.6, 126.8, 125.0, 119.0, 107.3, 106.6, 60.7, 60.5, 55.94, 55.90, 33.6, 25.6, 23.4. HRMS: Obsvd 379.1516 [M + Na+], Calcd for C21H24O5Na: 379.1516. HPLC (Method B): 16.18 min.

4.1.10. 3,4-Dimethoxy-6,7-dihydro-5H-benzo[7]annulen-9-yl trifluoromethanesulfonate (58)

Diisopropylamine (0.84 mL, 6.0 mmol) was dissolved in THF (20 mL) and cooled to −78 °C. n-BuLi (2.4 mL, 6.0 mmol) was added dropwise, and the solution was stirred for 15 min. Benzosuberone 13 (1.2 g, 5.4 mmol) dissolved in THF (10 mL) was added dropwise, and the reaction was stirred for 2 h at −78 °C. N-Phenyl-bis(trifluoromethanesulfonimide) (2.14 g, 5.99 mmol) dissolved in THF (10 mL) was then added dropwise, and the reaction mixture was stirred for 12 h while warming from −78 °C to room temperature. After 12 h, the THF was evaporated under reduced pressure, and the resulting solid was washed with water (50 mL) and extracted with EtOAc (3 x 50 mL). The organic layer was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 50 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 5%A / 95%B (1 CV), 5%A / 95%B → 40%A / 60%B (10 CV), 40%A / 60%B (2 CV); flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford triflate 58 (1.01 g, 2.87 mmol, 50%) as a yellow oil. NMR characterization was performed after the next step.

4.1.11. 3,4-Dimethoxy-9-(2′,3′,4′-trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulene (61)

Triflate 58 (0.46 g, 1.3 mmol) was dissolved in THF (25 mL) and 2,3,4-trimethoxyphenyl boronic acid (0.31 g, 1.4 mmol), barium hydroxide octahydrate (0.62 g, 2.0 mmol), and tetrakis(triphenylphosphine)palladium(0) (0.05 g, 0.04 mmol) were added to the solution, which was refluxed at 80 °C for 2 h. The solution was then filtered through Celite®, and the Celite® was washed with dichloromethane. The organic solution (dichloromethane and THF) was evaporated under reduced pressure. The crude reaction product was purified using flash chromatography using a pre-packed 100 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 45%A / 55%B (10 CV), 45%A / 55%B (2 CV); flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford benzosuberene 61 (0.07 g, 0.19 mmol, 15%) as a yellow solid. 1H NMR (500 MHz, CDCl3) δ 6.91 (1H, d, J = 8.5 Hz), 6.64 (2H, overlapping d, J = 8.5 Hz), 6.58 (1H, d, J = 8.5 Hz), 6.11 (1H, t, J = 7 Hz), 3.86 (3H, s), 3.84 (3H, s), 3.82 (3H, s). 3.81 (3H, s), 3.38 (3H, s), 2.86 (2H, t, J = 7 Hz), 2.15 (2H, p, J = 6 Hz), 1.95 (2H, q, J = 7 Hz). 13C NMR (125 MHz, CDCl3) δ 153.1, 151.7, 151.0, 146.2, 142.4, 140.1, 135.9, 134.9, 130.8, 128.4, 124.9, 123.5, 108.9, 106.7, 61.2, 60.6, 60.3, 55.9, 55.6, 34.4, 25.4, 23.9. HRMS: Obsvd 393.1740 [M + Na+], Calcd for C22H26O5Na: 393.1672. HPLC (Method B): 18.25 min.

4.1.12. 1-((tert-Butyldimethylsilyl)oxy)-2-methoxy-5-phenyl-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (44)

To an oven dried flask, THF (50 mL) and phenyl bromide (0.69 mL, 6.5 mmol) were added, and the solution was cooled to −78 °C. n-BuLi (2.74 mL, 6.86 mmol) was slowly added to the reaction mixture, which was then stirred at −78 °C for 1 h. TBS-protected 41 (1.55 g, 4.83 mmol) in THF (25 mL) was then added dropwise to the flask, and the reaction mixture was stirred while warming from −78 °C to room temperature over 12 h. The reaction mixture was washed with water and extracted with EtOAc (3 x 50 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 50 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 2%A / 98%B (1 CV), 2%A / 98%B → 20%A / 80%B (10 CV), 20%A / 80%B (2 CV); flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford tertiary alcohol 44 (0.80 g, 2.01 mmol, 42%) as a clear oil. NMR characterization was performed after the next step.

4.1.13 tert-Butyl((3-methoxy-9-phenyl-6,7-dihydro-5H-benzo[7]annulen-4-yl)oxy)dimethylsilane (51)

Acetic acid (10 mL) was added to alcohol 44 (0.80 g, 2.0 mmol), and the reaction mixture was stirred for 12 h at room temperature. The mixture was washed with water and extracted with EtOAc (3 x 30 mL). The combined organic phase was dried over sodium sulfate. The organic phase was evaporated under reduced pressure, and the crude reaction product was purified by flash chromatography using a pre-packed 10 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 2%A / 98%B (1 CV), 2%A / 98%B → 20%A / 80%B (10 CV), 20%A / 80%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford benzosuberene 51 (0.38 g, 1.0 mmol, 49%) as a yellow solid. 1H NMR (500 MHz, CDCl3) δ 7.28 (5H, m), 6.70 (1H, d, J = 8 Hz), 6.60 (1H, d, J = 8.5 Hz), 6.37 (1H, t, J = 7.5 Hz), 3.81 (3H, s), 2.79 (2H, t, J = 7 Hz), 2.13 (2H, p, J = 7 Hz). 1.98 (2H, q, J = 7.5 Hz), 1.07 (9H, s), 0.26 (6H, s). 13C NMR (125 MHz, CDCl3) δ 148.6, 143.0, 142.8, 141.6, 134.1, 133.3, 128.0, 127.3, 126.8, 122.1, 108.8, 108.4, 54.7, 33.8, 26.2, 25.6, 24.2, 19.0, −3.80.

4.1.14. 3-Methoxy-9-phenyl-6,7-dihydro-5H-benzo[7]annulen-4-ol (64)

TBS-protected benzosuberene 51 (0.38 g, 1.0 mmol) was dissolved in THF (25 mL), TBAF (1.20 mL, 1.20 mmol) was added, and the reaction mixture was stirred at room temperature for 12 h. The solution was washed with water and extracted with EtOAc (3 x 30 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 10 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 3%A / 97%B (1 CV), 3%A / 97%B → 30%A / 70%B (10 CV), 30%A / 70%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford benzosuberene analogue 64 (0.12 g, 0.45 mmol, 44%) as a pale yellow oil. 1H NMR (500 MHz, CDCl3) δ 7.28 (5H, m), 6.71 (1H, d, J = 8.5 Hz), 6.54 (1H, d, J = 8.5 Hz), 6.38 (1H, t, J = 7.5 Hz), 5.77 (1H, s), 3.91 (3H, s), 2.79 (2H, t, J = 7 Hz), 2.16 (2H, p, J = 7 Hz), 1.99 (2H, q, J = 7Hz). 13C NMR (125 MHz, CDCl3) δ 145.0, 142.8, 142.7, 142.4, 134.6, 128.02, 128.00, 127.8, 127.6, 126.9, 120.6, 107.7, 55.9, 33.5, 25.7, 23.5. HRMS: Obsvd 267.1385 [M + H+], Calcd for C18H19O2: 267.1380. HPLC (Method B): 17.89 min.

4.1.15. ((5-(3′, 5′-Bis(trifluoromethyl)phenyl)-2-methoxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-1-yl)oxy)(tert-butyl)dimethylsilane (45)

1-Bromo-3,5-bis(trifluoromethyl)benzene (0.36 g, 1.2 mmol) was dissolved in THF (13 mL), and the reaction flask was cooled to −78 °C. n-BuLi (0.55 mL, 2.5 M) was added to the reaction mixture, which was stirred for 1 h. Ketone 41 (0.29 g, 0.91 mmol) was dissolved in THF (5 mL) and slowly added to the reaction mixture over a period of 15 min. The reaction mixture was stirred for 20 h while warming from −78 °C to room temperature. The reaction mixture was diluted with H2O (25 mL) and extracted with EtOAc (2 × 25 mL), and the organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford alcohol 45 (0.40 g, 0.75 mmol, 82%) as a yellow solid. 1H NMR (CDCl3, 500 MHz) δ 7.77 (1H, s), 7.74 (2H, s), 6.95 (1H, d, J = 8.7 Hz), 6.70 (1H, d, J = 8.7 Hz), 3.80 (3H, s), 3.32 (1H, ddd, J = 14.8, 7.6, 2.0 Hz), 2.57 (1H, ddd, J = 14.2, 7.6, 3.0 Hz), 2.41 (1H, s), 2.34 – 2.21 (1H, m), 2.16 (1H, ddd, J = 13.8, 10.3, 3.1 Hz), 1.97 – 1.90 (1H, m), 1.75 – 1.68 (1H, m), 1.67 – 1.57 (1H, m), 1.56 – 1.48 (1H, m), 0.99 (9H, s), 0.18 (3H, s), 0.17 (3H, s). 13C NMR (CDCl3, 125 MHz) δ 149.9, 149.7, 142.5, 137.1, 132.7, 131.6 (q, J = 33.2 Hz), 127.3 (q, J = 3 Hz), 123.5 (q, J = 272.8 Hz), 121.2 (hept, J = 3.8 Hz), 120.3, 108.6, 79.8, 54.8, 41.6, 26.7, 26.2, 25.3, 25.3, 19.1, −3.94, −3.95.

4.1.16. ((9-(3′,5′-Bis(trifluoromethyl)phenyl)-3-methoxy-6,7-dihydro-5H-benzo[7]annulen-4-yl)oxy)(tert-butyl)dimethylsilane (52)

2 M HCl (8 mL, 16 mmol) was added to a well-stirred solution of alcohol 45 (0.68 g, 1.3 mmol) in EtOH (5 mL), and the reaction mixture was stirred for 12 h at ambient temperature. The reaction mixture was then extracted with EtOAc (4 × 15 mL), and the organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 2%A / 98%B (1 CV), 2%A / 98%B → 15%A / 85%B (10 CV), 15%A / 85%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford benzosuberene 52 (0.43 g, 0.84 mmol, 66%) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 7.77 (1H, s), 7.74 (2H, s), 6.73 (1H, d, J = 8.5 Hz), 6.50 (1H, t, J = 7.1 Hz), 6.49 (1H, d, J = 8.5 Hz), 3.84 (3H, s), 2.80 (2H, t, J = 6.9 Hz), 2.16 (2H, p, J = 7.0 Hz), 2.04 (2H, q, J = 7.1 Hz), 1.07 (9H, s), 0.27 (6H, s). 13C NMR (CDCl3, 125 MHz) δ 149.3, 145.0, 142.1, 141.1, 133.5, 132.5, 131.5 (q, J = 33.3 Hz), 130.8, 128.0 (q, J = 3.4 Hz), 123.7 (q, J = 272.7 Hz), 121.9, 120.6 (hept, J = 3.7 Hz), 109.0, 54.8, 33.8, 26.3, 26.0, 24.4, 19.2, −3.6.

4.1.17. 9-(3′,5′-Bis(trifluoromethyl)phenyl)-3-methoxy-6,7-dihydro-5H-benzo[7]annulen-4-ol (65)

To a solution of TBS-protected analogue 52 (0.43 g, 0.84 mmol) in THF (5 mL) was added TBAF (1.0 mL, 1 M in THF), and the reaction mixture was stirred for 18 h at ambient temperature and then concentrated under reduced pressure. The reaction mixture was washed with water (5 mL) and extracted with EtOAc (3 x 10 mL). The organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 10 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 6%A / 94%B (1 CV), 6%A / 94%B → 50%A / 50%B (10 CV), 50%A / 50%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford phenolic benzosuberene analogue 65 (0.26 g, 0.66 mmol, 78%) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 7.77 (1H, s), 7.74 (2H, s), 6.74 (1H, d, J = 8.3 Hz), 6.51 (1H, t, J = 7.3 Hz), 6.45 (1H, d, J = 8.4 Hz), 5.83 (1H, s), 3.93 (3H, s), 2.79 (2H, t, J = 6.9 Hz), 2.19 (2H, p, J = 7.1 Hz), 2.05 (2H, q, J = 7.2 Hz). 13C NMR (CDCl3, 125 MHz) δ 145.8, 144.9, 142.9, 140.8, 133.0, 131.5 (q, J = 33.4 Hz), 131.2, 128.03, 127.99, 123.6 (q, J = 272.8 Hz), 120.6 (hept, J = 3.9 Hz), 120.4, 108.2, 56.1, 33.4, 26.1, 23.7. 19F NMR (CDCl3, 470 MHz) δ −62.80. HRMS: Obsvd 401.0963 [M − H]−, Calcd for C20H15F6O2: 401.0976. HPLC (Method B): 20.39 min.

4.1.18. 9-(3′,5′-Bis(trifluoromethyl)phenyl)-3-methoxy-6,7-dihydro-5H-benzo[7]annulen-4-yl disodium phosphate (74)

To a well-stirred solution of phenol 65 (0.10 g, 0.25 mmol) in CH2Cl2 (10 mL), POCl3 (153.3 mg, 1.00 mmol) and pyridine (70.8 mg, 0.9 mmol) were added to the reaction flask. After the reaction mixture was stirred for 15 h at ambient temperature, the solvent was evaporated under reduced pressure. Saturated aqueous Na2CO3 (20 mL) was added to the flask, and the reaction mixture was stirred for another 2 h. The reaction mixture was concentrated to dryness with a stream of N2 gas and purified by flash chromatography using a prepacked C-18 30 g reversed phase column [solvent A: acetonitrile; solvent B: water; gradient: 30%A / 70%B (1 CV), 30%A / 70%B → 100%A / 0%B (10 CV), 100%A / 0%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford phosphate salt 74 (0.043 g, 0.082 mmol, 33 %) as a white solid. 1H NMR (D2O, 500 MHz) δ 7.96 (1H, s), 7.87 (2H, s), 6.91 (1H, d, J = 8.6 Hz), 6.72 (1H, d, J = 8.4 Hz), 6.62 (1H, t, J = 7.4 Hz), 3.84 (3H, s), 2.76 (2H, t, J = 7.0 Hz), 2.17 (2H, p, J = 7.1 Hz), 1.97 (2H, q, J = 7.2 Hz). 13C NMR (CD3OD, 125 MHz) δ 153.1, 146.6, 142.0, 141.9, 137.2, 133.3, 132.6 (q, J = 33.0 Hz), 132.4, 129.0 (q, J = 2.5 Hz), 124.9 (q, J = 271.3 Hz), 125.2 (hept, J = 3.8 Hz), 121.2, 111.1, 56.4, 34.6, 26.9, 25.9. 19F NMR (D2O, 470 MHz) δ −62.8. 31P NMR (D2O, 200 MHz) δ −3.5. HRMS: Obsvd 527.0429 [M + H]+, Calcd for C19H16F6O2Na2O5P: 527.0429. HPLC (Method A): 13.79 min.

4.1.19. 1-((tert-Butyldimethylsilyl)oxy)-5-(4-hydroxyphenyl)-2-methoxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (47)

To a solution of 4-methoxyphenyl bromide (0.52 g, 2.8 mmol) in THF (40 mL) at −78 °C was added n-BuLi (0.34 mL, 2.5 M in hexanes), and the reaction mixture was stirred for 30 min. Benzosuberone 41 (0.61 g, 1.9 mmol) in THF (20 mL) was added dropwise over a period of 15 min. The reaction mixture was allowed to reach room temperature over 12 h. Upon completion, water was added, and the mixture was extracted with EtOAc (3 x 20 mL). The organic extract was washed with brine, dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 50 g silica column [solvent A: EtOAc, solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 40 mL/min; monitored at 254 and 280 nm] to afford alcohol 47 (0.32 g, 0.75 mmol, 39%) as a clear oil. 1H NMR (CDCl3, 500 MHz) δ 7.26 (1H, d, J = 8.6 Hz), 7.15 (2H, d, J = 8.8 Hz), 6.81 (2H, d, J = 8.8 Hz), 6.73 (1H, d, J = 8.7 Hz), 3.81 (3H, s), 3.79 (3H, s), 3.30 (1H, dd, J = 14.6, 7.5 Hz), 2.67 – 2.59 (1H, m), 2.14 – 2.04 (2H, m), 1.77 – 1.65 (2H, m), 1.35 – 1.25 (2H, m), 0.99 (9H, s), 0.20 (3H, s), 0.14 (3H, s). 13C NMR (CDCl3, 125 MHz) δ 158.7, 149.2, 141.8, 139.0, 137.6, 132.7, 128.3, 119.1, 113.6, 107.8, 79.4, 55.2, 54.6, 41.2, 27.1, 26.7, 26.1, 25.5, −3.86, −4.22.

4.1.20. tert-Butyl((3-methoxy-9-(4′-methoxyphenyl)-6,7-dihydro-5H-benzo[7]annulen-4-yl)oxy)dimethylsilane (54)

Tertiary alcohol 47 (0.53 g, 1.2 mmol) was dissolved in acetic acid (5 mL) and refluxed for 5 h. No apparent change in TLC was observed, so water (15 mL) was added to the reaction mixture, which was refluxed for 2 h. The solvents were evaporated, and the resulting product was extracted with EtOAc (3 x 15 mL). The combined organic extracts were washed with sat. NaHCO3, brine, dried over Na2SO4, filtered, evaporated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc, solvent B: hexanes; gradient: 5%A / 95%B (1 CV), 5%A / 95%B → 50%A / 50%B (10 CV), 50%A / 50%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford a clear oil that solidified as a colorless solid of TBS-protected benzosuberene analogue 54 (0.43 g, 1.1 mmol, 85%). 1H NMR (CDCl3, 500 MHz) δ 7.20 (2H, d, J = 8.7 Hz), 6.83 (2H, d, J = 8.8 Hz), 6.68 (1H, d, J = 8.4 Hz), 6.58 (1H, d, J = 8.4 Hz), 6.26 (1H, t, J = 7.3 Hz), 3.81 (3H, s), 3.79 (3H, s), 2.75 (2H, t, J = 6.9 Hz), 2.09 (2H, p, J = 7.1 Hz), 1.93 (2H, q, J = 7.2 Hz), 1.04 (9H, s), 0.23 (6H, s). 13C NMR (CDCl3, 126 MHz) δ 158.7, 148.5, 142.4, 141.5, 135.5, 134.3, 133.3, 129.0, 125.7, 122.0, 113.4, 108.3, 55.3, 54.7, 33.94, 26.2, 25.5, 24.2, 19.0, −3.9.

4.1.21. 3-Methoxy-9-(4′-methoxyphenyl)-6,7-dihydro-5H-benzo[7]annulen-4-ol (67)

The TBS-protected analogue 54 (0.33 g, 0.8 mmol) was dissolved in THF (5 mL). To the solution, TBAF-3 H2O (0.96 mmol) was added, and the mixture was stirred for 3 h at room temperature. The reaction was quenched with water (15 mL), followed by the evaporation of organic solvent under reduced pressure. The resultant aqueous phase was then extracted with EtOAc (3 x 20 mL). The combined organic extracts were washed with brine solution, dried over Na2SO4, filtered, evaporated under reduced pressure, and purified by flash chromatography using a pre-packed 40 g silica column [solvent A, EtOAc, solvent B, hexanes; gradient 0%A/ 100%B →100%A/ 0%B over 9.0 min; flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford the benzosuberene analogue 67 (0.21 g, 0.71 mmol, 89%) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 7.21 (2H, d, J = 8.7 Hz), 6.83 (2H, d, J = 8.7 Hz), 6.70 (1H, d, J = 8.4 Hz), 6.54 (1H, d, J = 8.4 Hz), 6.28 (1H, t, J = 7.4 Hz), 5.72 (1H, s), 3.90 (3H, s), 3.81 (3H, s), 2.75 (2H, t, J = 7.0 Hz), 2.13 (2H, p, J = 7.0 Hz), 1.95 (2H, q, J = 7.2 Hz). 13C NMR (CDCl3, 126 MHz) δ 158.8, 144.9, 142.4, 142.2, 135.3, 134.8, 129.0, 127.8, 126.1, 120.6, 113.4, 107.6, 55.9, 55.3, 33.7, 25.6, 23.5. HRMS: Obsvd 297.1492 [M + H+], Calcd for C19H21O3: 297.1485. HPLC (Method B): 17.42 min.

4.1.22. 1-((tert-Butyldimethylsilyl)oxy)-2-methoxy-5-(3′,4′,5′-trimethoxyphenyl)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (49).31,33

To an oven dried flask, THF (50 mL) and 3,4,5-trimethoxyphenyl bromide (2.46 g, 9.97 mmol) were added, and the solution was cooled to −78 °C. n-BuLi (4.2 mL, 10 mmol) was slowly added to the reaction mixture, which was then stirred at −78 °C for 1 h. Benzosuberone 41 (2.37 g, 7.38 mmol) was then added dropwise to the flask, and the reaction mixture was stirred while warming from −78° C to room temperature over 12 h. The reaction mixture was washed with water and extracted with EtOAc (3 x 50 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 100 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 80%B (2 CV); flow rate: 40 mL/min; monitored at 254 and 280 nm] to afford compound 49 (1.80 g, 3.70 mmol, 50%) as a clear oil. NMR characterization was performed after the next step.

4.1.23. tert-Butyl((3-methoxy-9-(3′,4′,5′-trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulen-4-yl)oxy)dimethylsilane (56)

Acetic acid (20 mL) was added to tertiary alcohol 49 (1.80 g, 3.70 mmol), and the reaction mixture was stirred for 12 h at room temperature. The mixture was washed with water and extracted with EtOAc (3 x 30 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 50 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 40 mL/min; monitored at 254 and 280 nm] to afford TBS-protected benzosuberene 56 (1.43 g, 8.38 mmol, 83%) as a clear oil. 1H NMR (500 MHz, CDCl3) δ 6.67 (1H, d, J = 8.5 Hz), 6.61 (1H, d, J = 8.5 Hz), 6.50 (2H, s), 6.32 (1H, t, J = 7.5 Hz), 3.85 (3H, s), 3.78 (3H, s), 3.77 (6H, s), 2.78 (2H, t, J = 7 Hz), 2.11 (2H, p, J = 7 Hz), 1.95 (2H, q, J = 7.5 Hz), 1.06 (9H s), 0.25 (6H, s). 13C NMR (125 MHz, CDCl3) δ 152.8, 148.6, 143.1, 141.5, 138.6, 137.3, 133.8, 133.2, 126.7, 122.4, 108.4, 105.3, 60.7, 56.0, 54.5, 34.0, 26.2, 25.6, 24.2, 19.0, −3.8.

4.1.24. 3-Methoxy-9-(3′,4′,5′-trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulen-4-ol (69).30,31,33,44,56

Benzosuberene 56 (1.43 g, 3.04 mmol) was dissolved in THF (10 mL), TBAF (3.65 mL, 3.6 mmol) was added, and the reaction mixture was stirred at room temperature for 12 h. The solution was washed with water and extracted with EtOAc (3 x 30 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure affording benzosuberene 69 (0.66 g, 1.9 mmol, 61%) as an orange solid. 1H NMR (500 MHz, CDCl3) δ 6.72 (1H, d, J = 8.5 Hz), 6.58 (1H, d, J = 8 Hz), 6.51 (2H, s), 6.35 (1H, t, J = 7 Hz), 5.74 (1H, s), 3.93 (3H, s), 3.87 (3H, s), 3.81 (6H, s), 2.77 (2H, t, J = 7 Hz), 2.15 (2H, p, J = 7 Hz), 1.97 (2H, q, J = 7.5 Hz). 13C NMR (125 MHz, CDCl3) δ 152.8, 145.0, 142.8, 142.3, 138.5, 137.3, 134.2, 127.7, 127.2, 120.8, 107.6, 105.3, 60.9, 56.1, 55.9, 33.6, 25.7, 23.5.

4.1.25. 2-Methoxy-5-(3′,4′,5′-trimethoxyphenyl)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-1-ol (72)

To benzosuberene 69 (0.66 g, 1.9 mmol) was added methanol (50 mL) and 10% Pd/C (0.42 g). Hydrogen gas was added, and the reaction mixture was stirrred at room temperature for 12 h. The reaction mixture was filtered through Celite®, and the Celite® was washed with EtOAc (3 x 30 mL). The organic phase (MeOH and EtOAc) was evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford benzosuberane analogue 72 (0.16 g, 0.45 mmol, 24%) as a white solid. 1H NMR (500 MHz, CDCl3) δ 6.54 (1H, d, J = 8.5 Hz), 6.47 (2H, s), 6.17 (1H, d, J = 8 Hz), 5.84 (1H, s), 4.17 (1H, d, J = 9.5 Hz), 3.89 (3H, s), 3.84 (9H, s), 3.28 (1H, q, J = 7.5 Hz), 2.73 (1H, t, J = 12 Hz), 2.17(1H, m), 2.02 (2H, m), 1.86 (2H, m), 1.46 (1H, q, J = 12 Hz). 13C NMR (125 MHz, CDCl3) δ 153.1, 144.7, 142.6, 141.2, 139.6, 136.2, 128.4, 118.6, 108.1, 105.7, 60.9, 56.1, 55.9, 49.5, 34.7, 30.6, 27.2, 25.4. HRMS: Obsvd 381.1764 [M + Na+], Calcd for C21H26O5Na+: 381.1672. HPLC (Method B): 15.30 min.

4.1.26. 2-Methoxy-5-(3′,4′,5′-trimethoxyphenyl)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-1-yl disodium phosphate (73)

To benzosuberane analogue 72 dissolved in CH2Cl2 (25 mL) was added POCl3 (0.11 mL, 1.1 mmol) and pyridine (0.1 mL, 1 mmol), and the reaction mixture was stirred at room temperature for 12 h. 2 M NaOH (1.69 mL, 3.38 mmol) was added, and the reaction was stirred for 5 min and extracted with CH2Cl2, and the organic layer was evaporated under reduced pressure. NaOH (2 mL, 2 M) was added to the resulting oil, and the solution was refluxed at 60 °C for 15 min. Water was removed under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 12 g C-18 column [solvent A: water; solvent B: acetonitrile; gradient: 0%A / 100%B (1 CV), 0%A / 100%B → 100%A / 0%B (10 CV), 0%A / 100%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford the benzosuberane phosphate salt 73 (0.024 g, 0.050 mmol, 17%) as a white solid. 1H NMR (500 MHz, D2O) δ 6.43 (2H, s), 6.36 (1H, d, J = 8.5 Hz), 6.07 (1H, d, J = 8.5 Hz), 4.04 (1H, d, J = 9.5 Hz), 3.61 (6H, s) 3.60 (3H, s), 3.56 (3H, s), 3.26 (1H, m), 2.55 (1H, t, J = 12 Hz), 1.90 (1H, m), 1.65 (4H, m), 1.16 (1H, q, J = 10.5 Hz). 13C NMR (125 MHz, D2O) δ 152.2, 150.3, 142.8, 140.5, 140.4, 139.0, 137.3, 134.6, 121.8, 108.6, 105.9, 60.8, 55.4, 48.6, 33.7, 30.0, 33.7, 29.7, 26.6. 31P NMR (200 MHz, D2O, 85% phosphoric acid reference) δ 0.97. HRMS: Obsvd 483.1190 [M + H+], Calcd for C21H26O5Na2P+: 483.1155. HPLC (Method A): 14.23 min.

4.1.27. 1,2-Dimethoxy-5-(4′-methoxyphenyl)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (27)

To a solution of 4-methoxyphenyl bromide (0.719 g, 3.84 mmol) in THF (50 mL) at −78 °C was added n-BuLi (2.6 mL, 2.5 M in hexanes), and the reaction mixture was stirred for 30 min. Benzosuberone 13 (0.58 g, 2.6 mmol) in THF (15 mL) was added dropwise over 15 min. The reaction mixture was warmed to room temperature over 12 h. Upon completion, water was added, and the mixture was extracted with EtOAc (3 x 20 mL). The organic layer was washed with brine, dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 80 g silica column [solvent A, EtOAc, solvent B, hexanes; gradient 0%A/ 100%B →100%A/ 0%B over 20.3 min; flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford alcohol 27 (0.45 g, 1.4 mmol, 54%) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 7.39 (1H, d, J = 8.7 Hz), 7.15 (2H, d, J = 8.8 Hz), 6.83 (2H, d, J = 8.8 Hz), 6.79 (1H, d, J = 8.7 Hz), 3.89 (3H, s), 3.79 (3H, s), 3.75 (3H, s), 3.25 – 3.18 (1H, m), 2.67 – 2.59 (1H, m), 2.15 – 2.08 (2H, m), 1.93 – 1.86 (1H, m), 1.80 – 1.69 (2H, m), 1.43 – 1.35 (1H, m). 13C NMR (CDCl3, 126 MHz) δ 158.8, 151.7, 146.3, 139.1, 137.5, 135.4, 128.2, 122.31, 113.7, 108.8, 79.4, 61.0, 55.6, 55.2, 41.2, 27.3, 26.6, 25.2.

4.1.28. 3,4-Dimethoxy-9-(4′-methoxyphenyl)-6,7-dihydro-5H-benzo[7]annulene (36)

Tertiary alcohol analogue 27 (0.401 g, 1.22 mmol) was dissolved in acetic acid (10 mL), and the mixture was stirred for 12 h at ambient temperature. Water (30 mL) was added, and the reaction mixture was stirred for 2 h. The reaction mixture was extracted with EtOAc (3 x 20 mL). The organic solvent was evaporated under reduced pressure and the residue extracted with EtOAc (3 x 20 mL). The combined organic extracts were washed with brine, dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc, solvent B: hexanes; gradient: 5%A / 95%B (1 CV), 5%A / 95%B → 50%A / 50%B (10 CV), 50%A / 50%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford benzosuberene analogue 36 (0.31 g, 1.0 mmol, 82%) as a clear oil. 1H NMR (CD3OD, 500 MHz) δ 7.17 (2H, d, J = 8.8 Hz), 6.87 (1H, d, J = 8.5 Hz), 6.86 (2H, d, J = 8.8 Hz), 6.71 (1H, d, J = 8.5 Hz), 6.30 (1H, t, J = 7.4 Hz), 3.89 (3H, s), 3.85 (3H, s), 3.81 (3H, s), 2.74 (2H, t, J = 7.0 Hz), 2.15 (2H, p, J = 7.1 Hz), 1.94 (2H, q, J = 7.2 Hz). 13C NMR (CDCl3, 125 MHz) δ 158.8, 151.3, 146.1, 142.2, 135.9, 135.2, 134.3, 129.0, 125.9, 125.0, 113.5, 109.2, 61.2, 55.6, 55.3, 34.6, 25.5, 24.0. HRMS: Obsvd 281.1597 [M + H+], Calcd for C19H23O2: 281.1536. HPLC (Method B): 19.08 min.

4.1.29. 1,2-Dimethoxy-5-phenyl-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (19)

To an oven dried flask, THF (50 mL) and phenylbromide (0.25 mL, 2.4 mmol) were added, and the solution was cooled to −78 °C. n-BuLi (1.0 mL, 2.5 mmol) was slowly added to the reaction mixture, which was then stirred at −78 °C for 1 h. Benzosuberone 13 (0.39 g, 1.8 mmol) was then added dropwise to the flask, and the reaction mixture was stirred while warming from −78 °C to room temperature over 12 h. The reaction mixture was washed with water and extracted with EtOAc (3 x 50 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford tertiary alcohol 19 (0.29 g, 0.97 mmol, 55%) as a pale yellow oil. NMR characterization was performed after the next step.

4.1.30. 3,4-Dimethoxy-9-phenyl-6,7-dihydro-5H-benzo[7]annulene (28)

Acetic acid (15 mL) was added to tertiary alcohol 19 (0.29 g, 0.97 mmol), and the reaction mixture was stirred for 12 h at room temperature. The mixture was washed with water (50 mL) and extracted with EtOAc (3 x 30 mL). The combined organic phase was dried over sodium sulfate and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 10 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 5%A / 95%B (1 CV), 5%A / 95%B → 50%A / 60%B (10 CV), 40%A / 60%B (2 CV); flow rate: 12 mL/min; monitored at 254 and 280 nm] to afford benzosuberene analogue 28 (0.10 g, 0.36 mmol, 37%) as a yellow oil. 1H NMR (500 MHz, CDCl3) δ 7.30 (5H, m), 6.78 (2H, s), 6.40 (1H, t, J = 7.5 Hz), 3.91 (3H, s), 3.90 (3H, s), 2.81 (2H, t, J = 7 Hz), 2.19 (2H, p, J = 7Hz), 2.01 (2H, q, J = 7.5 Hz). 13C NMR (125 MHz, CDCl3) δ 151.5, 146.1, 142.9, 142.6, 135.9, 134.2, 128.1, 128.0, 127.5, 127.0, 125.1, 109.4, 61.2, 55.6, 34.5, 25.6, 24.1. HRMS: Obsvd 303.1363 [M + Na+], Calcd for C19H20O2Na: 303.1356. HPLC (Method B): 19.93 min.

4.1.31. 1,2-Dimethoxy-5-(3′,4′,5′-trimethoxyphenyl)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (26).31

To a solution of 3,4,5-trimethoxyphenyl bromide (0.67 g, 2.7 mmol) in THF (100 mL) at −78 °C was added n-BuLi (1.1 mL, 2.5 M in hexanes), and the reaction mixture was stirred for 30 min. Benzosuberone 13 (0.60 g, 2.7 mmol) in THF (15 mL) was added dropwise over 15 min. The reaction mixture was warmed to room temperature over 12 h. Water was added, and the mixture was extracted with EtOAc (100 mL). The organic extract was washed with brine, dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc, solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 56%A / 44%B (9.2 CV), 56%A / 44%B (1 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford alcohol 26 (0.39 g, 0.99 mmol, 34%) as a light yellow oil. 1H NMR (CDCl3, 500 MHz) δ 7.26 (1H, d, J = 8.7 Hz), 6.75 (1H, d, J = 8.8 Hz), 6.49 (2H, s), 3.87 (3H, s), 3.83 (3H, s), 3.74 (3H, s), 3.73 (6H, s), 3.26 – 3.20 (1H, m), 2.56 (1H, ddd, J = 14.1, 6.9, 3.0 Hz), 2.38 – 2.30 (1H, m), 2.21 – 2.21 (1H, m), 2.11 (1H, ddd, J = 14.0, 10.7, 3.1 Hz), 1.93 (1H, ddd, J = 15.3, 7.4, 3.8 Hz), 1.81-1.71 (2H, m), 1.50-1.42 (1H, m). 13C NMR (CDCl3, 126 MHz) δ 153.0, 151.8, 146.2, 141.6, 138.6, 137.2, 135.5, 123.0, 108.8, 104.2, 79.9, 61.0, 60.8, 56.1, 55.5, 41.3, 27.1, 26.3, 25.1.

4.1.32. 3,4-Dimethoxy-9-(3′,4′,5′-trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulene (35).31

Tertiary alcohol analogue 26 (0.5 g, 1 mmol) was dissolved in acetic acid (10 mL) and refluxed for 2 h. Water (30 mL) was added, and the reaction was refluxed for 2 h. The white precipitate thus obtained was filtered and washed with hexanes. On drying, it afforded benzosuberene analogue 35 (0.444 g, 1.2 mmol, 93%) as a colorless solid, which was not further purified. 1H NMR (CDCl3, 500 MHz) δ 6.79 (1H, d, J = 8.5 Hz), 6.77 (1H, d, J = 8.5 Hz), 6.51 (2H, s), 6.35 (1H, t, J = 7.3 Hz), 3.90 (3H, s), 3.89 (3H, s), 3.88 (3H, s), 3.82 (6H, s), 2.77 (2H, t, J = 7.0 Hz), 2.17 (2H, p, J = 7.1 Hz), 1.98 (2H, q, J = 7.2 Hz). 13C NMR (CDCl3, 126 MHz) δ 152.9, 151.5, 146.1, 142.9, 138.4, 137.4 135.9, 133.8, 127.1, 125.3, 109.3, 105.3, 61.3, 60.9, 56.17, 55.6, 34.6, 25.6, 24.2. HRMS: Obsvd 393.1682 [M + Na+], Calcd for C22H26O5Na: 393.1672. HPLC (Method B): 17.52 min.

4.1.33. 5-(3′,5′-Bis(trifluoromethyl)phenyl)-1,2-dimethoxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (25)

To a solution of 1-bromo-3,5-bis(trifluoromethyl)benzene (0.36 g, 1.2 mmol) in THF (13 mL) at −78 °C was added n-BuLi (0.55 mL, 2.5 M), and the reaction mixture was stirred for 1 h. Benzosuberone 13 (0.20 g, 0.91 mmol) in THF (5 mL) was added dropwise over 15 min. The reaction mixture was stirred for 20 h and was warmed to room temperature. The reaction mixture was diluted with H2O (25 mL) and extracted with EtOAc (2 × 25 mL). The organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (15 CV), 60%A / 40%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford alcohol 25 (0.45 g, 1.0 mmol, 84%) as a yellow solid. 1H NMR (CDCl3, 500 MHz) δ 7.70 (1H, s), 7.67 (2H, s), 6.92 (1H, d, J = 8.7 Hz), 6.63 (1H, d, J = 8.8 Hz), 3.76 (3H, s), 3.67 (3H, s), 3.16 (1H, ddd, J = 14.6, 7.8, 1.9 Hz), 2.50 (1H, s), 2.46 (1H, ddd, J = 14.3, 8.2, 2.8 Hz), 2.37 – 2.24 (1H, m), 2.06 (1H, ddd, J = 14.2, 9.6, 3.0 Hz), 1.91 – 1.85 (1H, m), 1.73 – 1.61 (1H, m), 1.59 – 1.50 (2H, m). 13C NMR (CDCl3, 125 MHz) δ 152.4, 149.8, 146.6, 137.2, 135.6, 131.6 (q, J = 33.1 Hz), 127.1 (q, J = 3.8 Hz), 123.5 (q, J = 272.7 Hz), 123.7, 121.3 (hept, J = 4.0 Hz), 109.5, 79.8, 61.1, 55.7, 41.6, 27.0, 25.2, 24.8.

4.1.44. 9-(3′,5′-Bis(trifluoromethyl)phenyl)-3,4-dimethoxy-6,7-dihydro-5H-benzo[7]annulene (34)

To a solution of tertiary alcohol 25 (0.45 g, 1.0 mmol) in EtOH (10 mL) was added 2 M HCl (10 mL, 20 mmol), and the reaction mixture was stirred overnight. The reaction mixture was then extracted using EtOAc (4 × 15 mL). The organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 5%A / 95%B (1 CV), 5%A / 95%B → 40%A / 60%B (10 CV), 40%A / 60%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford benzosuberene 34 (0.22 g, 0.54 mmol, 54%) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 7.75 (1H, s), 7.71 (2H, s), 6.77 (1H, d, J = 8.5 Hz), 6.63 (1H, d, J = 8.5 Hz), 6.49 (1H, t, J = 7.3 Hz), 3.90 (3H, s), 3.88 (3H, s), 2.76 (2H, t, J = 6.9 Hz), 2.18 (2H, p, J = 7.1 Hz), 2.03 (2H, q, J = 7.2 Hz). 13C NMR (CDCl3, 125 MHz) δ 152.2, 146.6, 144.7, 140.8, 136.1, 132.4, 131.6 (q, J = 33 Hz), 131.1, 128.0 (q, J = 3.8 Hz), 124.8, 123.6 (q, J = 272.7 Hz), 120.7 (hept, J = 4.0 Hz), 109.9, 61.4, 55.8, 34.3, 26.0, 24.3. 19F NMR (CDCl3, 470 MHz) δ −62.81. HRMS: Obsvd 401.0965 [M − CH3]−, alcd for C20H15F6O2: 401.0976. HPLC (Method B): 21.57 min.

4.1.45. 1,2-Dihydroxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-one (40).31,57

Ketone 13 (0.88 g, 4.0 mmol) was added to the ionic liquid [TMAH][Al2Cl7](20.0 mL, 0.497 M). The reaction mixture was subjected to microwave irradiation at 80 °C and 1 atm for 1 h. H2O (20 mL) was added to the mixture, and the resulting brown liquid was extracted with dichloromethane (3 x 20 mL). The organic extracts were dried over Na2SO4, filtered, evaporated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 5%A / 95%B (1 CV), 5%A / 95%B → 60%A / 40%B (13 CV), 60%A / 40%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford benzosuberone 40 (0.50 g, 2.6 mmol, 65% yield) as a brown solid. 1H NMR ((CD3)2CO, 500 MHz) δ 7.14 (1H, d, J = 8.3 Hz), 6.78 (1H, d, J = 8.8 Hz), 3.07 – 2.99 (2H, m), 2.67 – 2.59 (2H, m), 1.84 – 1.77 (2H, m), 1.77 – 1.71 (2H, m). 13C NMR ((CD3)2CO, 126 MHz) δ 205.4, 148.1, 142.0, 132.3, 128.9, 120.6, 112.3, 40.3, 24.4, 22.8, 21.0.

4.1.46. 1,2-Bis((tert-butyldimethylsilyl)oxy)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-one (43).31

To a solution of catechol 40 (0.68 g, 3.5 mmol) and DIPEA (2.7 mL, 16 mmol) in DMF (5 mL) at 0 °C was added TBSCl (1.60 g, 10.6 mmol) in portions. The reaction mixture was stirred for 18 h, diluted with H2O (5 mL), and extracted with Et2O (2 × 20 mL). The organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 0%A / 100%B (1 CV), 0%A / 100%B → 30%A / 70%B (10 CV), 30%A / 70%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford ketone 43 (1.51 g, 3.59 mmol, 99%) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 7.29 (1H, d, J = 8.5 Hz), 6.75 (1H, d, J = 8.5 Hz), 2.97 – 2.94 (2H, m), 2.70 (2H, t, J = 6.2 Hz), 1.89 – 1.70 (4H, m), 1.02 (9H, s), 0.96 (9H, s), 0.24 (6H, s), 0.15 (6H, s). 13C NMR (CDCl3, 125 MHz) δ 205.3, 151.2, 143.9, 135.5, 134.0, 122.6, 118.6, 41.0, 26.5, 26.5, 25.3, 25.1, 21.9, 19.2, 18.9, −3.15, −3.19.

4.1.47. 1,2-Bis((tert-butyldimethylsilyl)oxy)-5-(3′,4′,5′-trimethoxyphenyl)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (50).31

To a solution of 3,4,5-trimethoxyphenyl bromide (0.458 g, 1.85 mmol) in THF (20 mL) at −78 °C was added n-BuLi (0.96 mL, 2.5 M in hexanes), and the reaction mixture was stirred for 1 h. Benzosuberone 43 (0.639 g, 1.51 mmol) in THF (20 mL) was added dropwise over 15 min. The reaction mixture was stirred while warming to room temperature over 12 h. Water was added, and the mixture was extracted with EtOAc (4 x 20 mL). The organic extract was washed with brine, dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc, solvent B: hexanes; gradient: 10%A / 90%B (1 CV), 10%A / 90%B → 42%A / 58%B (6 CV), 42%A / 58%B→70%A / 30%B (1 CV), 70%A / 30%B → 100%A/0%B, 100%A/0% B (1.1 CV); flow rate: 40 mL/min; monitored at 254 and 280 nm] to afford alcohol 50 (0.480 g, 0.81 mmol, 54%) as a clear oil. 1H NMR (CDCl3, 500 MHz) δ 7.10 (1H, d, J = 8.7 Hz), 6.72 (1H, d, J = 8.6 Hz), 6.46 (2H, s), 3.83 (3H, s), 3.74 (6H, s), 3.23 – 3.15 (1H, m), 2.57 (1H, ddd, J = 14.0, 6.2, 3.0 Hz), 2.23 – 2.07 (3H, m), 1.94 – 1.84 (1H, m), 1.81 – 1.66 (2H, m), 1.46 – 1.33 (1H, m), 1.00 (9H, s), 0.95 (9H, s), 0.24 (3H, s), 0.23 (3H, s), 0.15 (3H, s), 0.10 (3H, s). 13C NMR (CDCl3, 126 MHz) δ 152.9, 146.4, 143.7, 141.8, 139.1, 137.1, 133.9, 120.0, 117.5, 104.1, 80.0, 60.8, 56.0, 40.9, 26.8, 26.3, 26.2, 26.1, 25.9, 18.9, 18.6, −3.4, −3.6.

4.1.48. ((9-(3′,4′,5′-Trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulene-3,4-diyl)bis(oxy))bis(tert-butyldimethylsilane) (57).31

Tertiary alcohol 50 (0.44 g, 0.75 mmol) was dissolved in acetic acid (5 mL) and stirred for 12 h at room temperature. The reaction was quenched with water (10 mL) and extracted with Et2O (3 x 10 mL). The combined organic extract was washed with sat. NaHCO3, brine, dried over Na2SO4, filtered, and evaporated under reduced pressure to afford the clear oil of TBS-protected benzosuberene analogue 57 (0.38 g, 0.66 mmol, 89%), which was used without further purification. 1H NMR (CDCl3, 500 MHz) δ 6.69 (1H, d, J = 8.4 Hz), 6.52 (1H, d, J = 8.4 Hz), 6.45 (2H, s), 6.33 (1H, t, J = 7.3 Hz), 3.85 (3H, s), 3.78 (6H, s), 2.70 (2H, t, J = 6.9 Hz), 2.10 (2H, q, J = 7.0 Hz), 1.95 (2H, q, J = 7.0 Hz), 1.04 (9H, s), 0.95 (9H, s), 0.24 (6H, s), 0.20 (6H, s). 13C NMR (CDCl3, 125 MHz) δ 152.7, 145.9, 143.4, 143.0, 138.6, 137.1, 134.4, 134.2, 126.8, 122.7, 117.9, 105.0, 60.9, 56.0, 33.9, 26.27, 26.25, 25.7, 24.5, 18.9, 18.7, −3.3, −3.4.

4.1.49. 9-(3′,4′,5′-Trimethoxyphenyl)-6,7-dihydro-5H-benzo[7]annulene-3,4-diol (70)

The di-TBS-protected analogue 57 (0.32 g, 0.56 mmol) was dissolved in THF (5 mL). To the solution, TBAF-3 H2O (1.4 mmol) was added and stirred for 3 h at room temperature. The reaction was quenched with water (15 mL), and the organic solvent was evaporated under reduced pressure. The resulting aqueous phase was then extracted with EtOAc (3 x 20 mL). The combined organic extract was washed with brine, dried over Na2SO4, filtered, evaporated under reduced pressure and purified by flash chromatography using a pre-packed 25 g silica gel column [solvent A, EtOAc, solvent B, hexanes; gradient 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (5.2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford catechol analogue 70 (0.17 g, 0.49 mmol, 88%) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 6.68 (1H, d, J = 8.2 Hz), 6.52 (1H, d, J = 8.2 Hz), 6.49 (2H, s), 6.33 (1H, t, J =7.4 Hz), 5.29 (1H, s), 5.28 (1H, s), 3.86 (3H, s), 3.79 (6H, s), 2.71 (2H, t, J = 7.0 Hz), 2.15 (2H, p, J = 7.1 Hz), 1.96 (2H, q, J = 7.2 Hz). 13C NMR (CDCl3, 126 MHz) δ 152.8, 142.9, 141.8, 140.8, 138.3, 137.3, 134.1, 128.5, 127.0, 121.7, 112.3, 105.3, 60.9, 56.1, 33.8, 25.6, 23.8. HRMS: Obsvd 365.1444 [M + H+], Calcd for C12H23O5: 365.1359. HPLC (Method B): 16.18 min.

4.1.50. 5-(3′,5′-Bis(trifluoromethyl)phenyl)-1,2-bis((tert-butyldimethylsilyl)oxy)-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-ol (46)

1-Bromo-3,5-bis(trifluoromethyl)benzene (0.36 g, 1.2 mmol) was dissolved in THF (13 mL) at −78 °C and n-BuLi (0.55 mL, 2.5 M) was then added. The reaction mixture was stirred for 1 h, and then ketone 43 (0.38 g, 0.91 mmol) in THF (5 mL) was added dropwise over 15 min. The reaction mixture was stirred for 20 h, warming from −78 °C to room temperature, and then diluted with H2O (25 mL) and extracted with EtOAc (3 × 25 mL). The organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure, and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 100%A / 0%B (10 CV), 100%A / 0%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford alcohol 46 (0.43 g, 0.68 mmol, 74%) as a yellow solid. 1H NMR (CDCl3, 500 MHz) δ 7.77 (1H, s), 7.72 (2H, s), 6.92 (1H, d, J = 8.6 Hz), 6.73 (1H, d, J = 8.7 Hz), 3.25 (1H, ddd, J = 14.7, 7.6, 1.9 Hz), 2.57 (1H, ddd, J = 14.2, 7.3, 3.1 Hz), 2.31 (1H, s), 2.22 – 2.14 (2H, m), 1.96 – 190 (1H, m), 1.74 – 170 (1H, m), 1.64 – 1.58 (1H, m), 1.54 – 148 (1H, m), 1.01 (9H, s), 0.97 (9H, s), 0.26 (3H, s), 0.23 (3H, s), 0.19 (3H, s), 0.09 (3H, s). 13C NMR (CDCl3, 125 MHz) δ 149.7, 147.2, 144.3, 137.6, 134.0, 131.6 (q, J = 33.1 Hz), 127.2 (q, J = 3.2 Hz), 123.5 (q, J = 273.0 Hz), 121.3 (hept, J = 4.0 Hz), 120.6, 118.3, 79.8, 41.2, 26.8, 26.39, 26.35, 25.9, 25.2, 19.0, 18.7, −3.1, −3.2, −3.5, −3.9.

4.1.51((9-(3′,5′-Bis(trifluoromethyl)phenyl)-6,7-dihydro-5H-benzo[7]annulene-3,4-diyl)bis(oxy))bis(tert-butyldimethylsilane) (53)

Tertiary alcohol 46 (0.43 g, 0.67 mmol) was dissolved in EtOH (5 mL) and 2 M HCl (10 mL, 20 mmol) was then added. The reaction mixture was stirred overnight and then extracted using EtOAc (4 × 15 mL). The organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 2%A / 98%B (1 CV), 2%A / 98%B → 15%A / 85%B (10 CV), 15%A / 85%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford benzosuberene 53 (0.22 g, 0.35 mmol, 53%) as a colorless oil. 1H NMR (CDCl3, 500 MHz) δ 7.75 (1H, s), 7.69 (2H, s), 6.72 (1H, d, J = 8.4 Hz), 6.49 (1H, t, J = 7.2 Hz), 6.40 (1H, d, J = 8.4 Hz), 2.73 (2H, t, J = 6.9 Hz), 2.15 (2H, p, J = 7.0 Hz), 2.03 (2H, q, J = 7.1 Hz), 1.07 (9H, s), 0.98 (9H, s), 0.26 (6H, s), 0.23 (6H, s). 13C NMR (CDCl3, 125 MHz) δ 146.8, 145.0, 144.0, 141.1, 134.7, 133.0, 131.5 (q, J = 33.0 Hz), 130.8, 127.9 (q, J = 3.1 Hz), 123.6 (q, J = 272.7 Hz), 122.3, 120.6 (hept, J = 3.9 Hz), 118.5, 33.8, 26.43, 26.39, 26.1, 24.8, 19.1, 18.9, −3.1, −3.2.

4.1.52. 9-(3′,5′-Bis(trifluoromethyl)phenyl)-6,7-dihydro-5H-benzo[7]annulene-3,4-diol (66)

TBS-protected analogue 53 (0.43 g, 0.84 mmol) was dissolved in THF (5 mL), and TBAF (1.00 mL, 1 M in THF) was added to the reaction flask. The reaction mixture was stirred for 18 h at ambient temperature, concentrated under reduced pressure, and H2O (5 mL) was then added. The reaction mixture was extracted with EtOAc (3 x 10 mL). The organic extract was dried over Na2SO4, filtered, concentrated under reduced pressure and purified by flash chromatography using a pre-packed 25 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 7%A / 93%B (1 CV), 7%A / 93%B → 60%A / 40%B (10 CV), 60%A / 40%B (2 CV); flow rate: 25 mL/min; monitored at 254 and 280 nm] to afford catechol 66 (0.077 g, 0.20 mmol, 57 %) as a white solid. 1H NMR (CDCl3, 500 MHz) δ 7.75 (1H, s), 7.71 (2H, s), 6.71 (1H, d, J = 8.2 Hz), 6.50 (1H, t, J = 7.3 Hz), 6.38 (1H, d, J = 8.2 Hz), 5.36 (1H, s), 5.25 (1H, s), 2.73 (2H, t, J = 6.9 Hz), 2.19 (2H, p, J = 7.0 Hz), 2.04 (2H, q, J = 7.2 Hz). 13C NMR (CDCl3, 125 MHz) δ 144.7, 142.4, 141.43, 140.9, 132.9, 131.6 (q, J = 32.9 Hz), 131.1, 128.8, 128.0 (q, J = 2.9 Hz), 123.6 (q, J = 272.7 Hz), 121.2, 120.7 (hept, J = 3.9 Hz), 112.9, 33.7, 26.0, 23.9. 19F NMR (CDCl3, 470 MHz) δ −62.83. HRMS: Obsvd 387.0805 [M − H]−, Calcd for C19H13F6O2: 387.0820. HPLC (Method B): 18.11 min.

4.1.53. 5-(3′-Methoxyphenyl)pent-4-enoic acid (2).31,33

To dissolved 3-(carboxypropyl)triphenyl phosphonium bromide (15.92 g, 37.09 mmol) in THF (500 mL) was added potassium tert-butoxide (8.20 g, 73.4 mmol), and the reaction mixture was stirred at room temperature for 1 h. 3-Methoxybenzaldehyde (4.5 mL, 37 mmol) was added, and the reaction mixture was stirred at room temperature for 12 h. The THF was evaporated, and the resulting material was quenched with 2 M HCl (75 mL) and extracted with EtOAc (3 x 50 mL). The combined organic phase was dried over sodium sulfate, filtered, and evaporated under reduced pressure. The crude reaction product was purified by flash chromatography using a pre-packed 100 g silica column [solvent A: EtOAc; solvent B: hexanes; gradient: 12%A / 88%B (1 CV), 12%A / 88%B → 70%A / 30%B (10 CV), 70%A / 30%B (2 CV); flow rate: 50 mL/min; monitored at 254 and 280 nm] to afford carboxylic acid 2 (5.63 g, 27.3 mmol, 74%) as a yellow solid. NMR characterization was performed after the next step.

4.1.54. 5-(3′-Methoxyphenyl)pentanoic acid (8).31,33,53

To dissolved carboxylic acid 2 (5.63 g, 27.3 mmol) in MeOH (100 mL) was added 10% palladium on carbon (0.44 g) and hydrogen gas. The reaction was stirred at room temperature for 12 h. The reaction mixture was then filtered through Celite®, and the Celite® was washed with EtOAc (3 x 50 mL). The organic phase (MeOH and EtOAc) was evaporated under reduced pressure to afford carboxylic acid 8 (4.27 g, 20.5 mmol, 75%) as a yellow oil. 1H NMR (500 MHz, CDCl3) δ 11.2 (1H, s), 7.03 (1H, d, J = 8 Hz), 6.62 (2H, d, J = 5 Hz), 6.59 (1H, d, J = 8.5 Hz), 3.59 (3H, s), 2.44 (2H, t, J = 7.5 Hz), 2.21 (2H, d, J = 7.5 Hz), 1.52 (4H, m). 13C NMR (125 MHz, CDCl3) δ 180.2, 159.7, 143.7, 129.4, 120.9, 114.3, 111.1, 55.0, 35.6, 34.1, 30.7, 24.5.

4.1.55. 2-Methoxy-6,7,8,9-tetrahydro-5H-benzo[7]annulen-5-one (14)