Abstract

The world-wide production of carbon nanotubes (CNTs) has increased substantially in the last decade, leading to occupational exposures. There is a paucity of exposure data of workers involved in the commercial production of CNTs. The goals of this study were to assess personal exposure to multi-walled carbon nanotubes (MWCNTs) during the synthesis and handling of MWCNTs in a commercial production facility and to link these exposure levels to specific activities. Personal full-shift filter-based samples were collected, during commercial production and handling of MWCNTs, R&D activities, and office work. The concentrations of MWCNT were evaluated on the basis of EC concentrations. Associations were studied between observed MWCNT exposure levels and location and activities. SEM analyses showed MWCNTs, present as agglomerates ranging between 200nm and 100 µm. Exposure levels of MWCNTs observed in the production area during the full scale synthesis of MWCNTs (N = 23) were comparable to levels observed during further handling of MWCNTs (N = 19): (GM (95% lower confidence limit–95% upper confidence limit)) 41 μg m−3 (20–88) versus 43 μg m−3 (22–86), respectively. In the R&D area (N = 11) and the office (N = 5), exposure levels of MWCNTs were significantly (P < 0.05) lower: 5 μg m−3 (2–11) and 7 μg m−3 (2–28), respectively. Bagging, maintenance of the reactor, and powder conditioning were associated with higher exposure levels in the production area, whereas increased exposure levels in the R&D area were related to handling of MWCNTs powder.

KEYWORDS: Commercial production, multi-walled carbon nanotubes, occupational exposure.

INTRODUCTION

Carbon nanotubes (CNTs) have the ability to improve the thermal, electrical, and mechanical properties of materials and are used, like other manufactured nano-objects (MNOs), to develop new products with improved characteristics. The market for CNTs is increasingly expanding, with applications in e.g. electronics, batteries, textile, concrete, sport equipment, solar cells, coatings, inks, and pharmaceutical/biomedical devices (Nowack et al., 2013).

Alongside the enormous potential of CNTs, concerns have been raised about possible human health risks. The understanding of the specific hazard potential of CNTs is complicated by its variability in structure and size. Animal studies have demonstrated that certain types of CNTs can cause cancer of the pleura. Additionally, inhalation of some CNTs have been shown to induce acute or persistent pulmonary inflammation, granuloma formation, fibrosis, and bronchiolar or bronchioloalveolar hyperplasia in rodents (Poland et al., 2008; Hubbs et al., 2009; Porter et al., 2009; Wolfarth et al., 2009; Mercer et al., 2010; Porter et al., 2010; Pauluhn, 2010; Mercer et al., 2011; Castranova et al., 2013; Grosse et al., 2014; Sargent et al., 2014). While in vitro studies of cultured human lung or mesothelial cells have shown that CNTs, induce genetic lesions such as DNA strand breaks, oxidized DNA bases, mutations, micronucleus formation, and chromosomal aberrations.

Due to the potential hazard of CNTs and increasing use, insight in exposure levels and exposure conditions of workers potentially exposed to CNTs is needed. A number of studies demonstrated the potential of occupational exposure to CNTs during activities with CNTs (Maynard et al., 2004; Bello et al., 2008; Han et al., 2008; Yeganeh et al., 2008; Bello, 2009; Tsai et al., 2009; Johnson et al., 2010; Methner et al., 2010; Bello et al., 2010; Lee et al., 2010; Wang and Pui, 2011; Ogura et al., 2011; Dahm et al., 2012; Methner et al., 2012; Takaya et al., 2012; Fleury et al., 2013; Hedmer et al., 2014; Bekker et al., 2015; Dahm et al., 2015). The assessment is complicated as it is difficult to find a sensitive and selective analytical method for CNTs. In addition, so far, most exposure studies have been conducted in small research and development (R&D) facilities, assessing the exposure during the synthesis and/or handling of a limited amount of CNTs (<1kg). However, with the growing market for CNTs, an increase in larger scale industrial manufacturing of CNTs can be expected (Invernizzi, 2011). To date, only a few studies assessed frequently occupational exposure during synthesis and/or handling of larger quantities (>1kg) of CNTs (Lee et al., 2010; Wang and Pui, 2011; Takaya et al., 2012). Of these three studies only Takaya et al. (2012) used a more refined mass-based method with elemental carbon (EC) as a proxy for CNTs exposure. However, none of the studies measured in the personal breathing zone (PBZ) frequently, which is the optimal strategy to assess a workers’ personal exposure.

The primary objective of this study was to assess and characterize shift-based personal inhalable exposure to multi-walled carbon nanotubes (MWCNTs) during low volume (R&D) and commercial synthesis and subsequent handling of MWCNTs using a technique based on EC (as a proxy for CNT mass), and Scanning Electron Microscopy (SEM). A secondary objective was to link the personal exposure measurements to performed activities. The personal exposure measurements will form a basis for exposure assessment in a cross-sectional study of early effect markers among the workers of this facility.

METHODS

Facility and products description

We conducted this study at a company commercially producing MWCNTs. The facility consisted of two areas: a production area with attached the main office of the company and a R&D area not connected to the production or office area.

In the production area, chemical vapor deposition (CVD) is used to produce MWCNTs in a large reactor. During the continuous synthesis period, >100kg MWCNTs is produced per day (further referred to as synthesis period). Besides the synthesis of MWCNTs, handling activities with MWCNTs are performed year round, including packaging and integrating MWCNT powder in coatings, dispersions, and plastics (during a period without synthesis further referred to as handling period). Both the synthesis process and the further handling of MWCNTs take place in a large open two-leveled area.

In the office, workers perform administrative deskwork. The office is connected to the production area at the first floor via a dressing room. Although, no activities are performed with MWCNTs in the office, exposure measurements were taken to study potential secondary exposure coming from the production area, with a total estimated volume between 1000 and 10 000 m3

In the R&D area not connected to the production or office area, workers are responsible for research and development, quality control, and technical support. Low quantities (<500g) of MWCNTs are handled per activity.

Sampling strategy

The sampling strategy focused on determining personal exposure to MWCNTs based on a specific EC method, characterizing MWCNT exposure by SEM and energy dispersive X-ray spectroscopy (EDX) and assessing the performed activities by observations and questionnaires. Workers in the production area (both during the synthesis and handling period), R&D area, and office were included in the study.

Exposure measurements were performed during 3 days in May 2013 without any synthesis activities (handling period) and 4 days in November 2013 during a period of full-scale synthesis of MWCNTs in the reactor (synthesis period). During the handling period, exposure measurements were performed in the production area and in the R&D area (2 days) while during the synthesis period measurements were performed in the production area and in the office (2 days). In the production area and the R&D area, every available worker (present between 6:00h and 22:00h) was assessed resulting in repeated measurements for individuals (with a maximum of 6), while in the office a random selection of the workers was measured based on availability.

Because pilot (static) measurements indicated levels of respirable size fraction below the limit of detection (data not shown), shift-based (4–8h) PBZ samples were collected for the inhalable size fraction. PBZ samples for analyses with SEM-EDX were collected from two randomly selected workers per measured day/shift with nickel-coated track-etched polycarbonate filters (25mm, pore size 0.4 µm, Nuclepore) in an IOM sampler connected to a personal pump (flow rate 0.7 l min−1). Simultaneously, PBZ samples for EC analyses were collected from every available worker, on 25-mm diameter quartz fiber filters (Whatman, Kent, UK) in an IOM sampler, connected to a personal pump (flow rate 2 l min−1), resulting in two double-equipped workers per day/shift.

From each measured worker, information was obtained on the performed activities for the shift-based measurement by questionnaires completed by the workers at the end of the shift, personal observations of the fieldworkers and a daily interview with the production manager.

SEM-EDX analyses

SEM-EDX was used for physicochemical characterization and determination of the particle size distribution of MWCNTs and a semi-quantitative estimate of the soot concentration (sources: ambient air and internal engines). The filters were screened at magnifications between 200× and 50000× suitable for the detection of agglomerates of MWCNTs as well as individual MWCNTs. Qualitative data is obtained about the type, size and shape of sampled particles, the degree of agglomeration or aggregation, and elemental composition.

All particles between 25nm and 100 µm were counted with automated particle analysis software (Olympus Soft Imaging Solutions GmbH, Germany) and were distributed in 18 size bins: 25–40, 40–65, 65–100, 100–160, 160–250, 250–400, 400–650, 650–1000nm and 1.0–1.6, 1.6–2.5, 2.5–4.0, 4.0–6.5, 6.5–10, 10–16, 16–25, 25–40, 40–65, and 65–100 um. Using both the secondary electron image and backscattered electron image of the microscope, MWCNTs could be distinguished from organic carbonaceous particles, soot, and inorganic particles. Soot structures are identified based on the typical morphological characteristics: fractal chain-like aggregates of spherical primary particles. A detailed description of the quantification method with SEM-EDX is described by Tromp et al. (in preparation).

Elemental carbon analyses

The analysis of EC is based on the thermal optical method as described in the American Standard Method NIOSH 5040. In agreement with Ono-Ogasawara and Myojo (2011) a modified IMPROVE protocol was used for the temperature and atmospheric gas settings. In the present study, a thermal optical carbon monitor (Sunset Laboratory Inc., USA) was used. From each quartz filter 1cm2 is punched for carbon analysis. EC is removed in the temperature range of 550–920°C at a mixture of helium and 2% oxygen (2% O2/He). The resulting CO2 is then converted to methane and detected by flame ionisation detection (FID). EC is categorized into EC1 (550°C), EC2 (650°C), and EC3 (920°C). The LOD for a punched filter is 0.5 µg cm−2 (based on reproducibility) corresponding to an airborne MWCNT concentration of 1.5 µg m−3.

Calculation of inhalable and respirable CNT exposure levels

Ono-Ogasawara and Myojo (2011, 2013) described that MWCNTs are usually observed as EC3, which can be used to approximate MWCNT exposure. However, in this study MWCNTs are found in the EC2 fraction also, due to their small diameter and due to altered oxidation temperatures as a result of high concentrations of catalyzing metals and the presence of other EC particles (soot).

Because soot is also present in EC2 the mass soot concentration per day/shift per location was subtracted from the total sum of EC2 and EC3, to obtain the MWCNT mass concentration. The mass soot concentration was calculated using a mass equation ((π/6) ρp (d pa/Sv)3, with ρp (particle density), d pa (particle size), and Sv (shape factor). SEM analyses provided soot structure counts and the d pa. A particle density of 1.5/g cm−3 and a volume shape factor of 1.5 were used (Tromp et al. in preparation. A detailed description of the adapted EC-based method for the assessment of MWCNTs mass and comparison with other approaches is described by Tromp et al. (in preparation).

Statistical analyses

To link the personal inhalable mass concentrations of MWCNTs to the performed activities, statistical analyses were performed. Inhalable mass concentration data showed a right skewed distribution and were log-transformed prior to statistical analysis.

A linear mixed-effects model fit by restricted maximum likelihood (REML) was used to assess associations between inhalable MWCNTs mass concentrations and area (production area, R&D area, office) and period (synthesis period and handling period), taking into account repeated measurements on the same worker (Rappaport et al., 1999).

In addition, linear mixed-effects models fit by REML were used to study associations between inhalable MWCNT mass concentrations (shift-based) and performed activities for the production area (combining the synthesis and handling period) and the R&D area separately. For multivariate model building, backward stepwise model building based on the Akaike information criterion (AIC) was used to arrive at models with an optimal balance between goodness of fit and model complexity.

For the production area, 42 measurements were available during which 15 activities were encountered. Activities were selected for inclusion in the multivariate model building based on univariate analyses with linear mixed-effects models fit by REML (P < 0.1) and the prevalence of the activity (N > 2). Pearson correlation coefficients were calculated to evaluate the correlation between all activities.

For the R&D area, 11 measurements were available and six activities were encountered. Due to this limited number of samples, activities were grouped into activities with direct contact to MWCNTs powder (n = 3) and activities without direct contact to MWCNTs powder (n = 3) (e.g. handling MWCNTs in a liquids or a matrix).

Geometric means (GMs) for the various areas and measurement periods were derived from the model estimates. All statistical analyses were performed using the statistical software R, with package NLME (R Development Core Team, 2011).

RESULTS

Description of activities

A description of the performed activities with the used technical exposure control measures per area and per measurement period is given in Table 1. In the production area, activities specifically related to the synthesis of MWCNTs only took place during the synthesis period and included the control of the reactor, catalyst production, big bag replacement, and powder conditioning. Activities related to packaging and formulation of MWCNT enabled products took place during both the synthesis and handling period and included the bagging of powder MWCNTs and the incorporation of MWCNTs in coatings, dispersions, and plastics. In addition, irregular activities performed during both periods included the maintenance of machines and cleaning with a vacuum cleaner (equipped with HEPA filters) of the area. Exposure control measures were used mainly during activities with MWCNTs powder (local exhaust ventilation, fume hood). General exhaust ventilation was active and doors/windows were more often opened during the synthesis period compared to the handling period, to cool down the production area.

Table 1.

Overview relevant activities per area and per measurement period. Information is included about the process and the available control measures

| Related activities | Description |

|---|---|

| Production area—synthesis | |

| Bagging | Dumping MWCNTs from big bags into smaller bags. The dumping is performed in a cabin with a semiclosed local ventilated bagging system |

| Big bag replacement | The produced MWCNTs are collected (close system) in big bags. During the big bag replacement an employee manually changes the big bag and the closed system is temporary opened |

| Catalyst production | The catalyst required for production is produced in the production area |

| Cleaning | Cleaning the production area with a HEPA filtered vacuum cleaner |

| Controlling operators | The production manager is regularly in contact with other operators |

| Controlling reactor | The synthesis of MWCNTs is monitored |

| Powder conditioning | Powder conditioning is a high energy process performed in a closed system but the system is manually opened for changing bags |

| Handling research grades | Prepare samples for research and development and quality control. Activities are performed in a fume hood |

| Maintenance | Maintenance of machines including the reactor |

| Production coatings | MWCNTs are applied in a coating. No control measures were observed |

| Production granules | MWCNTs are applied in granules. The process is locally ventilated and partly enclosed |

| Production area—handling | |

| Bagging | See above |

| Cleaning | See above |

| Control operators | See above |

| Handling research grades | See above |

| Maintenance | See above |

| Production coatings | See above |

| Production granules | See above |

| Stock management | Transferring bags of MWCNTs and preparing for distribution |

| R&D area | |

| Manufacturing MWCNTs | Production of MWCNT at pilot scale, used to test new structures |

| Micro compounding | Introduction of low volume powder in the micro compounder resulting after processing in a solid structure |

| Production composites | Production and/or handling of composites with CNT |

| Production granules | See above. In addition, volumes are lower compared to the production of granules in the production area |

| Rheology/liquid handling | Testing with water-based liquids and applied MWCNTs |

| Weighing of MWCNTs | Handling of low quantities of powder MWCNT for balancing purposes |

| Office | |

| Deskwork | Activities behind the desk |

Regularly performed activities in the R&D area were comparable with the production area but on a smaller scale and involved the use of a small-scale reactor, an extruder for the production of MWCNTs, composites, and application of different analyzing techniques. Exposure control measures were used including local exhausted ventilation, fume hoods and a closed reactor.

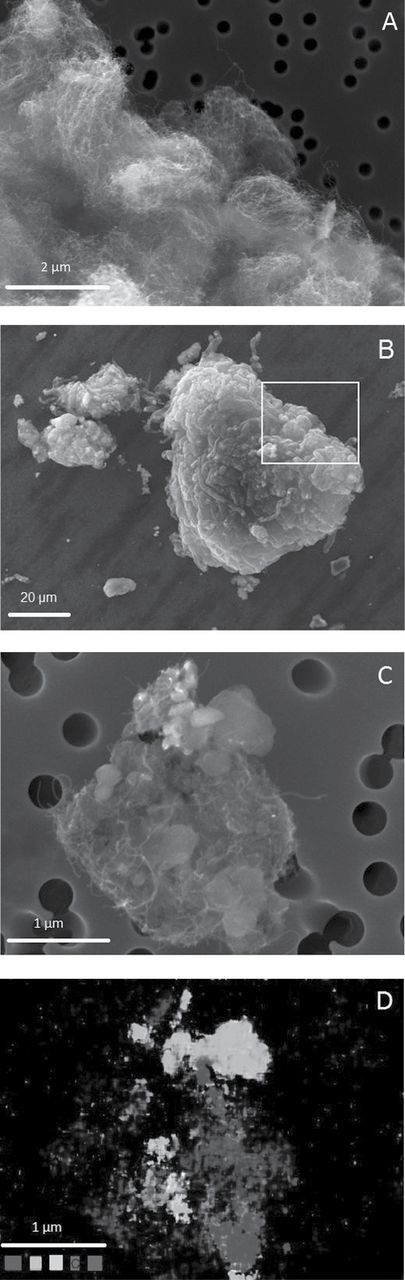

Characterization and particle size distribution

In total, we collected 30 nickel coated nucleopore filters of which 10 filters were analyzed. Seven were taken in the production area, two in the R&D area and one in the office. SEM-EDX analyses demonstrated agglomerated MWCNTs on all of these filters. (Examples are shown in Fig. 1A, B). The filters contained large agglomerates with tangled and bundled MWCNTs structures with other particles consisting of other (catalyst) metals attached to them (Fig. 1C, D). No individual MWCNTs (diameter < 10nm, length > 1µm) were observed. Soot concentrations (N = 10) collected per day/shift and per location were found ranging from 0.2 to 10.2 μg m−3 with a GM of 1.25 μg m−3 which were subtracted from the total sum of EC2 and EC3, to obtain the MWCNT mass concentration.

Figure 1.

SEM images of collected PBZ samples, with (A) detailed image of MWCNTs, part of a agglomerate, (B) different large MWCNT agglomerate, (C) detailed image of agglomerate with MWCNTs, (D) SEM mapping identifying attached particles at the agglomerate [as presented in (C)].

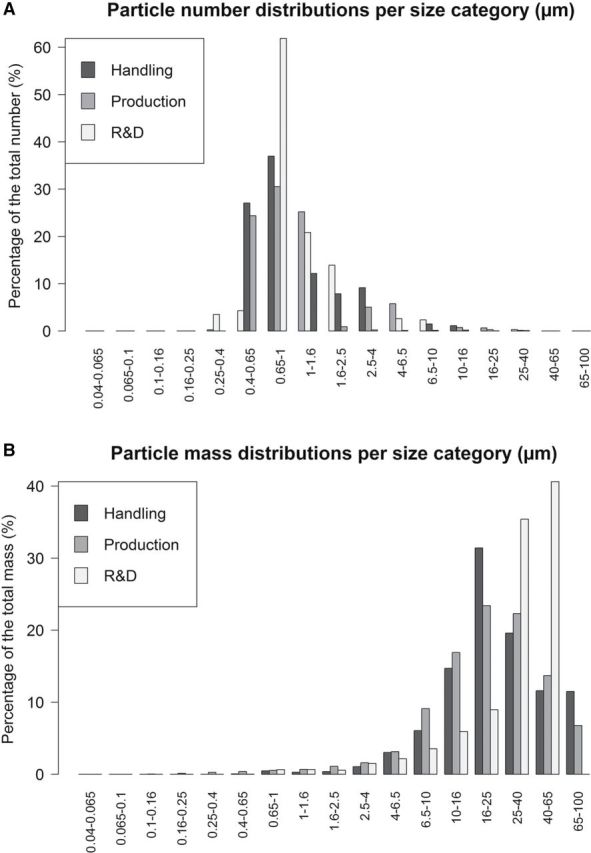

Figure 2A shows the mean particle size distributions obtained by SEM analysis for the production area (synthesis and handling period) and the R&D area, based on the percentage of particles of the total particle number concentration by size bin. In general, the particle size of the MWCNT agglomerates ranged from 200nm to 100 µm, indicating a modal distribution with a mode diameter between 650 and 1000nm. More smaller particles seem to be present during the synthesis period in the production area and in the R&D area, compared to the handling period in the production area. Figure 2B shows the mean particle size distributions based on the mass percentage by size bin. Using this representation also, the mode seemed to be smaller during the synthesis period (mode 10–20 µm) than the handling period (mode 20–50 µm). However, due to a high variation within the results, no clear conclusions can be drawn.

Figure 2.

Particle size distributions analyzed semiquantitatively with SEM collected in the production area (production period and handling period) and in the R&D area. Particles were distributed in 15 size bins, (A) results based per size bin on percentages of the total particles in the upper panel and (B) with results per size bin based on the percentage of the total mass in the lower panel.

Particle size distributions for the office could not be obtained because the overall inhalable mass concentrations were too low to derive robust distributions. Nevertheless, visual inspection showed agglomerates of MWCNTs, mainly ranging between 1 and 10 µm.

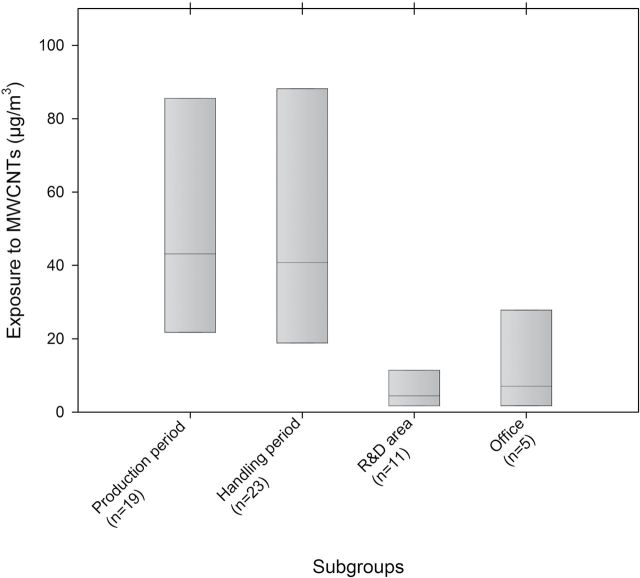

Mass concentrations

Overall, 58 quartz fiber filters were collected for EC analysis. Figure 3 shows the GM of the inhalable MWCNT mass concentrations [including 95% lower confidence limit (LCL) and 95% upper confidence limit (UCL)] for the different areas and measurement periods. Inhalable mass concentrations were significantly higher in the production area than in the R&D area or the office (P < 0.05). Inhalable mass concentrations in the production area during the handling period were comparable to concentrations obtained during the synthesis period. Furthermore, no significant difference was found between inhalable mass concentrations in the R&D area and the office. In the Supplementary Material, a detailed overview of the obtained results is included per collected sample.

Figure 3.

Estimated geometric mean inhalable personal inhalable MWCNT concentrations (TWA) at the production area (synthesis and handling period), R&D area and in the office. Bar ends represent the LCL 95%, and UCL 95%.

Determinants for inhalable mass concentrations MWCNTs

Table 2(A) shows the multivariate mixed effect model for the production area during synthesis, packaging and integrating MWCNT powder into products. Several activities significantly contributing to an elevation of the inhalable concentration were identified, all of which were performed in both the synthesis and the handling period. These activities are bagging, maintenance of the reactor, and powder conditioning. Pearson correlation coefficients between all individual activities showed negligible or weak linear correlations (r < 0.3), with the exception for powder conditioning and big bag replacement (r = 0.72). The model explained 45% of the total variance for the production area. The relatively high intercept indicates a high MWCNT background concentration, most likely caused by contamination of the production area.

Table 2.

Estimates of model variables in mixed effects models with (A) the production area during the synthesis of MWCNTs and the handling of MWCNTs and (B) the R&D area. The measured worker is included as a random effect

| (A) Production area | N a | N subjectsb | βc | P value |

|---|---|---|---|---|

| Interceptd | 2.90 | 0.0000 | ||

| Bagging | 4 | 2 | 2.81 | 0.0000 |

| Maintenance | 9 | 5 | 1.31 | 0.0030 |

| Powder conditioning | 9 | 8 | 1.46 | 0.0012 |

| Var_bw e | 3.45×10−5f | |||

| Var_ww f | 1.06 | |||

| Total explained variability by model | 45% | |||

| (B) R&D area | N a | N subjectsb | βc | P value |

| Interceptd | −0.24 | 0.7109 | ||

| Contact with MWCNTs | 8 | 6 | 2.79 | 0.0117 |

| Var_bw e | 1.73×10 −10g | |||

| Var_ww f | 1.55 | |||

| Total explained variability by model | 54.8% |

a# Measurements, b# persons measured, cfixed effect vector, dthe intercept gives the exposure to MWCNTs, not performing tasks with MWCNT powder (e.g. handling liquids and dispersions), evariance component between workers, fvariance component within workers, gvariance between workers cannot be accurately estimated.

Table 2(B) shows the multivariate mixed effect model for the R&D area. The inhalable mass concentrations were significantly higher for measurements in which workers had direct contact to MWCNTs powder (weighing of MWCNTs, Micro compounding, manufacturing MWCNTs), compared to the group without direct contact to bulk MWCNTs powder (production composites and granules, rheology/liquid handling). The model for the R&D area explained 55 % of the total variance. The relatively low intercept suggests no additional sources of MWCNTs in the R&D area.

DISCUSSION

Worldwide, the amount of produced MWCNTs and number of industrial applications are increasingly expanding, requiring more knowledge about the potential occupational exposure levels and related health effects. This study demonstrated significantly higher exposure levels during synthesis and subsequent handling of commercially produced MWCNTs (see Fig. 3) in a production area compared to similar activities performed with lower volumes of MWCNTs in a R&D area of the same company. In the production area, exposure levels were comparable during a period of full-scale synthesis, packaging and integrating MWCNT powder into products (synthesis period) and a period of only packaging and integrating MWCNT powder into products (handling period). Bagging, maintenance of the reactor, and powder conditioning of MWCNTs were associated with increased exposure levels in the production area. A high model intercept for the production area compared to the R&D area, suggested high background MWCNTs exposure as a result of contamination in the production area. In the R&D area, handling MWCNTs powder (weighing of MWCNTs or manufacturing MWCNTs) was associated with significant increased exposure levels. MWCNTs were mostly present as large agglomerates ranging between 200nm and 10 µm, with majority between 650 and 1000nm for both the production area and the R&D area.

Comparison across studies assessing occupational exposure to (MW)CNTs is complicated by variability in exposure assessment methods used. The current study demonstrated the absence of single MWCNTs and the presence of predominantly respirable agglomerates of MWCNTs (mainly between 500nm and 10 μm) with attached metals in the workplace air. These qualitative results are consistent with results from three other studies, which also used SEM or Transmission electron microscopy (TEM) to assess the type of exposure caused by activities with rigid and flexible MWCNTs, including synthesis, sonification in deionized water, transferring, harvesting, weighing, and mixing (Johnson et al., 2010; Dahm et al., 2012; Methner et al., 2012).

In addition to our study, four other studies (Dahm et al., 2012; Methner et al., 2012; Hedmer et al., 2014; Dahm et al., 2015) were identified that applied a refined mass-based method based on EC as a proxy for CNTs exposure as described by Ono-Ogasawara and Myojo (2011). Dahm et al. (2012), Methner et al. (2012), Hedmer et al. (2014), and Dahm et al. (2015) assessed mainly activities with low volumes and found personal inhalable EC concentrations between 0.68–7.86, 33–38, 0.08–7.4 µg m−3, and 0.01–79.57 µg m−3, respectively which are consistent with our findings in the R&D area (0.17–59.50 µg m−3). Furthermore, Dahm et al. (2012) indicated that in most cases, the aerosols sampled were most likely within the respirable size fraction. This conclusion is consistent with our findings, but mass-based particle size distributions showed the enormous contribution of large MWCNTs agglomerates to the inhalable MWCNT mass concentrations.

Two other studies assessing exposures during more comparable synthesis and/or (subsequent) handling of high volumes of (MW)CNTs have been identified. However, these studies have used non-selective proxies for CNTs. Lee et al. (2010) assessed exposure during the production of MWCNTs in three industrial plants and obtained PBZ concentrations ranging between 21.2 and 285.9 µg m−3, by using a gravimetric method. However, no SEM or TEM analyses were performed to characterize the particles and to confirm CNT structures. The gravimetric results are most likely an overestimate of CNT exposure due to interferences from other (background) particle sources. In the present study the EC1 fraction, which is not included in the more specific measure for CNTs, was substantial (EC1 range 2.6–484.1 µg m−3). Wang and Pui (2011) measured exposure in an industrial production area for CNT-imbedded nano composites. The particle number concentration was between 90 000 and 100 000 #/cm3, but it was believed that volatile polymer fumes were a major particle source.

Recently, NIOSH proposed that exposures to respirable EC mass-based MWCNTs should be kept below a recommended exposure limit (REL) of 1 μg m−3 as an 8-h time-weighted average (TWA) (NIOSH, 2013). The NIOSH REL is not a health-based exposure limit but is based on the current analytical limit of quantification with sampling and analytic methods. To get an indication of the respirable mass concentrations the measured inhalable mass concentrations were converted into corresponding respirable mass concentrations using the respirable convention as a percentage of the inhalable convention and the percentages MWCNTs per size category derived from the semi-quantitative SEM analyses according to CEN EN 481 (CEN, 1993). Respirable fractions ranging between 2 and 10% were obtained, resulting in converted respirable mass concentrations in the production area of 0.87–4.45 μg m−3 (0.08–29.97) and 0.76–2.71 μg m−3 (0.02–75.34) for the synthesis period and handling period, respectively, and 0.07–0.30 μg m−3 (0–3.84) for the R&D area. The calculated respirable mass concentrations for this study exceeded the REL frequently (67%, based on 4.95% respirable fraction) in the production area during both the synthesis period and handling period and occasionally (27%, based on 4% respirable fraction) in the R&D area. Because of the low MWCNT concentration in the office, no robust particle size distributions were obtained which made it impossible to calculate the respirable mass concentrations. The calculated respirable mass concentrations should be interpreted with caution, as the calculated respiratory levels may vary considerable as a result of the used methods and assumptions. First, PBZ samples for analyses with SEM-EDX were collected with flow rates of 0.7 l min−1 while the IOM sampler is usually operated at a flow rate of 2.0 l min−1. Originally, these samples were only intended to be used for qualitative characterization of the MWCNTs and for practical reasons a lower flow rate was used. According to Vincent (1989) and Sansone and Bernard (1976) a lower flow rate has a large effect on larger particles, which are less efficiently captured but for smaller particles in the size range of 2–20 µm no differences were observed (Vincent, 1989; NIOSH, 2013). Therefore, the respirable fractions as presented with a lower flow rate (0.7 l min−1) are likely to be comparable to the recommended flow rate of 2 l min−1. Next, uncertainty in deriving the respirable size fraction with SEM analysis is introduced by the counting technique. Currently, no standard protocol has been developed, with counting rules, or semi-automatic routines for SEM/TEM analysis including the use of standard reference materials for sizing and characterizing particles (Brouwer et al., 2012). The uncertainty in the derived respirable mass concentration due to analyzing only a small fraction of the filter estimated based on the Poisson distribution is 20%. Furthermore, SEM volume equivalent diameters are derived in this study, while uniform respirable convention percentages are based on the aerodynamic diameters, resulting in an uncertainty of approximately 40%. Lastly, the respirable fractions were determined once per area and per measurement day and subsequently used for the conversion of every inhalable mass concentration introducing additional uncertainty.

This is one of the first studies that have evaluated determinants of MWCNT exposure. The identified high exposure activities bagging, maintenance of the reactor and powder conditioning in the production area, are consistent with the findings of previous studies that assessed the emission potential of activities with (powdered) nanomaterials (including CNTs) and performed task-based exposure assessments (Methner et al., 2010; Ham et al., 2012). It should be noted that the relatively low number of measurements, the numerous activities and the relatively high surface contamination suggested by the high model intercept may have hampered the identification of all activities that resulted in high-exposure levels. In addition, since workers perform several activities over a day, often for a relatively short-time period, the obtained shift-based results are a complex combination of activities. Nevertheless, the relatively low Pearson correlation coefficients suggest an independent character of the identified activities with increased exposure levels.

No clear differences were found in exposure levels and particles size distributions between both measurement periods in the production area. As the synthesis process of MWCNTs was an automatic process, activities related to the synthesis process were mostly performed in a control room, monitoring the reaction process. Individual measurements of workers only present in the control room, revealed relatively low inhalable exposure levels of MWCNTs (range 7.83–32.62 µg m−3, n = 4). Therefore, the synthesis of MWCNTs itself does not appear to be a major source of exposure in this study.

Surprisingly, MWCNTs were detected in the office. This may be explained by a connection via two doors between the production area and the office that were regularly open, especially during the cleaning of the office, or by clothing contamination from several workers who work both in the production area and the office. Visual inspection during the fieldwork identified powder on most objects, floors, and walls, suggesting that MWCNTs easily dispersed through the area.

In conclusion, this study demonstrated significantly higher MWCNT exposure during synthesis and subsequent handling of high volumes of MWCNTs compared to R&D activities. To our knowledge, this is one of the first study describing personal occupational exposure related to commercial activities, by using EC as a proxy for MWCNTs. We identified several activities that are associated with significantly increased exposure, which will give focus to interventions aimed at reducing exposure levels by the company.

SUPPLEMENTARY DATA

Supplementary data can be found at http://annhyg.oxfordjournals.org/.

ACKNOWLEDGEMENTS

The research was partly funded by NanoNextNL, a micro and nanotechnology consortium of the Government of the Netherlands and 130 partners. The paper was reviewed by the funder and studied company prior to submission. We thank Roel Engel, Ruud Boessen and the supportive studied company for their contributions. None of the authors has a financial relationship with a commercial entity that has an interest in the subject of this manuscript.

REFERENCES

- Bekker C, Kuijpers E, Brouwer DH, et al. (2015) Occupational exposure to nano-objects and their agglomerates and aggregates across various life cycle stages: a broad-scale exposure study. Ann Occup Hyg; 59: 681–704. [DOI] [PubMed] [Google Scholar]

- Bello D. (2009) Exposure to nanoscale particles and fibers during machining of hybrid advanced composites containing carbon nanotubes. J Nanoparticle Res; 11: 231–49. [Google Scholar]

- Bello D, Hart AJ, Hallock M, et al. (2008) Particle exposure levels during CVD growth and subsequent handling of vertically-aligned carbon nanotube films. Carbon; 166: 974–81. [Google Scholar]

- Bello D, Wardle BL, Zhang J, et al. (2010) Characterization of exposures to nanoscale particles and fibers during solid core drilling of hybrid carbon nanotube advanced composites. Int J Occup Environ Health; 16: 434–50. [DOI] [PubMed] [Google Scholar]

- Brouwer D, Berges M, Virji MA, et al. (2012) Harmonization of measurement strategies for exposure to manufactured nano-objects; Report of a workshop. Ann Occup Hyg; 56: 1–9. [DOI] [PubMed] [Google Scholar]

- Castranova V, Schulte PA, Zumwalde RD. (2013) Occupational nanosafety considerations for carbon nanotubes and carbon nanofibers. Accounts Chem Res; 46: 642–49. [DOI] [PMC free article] [PubMed] [Google Scholar]

- CEN. (1993) (ed) Size Fraction Definition for Measurement of Airborne Particles, European Standard EN 481, CEN European Committee for Standardization, rue de Stassart 36, B-1050, Brussels, Belgium. [Google Scholar]

- Dahm MM, Evans DE, Schubauerberigan MK, et al. (2012) Occupational exposure assessment in carbon nanotube and nanofiber primary and secondary manufacturers. Ann Occup Hyg; 56: 542–56. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dahm MM, Schubauer-Berigan MK, Evans DE, et al. (2015) Carbon nanotube and nanofiber exposure assessments: An analysis of 14 site visits. Ann Occup Hyg; 59: 705–23. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fleury D, Bomfim JAS, Vignes A, et al. (2013) Identification of the main exposure scenarios in the production of CNT-polymer nanocomposites by melt-moulding process. J Cleaner Prod; 53: 22–36. [Google Scholar]

- Grosse Y, Loomis D, Guyton KZ, et al. on behalf of IARC. (2014) Carcinogenicity of fluoro-edenite, silicon carbide fibres and whiskers, and carbon nanotubes. Lancet Oncol; 15: 1427–28. [DOI] [PubMed] [Google Scholar]

- Ham S, Yoon C, Lee E, et al. (2012) Task-based exposure assessment of nanoparticles in the workplace. J Nanoparticle Res; 14: 9. [Google Scholar]

- Han JH, Lee EJ, Lee JH, et al. (2008) Monitoring multiwalled carbon nanotube exposure in carbon nanotube research facility. Inhalation Toxicol; 20: 741–49. [DOI] [PubMed] [Google Scholar]

- Hedmer M, Isaxon C, Nilsson PT, et al. (2014) Exposure and emission measurements during production, purification, and functionalization of arc-discharge-produced multi-walled carbon nanotubes. Ann Occup Hyg; 58: 355–79. [DOI] [PubMed] [Google Scholar]

- Hubbs A, Mercer R, Coad J, et al. (2009) Persistent pulmonary inflammation, airway mucous metaplasia, and migration of multi-walled carbon nanotubes from the lung after subchronic exposure. The Toxicologist; 108: A2193. [Google Scholar]

- Invernizzi N. (2011) Nanotechnology between the lab and the shop floor: What are the effects on labor? J Nanoparticle Res; 13: 2249–68. [Google Scholar]

- Johnson DR, Methner MM, Kennedy AJ, et al. (2010) Potential for occupational exposure to engineered carbon-based nanomaterials in environmental laboratory studies. Environ Health Perspect; 118: 49–54. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee JH, Lee S, Bae GN, et al. (2010) Exposure assessment of carbon nanotube manufacturing workplaces. Inhal Toxicol; 22: 369–81. [DOI] [PubMed] [Google Scholar]

- Maynard AD, Baron PA, Foley M, et al. (2004) Exposure to carbon nanotube material: aerosol release during the handling of unrefined single-walled carbon nanotube material. J Toxicol Environ Health; 67: 87–107. [DOI] [PubMed] [Google Scholar]

- Mercer RR, Hubbs AF, Scabilloni JF, et al. (2011) Pulmonary fibrotic response to aspiration of multi-walled carbon nanotubes. Particle Fibre Toxicol; 8: 21. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mercer RR, Hubbs AF, Scabilloni JF, et al. (2010) Distribution and persistence of pleural penetrations by multi-walled carbon nanotubes. Particle and Fibre Toxicol; 7: 28. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Methner M, Beaucham C, Crawford C, et al. (2012) Field application of the nanoparticle emission assessment technique (NEAT): Task-based air monitoring during the processing of engineered nanomaterials (ENM) at four facilities. J Occup Environ Hyg; 9: 543–55. [DOI] [PubMed] [Google Scholar]

- Methner M, Hodson L, Dames A, et al. (2010) Nanoparticle Emission Assessment Technique (NEAT) for the identification and measurement of potential inhalation exposure to engineered nanomaterials--Part B: Results from 12 field studies. J Occup Environ Hyg; 7: 163–76. [DOI] [PubMed] [Google Scholar]

- NIOSH. (2013) Occupational exposure to carbon nanotubes and nanofibers. Curr Intell Bull; 65. [Google Scholar]

- Nowack B, David RM, Fissan H, et al. (2013) Review: Potential release scenarios for carbon nanotubes used in composites. Environ Int; 59: 1–11. [DOI] [PubMed] [Google Scholar]

- Ogura I, Sakurai H, Mizuno K, et al. (2011) Release potential of single-wall carbon nanotubes produced by super-growth method during manufacturing and handling. J Nanoparticle Res 13: 1265–80. [Google Scholar]

- Ono-Ogasawara M, Myojo T. (2011) A proposal of method for evaluating airborne MWCNT concentration. Ind Health; 49: 726–34. [DOI] [PubMed] [Google Scholar]

- Ono-Ogasawara M, Myojo T. (2013) Characteristics of multi-walled carbon nanotubes and background aerosols by carbon analysis; particle size and oxidation temperature. Adv Powder Technol; 24: 263–9. [Google Scholar]

- Porter D, Wolfarth M, Chen B, et al. (2009) Pulmonary toxicity of inhaled multi-walled carbon nanotubes. The Toxicologist; 108: A2193. [Google Scholar]

- Porter DW, Hubbs AF, Mercer RR, et al. (2010) Mouse pulmonary dose- and time course-responses induced by exposure to multi-walled carbon nanotubes. Toxicology; 269: 136–47. [DOI] [PubMed] [Google Scholar]

- Pauluhn J. (2010) Subchronic 13-week inhalation exposure of rats to multiwalled carbon nanotubes: toxic effects are determined by density of agglomerate structures, not fibrillar structures. Toxicol Sci; 113: 226–42. [DOI] [PubMed] [Google Scholar]

- Poland CA, Duffin R, Kinloch I, et al. (2008) Carbon nanotubes introduced into the abdominal cavity of mice show asbestos-like pathogenicity in a pilot study. Nat. Nanotechnol; 3: 423–28. [DOI] [PubMed] [Google Scholar]

- Rappaport SM, Weavers M, Taylors D, et al. (1999) Application of mixed models to assess exposures, monitored by construction workers during hot processes. Ann Occup Hyg; 43: 457–69. [PubMed] [Google Scholar]

- Sansone EB, Bernard T. (1976) Particle collection by probes of nil and infinite bluntness, Atmos Environ; 10: 577–81. [Google Scholar]

- Sargent LM, Porter DW, Staska LM, et al. (2014) Promotion of lung adenocarcinoma following inhalation exposure to multi-walled carbon nanotubes. Particle Fibre Toxicol; 11: 1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Takaya M, Ono-Ogasawara M, Shinohara Y, et al. (2012) Evaluation of exposure risk in the weaving process of MWCNT-coated yarn with real-time particle concentration measurements and characterization of dust particles. Ind Health; 50: 147–55. [DOI] [PubMed] [Google Scholar]

- Tromp PC, Bekker C, Kuijpers E, Jedynska AD, Pronk A. A new approach to combine analytical methods for workplace exposure assessment to airborne MWCNT (in preparation). [DOI] [PMC free article] [PubMed]

- Tsai S, Hofmann M, Hallock M, et al. (2009) Characterization and evaluation of nanoparticle release during the synthesis of single-walled and multiwalled carbon nanotubes by chemical vapor deposition. Environ Sci Technol; 43: 6017–23. [DOI] [PubMed] [Google Scholar]

- Vincent JH. (1989) Aerosol sampling, science and practice. John Wiley & Sons Ltd. ISBN: 0471921750. [Google Scholar]

- Wang J, Pui DYH. (2011) Characterization, exposure measurement and control for nanoscale particles in workplaces and on the road. J Phys Confer Series; 304: 012008. [Google Scholar]

- Wolfarth M, Porter D, Hubbs A, et al. (2009) Pulmonary toxicity of multi-walled carbon nanotubes.The Toxicologist; 108: A2196. [Google Scholar]

- Yeganeh B, Kull CM, Hull MS, et al. (2008) Characterization of airborne particles during production of carbonaceous nanomaterials. Environ Sci Technol; 42: 4600–6. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.