Abstract

The influence of the type of material used, knot configuration, and use of an additional throw on the tensile force at failure, the elongation, and the mode of failure of different configurations of linear sutures and knotted suture loops was evaluated in this in-vitro mechanical study. We hypothesized that all types of knots would significantly influence the initial force and elongation of suture materials and would influence the force and elongation at which the knotted loops break, but not their mode of failure. A total of 432 samples of 4 types of size 3-0 suture material (polydioxanone, polyglecaprone 25, polyglactin 910, and nylon), representing 9 configurations, were tested in a tensiometer. The configurations were 1 linear suture without a knot and the following loops: square (SQ) knot; surgeon’s (SU) knot; granny (GR) knot; and sliding half-hitch (SHH) knot using either 4 and 5 or 3 and 4 throws, depending on the material. For polydioxanone, SQ and SU knots did not decrease the initial force at failure of the suture. Granny (GR) and SHH knots decreased the tensile force at failure and elongation by premature failure of the loop. For polyglecaprone 25, all knots decreased the initial force at failure of the suture, with SHH being weaker than the other knots. For coated polyglactin 910, all knots decreased the initial force at failure of the suture and slippage increased significantly compared with the other 3 sutures. The use of SQ knots with 3 throws did not result in a safe knot. For nylon, knots did not alter the original mechanics of the suture. In conclusion, all knots and types of suture material do not necessarily have the same effect on the initial tensile force at failure of suture materials.

Résumé

L’objectif de la présente étude était de déterminer, dans des conditions expérimentales contrôlées, l’influence de quatre types de noeud, du nombre de croisements et du type de matériel de suture utilisés sur le mode de rupture, l’élongation et la résistance de différentes configurations de boucles de suture. Un total de 432 échantillons de quatre types de fil de suture 3-0 (polydioxanone, polyglecaprone 25, polyglactin 910, nylon), représentant neuf configurations, ont été évalués à l’aide d’un tensiomètre. Plusieurs paramètres ont été analysés: la force atteinte lors de la rupture, l’élongation maximale de la boucle et son mode de rupture. Les différentes configurations sont: suture linéaire, noeud plat (NP), de chirurgien (NC), de vache (NV) et le noeud coulissant barré (NCB) en réalisant 4 et 5 croisements pour les monofilaments et 3 et 4 croisements pour le multifilament. Les différents matériaux et noeuds utilisés n’affectent pas tous de la même manière la force initiale du matériel de suture. Pour le polydioxanone, le NP et NC ne diminuent pas la force initiale du fil de suture. Le NV et le NCB diminuent la force initiale du fil de suture et diminuent son élongation par un bris prématuré du fil de suture. Pour le polyglecaprone 25, tous les noeuds réduisent la force initiale de la suture; le NCB est celui qui affecte le plus le matériel de suture. Pour le polyglactin 910 enrobé, tous les noeuds réduisent la force initiale de la suture; le glissement est augmenté de manière significative comparé aux trois autres types de matériels de sutures, une élongation significative de la boucle de suture a été observée avec la présence d’un NP avec trois croisements. Pour le nylon, les noeuds n’ont pas modifié les propriétés mécaniques d’origine du fil de suture. En conclusion, un NP et NC avec un polydioxanone 3-0 ne diminue pas la force initiale du fil de suture. Le polyglactin 910 enrobé est significativement associé à un glissement accru. Il n’y a pas de différence statistiquement significative à l’ajout d’un croisement à une boucle de suture 3-0.

(Traduit par les auteurs)

Introduction

Surgery is an essential part of veterinary medicine, regardless of the area of practice. Sutures play a crucial role in surgery. The knot is the weakest part of a suture and is generally the site of failure (1–3). Of the many types of knots, the following 4 are commonly used in small animal practice: square knot, surgeon’s knot, granny knot (technical error), and the sliding half-hitch.

The ideal knot should be quick and easy to make, while remaining safe and secure (4). A “safe knot” has been defined as a knot that breaks rather than unties due to slippage when tested to failure (5). Additionally, the knot should have as little affect as possible on the suture material. Many factors influence the safety of a suture, including the type of material, the type of knot, the number of throws, and the surgeon’s experience. Various studies have been conducted on the configuration of suture loops, evaluating the knot configuration (4,6), the number of throws (7,8), and the type of material (1,4,9,10). To our knowledge, there are no reports in the literature that evaluate, under the same experimental conditions, the behavior of 3-0 knotted loops of suture material frequently used in small animal surgery.

The aim of this study was to evaluate, under controlled experimental conditions, the influence of the type of material used, knot configuration, and use of an additional throw on the tensile force at failure, the elongation, and the mode of failure of different configurations of linear sutures and knotted suture loops. We hypothesized that all types of knots would significantly influence the initial force and elongation of each of the linear sutures. Our second hypothesis was that all types of knots would significantly influence the force and elongation at which the knotted loops break, but not their mode of failure.

Materials and methods

Suture material

Four types of size 3-0 suture materials were evaluated: polydioxanone (PDSII), polyglecaprone 25 (Monocryl), coated polyglactin 910 (Vicryl), and nylon (Ethilon) [Ethicon (Johnson & Johnson), Somerville, New Jersey, USA].

Suture configuration

Each type of suture material was evaluated in 9 configurations: 1 linear strand of suture without a knot (control group) and 8 loop configurations. All knots were individually tied by the same operator (BL) using 2-handed hand ties wrapped around the combination of a 20-mL syringe (Terumo, Somerset, New Jersey, USA) and an adjacent metallic pin (3-mm diameter) so that the suture loops could easily be removed from the syringe after the metallic pin is withdrawn, thus minimizing friction-related microtrauma to the suture loops. The knot ears were cut to a standardized length of 5 mm (1,3). The syringe was fixed in a vice on a bench top to ensure consistent tension when tightening the knots and all the knots were inspected for slippage before cutting the ears.

The 8 loop configurations were: square (SQ) knot; surgeon’s (SU) knot; granny (GR) knot; and the sliding half-hitch (SHH) knot, with a standard number of throws (4 for monofilament or 3 for multifilament) and another series was tied with a standard number of throws plus 1 (5 for monofilament or 4 for multifilament). For all configurations, the supplemental throws made over the initial throw consisted of square knots. The number of throws for monofilament (4) versus multifilament suture (3) was based on recommendations published earlier (11). For each configuration, 12 samples were tied (based on a pilot study). All knots were tied in an alternate sequential order according to the type of knot; square, surgeon’s, granny, sliding half-hitch: square +1, surgeon’s +1, granny +1, sliding half-hitch +1. The work was divided into 4 sessions to prevent surgeon fatigue and creating a potential bias. A total of 432 samples was obtained.

Mechanical testing

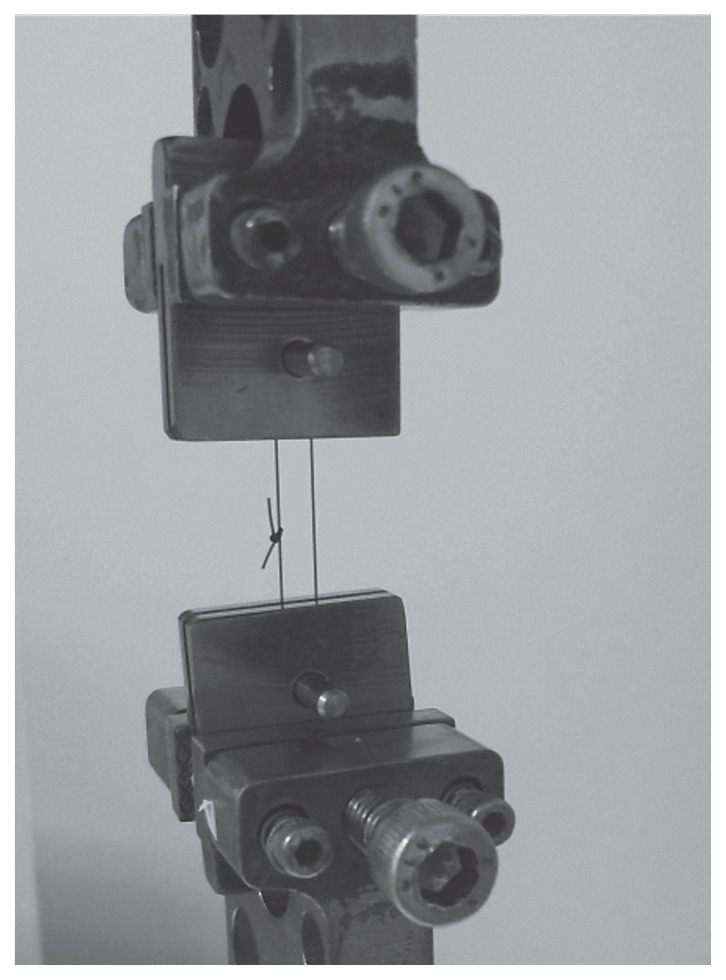

All samples were tested using a materials-testing machine (Electro Force 3200; Bose, Eden Prairie, Minnesota, USA). All samples were tested in the following sequential order for each type of suture: polydioxanone, polyglecaprone 25, coated polyglactin 910, and nylon. When placed in the materials-testing machine, each loop of tied suture was wrapped around 2 rods that were able to rotate, thus reducing constraints due to friction (Figure 1). The linear sutures were placed between 2 clamps using a previously described method (12).

Figure 1.

Testing jig of the materials-testing system with a knotted loop of suture positioned between the rods.

Samples were subjected to an initial tension of 5 Newtons (N) for 3 min and an elongation rate of 5 mm per min (to avoid the influence of the strain rate on the behavior of the suture material) until failure occurred. Tensile force and elongation were recorded continuously with dedicated software (WinTest 4.0; Bose). The following parameters were analyzed: (a) tensile force (N) measured at the failure of the loop; (b) elongation of the loop (mm) measured at the failure of the loop; and (c) mode of failure, defined as failure at the knot, failure of the suture excluding the knot, and slippage of the knot.

The mode of failure was determined by analyzing the “load-displacement” curves and visually inspecting the knotted loops. Video recordings were made to document all trials and were reviewed when needed to validate the mode of failure. For data analysis, failure forces and elongations at failure were considered for all the samples. Samples were excluded from the force data analysis only if the displacement limit of the testing machine was reached, but no failure occurred or if knot slippage resulted in the loop opening during testing (Table I). For elongation, however, loops that did not rupture at the end of the displacement were considered for statistical analyses. For the mode of failure, all samples were considered for descriptive analyses.

Table 1.

Results of mechanical sample testing for tensile force and elongation at failure

| Tensile force at failure (N) | Elongation at failure (mm) | ||||||

|---|---|---|---|---|---|---|---|

|

|

|

||||||

| Suture material | Knot configuration | n | Throws | Mean | SD | Mean | SD |

| Polydioxanone | Square knot | 12 | 4 | 58.21 | 1.60 | 11.18 | 0.64 |

| Surgeon’s knot | 12 | 4 | 54.37 | 5.07 | 10.61 | 0.96 | |

| Granny knot | 12 | 4 | 43.81★ | 8.06 | 8.91 | 1.13 | |

| Sliding half-hitch knot | 11* | 4 | 44.53 | 4.99 | 8.48★ | 1.80 | |

| Square knot | 8* | 5 | 60.28★ | 3.85 | 11.71 | 0.47 | |

| Surgeon’s knot | 10** | 5 | 54.11 | 2.84 | 10.58 | 0.88 | |

| Granny knot | 12 | 5 | 49.67★ | 3.55 | 9.28 | 0.94 | |

| Sliding half-hitch knot | 12 | 5 | 44.59★ | 6.94 | 8.38★ | 1.56 | |

| Linear suture (without knot) | 12 | N/A | 55.14 | 1.62 | 10.30 | 0.58 | |

| Polyglecaprone 25 | Square knot | 11** | 4 | 63.46★ | 3.64 | 10.69 | 0.4 |

| Surgeon’s knot | 12 | 4 | 57.65★ | 8.25 | 10.39 | 0.88 | |

| Granny knot | 12 | 4 | 55.19★ | 6.10 | 9.97 | 0.52 | |

| Sliding half-hitch knot | 12 | 4 | 52.18★ | 3.52 | 9.46 | 0.35 | |

| Square knot | 12 | 5 | 62.24★ | 6.46 | 10.78 | 0.82 | |

| Surgeon’s knot | 11* | 5 | 58.34★ | 5.45 | 10.82 | 0.58 | |

| Granny knot | 12 | 5 | 53.24★ | 7.72 | 9.59 | 0.79 | |

| Sliding half-hitch knot | 12 | 5 | 54.06★ | 4.68 | 9.77 | 0.66 | |

| Linear suture (without knot) | 12 | N/A | 74.27 | 6.71 | 10.92 | 1.10 | |

| Polyglactin 910 | Square knot | 10* | 3 | 34.38★ | 13.3 | 9.91★ | 1.66 |

| Surgeon’s knot | 12 | 3 | 41.05★ | 4.72 | 7.46 | 1.89 | |

| Granny knot | 12 | 3 | 21.72★ | 9.07 | 9.86★ | 1.68 | |

| Sliding half-hitch knot | 12 | 3 | 22.26★ | 11.7 | 9.20★ | 2.17 | |

| Square knot | 12 | 4 | 41.56★ | 7.79 | 6.98 | 1.01 | |

| Surgeon’s knot | 12 | 4 | 39.92★ | 10.8 | 6.62 | 1.37 | |

| Granny knot | 12 | 4 | 28.63★ | 11.3 | 9.47★ | 2.38 | |

| Sliding half-hitch knot | 12 | 4 | 33.99★ | 10.2 | 9.02★ | 2.54 | |

| Linear suture (without knot)) | 12 | N/A | 66.47 | 5.51 | 5.89 | 1.95 | |

| Nylon | Square knot | 12 | 4 | 40.41 | 2.16 | 9.86 | 0.32 |

| Surgeon’s knot | 12 | 4 | 37.84 | 3.76 | 9.46 | 1.20 | |

| Granny knot | 11* | 4 | 35.08 | 8.50 | 8.78 | 2.29 | |

| Sliding half-hitch knot | 10* | 4 | 34.38 | 4.68 | 8.42 | 1.43 | |

| Square knot | 12 | 5 | 40.07 | 3.12 | 9.68 | 1.08 | |

| Surgeon’s knot | 12 | 5 | 34.01 | 4.92 | 8.30 | 1.31 | |

| Granny knot | 9* | 5 | 37.24★ | 3.02 | 9.41 | 2.04 | |

| Sliding half-hitch knot | 12 | 5 | 35.71 | 2.46 | 7.83 | 0.60 | |

| Linear suture (without knot) | 12 | N/A | 40.74 | 2.68 | 9.00 | 1.57 | |

Machine displacement limit was reached.

Erroneous data acquisition.

Significant result (P < 0.05).

N/A — Not applicable.

Statistical analyses

A linear model was used to compare the tensile force and elongation. Given the large number of comparisons, the alpha level was adjusted to declare a significant difference to be more conservative. The sequential Bonferroni method was used to make this adjustment. A descriptive analysis was used for the failure mode. In each dataset, P < 0.05 was considered statistically significant. SAS version 9.3 software (SAS Institute, Cary, North Carolina, USA) was used to conduct the statistical analysis. A posteriori statistical analyses using logistic regression were used, with the occurrence of slippage as the dependent variable and the type of knot and number of throws as independent variables. For each type of knot, an exact Chi-square test was carried out to determine whether suture type was associated with the prevalence of slippage. This was followed by pairwise comparisons among suture types.

Results

A total of 432 samples were submitted for evaluation in the materials-testing machine. Seventeen specimens were excluded from data analysis of tensile force, 14 because the machine displacement limit was reached, but no failure occurred and 3 because of an erroneous data acquisition. The results of mechanical testing of the samples for tensile force and elongation are summarized in Table I.

Tensile force at failure

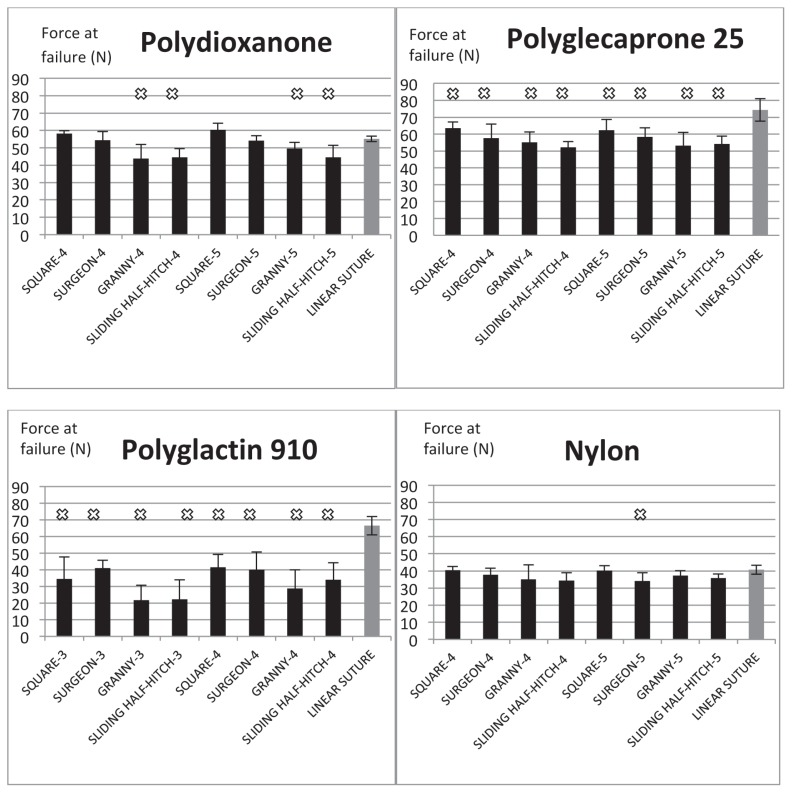

Influence of knot versus linear suture on force at failure —

As shown in Figure 2, for polydioxanone, the presence of a knot significantly decreased the tensile force at failure of the loops for granny and sliding half-hitch knots, but not for square and surgeon’s knots. For polyglecaprone 25 and coated polyglactin 910, all knots significantly decreased the force at failure of the loops and for nylon, only the surgeon’s knot with an additional throw significantly decreased the force at failure of the loops.

Figure 2.

Effect of 8 loop configurations on the tensile force Newton (N) at failure of 4 suture materials. All loop configurations are compared to linear suture for each type of suture material. Significant values are indicated by symbol:

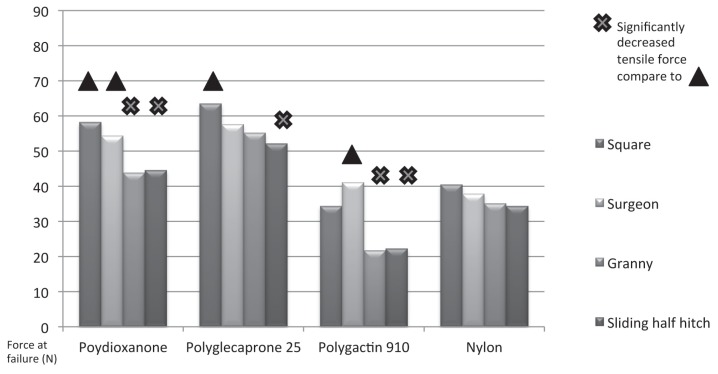

Influence of types of knots on force at failure —

As shown in Figure 3, for polydioxanone, the presence of a granny knot and a sliding half-hitch significantly decreased tensile force at failure of loops compared to square or surgeon’s knots. For polyglecaprone 25, the presence of a sliding half-hitch significantly decreased tensile force at failure compared to a square knot. For coated polyglactin 910, the presence of a granny knot or a sliding half-hitch significantly decreased tensile force at failure compared to a surgeon’s knot and for the nylon, there was no significant difference among the 4 types of knots.

Figure 3.

Effect of 4 loop configurations on the tensile force (N) at failure of 4 suture materials. Each knot configuration is compared to the other 3 configurations for each type of suture material. The number of throws is 4 for polydioxanone, polyglecaprone 25, and nylon and 3 for coated polyglactin 910.

Addition of supplemental throw —

There was no statistically significant difference in the tensile force at failure of suture loops associated with the addition of a supplemental throw for each type of the 4 suture materials.

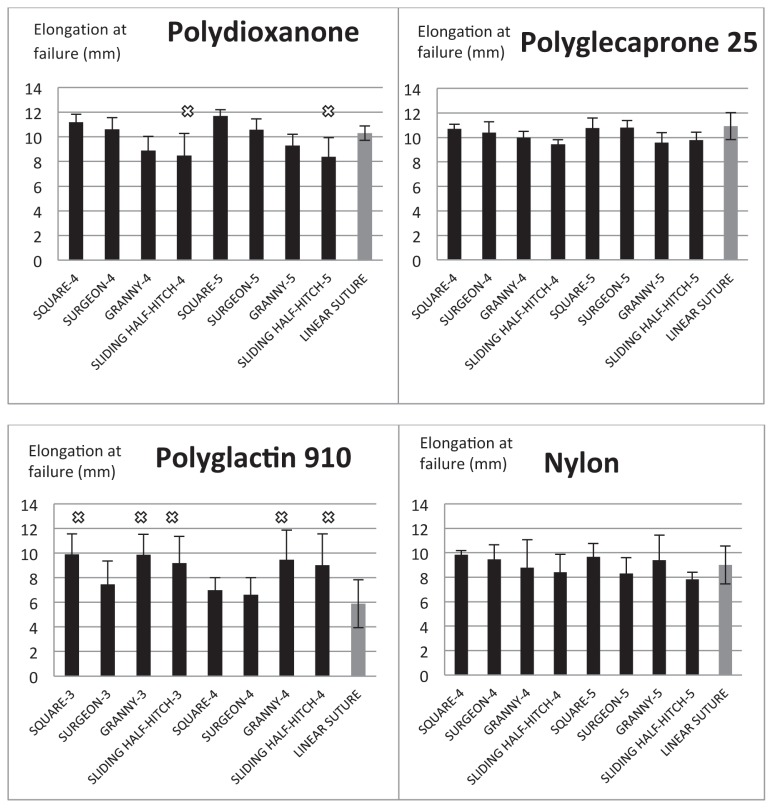

Elongation at failure

Influence of knot versus linear suture on elongation at failure —

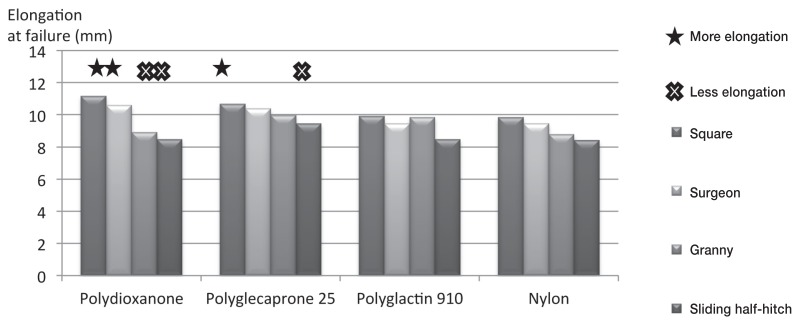

As shown in Figure 4, for polydioxanone, the presence of a sliding half-hitch significantly decreased the elongation of the loops at failure, which means the loop breaks earlier. For polyglecaprone 25 and nylon, there was no significant difference in loop elongation at failure. For coated polyglactin 910, significant loop elongation was observed with the presence of a square knot with 3 throws and with the granny and the sliding half-hitch knots.

Figure 4.

Effect of 8 loop configurations on the elongation (mm) at failure of 4 suture materials. All knot configurations are compared to linear suture for each type of suture material. Significant values are indicated by symbol:

Influence of types of knots on elongation at failure —

As shown in Figure 5, for polydioxanone, the presence of a granny and a sliding half-hitch knot significantly decreased elongation at failure of loops compared to square or surgeon’s knots. For polyglecaprone 25, the presence of a sliding half-hitch significantly decreased elongation at failure compared to a square knot. For coated polyglactin 910 and nylon, the presence of the knot did not significantly influence the elongation at failure of the loop.

Figure 5.

Effect of 4 loop configurations on the elongation (mm) at failure of 4 suture materials. All knot configurations are compared to each other for each type of suture material. The number of throws is 4 for polydioxanone, polyglecaprone 25, and nylon and 3 for coated polyglactin 910.

Addition of a supplemental throw —

There was no statistically significant difference in the loop elongation associated with the addition of a supplemental throw for each type of suture material.

Mode of failure

Polydioxanone —

Of the 96 samples, 2 were discarded due to erroneous data acquisition. Of the 94 samples, 89 (94, 6%) broke at the knot and 5 did not break (reached displacement limit).

Polyglecaprone 25 —

Of the 96 samples, 1 was discarded due to erroneous data acquisition. Of the 95 samples 92 (96, 8%) broke at the knot, 2 broke outside the knot, none slipped, and 1 did not break (reached displacement limit).

Coated polyglactin 910 —

Of the 96 samples, 48 (50%) broke at the knot, 45 (46, 8%) slipped, 1 broke outside the knot, and 2 did not break (reached displacement limit). Our a posteriori analyses showed that the prevalence of slippage is significantly increased when using coated polyglactin 910 compared to the other types of suture material. Furthermore, the type of knot (granny and sliding half-hitch) significantly increased slippage, but the number of throws did not.

Nylon —

Of 96 samples, 89 (92, 7%) broke at the knot, 1 broke outside the knot, none slipped, and 6 did not break (reached displacement limit).

Discussion

Suture failure can lead to both minor complications (delayed healing, inappropriate scarring, or superficial infection) and major complications (wound separation, wound dehiscence, or deep infection) that subsequently lead to catastrophic events, such as intestinal leakage, evisceration, and peritonitis (1–4,7). It is therefore important to objectively select the type of suture material used based on its intrinsic properties (strength, elongation, and failure mode) and the safety of the knot used. Moreover, depending on the type of suture material used, each type of knot will influence the tensile force and elongation at failure.

Our first hypothesis was that all types of knots would significantly influence the force and elongation at failure of each of the linear sutures. Our hypothesis with regard to the tensile force (Figure 2) was partially correct for polydioxanone, correct for polyglecaprone 25 and coated polyglactin 910, and incorrect for nylon, with the exception of the surgeon’s knot with 5 throws, which could be the result of a type-I error. Our hypothesis with regard to elongation (Figure 4) was partially correct for polydioxanone and coated polyglactin 910 and incorrect for polyglecaprone 25 and nylon.

Interestingly, in disagreement with several textbooks (13–15), we found that not all suture materials and knots affect the initial force at failure of linear suture materials and not to the same extent. For polydioxanone, polyglecaprone 25, coated polyglactin 910, and nylon, we documented a variation of the force at failure of the linear suture when using a knotted loop with a square knot of, respectively 5.6%, −14.6%, −48.3%, and −0.9%. When using a surgeon’s knot, the variations were: −1.4%, −22.4%, −38.2%, and −7.1%, respectively.

It has been reported that the knot is the weakest point in a suture line or a ligature, as tying a knot results in friction between 2 strands, which weakens the suture (13,15). Naleway et al (16) have shown that a single knot decreased the force at failure of nylon by 62%. It has also been previously reported that shear stresses at the point between the loop and the first throw of the loop weaken the suture material (4). In our study, we observed this behavior for polydioxanone when using a sliding half-hitch knot; loop elongation decreased significantly at failure due to premature breakage of the loop compared to the linear suture. Furthermore, when comparing the knotted loops, the use of a granny knot or sliding half-hitch knot significantly decreased loop elongation at failure compared to the square or surgeon’s knots. This finding is also associated with premature breakage of the loops.

Our second hypothesis was that all types of knots would significantly influence the force and elongation at which the knotted loop breaks, but not their mode of failure. Our hypothesis with regard to tensile force (Figure 3) was correct for polydioxanone, partially correct for polyglecaprone 25 and coated polyglactin 910, and incorrect for nylon. Our hypothesis with regard to elongation (Figure 5) was correct for polydioxanone, partially correct for polyglecaprone 25, and incorrect for coated polyglactin 910 and nylon. Furthermore, our a posteriori statistical analyses have shown that, for all knots, the use of coated polyglactin 910 significantly increased slippage versus breakage compared to polyglecaprone 25, polydioxanone, and nylon.

Regarding elongation in our study, each loop measured 2 cm in diameter, which corresponds to 62.8 mm. As the maximal elongation observed in our study was 12 mm, this correlates to 19% of elongation. In the healing process, this value is within physiological tolerance to deformation (100% for granulation tissue) (14). We propose that elongation of suture loops as evaluated in our study has no clinical relevance.

The square knot and the surgeon’s knot are the most common knots used in surgical procedures (8). It is not uncommon for the novice surgeon to create granny knots than square knots (8,17,18). The impact of this technical error has been outlined in the present study (premature failure, influence on elongation at failure). A square knot can easily become a sliding half-hitch when tied by a novice or even an experienced surgeon. It has been reported that 80% of square knots can slip into a sliding half-hitch depending on the suture material, the configuration of the knot, and the surgeon’s tying skills (1,6,7,17,18).

Marturello et al (1) showed that the surgeon’s experience and training were significant factors affecting knot security. We emphasized that a modification in the knot due to suboptimal technique could significantly affect the tensile force of a suture. Furthermore, it is important to recognize the consequences of tying a granny or sliding half-hitch knot by mistake, as these knots significantly decreased the tensile force and elongation at failure of the knotted loops because of the premature failure. We also noted that adding a supplemental throw did not significantly change our results. Marturello et al (1) also reported that 3 throws were as secure as 6 throws and, although the tensile failure load was greater with 6 throws, there was no significant difference in knot security with more than 4 throws for each suture material tested. It has also been reported by Van Rijssel et al (19) that the size of the suture material is more important than the number of throws for knot security.

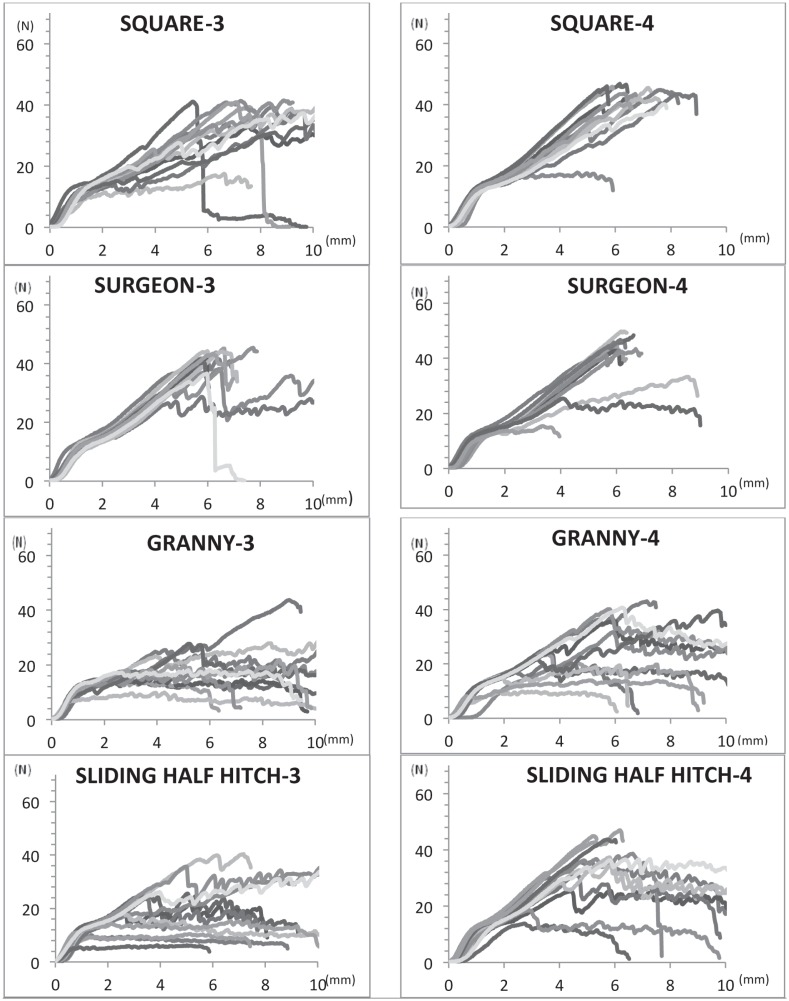

When selecting polyglactin 910 for our study, we considered it as a true multifilament because there was no mention on the packaging (box and suture envelopes) that it was coated. After analyzing our data, it was difficult to explain the results obtained. When looking closer at the monograph inside the box, we realized that polyglactin 910 was coated, even though this was not specified on the packaging. This may explain why this suture did not exhibit the behavior of a multifilament but behaved instead as a coated suture. Interestingly, as shown in Figure 6, the square knot with 4 throws and the surgeon’s knot exhibited the most constant behavior.

Figure 6.

Load-displacement curves of coated polyglactin 910. Each line represents a tested suture loop: 12 loops were evaluated per knot configuration. Tensile force (N) versus displacement (mm).

We have found that the mechanical properties of knotted loops using polyglactin 910 are similar to those reported in the literature (3,7,17,20,21). Polyglactin 910 seems to exhibit more slippage and its safety is uncertain, as the use of additional throws does not seem to be correlated with the safety of the knotted loop. In a study by Ching et al (8), when tensile strengths were evaluated for knots that failed by breakage and those that failed by slippage, the number of throws did not significantly affect the tensile strength of the polyglactin 910 (size 2-0) (8). Behm et al (20) reported that the failure rates for sizes 0 and 2-0 of polyglactin 910 were still fairly high (40%) even with 5 throws. As reported by Rodeheaver et al (21), when using polyglactin 910, knots were made secure by using 1 more throw than with coated polyglycolic acid sutures. Our findings are also consistent with the observations of Rosin et al (5) who evaluated the knot security of size 2-0 knotted sutures and observed that a surgeon’s knot was more secure than a square knot when using polyglactin 910. Finally, it has also been determined that, for size 0 polyglactin 910, knot security continued to improve until 5 throws were used (17).

Taking into account all the data evaluating the mechanical properties of 4 types of size 3-0 suture materials from this study, we can conclude that for polydioxanone, the use of a square or a surgeon’s knot did not decrease the tensile force at failure of the linear suture and the use of a granny or sliding half-hitch knot decreased the tensile force at failure and significantly reduced the elongation at failure of the knotted loop because of the premature failure. These 2 knots should therefore be avoided. For polyglecaprone 25, all the knots decreased the tensile force at failure of the linear suture and the sliding half-hitch knot was significantly less resistant than the other knots and should be avoided. For coated polyglactin 910, all knots decreased the tensile force at failure of the linear suture and this material was associated with a significantly high rate of slippage. Using a square knot with 3 throws with coated polyglactin 910 did not seem to result in a secure knot. For nylon, the tensile force and the elongation at failure were not influenced by the presence of a knot. Overall, however, nylon seemed to be the weakest suture material; the initial tensile force was 73.9%, 54.9%, and 61.3%, respectively, of the force at failure of linear suture with polydioxanone, polyglecaprone 25, and coated polyglactin 910.

This study had many limitations, including the difficulty of extrapolating the findings of an in-vitro experimental study to an in-vivo clinical situation. In addition, the knotted loops were not incubated in saline or plasma before mechanical testing, which might have mimicked a more physiological condition. Other suture materials, knot configurations, and numbers of throws could have been evaluated, thus evaluating fatigue, and cyclic loading was not tested. Further studies are warranted in order to evaluate the properties of knotted loops in more physiological conditions.

The observations made in this study indicate that, when using different types of size 3-0 suture material, the results from mechanical testing pertaining to tensile force, elongation, and mode of failure cannot be extrapolated among various types of sutures and knots.

Acknowledgments

The authors thank Le Fonds en santé des animaux de compagnie (FSAC) and Mike and Valeria Rosenbloom for financial support.

Footnotes

The authors declare that there are no financial or other conflicts of interest related to this study.

References

- 1.Marturello DM, McFadden MS, Bennett RA, Ragetly GR, Horn G. Knot security and tensile strength of suture materials. Vet Surg. 2014;43:73–79. doi: 10.1111/j.1532-950X.2013.12076.x. [DOI] [PubMed] [Google Scholar]

- 2.Good MM, Good LB, Mclntire DD, Brown SA, Wai CY. Surgical knot integrity: Effect of suture type and caliber, and level of residency training. J Surg Educ. 2013;70:156–160. doi: 10.1016/j.jsurg.2012.06.028. [DOI] [PubMed] [Google Scholar]

- 3.Muffly TM, Cook C, Distasio J, Bonham AJ, Blandon RE. Suture end length as a function of knot integrity. J Surg Educ. 2009;66:276–280. doi: 10.1016/j.jsurg.2009.10.003. [DOI] [PubMed] [Google Scholar]

- 4.Muffly TM, Boyce J, Kieweg SL, Bonham AJ. Tensile strength of a surgeon’s or a square knot. J Surg Educ. 2010;67:222–226. doi: 10.1016/j.jsurg.2010.06.007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Rosin E, Robinson G. Knot security of suture materials. Vet Surg. 1989;18:269–273. doi: 10.1111/j.1532-950x.1989.tb01083.x. [DOI] [PubMed] [Google Scholar]

- 6.Zhao C, Hsu CC, Moriya T, et al. Beyond the square knot: A novel knotting technique for surgical use. J Bone Joint Surg Am. 2013;95:1020–1027. doi: 10.2106/JBJS.K.01525. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Trimbos JB. Security of various knots commonly used in surgical practice. Obstet Gynecol. 1984;64:274–280. [PubMed] [Google Scholar]

- 8.Ching SS, Mok CW, Koh YX, Tan SM, Tan YK. Assessment of surgical trainees’ quality of knot-tying. J Surg Educ. 2013;70:48–54. doi: 10.1016/j.jsurg.2012.07.002. [DOI] [PubMed] [Google Scholar]

- 9.Muffly T, McCormick TC, Dean J, Bonham A, Hill RF. An evaluation of knot integrity when tied robotically and conventionally. Am J Obstet Gynecol. 2009;200:e18–20. doi: 10.1016/j.ajog.2008.08.058. [DOI] [PubMed] [Google Scholar]

- 10.Davis DA, Pellowski DM, Rawdon EJ. All monofilament knots assume sliding conformation in vivo. Dermatol Surg. 2013;39:729–733. doi: 10.1111/dsu.12112. [DOI] [PubMed] [Google Scholar]

- 11.Aanning HL, Hass T, Jorgensen DR, Wulf CA. Square not a running knot. J Am Coll S Surg. 2007;204:422–425. doi: 10.1016/j.jamcollsurg.2006.12.024. [DOI] [PubMed] [Google Scholar]

- 12.Tensile Testing of Coir Fibres and Yarns. Instron (homepage on the Internet) [Last accessed January 3, 2016]. Available from: http://www.instron.us/en-us/testing-solutions.

- 13.Fossum TW. Biomaterials, suturing and hemostasis. In: Fossum TW, editor. Small Animal Surgery. 3rd ed. St. Louis, Missouri: Mosby; 2007. pp. 57–78. [Google Scholar]

- 14.Hulse D, Hyman B. Fracture biology and biomechanics. In: Slatter D, editor. Textbook of Small Animal Surgery. 3rd ed. Vol. 2. Philadelphia, Pennsylvania: Saunders; 2003. pp. 1785–1792. [Google Scholar]

- 15.Tobias K, Johnston S. Veterinary Surgery: Small Animal. 1st ed. Vol. 1. St. Louis, Missouri: Elsevier; 2012. Instrument and tissue handling techniques; p. 211. [Google Scholar]

- 16.Naleway SE, Lear W, Kruzic JJ, Maughan C. Mechanical properties of suture materials in general and cutaneous surgery. J Biomed Mater Res B Appl Biomater. 2015;103:735–742. doi: 10.1002/jbm.b.33171. [DOI] [PubMed] [Google Scholar]

- 17.Muffly TM, Kow N, Iqbal I, Barber MD. Minimum number of throws needed for knot security. J Surg Educ. 2011;68:130–133. doi: 10.1016/j.jsurg.2010.11.001. [DOI] [PubMed] [Google Scholar]

- 18.Alzacko SM, Majid OW. “Security loop” tie: A new technique to overcome loosening of surgical knots”. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2007;104:1–4. doi: 10.1016/j.tripleo.2007.06.012. [DOI] [PubMed] [Google Scholar]

- 19.Van Rijssel EJC, Trimbos JB, Booster MH. Mechanical performance of square knots and sliding knots in surgery: A comparative study. Am J Obstet Gynecol. 1990;162:93–96. doi: 10.1016/0002-9378(90)90828-u. [DOI] [PubMed] [Google Scholar]

- 20.Behm T, Unger JB, Ivy JJ, Mukherjee D. Flat square knots: Are 3 throws enough? Am J Obstet Gynecol. 2007;197:172.e1–3. doi: 10.1016/j.ajog.2007.03.084. [DOI] [PubMed] [Google Scholar]

- 21.Rodeheaver GT, Thacker JG, Owen J, Strauss M, Masteron T, Edlich RF. Knotting and handling characteristics of coated synthetic absorbable sutures. J Surg Res. 1983;35:525–530. doi: 10.1016/0022-4804(83)90043-4. [DOI] [PubMed] [Google Scholar]