Abstract

Gluten-free muffins are generally made from purified flours and starches (from non-gluten sources) which are deficient in dietary fibre and have poor quality attributes. In this regard, the present work was undertaken to explore application of black carrot pomace dietary fibre concentrate (BCF) and xanthan gum (XG) in gluten-free rice muffins. Physicochemical properties of BCF and rice flour were studied. BCF was incorporated at three levels (3, 6 and 9 %) in rice flour, while XG was added at 0.5 % level to study their effect on muffin batters and physicochemical properties of muffins. BCF showed higher water absorption and oil absorption capacities than rice flour. Incorporation of BCF and XG increased flour paste viscosities and batter viscoelasticity. Incorporation of BCF increased total dietary fibre content (TDF) and decreased the L* and b* values, water activity (aw), specific volume and firmness. On the other hand, XG improved appearance and specific volume of the rice muffins prepared with and without BCF. Muffins prepared with 6 % BCF incorporation and XG were the most acceptable. This study demonstrated that BCF and XG can be used as viable functional ingredients in the preparation of gluten-free muffins.

Keywords: Dietary fibre, Gluten-free muffins, Pasting, Rheology, Texture, Black carrot, Xanthan gum

Introduction

The demand for gluten-free (GF) products (containing less than 20 ppm of gluten protein) is increasing as about one percent of the world population is suffering from gluten intolerance (Rai et al. 2014; Shevkani et al. 2015). The only known treatment is strict lifelong avoidance of products containing gluten. Most of the GF foods are generally made from purified starches or flours which are deficient in dietary fibre (DF). DF has been known to improve and maintain human health (mainly blood glucose attenuation and laxation). In the past, dietary fibres from cereal sources were used in bakery products, but nowadays novel and economic sources of fibres such as by-products from juice industry are gaining attention among health conscious consumers (Ayala-Zavala et al. 2011). DF concentrates from fruits have better nutritional quality than those found in cereals due the presence of high amounts of bioactive compounds and more balanced compositions (Nanditha and Prabhasankar 2008). GF products having DF incorporated have to meet quality requirements which include texture-taste, convenience, nutritionally added value, easy handling during processing, safety and palatability (Ronda et al. 2015). Rice is one of the suitable cereals for developing GF products as it is colourless, has low level of prolamine and is hypoallergenic (Sakac et al. 2011). However, the absence of gluten protein in rice leads to the failure in the entrapment of carbon dioxide, reducing the quality of the finished product (Sae-Eaw et al. 2007). Therefore, incorporation of hydrocolloids such as gums, proteins and fibres has been suggested to improve the quality characteristics of GF products. Xanthan gum (XG) is a polysaccharide which is secreted by Xanthomonas campestris and is used commonly as a thickening agent in food items. XG has been reported to improve the quality of GF cakes/muffins by increasing the viscosity of batters owing to its high water binding capacity which increases the values of batter moduli (Gomez et al. 2007; Preichardt et al. 2011; Singh et al. 2015).

Muffins are widely consumed sweet, spongy breakfast or evening snack foods prepared traditionally from wheat flour, sugar, oil/fat, milk and eggs. However, wheat-free muffins are of interest in the present times not only for people who are gluten intolerant, but also for people interested in GF foods (Nachay 2010). Moreover, eggless muffins can be consumed by lacto-vegetarians, especially in India where a significant proportion of the population is vegetarian (Singh et al. 2015). Black carrots (Daucus carota L. ssp. Sativus var. atrorubens Alef.) are anthocyanin rich (17.4 to 45.4 g/kg dry matter) attractive black/purple coloured vegetables mostly grown in Turkey, Egypt and India (Türkyılmaz et al. 2012). Although black carrots are much richer in antioxidants than commonly available orange carrot varieties, yet in India these have not been potentially utilized (only used in making a fermented beverage “Kanji” in rural areas). Black carrot juice is being used as natural food colourant due to high heat, light and pH stability (Suzme et al. 2014). However, its pomace (the by-product produced after juice extraction) has been underutilized despite having distinct advantages such as being easily incorporated into food products without the introduction of negative flavour or functional issues, while still retaining most of its bioactive components such as DF (Chantaro et al. 2008). Black carrot fibre (BCF) is a potential source of natural and functional food ingredients (related to health-promotion or disease prevention) for enriching eggless GF muffins. Dietary fibre enrichment and the addition of gums such as XG not only influences the overall quality of food by changing its physiological properties, but also significantly affects the sensorial properties of the products such as muffins (Kethireddipalli et al. 2002; Gomez et al. 2007). When gums and plant fibres are added to a food product, these contribute to water holding properties and viscosity of the product (Kethireddipalli et al. 2002). There have been no previous findings reporting the use of BCF in the preparation of GF muffins. Therefore, the objective of this work was to develop eggless GF muffins from rice flour containing various levels of BCF (3, 6 and 9 %) using XG. The combined effect of incorporation of BCF and XG on the pasting, batter rheological and muffin making properties of rice flour was also evaluated.

Materials and methods

Raw materials

Fresh black carrots were procured from Nijjer Agro Foods Ltd. (Jandiala, Amritsar, India). Rice flour (Kulwant nutrition, Batala, India), milk powder (EveryDay, Nestle India Ltd., Moga, India) containing carbohydrates (50.3 %), proteins (17.4 %) and fats (18.1 %) as major constituents, ground sugar (Mawana Sugars Ltd., New Delhi, India), soya protein isolates (Archer Daniels Midland Company, Chicago, USA) having 90 % protein content, salt (Tata chemicals, Mumbai, India), baking powder (Ajanta Food products, New Delhi, India), refined sunflower oil (Bunge India Pvt. Ltd., Patiala, India), glycerol monostearate (Loba chemicals, Mumbai, India), deionized water and XG (Titan Chemicals, Bhiwadi, India) were used in the preparation of muffins. Analytical grade hexane was purchased from Sisco research laboratories Ltd. (India). Total dietary fibre assay kit (K-TDFR) was purchased from Megazyme International (Wicklow, Ireland).

Preparation of black carrot dietary fibre concentrate

BCF was prepared using the methodology of Figuerola et al. (2005) with slight modifications. Briefly, black carrots were washed, peeled and juice was extracted using a commercial juicer (JX5 juicer mixer grinder, Bajaj Electricals, Mumbai, India). The obtained pomace was washed thrice with water at room temperature to remove free sugar and ash contents. It was then dried at 60 °C in cabinet drier for 2 h. The dried residue was afterwards ground and sifted through a 250 μm sieve to obtain BCF.

Composition of rice flour, BCF and their functional properties

Moisture, protein, fat and ash content of the raw materials (rice flour and BCF) was done according to AOAC (2000). Packed bulk density (BD) of rice flour and BCF was determined by filling these in 10 mL capacity tarred measuring cylinders and tapping them gently until there was no further reduction in the volume. Filled cylinders were reweighed and BD was expressed in g/mL. For water absorption capacity (WAC), 100 mg of raw material was mixed with 1 mL of deionized water. These dispersions were vortex-mixed for 1 min and centrifuged at 1800 g for 20 min. After centrifugation, the tubes were drained at 45° for 10 min and reweighed. For fat absorption capacity (FAC), 100 mg of raw material was vortex-mixed with 1 mL of sunflower oil. The mixtures were, then, incubated at room temperature for 30 min followed by centrifugation at 13,600 g for 10 min. The oil layer was decanted and the tubes were drained at 45° for 20 min. WAC and FAC were expressed as grams of water and oil, respectively absorbed per gram of raw material.

Pasting properties of rice flour and rice flour-BCF blends

Pasting properties of rice flour and rice flour-BCF blends (3 %, 6 % and 9 % BCF; with/without 0.5 g XG) were determined using a rheometer (MCR-102, Anton Paar, Austria) equipped with a starch cell (C-ETD 160) and a stirrer probe (ST 24-2D/2 V/2 V-30). A programmed heating and cooling cycle was set for 13 min, wherein sample suspensions (10 % dw) were held at 50 °C for 1 min, heated from 50 to 95 °C at a rate of 12.16 °C/min, held at 95 °C for 2.5 min, cooled from 95 to 50 °C at a rate of 11.84 °C/min, and held at 50 °C for 2 min (Kaur et al. 2015). The parameters recorded were pasting temperature (PT), peak viscosity (PV), breakdown viscosity (BV) and final viscosity (FV).

Batter and muffin preparation

Muffins were prepared following the method described earlier by Singh et al. (2015) with slight modifications. The recipe for rice based gluten-free muffin is given in Table 1. In order to investigate the effect of BCF and XG on the muffin making properties, rice flour was incorporated with BCF at replacement levels of 3, 6 and 9 % with/without 0.5 g XG. Rice flour, baking powder, ground sugar, salt and BCF were mixed for 1 min using a pin mixer (National Manufacturing Company, Lincoln, NE, USA). Then, oil, protein emulsion, milk powder and water were slowly poured and mixed for another 5 min to prepare muffin batter. Two batches of muffin batter were made, one having no gum added and the other having 0.5 g XG. This batter (35 g) was poured in muffin cups and baked for 22 min in a preheated oven set at 170 °C, which had rotating racks for equal heat distribution (National Manufacturing Company, Lincoln, NE, USA). Muffins were allowed to cool for 1 h after being removed from the oven and then were sealed in PET jars (stored at room temperature). The muffins were prepared in triplicate for each formulation.

Table 1.

Formulation of flour (0 % BCF) and BCF incorporated rice muffins with/without XG

| Muffin | Rice Flour (g) | Sugar (g) | Baking powder (g) | Salt (g) | Oil (g) | *Protein emulsion (g) | Milk powder (g) | BCF (g) | XG (g) | Water (g) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 % BCF | 100 | 65 | 5 | 1 | 40 | 45 | 15 | 0 | 0 | 85 |

| 0 % BCF + XG | 100 | 65 | 5 | 1 | 40 | 45 | 15 | 0 | 0.5 | 85 |

| 3 % BCF | 97 | 65 | 5 | 1 | 40 | 45 | 15 | 3 | 0 | 85 |

| 3 % BCF + XG | 97 | 65 | 5 | 1 | 40 | 45 | 15 | 3 | 0.5 | 85 |

| 6 % BCF | 94 | 65 | 5 | 1 | 40 | 45 | 15 | 6 | 0 | 85 |

| 6 % BCF + XG | 94 | 65 | 5 | 1 | 40 | 45 | 15 | 6 | 0.5 | 85 |

| 9 % BCF | 91 | 65 | 5 | 1 | 40 | 45 | 15 | 9 | 0 | 85 |

| 9 % BCF + XG | 91 | 65 | 5 | 1 | 40 | 45 | 15 | 9 | 0.5 | 85 |

BCF, Black carrot fibre; XG, Xanthan gum

*Protein emulsion consisted of 0.5 g glycerol monostearate and 12 g soy protein isolate mixed in 88 g deionized water

Rheology of muffin batters

Rheological properties of muffin batters were determined at 25 °C using a rheometer (MCR-102, Anton Paar, Austria) equipped with parallel plate geometry (40 mm measuring probe, PP40). Gap between the plates, stress and frequency were set at 1 mm, 0.1 Pa and 1 rad/s, respectively. These values were within the linear viscoelastic range (LVR). Storage modulus (G′) and loss modulus (G″) of the batters were recorded. Batters were allowed to equilibrate between the plates for 5 min before measurements (Shevkani et al. 2015).

Muffin characteristics

Characteristics of muffins (colour of crust as well as crumb, water activity, height, volume and texture) were determined 24 h after baking (Matos et al. 2014). Colour parameters (L*, a* and b*) of muffin crust and crumb were recorded using Ultra Scan VIS Hunter Lab (Hunter Associates Laboratory Inc., Reston, VA, USA) where L* indicated lightness/darkness (L* = 0 [black], L* = 100 [white]), a* indicated hue on a green (−a*) to red (+a*) axis, and b* indicated hue on a blue (−b*) to yellow (+b*) axis. Height of the muffins was measured using a digital calliper from the bottom to the highest point. Muffin volume was determined by Millet-seed displacement method and was expressed as specific volume (mL/g). Water activity was determined using the crumb taken from the centre of the muffin (Aqua Lab; Decagon Devices, Pullman, WA, USA). Texture profile analysis of the crumb was performed on cubes (12.5 mm3) taken from the centre of each muffin using texture analyzer (TA/TX2-plus; Stable Micro systems, Surrey, UK) equipped with a 5 kg load cell. The crumb cubes were placed at the centre of a heavy duty platform (HD P/90) and subjected to a compression (50 %) using 75 mm diameter flat aluminium probe (P/75) at a test speed of 1 mm/s (Shevkani and Singh 2014). Textural characteristics i.e. firmness, cohesiveness, springiness and gumminess were calculated from the force-time curves following the methodology of Bourne (1978).

Total dietary fibre of muffins

Muffins were defatted with hexane, dried, ground using a blender and passed through a 60 mesh sieve (250 μm) for subsequent analysis of total dietary fibre content (TDF). Soluble, insoluble and TDF of muffins was determined and reported as g/100 g dry weight (dw) of the sample, using total dietary fibre assay kit following AOAC method 985.29 (2000).

Sensory analysis of muffins

Sensory analysis of the muffins was done according to the methodology of Lu et al. (2010) with slight modifications. Forty untrained panelists including students, faculty and staff members from Department of Food science and Technology (Guru Nanak Dev University, Amritsar) were selected for sensory analysis. They evaluated randomly presented muffins identified with random three-digit numbers for colour, appearance, texture, taste and overall acceptability using a 9-point hedonic scale. Samples were served at room temperature (25 °C). Panelists evaluated the samples in a testing area and were instructed to rinse their mouths with water between samples to minimise any residual effect.

Statistical analysis

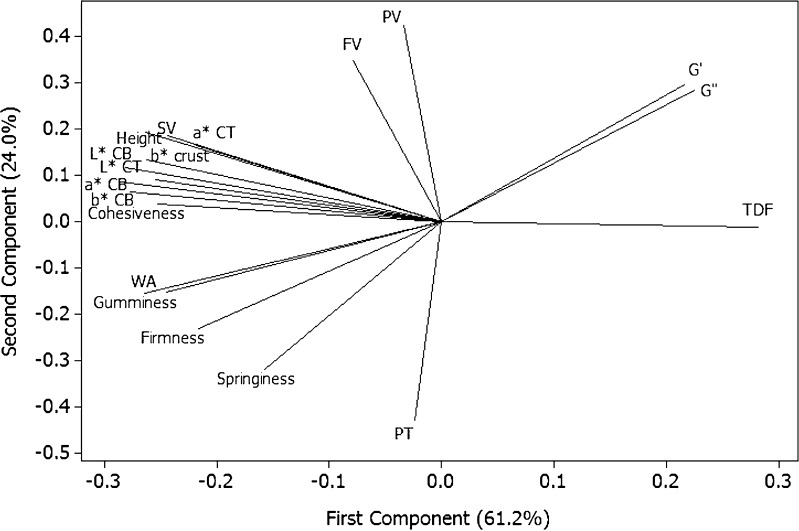

The data reported is average of triplicate observations. It was subjected to analysis of variance (ANOVA) using Minitab Statistical Software (State College, PA, USA) and Duncan’s test (P < 0.05) was used to determine significance of differences between the means. Principal component analysis (PCA) was also done using Minitab Statistical Software. PCA loading plot (Fig. 1) was used to determine the relationships between the assays performed.

Fig. 1.

PCA loading plot showing relations between various tests performed of BCF incorporated rice muffins with/without XG (PV peak viscosity, FV final viscosity, PT peak temperature, CT crust, CB crumb, SV specific volume, TDF total dietary fibre, WA water activity; G′ storage modulus; G″ loss modulus)

Results and discussions

Composition of rice flour and their functional properties

Rice flour showed total carbohydrate, moisture, protein, fat and ash content of 81.77, 10.95, 6.73, 0.34 and 0.21 g per 100 g dw, respectively, while 77.56, 9.95, 5.46, 0.12 and 6.91 g per 100 g dw, respectively were observed for BCF. Rice flour had a BD of 0.95 g/mL, while it was 1.21 g/mL for BCF. BD gives an indication of the relative volume of packaging material required, with flours having a low BD can be easily transported to different locations (Shevkani et al. 2015). WAC was 1.53 g/g for rice flour, while it was 9.89 g/g for BCF. On the other hand, FAC was 0.64 g/g for rice flour and 1.62 g/g for BCF. Chau et al. (2007) reported WAC and FAC of 12.5 g/g and 1.92 g/g, respectively for carrot insoluble fibre. Hydration properties of dietary fibres are related to factors such as temperature, pH, porosity and particle size of the components. Moreover, the source of dietary fibre plays an important role in the determining the ability of the dietary fibres to hold water, such as fruit juice by-products have more affinity for water and oil than cereal derivatives. A substrate having high WAC can be used to modify the viscosity and texture of formulated products, while a high FAC allows stabilisation of high fat food products and emulsions (Grigelmo-Miguel et al. 1999).

Pasting properties

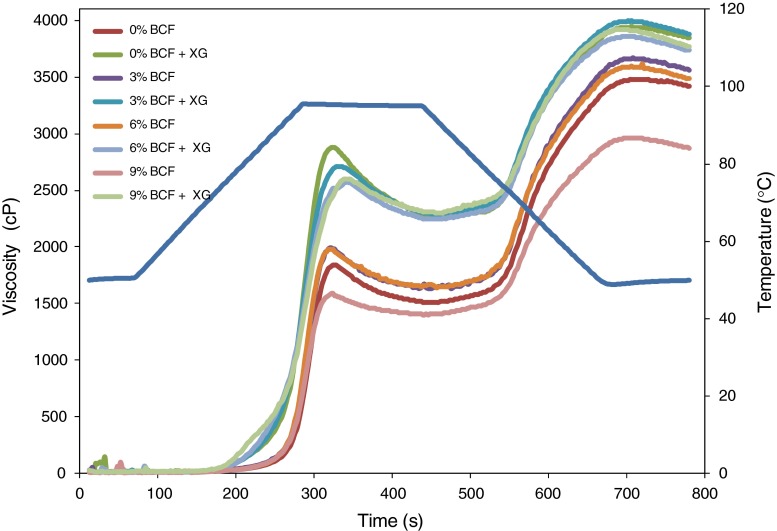

Pasting properties of flours provide information about the changes in behaviour of flour paste viscosity with change in temperature which varies mainly with flour composition and characteristics of starches and proteins (Shevkani et al. 2015). During heating, starch granules absorb water and swell as a result of gelatinization leading to an increase in viscosity, which is followed by a decrease in the viscosity due to breakdown of starch granules at high temperatures. During cooling, the viscosity increases due to the association of flour components. The viscosity of rice flour and rice flour-BCF-XG suspensions increased due to absorption of water and gelatinization of starch granules (Fig. 2). The temperature at which viscosity begins to rise was termed as PT. PT varied between 79.7 ± 0.6 °C (9 % BCF + XG) and 88.9 ± 0.8 °C (3 % BCF). PV represents primarily the point of maximum starch granular swelling. The lowest PV was observed for rice flour (1840 ± 75 cP), while it increased with increase in level of BCF and addition of XG. The highest value of PV was observed for blends having 9 % BCF plus XG (2600 ± 49 cP). BV, a measure of the resistance of gel to disintegrate with shearing at high temperatures and was the highest for rice flour containing XG (610 ± 31 cP), whereas it was the lowest for flour having 9 % BCF without XG (190 ± 20 cP). This may be due to the increased capacity of starch granules to swell during heating and more breakdown during holding at 95 °C in the presence of XG, possibly by reducing the leaching out of amylose (Hong et al. 2015). Contrarily, in the presence of BCF (at 9 % level) more amylose may have leached during heating restricting the swelling and breakdown in the viscosity. Viscosity of cooked gels increased upon cooling, possibly, as a result of retrogradation or tendency of components of the gel to reassociate. Final viscosity indicating the ability of flours to form a viscous paste, increased with the level of incorporation of BCF, with the highest for flour containing 9 % BCF plus XG (3770 ± 73 cP). Figure 1 also revealed that PV and FV were negatively related with PT. The transformation of an aqueous, fluid batter into a solid, porous cake/muffin structure depends upon the starch. Kim and Walker (1992) reported that the baking performances and collapse of the structure varies with the pasting temperatures as well as water absorption by the starch and sugar. Hence, pasting properties provide useful information for batter baking process.

Fig. 2.

Pasting curve of rice flour (0 % BCF) and BCF-rice flour blends with/without XG (BCF black carrot dietary fibre concentrate, XG xanthan gum)

Batter rheology

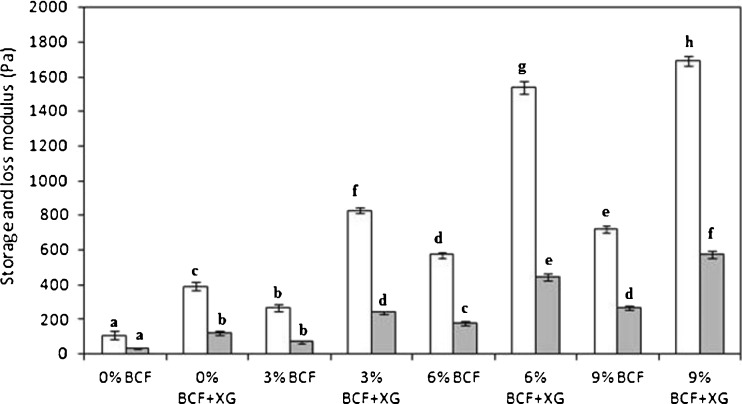

G′ and G″ of GF rice flour batters containing varying levels of BCF and XG is shown in Fig. 3. G′ represents the elastic (solid) behaviour in batter and is a measure of deformation energy stored in the sample during shear process. On the other hand, G″ represents the viscous (liquid) behaviour of the batter and is a measure of deformation energy used up and lost during shearing. For preparation of good quality muffins, the batter should be optimally viscous for trapping gas bubbles during mixing and retaining them during baking. On the contrary, a too highly viscous batter can restrict its expansion during baking (Rahmati and Tehrani 2014). G′ was greater than G″ for all the batters, indicating a predominance of elastic behaviour. Similar results have been reported by Matos et al. (2014) and Shevkani et al. (2015) for rice batters. G′ and G″ values (108.8 and 32.8 Pa, respectively) were the lowest for batters made from rice flour alone, while the highest values (1691.7 and 576.2 Pa, respectively) were observed for batters containing 9 % BCF plus XG. This increase in batter moduli with increase in BCF level might be due to the presence of fibres in BCF which reduced the amount of free water available to facilitate the movement of particles in batters (Ronda et al. 2011). These observations were similar to that of the viscosity profile. Moreover, Fig. 1 showed that G′ and G″ were positively related with PV and FV. XG also increased both the G′ and G″ of batters as clearly noticeable from Fig. 3. This was due to high water binding capacity of XG, which is desirable for the preparation of high quality muffins. Two-way ANOVA (Table 2) indicated a significant effect of both BCF and XG on the batter moduli (P < 0.05). However, higher F values for XG both in case of G′ and G″ than BCF levels indicated that it had more prominent effect than BCF which might be due to the high ability of the gums to increase the viscosity of batters. Jyotsna et al. (2004) also reported an increase in both G′ and G″ with the use of emulsifier gels in cake batters which indicated that these might be used successfully in cake batters for improving the end product quality.

Fig. 3.

Storage and loss modulus of rice flour (0 % BCF) and BCF-rice flour blends with/without XG (BCF black carrot dietary fibre concentrate; XG xanthan gum; White bars Storage modulus; Grey bars Loss modulus)

Table 2.

F values obtained from the analysis of variance data

| Source | BCF | XG | Interaction |

|---|---|---|---|

| Storage modulus | 2002.2** | 4875.4** | 279.3** |

| Loss modulus | 239.9** | 432.8** | 24.6** |

| Crust L* | 5777.9** | 124.75** | 7.1** |

| Crust a* | 3224.6** | 222.8** | 64.9** |

| Crust b* | 3071.9** | 154.6** | 4.04* |

| Crumb L* | 2252.2** | 182.5** | NS |

| Crumb a* | 5542.0** | NS | 117.6** |

| Crumb b* | 12,236.6** | NS | 44.2** |

| aw | 30.93** | 13.52** | NS |

| Height | 17.93** | 7.54* | NS |

| SV | 43.1** | 14.78** | NS |

| Firmness | 58.2** | 132.0** | 22.99** |

| Cohesiveness | 20.77** | NS | 5.79* |

| Springiness | 15.31** | 40.61** | NS |

| Gumminess | 33.57** | 25.05** | 9.28** |

| Total dietary fibre | 16,356.3** | NS | NS |

BCF, Black carrot fibre; XG, Xanthan gum; SV, Specific volume; a w, Water activity;

*= P < 0.05; ** = P < 0.005; NS = non-significant

Colour characteristics

The effect of BCF and XG on colour characteristics of GF muffin crusts as well as crumbs is given in Table 3. Colour of a baked product can be attributed to the individual ingredients present in it and their interactions (Walker et al. 2014). It has been noticed that consumers interpret darker muffins as being healthier than the light ones (Walker et al. 2014). BCF had a greyish-purple colour due to presence of anthocyanin pigments, which darkened the colour of muffins (decreased L* of crusts and crumbs) depending on the level of incorporation and also due to interaction between polyphenols and other constituents (Xu and Diosady 2000). The a* value of crusts and crumbs decreased with 6 % BCF incorporation, followed by an increase up to 9 % level. The b* value decreased (yellowness decreased) with increase in level of BCF incorporation. Two-way ANOVA (Table 2) also indicated a significant effect of BCF incorporation on the b* value of both crusts and crumbs (P < 0.05). Lu et al. (2010) observed similar results reporting lower L* and b* for cakes prepared with added green tea than those without addition. XG increased L* for both crusts and crumbs. XG had a significant effect on a* value of crusts, but it showed insignificant effect on crumbs (Table 2). It was also noticed that XG addition lowered the b* of the crusts only.

Table 3.

Colour parameters of crust and crumb of flour (0 % BCF) and BCF incorporated rice muffins with/without XG

| Muffin | Crust | Crumb | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| 0 % BCF | 71.2 ± 0.2e | 2.1 ± 0.0f | 25.7 ± 1.1e | 71.8 ± 0.3f | 1.2 ± 0.0e | 21.2 ± 0.2f |

| 0 % BCF + XG | 74.5 ± 0.3f | 2.1 ± 0.0f | 28.6 ± 0.3f | 76.4 ± 0.8g | 0.4 ± 0.0d | 19.9 ± 0.2e |

| 3 % BCF | 51.2 ± 0.2d | −4.3 ± 0.0b | 7.7 ± 0.1b | 54.8 ± 0.4d | −3.4 ± 0.1b | 8.6 ± 0.2d |

| 3 % BCF + XG | 53.4 ± 0.2d | −3.9 ± 0.1c | 9.3 ± 0.1d | 58.4 ± 1.2e | −3.3 ± 0.0b | 8.8 ± 0.2d |

| 6 % BCF | 43.4 ± 0.6c | −4.7 ± 0.2a | 5.1 ± 0.1a | 46.6 ± 0.5b | −3.8 ± 0.1a | 6.1 ± 0.0b |

| 6 % BCF + XG | 44.2 ± 0.8c | −2.8 ± 0.1d | 8.0 ± 0.4c | 50.6 ± 0.3c | −3.1 ± 0.1c | 6.8 ± 0.0c |

| 9 % BCF | 36.7 ± 0.5a | −3.1 ± 0.1c | 5.6 ± 0.3a | 43.0 ± 0.9a | −3.4 ± 0.1b | 5.6 ± 0.1a |

| 9 % BCF + XG | 39.5 ± 0.6b | −2.4 ± 0.1e | 7.2 ± 0.1b | 45.8 ± 0.3b | −3.3 ± 0.1b | 5.6 ± 0.2a |

BCF, Black carrot fibre; XG, Xanthan gum

Values are mean ± SD. Means with same letter in a column did not differ significantly (P > 0.05)

Specific volume and height

Specific volume and height of the GF muffins is shown in Table 4. Specific volume of muffins decreased with BCF incorporation being highest for 0 % BCF with XG (1.87 g/ml) and the lowest for 9 % BCF without XG (1.71 g/ml). This decrease might be due to the presence of fibres in BCF which might have collapsed the carbon dioxide gas bubbles during baking and led to the reduction in the volume (Walker et al. 2014). On the other hand, XG did not show any significant changes in muffin volume up to 6 % BCF level, while it increased at 9 % BCF level in the presence of XG. Gomez et al. (2007) and Singh et al. (2015) reported that this increase might be due to the increase in batter viscosity with XG addition. Moreover Gomez et al. (2007) reported that on XG addition, when an increase in starch gelatinization temperature takes place, the change of batter from fluid (aerated emulsion) to a solid (porous structure) happens later which allows the muffins to increase their volume for a longer time. Two-way ANOVA also indicated that addition of both BCF as well as XG had a significant effect (P < 0.05) on the specific volume of muffins (Table 2). Similarly, Lu et al. (2010) and Rupasinghe et al. (2008) reported a decrease in volume with the addition of green tea and apple pomace, respectively in cakes and muffins.

Table 4.

Physical and textural properties of flour (0 % BCF) and BCF incorporated rice muffins with/without XG

| Muffin | SV (mL/g) |

Height (mm) |

aw | Texture properties | |||

|---|---|---|---|---|---|---|---|

| Firmness (N) | Cohesiveness | Springiness | Gumminess | ||||

| 0 % BCF | 1.85 ± 0.3c | 34.8 ± 0.8b | 0.92 ± 0.01c | 2.4 ± 0.1c | 0.61 ± 0.12d | 0.83 ± 0.02e | 1.46 ± 0.16f |

| 0 % BCF + XG | 1.87 ± 0.2c | 35.4 ± 0.3b | 0.90 ± 0.01c | 1.9 ± 0.2b | 0.58 ± 0.05c | 0.77 ± 0.02c | 1.11 ± 0.20e |

| 3 % BCF | 1.76 ± 0.4b | 33.6 ± 1.3ab | 0.90 ± 0.02c | 2.4 ± 0.1c | 0.60 ± 0.03cd | 0.84 ± 0.03e | 1.44 ± 0.05f |

| 3 % BCF + XG | 1.78 ± 0.1b | 34.8 ± 1.1b | 0.89 ± 0.01c | 1.5 ± 0.3a | 0.53 ± 0.11c | 0.80 ± 0.03d | 0.82 ± 0.08c |

| 6 % BCF | 1.75 ± 0.3b | 32.2 ± 1.2a | 0.88 ± 0.00b | 2.0 ± 0.2b | 0.47 ± 0.05b | 0.82 ± 0.02e | 0.96 ± 0.10d |

| 6 % BCF + XG | 1.77 ± 0.2b | 33.1 ± 0.1a | 0.88 ± 0.01b | 1.1 ± 0.2a | 0.45 ± 0.02b | 0.76 ± 0.05b | 0.51 ± 0.19a |

| 9 % BCF | 1.71 ± 0.3a | 31.3 ± 0.2a | 0.87 ± 0.02a | 1.3 ± 0.1a | 0.33 ± 0.01a | 0.76 ± 0.05b | 0.44 ± 0.03a |

| 9 % BCF + XG | 1.76 ± 0.4b | 32.5 ± 0.7a | 0.86 ± 0.01a | 1.4 ± 0.0a | 0.47 ± 0.06b | 0.74 ± 0.00a | 0.66 ± 0.09b |

SV, Specific volume; a w, Water activity; BCF, Black carrot fibre; XG, Xanthan gum

Values are mean ± SD. Means with same letter in a column did not differ significantly (P > 0.05)

Height of the muffins decreased gradually with the increase in level of BCF. As shown in Table 4, muffins without BCF and with XG had the highest height (35.4 ± 0.3 mm), while the lowest was observed for those containing 9 % BCF (31.3 ± 0.2 mm). On the contrary, XG increased muffin height which might be due to the ability of hydrocolloids to assist in proper rising of muffins and cakes. Two-way ANOVA also revealed a significant effect of both BCF and XG on muffin height (Table 2). Arozarena et al. (2001) also reported an increase in height of eggless yellow cakes with the addition of XG. In addition, muffin height and specific volume were positively related with each other, and also with L*, a* and b* of crusts and crumbs as shown in Fig. 1.

Water activity and textural properties

Water activity and texture parameters for GF muffins are shown in Table 4. Water activity (aw) is an important indicator for the shelf life of the foods, as it strongly influences the growth of microorganisms. It describes the unbound/available or free water in the food products. The aw decreased with BCF incorporation, the highest being for muffins prepared without BCF and it decreased significantly at 6 % BCF level and afterwards was the lowest at 9 % BCF level (Table 4). The decrease in aw might be possibly due to the high water absorption capacities of the fibres which makes less free water available. XG addition also decreased aw of the muffins. Two-way ANOVA also revealed significant effect of both BCF and XG on aw of muffins (Table 2). PCA analysis revealed a negative relation of aw with G′ and G″ (Fig. 1).

Firmness defined as the highest force that was required to compress the muffin crumb under a constant deformation. It decreased with the increase in the level of BCF from 2.4 N to 1.3 N (Table 4). The effect of XG on firmness was more prominent than BCF addition. This might be due to some interaction of starch and XG which affected its retrogradation (Gomez et al. 2007). Cohesiveness quantifies the internal resistance of food structure under some compression. A product with strong cohesion is more tolerant of manufacturing, packaging and delivery stresses, and thus will be presented to the consumers in its expected state. Cohesiveness decreased with the increase in level of BCF (up to 6 %) with XG, while it increased in muffins having 9 % BCF plus XG. Springiness measured the elasticity of the muffins by measuring the extent of recovery between the first and second compression and was a desirable muffin property associated with elastic and fresh aerated product (Shevkani and Singh 2014). Springiness increased with incorporation of 3 % BCF and afterwards decreased at 6 % and 9 % BCF incorporation levels. Gumminess decreased with the increased level of BCF with/without XG up to 6 % incorporation level, while it again increased with 9 % incorporation level with XG. Walker et al. (2014) observed an increase in firmness and a decrease in springiness with the increase in level of wine grape pomace in muffins. Similarly, Lu at el. (2010) observed increase in firmness, gumminess and decrease in springiness of sponge cakes with the addition of green tea powder. The decrease in firmness reported by these authors was due to the decrease in sponge cake volume with green tea powder addition. ANOVA (Table 2) indicated a significant effect of BCF and XG on the firmness, springiness and gumminess. Figure 1 revealed that firmness, gumminess, springiness, aw and cohesiveness were positively related with one another, while these were negatively related with G′ and G″.

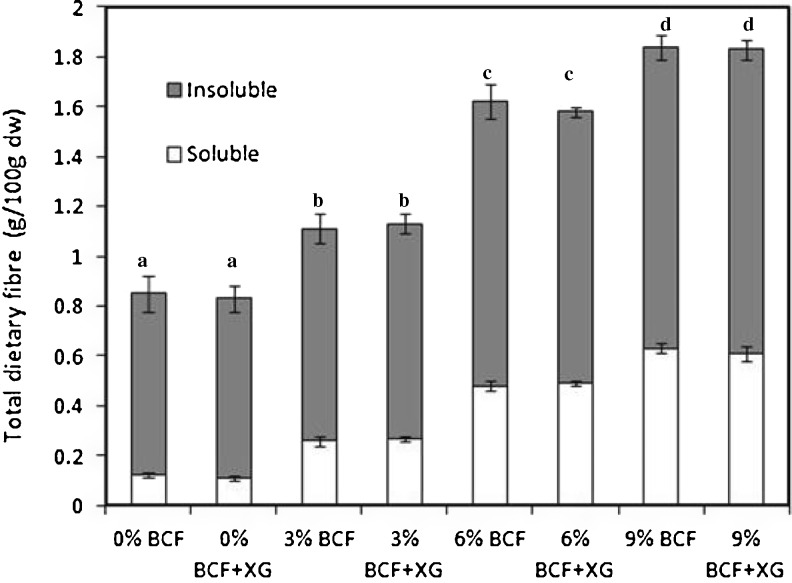

Total dietary fibre of muffins

Dietary fibre is the edible part of plants that is resistant to digestion and absorption in the human small intestine, with complete or partial fermentation in the large intestine. TDF was 1.86 g/100 g for rice flour, while it was 64.95 g/100 g for BCF. Chantaro et al. (2008) reported a TDF of 45.45 g/100 g for fresh carrot peels which indicated that the peel portion was rich in dietary fibre. TDF (soluble as well as insoluble) of GF muffins is shown in Fig. 4. BCF increased the TDF of the muffins significantly from 0.83 ± 0.07 to 1.84 ± 0.09 g/100 g. It was also observed that soluble dietary fibre was present in lesser amounts for all muffins than insoluble dietary fibre. Two-way ANOVA (Table 2) indicated that BCF incorporation had a significant effect (P < 0.05) on TDF of the muffins, but effect of XG addition was not significant. Figure 1 also revealed that TDF was positively related with G′ and G″, while negatively related with colour values (crusts and crumbs), texture parameters, aw and specific volume.

Fig. 4.

Total dietary fibre (insoluble and soluble) of rice flour (0 % BCF) and BCF-rice flour blends with/without XG (BCF black carrot dietary fibre concentrate; XG xanthan gum)

Sensory analysis of muffins

Sensory characteristics of GF muffins are shown in Table 5. Colour, appearance, texture, taste and overall acceptability scores of muffins containing varying levels of BCF ranged from 6.2 to 7.2, 6.4 to 7.4, 6.4 to 7.2, 7.3 to 7.8 and 6.6 to 7.4, respectively. The results indicated that muffins with highest sensory scores could be prepared using 6 % BCF and 0.5 g XG. Durrani et al. (2011) found that positive sensory scores were obtained by using carrot in honey based candy. Grigelmo-Miguel et al. (1999) and Ayadi et al. (2009) showed that cake dough enhanced with prickly pear cladode fibre and muffin batters having peach dietary fibre, respectively at levels up to 5 % were as acceptable as the control based on sensory scores.

Table 5.

Sensory characteristics of flour (0 % BCF) and BCF incorporated rice muffins with/without XG

| Muffin | Colour | Appearance | Texture | Taste | Overall acceptability |

|---|---|---|---|---|---|

| 0 % BCF | 6.2 ± 2.1a | 6.7 ± 1.4a | 6.4 ± 0.8a | 7.3 ± 1.5a | 6.6 ± 0.8a |

| 0 % BCF + XG | 6.7 ± 1.6a | 7.1 ± 1.5a | 7.2 ± 1.5a | 7.5 ± 1.7a | 7.1 ± 0.6b |

| 3 % BCF | 6.9 ± 0.9a | 6.8 ± 0.9a | 6.7 ± 1.0a | 7.4 ± 0.7a | 6.9 ± 0.5ab |

| 3 % BCF + XG | 7.1 ± 2.3a | 7.2 ± 1.3b | 7.2 ± 1.8a | 7.7 ± 1.1a | 7.3 ± 0.9d |

| 6 % BCF | 7.1 ± 1.5a | 6.8 ± 1.4a | 6.8 ± 1.2a | 7.3 ± 1.7a | 7.0 ± 0.7c |

| 6 % BCF + XG | 7.2 ± 1.7a | 7.4 ± 1.4b | 7.1 ± 1.5a | 7.8 ± 2.1a | 7.4 ± 0.9d |

| 9 % BCF | 6.7 ± 1.2a | 6.4 ± 0.7a | 6.6 ± 0.7a | 7.2 ± 1.8a | 6.7 ± 0.5b |

| 9 % BCF + XG | 6.9 ± 0.6a | 6.9 ± 0.8a | 7.1 ± 0.9a | 7.3 ± 2.3a | 7.0 ± 0.4ab |

BCF, Black carrot fibre; XG, Xanthan gum

Values are mean ± SD. Means with same letter in a column did not differ significantly (P > 0.05)

Conclusion

BCF incorporation increased total dietary fibre content and decreased lightness, yellowness, water activity (aw), specific volume and firmness of muffins. Contrarily, XG addition improved the appearance and specific volume, while decreased aw of the GF muffins. BCF and XG in combination improved the volume and appearance while decreased aw of muffins. Moreover, sensory analyses also indicated that incorporation BCF at 6 % level with 0.5 % XG improved the consumer acceptability of muffins. Thus, BCF incorporation and XG addition in GF rice muffins is a potential ingredient for new functional food products.

Acknowledgments

Authors acknowledge financial support from UGC (UPE), New Delhi and MOFPI (SERB/MOFPI/0043/2013), New Delhi. JPS also wishes to thank Dr. Khetan Shevkani for his useful suggestions.

Footnotes

Highlights: Black carrot pomace dietary fibre concentrate was incorporated in rice flour and was evaluated for pasting, rheological and muffin making properties. Xanthan gum was used to improve the quality characteristics of the gluten-free muffins. Black carrot fibre concentrate increased dietary fibre content, while xanthan gum increased specific volume of the muffins.

References

- AOAC . Official methods of analysis of AOAC international. 17th. Gaithersburg, MD, USA: AOAC International; 2000. [Google Scholar]

- Arozarena I, Bertholo H, Empis J, Bunger Sousa I. Study of the total replacement of egg by white lupine protein, emulsifiers xanthan gum in yellow cakes. Eur Food Res Technol. 2001;213:312–316. doi: 10.1007/s002170100391. [DOI] [Google Scholar]

- Ayadi MA, Abdelmaksoud W, Ennouri M, Hamadi A. Cladodes from opuntica ficus indica as a source of dietary fiber: effect on dough characteristics and cake making. Ind Crop Prod. 2009;30:40–47. doi: 10.1016/j.indcrop.2009.01.003. [DOI] [Google Scholar]

- Ayala-Zavala JF, Vega-Vega V, Rosas-Domínguez C, Palafox-Carlos H, Villa-Rodriguez JA, Siddiqui MW, González-Aguilar GA. Agro-industrial potential of exotic fruit byproducts as a source of food additives. Food Res Int. 2011;44:1866–1874. doi: 10.1016/j.foodres.2011.02.021. [DOI] [Google Scholar]

- Bourne MC. Texture profile analysis. Food Technol. 1978;32:62–66. [Google Scholar]

- Chantaro P, Devahastin S, Chiewchan N. Production of antioxidant high dietary fiber powder from carrot peels. LWT-Food Sci Technol. 2008;41:1987–1994. doi: 10.1016/j.lwt.2007.11.013. [DOI] [Google Scholar]

- Chau CF, Wang YT, Wen YL. Different micronization methods significantly improve the functionality of carrot insoluble fibre. Food Chem. 2007;100:1402–1408. doi: 10.1016/j.foodchem.2005.11.034. [DOI] [Google Scholar]

- Durrani A, Srivastava P, Verma S. Development and quality evaluation of honey based carrot candy. J Food Sci Technol. 2011;48:502–505. doi: 10.1007/s13197-010-0212-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Figuerola F, Hurtado ML, Estévez AM, Chiffelle I, Asenjo F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005;91:395–401. doi: 10.1016/j.foodchem.2004.04.036. [DOI] [Google Scholar]

- Gomez M, Ronda F, Caballero PA, Blanco CA, Rosell CM. Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 2007;21:167–173. doi: 10.1016/j.foodhyd.2006.03.012. [DOI] [Google Scholar]

- Grigelmo-Miguel M, Gorinstein S, Martin-Belloso O. Characterization of peach dietary fibre concentrate as a food ingredient. Food Chem. 1999;5:175–181. doi: 10.1016/S0308-8146(98)00190-3. [DOI] [Google Scholar]

- Hong Y, Wu Y, Liu G, Gu Z. Effect of amylose on pasting and rheological properties of corn starch/xanthan blends. Starch-Starke. 2015;67:98–106. doi: 10.1002/star.201400126. [DOI] [Google Scholar]

- Jyotsna R, Prabhasankar P, Indrani D, Rao GV. Improvement of rheological and baking properties of cake batters with emulsifier gels. J Food Sci. 2004;69:SNQ16–SNQ16. doi: 10.1111/j.1365-2621.2004.tb17880.x. [DOI] [Google Scholar]

- Kaur A, Shevkani K, Singh N, Sharma P, Kaur S. Effect of guar gum and xanthan gum on pasting and noodle-making properties of potato, corn and mung bean starches. J Food Sci Technol: 2015 doi: 10.1007/s13197-015-1954-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kethireddipalli P, Hung YC, Phillips RD, McWatters KH. Evaluating the role of cell wall material and soluble protein in the functionality of cowpea (Vigna unguiculata) pastes. J Food Sci. 2002;67:53–59. doi: 10.1111/j.1365-2621.2002.tb11358.x. [DOI] [Google Scholar]

- Kim CS, Walker CE. Interactions between starches, sugars, and emulsifiers in high-ration cake model systems. Cereal Chem. 1992;69:206–212. [Google Scholar]

- Lu TM, Lee CC, Maud JL, Lin SD. Quality and antioxidant property of green tea sponge cake. Food Chem. 2010;119:1090–1095. doi: 10.1016/j.foodchem.2009.08.015. [DOI] [Google Scholar]

- Matos ME, Sanz T, Rosell CM. Establishing the function of proteins on the rheological and quality properties of rice-based gluten-free muffins. Food Hydrocoll. 2014;35:150–158. doi: 10.1016/j.foodhyd.2013.05.007. [DOI] [Google Scholar]

- Nachay K. Gluten-free offerings increase. Food Technol. 2010;64:13–14. [Google Scholar]

- Nanditha B, Prabhasankar P. Antioxidants in bakery products: a review. Crit Rev Food Sci. 2008;49:1–27. doi: 10.1080/10408390701764104. [DOI] [PubMed] [Google Scholar]

- Preichardt LD, Vendruscolo CT, Gularte MA, Moreira ADS. The role of xanthan gum in the quality of gluten free cakes: improved bakery products for coeliac patients. Int J Food Sci Technol. 2011;46:2591–2597. doi: 10.1111/j.1365-2621.2011.02788.x. [DOI] [Google Scholar]

- Rahmati NF, Tehrani MM. Influence of different emulsifiers on characteristics of eggless cake containing soy milk: modeling of physical and sensory properties by mixture experimental design. J Food Sci Technol. 2014;51:1697–1710. doi: 10.1007/s13197-013-1253-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rai S, Kaur A, Singh B. Quality characteristics of gluten free cookies prepared from different flour combinations. J Food Sci Technol. 2014;51:785–789. doi: 10.1007/s13197-011-0547-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ronda F, Oliete B, Gómez M, Caballero PA, Pando V. Rheological study of layer cake batters made with soybean protein isolate and different starch sources. J Food Eng. 2011;102:272–277. doi: 10.1016/j.jfoodeng.2010.09.001. [DOI] [Google Scholar]

- Ronda F, Perez-Quirce S, Lazaridou A, Biliaderis CG. Effect of barley and oat β-glucan concentrates on gluten-free rice-based doughs and bread characteristics. Food Hydrocoll. 2015;48:197–207. doi: 10.1016/j.foodhyd.2015.02.031. [DOI] [Google Scholar]

- Rupasinghe HPV, Wang L, Huber G, Pitts N. Effect of baking on dietary fibre and phenolics of muffins incorporated with apple skin powder. Food Chem. 2008;107:1217–1224. [Google Scholar]

- Sae-Eaw A, Chompreeda P, Prinyawiwatkul W, Haruthaithanasan V, Suwonsichon T, Saidu JE, Xu Z. Acceptance and purchase intent of US consumers for nonwheat rice butter cakes. J Food Sci. 2007;72:S92–S97. doi: 10.1111/j.1750-3841.2006.00256.x. [DOI] [PubMed] [Google Scholar]

- Sakac M, Torbica A, Sedej I, Hadnadev M. Influence of bread making on antioxidant capacity of gluten free breads based on rice and buckwheat flours. Food Res Int. 2011;44:2806–2813. doi: 10.1016/j.foodres.2011.06.026. [DOI] [Google Scholar]

- Shevkani K, Singh N. Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int J Food Sci Technol. 2014;49:2237–2244. doi: 10.1111/ijfs.12537. [DOI] [Google Scholar]

- Shevkani K, Kaur A, Kumar S, Singh N. Cowpea protein isolates: functional properties and application in gluten-free rice muffins. LWT-Food Sci Technol. 2015;63:927–933. doi: 10.1016/j.lwt.2015.04.058. [DOI] [Google Scholar]

- Singh JP, Kaur A, Shevkani K, Singh N. Influence of jambolan (Syzygium cumini) and xanthan gum incorporation on the physicochemical, antioxidant and sensory properties of gluten-free eggless rice muffins. Int J Food Sci Technol. 2015;50:1190–1197. doi: 10.1111/ijfs.12764. [DOI] [Google Scholar]

- Suzme S, Boyacioglu D, Toydemir G, Capanoglu E. Effect of industrial juice concentrate processing on phenolic profile and antioxidant capacity of black carrots. Int J Food Sci Technol. 2014;49:819–829. doi: 10.1111/ijfs.12370. [DOI] [Google Scholar]

- Türkyılmaz M, Yemiş O, Özkan M. Clarification and pasteurisation effects on monomeric anthocyanins and percent polymeric colour of black carrot (daucus carota L.) juice. Food Chem. 2012;134:1052–1058. doi: 10.1016/j.foodchem.2012.03.013. [DOI] [PubMed] [Google Scholar]

- Walker R, Tseng A, Cavender G, Ross A, Zhao Y. Physicochemical, nutritional, and sensory qualities of wine grape pomace fortified baked goods. J Food Sci. 2014;79:S1811–S1822. doi: 10.1111/1750-3841.12554. [DOI] [PubMed] [Google Scholar]

- Xu L, Diosady LL. Interactions between canola proteins and phenolic compounds in aqueous media. Food Res Int. 2000;33:725–731. doi: 10.1016/S0963-9969(00)00062-4. [DOI] [Google Scholar]