Abstract

Engineering the cofactor specificity of a natural enzyme often results in a significant decrease in its activity on original cofactor. Here we report that a NADH-dependent dehydrogenase (d-LDH) from Lactobacillus delbrueckii 11842 can be rationally engineered to efficiently use both NADH and NADPH as cofactors. Point mutations on three amino acids (D176S, I177R, F178T) predicted by computational analysis resulted in a modified enzyme designated as d-LDH*. The Kcat/Km of the purified d-LDH* on NADPH increased approximately 184-fold while the Kcat/Km on NADH also significantly increased, showing for the first time that a rationally engineered d-LDH could exhibit comparable activity on both NADPH and NADH. Further kinetic analysis revealed that the enhanced affinity with NADH or NADPH and the significant increased Kcat of d-LDH* resulted in the significant increase of d-LDH* activity on both NADPH and NADH. This study thus demonstrated that the cofactor specificity of dehydrogenase can be broadened by using targeted engineering approach, and the engineered enzyme can efficiently function in NADH-rich, or NADPH-rich, or NADH and NADPH-rich environment.

Dehydrogenases are important enzymes involved in the biosynthesis of chemicals. In nature, most microbial dehydrogenases prefer to use a single molecule, either NADH or NADPH, as its main cofactor. Sufficient supply of reducing equivalent, NADH or NADPH, and their efficient regeneration, are crucial for production of bulk chemicals via metabolic engineering1,2,3,4. However, except for a few examples, for instance glutamate dehydrogenase which is active on both NADH and NADPH5, most natural dehydrogenases prefer to use either NADH, or NADPH, as its main cofactor. Usually NADH is the major reducing equivalent in heterotrophic microorganism, such as E. coli, while NADPH is the major reducing equivalent in photoautotrophic microorganisms, such as cyanobacteria4,6. This means NADPH-dependent enzyme may not function well in E. coli. For example, introduction of the NADPH-dependent ketol-acid reductoisomerase into E. coli did not contribute to production of isobutanol production1. Similarly, NADH-dependent enzyme, for instance the NADH-dependent lactate dehydrogenase (LDH), may not work well in cyanobacteria2,3,4. Development of an enzyme that can efficiently use NADH or NADPH as cofactor would be useful, as the activity of such an enzyme will not be limited by the availability of NADH or NADPH.

Cofactor specificity can be altered by co-expression of a transhydrogenase, or both a transhydrogenase and a NAD kinase, to accelerate the interconversion between NADH and NADPH1,2,4. This strategy increased the production of isobutanol1 and lactate2,4. Nevertheless, manipulations of the expression levels of transhydrogenase and NAD kinase were required to meet the specific cofactor requirement1. Cofactor specificity can also be changed via site-directed mutagenesis. For instance, engineering the cofactor specificity of the NADH-dependent l-lactate dehydrogenase (l-LDH)3 and d-lactate dehydrogenase (d-LDH)7. However, the activity of the engineered LDHs on NADPH was much lower than that of the wild-type on NADH, and the activity of the engineered LDHs on NADH was also significantly decreased3,7. This suggests that the engineered LDHs are of little practical value, although the cofactor specificity was successfully altered.

Recently, biosynthesis of lactate from biomass or carbon dioxide becomes very attractive, with the hope of producing biodegradable polymer polylactide (PLA) to address the global energy and environment challenges2,3,4,8,9,10,11. l-lactate and d-lactate are two optical isomers of lactate, whereas, d-lactate is the essential moiety for the thermostability of PLA9,10. Biosynthesis of d-lactate is more difficult than that of l-lactate because the d-lactate dehydrogenase (d-LDH) is not widely present in nature12. Almost all natural d-LDH characterized to date are dependent on NADH13, which makes production of d-lactate in NADPH-rich microbes difficult.

The aim of this study was to investigate whether it is possible to broaden the cofactor specificity of the d-LDH without decreasing its activity on original cofactor. We used a rational engineering strategy based on enzyme structure comparison and analysis to engineer the NADH-dependent d-LDH from Lactobacillus delbrueckii 11842, which shows the highest d-LDH activity reported to date7,10,14. Using the rational engineering strategy, we obtained an engineered d-LDH which showed great activity on both NADH and NADPH.

Results

Identification of the target sites for engineering d-LDH

It is known that the structure of the cofactor binding pocket determines the cofactor specificity15,16. Comparing the structure of the NADH binding pocket and the NADPH binding pocket may help to reveal the difference, thus providing clues for rational design to alter the cofactor specificity. d-LDH is an NADH-dependent enzyme and 1J4915 is the crystal structure of d-LDH. To find NADPH-dependent enzyme with structure similar to that of 1J49, we subjected the sequence of 1J49 (Fig. S1) to RCSB PDB and the results were sorted by similarity. Two types of NADPH bound crystal structures were selected: glyoxylate reductase 2DBQ17 (EC 1.1.1.26, E-Value: 8.12976E-17, Identities: 73/259 (28%), Positives: 121/259 (47%), Gaps: 25/259 (10%)) and 2GCG18 (EC 1.1.1.79, E-value: 2.23185E-15, Identities: 73/294 (25%), Positives: 126/294 (43%), Gaps: 23/294 (8%)). To reveal the difference on the selectivity of the binding pockets, the three crystal structure of 1J49, 2DBQ and 2GCG were aligned and analyzed. The RMSD between 1J49 and 2DBQ is 1.958, the RMSD between 1J49 and 2GCG is 1.819. Because of the structure similarity of NADH and NADPH, the binding pockets structure and residues type of 1J49, 2DBQ and 2GCG are also highly similar if not identical (Fig. 1 and Fig. S2). The only notable structure difference between NADH and NADPH binding pockets is the 177-loop in 1J49 (181-loop in 2DBQ and 183-loop in 2GCG). In this selectivity control loop, 2DBQ has the same residues number with 1J49 (YSRTR:YDIFR), whereas the 2GCG has one more residue in this loop (YTGRQP: YDIFR). Furthermore, the 181-loop of 2DBQ has a higher sequence similarity with that of the 177-loop of 1J49: the residues at the beginning and the end are the same, while the three residues located in the middle are different. As one of the key objectives of engineering d-LDH is to minimize the impact on NADH-dependent activity, we thus selected the 181-loop of 2DBQ as a template to engineer the d-LDH (1J49) to minimize the structure instability.

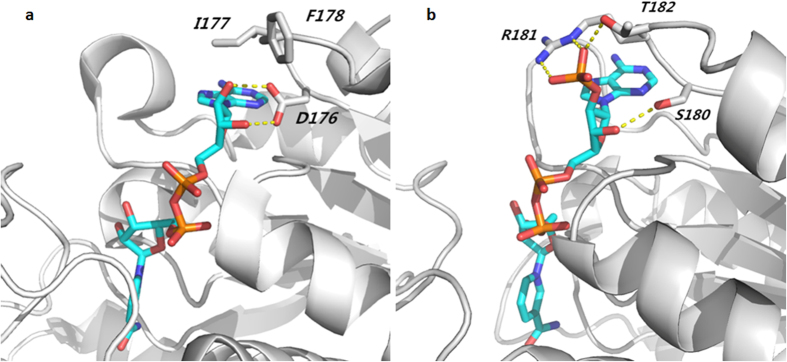

Figure 1. Alignment of three pdb, 1J49 (cyan), 2DBQ (magenta) and 2GCG (green).

The only notable difference between these three binding pocket is at 177-loop of 1J49 (181-loop of 2DBQ, 183-loop of 2GCG). Abbreviations: pdb, protein data ban; 1J49, d-LDH which is NADH-dependent enzyme; 2DBQ and 2GCG, glyoxylate reductases which are NADPH-dependent enzymes.

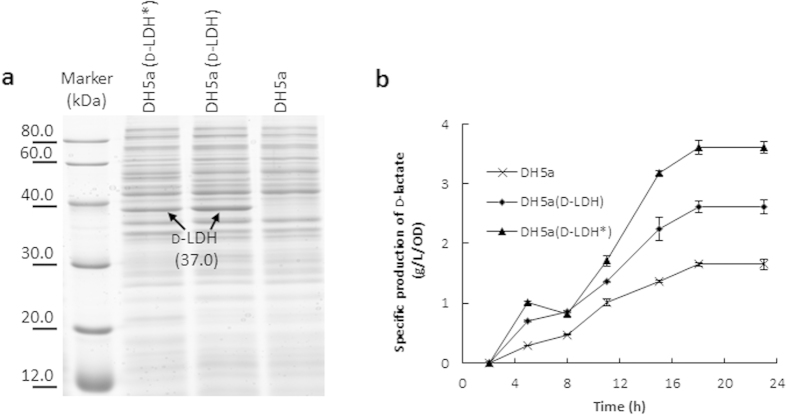

In 177-loop of 1J49, the residue D176 has two hydrogen-bonds with the ribose of NAD+ (Fig. 2a), while residue I177 has hydrophobic interaction with the purine ring. In 181-loop of 2DBQ, the residues R181 and T182 have three hydrogen bonds with the phosphate group of NADP+ (Fig. 2b), while the residue S180 has one hydrogen bond with the ribose of NADP+. All these three middle residues in 2DBQ have hydrogen bond interaction with NADP+. Therefore, introducing mutations into all these three residues are expected to change the cofactor specificity of 1J49 (EC 1.1.1.28), and the YDIFR loop of d-LDH will be replaced with the YSRTR loop, which prefers to bind NADPH.

Figure 2. Interaction analysis of the two notable difference loops with its prefer cofactor.

(a) Interaction analysis of 177-loop of 1J49 with NAD+. D176 has two hydrogen-bond with ribose of NAD+ and residue I177 has hydrophobic interaction with purine ring. (b) Interaction analysis of 181-loop of 2DBQ with NADP+. R181 and T182 have three hydrogen bond with phosphate group of NADP+. Residue S181 has one hydrogen bond with ribose of NADP+.

Engineering cofactor binding pocket enables d-LDH to efficiently use NADPH

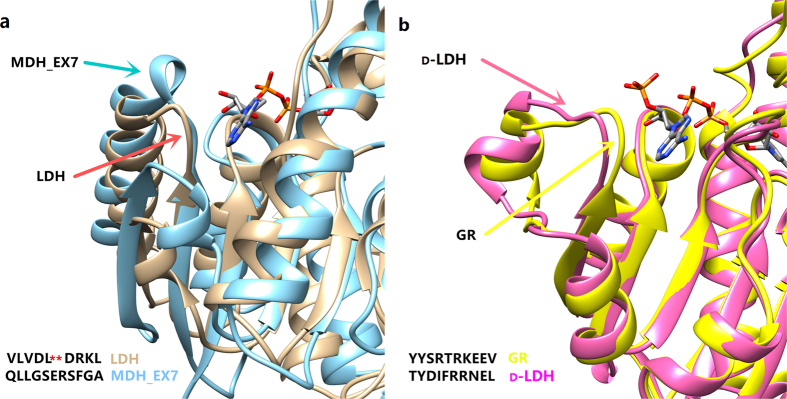

To replace the YDIFR loop of 1J49 with the NADPH binding loop YSRTR, point mutations on three amino acids (D176S, I177R, F178T) were introduced into d-LDH, resulting in a mutant designated as d-LDH*. To investigate the effect of the loop replacement, the specific activity of crude d-LDH* using NADPH as cofactor was determined. As the enzyme has not yet been purified, the expression levels of d-LDH* and d-LDH in E. coli DH5α were investigated prior to the enzymatic activity assay. SDS-PAGE shows that similar expression levels of d-LDH* and d-LDH were achieved (Fig. 3a). As d-LDH is a NADH-dependent enzyme, the specific activity of wild-type d-LDH using NADPH as cofactor was very low (Table S1). The specific activity of d-LDH*, in which YDIFR was replaced with YSRTR, was significantly higher than d-LDH using NADPH as cofactor (Table S1), demonstrating that this loop replacement strategy is working. Compared to wild-type d-LDH, the specific activity of d-LDH* using NADPH as cofactor increased approximately 57-fold (Table S1) through this rational engineering approach.

Figure 3. Crude enzymatic activity analysis of d-LDH and d-LDH*.

(a) Detection of d-LDH and d-LDH* gene expression in corresponding strain via 12% SDS-PAGE analysis. Lane 1, Protein Markers; Lane 2, DH5a (d-LDH*); Lane 3, DH5a (d-LDH); Lane 4, DH5a. (b) Time course of d-lactate production.

Engineered d-LDH* also increases its activity on NADH

It is very common that enzyme engineering approaches altering the cofactor specificity usually result in a sharp decrease of the enzyme activity on original cofactor7. To investigate whether the natural enzymatic activity of d-LDH* on NADH was affected by replacing the loop YDIFR with YSRTR, the specific activities of the d-LDH* and wild-type d-LDH were assayed using NADH as cofactor. To our surprise, the specific activity of crude d-LDH* using NADH as cofactor was not decreased, but much higher than that of the wild-type d-LDH using NADH as cofactor (Table S1). The specific activity of crude d-LDH* using NADH as cofactor increased approximately 4-fold (Table S1) through this rational engineering approach. Moreover, the specific activity of crude d-LDH* using NADPH as cofactor (37.84 ± 3.33 μmol/min/mg crude cell extraction) was comparable with the specific activity of d-LDH* using NADH as cofactor (34.47 ± 3.81) μmol/min/mg crude cell extraction), indicating such a rational design successfully altered the cofactor specificity of d-LDH, and significantly altered its activities on both NADH and NADPH.

Engineered d-LDH* shows increased Kcat/Km values on both NADH and NADPH

To better understand the effect of this rational engineering approach on enzyme properties, d-LDH and d-LDH* with his6-tag at their C terminus were constructed, expressed in BL21(DE3), and purified by using Ni2+ affinity chromatography (Fig. S3). The purified d-LDH and d-LDH*were subjected to further characterization.

The specified activities of the purified his-tagged d-LDH and d-LDH* were shown in Table 1. The specific activity of purified d-LDH* using NADH as cofactor increased by 28% as compared to that of the purified wild-type d-LDH, demonstrating that such a rational engineering approach did not decrease the original enzyme activity indeed. The specific activity of purified d-LDH* using NADPH as cofactor increased approximately 62-fold compared to that of the purified wild-type d-LDH. Specific activity assay using crude cell extract and purified d-LDH* using NADPH as cofactor showed highly similar degree of increment, demonstrating the activity of d-LDH* on NADPH was greatly improved.

Table 1. The kinetic parameters of the purified his-tagged LDH and LDH*.

| Enzymes | Specific activity | Kinetic parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| NADH (μmol/min/mg) | NADPH (μmol/min/mg) | NADH | NADPH | ||||||

| Kcat (s−1) | Km (mM) | Kcat/Km (M−1s−1) | Kcat (s−1) | Km (mM) | Kcat/Km (M−1s−1) | ||||

| d-LDH | 1240 ± 38 | 49 ± 3 | 7801 | 1.40 | 5.57 × 106 | 821 | 4.55 | 1.82 × 105 | |

| d-LDH* | 1587 ± 52 | 3101 ± 47 | 8540 | 1.01 | 8.46 × 106 | 8643 | 0.257 | 3.36 × 107 | |

d-LDH, wild-type d-lactate dehydrogenase; d-LDH*, engineered d-lactate dehydrogenase. Data were relative to three independent measurements (±SD).

To further address why the engineered enzyme d-LDH* can efficiently use both NADH and NADPH as cofactors, the kinetic parameters of d-LDH* and its wild-type d-LDH were determined and comparably analyzed. As shown in Table 1, the Kcat value of d-LDH* for NADH increased slightly and Km value decreased, leading to that the Kcat/Km value of d-LDH* for NADH increased by 52% compared with that of the d-LDH. Most strikingly, Kcat/Km value of d-LDH* for NADPH increased by 184-fold, due to the 9.6-fold increased Kcat and the 16.7-fold decreased Km, as compared with that of d-LDH. The purified d-LDH* exhibited a high and similar Kcat when using NADH or NADPH, suggesting the d-LDH* can catalyze dehydrogenation reaction in a similar rate no matter NADH or NADPH is used as cofactor. Moreover, the Km of d-LDH* on NADH decreased by 38.6%, while the Km of d-LDH* on NADPH was 16.7-fold lower than that of the d-LDH. This suggests the d-LDH* has acquired a significantly improved affinity on NADPH.

Increased production of d-lactate in E. coli using d-LDH*

To further confirm the improvement of enzymatic efficiency of the engineered d-LDH* in vivo, the d-lactate production in E. coli DH5α cells expressing d-LDH or d-LDH* were investigated. Profiles of d-lactate production (Fig. 3b) showed that the production of d-lactate per OD cells reached the highest at 18 hour. The highest titer of the d-lactate produced by E. coli expressing the d-LDH* was 37% higher than that of expressing the original d-LDH, indicating that the in vivo activity of d-LDH* increased.

Discussion

Creating enzymes with novel properties by protein engineering is an important approach for metabolic engineering, with the aim to increase the titers and productivities of target products, or to produce non-natural compounds19. In a previous work, NADH-dependent phenylalanine dehydrogenase was successfully developed by engineering an NADPH-dependent glutamate dehydrogenase to achieve partial biosynthesis of a nonproteinogenic amino acid20. In another work, d-lactate dehydrogenase activity was evolved from glycerol dehydrogenase by protein engineering and production of d-lactate from lignocellulose was achieved21.

Methods for protein engineering include random and targeted mutagenesis19. Efforts have been made to alter cofactor specificity of LDH from NADH to NADPH by using site-directed mutagenesis approach3,7,22. However, there are little successful examples of targeted mutagenesis for improving the properties of LDH. Target mutagenesis of the NADH-dependent d-LDH from L. delbrueckii 11842 on cofactor binding site D175A resulted in a moderate increase in catalytic activity on NADPH but a 7.5-fold decrease in catalytic activity on NADH22. In addition, targeted mutagenesis of NADH-dependent l-LDH from B. subtilis on cofactor binding site V38R resulted in a 50% decrease in catalytic activity on NADH and the activity on NADPH was only 1/6 of the wild-type activity on NADH3. Further analysis showed it was the improvement of the expression level of the l-LDH V38R mutant, rather than the improved specific activity, resulted in the increased lactate production in cyanobacteria3. In a word, although the engineered LDHs can use NADPH as cofactor, the activity was far too low to have practical significance.

Usually random mutagenesis and targeted mutagenesis are combined to improve an enzyme20. To date, the only successful example for engineering the NADH-dependent l-LDH from B. subtilis was achieved by using saturation mutagenesis. A point mutation on the cofactor binding site V39R resulted in a significant improvement of catalytic activity on NADH and a 100-fold increase of activity on NADPH23. However, the saturation mutagenesis based on five created mutation library, is more time-consuming and laborious than the rational engineering strategy described in our study.

The highlight of this work is that the rationally engineered d-LDH* can use both NADH and NADPH as cofactor, efficiently. Comparative analysis of the crystal structure of the NADH-dependent d-LDH and two other NADPH-dependent enzymes identified the only notable different loop of cofactor binding pockets. Subsequently, three amino acid residues were mutated based on the analysis of the interaction of cofactor with its binding loop. Benefited from this rational design, simple modification on three amino acid residues resulted in a 184-fold increased Kcat/Km on NADPH and a 52% increased Kcat/Km on NADH, as determined using the purified enzyme. d-LDH from L. delbrueckii 11842 is already the most active d-LDH reported to date in terms of its activity on NADH. The further increased activity on NADH, together with acquisition of the comparable activity on NADPH, have made the d-LDH* an attractive enzyme candidate for improving d-lactate production. Although the Kcat/Km value of d-LDH on NADPH could be increased by directed mutagenesis, they were usually at the cost of decreased Kcat/Km of d-LDH on NADH7,22 (Table 2). Here we showed an exception that the cofactor specificity of d-LDH can be shifted from NADH to NADPH without sacrificing its activity on original cofactor by directed mutagenesis.

Table 2. Comparison of kinetic parameters for different wild-type LDH and corresponding mutants.

| Enzyme | Mutated site | NADH | NADPH | References | ||

|---|---|---|---|---|---|---|

| Kcat (s−1) | Kcat/Km (M−1 s−1) | Kcat (s−1) | Kcat/Km (M−1 s−1) | |||

| LdhD | WT | 561 | 2.4 × 105 | ND | ND | 7 |

| LdhDnARSdR | D176A, I177R F178S, N180R | 129 | 8.5 × 103 | 163 | 4.4 × 104 | |

| L. bulgaricus d-LDH | WT | 875 | 1.1 × 107 | 425 | 2.6 × 105 | 22 |

| L. bulgaricus* d-LDH | D175A | 575 | 1.15 × 106 | 725 | 1.2 × 106 | |

| BsLDH | WT | 77.5 | 1.5 × 106 | 1.3 | 9.4 × 103 | 23 |

| BsLDH* | V39R | 291.6 | 4.9 × 106 | 140.4 | 2.3 × 106 | |

| Tt27LDH | WT | 39.9 | 5.24 × 106 | 5.93 | 4.33 × 104 | 24 |

| Tt27LDH-EX7 | D32LDRKLA38 | 11.2 | 3.24 × 104 | 127 | 1.07 × 105 | |

| G32SERSFQ38 | ||||||

| d-LDH | WT | 7801 | 5.57 × 106 | 821 | 1.82 × 105 | This research |

| d-LDH* | D176S, I177R F178T | 8540 | 8.46 × 106 | 8643 | 3.36 × 107 | |

ND: not determined.

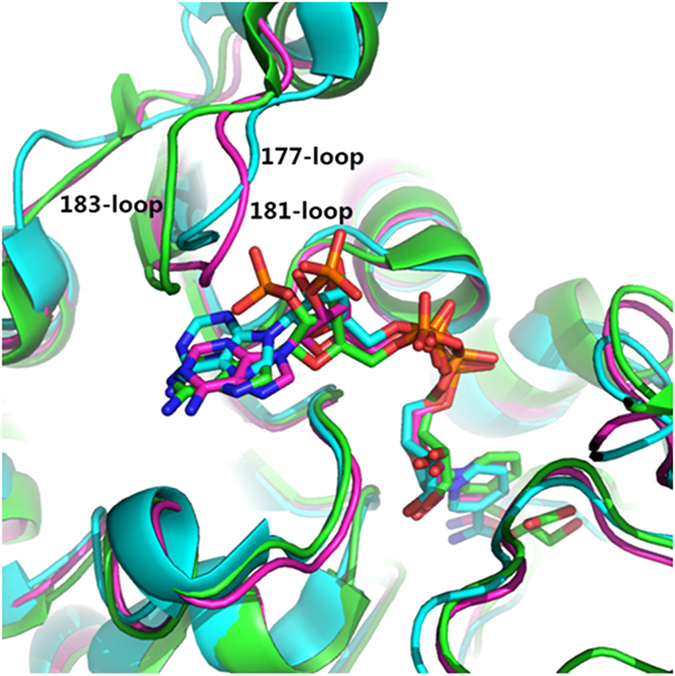

The selection of the template enzyme for rational design is crucial for the success of the targeted mutagenesis, while minimizing the difference on the structure of enzymes is the principle for minimizing the negative impact on original enzyme activity. In a previous study24, a NADPH binding loop region containing seven amino acid residues from a NADPH-dependent malate dehydrogenase was introduced into the cofactor binding site of the LDH from Thermus thermophilus. Although the cofactor specificity was shifted to NADPH, the activity on NADH was dramatically decreased. It seems likely that the authors24 did not consider the difference in crystal structures of the two proteins when deciding to replace the sequence “DLDRKLA” of LDH with sequence “GSERSFQ” of MDH_EX7. As shown in Fig. 4a, MDH_EX7 has a circle of helix and a loop binding to NADPH, whereas LDH only has a loop binding to NADH. Replacement of the sequence “DLDRKLA” with “GSERSFQ” might generate side-effects as the binding affinity of the substitute might be weakened by improper steric configuration. In such a case, we argue that replacing a shorter sequence “DLDR” of LDH with “GSERSF”, rather than replacing “DLDRKLA”, might generate a better result. The reason is that replacing a shorter sequence “DLDR” of LDH with “GSERSF” might build a similar 3D structure like MDH_EX7.

Figure 4. Alignment of crystal structure and sequence of cofactor binding loops.

(a) MDH EX7(1WZI) and LDH(2E37). (b) d-LDH (1J49) and GR(2DBQ).

In this study, we selected the glyoxylate reductase (2DBQ) from Pyrococcus horikoshii OT3 for comparison with the d-LDH (1J49) from L. delbrueckii 11842, as the length of cofactor binding loops of these two enzymes are the same (Fig. 4b). The only notable difference between cofactor binding pockets of these two enzymes is the NADH binding loop YDIFR of d-LDH (1J49) and the NADPH binding loop YSRTR from 2DBQ. Such a minor modification may account for why the activity of d-LDH* on NADPH is comparable with that of wild-type d-LDH on NADH, which is superior compared with previous studies3,22,24. The structure of 1J49 and 2DBQ is almost identical except for the difference of the two loops, thus the impact of the targeted mutagenesis on protein structure was minimized. Besides the YDIFR loop, 1J49 also contains other NADH binding sites in its cofactor binding pocket15. The residue S180 in the substitute loop YSRTR may interact with the ribose group of NADH, which might explain the significantly increased activity of d-LDH* on NADH upon engineering.

Taken together, a novel d-LDH*, with much higher activity on NADPH and improved activity on NADH, was obtained based on our discovery of the only notable different loop between NADH and NADPH binding pockets. Such a superior d-LDH* will encourage researchers to use NADPH-rich cells, such as cyanobacteria, as hosts for d-lactate production. In addition, it provides an example to show how rational design can be used to engineer enzymes for altering its cofactor specificity without affecting its original activity.

Materials and Methods

Chemicals and reagents

All chemicals and solvents were purchased form Sigma-Aldrich unless otherwise specified. PrimeSTAR HS DNA Polymerase, pMD-18t-simple vector were purchased from Takara, while restriction enzyme and T4 DNA ligase were purchased from New England BioLabs.

Crystal structure alignment and analysis

Crystal structures of 1J4915 (d-LDH), 2DBQ17 (a glyoxylate reductase from Pyrococcus horikoshii OT3) and 2GCG18 (a glyoxylate reductase from Homo sapiens) were retrieved from the RCSB protein data bank (www.pdb.org), respectively. Alignment of the structure of 1J49 , 2DBQ, and 2GCG were performed using UCSF chimera 1.10.1 software25 and the graph of protein structure was drawn using pymol1.5 software (The PyMOL Molecular Graphics System, Version 1.5 Schrödinger, LLC.).

Strains and growth conditions

E. coli strain DH5α was used for construction of vectors. E. coli strains were cultured in LB medium at 37 °C in a shaking incubator at 200 rpm or on solidified LB plates containing 1.5% (w/v) agar. M9 medium supplemented with 30 g/L glucose as the sole carbon source and 100 mM MOPS as pH buffer was used for d-lactate production. For the measurements of d-lactate production, E. coli strains were first cultured in LB medium until exponential phase. Cells were then harvested by centrifugation at 5000 rpm for 6 min. The pellets were washed twice with M9 medium and re-suspended in M9 medium. These cultures were inoculated into 100 ml anaerobic bottles containing 30 ml M9 medium with an initial OD600 of 0.2, and cultivated at 37 °C. At selected time point, bacterial growth was measured by detecting the optical density at the wavelength of 600 nm and d-lactate production was determined by High Performance Liquid Chromatography (HPLC) described below.

Computer-aided site-directed mutagenesis of d-LDH

The plasmids used and constructed in this study were listed in Table S2. The cloning vector pMD-18t-simple was served as a backbone for all plasmids constructed. pMD-Dldh26 containing Pcpc-Dldh-TrbcL DNA fragment, which consisted of the promoter Pcpc, structural gene d-ldh and terminator TrbcL was used as template. Site-directed mutagenesis was performed to introduce three continuous amino acids mutations to the d-ldh. Nucleotides AGTCGGACC were designed to replace GATATTTTT in the d-ldh to produced D176S (ASP176 → SER), I177R (ILE177 → ARG) and F178T (PHE178 → THR) described below. The mutated Pcpc-Dldh*-TrbcL DNA fragment was obtained by Overlap Extension PCR27. During the first round of PCR, forward primer Pcpc-F (5′-ccgctcgagacctgtagagaagagtccct-3′) and reverse primer ldh*-R (substitution sites underlined, 5′-CTTCTCTAATTCGGGATTCCGGGTCCGACTATAGGCAATAACCTTCGCG-3′) were used to amplify the first intermediate fragment, and forward primer ldh*-F (substitution sites underlined, 5′-CGCGAAGGTTATTGCCTATAGTCGGACCCGGAATCCCGAATTAGAGAAG-3′) and reverse primer Trbcl-R (5′-CCGCTCGAGGCTGTCGAAGTTGAACATCA-3′) were used to amplify the second intermediate fragment, both with pMD-Dldh as the PCR template, these two intermediate fragments were mixed for the second round of PCR using flanking primers Pcpc-F and Trbcl-R to create Pcpc560-Dldh*-TrbcL. The Pcpc-Dldh*-TrbcL DNA fragment was excised using Xho1, followed by insertion into the corresponding site of pSM228.

Expression of protein and enzyme assays

Three milliliter E. coli DH5α cells with or without plasmids grown to OD600 of 2.5 were harvested by centrifugation at 14,000 rpm for 3 min and resuspended in 1 ml TE buffer (10 mM Tris-HCl, 1 mM EDTA pH = 8.0). Cells were broken using an ultrasonic cell disruptor on ice for 5 min and then removed the cell debris by centrifugation at 14,000 rpm for 3 min. Part of the supernatant was used to detect the protein concentration using Bradford method, and the rest was used to analyze the protein expression pattern on 12% SDS-PAGE.

Crude enzymatic activity assays for d-LDH and d-LDH* were performed as described in literature26 to determine the cofactor specificity, by monitoring the decrease in the absorbance of NADH or NADPH at 340 nm. The reaction mixture (200 μL) contained 150 mM sodium phosphate (pH 6.5), 300 μM NADH or NADPH, 2.5 mM MgCl2, and 3 μg crude extract protein. The reaction was initiated by addition of 30 mM sodium pyruvate, all reactions were performed in 96-well plate reader at 30 °C.

To further determine the kinetic parameters of d-LDH and d-LDH*, the two enzymes expressed in E. coli were purified using Immobilized Metal Affinity Chromatography (IMAC)29.

To determine the kinetic parameters of d-LDH and d-LDH*, the activity of d-LDH and d-LDH* under different concentrations of NADH or NADPH were determined. The reaction mixture (200 μL) contained 100 mM PBS buffer (pH 6.5), 2.5 mM MgCl2, 20 mM sodium pyruvate, and different concentrations of NADH or NADPH. One unit of enzyme activity was defined as the amount of enzyme required to convert 1 μmol NAD(P)H into NAD(P)+ per minute. Michaelis-Menten equation was used to calculate the kinetic parameters.

Assay for lactic acid

The lactic acid concentrations in batch culture samples harvested at selected time points were analyzed by HPLC as described previously30. Briefly, cells were removed by centrifugation at 14,000 rpm for 2 min and then the supernatant (700 μL) was filtered and then analyzed by HPLC (Agilent 1260 Infinity Series), equipped with an Aminex HPX-87H ion exchange column (7.8 × 300 mm; Bio-Rad Laboratories, Inc., Hercules, CA, USA) and a refractive index (RI) detector (Agilent). 5 mM aqueous sulfuric acid was used as mobile phage at a flow rate of 0.50 ml/min at 15 °C.

Additional Information

How to cite this article: Meng, H. et al. Engineering a d-lactate dehydrogenase that can super-efficiently utilize NADPH and NADH as cofactors. Sci. Rep. 6, 24887; doi: 10.1038/srep24887 (2016).

Supplementary Material

Acknowledgments

This work was supported by the “Strategic Priority Research Program” of the Chinese Academy of Sciences (XDA07040405), National Basic Research Program of China (973, 2011CBA00800) and the National Natural Science Foundation of China (31470231). We thank Dr. Bo Yu for helpful discussion.

Footnotes

Author Contributions P.L. and J.L. performed protein structure analysis and provide the strategy of rational design. J.Z., Z.C. and H.M. designed the bench research. H.M., H.S. and J.Z. performed bench work. Y.L. designed the project and supervised the research. Y.L., J.Z., P.L. and H.M. wrote the manuscript. All authors analyzed data and discussed the results.

References

- Shi A., Zhu X., Lu J., Zhang X. & Ma Y. Activating transhydrogenase and NAD kinase in combination for improving isobutanol production. Metab Eng 16, 1–10 (2013). [DOI] [PubMed] [Google Scholar]

- Angermayr S., Paszota M. & Hellingwerf K. Engineering a cyanobacterial cell factory for production of lactic acid. Appl Environ Microbiol 78, 7098–7106 (2012). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Angermayr S. et al. Exploring metabolic engineering design principles for the photosynthetic production of lactic acid by Synechocystis sp. PCC 6803. Biotechnol Biofuels 7, 99 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Varman A., Yu Y., You L. & Tang Y. Photoautotrophic production of D-lactic acid in an engineered cyanobacterium. Microb Cell Fact 12, 117 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Carrea G., Bovara R., Cremonesi P. & Lodi R. Enzymatic preparation of 12-ketochenodeoxycholic acid with NADP regeneration. Biotechnol Bioeng 26, 560–563 (1984). [DOI] [PubMed] [Google Scholar]

- Tamoi M., Miyazaki T., Fukamizo T. & Shigeoka S. The Calvin cycle in cyanobacteria is regulated by CP12 via the NAD(H)/NADP(H) ratio under light/dark conditions. Plant J 42, 504–513 (2005). [DOI] [PubMed] [Google Scholar]

- Li C. et al. Enhancing the light-driven production of D-lactate by engineering cyanobacterium using a combinational strategy. Sci Rep 5, 9777 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Okano K., Tanaka T., Ogino C., Fukuda H. & Kondo A. Biotechnological production of enantiomeric pure lactic acid from renewable resources: recent achievements, perspectives, and limits. Appl Microbiol Biotechnol 85, 413–423 (2010). [DOI] [PubMed] [Google Scholar]

- Wang Y., Tashiro Y. & Sonomoto K. Fermentative production of lactic acid from renewable materials: Recent achievements, prospects, and limits. J Biosci Bioeng, http://dx.doi.org/10.1016/j.jbiosc.2014.1006.1003 (2014). [DOI] [PubMed] [Google Scholar]

- Zhou J., Zhang H., Meng H., Zhang Y. & Li Y. Production of optically pure D-lactate from CO2 by blocking the PHB and acetate pathways and expressing D-lactate dehydrogenase in cyanobacterium Synechocystis sp. PCC 6803. Process Biochem 49, 2071–2077 (2014). [Google Scholar]

- van der Woude A. D., Angermayr S. A., Puthan Veetil V., Osnato A. & Hellingwerf K. J. Carbon sink removal: Increased photosynthetic production of lactic acid by Synechocystis sp. PCC 6803 in a glycogen storage mutant. J Biotechnol 184, 100–102 (2014). [DOI] [PubMed] [Google Scholar]

- Zheng Z. et al. Relative catalytic efficiency of ldhL- and ldhD-encoded products Is crucial for optical purity of lactic acid produced by Lactobacillus strains. Appli Environ Microbiol 78, 3480–3483 (2012). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Garvie E. Bacterial lactate dehydrogenases. Microbiol Rev 44, 106–139 (1980). [DOI] [PMC free article] [PubMed] [Google Scholar]

- van de Guchte M. et al. The complete genome sequence of Lactobacillus bulgaricus reveals extensive and ongoing reductive evolution. Proc Natl Acad Sci USA 103, 9274–9279 (2006). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Razeto A. et al. Domain closure, substrate specificity and catalysis of D-lactate dehydrogenase from Lactobacillus bulgaricus. J Mol Biol 318, 109–119 (2002). [DOI] [PubMed] [Google Scholar]

- Petschacher B., Leitgeb S., Kavanagh Kathryn L., Wilson David K. & Nidetzky B. The coenzyme specificity of Candida tenuis xylose reductase (AKR2B5) explored by site-directed mutagenesis and X-ray crystallography. Biochem J 385, 75–83 (2005). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yoshikawa S. et al. Structure of archaeal glyoxylate reductase from Pyrococcus horikoshii OT3 complexed with nicotinamide adenine dinucleotide phosphate. Acta Crystallogr D Biol Crystallogr 63, 357–365 (2007). [DOI] [PubMed] [Google Scholar]

- Booth M. P. S., Conners R., Rumsby G. & Brady R. L. Structural basis of substrate specificity in human glyoxylate reductase/hydroxypyruvate reductase. J Mol Biol 360, 178–189 (2006). [DOI] [PubMed] [Google Scholar]

- Marcheschi R. J., Gronenberg L. S. & Liao J. C. Protein engineering for metabolic engineering: Current and next-generation tools. Biotechnol J 8, 545–555 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li H. & Liao J. C. Development of an NADPH-dependent homophenylalanine dehydrogenase by protein engineering. ACS Synth Biol 3, 13–20 (2013). [DOI] [PubMed] [Google Scholar]

- Wang Q., Ingram L. O. & Shanmugam K. T. Evolution of D-lactate dehydrogenase activity from glycerol dehydrogenase and its utility for D-lactate production from lignocellulose. Proc Natl Acad Sci USA 108, 18920–18925 (2011). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bernard N., Johnsen K., Holbrook J. J. & Delcour J. D175 Discriminates between NADH and NADPH in the coenzyme binding site of Lactobacillus delbrueckii subsp. Bulgaricus D-Lactate dehydrogenase. Biochem Biophys Res Commun 208, 895–900 (1995). [DOI] [PubMed] [Google Scholar]

- Richter N., Zienert A. & Hummel W. A single-point mutation enables lactate dehydrogenase from Bacillus subtilis to utilize NAD+ and NADP+ as cofactor. Eng Life Sci 11, 26–36 (2011). [Google Scholar]

- Tomita T., Kuzuyama T. & Nishiyama M. Alteration of coenzyme specificity of lactate dehydrogenase from Thermus thermophilus by introducing the loop region of NADP(H)-dependent malate dehydrogenase. Biosc Biotechnol Biochem 70, 2230–2235 (2006). [DOI] [PubMed] [Google Scholar]

- Pettersen E. F. et al. UCSF Chimera—A visualization system for exploratory research and analysis. J Comput Chem 25, 1605–1612 (2004). [DOI] [PubMed] [Google Scholar]

- Zhou J. et al. Discovery of a super-strong promoter enables efficient production of heterologous proteins in cyanobacteria. Sci Rep 4, 4500 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vallejo A. N., Pogulis R. J. & Pease L. R. PCR mutagenesis by overlap extension and gene SOE. Cold Spring Harbor Protocols 2008, pdb.prot4861 (2008). [DOI] [PubMed] [Google Scholar]

- Zhou J., Zhang H., Zhang Y., Li Y. & Ma Y. Designing and creating a modularized synthetic pathway in cyanobacterium Synechocystis enables production of acetone from carbon dioxide. Metab Eng 14, 394–400 (2012). [DOI] [PubMed] [Google Scholar]

- Bornhorst J. A. & Falke J. J. Purification of proteins using polyhistidine affinity tags. Method Enzymol 326, 245–254 (2000). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Joseph A. et al. Utilization of lactic acid bacterial genes in Synechocystis sp. PCC 6803 in the production of lactic acid. Biosci Biotechnol Biochem 77, 966–970 (2013). [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.