Abstract

Friction factor is an important element in both flow simulations and river engineering. In hydraulics, studies on the friction factor in turbulent regions have been based on the concept of three flow regimes, namely, the fully smooth regime, the fully rough regime, and the transitional regime, since the establishment of the Nikuradze’s chart. However, this study further demonstrates that combining the friction factor with Reynolds number yields a united formula that can scale the entire turbulent region. This formula is derived by investigating the correlation between friction in turbulent pipe flow and its influencing factors, i.e., Reynolds number and relative roughness. In the present study, the formulae of Blasius and Stricklerare modified to rearrange the implicit model of Tao. In addition, we derive a united explicit formula that can compute the friction factor in the entire turbulent regimes based on the asymptotic behavior of the improved Tao’s model. Compared with the reported formulae of Nikuradze, the present formula exhibits higher computational accuracy for the original pipe experiment data of Nikuradze.

1. Introduction

Fluid turbulence is one of the most intensively studied and most perplexing areas in classical physics [1]. This field comprises a host of properties that represent the most complicated aspects of our physical world: irregularity, diffusivity, rotational flow, and three-dimensionality. Previous researchers,such as Nikuradze [2], Blasius [3], and Strickler [4], have focused mainly on the interrelationship among several variables of turbulent flow, such as the Reynolds number Re, the roughness conditions ε, and the friction factor f. Nearly a century ago, Nikuradze conducted a series of experiments on pipe flow. He measured f against Re in various circular pipes that covered an extensive range of relative roughness ε values. Consequently, a comprehensive but nonlinear correlation among these three parameters was reported [2] and presented in a graph (Fig 1), called Nikuradze’s chart, which became a benchmark in the study of the friction factor in hydraulics.

Fig 1. Friction factor of pipe flow in a rough pipe extracted from Nikuradze’s tabular and graphical presentation [2].

In laminar pipe flow, resistance is caused solely by the viscosity shear stress[5]. The shear stress solved from the energy equation is presented as

| (1) |

where ρ is the fluid density, gis the acceleration due to gravity, r is the radial coordinate measured from the center, and Sis the hydraulic slope.

Simultaneously, shear stress can also be computed from Newton’s law of inner friction [7] as follows (Fig 2):

| (2) |

Fig 2. Diagram of the velocity distribution in a full-flow pipe [6].

By substituting Eq (2) into Eq (1), we obtain du = − ρgSrdr/2μ. When this result is implemented across the entire section, we obtain mean velocity , which corresponds to the Darcy–Weisbach formula f = 2gdS/U2[8]. Hence, we determine f = 64/Re.

In the turbulence region, f passes through the hydraulically smooth, the transitional, and the hydraulically rough regions. In the hydraulically smooth region, the relationship between f and Re is f ~ Re−1/4 according to Blasius [3]. When f Re = 64 in the laminar region, we also maintain the form of f Re; thus, f Re ~ Re3/4 is written for a fully smooth regime. In the hydraulically rough region, the relationship between f and ε is f ~ ε1/3, as suggested by Strickler [4]. Similarly, we obtain f Re ~ Reε1/3. Tao [9] proposed an implicit function G(x) based on these two form-changed formulae to rescale Fig 1 as follows:

| (3) |

where ξ = 2 and Cs = 3×10−5 are adjustable parameters computed by Tao based on the degree of discreteness [9] of the data. G(x) is an implicit function with certain characteristics that conform to the boundary conditions. This function is discussed in the following section.

2. Interpolation Method

2.1 Model Modification

Recently, Gioia et al. [10] modified Strickler’s formula and revised the relationship into f ~ εα, where α = 1/3 + η/2, and η = 0.02 was calculated by Mehrafarin and Pourtolamiilarly in a phenomenon argument [11] by modifying the finding of Goldenfeld [12]. Thus, Strickler’s formula can be modifiedinto f Re ~ εαRe. When the revision proposed by Gioia et al. [10] is considered, Tao’s formula [9] can be revised into

| (4) |

We observed the limited condition of Eq (4) and found that when Re was relatively small, as hinted by Tao [9], Cs was used to ensure Cs Reς εςα → 0; hence, Eq (4) became f Re = G(Re3/4). Consequently, the requirements f Re ~ Re3/4 for Blasius’ formula and f Re ~ (Re)0 for laminar flow can be fulfilled, which is consistent with the laminar regime. When Re is extremely large, Eq (4) can be written as f Re ~ G[Reς(Re3/4−ς + Csεςα)]. In this case, ς > 3/4 is required to guarantee Re3/4−ς → 0 or f Re ~ G[Reς Csεςα)]; thus, to maintain Eq (4)coordination with the revised Strickler’s formula, only G(Reς Csεςα)~(Reς Csεςα)1/ςis required.

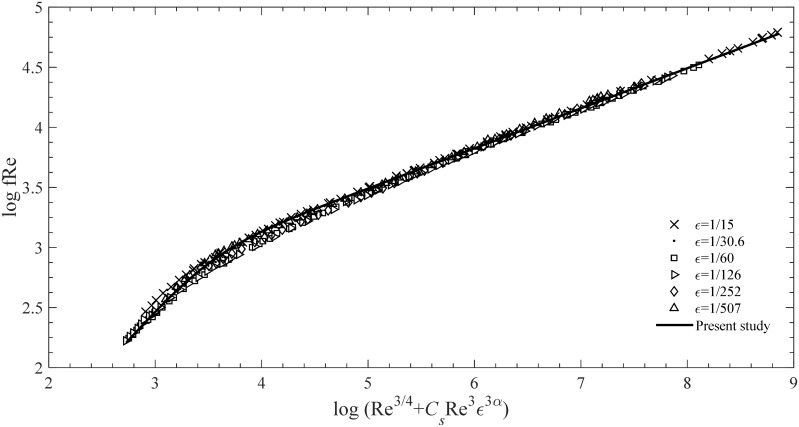

Now, we apply Eq (4) to the turbulent regime, i.e., Eq (4), along with Nikuradze’s turbulence data, as shown in Fig 3. In this regime, Cs = 1×10−8 and ξ = 3 are obtained based on the least squares procedure.

Fig 3. Data of Nikuradze’s experiment rescaled using Eq (4).

2.2 Explicit Formula

In Fig 3, the experimental points generally converge onto a monotonous curve that simplifies Nikuradze’s chart. This curve provides further insight into the dependence of fon Re and ε. Moreover, if this curve is extended at both ends, then its two sides asymptote to two straight lines. That is, when the limit Re is regarded as zero, the parameter Cs Re3 ε3α tends to be zero relative to Re3/4. In this case, we have . Thus, Eq (4) is reduced to f Re = G(Re3/4). To conform to Blasius’ formula f ~ Re−1/4 [3], or equivalently, f Re ~ Re3/4, G(x) should be a linear function. That is, Eq (4) should asymptote into a straight line with a gradient of 1 in a log–log plot. The expression fitted to the experiment data can be written as

| (5) |

where K1 = 1,C1 = −0.5098,and x = Re3/4 +Cs Re3 ε3α.

We now relate this to Eq (4) by obtaining G(Re3/4+CsRe3ε3α) ~ G[Re3(Re9/4+Csε3α)]. For large Reynolds numbers, an equation similar to Eq (3) must satisfy the revised Strickler’s formula [4], namely, f ~ εα,or equivalently, f Re ~ εα Re. Thus, Eq (4) should take the form of G(Re3/4 +Cs Re3 ε3α)~[Re3(Re−9/4 +Csε3α)]1/3 (in this case, Re−9/4 can be regarded as zero). Therefore, we derive an explicit expression for the linear asymptote at a large Re (this expression can also be adopted when turbulence is fully developed):

| (6) |

where K1 = 1/3and C2 = −1.825

Given these two tending character of the curves in Fig 1, we combine Eq (5) and Eq (6) to establish

| (7) |

where log10x0 = (C1−C2)/(K2−K1), and β is the transitional shape parameter first used by Guo [13]. The turbulence region lies between two extended lines; hence, Eq (7) is accessible in the turbulence region. The shape parameter can be determined by using the collocation method suggested by Griffiths and Smith [13]. In particular, for x<<x0, log10[1+(x/x0)β]→0, then Eq (7) is transformed into Eq (5); for x>>x0, log10[1+(x/x0)β]→β(log10 x−log10 x0), then Eq (7) is transformed into Eq (6).

After validating Eq (7) with specific data [14], we obtain an integrated expression for the friction factor that covers an extensive range of turbulence region as follows:

| (8) |

which is plotted in Fig 4, where β = 8/5.

Fig 4. Comparison of the curves obtained from Tao’s model for various ε values with Eq (6).

2.3 Comparison with Nikuradze’s Formulae

In deriving Eq (8), f Re (the product of the friction factor and the Reynolds number) can be regarded as a single parameter to establish an improved mathematical law. Hence, the relationship among f, Re, and ε becomes a relationship among f Re, Re3/4, and Re3 ε3α; such a relationship provides an easier representation of the data to be studied (compare Fig 1 with Fig 4). Therefore, when comparing the results of the present study with those from the original data or the previous formulae, we adopt f Re to replace the single f, thereby verifying the accuracy of our analysis in a clear and convenient manner.

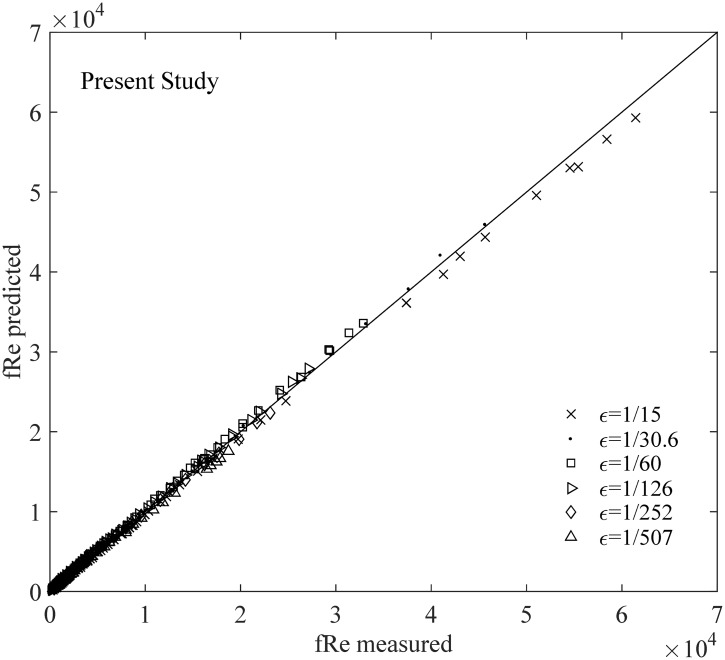

First, the values of f Re that are calculated using Eq (8) are compared with those obtained from the experimental data of Nikuradze for the entire turbulence region. The result presented in Fig 5 and Table 1 shows that Eq (8) exhibits a strong linearity for the entire turbulent regime.

Fig 5. Comparison between the results of the present study and the experimental data for the entire turbulence regime.

Table 1. Prediction Errors for Different Formulae.

Moreover, Nikuradze’s formulae for the smooth zone and the rough zone are compared with the data from his experiments (Fig 6). Nikuradze’s formulae are [6],

| (9) |

for , i.e., in the hydraulically smooth turbulence zone, and

| (10) |

for , i.e., in the hydraulically rough turbulence zone.

Fig 6. Comparison between Nikuradze’s formulae and the experimental data for the smooth and rough turbulence zones.

Finally, the values of f Re predicted using Eq (8) are also validated against the experimental data of Nikuradze for both smooth and rough zones (Fig 7).

Fig 7. Comparison between the present study and the experimental data for the smooth and rough turbulence zones.

Meanwhile, the relative errors computed as |measured−predicted|/|measured| in the aforementioned figures (Figs 5–7) are listed in Table 1. This table shows that the f value from Eq (8), which has an error of 5.4%, is applicable in calculating or predicting the friction factor for different turbulent pipe flows. We suggest that Eq (8) is a useful and reliable method for hydraulic research and applications. The result shows that the relative error obtained from Nikuradze’s formula (9) for the hydraulically smooth turbulence region is 30.8%, which is nearly 10 times higher than that obtained from Eq (8). The relative error of Nikuradze’s formula (10) is 20.1%, which is thrice higher than that obtained from Eq (8). Therefore, the prediction of the present study for the friction factor f (or f Re) is significantly more reliable than that of Nikuradze’s formulae for the two boundary zones. Moreover, unlike Eq (8), Nikuradze did not provide a formula for the transition zone. A single formula that covers all the three zones is clearly more convenient for calculations. Furthermore, Nikuradze’s formula (9) is an implicit expression for f, whereas Eq (8) is explicit.

3. Discussion

In the past, the calculation and analysis of the friction factor f has been a consistent concern among hydraulic researchers because of the significance of this factor in understanding pipe flow and sediment transport. Accordingly, several formulae (Colebrook [15]; Brownlie [16]; Cheng and Chiew [17]; Ligrani and Moffat [18]; Yalin and daSilva [19]) have been proposed in the literature to estimate the friction factor; however, they must be computed separatelyunder laminar, fully smooth, and rough turbulent flow conditions. Compared with these formulae, the proposed formula can scale the entire turbulent regimes, and thus, is definitely more practical to use. To the best of our knowledge, no single formula that canexplicitly calculate the friction factor in various flow regimeshas yet been established, except for the combination approach of Cheng [20]. In his study, the friction factor was assumed to have the function form of , where fL is a friction factor for laminar flow, fT is that for turbulent flow, and ∂ is the weighing factor. However, the present formula is based on the combination of a new parameter, i.e., f Re, in which we do not have to consider the flow regimes. Therefore,the proposed formula is entirely different from Cheng’s formulae.

Motivated by the idea of deriving a single monotonic function, we developed an explicit expression for the friction factor of pipe flow that covered the entire Re range by interpolating the two asymptotic expressions into a single monotonic function through the rescaling the experimental data of Nikuradze. The comparisons between the curves of the data suggest that the predictions obtained using our formula are accurate and reliable, including those that correspond to the transition zone of the original Nikuradze chart. In this study, we have noted and verified that parameter f Re should be regarded as a relevant parameter by checking it against the boundary conditions for Re and ε. A revised rescaled function (Tao [9]) is then possible. This method is proven to be highly helpful in explicitly uncovering the dependence of the friction factor. In hydraulics, the results provided by Nikuradse’s experiments have served as the basis of research on friction resistance. The concepts of a hydraulically smooth zone, a hydraulic transitional zone, and a hydraulically rough zone have been used for nearly a century to study the friction factor given the lack of knowledge on the united relationship among the three zones. Thus, this study is the first to unite these three zones and to provide a united formula that can scale the entire turbulence regime. The convenience brought by uniting the empirical equations does not only considerably aid in the computation of hydraulic parameters, such as frictional head loss, but also further enhances the understanding of flow resistance.

Supporting Information

(PDF)

(XLS)

Acknowledgments

The authors acknowledge the financial support of the Natural Science Foundation of China (Nos. 51439007and 11372232) and the Specialized Research Fund for the Doctoral Program of Higher Education (No. 20130141110016). We also thank Dr. J. Tao for bringing our attention to obtaining the explicit formula of the monotonous curve.

Data Availability

All relevant data are obtained from Nikurades's original paper, which is uploaded in attachment as 'supporting information'.

Funding Statement

The authors, especially WENXIN HUAI, are grateful to the financial support of Natural Science Foundation of China (Grant Nos. 51479007, 11172218, and 11372232) and Specialized Research Fund for the Doctoral Program of Higher Education (Grant No. 20130141110016). The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

References

- 1.Chanson H. (1996). The hydraulics of open channel flow, butterworth-heinemann. Computer Science Logic. [Google Scholar]

- 2.Nikuradze J. (1950). Laws of flow in rough pipes. Washington: National Advisory Committee for Aeronautics. [Google Scholar]

- 3.Blasius, H. (1913). The law of similarity of frictional processes in fluids. originally in German), ForschArbeitIngenieur-Wesen, Berlin, 131.

- 4.Strickler, A. (1981). Contributions to the question of a velocity formula and roughness data for streams, channels and closed pipelines.

- 5.Shames I. H. (1982). Mechanics of fluids. McGraw-Hill. [Google Scholar]

- 6.Li W. and Xu X. (2000), Hydraulics. (Wuhan University of Hydraulic and Electrical Engineering Publishing Company Press; ). [Google Scholar]

- 7.Batchelor G. K. (1973). An introduction to fluid dynamics. cambridge university press. Scenarios, Narratives and Patterns, in Rosemary Luckin; Peter Goodyear; Barbara Grabowski; Sadhana Puntambekar; Niall Winters, 10(1), 454–455. [Google Scholar]

- 8.Yuhong Z., & Wenxin H. (2009). Application of artificial neural network to predict the frictionfactor of open channel flow. Communications in Nonlinear Science and Numerical Simulation, 14(5), 2373–2378. [Google Scholar]

- 9.Tao J., Phys. Rev. Lett. 103(26), 264502 (2009). [DOI] [PubMed] [Google Scholar]

- 10.Gioia G, & Pinaki C. (2005). Turbulent friction in rough pipes and the energy spectrum of the phenomenological theory. Physical Review Letters, 96(4). [DOI] [PubMed] [Google Scholar]

- 11.Mohammad M., & Nima P. (2008). Intermittency and rough-pipe turbulence. Physical Review E Statistical Nonlinear & Soft Matter Physics, 77(77), 463–470. [DOI] [PubMed] [Google Scholar]

- 12.Goldenfeld N., Phys, Rev.Lett. 96, 044503 (2006). [DOI] [PubMed] [Google Scholar]

- 13.Guo J. (2002). Logarithmic matching and its applications incomputational hydraulics and sedimenttransport. Journal of Hydraulic research, 40(5), 555–565. [Google Scholar]

- 14.Griffiths D. V., & Smith I. M. (2010). Numerical methods for engineers.Mcgraw-Hill Publ.Comp., 22(6), 59–68. [Google Scholar]

- 15.Colebrook C. F. (1939). Correspondence. turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. (includes plates). Journal of the Ice, 12(8), 393–422. [Google Scholar]

- 16.Brownlie W. R. (2014). Re-examination of nikuradse roughness data.Journal of the Hydraulics Division, 107(1), 115–119. [Google Scholar]

- 17.Cheng N. S., & Chiew Y. M. (1998). Modified logarithmic law for velocity distribution subjected to upward seepage. Journal of Hydraulic Engineering, 124(12), 1235–1241. [Google Scholar]

- 18.Ligrani P. M., & Moffat R. J. (1985). Structure of transitionally rough and fully rough turbulent boundary layers. Journal of Fluid Mechanics,162(162), 69–98. [Google Scholar]

- 19.Yalin M. S., and Da Silva A. M. A. F. 2001. Fluvial processes, IAHR,Delft, The Netherlands. [Google Scholar]

- 20.Cheng N. S. (2008). Formulae for friction factor in transitional regimes. Journal of Hydraulic Engineering, 134(9), 1357–1362. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

(PDF)

(XLS)

Data Availability Statement

All relevant data are obtained from Nikurades's original paper, which is uploaded in attachment as 'supporting information'.