Abstract

Objectives:

Because of poor bond between resin cement and zirconia ceramics, laser surface treatments have been suggested to improve adhesion. The present study evaluated the effect of CO2 and Nd:YAG lasers on the shear bond strength (SBS) of resin cement to zirconia ceramic.

Materials and Methods:

Ninety zirconia disks (6×2 mm) were randomly divided into six groups of 15. In the control group, no surface treatment was used. In the test groups, laser surface treatment was accomplished using CO2 and Nd:YAG lasers, respectively (groups two and three). Composite resin disks (3×2 mm) were fabricated and cemented to zirconia disks with self-etch resin cement and stored in distilled water for 24 hours. In the test groups four-six, the samples were prepared as in groups one-three and then thermocycled and stored in distilled water for six months. The SBS tests were performed (strain rate of 0.5 mm/min). The fracture modes were observed via stereomicroscopy. Data were analyzed with one and two-way ANOVA, independent t and Tukey’s tests.

Results:

The SBS values of Nd:YAG group (18.95±3.46MPa) was significantly higher than that of the CO2 group (14.00±1.96MPa), but lower than that of controls (23.35±3.12MPa). After thermocycling and six months of water storage, the SBS of the untreated group (1.80±1.23 MPa) was significantly lower than that of the laser groups. In groups stored for 24 hours, 60% of the failures were adhesive; however, after thermocycling and six months of water storage, 100% of failures were adhesive.

Conclusion:

Bonding durability of resin cement to zirconia improved with CO2 and Nd:YAG laser surface treatment of zirconia ceramic.

Keywords: Yttria Stabilized Tetragonal Zirconia; Resin Cements; Lasers, Gas; Lasers, Solid-State

INTRODUCTION

Zirconia ceramic is an alternative to metal restorations in prosthetic treatments and is used for the fabrication of all-ceramic restorations due to its favorable optical and biomechanical properties and biocompatibility [1,2]. Pure zirconia is an unstable compound of zirconia dioxide; therefore, yttria stabilized tetragonal zirconia polycrystalline (Y-TZP) is used in dentistry [2–4].

Generally, zirconia restorations do not form a proper bond to tooth structure and acid etching technique cannot cause significant topographic changes on zirconia ceramic surface for micromechanical bonding to resin cement [3,5, 6]. Evidence shows that bond to Y-TZP ceramics can be improved by using products with chemical affinity to metal oxides [7,8]. It has been suggested that use of resin cements containing 10-methacryloyloxydecyl dihydrogen phosphate (10MDP) may help bond these restorations to tooth structure [3,8–10]. If a sufficient bond does not form between the restoration and tooth structure, retention and fracture resistance of the restoration will decrease; in addition, the odds of recurrent caries increase with a decrease in marginal adaptation [5]. Improving the micromechanical bond between the resin cement and zirconia ceramic requires roughening of the internal surface of ceramic restoration in order to increase its contact area for resin penetration. At present, surface treatment is carried out using techniques such as surface grinding, air abrasion with diamond burs, air abrasion with Al2O3 or silicate particles, selective infiltration etching and recently, irradiation of lasers such as CO2, Er:YAG and Nd:YAG for Y-TZP ceramic [11,12].

Some studies have suggested the use of CO2 and Nd:YAG lasers to enhance the micromechanical interlocking of luting cements into the surface of zirconia ceramics and improve the bond to resin cements and tooth structure [1,13, 14]. However, it has been reported that techniques such as air abrasion, laser pretreatment or air abrasion with the use of silane cannot result in a durable bond between the zirconia ceramic and resin cement after long-term water storage [10,12,15,16]. Since little data and contradictory results have been reported in this regard, the present study was carried out to evaluate the six-month durability of the bond between zirconia ceramic and resin cement after pretreatment of zirconia with CO2 and Nd:YAG lasers. The effects of these two lasers were also compared. Our null hypotheses were: 1-Surface treatment of zirconia ceramic with CO2 and Nd:YAG lasers would have no immediate effect on increasing the SBS of zirconia ceramic to resin cement. 2-Surface treatment of zirconia ceramic with CO2 and Nd:YAG lasers would have no effect on the durability of the bond between the zirconia ceramic and resin cement after thermocycling and storage in water for six months.

MATERIALS AND METHODS

Ninety zirconia disks (Sirona Incoris ZI, Mono L F1, Heidelberg, Germany) were used in this in vitro experimental study. The zirconia disks, measuring 6 mm in diameter and 2 mm in thickness, were fabricated using the CAD/CAM system (Sirona, Inlab, MC XL, Bensheim, Germany) based on the manufacturer’s instructions. The surfaces of the samples were wet polished with silicon carbide paper (600-grit, Matador 991A, Soflex, Starcke GmbH & Co., Melle, Germany) and were treated by airborne abrasion with 50-μm Al2O3 particles at 2-bar pressure (Carlo De Giorgi, model: Sandy 2, Baranzate di Bollate, Italy) to standardize them. The specimens were cleaned by an ultrasonic cleaner (Elmasonic-S60H, Elma, Singen/Htw, Germany) in isopropanol for three minutes. The specimens were dried under air stream before surface treatment. Then, the samples were randomly divided into six groups of 15.

Group one: No laser treatment was carried out in this group as the control group.

Group two: The zirconia disk surface was irradiated with CO2 laser (Smart US 20D, Deka, Florence, Italy). Since different laser parameters have been used in different studies and uniform guidelines have not been suggested, the parameters of the CO2 laser were selected based on previous studies [11,13,14,17].

The CO2 laser (λ=10.6μm) was delivered by a600 μm-diameter hollow ceramic tip at a 90° angle relative to the ceramic surface. The laser parameters were set at 3W, pulse mode with a pulse repetition rate of 100Hz and pulse duration of 160ms. The ceramic tip was hand-adjusted at a distance of approximately 1 mm from the surface. The whole surface of the zirconia disk (6mm in diameter) was lased for 10 seconds at a rate of 2mm/s using horizontal surface scanning technique. Air coolant was used during laser irradiation.

Group three: The surface of zirconia disk was irradiated with Nd:YAG laser (λ=1064nm, Fidelis Plus III, Fotona; Ljubljana, Slovenia). The Nd:YAG laser parameters were selected based on previous studies in order to create micromechanical retention [1,13, 18]. The laser parameters were set at 2W output power, pulse duration of 300μs, pulse energy of 100mJ and pulse repetition rate of 20Hz. Laser energy was delivered by 300μm-diameter optic fiber. The tip of the optic fiber was placed by hand at an approximate distance of 1mm perpendicular to the disk surface. The zirconia disk surface (6mm in diameter) was lased at a rate of 2mm/s using horizontal surface scanning technique for 10 seconds with no water spray or air cooling stream.

Group four: Samples in this group were prepared as in group one but underwent a thermocycling procedure (3000 cycles at 5–55°C with a dwell time of 30 seconds). Then, they were stored in distilled water at 37°C for six months.

Group five: Surface treatment was performed in a manner similar to that in group two using CO2 laser. Then, the samples were thermocycled and stored in distilled water at 37°C for six months.

Group six: Surface treatment was carried out in a manner similar to that in group three using Nd:YAG laser.

Then, the samples underwent a thermocycling procedure and stored in distilled water at 37°C for six months. For evaluation of the micro-morphology of zirconia surface before and after laser pretreatment, one additional specimen in groups one to three was prepared and sputter-coated with gold. The samples were analyzed using a scanning electron microscope (SEM; JSM-6335F, JEOL, Tokyo, Japan) at ×1000 and ×2500 magnifications.

Composite resin disks (Filtek Z250, 3M ESPE, St. Paul, MN, USA) measuring 3 mm in diameter and 2 mm in thickness, were fabricated by packing one bulk of composite resin into transparent plastic molds on glass slabs. Composite was light-cured for 40 seconds at a distance of 1 mm using a light-curing unit (Demi, Kerr Corporation, Middleton, USA) with a light intensity of 1000mW/cm2. The composite resin disks were cemented on the surface of zirconia disks with dual-cure resin cement (Panavia F2.0, Kuraray Co., Osaka, Japan). According to the manufacturer’s instructions, first ED primers A and B were mixed and were then applied to the surface of ceramic and composite resin with a microbrush. After 20 seconds, the resin cement tubes A and B were mixed and applied between the ceramic disks and composite resin. Based on previous studies, each composite resin disk was bonded to a zirconia disk by finger pressure [1,11, 14]. Excess cement was removed and light cured for 20 seconds. In groups one, two and three, the samples were stored in distilled water at 37°C for 24 hours before SBS testing. In groups four, five and six, the samples were thermocycled at 5–55°C for 3000 cycles and stored in distilled water at 37°C for six months before SBS testing. The SBS was determined by subjecting the samples to a shearing force at composite resin-zirconia interface in a mechanical testing machine (Santam, STM-20, Tehran, Iran) with a chisel-shaped blade at a strain rate of 0.5 mm/min.

All the fractured samples were evaluated under a stereomicroscope (SZ40, Olympus, Tokyo, Japan) at ×40 magnification by one operator twice to determine the fracture mode. The fracture modes were classified as cohesive (within the cement, within the ceramic or within the composite resin), adhesive (at ceramic-cement or composite resin-cement interface) or mixed (a mixture of adhesive and cohesive fractures).

Normal distribution of data was verified by Kolmogorov-Smirnov test. Data were analyzed by SPSS 13, using two-way ANOVA, independent t-test, one-way ANOVA and Tukey’s HSD tests. Alpha of 0.05 was considered for type 1 error and in conjunction, the adjusted p-value to limit the family error was considered to be 0.02 for Tukey’s test.

RESULTS

Table 1 presents the mean values and standard deviations of SBS immediately (storage for 24 hours) and after thermocycling and storage in water at 37°C for six months in the groups.

Table 1.

The mean shear bond strength values and standard deviations (SD) of groups

| Groups | Non thermocycled | Thermocycled and stored for 6 months |

|---|---|---|

| Control | 23.35± 3.12 | 1.80± 1.23 |

| Nd:YAG laser | 18.95± 3.46 | 4.77± 1.72 A |

| CO2 laser | 14.00± 1.96 | 3.70± 1.56 A |

N=15 and all groups were significantly different by Tukey’s test, except the groups with the same superscripted letters (Adjusted P>0.02)

The highest and lowest mean SBS values were observed in the control group with water storage for 24 hours (23.35±3.12MPa) and in the untreated laser group with thermocycling and water storage for six months (1.80±1.23 MPa), respectively.

Based on Kolmogorov-Smirnov test, the data were distributed normally. Therefore, parametric two-way ANOVA was used for data analysis. Two-way ANOVA showed that surface preparation with laser (P<0.001) and thermocycling and water storage for six months at 37°C (P<0.001) affected the SBS of resin cement to zirconia ceramic. Since the interaction of these two factors on SBS was significant (P<0.001), independent t-test and one-way ANOVA for both storage times were performed. Independent t-test showed significant differences between SBS values of immediately tested groups vs. thermocycled/water stored groups (P<0.001). The one-way ANOVA for the immediately tested groups (24 hours) revealed significant differences in SBS between the groups (P<0.001).

Comparison of the groups with Tukey’s HSD test showed that use of Nd:YAG and CO2 lasers resulted in a significant decrease in SBS values compared to the control group (P<0.001).

However, the SBS of resin cement after zirconia ceramic surface treatment with Nd:YAG laser was significantly higher than that following surface treatment with CO2 laser (P<0.001).

In samples subjected to thermocycling and six months of water storage, one-way ANOVA and post-hoc Tukey’s HSD test showed a significant increase in the SBS of resin cement to zirconia ceramic after surface treatments with Nd:YAG (P<0.001)and CO2 lasers (P=0.014) compared to the untreated laser group. Tukey’s HSD test showed that after thermocycling and water storage, the mean value of bond strength in the Nd:YAG laser group was higher than that in the CO2 laser group; however, this difference was not statistically significant (P>0.02).

Evaluation of the mode of failure in groups tested after 24 hours showed that 60% of the failures were adhesive (between zirconia and cement) and 40% were mixed (between the composite resin and resin cement). In thermocycled and six months water-stored groups, all fractures were adhesive between zirconia ceramic and resin cement. No cohesive failure was observed in the groups.

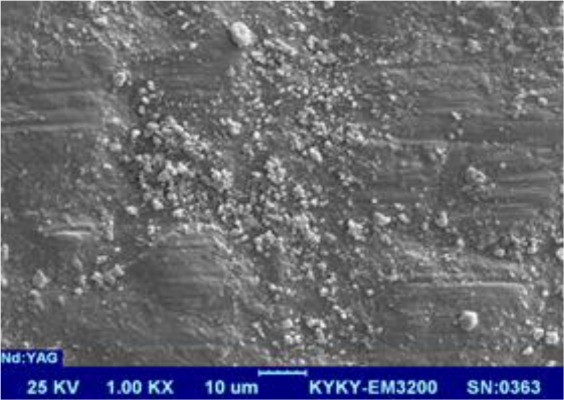

The SEM photographs of zirconia ceramic surface before and after treatment with CO2 and Nd:YAG lasers (Figs. 1 to 5) show that irradiation of CO2 laser to the surface of zirconia ceramic produced microcracks on the ceramic surface. Surface treatment with Nd:YAG laser resulted in enhancement of surface roughness with blister-like spheres and bubbles.

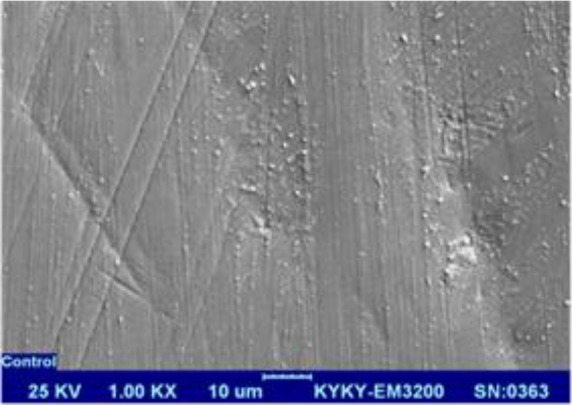

Fig. 1.

Electron microscopic view of zirconia surface in the control group (×1000).

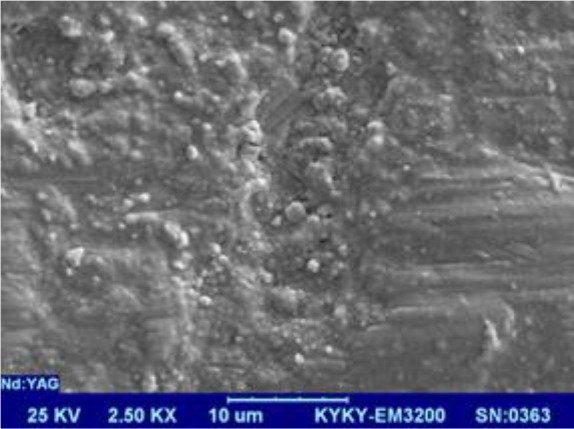

Fig. 5.

Zirconia surface after preparation with Nd:YAG laser (×2500). Note the rough surface containing blister-like spheres.

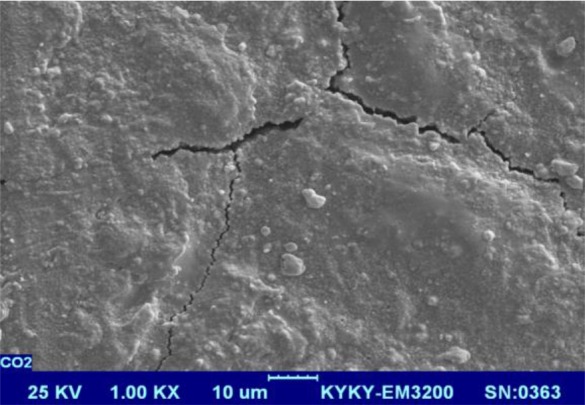

Fig. 2.

An electron microscopic view of zirconia surface after treatment with CO2 laser (×1000). Note the relatively rough surface with microcracks.

DISCUSSION

Bond strength of resin cement to zirconia ceramics has been evaluated in various studies [1,8,11,14,16]. Wegner and Kern reported that diphosphate ester monomers such as MDP exhibit a chemical reaction with zirconium oxide and form a high strength bond with zirconia ceramics [9].

Therefore, in the present study Panavia cement, which contains MDP, was used in all the groups for bonding of composite resin to zirconia ceramic.

In our study, the highest SBS (23.35±3.12MPa) was observed in the control group without thermocycling and water storage, clearly indicating that treatment of zirconia surface with CO2 or Nd:YAG laser without thermocycling and water storage decreases the SBS of resin cement to zirconia (P<0.001).

Therefore, the first null hypothesis of the study was confirmed.

The results of some previous studies are consistent with our finding that application of CO2 [1,10] or Nd:YAG [13,18] laser decreases the bond strength of resin cement to zirconia ceramic. The formation of a damaged layer and micro-cracks due to overheating after CO2 or Nd:YAG laser application to the surface of zirconia ceramic may be responsible for the decrease in SBS compared to the control group [1,13,14,18].

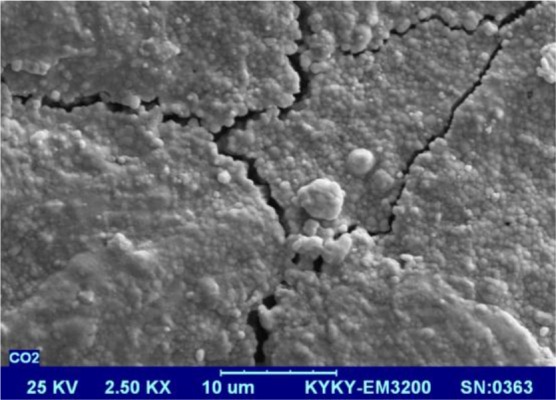

Micro-morphological evaluation with SEM in the current study showed that the damaged surface layer of zirconia had bubbles after irradiation with Nd:YAG laser (Fig. 5) and fine cracks were noted on the surface after treatment with CO2 laser (Fig. 3), which can affect the bond strength of laser-irradiated specimens. However, micro-morphological evaluation of the surface of ceramics showed that CO2 and Nd:YAG laser irradiation produced a rough surface; it is speculated that resin penetration into microcracks leads to increased bond strength of resin cement to zirconia. But we observed a decrease in bond strength. This reduction in SBS compared to the control group may be attributed to the formation of a damaged underlying layer and micro-cracks due to overheating following CO2 or Nd:YAG laser application to the surface of zirconia ceramic [1,13,14,18].

Fig. 3.

Zirconia surface after treatment with CO2 laser (×2500); CO2 laser has produced cracks on the surface of zirconia ceramic.

Contrary to the results of the current study, some studies have shown that irradiation of CO2 and Nd:YAG lasers to the zirconia ceramic surface increases the bond strength of resin cement to zirconia ceramic [11,17, 19]. Differences in the results of different studies may be attributed to the differences in laser parameters, resin cement type, thermocycling procedures and duration of water storage.

The critical factors affecting the bond between the resin cement and lased zirconia ceramic are the type of laser and the laser parameters used. Since the most important effect of laser is to convert radiant energy to heat (the thermo-mechanical effect), absorption of laser energy by the surface of the material is the most important interaction between the material and laser [19].Therefore, selection of appropriate laser parameters to change the surface properties of the zirconia surface is of utmost importance. Ural et al. showed that the output power of the laser and the energy level are critical factors affecting the bond strength of resin cement to zirconia ceramic [17].

On the other hand, the results of the current study showed that surface pretreatment with CO2 and Nd:YAG lasers increased the SBS of resin cement to zirconia ceramic after thermocycling and storage in water for six months, compared to the untreated laser group (P<0.001); therefore, the second null hypothesis of the study was refuted.

If the resin cement does not form a chemical bond with zirconia ceramic, thermocycling and water storage may significantly decrease the bond strength in untreated laser group [20,21]. Blister-like globules and the surface cracks on the surface structure of zirconia ceramic in the laser-irradiated groups lead to enhanced roughness and greater penetration of resin; which may contribute to the micromechanical bond strength in laser-irradiated groups [13]. This morphological change caused an increase in the bond strength (through micro-mechanical bonding) compared to the untreated six-month water stored control group.

Foxton et al. evaluated the durability of resin cement bond to zirconia ceramic after pretreatment of the surface with different techniques. They reported that pretreatment of the zirconia ceramic surface with Er:YAG laser did not result in a durable bond between the zirconia ceramic and resin cement [15]. However, the results of the current study showed that use of CO2 and Nd:YAG lasers resulted in a more durable bond between the resin cement and zirconia ceramic compared to the untreated laser group. The discrepancy between the results may be attributed to the low potential of zirconia ceramic for Er:YAG laser energy absorption compared to CO2 and Nd:YAG lasers [13].

In the current study, the lowest bond strength was seen in the untreated laser group subjected to thermocycling and water storage for six months (1.80±1.23 MPa). As mentioned in previous in-vitro studies, water storage and thermocycling are two factors that decrease bond strength; therefore, adhesion of resin cements (especially cements without MDP) is not durable [15,20, 21].

Since the majority of active monomers in the chemical structure of resin cements are hydrophilic resin esters, they are susceptible to hydrolytic degradation in the polymer network after long-term water storage [22,23]. Furthermore, the mismatch between the thermal expansion coefficients of the bonded materials (zirconia ceramic, the luting agent and composite resin) may induce stresses at the ceramic-resin cement interface during thermocycling of the samples and decrease the bond strength [23]. The cumulative effects of water storage, thermocycling and instability of the bonding agent composition explain the decrease in bond strength and durability of bond; consistent with the results of the current study.

Our findings showed that in six-month water-stored samples, there was a significant difference between the untreated laser group and laser-irradiated groups.

After thermocycling and water storage for six months, surface preparation of zirconia with CO2 and Nd:YAG lasers resulted in an increase in SBS compared to the control group (P=0.004 and P=0.000, respectively). As seen in SEM images (Figs. 3 and 4), micro-fine cracks and surface roughness in laser-irradiated samples may help increase resin penetration and micromechanical retention as factors effective in the durability of the bond between cement and ceramic. Some studies have shown that the role of micromechanical retention in bonding increases with an increase in the number of undercuts in zirconia laser-irradiated groups [1,13]. In water-stored samples, the bond strength values were higher in Nd:YAG laser group compared to the CO2 laser group; however, this difference was not statistically significant (P=0.143).

Fig. 4.

An electron microscopic view of zirconia ceramic surface after treatment with Nd:YAG laser (×1000).

The SEM images show that preparation of zirconia surface with Nd:YAG laser results in a surface containing blister-like spheres along with some bubbles, surrounded by a flat porous layer. Such a surface is suitable for micromechanical bonding. However, SEM images in relation to the application of CO2 laser show that surface roughness is associated with micro-cracks; which might have compromised the surface layer of zirconia ceramic (Figs. 3 and 5). Some previous SEM studies on surface micro-morphology after surface treatment with Nd:YAG and CO2 lasers have confirmed these results [1,14].

In groups two and three, laser surface treatment of zirconia ceramic theoretically leads to an increased bond strength via making undercuts and roughening the ceramic surface. However, it should be mentioned that laser irradiation may cause surface and sub-surface destruction of ceramic as well as micro-crack formation, which result in decreased cohesive strength of sub-surface layer of zirconia.

As reduction in cohesive strength of ceramic due to sub-surface destruction is greater than the increase in micromechanical surface bond strength, which happens as the result of higher ceramic surface coarseness, samples with no water storage showed decreased composite to ceramic bond strength. But after passage of time and water storage, this process was completely reversed. Thermocycling and water storage significantly decreased the bond strength in all groups (four, five and six) especially in the untreated laser group (group four) because bond strength of zirconia ceramic surface was achieved not only by micromechanical retention but also by bonding agent used in the current study, which consisted of active MDP monomer with chemical bond to surface. After thermocycling and six months of water storage, chemical bond strength of MDP active agent diminished. By reduction of chemical bond to ceramic surface, the effect of increased surface coarseness and micromechanical bond of undercuts was greater than the chemical bond and subsurface destruction, which increase the bond strength of composite to laser treated surface in comparison to the untreated six-month water stored control group. Further studies are suggested with different parameters of Nd:YAG and CO2 lasers in order to determine the differences in the effects of these two lasers on ceramic surfaces and the bond strength of resin cement to zirconia surface. No cohesive failure mode was found in our study and the evaluation of failure modes after SBS testing showed that the odds of adhesive failure at resin cement-zirconia disk interface decreases with an increase in SBS. In specimens that did not undergo water storage and thermocycling procedures, 60% of failures were adhesive (between the zirconia and cement) and 40% were mixed (between the composite resin and resin cement). In samples thermocycled and stored in water for six months, 100% of the failures were adhesive. Both of these findings are consistent with the results of previous studies [1,13,14,19].

The majority of previous studies have evaluated the short-term bond strength of zirconia ceramic to resin cement after surface treatment with laser; however, evaluation of bond durability is an important clinical factor as well. Therefore, it is suggested that long-term studies be carried out in order to determine guidelines for adhesion of zirconia-based ceramics. Furthermore, there should be considerations regarding the mechanical effect of cracks generated by laser irradiation on zirconia. Strong bond is important but it is not the only factor that determines the performance of zirconia restorations.

CONCLUSION

Based on the results of the present study, laser treatment of zirconia ceramic surfaces with CO2 and Nd:YAG lasers results in an increase in durability of resin cement bond to zirconia ceramic after thermocycling and water-storage for six months.

ACKNOWLEDGMENT

The authors would like to thank the Dental Research Center and the Vice Chancellor of Research of Hamadan University of Medical Sciences for supporting this study.

REFERENCES

- 1-. Paranhos MP, Burnett LH, Jr, Magne P. Effect Of Nd:YAG laser and CO2 laser treatment on the resin bond strength to zirconia ceramic. Quintessence Int. 2011. January; 42( 1): 79–89. [PubMed] [Google Scholar]

- 2-. Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008. March; 24( 3): 299– 307. [DOI] [PubMed] [Google Scholar]

- 3-. Blatz MB, Sadan A, Martin J, Lang B. In vitro evaluation of shear bond strengths of resin to densely-sintered high-purity zirconium -oxide ceramic after long-term storage and thermal cycling. J Prosthet Dent. 2004. April; 91( 4): 356– 62. [DOI] [PubMed] [Google Scholar]

- 4-. Christel P, Meunier A, Heller M, Torre JP, Peille CN. Mechanical properties and short-term in vivo evaluation of yttrium-oxide-partially-stabilized zirconia. J Biomed Mater Res. 1989. January; 23( 1): 45– 61. [DOI] [PubMed] [Google Scholar]

- 5-. Burke FJ, Fleming GJ, Nathanson D, Marquis PM. Are adhesive technologies needed to support ceramics? An assessment of the current evidence. J Adhes Dent. 2002. Spring; 4( 1): 7– 22. [PubMed] [Google Scholar]

- 6-. Luthy H, Loeffel O, Hammerle CH. Effect of Thermocycling on bond strength of luting cements to zirconia ceramic. Dent Mater. 2006. February; 22( 2): 195– 200. [DOI] [PubMed] [Google Scholar]

- 7-. Yoshida K, Tsuo Y, Atsuta M. Bonding of dual-cured resin cement to zirconia ceramic using phosphate acid ester monomer and zirconate coupler. J Biomed Mater Res B Appl Biomater. 2006. April; 77( 1): 28– 33. [DOI] [PubMed] [Google Scholar]

- 8-. Wolfart M, Lehmann F, Wolfart S, Kern M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent Mater. 2007. January; 23( 1): 45– 50. [DOI] [PubMed] [Google Scholar]

- 9-. Wegner SM, Kern M. Long-term resin bond strength to zirconia ceramic. J Adhes Dent. 2000. Summer; 2( 2): 139– 47. [PubMed] [Google Scholar]

- 10-. Tanaka R, Fujishima A, Shibata Y, Manabe A, Miyazaki T. Cooperation of phosphate monomer and silica modification on zirconia. J Dent Res. 2008. July; 87( 7): 666– 70. [DOI] [PubMed] [Google Scholar]

- 11-. Ural C, Kulunk T, Kulunk Ş, Kurt M. The effect of laser treatment on bonding between zirconia ceramic surface and resin cement. Acta Odontol Scand. 2010. November; 68( 6): 354– 9. [DOI] [PubMed] [Google Scholar]

- 12-. Cavalcanti AN, Pilecki P, Foxton RM, Watson TF, Oliveira MT, Gianinni M, et al. Evaluation of the surface roughness and morphologic features of Y-TZP ceramics after different surface treatments. Photomed Laser Surg. 2009. June; 27( 3): 473– 9. [DOI] [PubMed] [Google Scholar]

- 13-. Akyil MS, Uzun IH, Bayindir F. Bond strength of resin cement to yttrium-stabilized tetragonal zirconia ceramic treated with air abrasion, silica coating, and laser irradiation. Photomed Laser Surg. 2010. December; 28( 6): 801– 8. [DOI] [PubMed] [Google Scholar]

- 14-. Akın H, Ozkurt Z, Kırmalı O, Kazazoglu E, Ozdemir AK. Shear bond strength of resin cement to zirconia ceramic after aluminum oxide sandblasting and various laser treatments. Photomed Laser Surg. 2011. December; 29( 12): 797– 802. [DOI] [PubMed] [Google Scholar]

- 15-. Foxton RM, Cavalcanti AN, Nakajima M, Pilecki P, Sherriff M, Melo L, et al. Durability of resin cement bond to aluminum oxide and zirconia ceramics after air abrasion and laser treatment. J Prosthodont. 2011. February; 20( 2): 84– 92. [DOI] [PubMed] [Google Scholar]

- 16-. Cavalcanti AN, Foxton RM, Watson TF, Oliveira MT, Giannini M, Marchi GM. Bond strength of resin cements to a zirconia ceramic with different surface treatments. Oper Dent. 2009. May-Jun; 34( 3): 280– 7. [DOI] [PubMed] [Google Scholar]

- 17-. Ural C, KalyoncuoĞlu E, Balkaya V. The effect of different power outputs of carbon dioxide laser on bonding between zirconia ceramic surface and resin cement. Acta Odontol Scand. 2012. December; 70( 6): 541– 6. [DOI] [PubMed] [Google Scholar]

- 18-. Lin Y, Song X, Chen Y, Zhu Q, Zhang W. Effect of Er:YAG laser irradiation on bonding property of zirconia ceramics to resin cement. Photomed Laser Surg. 2013. December; 31( 12): 619– 25. [DOI] [PubMed] [Google Scholar]

- 19-. Usumez A, Hamdemirci N, Koroglu BY, Simsek I, Parlar O, Sari T. Bond strength of resin cement to zirconia ceramic with different surface treatments. Lasers Med Sci. 2013. January; 28( 1): 259– 66. [DOI] [PubMed] [Google Scholar]

- 20-. Inokoshi M, Kameyama A, De Munck J, Minakuchi S, Van Meerbeek B. Durable bonding to mechanically and/or chemically pre-treated dental zirconia. J Dent. 2013. February; 41( 2): 170– 9. [DOI] [PubMed] [Google Scholar]

- 21-. May LG, Passos SP, Capelli DB, Ozcan M, Bottino MA, Valandro LF. Effect of silica coating combined to a MDP-based primer on the resin bond to Y-TZP ceramic. J Biomed Mater Res B Appl Biomater. 2010. October; 95( 1): 69– 74. [DOI] [PubMed] [Google Scholar]

- 22-. Valandro LF, Ozcan M, Amaral R, Leite FP, Bottino MA. Microtensile bond strength of a resin cement to silica-coated and silanized In-Ceram Zirconia before and after aging. Int J Prosthodont. 2007. Jan-Feb; 20( 1): 70–2. [PubMed] [Google Scholar]

- 23-. Wegner SM, Gerdes W, Kern M. Effect of different artificial aging conditions on ceramic-composite bond strength. Int J Prosthodont. 2002. May-Jun; 15( 3): 267–72. [PubMed] [Google Scholar]