Abstract

Aims:

The purpose of this study was to evaluate the resistance to torsional failure and cyclic fatigue resistance of ProTaper Next (PTN), WaveOne, and Mtwo files in continuous and reciprocating motion.

Settings and Design:

Randomized control trial in a tertiary care setting.

Subjects and Methods:

A total of 10 new size 25.06 taper PTN X2, 25.06 taper Mtwo files, and 25.08 taper WaveOne primary files each was selected. A custom fabricated cyclic fatigue testing device with a 70° angle of curvature and 3 mm width; curvature starting at 6 mm from the tip was used. All instruments were rotated and reciprocated till fracture occurred and time till fracture of each instrument was recorded in seconds. For torsional failure testing 5 mm tip of each file was embedded in composite resin block and uniform torsional stresses (300 rpm, 2.0 Ncm) were applied repetitively by an endodontic motor with auto stop mode until file succumbed to torsional failure. Number of load applications leading to failure was recorded.

Statistical Analysis Used:

Data were analyzed using t-test for equality of means, Pearson correlation, and ANOVA test.

Results:

All the files showed superior resistance to cyclic fatigue in reciprocating motion when compared with continuous rotation mode. WaveOne primary files displayed maximum resistance to cyclic fatigue both in continuous and reciprocating motion. WaveOne primary files also demonstrated maximum resistance to torsional failure followed by PTN with Mtwo files exhibiting least resistance.

Conclusions:

Operating files in reciprocating motion enhances their cyclic fatigue resistance. WaveOne files showed maximum resistance to cyclic fatigue and torsional failure due to their cross-sectional diameter coupled M-Wire technology.

Keywords: Cyclic fatigue, ProTaper Next, reciprocation, torsional failure

INTRODUCTION

Fracturing of rotary nickel-titanium (NiTi) instruments occurs due torsion or flexural fatigue.[1] Torsional fracture occurs when an instrument tip or another part of the instrument is locked in the canal while the shank continues to rotate. When the elastic limit of the metal is exceeded by the torque exerted by the handpiece, fracture of the tip becomes inevitable.[2] Cyclic fatigue failure is reported to occur unexpectedly without any sign of previous permanent deformation. This occurs because of the alternating tension/compression cycles that instruments are subjected to when flexed in the region of maximum curvature of the canal.[3]

Several strategies have been incorporated in the manufacturing process to reduce the incidence of separation of NiTi instruments. These methods include (a) advanced surface treatment or electropolishing that finishes the surface and prevents crack propagation (b) varying the taper within one file and modifying the cross-section, thus reducing the contact area of the instrument with the canal walls (c) heat treatment or thermal processing the optimizes the microstructure of NiTi alloys.[4,5,6,7,8]

Using NiTi instruments in reciprocating motion can enhance the cyclic fatigue resistance.[9] Reciproc (VDW, Munich, Germany) and WaveOne (Dentsply Maillefer, Ballaigues, Switzerland) are two reciprocating systems that are currently available. Various studies conducted using twisted files, Mtwo, RaCe, ProTaper files in reciprocating motion have proved that reciprocation increases the resistance to cyclic fatigue[1,10,11,12]

Mtwo (VDW, Munich, Germany) have shown superior resistance to cyclic fatigue both in rotation and reciprocating motion when compared that of RaCe files.[10] Mtwo and Reciproc files also show a similarity in cross-section. ProTaper Next (PTN) files (Dentsply Maillefer, Ballaigues, Switzerland) which have been recently launched are designed in such a way that the center of mass and or center of rotation is offset. This offset design minimizes the contact between file and dentin and in addition it enhances augering debris out of the canal.[13] They are manufactured using M-Wire technology which in combination with the offset design improves the flexibility along the active portion of the file.[13,14]

However to date, the effect of reciprocating motion on PTN files has not been evaluated, and a comparison of cyclic fatigue resistance of PTN with Mtwo and WaveOne have not been reported much in scientific literature. The null hypothesis is that there exists no difference in cyclic fatigue resistance of PTN, Mtwo, and WaveOne files in continuous and reciprocating motion.

Failure due to the torsional overload is one of the most frequent cause of fracture of NiTi rotary files, and this occurs due to repeated stressing at levels below its yield point.[15,16] When a torque-controlled motor is used, clinically it is possible that repeated locking (and release) of rotary instruments would occur.[17] The probability that rotary instruments are subjected to such repetitive loads is much higher in narrow canals than in wider canals.[18] This study also compares the fracture resistance of PTN, WaveOne, and Mtwo files on the application of repetitive torsional loads.

SUBJECTS AND METHODS

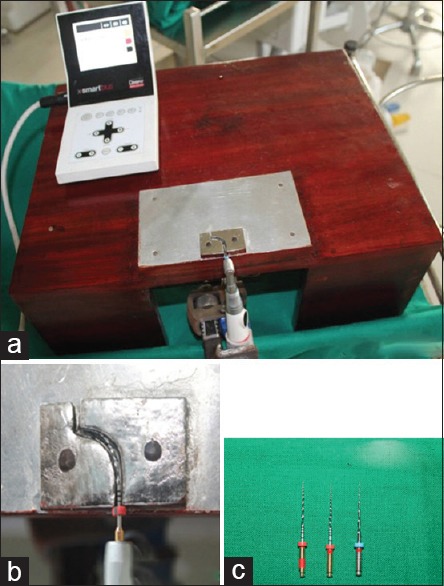

A total of 10 new size 25.06 taper PTN X2, 25.06 taper Mtwo files, and 25.08 taper WaveOne Primary files each was selected [Figure 1c]. All the selected files were 25 mm in length. Each file was screened for any defects before fatigue testing using a dental operating microscope (zoom stereo binocular microscope-111, Hicksville, NY, USA) at × 20 magnification.

Figure 1.

(a) Cyclic fatigue testing apparatus. (b) Artificial canal system. (c) WaveOne, ProTaper next, and Mtwo files

Cyclic fatigue testing

Cyclic fatigue testing was evaluated using a custom fabricated device. The artificial canal system made of tempered steel was a mounted on a framework made of iron and wood to which support for handpiece was attached [Figure 1a]. The canal system, which comprised two adjustable stainless steel blocks had a 70° angle of curvature and 3 mm width; curvature starting at 6 mm from the tip [Figure 1b]. Using X-Smart Plus Motor, files were used in rotation (300 RPM, 2 nm) and reciprocative mode (WaveOne program counter-clockwise [CCW] =170, clockwise [CW] = 50), and the time till fracture in seconds was recorded to evaluate their cyclic fatigue resistance.

After instrumentation with each file, glycerin was used to lubricate the canal system. To precisely determine the time of fracture, the rotating and reciprocating files were observed under dental operating microscope (Seiler Microscope, St Louis, MO, USA) at a magnification of × 25. The first operator performed the fatigue testing while the second operator simultaneously operated the stopwatch.

Torsional failure testing

A static torsional fatigue testing device was custom fabricated for this study. It consisted of the main framework made of wood and iron to which a wooden block with a cubical hole of 5 mm3 volume in its center and support for the handpiece were being attached. Apical 5 mm of the files were rigidly held in place by filling the mold with composite resin Filtek Z350 (3M ESPE, St. Paul, MN, USA), and light cured. Uniform torsional stresses (300 rpm, 2.0 Ncm) were applied repetitively using an X-smart motor until the files succumbed to torsional failure. The number of loads applied till failure was calculated for each file.

Statistical analysis

Cyclic fatigue testing

t-test for equality of means was used to compare the average time till fracture of individual files in the rotation and reciprocating motion

Consecutively, the relationship of the variables rotations and reciprocation were analyzed using Pearson correlation

The average time till fracture in reciprocating motion among the 3 files were compared using ANOVA test

The average time in a fracture in rotation motion among 3 files were compared using ANOVA test.

Resistance to torsional failure

The average number loads applied till failure of among three groups of files was compared using ANOVA test

A P < 0.05 was used as a criterion for statistical significance.

RESULTS

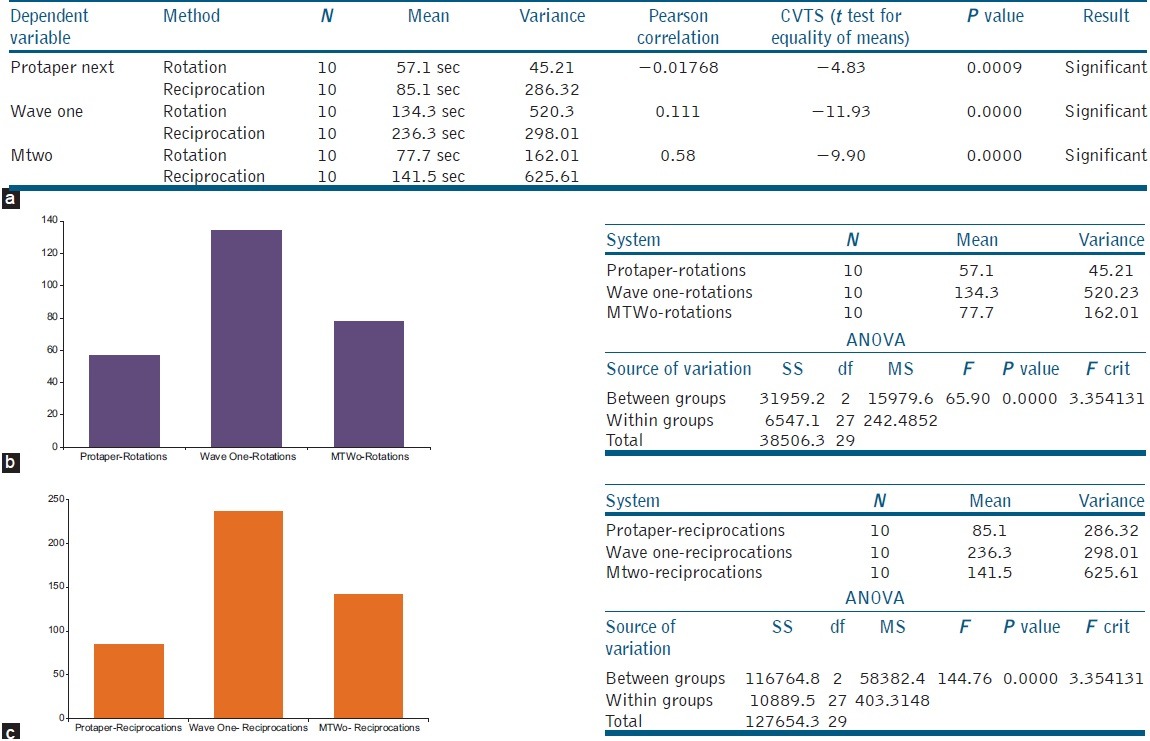

The descriptive statistics for cyclic fatigue resistance in rotation and reciprocating motion of the three respective files are given in Table 1a–c

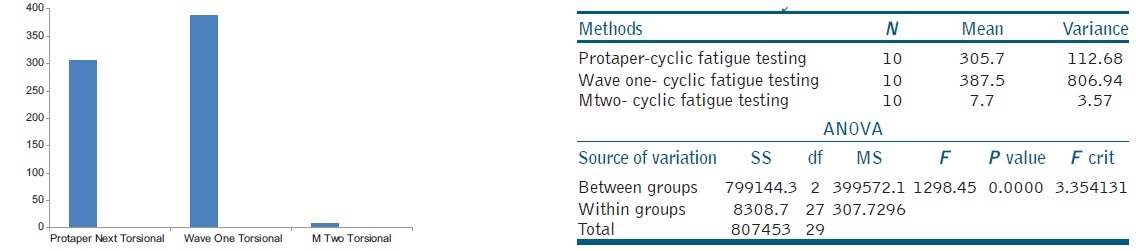

Statistical analysis of resistance to torsional failure is elaborated in Table 2

All the files showed superior resistance to cyclic fatigue in reciprocating motion when compared with continuous rotation mode

WaveOne primary files displayed maximum resistance to cyclic fatigue both in continuous and reciprocating motion

WaveOne primary files also demonstrated maximum resistance to torsional failure followed by PTN with Mtwo files exhibiting least resistance.

Table 1.

(a-c) Descriptive statistics for cyclic fatigue resistance in rotation and reciprocating motion

Table 2.

Statistical analysis of resistance to torsional failure

DISCUSSION

The study compared the cyclic fatigue resistance of three commercial brands available, namely, PTN, WaveOne, and Mtwo files in continuous and reciprocating motion. The study showed that all the files exhibited improved resistance to cyclic fatigue in reciprocating motion than in continuous mode and thus the null hypothesis is rejected.

A study published by Vadhana et al.,[10] proved the superiority of Mtwo and RaCe files to cyclic fatigue in reciprocating motion. This study aims to compare the established superiority of Mtwo files in reciprocating motion to PTN and Wave One files that had M-Wire technology incorporated in them. As PTN files were recently introduced in the market, not much literature is available regarding the use of this file in reciprocating motion. Furthermore, the effect of cross-section on cyclic fatigue and torsional failure was studied. Three files used in the study had 3 different cross-sections. WaveOne primary file with a modified convex triangular cross-section, PTN with offset rectangular cross-section, and Mtwo files with italic “S” shaped cross-section.

In WaveOne all modes incorporating reciprocation (CCW = 170, CW = 50), the CCW movement exceeds the CW movement. CCW movement advances the instrument, at the same time performing cleaning and shaping of the canal. CW movement disengages the instrument from the canal walls before it can taper lock and succumb to failure. Three reciprocating cycles complete one complete reverse rotation and the instrument gradually advances into the canal with little apical pressure required.[19] The stresses are distributed to three points around the working portion of the file, minimizing the opening of surface cracks.[20]

In our study, the cyclic fatigue resistance of PTN files in reciprocating motion was 1.49 times more than that of continuous rotation, whereas WaveOne files showed 1.75 times increase in reciprocating motion. Mtwo files also showed 1.82 times increase in cyclic fatigue resistance in reciprocating motion.

Various factors that can influence the resistance to cyclic fatigue include the diameter, metal mass, flexibility, cross-sectional shape, and surface finish of rotary files.[21] In our study, WaveOne files showed maximum resistance to cyclic fatigue both in the rotation and reciprocating motion. WaveOne primary files have 8% taper (larger core) with a convex triangular cross-section and M-Wire technology which made them clinically superior to Mtwo and PTN files both in the rotation and reciprocating motion.

PTN files have shown superior resistance to cyclic fatigue resistance to Hyflex and ProTaper Universal in earlier studies[14] and were expected to perform better than Mtwo files. The shape of the file at its circumference is another factor that can modify the cyclic fatigue resistance. A file with a greater mass of rounded surface following the cutting edge at its circumference can decrease the forces required to disrupt the molecular attraction.[21] At the radial extremity, PTN files have a more angular surface because of their rectangular cross-section in comparison with Mtwo files. This might lead to increased stresses in a small area, which ultimately resulted in cyclic fatigue with less tension.

Elnaghy[14] evaluated the cyclic fatigue of PTN in rotation motion. He used an optimum degree of curvature of 45°. The degree of curvature given for the canal system in this study was 70° measured according to Schneider's method (1971) with curvature starting at 6 mm from the tip. The curvature is severe when compared with root canal configurations encountered in routine endodontic practice. However, this study intended to test the effect of a thermomechanical treatment such as M-Wire technology (PTN and WaveOne) on cyclic fatigue in severe curvatures. The study also evaluated the effect of offset rectangular cross- section and offset center of mass in PTN on the cyclic fatigue in severe curvatures.

The width of the artificial canal system used is 3 mm which is greater than the maximum diameters of all the files used including the 25/0.08 WaveOne primary files. As files of different tapers were used in the study, the canal system was designed in such a way that all the files would be accommodated, but the intimate adaptation of files to canal system was marginally compromised. According to Plotino et al.,[22] fracture caused by fatigue through flexure occurs because of metal fatigue. The instrument does not bind in the canal, but it rotates freely in a curvature, generating tension/compression cycles at the point of maximum flexure until the fracture occurs. As files of different tapers were intended to freely rotate in the curved canal with minimal cutting, intimate adaptation had to be compromised.

All files were used in rotation motion at 300 rpm and torque of 2 nm. In reciprocating motion, all files are used in WaveOne mode using an X-Smart Plus motor. In continuous rotation motion, the assessment of the number of cycles to fracture (NCF) can be obtained by simply multiplying the rotational speed by the time elapsed until fracture occurred. However, in reciprocation motion, the NCF can be determined only by knowing the amplitude of the oscillating motion with a constant time unit, which is not provided by the manufacturers.[20]

The resistance to torsional failure of NiTi files depends on its cross-sectional design, chemical composition of alloy, and thermomechanical process applied during manufacturing.[23,24,25] The relative size of the instrument in the canal also has a significant influence on the amount of torsional load on the file.[18] In this study to simulate the repetitive locking of NiTi files during canal preparation consistent, torsional stresses were applied using the custom made apparatus. Higher resistance to torsional failure indicated by the higher number of load applications till failure.

In our study, the WaveOne primary files showed the maximum resistance to torsional failure followed by PTN with Mtwo files showing least resistance. Both WaveOne and PTN files manufactured by Dentsply Maillefer incorporate M-Wire innovative heat treatment that resulted in increased resistance to torsion. Furthermore, the cross-sectional area of WaveOne primary file (convex triangular and 8% taper) was greater than of PTN (rectangular offset and 6% taper) which is still superior to Mtwo (Italic “S” shape and 6% taper).

The off-centered rectangular cross-section design of PTN coupled with M-Wire technology might have resulted in increased strength and torsional resistance when compared to Mtwo files.[13,14,26] Various studies have proved that increasing the central core diameter of the file cross-section will improve the resistance of a rotary file to the torsional stress.[8,24,27,28] The rectangular cross-section design of PTN files as compared with the italic “S” shaped cross-section of Mtwo could explain the higher resistance before fracture. Despite having a rectangular cross-section with greater core diameter, the PTN files were inferior to WaveOne primary files having a convex triangular cross-section as the primary files had 8% taper compared with 6% taper of PTN files.

A disadvantage of this study was that we could not standardize on the taper of these files selected. At present, there are three files in the WaveOne single-file reciprocating system available in lengths of 21, 25, and 31 mm:

The WaveOne small file with tip size of ISO 21 and a continuous taper of 6% is used in fine canals

The WaveOne primary file with tip size of ISO 25 and an apical taper of 8% that reduces toward the coronal end is used in the majority of canals

The WaveOne large with a tip size of ISO 40 an apical taper of 8% that reduces toward the coronal end is used in large canals.

If we standardized on the taper of files, i.e., using WaveOne small file with 6% taper, we would lose the standardization on the tip sizes. No studies have yet been published comparing the cyclic fatigue resistance and resistance to torsional failure of WaveOne, ProTaper, and Mtwo files.

CONCLUSION

Within the limitations of the study:

Operating files in reciprocating motion enhance their cyclic fatigue resistance

WaveOne files showed maximum resistance to cyclic fatigue and torsional failure due to their cross-sectional diameter coupled M-Wire technology.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest

REFERENCES

- 1.Pedullà E, Grande NM, Plotino G, Gambarini G, Rapisarda E. Influence of continuous or reciprocating motion on cyclic fatigue resistance of 4 different nickel-titanium rotary instruments. J Endod. 2013;39:258–61. doi: 10.1016/j.joen.2012.10.025. [DOI] [PubMed] [Google Scholar]

- 2.Martín B, Zelada G, Varela P, Bahillo JG, Magán F, Ahn S, et al. Factors influencing the fracture of nickel-titanium rotary instruments. Int Endod J. 2003;36:262–6. doi: 10.1046/j.1365-2591.2003.00630.x. [DOI] [PubMed] [Google Scholar]

- 3.Peters OA. Current challenges and concepts in the preparation of root canal systems: A review. J Endod. 2004;30:559–67. doi: 10.1097/01.don.0000129039.59003.9d. [DOI] [PubMed] [Google Scholar]

- 4.Shen Y, Zhou HM, Zheng YF, Peng B, Haapasalo M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod. 2013;39:163–72. doi: 10.1016/j.joen.2012.11.005. [DOI] [PubMed] [Google Scholar]

- 5.Clauder T, Baumann MA. ProTaper NT system. Dent Clin North Am. 2004;48:87–111. doi: 10.1016/j.cden.2003.10.006. [DOI] [PubMed] [Google Scholar]

- 6.Koch KA, Brave DG. Real world Endo sequence file. Dent Clin North Am. 2004;48:159–82. doi: 10.1016/j.cden.2003.11.004. [DOI] [PubMed] [Google Scholar]

- 7.Twisted File Product Brochure. [Last accessed on 2015 Aug 25]. Available from: http://www.tfwithrphase.com .

- 8.Park SY, Cheung GS, Yum J, Hur B, Park JK, Kim HC. Dynamic torsional resistance of nickel-titanium rotary instruments. J Endod. 2010;36:1200–4. doi: 10.1016/j.joen.2010.02.016. [DOI] [PubMed] [Google Scholar]

- 9.Yared G. Canal preparation using only one Ni-Ti rotary instrument: Preliminary observations. Int Endod J. 2008;41:339–44. doi: 10.1111/j.1365-2591.2007.01351.x. [DOI] [PubMed] [Google Scholar]

- 10.Vadhana S, SaravanaKarthikeyan B, Nandini S, Velmurugan N. Cyclic fatigue resistance of RaCe and Mtwo rotary files in continuous rotation and reciprocating motion. J Endod. 2014;40:995–9. doi: 10.1016/j.joen.2013.12.010. [DOI] [PubMed] [Google Scholar]

- 11.Gambarini G, Rubini AG, Al Sudani D, Gergi R, Culla A, De Angelis F, et al. Influence of different angles of reciprocation on the cyclic fatigue of nickel-titanium endodontic instruments. J Endod. 2012;38:1408–11. doi: 10.1016/j.joen.2012.05.019. [DOI] [PubMed] [Google Scholar]

- 12.De-Deus G, Moreira EJ, Lopes HP, Elias CN. Extended cyclic fatigue life of F2 ProTaper instruments used in reciprocating movement. Int Endod J. 2010;43:1063–8. doi: 10.1111/j.1365-2591.2010.01756.x. [DOI] [PubMed] [Google Scholar]

- 13.Protaper Next Technique - Advanced Endodontics. [Last accessed 2015 Aug 26]. Available from: http://www.Endoruddle.com .

- 14.Elnaghy AM. Cyclic fatigue resistance of ProTaper Next nickel-titanium rotary files. Int Endod J. 2014;47:1034–9. doi: 10.1111/iej.12244. [DOI] [PubMed] [Google Scholar]

- 15.Sattapan B, Palamara JE, Messer HH. Torque during canal instrumentation using rotary nickel-titanium files. J Endod. 2000;26:156–60. doi: 10.1097/00004770-200003000-00007. [DOI] [PubMed] [Google Scholar]

- 16.Askeland DR, Fulay PP. Essentials of Material Science and Engineering. 2nd ed. Toronto, Canada: Cengage Learning; 2009. [Google Scholar]

- 17.Best S, Watson P, Pilliar R, Kulkarni GG, Yared G. Torsional fatigue and endurance limit of a size 30.06 ProFile rotary instrument. Int Endod J. 2004;37:370–3. doi: 10.1111/j.1365-2591.2004.00814.x. [DOI] [PubMed] [Google Scholar]

- 18.Peters OA, Peters CI, Schönenberger K, Barbakow F. ProTaper rotary root canal preparation: Assessment of torque and force in relation to canal anatomy. Int Endod J. 2003;36:93–9. doi: 10.1046/j.1365-2591.2003.00628.x. [DOI] [PubMed] [Google Scholar]

- 19.Webber J, Machtou P, Pertot W, Kuttler S, Ruddle C, West J, et al. The WaveOne single-file reciprocating system. Roots. 2011;1:28–33. [Google Scholar]

- 20.Lopes HP, Elias CN, Vieira MV, Siqueira JF, Jr, Mangelli M, Lopes WS, et al. Fatigue Life of Reciproc and Mtwo instruments subjected to static and dynamic tests. J Endod. 2013;39:693–6. doi: 10.1016/j.joen.2012.11.048. [DOI] [PubMed] [Google Scholar]

- 21.McSpadden JT. Mastering Endodontic Instrumentation. 1st ed. Chattanooga, TN: Cloudland Institute; 2007. pp. 51–6. [Google Scholar]

- 22.Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J Endod. 2009;35:1469–76. doi: 10.1016/j.joen.2009.06.015. [DOI] [PubMed] [Google Scholar]

- 23.Turpin YL, Chagneau F, Vulcain JM. Impact of two theoretical cross-sections on torsional and bending stresses of nickel-titanium root canal instrument models. Endod. 2000;26:414–7. doi: 10.1097/00004770-200007000-00009. [DOI] [PubMed] [Google Scholar]

- 24.Kim TO, Cheung GS, Lee JM, Kim BM, Hur B, Kim HC. Stress distribution of three NiTi rotary files under bending and torsional conditions using a mathematic analysis. Int Endod J. 2009;42:14–21. doi: 10.1111/j.1365-2591.2008.01481.x. [DOI] [PubMed] [Google Scholar]

- 25.Kim HC, Kim HJ, Lee CJ, Kim BM, Park JK, Versluis A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int Endod J. 2009;42:593–602. doi: 10.1111/j.1365-2591.2009.01553.x. [DOI] [PubMed] [Google Scholar]

- 26.Pereira ES, Singh R, Arias A, Peters OA. In vitro assessment of torque and force generated by novel ProTaper Next Instruments during simulated canal preparation. J Endod. 2013;39:1615–9. doi: 10.1016/j.joen.2013.07.014. [DOI] [PubMed] [Google Scholar]

- 27.Xu X, Eng M, Zheng Y, Eng D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J Endod. 2006;32:372–5. doi: 10.1016/j.joen.2005.08.012. [DOI] [PubMed] [Google Scholar]

- 28.Wycoff RC, Berzins DW. An in vitro comparison of torsional stress properties of three different rotary nickel-titanium files with a similar cross-sectional design. J Endod. 2012;38:1118–20. doi: 10.1016/j.joen.2012.04.022. [DOI] [PubMed] [Google Scholar]