Abstract

The development of composite materials that are simultaneously strong and tough is one of the most active topics of current material science. Observations of biological structural materials show that adequate introduction of reinforcements and interfaces, or interphases, at different scales usually improves toughness, without reduction in strength. The prospect of interphase properties tuning may lead to further increases in material toughness. Here we use evaporation-driven self-assembly (EDSA) to deposit a thin network of multi-wall carbon nanotubes on ceramic surfaces, thereby generating an interphase reinforcing layer in a multiscale laminated ceramic composite. Both strength and toughness are improved by up to 90%, while keeping the overall volume fraction of nanotubes in a composite below 0.012%, making it a most effective toughening and reinforcement technique.

Realities of the modern world demand that engineering materials simultaneously possess high stiffness, strength and impact toughness, which is not a trivial task1. Typically, stiff and strong materials such as ceramics are brittle, whereas tough materials, for example rubber, are soft and weak. On an Ashby plot2 this translates into an inverse correlation between strength and toughness3. Such problematic behavior, however, is much less pronounced in natural composites like nacre4, bone5, turtle shell6 or sponge spicule7, where a number of complex reinforcing mechanisms (including crack bridging, crack deflection and geometric/structural intricacy) provide resistance to fracture propagation and impact toughness8. The possibility of applying similar mechanisms in synthetic materials is an important – albeit difficult – target of modern materials science and engineering. Recently a number of research groups have indeed succeeded in preparing remarkably tough composites by adapting such mechanisms to inherently brittle materials9,10,11.

Key parameters affecting the impact toughness of composites are the quality and strength of interfaces (quasi-two-dimensional boundaries between phases) and interphases (three-dimensional regions between phases)12, as schematically illustrated in Fig. 1a. If mechanically weak (in the broad sense), these regions may both limit the material stiffness and divert cracks, leading to an increase in overall toughness13. In fact, it is possible to engineer the interfaces/interphases so as to “direct” cracks and toughen the material. Interfacial failure can therefore be viewed as a “rate determining step”, as in a chemical reaction. A notable example of this approach is the work by Barthelat et al.14, where the controlled introduction of microdefects (and thus the creation of new interfaces) into monolithic glass structures has resulted in more than a hundredfold increase in structural toughness.

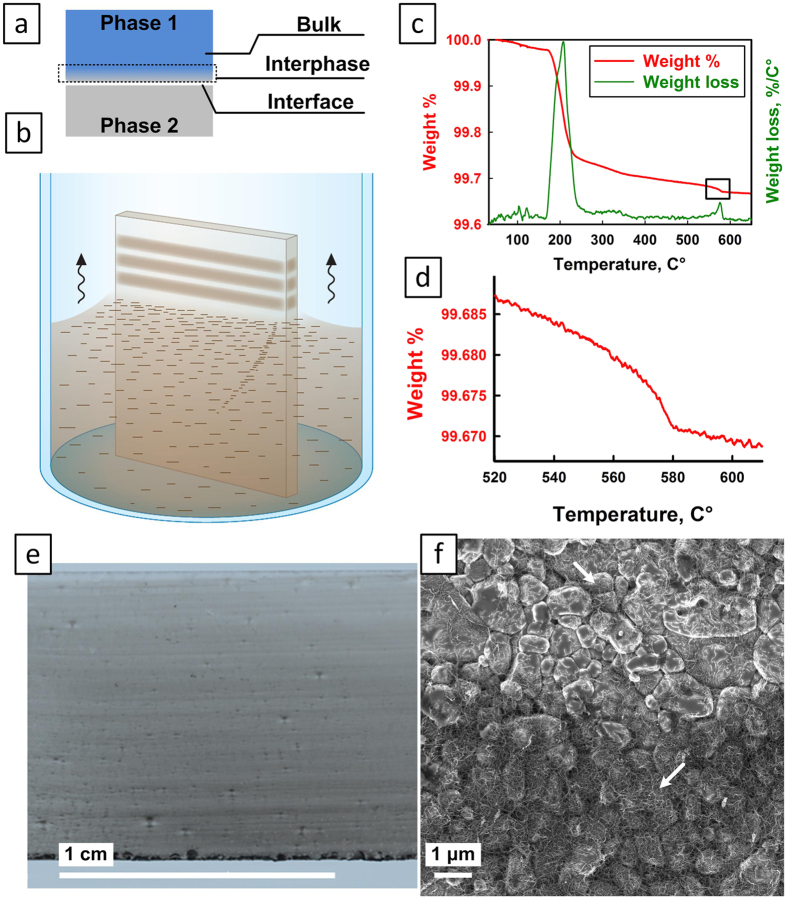

Figure 1. EDSA process.

(a) Schematic representation of 3D interphase. (b) Schematic illustration of the EDSA process. (c–d) TGA weight % (red) and weight loss (green) plots of the CNT-n coated Al2O3 substrate and an enlarged portion of the red graph. (e) A photo of CNT-n coated Al2O3 substrate. (f) SEM image of CNT-n coated Al2O3 substrate, showing the boundary between a darker and lighter region. White arrows point to CNT bundles. Scale bars: (e) 1 cm; (f) 1 μm.

Another potentially effective method to improve material toughness is through the introduction of reinforcing elements, such as nanoparticles or carbon nanotubes (CNTs)15. Either in their single-walled (SWNT) or multi-walled (MWNT) versions, carbon nanotubes seem especially suitable as reinforcing elements due to their exceptional stiffness16, tensile strength17 and elongation to failure18. SWNTs and MWNTs have been successfully used to improve the mechanical characteristics of polymers19, ceramics20 and composite materials21. In most cases, however, CNTs are introduced as bulk reinforcement in the matrix of fiber-based composites, leaving the fiber-matrix interfaces relatively unaffected. As far as we know, however, only little research has been performed to selectively reinforce interphase regions of materials with CNTs. One advantage of such selective reinforcement is the very low volume fraction of CNTs needed to achieve an effect, hopefully positive, compared to bulk reinforcement.

Following our previous work, we concentrated on planar laminated structures made of ceramic layers separated by thin interlayers of polymeric adhesives9. This is inspired by the layered structure of sponge spicules, as explained in our previous work. Here, however, a thin network of carbon nanotubes was created on the surface of the ceramic layers. Note that this is contrast with the traditional method that consists in dispersing CNTs in the polymer matrix prior to composite preparation. We used evaporation-driven self-assembly (EDSA)22, a technique which generates a few nanotube-thick coating on a smooth substrate23 (Fig. 1b). In essence, the EDSA technique is based on the self-assembly process that occurs to dispersed particles or nanotubes upon evaporation of a solvent24. The dispersed nanotubes arrange themselves on the walls of a container or on any other vertically aligned flat surface. This is commonly known as the “coffee ring effect”, which has been well-studied25. In principle, the thickness and uniformity of the EDSA-produced coating can be precisely controlled. Moreover, EDSA does not require complicated equipment or expensive materials, and can be easily replicated. Additional information on the EDSA process can be found in the SI and references therein.

To create the nanotube network, MWNTs were dispersed in deionized water with the help of an ionic surfactant. Cleaned (using sonication in DI water, then in ethanol and acetone) alumina (Al2O3) slides were placed into specially designed tanks, and immersed in the dispersion. The tanks were left to dry for 72 hours at room conditions under a constant air flow. The solvent gradually evaporated, leaving a thin coating on the alumina surface (Fig. 1b). After complete evaporation, the slides coated with nanotubes were rinsed in ethanol to remove any excess of nanotubes and surfactant, and then analyzed by thermogravimetry (TGA) and electron microscopy. TGA under oxygen resulted (Fig. 1c,d) in a small but not insignificant weight loss (0.012%) at the temperature corresponding to MWNT evaporation26.

Figures 1e,f show an optical photograph of an alumina slide and a SEM image of the network, revealing its morphology at different scales. As seen, the EDSA-induced coating consists of interconnected bundles of CNTs, termed here “CNT network” or CNT-n. Darker and lighter domains or stripes on the specimen (Fig. 1f) correspond to higher and lower MWNT concentrations on the surface; as seen, no region is completely devoid of nanotubes, (for additional high magnification images, refer also to Figure S1 in the SI). The stripes arise due to the nature of the EDSA process22. The SEM image on Fig. 1 was obtained without gold-sputtering of the alumina substrate; thus the CNT-n film is conductive enough to prevent electron microscope beam damage to the sample. The CNT-n thickness was estimated from TGA measurements data (Fig. 1c,d). Assuming the MWNT density to be 1.8 g/cm3.27, the average thickness of the CNT-n coating is 64 nm, thus a few multi-walled nanotubes only, which corresponds well with the SEM observations (the diameter of single nanotubes, based on SEM, is 12–15 nm, see Figure S3 in the SI).

Spin-coating was then used to prepare sandwich-type composites with ceramic layers and polymer interlayers, similarly to what was performed in our previous work9. Two alumina slides with CNT-n coatings and with spin-coated adhesive interlayers of polyvinyl alcohol (PVA) were held together at 120 °C under a constant pressure to evaporate the excess solvent and reduce the amount of air bubbles, resulting in an Al2O3-PVA-Al2O3 sandwich-type composite with a ~2–3 µm thick PVA interlayer (Fig. 2a). Control samples without CNT-n were prepared exactly in the same way. The process was repeated to achieve the desired number of layers (2, 3, 4 and 6). For illustration, Fig. 2a shows a 2-layer composite. After preparation, the composites were carefully cut to the desired dimensions (Figure S5a in the SI) using a diamond saw. Based on the TGA results and the calculated average CNT-n thickness, the average volume fraction of CNT-n in a sandwich composite was found to be 0.025%.

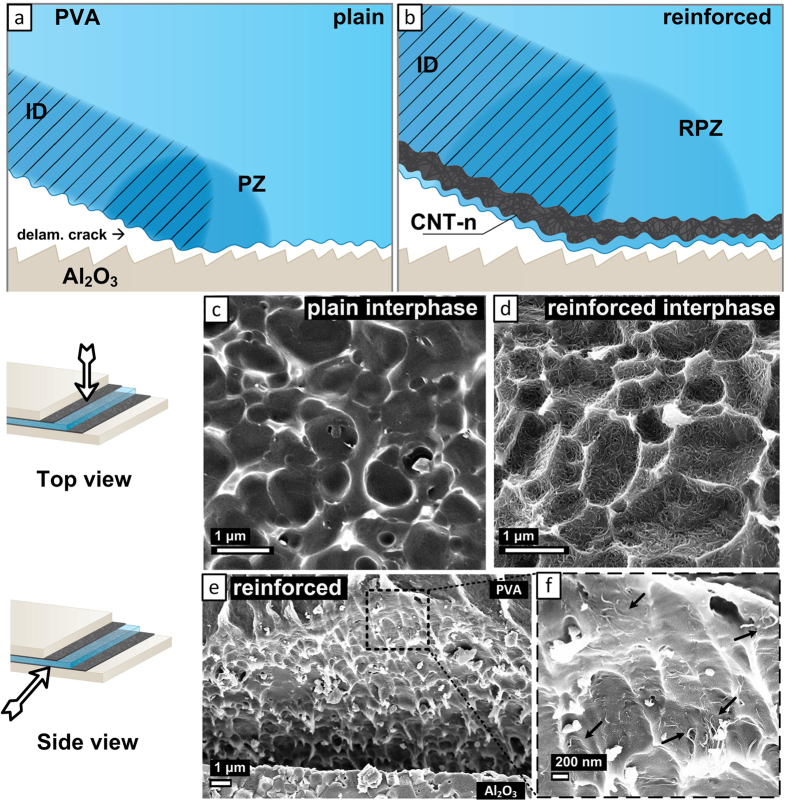

Figure 2. Multiscale layered composite structure and mechanical properties.

(a) Schematic illustration of a 2-layer CNT-n reinforced composite with short descriptions of each layer and preparation stage. (a1–a4) SEM images of various phases of the composite. Full-scale a1–a4 images can be found in the SI. The arrows point to CNT bundles. (b–e) Representative load-displacement plots of the plain and reinforced composites of 2, 3, 4 and 6 layers. Scale bars: (a1–a4) 1 μm.

All composites phases and interphases were carefully studied by electron microscopy (Fig. 2a1–a4). Inset a1 shows an alumina layer prior to the EDSA process; a2 – alumina layer coated with CNT-n after EDSA process (similar to Fig. 1f); a3 – PVA polymer wetting the CNT-n after spin-coating; and a4 – CNT-n completely wetted by and transferred to the polymer interphase. The hardness of the polymer-alumina interphase, with and without CNT-n, was measured by nanoindentation. The specimens that contained nanotube networks were found to be almost 100% harder than those with no CNT-n (0.26 ± 0.02 GPa and 0.14 ± 0.04 GPa, respectively).

3-point bending tests were performed to determine the strength and work of impact fracture (Wf) of the composites. The crosshead speed during all the measurements was relatively high, 3 m/s, to simulate impact. Representative load-displacement plots are shown in Fig. 2b–e for 2, 3, 4 and 6-layer composites, respectively. In all cases the CNT-n reinforced specimens failed at higher loads and had larger area under the load-displacement plot.

Toughness/work of impact fracture and strength were calculated for all specimens as described in the Methods section. The results are summarized in Table 1. The column for “1-layered” specimens relates to single alumina layers with and without CNT-n coating, without polymer interlayer, and is included for comparison purposes. In all cases, reinforced specimens are both stronger and tougher than their plain counterparts. The observed decrease in strength (both in plain and CNT-reinforced composites) with the number of layers is likely due to poor interfacial stress transfer of the polymer interlayers – the more interlayers, the less stress is transferred to the next alumina layers, due to imperfect adhesion between polymer and alumina28. The appearance of air bubbles and matrix defects during composite preparation enhances this effect even further29. Contrasting with this, the work of impact fracture increases with the number of layers, in agreement with both literature and our previous work30,31,9, with the exception of the 6-layered specimens. We assume that the latter exhibit lower mechanical properties, both in terms of strength and Wf, due to less effective heating due to their thickness, and as a result, formation of larger amounts of air bubbles during specimen preparation. In case of “1 layer” specimens, i.e. CNT-n coated alumina layers with no polymer interlayer, the difference between reinforced and plain results is negligible, as expected. In other words, in the absence of a polymer interlayer, CNT-n coating plays no reinforcing role.

Table 1. Mechanical properties of layered composites.

| Number of layers | 1a | 2 | 3 | 4 | 6 |

|---|---|---|---|---|---|

| Strength (plain) [MPa] | 439 ± 125 | 205 ± 63 | 152 ± 32 | 124 ± 22 | 96 ± 17 |

| Strength (reinforced) [MPa] | 483 ± 119 | 239 ± 51 | 179 ± 53 | 186 ± 29 | 131 ± 16 |

| Wf (plain) [kJ/m2] | 0.66 ± 0.29 | 0.99 ± 0.46 | 1.29 ± 0.31 | 2.36 ± 0.42 | 1.99b ± 0.27 |

| Wf (reinforced) [kJ/m2] | 0.72 ± 0.17 | 1.21 ± 0.21 | 2.07 ± 1.46 | 4.02 ± 0.76 | 2.59b ± 0.30 |

aSingle alumina layers without polymer interlayer. This column is included for comparison purposes.

bLower numbers possibly due to ineffective heating during sample preparation.

Our interpretation of the reinforcement mechanism, based on the SEM analysis of the fractured specimens, is illustrated in Fig. 3. Extensive observations, including from previous works9, appear to confirm that layer delamination is the main crack deflection mechanism in this type of composites, arising from the shear stress induced by the 3-point loading configuration30. A delaminating crack, in plain and CNT-n reinforced specimens, is schematically shown in Fig. 3a,b, respectively. As delamination proceeds, the alumina layer, having much higher stiffness, remains unaffected, but the polymer interphase undergoes significant plastic deformation, starting at the tip of delamination crack. In a reinforced specimen, the interphase deformation region (“ID” on Fig. 3a,b) contains a high concentration of carbon nanotubes. Delaminated PVA surface, shown on Fig. 3c,d, contains numerous surface deformations, indicating that PVA has filled the gaps between the surface grains of the ceramic, providing strong cohesive forces for the laminates. In Fig. 3d, almost all CNTs are embedded in the polymer matrix and do not expose their ends out, indicating that the superior mechanical performance of the reinforced composite does not result from occasional nanotube bridging between the ceramic and the PVB, but likely from the plastic deformation of the CNT-reinforced interphase. As the crack grows, the plastic zone around the crack tip moves forward, and the deformed polymer behind the crack tip unloads. This plastic loading and unloading around the crack tip, as well as post-debonding friction between the polymer and alumina32 leads to energy dissipation, which contributes to fracture toughness33.

Figure 3. Reinforcement mechanism.

(a,b) Schematic illustrations of the delaminating crack propagation in a plain (a) and reinforced (b) specimen. ID stands for “interphase deformation”, PZ for “plastic zone”, and RPZ for “reinforced plastic zone”. (c,d) Top-view SEM images of the plain (c) and reinforced interphase. (e) Side-view SEM image of the reinforced interphase. (f) Zoom-in of (e); black arrows show CNT fibers protruding from the PVA matrix. Scale bars: (c–e) 1 μm; (f) 200 nm. Additional SEM images of the interphase can be found in the SI.

As the applied load increases, the plastic strain of the polymer at the interface has to grow to a certain degree to cause the delamination crack growth. We can assume that the interphase with CNT-n embedded into the polymer matrix (Fig. 2a4, refer also to Figures S7 and S8a in the SI) would yield higher interphase shear modulus than the pristine polymer. This is supported by both nanoindentation hardness measurements and published works34. Given the larger interphase shear modulus, during the development of the plastic zone at the crack tip, the plastic strain of the reinforced polymer interphase should require more energy than that of plain polymer, leading to a larger plastic zone. This difference between plain and reinforced plastic zones is schematically illustrated on Fig. 3a,b (“PZ” vs. “RPZ”). The dissipated energy generated by delamination crack growth at the reinforced interphase is thus larger than that for the plain one.

Figure 3e,f, show side-view SEM images of the interphase deformation zone of the reinforced composite, illustrating the many distortions and deformations of the interphase, caused by delamination. Such distortions are common for soft matrix composite materials, and are known as “shear hackles”35. As the delaminating crack progresses, the shear hackles are subjected to tensile forces, tear and pull out (similar to fibers, pulled out of the matrix in an oblique manner36). In the case of a reinforced specimen, the shear hackles contain high concentrations of carbon nanotubes (Fig. 3f), that ensure higher strain energy release rates of the processes mentioned above. In addition, some top-view SEM images of the reinforced interface show longitudinal cracks, with CNT-n branches bridging (Figures S8a,b in the SI). All these factors contribute to the toughening of the CNT-n reinforced specimens, which is confirmed here to be a complex multiscale, multi-mechanism process32. Note that the failure is likely a mixture of Mode I and Mode II failure, however from the shapes of the “hackles” and from observations during the fracture experiments Mode I appears to be more prevalent.

As discussed previously, the yielding strength of the laminates is governed by the efficiency of stress transfer29 and the interfacial shear strength15,37,38 of the composite. We speculate here, based on observed data and published works33, that the CNT-n reinforced interlayers have higher interfacial shear strength and thus provide better stress transfer than plain ones. Since the strength of the composites decreases with the number of polymer interlayers, it can be said that the CNT-n reinforcement somewhat compensates for this effect.

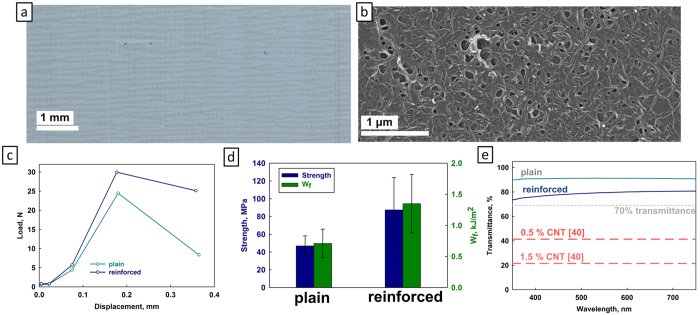

To demonstrate the universality and applicability of the interphase reinforcement mechanism, we prepared two-layer sandwich composites with glass layers (instead of alumina) and PVB interlayers (instead of PVA), mimicking standard two-ply glass widely used in car windows and other applications39. Common microscope slides were used as glass substrates. Figure 4a is an optical photograph of such a slide, with a CNT-n coating arranged in a characteristic “stripe” pattern. Figure 4b shows a SEM micrograph of the CNT-n coated glass slide. The control and reinforced substrates were spin-coated with a PVB solution, and 2-layer composites were prepared in the same manner as before. 3–point bending specimens were shaped into desired dimensions using a diamond saw. The average volume fraction of CNT-n in the glass-PVB sandwich composite was found to be 0.012%.

Figure 4. Glass-PVB composites.

(a) Optical photograph of a glass microscopy slide, showing the CNT-n coating. (b) SEM image of the CNT-n coated glass slide. (c) Representative load-displacement plot of the plain and reinforced glass-PVB composites. (d) Comparison between the plain and reinforced composites’ strength (blue) and work of impact fracture (green). (e) Transmission plots for plain and reinforced glass composites compared to literature analogues (red lines, adapted from [40]) and industrial standard41. Scale bars: (a) 1mm; (b) 1 μm.

Figure 4c shows typical load-displacement traces for the plain and reinforced composites, which again shows a significant positive effect of the CNT-n interphase reinforcement on the fracture process. It thus appears that the reinforcement mechanism is not dependent on the type of substrate or polymer matrix, and is likely to be active in other layered materials based on soft polymer matrices. Figure 4d shows a comparison between the flexural strength and work of impact fracture of plain and reinforced composites. In both cases the advantage of the reinforced samples is apparent.

Another essential parameter of 2-ply glass-PVB composites is the optical transmittance, for example for car windows applications. Figure 4e shows the optical transmittance measurements of plain and reinforced samples, underlining the advantage of the CNT-n coating which allows the use of very small amounts of nanotubes. The resulting ~80% transmittance of the reinforced specimen (dark blue line in Fig. 4e) is not only higher than other CNT-reinforced 2-ply glasses with 0.5 and 1.5% CNT (~40% and ~20% transmittance, respectively, red lines in Fig. 4e)40, but is also higher than the 70% minimum transmittance required for real-life applications in car windows41 (grey line in Fig. 4e).

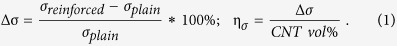

Table 2 demonstrates the effectiveness of interphase reinforcement by comparing strength and toughness reinforcement efficiency for this and selected literature works. Stress reinforcement efficiency (ησ) was calculated by dividing the composite strength increase after reinforcement (Δσ) by the total CNT volume fraction in the composite:

Table 2. Comparison of strength and toughness reinforcement efficiencies for current and selected literature works.

| Specimen | Reinforcement type | CNT vol%a | Δσb, [%] | Reinforcement efficiency (ησ)c | ΔRd, [%] | Reinforcement efficiency (ηR)e | Reference |

|---|---|---|---|---|---|---|---|

| Al2O3-PVA (4L) | Interphase | 0.025% | 50% | 2000 | 70% | 2800 | This work |

| Glass-PVB | Interphase | 0.012% | 89% | 7415 | 90% | 7500 | This work |

| PC | Solvent dispersion | 5% | 32% | 6.4 | – | – | 42 |

| Epoxy | Solvent dispersion | 0.3% | – | – | 17% | 57 | 43 |

| Epoxy | Solvent dispersion | 0.5% | 25% | 50 | 46% | 92 | 44 |

| PMMA | Melt dispersion | 1% | – | – | 170% | 170 | 45 |

| Carbon fiber-Epoxy | Fiber grafting | 0.5% | – | – | 40% | 80 | 21 |

| Al2O3 | Ceramic | 10% | – | – | 194% | 19.4 | 20 |

| Al2O3 | Ceramic | 10% | – | – | 9% | 0.9 | 46 |

| Glass-PVB | Laminate | 1.5% | 30% | 20 | 341% | 227 | 40 |

| Preform-Epoxy | Laminate | 0.3% | – | – | 48% | 160 | 43 |

| SiC fabric-Epoxy | Laminate | 2% | 240% | 120 | 348% | 174 | 47 |

| PEI/PAA | Layer-by-layer | 50% | 2400% | 48 | – | – | 48 |

aWhenever applicable, calculated from weight fraction (wt%) using the CNT density of 1.8 g/cm3 27.

bCalculated by: Δσ = (σreinforced − σplain)/σplain * 100%, where σ is the reported composite yield strength.

cCalculated by: ησ = Δσ/CNT vol%.

dCalculated by: ΔR = (Rreinforced − Rplain)/Rplain * 100%, where R is the reported composite toughness, fracture toughness or work of fracture.

eCalculated by: ηR = ΔR/CNT vol%.

|

The resulting dimensionless number represents the efficiency of strength reinforcement in composites. Toughness reinforcement efficiency (ηR) was calculated by the same manner:

|

where R is one of the toughness parameters: impact toughness, fracture toughness or (as in this work) work of fracture. If the amount of carbon nanotubes in a composite was given in the literature in terms of weight rather than volume fraction, a conversion was made using the CNT density value of 1.8 g/cm3 27. Literature examples include bulk reinforcement of polymers prepared via solvent19,37,42,43,44 and melt45 nanotube dispersions, CNT grafting on fibers in fiber-polymer composites21, bulk reinforcement of ceramic composites via CNT insertion prior to sintering20,46 and CNT-reinforced laminates40,43,47,48. As can be convincingly seen from the data in Table 2, interphase reinforcement is more than an order of magnitude more efficient than other known reinforcement pathways.

To summarize, we present here a new approach designed to reinforce (both in terms of strength and toughness) layered composites using carbon nanotubes. This approach utilizes the premise that interfacial/interphasial failure is a key early step in the failure of layered composites. The method is based upon preparing the composite material in such a way that significant concentrations of carbon nanotube reinforcement are present only in the interphase area (thus, not in the bulk, Fig. 1a), which significantly improves the mechanical properties of the interphase. In this way, very small amounts of carbon nanotubes are enough to produce a significant effect. The reinforcement effect arises from a multiscale combined effect of well-known reinforcement mechanisms (delamination, plastic zone growth, crack bridging, and oblique CNT pull-out). It is shown here that this interphase reinforcement approach is general as it can be applied to various substrates. It also can be scaled up or down from the centimeter-size substrates shown in this manuscript, making it suitable for various production volumes. As such, it has extensive appeal for potential applications.

Methods

The EDSA process

MWNT dispersion was prepared as follows. CVD-grown MWNTs (50 mg) were put into 100 ml of DI water and sonicated for 20 minute. Then, 0.5 g. of sodium dodecyl sulphate (SDS) was added to the dispersion, which was sonicated for a further 2 hours. Resulting dispersion was stable in ambient conditions for several weeks. Al2O3 0.25 mm thick plates (99.6% pure, as-fired, unpolished, purchased from Valley Design Corp., Shirley, MA) were cut using a diamond saw to 30 mm × 10 mm substrate slides. The slides were sonicated in DI water, ethanol and acetone and then put into a specially designed EDSA tank (see Figure S5b in the SI). MWNT dispersion was filtered through cotton wool to remove large aggregates, and then added to the tank until the substrates were completely covered by the liquid. The tanks were left in ambient conditions for 72 hours until all the water evaporated. CNT-n coated substrates were gently rinsed with ethanol to remove excess SDS and dried under an air stream. The same procedure was repeated for the glass substrates.

Composite preparation

Polyvinyl alcohol (PVA) (99.7% purity, 78000 Mw, hydrolyzed; Polysciences, Inc., Taipei, Taiwan) was gradually dissolved in heated DI water until the concentration reached 17 wt%. A Laurell WS650 spin-coater (North Wales, PA) was used at 5000 rpm for 45 s on both CNT-n treated and untreated Al2O3 substrates. The final thickness of a single spin-coated polymer layer was ~1–1.5 μm as measured by gravimetric analysis and by focused ion beam FIB spectroscopy. After spin-coating, two alumina slides with PVA coatings were held together under 1.5 kg pressure and heated to 120 °C for 2 min to evaporate the excess solvent and reduce the amount of air bubbles, resulting in an alumina–polymer–alumina sandwich composite with a ~2–3 μm polymer interlayer in-between. The process was repeated to reach the required layered composite thickness (i.e. 2, 3, 4 and 6 layers).

Glass-PVB composites were prepared in the same way. Polyvinyl butyrate (PVB) was gradually dissolved in heated dimethyl formamide (DMF) until the concentration reached 20 wt%. After spin-coating, two glass slides with PVB coatings were held together under 1.5 kg pressure and heated to 160 °C for 2 min. The rest of the procedure was exactly the same.

3-point bending

Alumina and glass composites of various thicknesses were carefully cut using a diamond saw, resulting in final lateral dimensions of 30 mm × 5 mm. 3-point bending tests were performed on a Bose ElectroForce 3200 UTM instrument, with crosshead speed of 3 m/s, to simulate impact. All specimens were pre-loaded at 2 N prior to fracture. At least seven specimens of each type were tested.

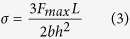

Flexural strength and work of impact fracture were calculated from the load-displacement plots. Strength (σ) was obtained as follows:

|

where L is the support span, b is the specimen width, h is the specimen height and Fmax is the maximum force9.

The work of impact fracture (Wf) was calculated as follows:

|

where SLD is the total area under the load-deflection curve9.

SEM analysis

High-resolution scanning electron microscopy (HRSEM) pictures were taken using SUPRA-55 VP Zeiss and ULTRA-55 Zeiss (Oberkochen, Germany) instruments using an In-Lens detector. Images were collected at acceleration voltage of 3 kV and working distance of 4–5 mm. In some cases, the SEM specimens were used as-is (Figs 1 and S1 in the SI); In other cases to prevent sample charging, the samples were sputtered with gold–palladium alloy prior to SEM imaging, using an Edwards (Sanborn, NY) S150 sputter coater.

Additional Information

How to cite this article: Livanov, K. et al. Interphase tuning for stronger and tougher composites. Sci. Rep. 6, 26305; doi: 10.1038/srep26305 (2016).

Supplementary Material

Acknowledgments

We acknowledge support from the G.M.J. Schmidt Minerva Centre of Supramolecular Architectures. This research was supported by the Minerva Foundation with funding from the Federal German Ministry for Education and Research and from the INNI Focal Technology Area program “Inorganic nanotubes (INT): from nanomechanics to improved nanocomposites”. In addition, this research was supported by THE ISRAEL SCIENCE FOUNDATION (grant No. _727/14). It was also made possible in part by the generosity of the Harold Perlman family. H.D.Wagner is the recipient of the Livio Norzi Professorial Chair in Materials Science. We thank Dr. Sidney Cohen for nanoindentation measurements.

Footnotes

Author Contributions K.L. and H.D.W. designed the research, K.L. and A.N. developed the coating method and prepared the samples, K.L. characterized the samples and performed mechanical measurements, L.Y. developed the reinforcement mechanism, all authors contributed to results analysis and discussion, K.L. and H.D.W. wrote the manuscript.

References

- Ritchie R. O. The conflicts between strength and toughness. Nature Mater. 10, 817 (2011). [DOI] [PubMed] [Google Scholar]

- Wegst U. G. K. & Ashby M. F. The mechanical efficiency of natural materials. Philosoph. Mag. 84, 2167–2181 (2004). [Google Scholar]

- Barthelat F. & Mirkhalaf M. The quest for stiff, strong and tough hybrid materials: an exhaustive exploration. J R Soc Interface 10, 20130711 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Studart A. R. Towards high-performance bioinspired composites. Adv. Mater. 24, 5024–5044 (2012). [DOI] [PubMed] [Google Scholar]

- Weiner S. & Wagner H. D. The material bone: Structure-mechanical function relations. Annu. Rev. Mater. Sci. 28, 271–98 (1998). [Google Scholar]

- Achrai B. & Wagner H. D. Micro-structure and mechanical properties of the turtle carapace as a biological composite shield. Acta Biomaterialia 9, 5890–5902 (2013). [DOI] [PubMed] [Google Scholar]

- Mayer G. New toughening concepts for ceramic composites from rigid natural materials. J. Mechan. Behav. Biomed. Mat. 4, 670–681 (2011). [DOI] [PubMed] [Google Scholar]

- Wegst U. G. K., Bai H., Saiz E., Tomsia A. P. & Ritchie R. O. Bioinspired structural materials. Nature Mater. 14, 23–36 (2015). [DOI] [PubMed] [Google Scholar]

- Livanov K. et al. Tough alumina/polymer layered composites with high ceramic content. J. Am. Ceram. Soc. 98, 1285–1291 (2015). [Google Scholar]

- Demetriou M. D. et al. A damage-tolerant glass. Nature Mater. 10, 123 (2011). [DOI] [PubMed] [Google Scholar]

- Bouville F. et al. Strong, tough and stiff bioinspired ceramics from brittle constituents. Nature Mater. 13, 508–514 (2014). [DOI] [PubMed] [Google Scholar]

- Drzal L. T., Rich M. J. & Lloyd P. F. Adhesion of graphite fibers to epoxy matrices: I. The role of fiber surface treatment”, J. Adhesion 16, 1–30 (1983). [Google Scholar]

- Talreja R. Assessment of the fundamentals of failure theories for composite materials. Comp. Sci. Tech. 105, 190–201 (2014). [Google Scholar]

- Mirkhalaf M., Dastjerdi A. K. & Barthelat F. Overcoming the brittleness of glass through bio-inspiration and micro-architecture. Nature Commun 5, 3166 (2014). [DOI] [PubMed] [Google Scholar]

- Coleman J. N., Khan U., Blau W. J. & Gun’ko Y. K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 44, 1624–1652 (2006). [Google Scholar]

- Demczyk B. G. et al. Direct mechanical measurement of the tensile strength and elastic modulus of multiwalled carbon nanotubes. Mater. Sci. Eng. A 334, 173–178 (2002). [Google Scholar]

- Yu M.-F. et al. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 287, 637 (2000). [DOI] [PubMed] [Google Scholar]

- Walters D. A. et al. Elastic strain of freely suspended single-wall carbon nanotube ropes. Appl. Phys. Lett. 74, 3803 (1999). [Google Scholar]

- Dufresne A. et al. Processing and characterization of carbon nanotube/poly(styrene- co-butyl acrylate) nanocomposites. J. Mater. Sci. 37, 3915–23 (2002). [Google Scholar]

- Zhan G.-D., Kuntz J. D., Wan J. & Mukherjee A. K. Single-wall carbon nanotubes as attractive toughening agents in alumina-based nanocomposites. Nature Mater 2, 38 (2003). [DOI] [PubMed] [Google Scholar]

- Tang Y., Ye L., Zhang Z. & Friedrich K. Interlaminar fracture toughness and CAI strength of fibre-reinforced composites with nanoparticles - A review. Comp. Sci. Tech. 86, 26–37 (2013). [Google Scholar]

- Shastry T. A. et al. Large-area, electronically monodisperse, aligned single-walled carbon nanotube thin films fabricated by evaporation-driven self-assembly. Small 9, 45–51 (2013). [DOI] [PubMed] [Google Scholar]

- Xiao L., Wei J., Gao Y., Yang D. & Li H. Formation of gradient multiwalled carbon nanotube stripe patterns by using evaporation-induced self-assembly. ACS Appl. Mater. Interfaces 4, 3811−3817 (2012). [DOI] [PubMed] [Google Scholar]

- Watanabe S. & Miyahara M. T. Particulate pattern formation and its morphology control by convective self-assembly. Adv. Powder Tech. 24, 897–907 (2013). [Google Scholar]

- Deegan R. D. et al. Capillary flow as the cause of ring stains from dried liquid drops. Nature 389, 827 (1997). [Google Scholar]

- Lehman J. H., Terrones M., Mansfield E., Hurst K. E. & Meunier V. Evaluating the characteristics of multiwall carbon nanotubes. Carbon 49, 2581–2602 (2011). [Google Scholar]

- Laurent C., Flahaut E. & Peigney A. The weight and density of carbon nanotubes versus the number of walls and diameter. Carbon 48, 2989–2999 (2010). [Google Scholar]

- Asloun E. M., Nardin M. & Schultz J. Stress transfer in single-fibre composites: effect of adhesion, elastic modulus of fibre and matrix, and polymer chain mobility. J. Mater. Sci. 24, 1835–1844 (1989). [Google Scholar]

- Leger L. & Creton C. Adhesion mechanisms at soft polymer interfaces. Phil. Trans. R. Soc. A, 366, 1425–1442 (2008). [DOI] [PubMed] [Google Scholar]

- Phillipps A. J., Clegg W. J. & Clyne T. W. Fracture behaviour of ceramic laminates in bending - I. Modelling of crack propagation. Acta Metall Mater. 41, 805–817 (1993). [Google Scholar]

- Phillipps A. J., Clegg W. J. & Clyne T. W. Fracture behaviour of ceramic laminates in bending - II. Comparison of model predictions with experimental data. Acta Metall. Mater. 41, 819–827 (1993). [Google Scholar]

- Kim J.-K. & Ma Y.-W. Engineered interfaces in fiber reinforced composites, 1st edn, Ch. 6, 239–277, (Elsevier, 1998).

- Orowan E. Fracture and strength of solids. Reports on Progress in Physics XII, 185–232 (1948). [Google Scholar]

- Yang L. et al. Interfacial shear behavior of 3D composites reinforced with CNT-grafted carbon fibers. Comp.: A 43, 1410–1418 (2012). [Google Scholar]

- Piggott M. Load bearing fibre composites, 2nd ed. Ch. 6, (Kluwer 2002).

- Norman D. A. & Robertson R. E. The effect of fiber orientation on the toughening of short fiber-reinforced polymers. J. Appl. Polymer Sci. 90, 2740–2751 (2003). [Google Scholar]

- Cadek M., Coleman J. N., Barron V., Hedicke K. & Blau W. J. Morphological and mechanical properties of carbon-nanotube-reinforced semicrystalline and amorphous polymer composites. Appl. Phys. Lett. 81, 5123–5125 (2002). [Google Scholar]

- Fu S.-Y., Feng X.-Q., Lauke B. & Mai Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Comp. B 39, 933–961 (2008). [Google Scholar]

- Ball A. & McKenzie H. W. On the low velocity impact behaviour of glass plates. J De Physique IV 4, 783–8 (1994). [Google Scholar]

- Alhazov D. & Zussman E. Study of the energy absorption capabilities of laminated glass using carbon nanotubes. Comp. Sci. Tech. 72, 681–687 (2012). [Google Scholar]

- Dietz A. G. H. Composite engineering laminates, Ch. 7. 5 (Massachusetts Institute of Technology Press, 1969).

- Eitan A., Fisher F. T., Andrews R., Brinson L. C. & Schadler L. S. Reinforcement mechanisms in MWCNT-filled polycarbonate. Comp. Sci. Tech. 66, 1162–1173 (2006). [Google Scholar]

- Mirjalili V., Ramachandramoorthy R. & Hubert P. Enhancement of fracture toughness of carbon fiber laminated composites using multi wall carbon nanotubes. Carbon 79, 413–423 (2014). [Google Scholar]

- Li D. et al. Toughness improvement of epoxy by incorporating carbon nanotubes into the resin. J. Mater. Sci. Lett. 22, 791–793 (2003). [Google Scholar]

- Gorga R. E. & Cohen R. E. Toughness enhancements in poly(methyl methacrylate) by addition of oriented multiwall carbon nanotubes. J Polym Sci Part B: Polym Phys. 42, 2690–702 (2004). [Google Scholar]

- Wang X., Padture N. P. & Tanaka H. Contact-damage-resistant ceramic/single-wall carbon nanotubes and ceramic/graphite composites. Nature Mater. 3, 539 (2004). [DOI] [PubMed] [Google Scholar]

- Veedu V. P. et al. Multifunctional composites using reinforced laminae with carbon-nanotube forests. Nature Mater. 5, 457 (2006). [DOI] [PubMed] [Google Scholar]

- Mamedov A. A. et al. Molecular design of strong single-wall carbon nanotube/polyelectrolyte multilayer composites. Nature Mater. 1, 190 (2002). [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.