Abstract

A short-term sensitivity loss in LiF:Mg,Cu,P thermoluminescent dosemeters (TLDs) was observed and is described. Its observation occurred during a pre-irradiation anneal with a slightly elevated maximum temperature (5–15°C), which causes notable under-response (5–10 %) of the subsequent read at the recommended time–temperature profile (TTP), which has a peak temperature of 260°C. A subsequent irradiation and reading using the recommended TTP showed partial or complete recovery of the TLD's sensitivity. To the best of our knowledge, there were no publications on possible implications of a one-time 5–15°C overheat of LiF:Mg,Cu,P TLDs during anneal. This is not unusual when several readers with some variations in their heating cycles are used to calibrate and process the same population of dosemeters. A special test to identify if a small uncontrolled overheating of a dosemeter element has occurred was developed and tested. Two practical implications of the effect of a short-term sensitivity loss in LiF:Mg,Cu,P, e.g. inconsistency in results of metrological traceability verification and reporting of false neutron doses, are described in detail. Simple indicators of a small uncontrolled overheating are provided.

INTRODUCTION

The US Navy monitors personnel radiation doses using the Harshaw 8840/8841 thermoluminescent dosemeter (TLD), which is commercially produced by Thermo Fisher Scientific. This dosemeter consists of a TLD card and holder. The card has four LiF:Mg,Cu,P elements encapsulated in Teflon and mounted on an aluminium substrate. Elements 1, 2 and 4 are 0.381 mm thick, and element 3 is 0.254 mm thick. Three elements (1, 2 and 3) are made of the TLD-700H material (7LiF:Mg,Cu,P) and are sensitive primarily to photon and beta radiations. The fourth element uses the TLD-600H (6LiF:Mg,Cu,P) material, which is sensitive to photons, betas and low-energy albedo neutrons. The plastic holder has four discriminating filters to allow measurements of irradiations from gamma rays, betas, X-rays and neutrons. LiF:Mg,Cu,P is one of the most well-studied TLDs. More than a decade of experience at the Naval Dosimetry Center (NDC) has demonstrated the high accuracy, reliability and full compliance of this dosemeter with the national and international dosimetry standards (see(1) for details).

The LiF:Mg,Cu,P glow curve consists of several overlapping glow peaks. The integral intensity of the main peak at approximately 210°C, known as Peak 4, is used for dose measurements(2). Among the many advantages of LiF:Mg,Cu,P are high sensitivity(2, 3), near tissue equivalence and linearity of dose response across a broad dose range(4), e.g. from 1 µGy to 20 Gy(5), and it is neutron sensitive when enriched with 6Li. These advantages make this TLD ideal for broad use in personnel dosimetry applications(1, 4–7). Unfortunately, loss of sensitivity even at small overheats(2, 8–11) and increasing residual signal at repeated irradiation–read cycles are well-known problems in this material. A number of studies document the latter phenomenon, and suggested that recipes to improve stability of this TLD have been tested (see(12, 13), for example). The outcome of sensitivity loss of calibration TLDs at multiple read–irradiation cycles on TLD reader calibration was described in(11). However, to the best of our knowledge, there were no publications on possible implications of a one-time 5–15°C overheat of LiF:Mg,Cu,P TLDs during anneal, which is not unusual when several readers with some variations in their heating cycles are used to calibrate and process the same population of dosemeters.

The Harshaw Model 8800PC is utilised by the Navy to read Harshaw 8841 cards. This reader uses gaseous nitrogen to heat the TLD elements encapsulated in Teflon. It has four thermocouples, which measure and control temperature of the nitrogen that is used to heat the four TLD elements. These thermocouples are located on top (exit) of the four heater nozzles, one for each element. Several factors need to be taken into consideration when choosing an appropriate maximum temperature for the automatic TLD reader. It needs to be higher than the temperature of Peak 4, which has a maximum intensity at 210°C(2). It is necessary to read the whole peak for maximum measured sensitivity. In the Harshaw 8800PC, there is some distance between the nozzle (and thermocouple) and the TLD element to be heated, and there is also a layer of Teflon in between each element and the gas. It was reported in(6) that the maximum temperature on thermocouples is ∼265–270°C before a TLD element begins to lose sensitivity. The Thermo Fisher Scientific recommended maximum temperature of the nitrogen at a nozzle top in the Harshaw 8800PC reader for LiF:Mg,Cu,P elements is 260°C.

There are uncontrolled variations (and fluctuations) in the actual heat temperatures of the TLD card elements on different readers because of variations in the cards and thermocouple mutual positioning as well as accuracy in the thermocouple calibrations. There is also a possibility of a change of thermocouple calibration during its life time because of oxidation of its junction and aging. It cannot be excluded that the actual maximum temperature can be slightly higher or lower on different readers than the nominal maximum value of 260°C. That is why it is important to investigate if this small, and in many cases uncontrolled variation of temperature, can affect dose measurements. Another important related aspect is inter-card variability of the dosimetric Peak 4 temperature. This value is also critical to define the maximum temperature of LiF:Mg,Cu,P TLDs during the read cycle.

The goals of this article are

To report results of the investigation of a one-time small (5–15°C) overheat on sensitivity of LiF:Mg,Cu,P and inter-dosemeter variability of its glow curve Peak 4 temperature,

To describe a developed test that allows identification of such uncontrolled overheats,

To provide practical examples of the implications of short-term uncontrolled overheats on personnel dosimetry operation and ways to deal with them.

MATERIALS AND METHODS

Two standard Harshaw Model 8800PC TLD readers were used in this study to anneal and read TLDs. The following standard time–temperature profile (TTP) was applied (except where it is specifically stated) to the TLDs under investigation: pre-read annealing to remove the low temperature peaks at a constant temperature of 165°C for 10 s, linear heating at 15°C s−1 from 165°C to a maximum temperature of 260°C for acquisition of data over a total time of 16.66 s and post-read annealing for 10 s at 260°C. Each reader has a National Institute of Standards and Technology (NIST) traceable 90Sr irradiator, calibrated to 137Cs dose equivalent, which was used as the source of irradiation. Thirty calibration cards were used once per week to calibrate and accept the reader calibration factor (RCF) for each channel, and 10 calibration cards were used daily to verify that the changes in the RCF for each channel were within ±5 % of 1.00 and the maximum allowed standard deviation for each channel was ±5 %.

The design of the experiment intended to recreate or simulate normal dosimetry laboratory operations using two readers, and one of them is uncontrollably overheating a TLD card on channel 1. Ten new standard TLD cards purchased from Thermo Fisher Scientific were utilised to test card responses on channel 1 after alternating the maximum temperature during the read cycle. Two baseline response tests were performed on the 10 TLD cards using the standard (recommended) TTP with a maximum temperature of 260°C on Reader 1. Following the baseline response, each dosemeter was irradiated to 5 mSv, read and annealed with a temperature of 265°C on channel 1 and 260°C for the other channels on Reader 2. The dosemeters were then irradiated, read and annealed using a temperature of 260°C on all channels on Reader 1 to investigate any effects on the element's response. Following the response test, the dosemeters were irradiated to the same dose again, read and annealed again using a temperature of 260°C to see if channel 1 displayed a response recovery. The test process would be repeated at 270°C and again at 275°C. Altogether there were 12 steps in this experiment, which are graphically presented in Figure 1.

Figure 1.

Flow chart of the overall experiment.

The knowledge of the exact temperature of Peak 4 and its width is critically important for verification that the same TTP can be used for reading the dose of different TLD cards. Even if the exact same technology and the same materials are used to manufacture the TLD cards, the elements of different cards will have slightly different TL properties. A complete glow curve of the element provides unique information of its TL properties. The most important parameters (and their inter-card variability) are temperature and width of the glow curve peaks. The temperature of Peak 4 was determined in 28 TLD cards purchased from Thermo Fisher Scientific from 2002 to 2012 using a specially developed TTP to characterise cards. This TTP uses a 1°C s−1 heat rate from 50 to 280°C. The cards were first annealed using the standard TTP, then irradiated from the internal 90Sr source to 1 mSv and then read using the characterisation TTP. All 28 cards were annealed, irradiated and read within the same day on the same reader.

RESULTS AND DISCUSSION

Figure 2 presents the results of the experiment described in Figure 1. The average over the 10 card response of element 1 was normalised on the average response of two runs of the same 10 cards at a standard TTP (maximum temperature of heat was 260°C).

Figure 2.

Results of average read over 10 TLD cards of element 1 at alternation of maximum temperature of anneal precluded irradiation to 5 mSv. The responses were normalised on the average response of two runs of the same 10 cards at standard TTP (maximum temperature of heat was 260°C). Error bars were calculated as the standard deviation for all 10 TLD cards.

There are at least three conclusions that can be drawn based on the results of this experiment:

A pre-irradiation anneal with a slightly elevated maximum temperature (5–15°C) causes notable under-response (5–10 %) of the subsequent read at the recommended temperature of 260°C or, in other words, loss of sensitivity (steps 3, 8 and 11);

Subsequent irradiation and reading of TLDs at the recommended maximum temperature showed partial or complete recovery of the TLD's sensitivity (steps 4, 9 and 12), e.g. about half of the used TLDs after steps 4, 9 and 12 showed full recovery of sensitivity, and the other half showed partial recovery;

If pre-irradiation anneal and read have the same temperature or the read has a higher elevated maximum temperature than the anneal, then there is no notable loss of sensitivity (steps 2, 7 and 10).

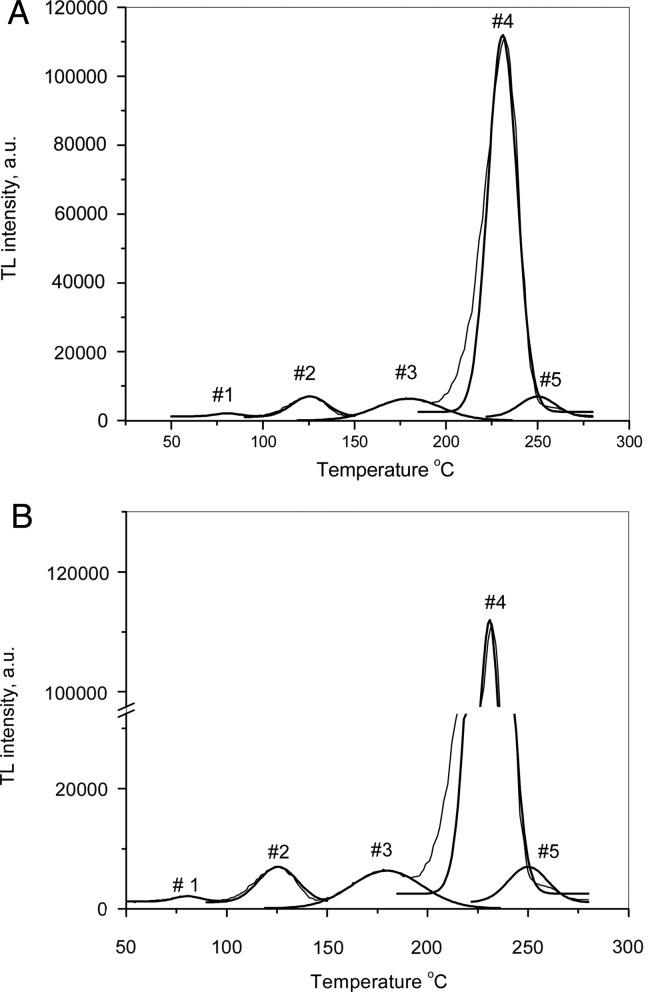

To the best of our knowledge, there were no publications on short-term loss of TLD sensitivity with subsequent full or partial recovery. Observed phenomena can be explained by the complex structure of LiF:Mg,Cu,P glow curves with multiple overlapping peaks. Similar to Figure 2 from(2), which shows a complete glow curve for this TLD material as measured in a chip using direct heat (planchet reader), the glow curve in TLD cards were measured using indirect gaseous heating with the Harshaw 8800PC reader. The glow curve shown in Figure 3 was measured using a 1°C s−1 heat rate at a temperature range of 50–280°C. The use of temperature >280°C was not possible because of the concern that Teflon encapsulation of Harshaw 8841 cards will not tolerate such high temperatures(2). Similar to(2, 14) but using OriginPro 8 SR1 (OrigiLab Corporation), a multi-peak fit by Gaussians five peaks of the glow curve was identified (Figure 3). Table 1 provides a comparison of the maximum peak temperatures determined in this study with those published in(2). The difference in the temperatures' values can be explained by differences in the way the TLD element was heated and the location of the thermocouple. In the case of the Harshaw 8800PC reader, all glow curve peak temperatures (except Peak 1) are significantly higher than those reported in(2), which is not surprising. Figure 3 and Table 1 show that in the vicinity of Peak 4, there are two other tightly overlapping peaks with slightly higher peak temperatures, e.g. Peaks 5 and 6. Annealing at slightly (uncontrolled) higher temperature (5–15°C) can cause emptying traps associated with Peaks 5 and 6. Therefore, the very next read at a lower (standard) temperature will show significantly lower response. The sensitivity recovery mechanism can be associated with a process of redistribution of empty traps between overlapped Peaks 4, 5 and 6 each time during 260°C anneal.

Figure 3.

Representative experimental glow curve of LiF:Mg,Cu,P measured in element 1 of Harshaw 8841 TLD card in range 50–280°C with 1°C s−1 heat rate using Harshaw TLD reader 8800PC and its deconvolution by five Gaussians: (a) general view and (b) view with details for Peaks 1, 2, 3 and 5.

Table 1.

Maximum temperatures of LiF:Mg,Cu,P glow curve peaks as determined by its experimental glow curve deconvolution by Gaussian functions in element 1 in the TLD card (Figure 3) and similar data for TLD chip published in(2).

| Peak # | TLD card Tmax (°C) | TLD chip Tmax (°C)(2) |

|---|---|---|

| 1 | 80 | 78 |

| 2 | 125 | 110 |

| 3 | 180 | 162 |

| 4 | 230 | 210 |

| 5 | 250 | 232 |

| 6 | 242 | |

| 7 | 263 |

The average temperature of Peak 4 was determined in 28 TLD cards as 228 ± 3°C with a total width of Peak 4 determined to be about 60°C. The average sum of half-width and average peak temperature is 258±3°C, which is very close to the manufacturer's recommended maximum temperature of 260°C. On average, the maximum temperature of the standard TTP seems to be in agreement with our results; however, some cards showed a significantly higher temperature in Peak 4 (see Figure 4), which may cause some vulnerability of such cards to the uncontrolled variation of the temperature output from different readers because of the possibility of an incomplete read of Peak 4. The observed inter-card variability can explain why some cards demonstrated full recovery of their sensitivity after small overheat during the anneal, whereas other cards showed only a partial recovery.

Figure 4.

Two extreme glow curves with Peak 4 maximum temperature 227°C (#086728) and 234°C (card #414240) are shown.

In order to estimate the possible effects of the variation of Peak 4 maximum temperature on light output of a TLD element, a Gaussian fit of this peak (Figure 3) can be used. Integral intensity of Peak 4 Gaussian fit with different Peak 4 maximum temperatures in the same temperature range of 165–260°C provides a reasonable estimation of the significance of this effect (Figure 5). One can see that the peak maximum temperature needs to be at least 245°C instead of the standard 230°C to have a noticeable effect (3 %) on dose readout, whereas the maximum measured difference was only 7°C (Figure 4).

Figure 5.

Effect of the shift of Peak 4 temperature on its integral intensity in 165–260°C range as calculated using Gaussian fit of Peak 4 shown in Figure 3.

Results on short-term sensitivity loss in LiF:Mg,Cu,P (Figure 2) underline the importance of identifying such an event. A shift from the centre (channel 100) to the left position of the TLD element glow curve and higher than normal peaks are good indicators that uncontrolled overheating has taken place. Figure 6 shows an example of a suspicious glow curve appearance when compared with the normal one as seen on the reader screen. The other indicator of such occurrences is remarkably lower dose readouts of element 1 when compared with all three other elements. In this study, it was about 10 %. In most cases (except for very low-energy photon or beta exposures), dose readouts of elements 1 and 2 are very close. The NDC even has a policy in some problematic cases (broken element, partial shielding, etc.) to allow substitution of the dose readouts from elements 1 and 2 for either deep or neutron dose equivalents calculations.

Figure 6.

Glow curves appearances at slight uncontrolled overheat of element 1 when compared with normally heated element 2. Standard TTP was used for both the elements.

A simple test has been developed to verify that a small uncontrolled overheating has taken place. At least five TLD cards need to be annealed on the suspicious reader and irradiated to 1 mSv from its internal 90Sr source. Then, the cards need to be read, irradiated to 1 mSv and read again on the other (presumably normally operating) reader with central (at channel 100) positions of all four glow curves. A noticeable under-response (5–10 %) of the first read compared with the second one is a clear indicator of overheating on the first (suspicious reader).

Implications on personnel dosimetry operation of the effect of short-term sensitivity loss in LiF:Mg,Cu,P

At least two direct negative consequences of uncontrolled short-term sensitivity loss in LiF:Mg,Cu,P have been found. A proper identification of the root cause of inconsistency in some tests prevented potential errors in personnel dose reporting. The developed test was able to identify the root cause of the problem as an uncontrolled overheat of element 1 during its anneal (or read) prior to irradiation. The following is a brief description of these incidents.

Inconsistency in results of metrological traceability verification

According to(15, 16), metrological traceability is a property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty. Periodic verification of the metrological traceability is an important requirement for accredited dosimetric service. NDC performs this verification every 6 months. It consists of the direct comparison of two dose readouts after two subsequent irradiations of the same 10 dosemeters from two different irradiators. The first readout is after the irradiation of the 10 TLD cards in holders on a standard poly(methyl methacrylate) (PMMA) slab phantom to 5 mSv from horizontal 137Cs source at a distance of 195 cm at the NIST. The NIST 137Cs source is used in the USA to support the calibration programme for disseminating the primary standard for air kerma(17). The second readout is performed after irradiation of the same 10 TLD cards to the same dose of 5 mSv from the reader's internal 90Sr source, which is routinely used to calibrate the reader, to calibrate dosemeters and to irradiate quality control dosemeters to ensure a proper response. Five control dosemeters are utilised in this procedure to account for radiation background dose accumulated by the irradiated dosemeters between these two irradiations (at NIST and NDC). Prior to each irradiation (at NIST and NDC), the TLDs are annealed to <20 µSv of residual dose on all elements. The established passing limit of traceability verification is ±5 % dose bias between the NIST 137Cs and the NDC 90Sr reader sources. On one occasion, the 90Sr internal sources of three NDC readers showed similar negative biases of about 8–9 % for channel 1; the rest of the channels of all readers were well in the limits of ±5 %. Repetition of the NIST traceability verification with another set of the TLDs for the same readers was successful, e.g. all channels of the internal 90Sr sources on all readers showed bias well below the limit of ±5 %. The internal 90Sr source built in the Harshaw TLD reader 8800PC has a very stable exposure rate, which typically requires no correction. Several hypotheses were proposed to explain the discrepancy between results of two subsequent traceability verifications for the same readers. Among them were

Inconsistent TLD irradiation at NIST,

Change of TLD calibration factors for channel 1.

The first explanation was ruled out because any inconsistency during the NIST irradiation, e.g. error in irradiation time calculation, erroneous distance setup between phantom and sources during one of the irradiations, should affect all four chips to the same degree, but not only channel 1 as it was in our case. Specially designed experiments showed that phantom orientation also cannot be responsible for the almost 10 % bias found in channel 1. The second explanation was ruled out after irradiation of each set of TLD cards to 1 mSv demonstrated that their responses were less than ±5 % bias. Only the previously described short-term sensitivity loss of chip 1 for all TLDs used in the first metrological traceability verification can explain the observed discrepancy in the results found during metrological traceability verification. In fact, two different readers were used to anneal the TLD cards in these two subsequent metrological traceability verifications. The simple test consisted of annealing TLD cards on the same reader used during the first traceability verification and the subsequent irradiation and read on the other reader showed again a similar under-response for channel 1. It is interesting to note that the discovered overheating was not apparent, e.g. was not caused by the modified TTP change and could be detected only if this specially designed experiment had been performed. The cause of uncontrolled overheating is still unknown, but the suspected cause is that the actual temperature is higher than the indicated temperature due to an improper calibration of the thermocouple. Another cause could be due to inconsistent nitrogen flow causing overheating from an increase in delivered thermal energy to the chip. Replacement of the reader heating board [Hot Gas Heater Station Assembly (PL-23013)/Pressure Sensor (151935)] and recalibration of the thermocouple were sufficient to eliminate the overheating.

Report of false neutron dose

During 3 months of operation, 27 personnel TLDs were reported with neutron doses greater than the detection limit (30 µSv) for work places where no neutron radiation levels existed. Dose investigations were initiated to identify a potential neutron source. Several suspected causes were investigated though none were confirmed to be the reason for the false neutron doses. These suspected causes included

Physically damaged TLD elements,

Contaminants on the TLDs,

Method of TLD attachment for workers affected,

Ratios between the chips were incorrect,

Contamination of the holders/cards,

Workers locations and potential radiation hot spots,

Commonalities with the processing of the dosemeters,

Commonalities with the work being conducted by the personnel who had false neutrons,

Exposure to sources where the TLDs were being stored,

Exposure to the source inside of the Harshaw 8800PC TLD reader,

Contamination of the TLD reader/source leakage within the TLD reader.

The Harshaw 8840/8841 dosemeter is an albedo dosemeter that measures scattered thermal neutrons emitted from the body. The neutron dose equivalent is calculated by subtraction of the 7Li response (measured by element 1) from the 6Li response (measured by element 4) and multiplying the result by correction factor that is a function of neutron energy, distance between the source and person, geometry of the surroundings and the material properties of the surroundings. An under-response of element 1 can cause an overestimation of the reported neutron dose equivalent. It is important to note that the reader suspected of overheating element 1 had the same (standard) TTP values both displayed on the reader and in the thermocouple files (see Table 2). As mentioned in previous section, indicators of element 1 overheating were clearly noticeable, e.g. remarkably lower dose readout of the element 1 when compared with the other three elements; in this study, it was about 10 %. For real neutron exposures, element 4 typically has the highest dose readout among the four elements. In most cases (except very low-energy photon or beta exposures), dose readouts of elements 1 and 2 are very close. This study was able to confirm that there was overheating at element 1. Similar to the previous case, replacement of the reader heating board [Hot Gas Heater Station Assembly (PL-23013)/Pressure Sensor (151935)] and recalibration of the thermocouple were sufficient to eliminate the overheating. Both pre- and post-repair, the temperatures were measured at the thermocouple and recorded (Table 2). Changes in measured temperatures subsequent to the replacement of the components were not indicative of overheating at position 1.

Table 2.

Temperature readings of the reader suspected in overheating element 1 pre- and post-repair.

| TTP part | Pre-anneal |

Anneal |

||||||

|---|---|---|---|---|---|---|---|---|

| Pre-repair | ||||||||

| Position | P1 | P2 | P3 | P4 | P1 | P2 | P3 | P4 |

| Display, °C | 166 | 166 | 166 | 166 | 260 | 260 | 260 | 260 |

| Thermocouple, °C | 166.8 | 165.6 | 164.2 | 164.5 | 259.5 | 259.5 | 257.9 | 259.5 |

| Post-repair | ||||||||

| Position | P1 | P2 | P3 | P4 | P1 | P2 | P3 | P4 |

| Display, °C | 166 | 166 | 166 | 166 | 260 | 260 | 260 | 260 |

| Thermocouple, °C | 166.8 | 165.7 | 165.3 | 164.6 | 260.5 | 259.6 | 258.4 | 259.4 |

Although there was no indication of overheating at position 1 from the readings of the thermocouple temperatures, the improvement of TLD results and glow curve shape at position 1 after the replacement are consistent with overheating.

CONCLUSIONS

Specially designed experiments demonstrated that there is a short-term sensitivity loss (∼10 %) in LiF:Mg,Cu,P TLDs caused by a small (5–15°C) overheat during an anneal preceding irradiation. Unlike the well-known effect of sensitivity loss(2, 8, 10–13), a complete or partial recovery of the sensitivity was observed when subsequent anneal(s) were conducted at a normal (lower) temperature. Furthermore, it appeared that there was no sensitivity loss if the read temperature was the same as the temperature of proceeding anneal. The latter observations (properties) indicate that this effect has a different nature (origin) than the well-known effect of permanent loss of sensitivity in this material. It is believed that short-term loss of sensitivity can be explained by metastable redistribution of empty traps between tightly overlapping glow curve Peaks 4 (main), 5 and 6. The relatively small size of the sensitivity loss (∼10 %) reflects that Peaks 5 and 6 are much lower than main Peak 4.

At least two possible implications of the observed effect of a short-term sensitivity loss with a small uncontrolled overheat during an anneal preceding irradiation on personnel dosimetry operation were found, e.g. inconsistency in the results of metrological traceability verification and possible reporting of false neutron dose. The test for determination if an uncontrolled overheating takes place has been developed and verified. Possible indicators (left-shifted position of glow curve of overheated element and its lower dose readout when compared with other elements of the same TLD card) were described.

FUNDING

The study was funded through US Department of Defense operational and maintenance budget.

DISCLAIMER

The views expressed in this article are those of the authors and do not necessarily reflect the official policy or position of the Navy and Marine Corps Public Health Center, Navy Bureau of Medicine and Surgery, Department of the Navy, Department of Defense or the US Government.

REFERENCES

- 1.Romanyukha A., King D. L., Kennemur L. K. Impact of Fukushima nuclear accident on background radiation doses measured by control dosimeters in Japan. Health Phys. 102, 535–541 (2012). [DOI] [PubMed] [Google Scholar]

- 2.Horowitz Y. S., Moscovitch M. Highlights and pitfalls of 20 years of application of computerised glow curve analysis to thermoluminescence research and dosimetry. Radiat. Prot. Dosim. 153, 1–22 (2013). [DOI] [PubMed] [Google Scholar]

- 3.Nakajima T., Maruyama Y., Matsuzawa T., Koyano A. Development of a new highly sensitive LiF thermoluminescence dosimeter and its applications. Nucl. Instrum. Methods 157, 155–162 (1978). [Google Scholar]

- 4.Moscovitch M. Personnel dosimetry using LiF:Mg,Cu,P. Radiat. Prot. Dosim. 85, 49–56 (1999). [Google Scholar]

- 5.Velbeck K. J., Luo L. Z., Ramlo M. J., Rotunda J. E. The dose-response of Harshaw TLD-700H. Radiat Prot Dosim. 119, 255–258 (2006). [DOI] [PubMed] [Google Scholar]

- 6.Cassata J. R., Moscovitch M., Rotunda J. E., Velbeck K. J. A new paradigm in personal dosimetry using LiF:Mg,Cu,P. Radiat. Prot. Dosim. 101, 27–42 (2002). [DOI] [PubMed] [Google Scholar]

- 7.Moscovitch M., St John T. J., Cassata J. R., Blake P. K., Rotunda J. E., Ramlo M., Velbeck K. J., Luo L. Z. The application of LiF:Mg,Cu,P to large scale personnel dosimetry: current status and future directions. Radiat. Prot. Dosim. 119, 248–254 (2006). [DOI] [PubMed] [Google Scholar]

- 8.DeWerd L. A., Cameron J. R., Da-ke W., Papini T., Das I. J. Characteristics of a new dosemeter material: LiF(Mg, Cu, P). Radiat. Prot. Dosim. 6, 350–352 (1983). [Google Scholar]

- 9.Kim J., Lee J., Pradhan A., Kim B., Kim S. Further studies on dosimetric characteristics of LiF: Mg, Cu, Si-A high sensitivity thermoluminescent dosimeter (TLD). Radiat. Meas. 43, 446–449 (2010). [Google Scholar]

- 10.Konnai A., Ozasa N., Lee J. A study on thermal degradation of LiF: Mg, Cu, P and LiF: Mg, Cu, Si. Radiat. Meas. 45, 533–536 (2010). [Google Scholar]

- 11.Voss S. P., Sucheta A., Romanyukha A., Moscovitch M., Kennemur L. K., Benevides L. A. Effect of TLD-700H (LiF:Mg,Cu,P) sensitivity loss at multiple read-irradiation cycles on TLD reader calibration. Radiat. Meas. 46, 1590–1594 (2011). [Google Scholar]

- 12.Oster L., Horowitz Y. S., Horowitz A. Glow curve readout of LiF:Mg,Cu,P (GR-200) chips at maximum temperatures between 240°C and 280°C: Elimination of residual signal. Radiat. Prot. Dosim. 49, 407–411 (1993). [Google Scholar]

- 13.Tang K., Cui H., Fan H., Zhu H., Liu Z. Influence of sintering temperatures on LiF:Mg,Cu,P with various magnesium concentrations. Radiat. Meas. (2014), doi:10.1016/j.radmeas.2014.07.016. [Google Scholar]

- 14.Pagonis V., Kitis G. On the possibility of using commercial software packages for thermoluminescence glow curve deconvolution analysis. Radiat. Prot. Dosim. 101, 93–98 (2002). [DOI] [PubMed] [Google Scholar]

- 15.ISO/IEC Conformity assessment—General requirements for proficiency testing. (ISO/IEC 17043:2010(E)) ISO; (2010). [Google Scholar]

- 16.Personnel Dosimetry Performance. Criteria for testing. American National Standard for Dosimetry; ANSI HPS N13.11-2009. [Google Scholar]

- 17.Minniti R., Seltzer S. M. Calibration of a 137Cs γ-ray beam irradiator using large size chambers. Appl. Radiat. Isot. 65, 401–406 (2007). [DOI] [PubMed] [Google Scholar]