Abstract

Pure silver is used extensively in the preparation of high-temperature superconductor wires, tapes, films, and other configurations in which the silver not only shields the superconducting material from the surrounding materials, but also provides a degree of flexibility and strain relief, as well as stabilization and low-resistance electrical contact. Silver is relatively expensive, but at this stage of superconductor development, its unique combination of properties seems to offer the only reasonable means of achieving usable lengths of conductor. In this role, the low-temperature physical (electrical, thermal, magnetic, optical) and mechanical properties of the silver all become important. Here we present a collection of properties data extracted from the cryogenic literature and, to the extent possible, selected for reliability.

Keywords: conductivity, cryogenic, elastic, electrical, magnetic, mechanical, optical, properties, review, resistivity, silver, superconductor, thermal, thermodynamic, transport

1. Introduction

Most applications of high-temperature superconductors involve the use of silver. In thin-film devices, it serves as an electrical contact with acceptably low contact resistance, on the order of 10−8 Ω·cm2. In large-scale devices the contact application is also important; the contact resistance can be higher, but the contact area is large. In conductor applications silver also provides (1) containment for the precursor powder mix during mechanical processing; (2) containment for the powder while allowing passage of oxygen during heat treatment to form the superconducting structure; (3) stabilization of the conductor in operation by providing an alternate current path and a thermal path to the coolant; (4) providing mechanical strength to the finished conductor; and (5) providing internal strain relief for the brittle superconductor when mixed as part of the powder. In low-temperature superconductors, most of these roles are carried out by copper. Silver, however, is required in high-temperature superconductors because of its unique ability to allow passage of diffusing oxygen. The low-temperature properties of silver also make it an attractive choice in applications that are not directly related to superconductivity. These properties are its high thermal and electrical conductivities, diamagnetism, high reflectance, and low emittance.

Over the past two decades, we have produced two versions [1, 2] of a wall chart presenting the cryogenic properties of copper. This chart has been popular with the low-temperature superconductor community. With the advent of high-temperature superconductors, we decided that a similar wall chart of cryogenic properties of silver would be valuable. This new chart, Cryogenic Properties of Silver, became available for distribution in January 1994 [3]. Limitations on the size of the chart did not allow us to present all the cryogenic-property data which were found in our review of the literature. Furthermore, the chart provided very little room for presentation of tabular data or commentary. Providing that additional information is the purpose of this paper.

Here we present figures and tables of the electrical, magnetic, mechanical, optical, thermal, and thermodynamic properties of pure silver, culled from more than 200 documents covering a period of over 60 years. While we concentrated on these properties, we have also included information in areas such as metal physics and effects of irradiation by high-energy particles on resistivity.

In general, we treated only pure silver. However, one paper on coin silver was included because this alloy is commonly available and might be of use at cryogenic temperatures. Also, mention is made (see Sec. 3.1, Ref. [137]) of a new material, a dispersion-hardened silver alloy which can provide additional strength and resistance to thermal shock, while maintaining acceptable thermal and electrical properties. The door to the properties of other alloys of silver was not cracked further open.

This work is not a complete survey of all the literature available on silver. While we made a strong effort to identify those papers of most use to workers interested in the cryogenic applications of silver, resources did not permit an exhaustive search of all the current literature. We believe that we located most, if not all, of the important sources of available data. Each bibliographic reference to a paper has been annotated by a capsule summary of the content specifically related to cryogenic applications of silver. Before the reader uses any data for engineering design or other critical applications, the reader is strongly urged to consult the original reference(s) for complete details of the conditions of measurement.

Some mention needs to be made regarding the techniques by which data were transferred from the graphs and plots in the original documents into the form presented here. Where tabular data were available there was no problem, and the plots were made directly. However, most of the documents provided data in graphical form, and often only as very small graphs and of quality less than that available now in the era of desktop publishing. In those cases, a combination of enlargement by photocopier, use of a graphics tablet, and commercial plotting software allowed extraction and smoothing of the data while maintaining the accuracy of the original plot. Because of the increased size of many of the plots, some curves show a minor lack of smoothness. All such variations lie within the accuracy of the data as plotted in the original publication.

2. Properties Data

In the following descriptions of tables and figures, a bullet (•) at the beginning of a paragraph denotes a description corresponding to a table or figure used in the wall chart, Cryogenic Properties of Silver [3]. Those tables or figures were selected for inclusion in the chart because of widest appeal or interest. For each graph or table in this paper there is always a corresponding bibliographic entry in Sec. 3, similarly marked with a dagger (†) and index number. The additional documents in the bibliography, under the topics listed here, contain further information on these properties.

2.1 General

The fundamental physical and chemical properties of silver are summarized in Table 1. It is fairly easy to find more than one secondary source for many of the data in the table, and there are usually small (within one or two percent) disagreements among the various values for a given property. Where multiple values were found, a representative (most frequently occurring) value was chosen for listing in this table.

Conversion factors between SI units and other systems, such as traditional (“British”) units are given in Tables 2a and 2b.

Table 1.

Physical and chemical properties of silver (Ag: argentum)

| Atomic number, Z | 47 | Melting point | 961.93 °C |

| Atomic mass, A | 107.8682 u | Density (20 °C) | 10.492 g/cm3 |

| Isotopes (A=107) | 106.9051 u (51.84 %) | (0 K) | 10.63 g/cm3 |

| (A=109) | 108.9048 u (48.16%) 0.2883 | Debye | 226.5 K (0 K) |

| Atomic diameter | nm | temperature | 215 K (20 °C) |

| Electronic structure | [Kr] 4d10 5s1 | Thermoelec. power | 1.35 μV/K (20 °C) |

| Valence states | 1, 2 | Elec. resistivity | 0.0147 μΩ·m (0 °C) |

| Crystal structure | face-centered cubic, Fm3m | Elastic constatnts (0 K) |

C11 = 131.5 GPa C12 = 97.33 GPa |

| Lattice spacing, a0 | 0.4078 nm (20 °C) | C44 = 51.1 GPa | |

| Electrochemical potential | 0.798 V (Ag++e− ⇋ Ag) |

Young’s modulus | 82.5 GPa (293 K) 91.3 GPa (0 K) |

| Ionization potentials | 7.574 V (I) | Poisson ratio | 0.364 (293 K) |

| 21.960 V (II) | Hall coefficient: | ||

| 36.10 V (III) | (290 K) | −9.0×10−11 m3/(A·s) | |

| Cohesive energy | 2.96 eV/atom, | (20 K) | −10.2×1011 m3/(A·s) |

| (25 °C) | 285.8 kJ/mol | Fermi energy | 5.52 eV = 8.84×10−19 J |

| Magnetic (mass) susceptibility | −2.300×10−9 m3/kg (4.2 K) | Fermi surface | Spherical, with necks at (111) |

| −2.27×10−9 m3/kg (295 K) |

Constants: u = 12C/12 = 1.66×10−27 kg

1 eV = 1.602×10−19 J

NA = 6.023×1023 molecules per mole

Table 2a.

Conversion factors—I

| K | = °C+273.15 | = (°F−32)/1.8+273.15 |

| 1 J | = 0.239 cal | = 9.480×10−4 Btu |

| 1 W/(m·K) | = 2.39×10−3 cal/(s·cm·°C) | = 0.578 Btu/h·ft·°F) |

| 1 J/(kg·K) | = 2.39×10−4 cal/(g·°C) | = 2.39×10−4 Btu/(lbm·°F) |

| 1 m2/s | = 104 cm2/s | = 10.76 ft2/s |

| 1 Pa | = 10 dyne/cm2 | = 1.45×10−4 lbf/in2 |

| 1 T | = 104G | |

| μ0 | = 4π×10−7 H/m | |

| 1 m3/kg | = 79.58 emu/g | (Magnetic susceptibility) |

| 1 (SI) | = 7.958×10−2 emu/cm3 | (Magnetic susceptibility) |

Table 2b.

Conversion factors—II

| Multiply | By | To obtain |

|---|---|---|

| kips | 453.59 | kg |

| kg | 2.20463 | lbm |

| kips/in2 | 0.7031 | kg/mm2 |

| kg/mm2 | 1.4223 | kips/in2 |

| kg/mm2 | 9.080665 | MPa |

| lb/in3 | 27.68 | g/cm3 |

| lb/ft3 | 0.01602 | g/cm3 |

| g/cm3 | 62.4219725 | lb/ft3 |

2.2 Electrical Resistivity

Matthiessen’s rule assumes that the total electrical resistivity ρel is well approximated by a sum of two terms. The first is a temperature-dependent intrinsic term ρint(T), which is zero at absolute zero. The second term is a residual term ρ0 due to the effect of impurities and crystal defects, and does not vanish at absolute zero. In Fig. 1 the total electrical resistivity of silver as a function of temperature is plotted for four different values of RRR (residual resistance ratio; a measure of impurity content), and a value for ρint at 0 °C is given. For metals in electrical applications, values for RRR are a more sensitive measure of purity than total content of chemical impurities. Above 80 K the resistivity of dilute alloys of silver is independent of impurity content, whereas below 80 K the resistivity is sensitive to impurity content. At room temperature the variation of resistivity with temperature is nearly linear.

Table 3 lists the change in electrical resistivity per “atomic percent” (mole fraction) of alloying element for 20 different metallic elements in pure silver. The effect of alloying small amounts of impurities with silver is to increase its resistivity. The change, initially linear with very small increases in concentration, is nonlinear as larger amounts of alloying element are added. The transition point to nonlinear dependence on concentration is different for different impurities. Hence the values listed in the table should be used only as a guide, and then very cautiously. One can assume without large error that the effects of several impurities are additive in small quantities.

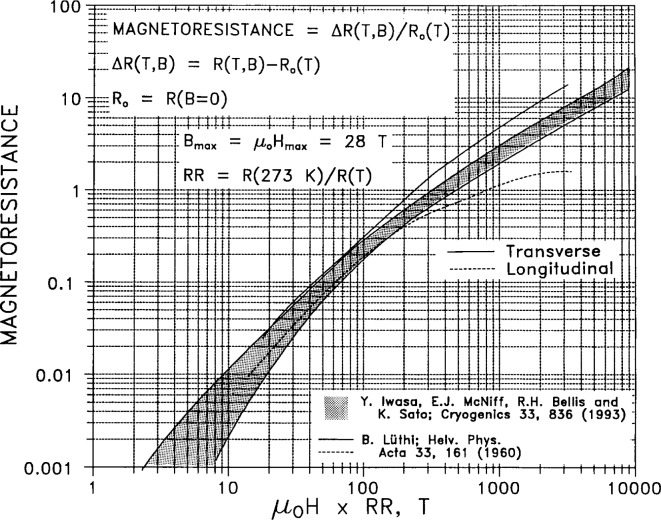

Magnetoresistance, the dependence of electrical resistivity on applied magnetic field, is given in Fig. 2 as a Kohler plot. For many polycrystalline metals, data covering wide ranges of temperature and metallic purity reduce to a single curve for the transverse case (field normal to current), and data for many different metals will fall on the curve. This is known as Kohler’s rule. However, it is frequently not obeyed, and the silver data in particular seem not to obey the rule. Regardless, application of relatively modest magnetic fields can cause large changes in resistance at low temperatures. The longitudinal magnetoresistance, measured with the field parallel to the current, saturates for most metals at a relatively low value, as seen here. In single-crystal specimens, the magnetoresistance is a strong function of crystal orientation, and measurements of magnetoresistance are used to determine the detailed topology of the Fermi surface.

Fig. 1.

Electrical resistivity ρ as a function of temperature; ρint is the temperature-dependent intrinsic resistivity, and ρ0 is the residual (0 K) resistivity, due to impurities. Residual resistivity ratio RRR is defined as ρ(273 K)/ρ(4.2 K). [67] (A number in square brackets following each figure caption denotes a bibliographic reference number (Sec. 3) to the source paper.)

Table 3.

Residual resistivities, per atomic percent Ag for solute element, nΩ·m/(at/0)

| Al | As | Au | Bi | Cd | Cu | Ga | Ge | Hg | In |

|---|---|---|---|---|---|---|---|---|---|

| 19.5 | 84.6 | 3.8 | 73 | 3.82 | 0.68 | 22.8 | 55.2 | 7.9 | 17.8 |

|

| |||||||||

| Mg | Mn | Ni | Pb | Pd | Pt | Sb | Sn | Tl | Zn |

|

| |||||||||

| 5 | 16 | 11 | 46.4 | 4.36 | 15.9 | 72.6 | 43.2 | 22.7 | 6.2 |

Frank J. Blatt, Physics of Electronic Conduction in Solids, p. 199 (McGraw-Hill, NY, 1968): Al, Mg, Mn, Ni.

J. O. Linde, Ann. Phys. (Leipzig), 5. Folge, Band 14, 353–366 (1932): As-In, Pb-Zn.

Fig. 2.

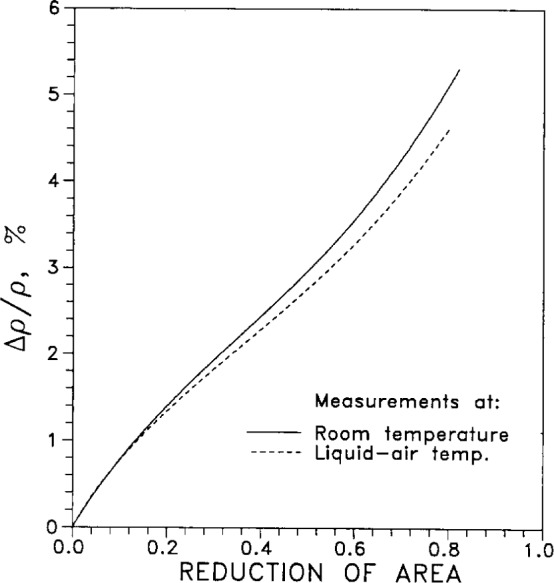

Kohler plot of magnetoresistance (as a function of product of magnetic field H and resistance ratio RR). [98, 100]

Figure 3 plots the relative change in resistivity due to cold working (increasing the number of defects in the specimen; the reduction in the cross-sectional area of specimen accompanying the cold working is taken into account in computing the resistivity). This figure shows that the dependence on cold working varies somewhat with temperature. That is, Matthiessen’s rule does not strictly apply. Cold working should affect only the number of geometrical defects such as vacancies and interstitials, which are independent of temperature (until annealing begins to occur, at temperatures well above room temperature); the ideal temperature-dependent intrinsic resistivity ρint(T) due only to lattice vibrations should not be affected by cold working.

Fig. 3.

Relative change in electrical resistivity due to cold working at room temperature and liquid-air temperature, as a function of reduction of area. [81]

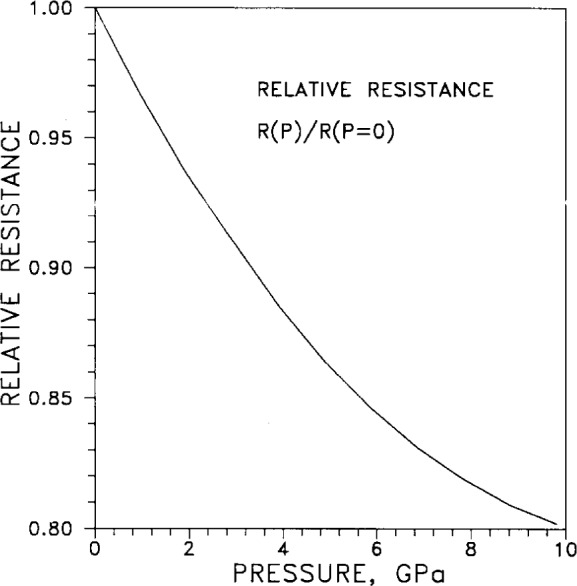

Electrical resistance depends weakly on applied pressure. The relative resistance R(P)R(P=0), normalized to unity at “zero pressure,” is plotted in Fig. 4. Both the relative resistance and the relative volume of silver, also normalized to unity at “zero pressure,” are tabulated in Table 4. One assumes that “zero pressure” is, in practice, atmospheric pressure, about 100 kPa or 10−4 GPa; the error in this assumption is minuscule.

Fig. 4.

Relative resistance R (P)/R (P=0) as a function of pressure P. [111]

Table 4.

Relative resistance and relative volume of silver as functions of pressure

| Pressure GPa | Rp/R0a | VP/V0b |

|---|---|---|

| 0.00 | 1.000 | 1.00000 |

| 0.98 | 0.966 | 0.99062 |

| 1.96 | 0.936 | 0.98180 |

| 2.93 | 0.910 | 0.97381 |

| 3.91 | 0.885 | |

| 4.89 | 0.864 | |

| 5.87 | 0.846 | |

| 6.85 | 0.831 | |

| 7.82 | 0.819 | |

| 8.80 | 0.809 | |

| 9.78 | 0.802 |

P. W. Bridgman, Proc. Amer. Acad. Arts, Sci. 81, 165 (1952).

A. W. Lawson, Progress in Metal Physics, Vol. 6, Pergamon, NY (1956).

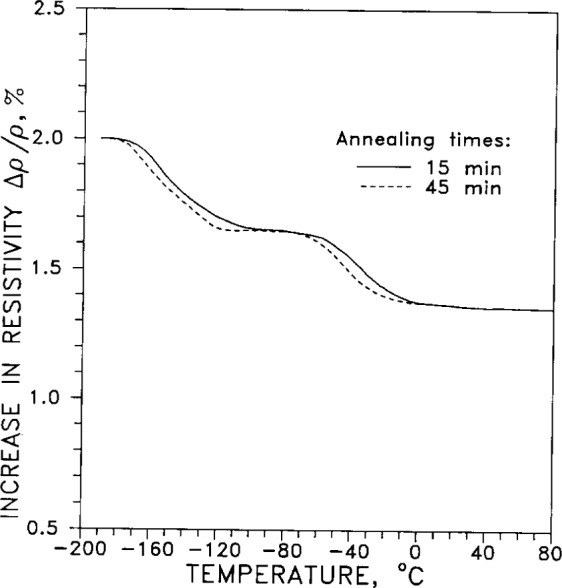

Figure 5 plots the isochronal recovery of resistivity of silver wires after deformation under tension. After the deformation, carried out at −183 °C (90 K), the temperature of the wire was raised by a constant amount and held at that temperature for a fixed period of time. The holding time was the same (“isochronal”) for all annealing temperatures. From the shape of the curve, the two values for energy of activation of recovery, 0.18 eV and 0.69 eV, were deduced.

Fig. 5.

Isochronal recovery of resistivity, for wires deformed in tension at −183 °C (90 K), as a function of temperature. Recovery activation energies are: “low temperature,” 0.18 eV; “high temperature,” 0.69 eV. [66]

Another study of isochronal annealing at 77 K gave “resistivity differential curves of fractional isochronal annealing” after torsional deformation, for silver and silver alloys. Figure 6 gives the plot for pure silver. The peaks in the curve at 110 K and 250 K are interpreted as major annealing stages. (We question whether the ordinate is correctly given as Δ(Δρ/Δρ0)/ΔT in the original paper, because ρo should not change in the given experiment. The ordinate should rather be Δ(Δρ/ρ0)/ΔT, the change in fractional recovery of resistivity with temperature.)

Fig. 6.

Differential fractional isochronal annealing after torsional deformation at 77 K, as a function of temperature. The specimen (“99.999 % pure”) was annealed for 360 s at each temperature, over 20 K intervals. The peaks at 110 K and at 250 K identify major annealing stages. The residual resistivity ρ0 was measured at 4.2 K. The original paper had, as the ordinate label, Δ(Δρ/Δρ0)/ΔT. However, ρ0 should not change in the given experiment. We believe the correct ordinate is Δ(Δρ/Δρ0)/ΔT, the change in fractional recovery of resistivity with temperature. [30]

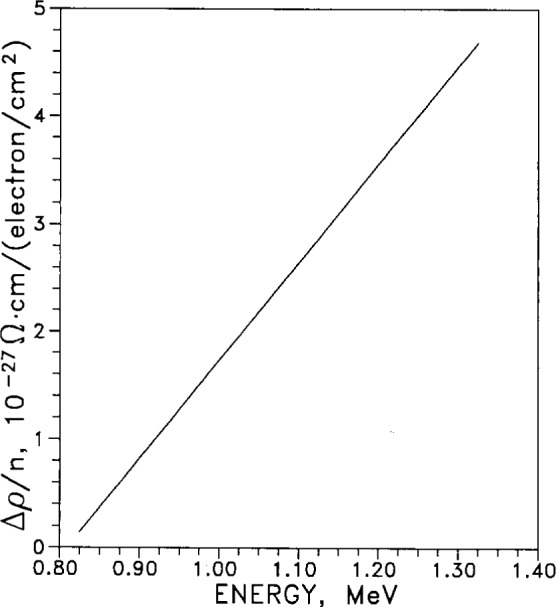

The use of superconducting magnets in applications involving high-energy particle beams motivated the inclusion of Fig. 7. This shows the relative change in resistivity per unit electron flux, as a function of average energy of the bombarding electrons. The bombardment was performed at specimen temperatures of 20.4 K.

Fig. 7.

Ratio of resistivity change Δρ to electron flux n (electrons per unit area) as a function of average bombarding energy. [86]

2.3 Thermal Properties

2.3.1 Thermal Conductivity

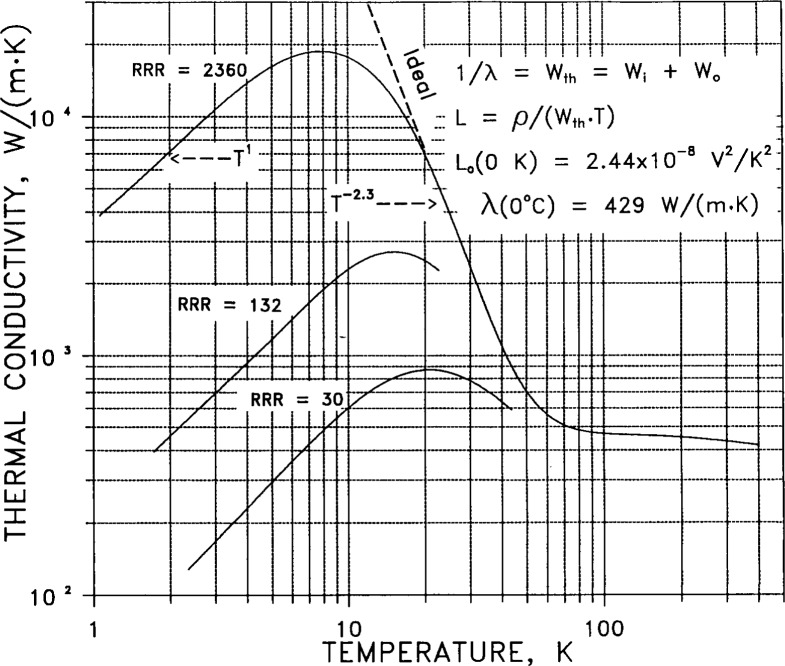

Thermal conductivity λ is the measure of steady-state conductive flow of heat. Figure 8 gives the thermal conductivity of silver for various values of RRR (residual resistance ratio, a measure of impurity content). The expression 1/λ=Wth =Wi + W0 is the thermal analog of Matthiessen’s rule; here Wth is the total thermal resistance, Wi is the ideal temperature-dependent resistance, and W0 is the resistance due to impurities. The Lorenz number L=ρel/(Wth • T), where ρel is electrical resistivity and T is absolute temperature, is theoretically a constant for all metals at absolute zero. Theory predicts that λ should vary linearly with temperature at very low temperatures (below the three conductivity peaks near 10 K). The slope immediately above the peak is observed empirically to vary approximately as T−2.3. This gives the slope at which the conductivity would continue to rise with decreasing temperature in the absence of any physical defects or chemical impurities (thermal resistance decreasing to zero at absolute zero). The conductivity is observed empirically to become independent of impurity content above about 70 K.

Fig. 8.

Thermal conductivity λ as a function of temperature for residual resistance ratios (RRR) of 30, 132, and 2360. [161]

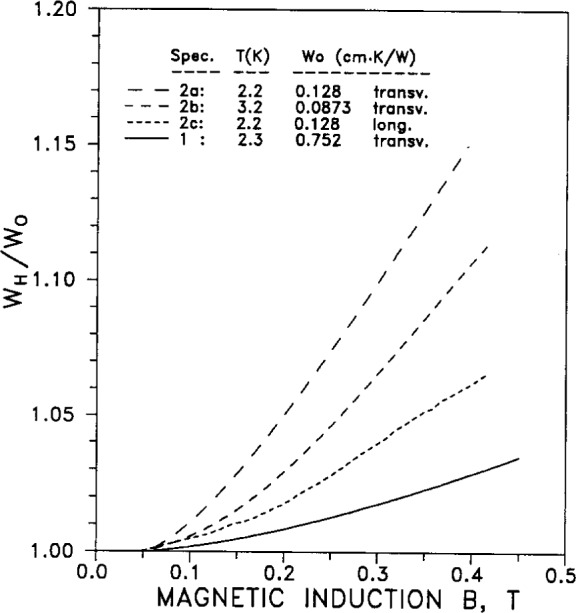

Thermal conductivity can vary with magnetic field, due to the effect of the field on the conduction electrons. This magneto-thermal resistance is shown in Fig. 9 in the form of thermal resistance W, normalized to the zero-field resistance W0=W(B=0), as a function of magnetic induction B. The four curves are for different values of W0 and specimen orientation (longitudinal or transverse to the thermal current); the temperatures of the measurement were also slightly different for each experiment.

Fig. 9.

Normalized thermal resistance WH/WO as a function of magnetic induction; WH is the thermal resistance in a magnetic field H, oriented longitudinally or transverse to the specimen axis. [172]

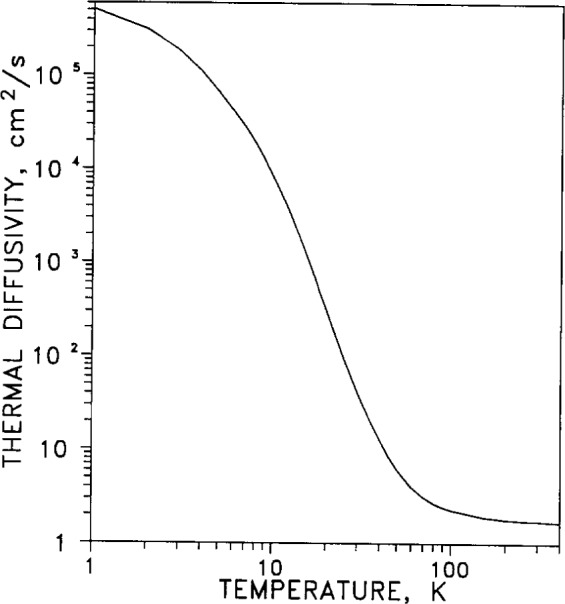

2.3.2 Thermal Diffusivity

Thermal diffusivity a is a measure of the transient flow of heat through a material. (The symbol a is chosen here for diffusivity to avoid confusion between diffusivity and thermal expansion, both of which are conventionally represented by the symbol α). The relation a=λ/(Cp·ρ) defines the thermal diffusivity in terms of the thermal conductivity λ, the specific heat Cp and the density ρ. Fig. 10 shows the diffusivity as a function of temperature.

Fig. 10.

Thermal diffusivity as a function of temperature. The diffusivity α = λ/ρCp was calculated from the thermal conductivity λ, density ρ, and specific heat Cp, as functions of temperature. The specimen was described as “well-annealed;” RRR=2360. [175]

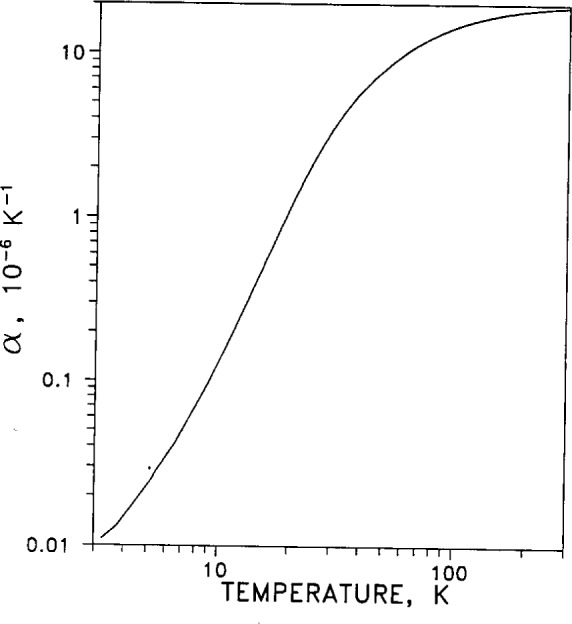

2.3.3 Thermal Expansion

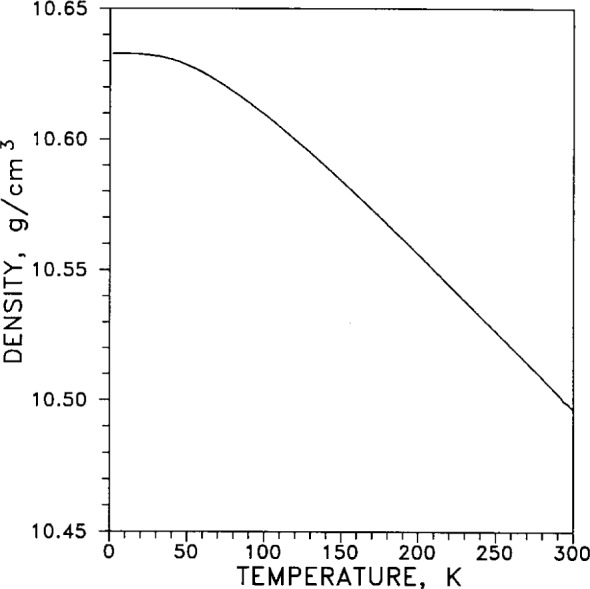

The linear thermal expansion coefficient measures the one-dimensional expansion of a material with changing temperature. It is defined by α =(dL/dT)/L0=dln(L)/dT, where L0 is the length of the specimen at a reference temperature, conventionally taken to be 293 K (20 °C). For silver it varies with temperature as shown in Fig. 11. Because α varies by several orders of magnitude between liquid-helium temperature and room temperature, the curve is given as a log-log plot. The volumetric expansion coefficient, γ=dln(V)/dT, measures the three-dimensional variation of volume with temperature, and is well approximated by γ =3α. The variation of density ρ with temperature is given by ρ(T)=m/V(T)=m/(V0(1+γ(T)), where m is the mass of the specimen. The areal, or two-dimensional, thermal expansion coefficient is β =dln(A)/dT and is well approximated by β =2α.

Fig. 11.

Linear thermal expansion coefficient α = ΔL/(L293 ΔT) as a function of temperature T. [181]

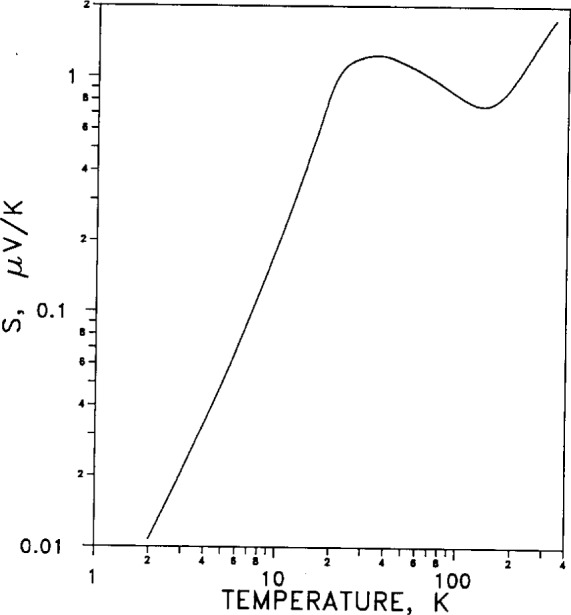

2.3.4 Thermoelectric Power

The absolute thermoelectric power S=dE/dT is a measure of the rate of change of absolute thermoelectric emf E with temperature. An electrical circuit involving two junctions of silver (of thermoelectric power Sa) with another metal (of thermoelectric power Sb) will generate an output emf per degree equal to Sa−Sb when the junctions are at different temperatures. Because of its strong dependence on temperature, it is given on a log-log plot in Fig. 12.

Fig. 12.

Absolute thermoelectric power S as a function of temperature. [202]

2.4 Magnetic Properties

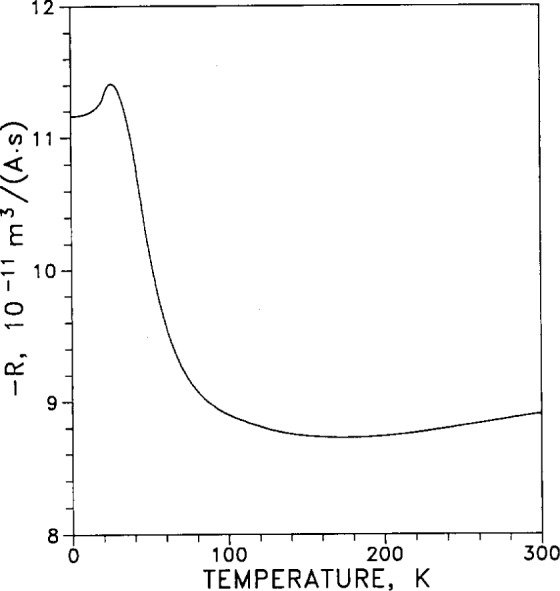

2.4.1 Hall Coefficient

The Hall coefficient −RH(T) is plotted in Fig. 13 as a function of temperature for silver in a magnetic induction B=1.5155 T. (Because electrons are the charge carriers in silver, the Hall coefficient for silver is negative; so −RH is plotted vertically upward).

Fig. 13.

Hall coefficient R(R < 0) as a function of temperature in a magnetic field of 1.5155 T. The specimen was polycrystalline, annealed, and “99.9999 % pure.” [88]

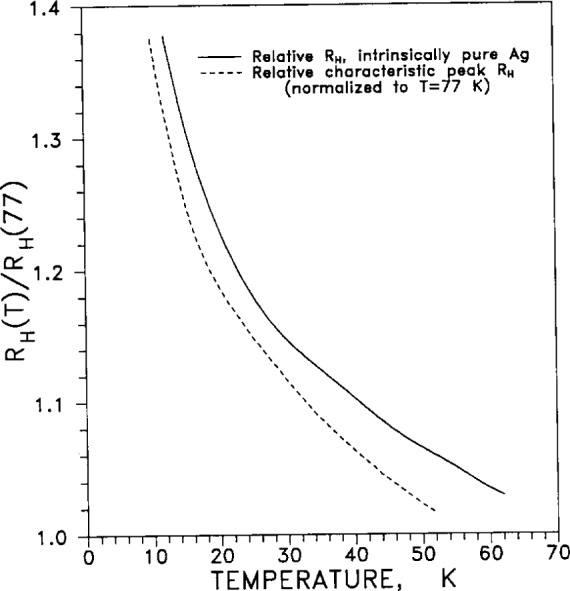

The low-field dependence with temperature of the relative Hall coefficient RH(T), normalized to its value at 77 K, is given in Fig. 14.

Fig. 14.

Low-field (B = 8.5 mT) relative Hall coefficient, RH(T)/RH (77 K), as a function of temperature. [89]

In Fig. 15, the temperature dependence of the same normalized (relative) Hall coefficient is graphed for two different values of applied magnetic induction (solid lines: B=0.5145 T; dashed lines: B=8.5 mT). For each value of magnetic field, the normalized coefficient is graphed for three different values of RRR (residual resistance ratio, a measure of impurity content), values of 510, 3250, and 3550).

Fig. 15.

Relative Hall coefficient, RH(T)/RH(77 K), for magnetic inductions B = 0.5145 T and B = 0.0085 T, as a function of temperature, for three different RRR values. [89]

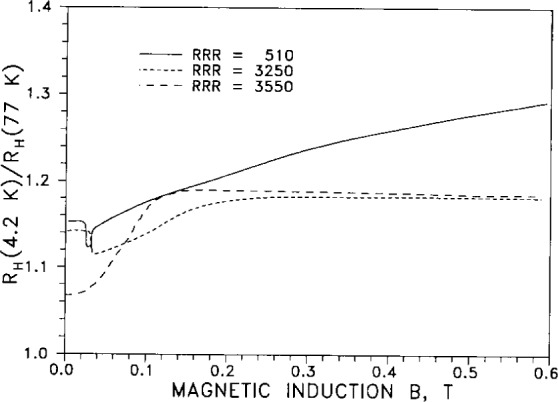

Figure 16 displays the relative Hall coefficients at 4.2 K, normalized to the value at 77 K, as a function of magnetic induction B and RRR value. These are the same specimens (and same RRR values) as in Fig. 15. The relative Hall coefficients for the specimens having RRR=3250 (specimen 1) and 3550 (specimen 2) show saturation at magnetic inductions above 0.2 T, while that for the low-purity (specimen 3: RRR=510) did not saturate. The authors could offer no explanation for the occurrence of minima in the RH curves for specimens 2 and 3 and the apparent absence of a minimum in RH for specimen 1 (intermediate purity); possibly this specimen has a minimum at B=0 T.

Fig. 16.

Hall coefficient at 4.2 K, RH(4.2)/RH(77 K), relative to the value at 77 K, as a function of magnetic induction, for three different RRR values. [89]

2.4.2 Anisotropy Factor

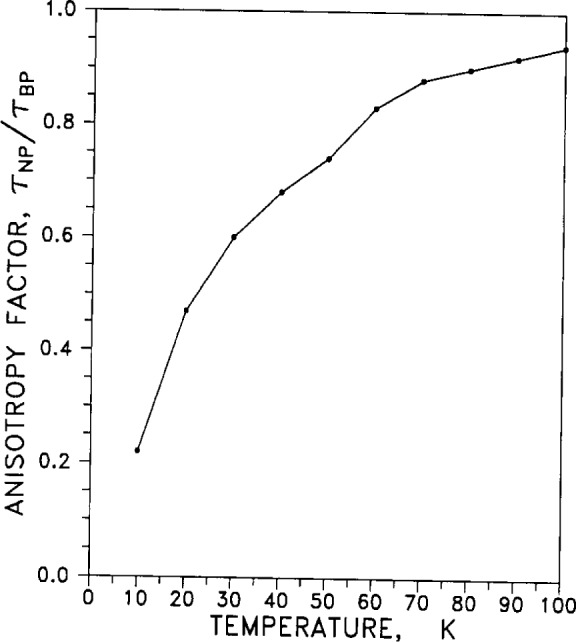

The anisotropy factor τNP/τBP is a measure of relaxation time τ on the “neck” (N) of the Fermi surface (FS) normalized by the relaxation time for the FS “belly” (B), for electron-phonon (P) scattering. Fig. 17 plots the anisotropy factor for pure silver.

Fig. 17.

Anisotropy factor for electron-phonon scattering in “intrinsically pure” Ag, as a function of temperature. τ is the isotropic relaxation time; subscripts N and B refer to neck and belly of the Fermi surface, and P refers to electron-phonon scattering. [89]

2.5 Optical and High-Frequency Properties

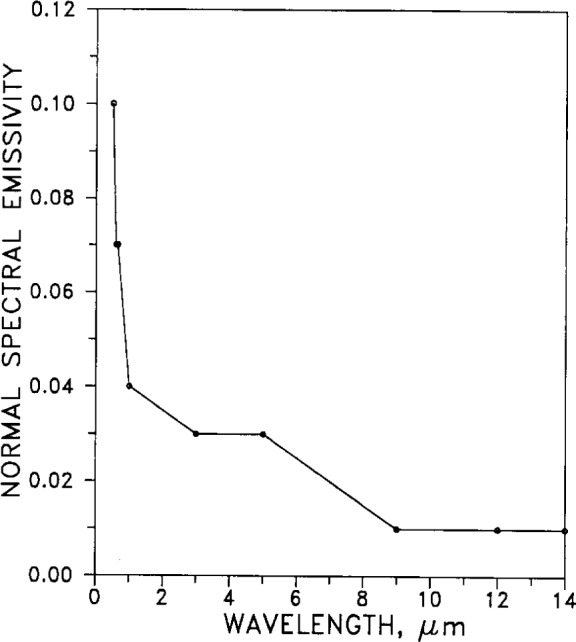

2.5.1 Spectral Emissivity

Figure 18 shows how normal spectral emissivity of silver at 295 K depends on (visible and infrared) wavelength.

Fig. 18.

Normal spectral emissivity as a function of wavelength for a specimen at 295 K. [2]

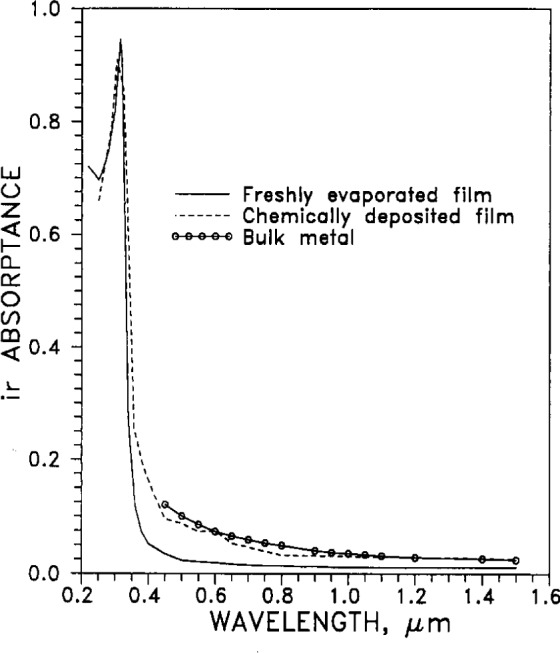

2.5.2 Absorptance

The absorptance of electromagnetic radiation from the near ultraviolet (220 nm) through the visible (400 nm to 700 nm), to the near infrared (5000 nm), is tabulated in Table 5 and plotted in Fig. 19. Values are given for freshly evaporated film, for bulk metal, and for a polished, chemically deposited surface. The latter two sets are probably more realistic for modeling the optical properties of silver-sheathed superconducting wire in practical applications.

Table 5.

Infrared absorptance of silver

| Freshly evaporated filma | Bulk metalb | Chemically deposited: polished surfacec | |||

|---|---|---|---|---|---|

|

| |||||

| wave-length μm |

absorptance | wave-length μm |

absorptance | wave-length μm |

Absorptance |

| 0.220 | 0.720 | 0.45 | 0.12 | 0.251 | 0.659 |

| 0.240 | 0.705 | 0.50 | 0.10 | 0.288 | 0.788 |

| 0.250 | 0.696 | 0.55 | 0.085 | 0.305 | 0.909 |

| 0.260 | 0.708 | 0.60 | 0.073 | 0.326 | 0.854 |

| 0.280 | 0.748 | 0.65 | 0.065 | 0.357 | 0.255 |

| 0.300 | 0.824 | 0.70 | 0.059 | 0.385 | 0.186 |

| 0.315 | 0.945 | 0.75 | 0.053 | 0.420 | 0.134 |

| 0.320 | 0.911 | 0.80 | 0.049 | 0.450 | 0.095 |

| 0.340 | 0.271 | 0.90 | 0.040 | 0.500 | 0.087 |

| 0.360 | 0.118 | 0.95 | 0.037 | 0.550 | 0.073 |

| 0.380 | 0.072 | 1.00 | 0.035 | 0.600 | 0.074 |

| 0.400 | 0.052 | 1.05 | 0.033 | 0.650 | 0.053 |

| 0.450 | 0.034 | 1.10 | 0.031 | 0.700 | 0.046 |

| 0.500 | 0.023 | 1.20 | 0.028 | 0.800 | 0.032 |

| 0.550 | 0.021 | 1.40 | 0.026 | 1.00 | 0.030 |

| 0.600 | 0.019 | 1.50 | 0.024 | 1.50 | 0.026 |

| 0.650 | 0.017 | 1.75 | 0.022 | ||

| 0.700 | 0.015 | 2.00 | 0.021 | ||

| 0.750 | 0.014 | 2.50 | 0.02 | ||

| 0.800 | 0.014 | 3.00 | 0.02 | ||

| 0.850 | 0.013 | 3.50 | 0.02 | ||

| 0.900 | 0.013 | 4.00 | 0.02 | ||

| 0.950 | 0.012 | ||||

| 1.0 | 0.011 | ||||

| 1.5 | 0.011 | ||||

| 2.0 | 0.011 | ||||

| 3.0 | 0.011 | ||||

| 4.0 | 0.011 | ||||

| 5.0 | 0.011 | ||||

George Hass, Engineer Research and Development Laboratories, American Institute of Physics Handbook, McGraw-Hill, NY (1957) pp. 6–108.

Ibid. pp. 6–110.

Ibid. pp. 6–109.

Fig. 19.

Infrared absorptance (1–reflectance) as a function of wavelength, for (a) freshly vacuum-evaporated film, (b) chemically deposited film, and (c) bulk metal. [2]

2.5.3 Angular Reflectivity

The angular reflectivity of silver, for visible light of wavelength λ =546 nm, is given in Fig. 20 as a function of angle of incidence.

Fig. 20.

Angular reflectivity, at λ = 546 nm, as a function of angle of incidence. [143]

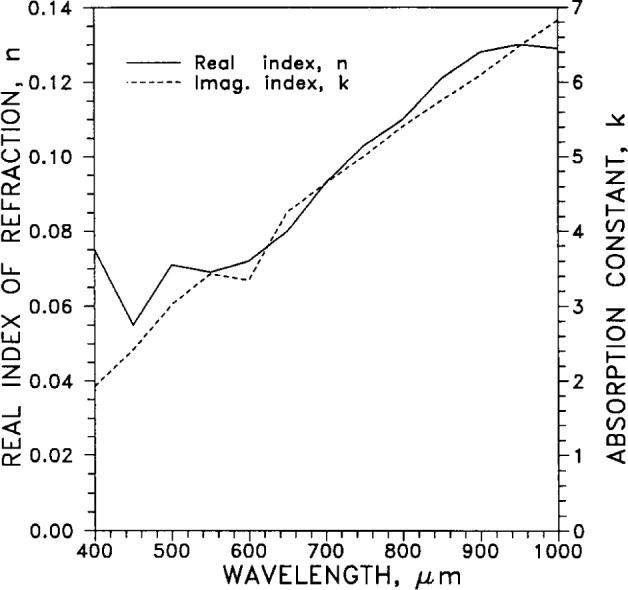

2.5.4 Index of Refraction

Table 6 lists the real and imaginary components, n and k, of the complex optical index of refraction N=n−ik, along with the reflectance R, for the visible and near infrared parts of the spectrum. The values are also plotted in Fig. 21. Optical reflectance plus absorptance for a metal sum to unity. It follows that surface films of oil, grease or dust, compromising the cleanliness of the silver and increasing its optical absorptance, easily reduce its reflectance.

Table 6.

Real index of refraction and absorption constant of silver, as functions of wavelength

| Wave-length μm |

n | k |

R % |

|---|---|---|---|

| 400 | 0.075 | 1.93 | |

| 450 | 0.055 | 2.42 | |

| 500 | 0.071 | 3.020 | 97.3 |

| 550 | 0.069 | 3.429 | 97.9 |

| 600 | 0.072 | 3.348 | 98.2 |

| 650 | 0.080 | 4.257 | 98.4 |

| 700 | 0.093 | 4.645 | 98.4 |

| 750 | 0.103 | 5.005 | 98.4 |

| 800 | 0.110 | 5.409 | 98.6 |

| 850 | 0.121 | 5.757 | 98.6 |

| 900 | 0.128 | 6.089 | 98.7 |

| 950 | 0.130 | 6.476 | 98.8 |

| 1000 | 0.129 | 6.829 | 98.9 |

Optical Constants:

N = n–ik = complex index

n = (real) index of refraction

k = absorption constant (imaginary index)

R = reflectance (computed)

American Institute of Physics Handbook, McGraw-Hill, NY (1957) pp. 6–104.

Fig. 21.

Index of refraction n and absorption constant k as functions of wavelength, n is the (real) index of refraction, and k is the absorption constant (imaginary index); the complex index N = n−ik. [2]

2.6 Thermodynamic Properties

2.6.1 Density

From the temperature dependence of the linear thermal expansion coefficient α, plotted in Fig. 11, the volumetric expansion coefficient can be calculated, and then the dependence of density ρ with temperature. The results of this calculation is given in Fig. 22; a value of 10.492 g/cm3 (see Table 1) was assumed for the value of density at 20 °C.

Fig. 22.

Density as a function of temperature. Density was calculated from the linear thermal expansion function and the density (10.492 g/cm3) at 300 K. [181]

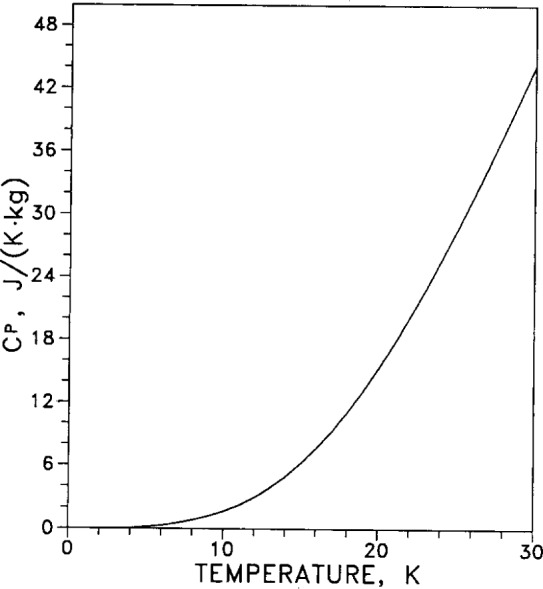

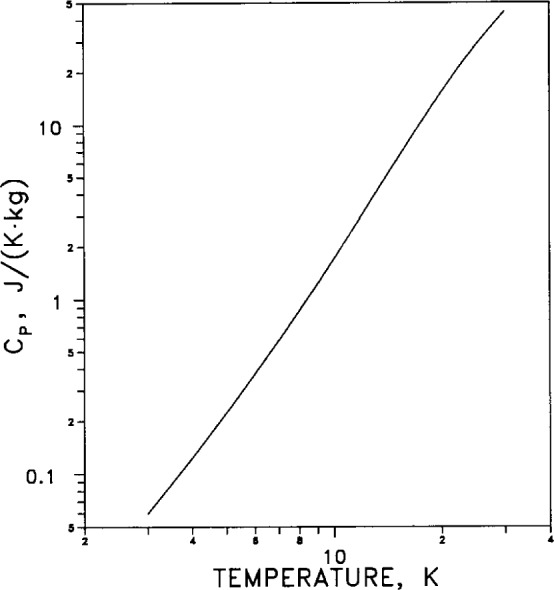

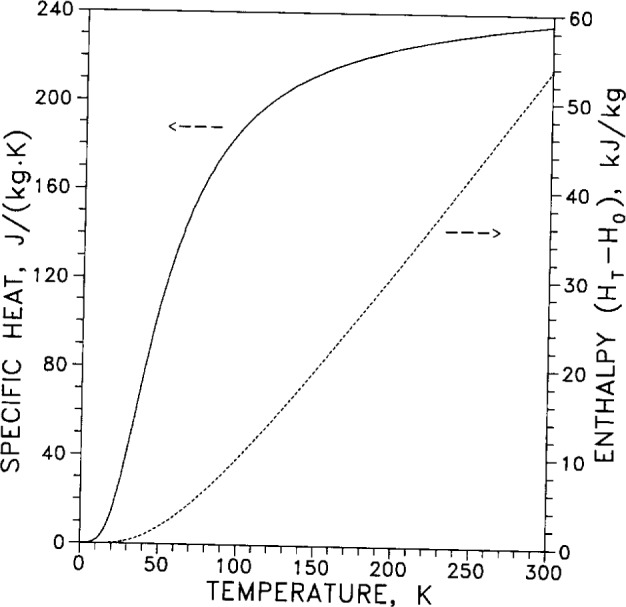

2.6.2 Specific Heat, Entropy, Enthalpy, and Gibbs Energy

For the low-temperature range (temperatures from 3 K to 30 K) the temperature dependence of specific heat Cp is tabulated in Table 7. The low-temperature specific heat is graphed in Fig. 23 on a linear scale to show the high-temperature behavior, and in Fig. 24 on a log-log scale to emphasize the low-temperature behavior.

Table 7.

Low-temperature specific heat CP, and calorimetric Debye temperature, ΘCAL, for silver (purity: 99.999 %)

| Temperature K | Specific heat J/(kg·K) | Specific heat J/(K·g-atom) | Specific heat cal/(K·g-atom) | Debey ΘCALL (calorimetric) K |

|---|---|---|---|---|

| 3 | 0.0598 | 0.006 45 | 0.001 541 | 226.6 |

| 4 | 0.1230 | 0.013 27 | 0.003 172 | 226.6 |

| 5 | 0.2234 | 0.024 10 | 0.005 760 | 226.6 |

| 6 | 0.3711 | 0.040 04 | 0.009 569 | 226.4 |

| 7 | 0.5786 | 0.062 43 | 0.014 92 | 225.8 |

| 8 | 0.8587 | 0.092 63 | 0.022 14 | 224.9 |

| 9 | 1.2256 | 0.1322 | 0.031 60 | 223.8 |

| 10 | 1.6980 | 0.1832 | 0.043 78 | 222.4 |

| 11 | 2.2879 | 0.2468 | 0.058 99 | 221.0 |

| 12 | 3.0158 | 0.3253 | 0.077 76 | 219.5 |

| 13 | 3.9055 | 0.4213 | 0.1007 | 217.9 |

| 14 | 4.9604 | 0.5351 | 0.1279 | 216.4 |

| 15 | 6.2093 | 0.6699 | 0.1601 | 214.9 |

| 16 | 7.6714 | 0.8276 | 0.1978 | 213.4 |

| 17 | 9.3081 | 1.0042 | 0.2400 | 212.3 |

| 18 | 11.1387 | 1.2016 | 0.2872 | 211.4 |

| 19 | 13.1361 | 1.4171 | 0.3387 | 210.8 |

| 20 | 15.3196 | 1.6527 | 0.3950 | 210.3 |

| 21 | 17.6816 | 1.9075 | 0.4559 | 209.9 |

| 22 | 20.1792 | 2.1769 | 0.5203 | 209.7 |

| 23 | 22.8165 | 2.4614 | 0.5883 | 209.6 |

| 24 | 25.6090 | 2.7627 | 0.6603 | 209.5 |

| 25 | 28.5100 | 3.0757 | 0.7351 | 209.5 |

| 26 | 31.4925 | 3.3974 | 0.8120 | 209.6 |

| 27 | 34.5758 | 3.7300 | 0.8915 | 209.7 |

| 28 | 37.7289 | 4.0702 | 0.9728 | 209.9 |

| 29 | 40.9557 | 4.4183 | 1.056 | 210.0 |

| 30 | 44.2136 | 4.7698 | 1.140 | 210.2 |

Douglas, L. Martin, Phys. Rev. 141(2), 576–582 (1966).

Fig. 23.

Low-temperature specific heat Cp as a function (linear plot) of temperature for 0 K < T < 30 K. [191]

Fig. 24.

Low-temperature specific heat Cp as a function (log-log plot) of temperature for 0 K < T < 30 K, emphasizing the low-temperature behavior. [191]

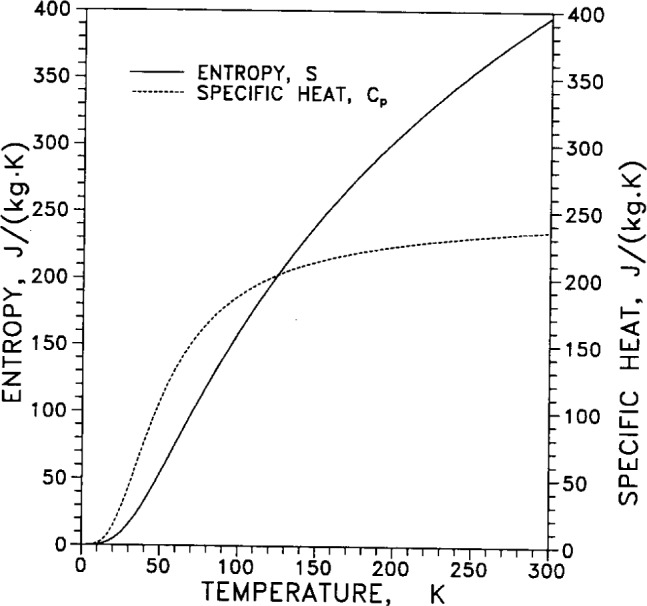

Table 8 gives the temperature dependence over the range of temperatures from 0 K to 300 K for specific heat Cp, entropy S, enthalpy H°T, Gibbs energy G°T, enthalpy function (H°T −H°0)/T, and Gibbs energy function −(G°T−H°0)/T. The enthalpy function H°T is the enthalpy at 101 kPa (1 atm) and temperature T, and similarly for the Gibbs energy. The reference function H°0 is the enthalpy at 101 kPa and 0 K.

Specific heat capacity Cp and enthalpy, H°T−H°0, are both plotted as functions of temperature in Fig. 25 for ease of comparison. The entropy S and specific heat Cp are both plotted in Fig. 26 for ease of comparison. Entropy is the integral over temperature of the specific heat function divided by temperature. Consequently, as the specific heat approaches a constant value at high temperatures (law of Dulong and Petit) the entropy tends to increase linearly with temperature.

Table 8.

Thermodynamic functions for silver (for definitions of symbols, see text)

| Temperature | Specific heat Cp | Enthalpy H°T−H°0 | Enthalpy function (H°T−H°0)/T | Entropy S | Gibbs energy −(G°T− H°0)/T | Gibbs energy function−(G°T− H°0)/T |

|---|---|---|---|---|---|---|

| K | J/(kg·K) | J/kg | J/kg | J/(kg·K) | J/kg | J/(kg·K) |

| 1.0 | 0.00758 | 0.00340 | 0.00340 | 0.00654 | 0.00314 | 0.00314 |

| 2.0 | 0.02457 | 0.01830 | 0.00915 | 0.0162 | 0.01413 | 0.00706 |

| 3.0 | 0.06026 | 0.05868 | 0.0196 | 0.0322 | 0.03760 | 0.01253 |

| 4.0 | 0.1242 | 0.14796 | 0.0370 | 0.0574 | 0.08147 | 0.02037 |

| 5.0 | 0.2253 | 0.31937 | 0.0639 | 0.0955 | 0.1567 | 0.03133 |

| 6.0 | 0.3736 | 0.61435 | 0.1024 | 0.1483 | 0.2770 | 0.04617 |

| 7.0 | 0.5803 | 1.0837 | 0.1548 | 0.2206 | 0.4601 | 0.06573 |

| 8.0 | 0.8594 | 1.8022 | 0.2253 | 0.3161 | 0.7261 | 0.09076 |

| 9.0 | 1.224 | 2.8367 | 0.3152 | 0.4376 | 1.1013 | 0.1244 |

| 10.0 | 1.696 | 4.2829 | 0.4283 | 0.5896 | 1.6131 | 0.1613 |

| 11.0 | 2.290 | 6.2633 | 0.5694 | 0.7778 | 2.2944 | 0.2086 |

| 12.0 | 3.013 | 8.9107 | 0.7426 | 1.010 | 3.1816 | 0.2651 |

| 13.0 | 3.903 | 12.346 | 0.9497 | 1.279 | 4.3241 | 0.3326 |

| 14.0 | 4.960 | 16.768 | 1.198 | 1.613 | 5.7625 | 0.4116 |

| 15.0 | 6.211 | 22.332 | 1.489 | 1.993 | 7.5591 | 0.5039 |

| 16.0 | 7.657 | 29.250 | 1.828 | 2.438 | 9.7747 | 0.6109 |

| 17.0 | 9.289 | 37.704 | 2.218 | 2.948 | 12.455 | 0.7326 |

| 18.0 | 11.115 | 47.891 | 2.661 | 3.532 | 15.691 | 0.8717 |

| 19.0 | 13.108 | 59.993 | 3.158 | 4.190 | 19.551 | 1.0290 |

| 20.0 | 15.268 | 74.173 | 3.709 | 4.913 | 24.092 | 1.2046 |

| 25.0 | 28.423 | 181.86 | 7.274 | 9.669 | 59.757 | 2.3903 |

| 30.0 | 44.257 | 362.85 | 12.095 | 16.223 | 123.76 | 4.1253 |

| 35.0 | 61.296 | 626.48 | 17.899 | 24.316 | 224.53 | 6.4151 |

| 40.0 | 78.048 | 975.25 | 24.381 | 33.605 | 368.85 | 9.2213 |

| 45.0 | 93.724 | 1405.02 | 31.223 | 43.710 | 561.84 | 12.485 |

| 50.0 | 108.09 | 1910.17 | 38.203 | 54.343 | 806.90 | 16.138 |

| 55.0 | 120.89 | 2483.59 | 45.156 | 65.264 | 1105.9 | 20.108 |

| 60.0 | 132.29 | 3117.09 | 51.951 | 76.277 | 1459.6 | 24.327 |

| 65.0 | 142.30 | 3804.25 | 58.527 | 87.272 | 1868.6 | 28.748 |

| 70.0 | 151.11 | 4537.96 | 64.828 | 98.174 | 2332.3 | 33.318 |

| 75.0 | 158.89 | 5315.55 | 70.847 | 108.83 | 2850.0 | 37.999 |

| 80.0 | 165.66 | 6125.15 | 76.564 | 119.31 | 3420.3 | 42.753 |

| 85.0 | 171.78 | 6969.10 | 81.989 | 129.51 | 4042.4 | 47.557 |

| 90.0 | 177.16 | 7841.94 | 87.133 | 139.52 | 4715.3 | 52.393 |

| 95.0 | 181.98 | 8739.96 | 92.000 | 149.25 | 5437.4 | 57.236 |

| 100.0 | 186.34 | 9659.78 | 96.598 | 158.71 | 6207.5 | 62.075 |

| 105.0 | 190.23 | 10603.2 | 100.98 | 167.89 | 7024.0 | 66.895 |

| 110.0 | 193.66 | 11563.9 | 105.13 | 176.79 | 7885.7 | 71.688 |

| 115.0 | 196.81 | 12540.5 | 109.05 | 185.50 | 8791.0 | 76.444 |

| 120.0 | 199.68 | 13530.7 | 112.76 | 193.94 | 9739.7 | 81.164 |

| 125.0 | 202.28 | 14531.4 | 116.25 | 202.10 | 10730 | 85.840 |

| 130.0 | 204.60 | 15558.5 | 119.68 | 210.07 | 11761 | 90.470 |

| 135.0 | 206.82 | 16582.5 | 122.83 | 217.85 | 12828 | 95.022 |

| 140.0 | 208.77 | 17624.9 | 125.89 | 225.46 | 13939 | 99.564 |

| 145.0 | 210.62 | 18671.1 | 128.77 | 232.78 | 15082 | 104.01 |

| 150.0 | 212.29 | 19729.3 | 131.53 | 239.92 | 16270 | 108.46 |

| 155.0 | 213.87 | 20792.2 | 134.14 | 246.96 | 17487 | 112.82 |

| 160.0 | 215.26 | 21863.4 | 136.65 | 253.73 | 18734 | 117.09 |

| 165.0 | 216.65 | 22944.3 | 139.06 | 260.41 | 20023 | 121.35 |

| 170.0 | 217.85 | 24030.4 | 141.36 | 266.90 | 21339 | 125.52 |

| 175.0 | 219.06 | 25123.3 | 143.56 | 273.20 | 22696 | 129.69 |

| 180.0 | 220.17 | 26214.9 | 145.64 | 279.41 | 24079 | 133.77 |

| 185.0 | 221.19 | 27320.4 | 147.68 | 285.44 | 25485 | 137.76 |

| 190.0 | 222.12 | 28428.7 | 149.62 | 291.37 | 26924 | 141.71 |

| 195.0 | 223.05 | 29543.8 | 151.51 | 297.12 | 28399 | 145.64 |

| 200.0 | 223.97 | 30666.5 | 153.33 | 302.77 | 29895 | 149.48 |

| 205.0 | 224.71 | 31775.3 | 155.00 | 308.33 | 31428 | 153.30 |

| 210.0 | 225.55 | 32900.7 | 156.67 | 313.80 | 32984 | 157.07 |

| 215.0 | 226.29 | 34042.8 | 158.34 | 319.09 | 34561 | 160.75 |

| 220.0 | 227.03 | 35175.1 | 159.89 | 324.28 | 36172 | 164.42 |

| 225.0 | 227.68 | 36314.5 | 161.40 | 329.38 | 37804 | 168.02 |

| 230.0 | 228.33 | 37449.9 | 162.83 | 334.38 | 39467 | 171.60 |

| 235.0 | 228.89 | 38590.8 | 164.22 | 339.30 | 41153 | 175.12 |

| 240.0 | 229.54 | 39745.6 | 165.61 | 344.12 | 42860 | 178.59 |

| 245.0 | 230.09 | 40891.6 | 166.90 | 348.85 | 44594 | 182.02 |

| 250.0 | 230.65 | 42041.3 | 168.17 | 353.57 | 46343 | 185.37 |

| 255.0 | 231.11 | 43189.5 | 169.37 | 358.12 | 48121 | 188.71 |

| 260.0 | 231.67 | 44349.7 | 170.58 | 362.57 | 49927 | 192.03 |

| 265.0 | 232.13 | 45512.1 | 171.74 | 367.02 | 51752 | 195.29 |

| 270.0 | 232.59 | 46671.2 | 172.86 | 371.37 | 53600 | 198.52 |

| 273.2 | 232.87 | 47413.2 | 173.58 | 374.06 | 54772 | 200.52 |

| 275.0 | 233.06 | 47836.3 | 173.95 | 375.64 | 55464 | 201.69 |

| 280.0 | 233.52 | 49007.1 | 175.03 | 379.81 | 57355 | 204.84 |

| 285.0 | 233.99 | 50172.9 | 176.05 | 383.98 | 59262 | 207.94 |

| 290.0 | 234.36 | 51338.1 | 177.03 | 388.06 | 61194 | 211.01 |

| 295.0 | 234.73 | 52518.6 | 178.03 | 392.05 | 63138 | 214.03 |

| 298.2 | 235.01 | 53261.8 | 178.64 | 394.55 | 64381 | 215.94 |

| 300.0 | 235.19 | 53695.2 | 178.98 | 396.03 | 65114 | 217.05 |

G. T. Furukawa, W. G. Saba, and M. L. Reilly, Natl. Stand. Ref. Data Series 18, Natl. Bur. Stand. (U.S) (1968).

Fig. 25.

Specific heat Cp (constant pressure) and enthalpy as functions of temperature. [183]

Fig. 26.

Entropy and specific heat as functions of temperature. [183]

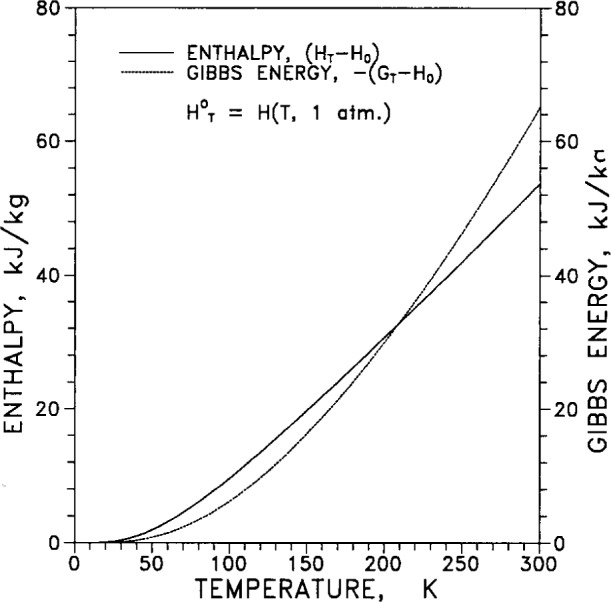

Enthalpy (H°T−H°0) and Gibbs energy −(G°T−H°0) are plotted together in Fig. 27 as functions of temperature for ease of comparison.

Fig. 27.

Enthalpy H and Gibbs energy G as functions of temperature. The reference function H°T is the enthalpy at 100 kPa (1 atm) and temperature T. [183]

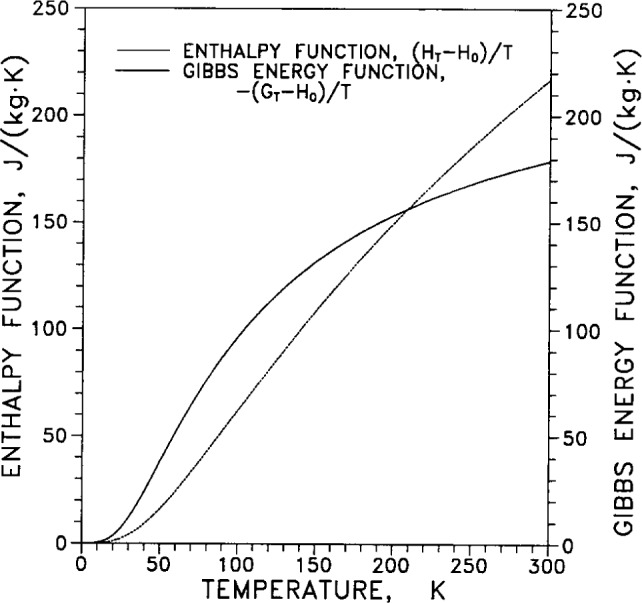

The enthalpy function (H°T−H°0)/T and Gibbs energy function −(G°T−H°0)/T are plotted in Fig. 28 as functions of temperature. These functions are sometimes useful to know because of the thermodynamic identity between Gibbs energy G, enthalpy H and entropy S: G−H= −TS. From this identity it follows that −(G−H)/T=S, and then −(G°T−H°0)/T+(H°T−H°0)/T=S (the superscripts “°” denote the function at 1 nominal atmosphere of pressure; the subscripts denote the temperature). The reference function H°0 is the enthalpy at 101 kPa and 0 K.

Fig. 28.

Enthalpy function (H°T−H°0)/T and Gibbs energy function −(G°T−H°0)/T as functions of temperature. The reference function H°T is the enthalpy at 100 kPa (1 atm) and temperature T. [183]

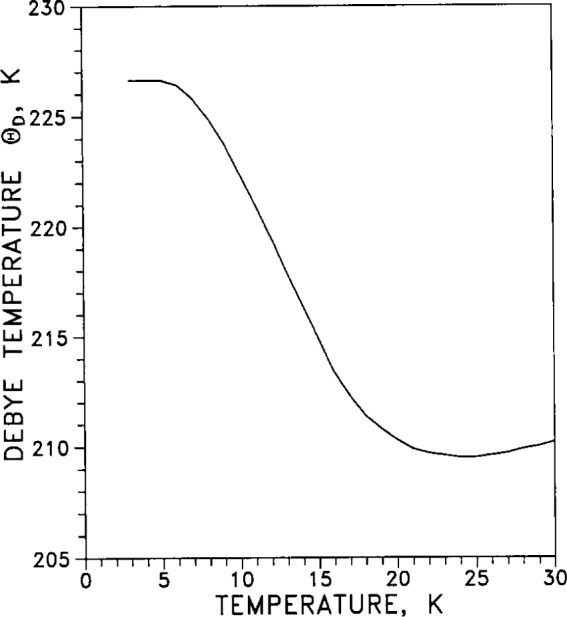

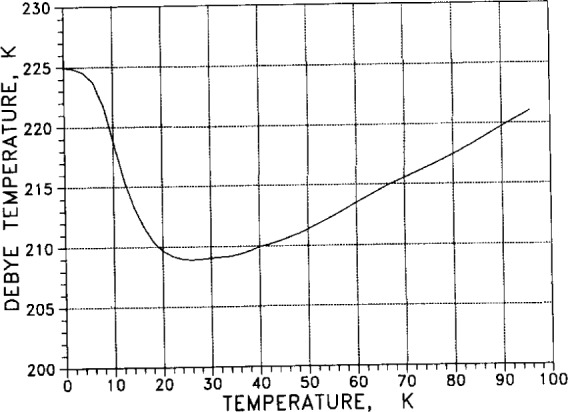

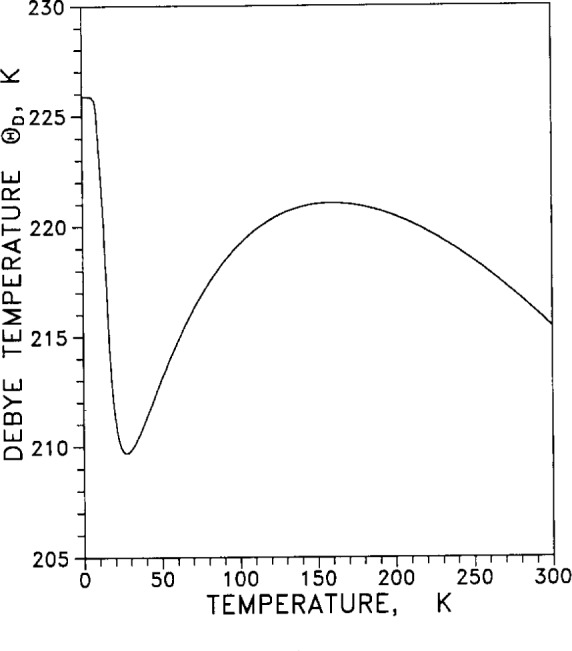

From the specific heat (calorimetric) measurements of Table 7, the low-temperature Debye characteristic temperature Θcal= ΘD as a function of temperature was also obtained, and values are listed in Table 7; the values are plotted in Fig. 29 for temperatures 0 K < T < 30 K. From a different set of specific heat measurements, Debye characteristic temperatures were obtained and plotted in Fig. 30 for temperatures 0 K< T < 100 K. From the specific heat measurements of Table 8, values for the Debye characteristic temperature ΘD were obtained and are plotted in Fig. 31 for temperatures 0 K < T < 300 K. These three different plots of ΘD cover somewhat different, but equally useful, ranges of temperature.

Fig. 29.

Low-temperature Debye temperature (calorimetric) as a function of temperature for 0 K < T < 30 K. [191]

Fig. 30.

Debye temperature as a function of temperature for 0 K < T < 100 K. For this specimen the electronic specific heat γ was 0.66 mJ/(mol·K2) and the effective mass m*/m was 0.95. [193]

Fig. 31.

Debye temperature as a function of temperature for 0 K < T < 300 K. For this specimen the electronic specific heat γ was 0.65 mJ/(mol·K2). [183]

2.7 Mechanical Properties

2.7.1 Hardness, Tensile Strength

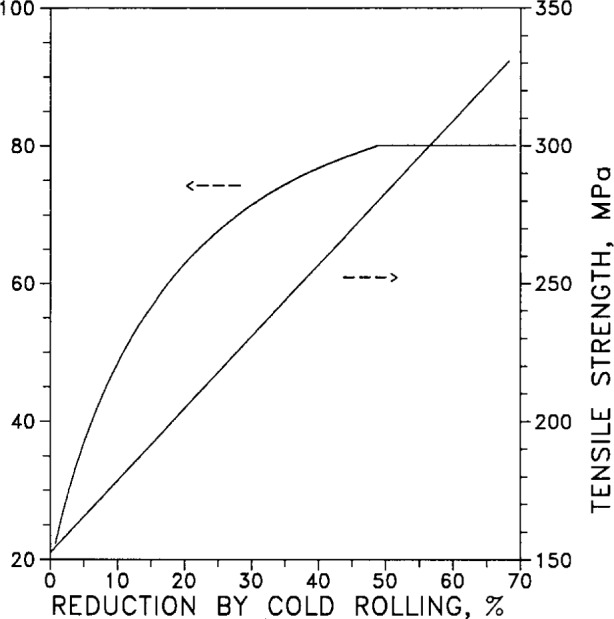

Figure 32 displays Rockwell F hardness and tensile strength for the same specimens of pure silver, subjected to varying degrees of reduction by cold rolling at room temperature.

Fig. 32.

Rockwell F hardness and tensile strength as functions of percent reduction by cold rolling. [124]

2.7.2 Ultimate Tensile Strength

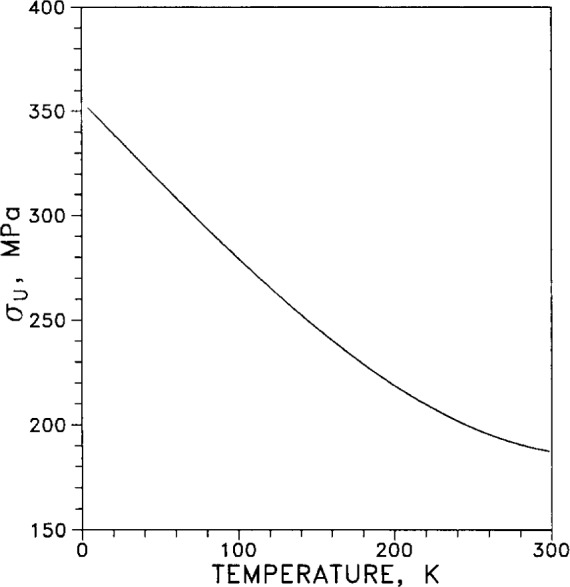

Ultimate tensile strength σU of annealed silver is plotted in Fig. 33 for temperatures from 0 K to 300 K. The effects of duration and temperature of annealing were not explored in this work (applies also to Figs. 34 and 44).

Fig. 33.

Ultimate tensile strength σu as a function of temperature for a “99.995 % pure” specimen, annealed in Ar at 620 °C. [140]

Fig. 34.

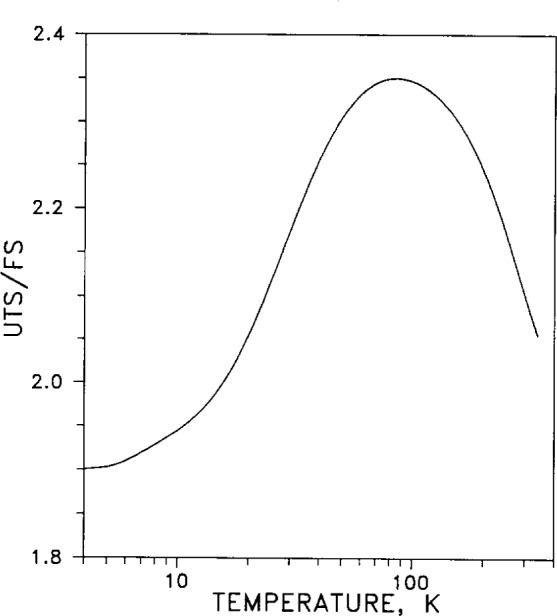

Ultimate tensile strength (UTS), normalized by fatigue strength (FS: peak stress for fracture in 105 cycles), as a function of temperature. [140]

Fig. 44.

Tension-compression fatigue: peak alternating stress as a function of number of cycles to fracture, for temperatures of 4.2 K, 20 K, 90 K, and 293 K. [140]

Ultimate tensile strength (UTS) is plotted in Fig. 34 as a function of temperature. The UTS has been normalized by dividing it by the fatigue strength, defined as the peak stress for fracture in 105 cycles. The fatigue strength rises to a peak as the temperature is lowered below room temperature to about liquid-nitrogen temperature (78 K), but then falls off at temperatures below 78 K. The effects of duration and temperature of annealing were not explored in this work (applies also to Figs. 33 and 44).

2.7.3 Tensile Stress vs Strain

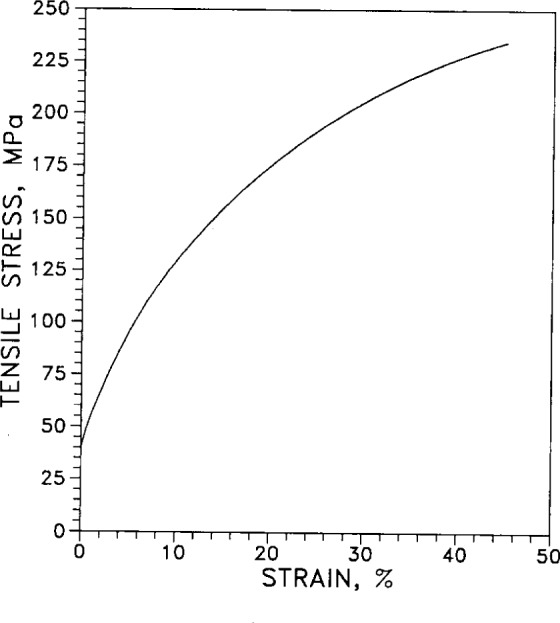

Figure 35 gives tensile stress as a function of percent strain for cold-worked polycrystalline silver. The apparent intercept of the curve with the stress axis at 40 MPa is only an artifact; the original figure as published was quite small and the curve could not be resolved from the axis below this value.

Fig. 35.

Tensile stress as a function of strain for cold-worked polycrystalline silver, “99.99% pure;” the grain size was 20 μm. [27]

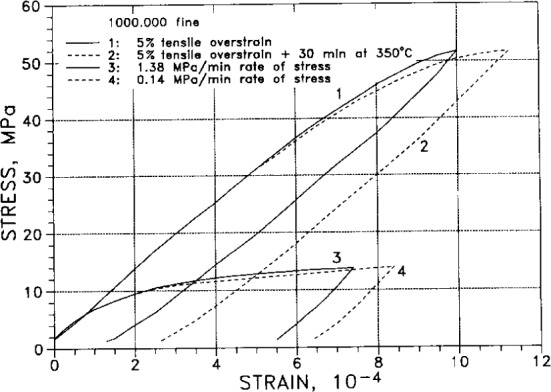

Figure 36 displays stress as a function of strain for different values of stress rate and overstrain, all for the same same specimen. The source paper gives no information on the rate of stress for curves 1 and 2. Tables V and VI of the original paper give the following information: for curve 1, the limit of proportionality was 17.9 MPa (1.3 ton/in2), the 0.01 % proof stress was 45.5 MPa (3.3 ton/in2), the elastic modulus was 69.7 GPa (10.1 Mpsi), the maximum applied stress was 51.9 MPa (3.76 ton/in2), the strain at maximum stress was 10.0×10−4, and the permanent strain was 1.34×10−4. For curve 4: the maximum applied stress was 13.8 MPa (1 ton/in2), the strain at maximum stress was 8.42×10−4, and the permanent strain was 6.4×10−4.

Fig. 36.

Stress as a function of strain for different values of stress rate and overstrain, for “1000.000 fine” silver. [132]

2.7.4 Elastic Moduli

Adiabatic elastic coefficients, or moduli, (commonly termed “constants” even though they vary with temperature and pressure) are listed in Table 9. Of the six quantities listed in the table, only three are independent, and these are usually taken to be C11, C12 and one adiabatic elastic shear modulus, C44. Another elastic shear modulus is defined as C′=(C11−C12)/2, the bulk modulus is B=(C11+2C12)/3, and the longitudinal elastic modulus is CL = (C11+C12+C44)/2. The elastic anisotropy is defined as C44/C′=2C44/(C11−C12).

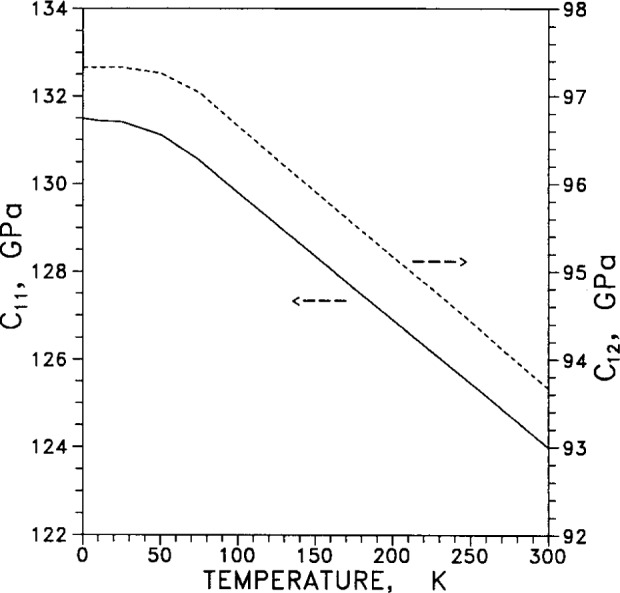

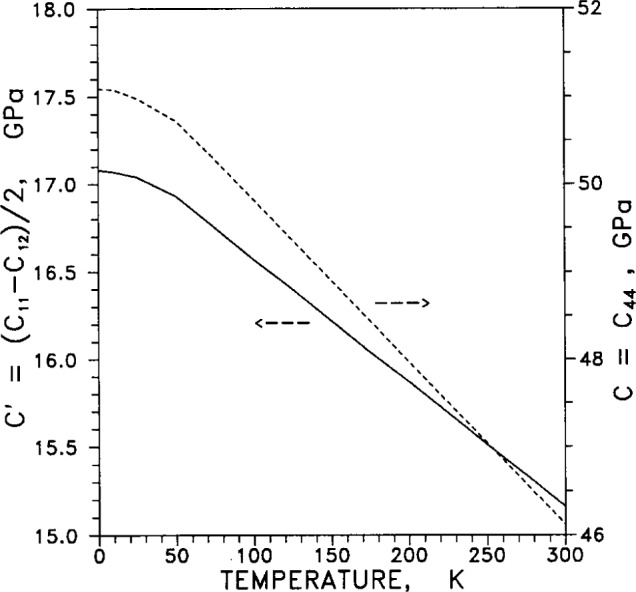

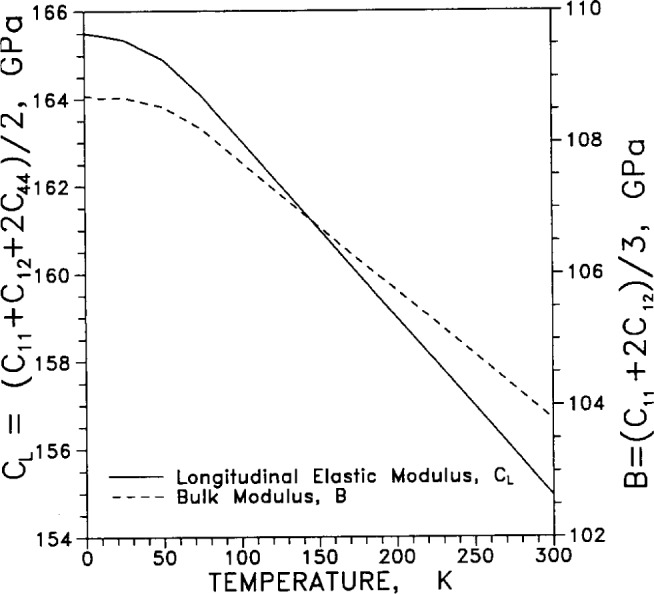

The two elastic stiffness moduli C11 and C12 are plotted in Fig. 37 as functions of temperature (the changes in slope at low temperature are artifacts of the finite number of data points). Fig. 38 displays two adiabatic elastic shear moduli, C=C44 and C′=(C11′C12)/2, plotted together as functions of temperature. The bulk modulus B and the longitudinal elastic modulus CL are plotted together in Fig. 39 as functions of temperature. All the elastic moduli are extremal at liquid-helium temperatures.

Table 9.

Adiabatic elastic coefficient for silvera

Shear constants: C = C44

C′ = (C11 − C12)/2

Longitudinal modulus: CL = (C11 + C12 + 2C44)/2

Bulk modulus: B = (C11 + 2C12)/3

Young’s modulus: E

| Temperauture | C11 | C12 | C=C44 | C′ | B | CL | Eb |

|---|---|---|---|---|---|---|---|

| K | GPa | GPa | GPa | GPa | GPa | GPa | GPa |

| 0 | 131.49 | 97.33 | 51.09 | 17.08 | 108.72 | 165.50 | 91.23 |

| 10 | 131.44 | 97.30 | 51.08 | 17.07 | 108.68 | 165.45 | 91.21 |

| 25 | 131.41 | 97.33 | 50.98 | 17.04 | 108.69 | 165.35 | 91.05 |

| 50 | 131.12 | 97.26 | 50.72 | 16.93 | 108.55 | 164.91 | 90.55 |

| 75 | 130.54 | 97.04 | 50.28 | 16.75 | 108.21 | 164.07 | 89.82 |

| 100 | 129.80 | 96.66 | 49.82 | 16.57 | 107.71 | 163.05 | 88.979 |

| 125 | 129.08 | 96.28 | 49.36 | 16.40 | 107.21 | 162.04 | 88.154 |

| 150 | 128.35 | 95.91 | 48.90 | 16.22 | 106.72 | 161.03 | 87.327 |

| 175 | 127.62 | 95.54 | 48.44 | 16.04 | 106.23 | 160.02 | 86.500 |

| 200 | 126.91 | 95.17 | 47.97 | 15.87 | 105.75 | 159.01 | 85.681 |

| 225 | 126.19 | 94.81 | 47.50 | 15.69 | 105.27 | 158.00 | 84.843 |

| 250 | 125.46 | 94.44 | 47.04 | 15.51 | 104.78 | 156.99 | 84.015 |

| 275 | 124.73 | 94.05 | 46.58 | 15.34 | 104.28 | 155.97 | 83.202 |

| 300 | 123.99 | 93.67 | 46.12 | 15.16 | 103.78 | 154.95 | 82.372 |

J. R. Neighbours and G. A. Alers, Phys. Rev. 111, 707 (1958).

H. Ledbetter, private communication (Ref.134).

Fig. 37.

Elastic stiffness moduli, C11 and C12, as functions of temperature. [36]

Fig. 38.

Adiabatic elastic shear moduli, C and C′, as functions of temperature. [36]

Fig. 39.

Bulk modulus B and longitudinal elastic modulus CL as functions of temperature. [36]

Figure 40 shows the elastic anisotropy coefficient 2C44/(C11−C12) as a function of temperature. It is minimal at 0 K.

Fig. 40.

Elastic anisotropy coefficient, 2C44/(C11−C12) as a function of temperature. [36]

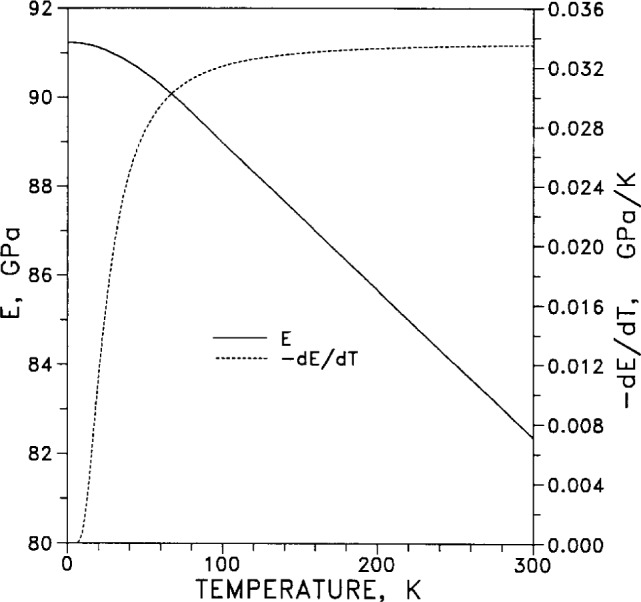

2.7.5 Young’s Modulus

Young’s modulus E and its temperature derivative dE/dT are plotted in Fig. 41 as functions of temperature. The values for E and dE/dT were calculated from elastic-coefficient data.

Fig. 41.

Young’s modulus E and its temperature derivative dE/dT as functions of temperature. [134]

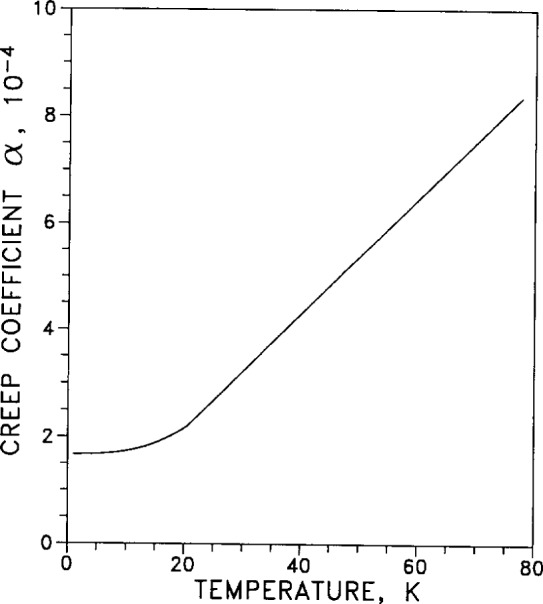

2.7.6 Creep

The creep coefficient α is plotted in Fig. 42 as a function of temperature for an applied stress of 5.9 MPa. The creep strain is given by the expression ∊ =α·ln(γt+1), where γ is a “time proportionality constant” and t is time. Values for γ were not given in the source paper. In Fig. 1 of the original paper (Sec. 3.1, Ref. [128]) creep is plotted as functions of both time and log(time), but corresponding plots are not related by just a single mapping (linear to logarithmic). Careful study raises many unanswered questions, so the reader is cautioned to be careful in using the information from Fig. 1 of Ref. [128].

Fig. 42.

Low-temperature creep as a function of temperature. Strain ϵ = α·ln(γt+l), where α is the creep coefficient and γ is the time proportionality constant. Specimen was a single crystal in “easy-glide stage,” at a deformation stress of 5.9 MPa. [128]

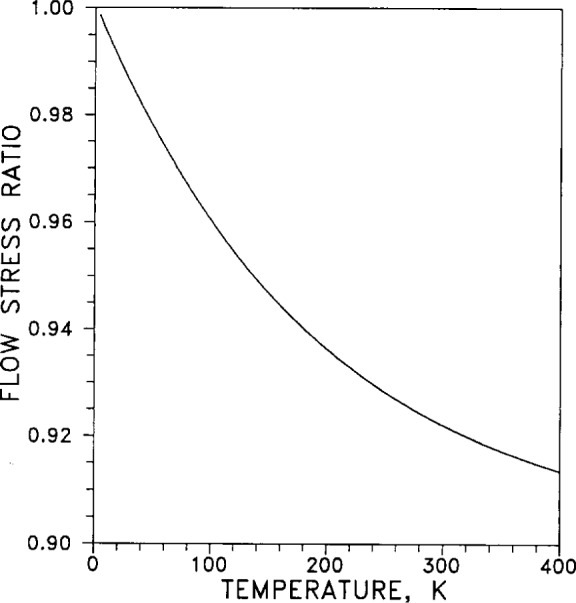

2.7.7 Flow Stress

The ratio τT/GT of flow stress τ to shear modulus G, normalized to unity at T=0, (τT/GT)/(τ0/G0), is plotted in Fig. 43 as a function of temperature. The subscripts T denote temperature dependence.

Fig. 43.

Ratio of flow stress τ to shear modulus G (ratio normalized to unity at T =0): (τT/GT)/(τ0/G0), as a function of temperature T. [134]

2.7.8 Fatigue

Tension-compression fatigue is plotted in Fig. 44 as a function of number of cycles to fracture for test temperatures of 4.2 K, 20 K, 90 K, and 293 K. The effects of temperature and duration of annealing were not explored in this work (applies also to Figs. 33 and 34).

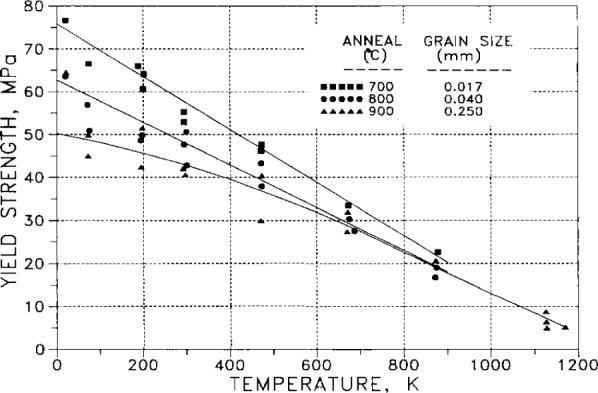

2.7.9 Yield Strength

Yield strength (defined as stress at 0.005 strain) is plotted as a function of temperature for specimens of high-purity (0.9997+) silver in Fig. 45. The specimens, of three different grain sizes (0.017 mm, 0.040 mm, and 0.250 mm), had been annealed at temperatures of 700 °C, 800 °C, and 900 °C, respectively.

Fig. 45.

Yield strength as a function of temperature for three different annealing temperatures and concomitant grain sizes. [120]

In Fig. 46, tensile strength is plotted as a function of temperature and compared to the yield strength, for the same three grain sizes (related to annealing conditions) of Fig. 45.

Fig. 46.

Tensile strength as a function of temperature (for the same annealing temperatures and grain sizes as in Fig. 45). [120]

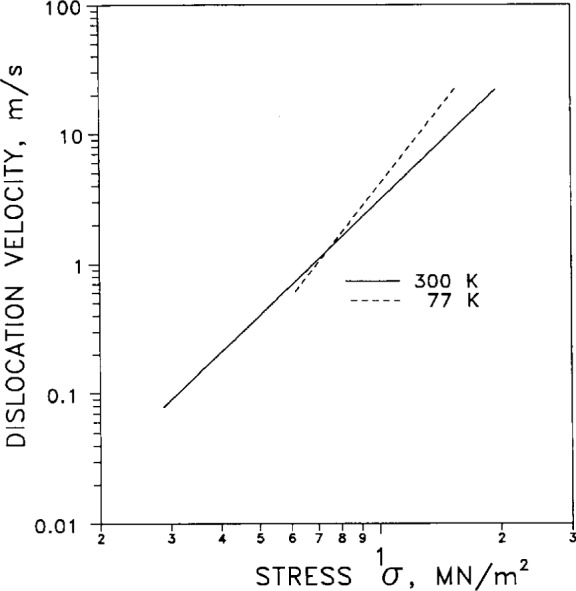

2.7.10 Velocity of Dislocations

Fig. 47 shows the velocities of dislocations moving in a <110>{111} glide system as a function of stress σ, for specimen temperatures of 77 K and 300 K. There is a crossover at a stress of about 7 MN/m2; above this stress the dislocation velocity is greater at 77 K, but below this crossover stress the velocity is greater at 300 K.

Fig. 47.

Velocity of dislocations moving in a < 110 > {111 } glide system, at temperatures of 300 K and 77 K, as a function of stress σ. [28]

2.7.11 Displacement Cross Section

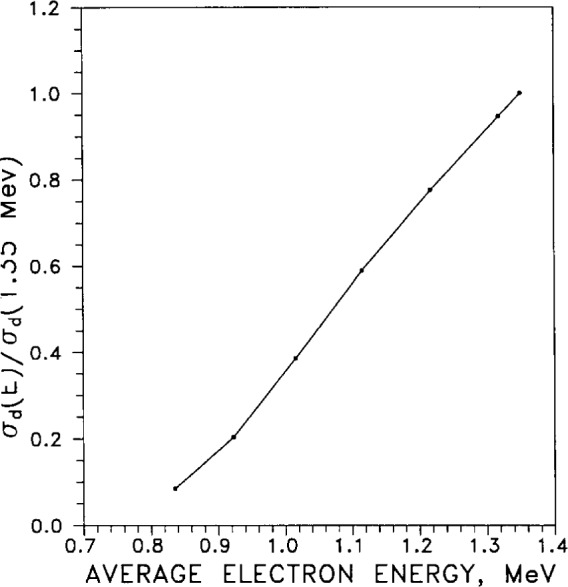

The displacement cross section as a function of electron energy required to displace a silver atom from a lattice site (in bulk silver) is graphed in Fig. 48. The cross sections were normalized by dividing by the displacement cross section at 1.35 MeV, the largest electron energy used. The associated threshold energy for displacement was 28 eV.

Fig. 48.

Displacement cross section σd as a function of electron energy required to displace an Ag atom from a lattice site, normalized to the cross-section value at 1.35 MeV. The displacement threshold energy was 28 eV. [25]

2.8 Miscellaneous

For the convenience of those working with cryogenic fluids, some useful thermodynamic properties are listed in Table 10. For commonly used cryogenic liquids at normal boiling points and for vapors at 101 kPa (1 atm), density, enthalpy, and specific heat are tabulated.

Table 10.

Properties of cryogenic fluidsa

| Liquid at normal boiling point | Vapor at 1.013×105 Pa (1 atm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

|

| |||||||||

| Fluid | Atomic mass u | Temp. | Density | Enthalpy | Spec. ht. CP | Temp. | Density | Enthalpy | Spec. ht. CP |

| K | mol/L | J/mol | J/(mol·K) | K | mol/L | J/mol | J/(mol·K) | ||

| Helium | 4.0026 | 4.222 | 31.20 | −21.0 | 21.10 | 4.222 | 4.226 | 62 | 36.73 |

| 20.27 | 0.601 | 419 | 21.01 | ||||||

| 27.09 | 0.449 | 562 | 20.91 | ||||||

| 77.37 | 0.157 | 1609 | 20.80 | ||||||

| 90.20 | 0.135 | 1876 | 20.79 | ||||||

| 273.15 | 0.045 | 5679 | 20.79 | ||||||

| Hydrogen (para) | 2.0159 | 20.27 | 35.12 | −516 | 19.49 | 20.27 | 0.664 | 382 | 24.68 |

| 27.09 | 0.471 | 539 | 22.15 | ||||||

| 77.37 | 0.158 | 1632 | 23.36 | ||||||

| 90.20 | 0.135 | 1944 | 25.38 | ||||||

| 273.15 | 0.045 | 7657 | 30.36 | ||||||

| Neonb | 20.180 | 27.09 | 59.71 | −1203 | 38.8 | 27.09 | 0.476 | 525 | 24.1 |

| 77.37 | 0.158 | 1602 | 20.9 | ||||||

| 90.20 | 0.135 | 1869 | 20.9 | ||||||

| 273.15 | 0.045 | 5676 | 20.8 | ||||||

| Nitrogen | 28.134 | 77.37 | 28.86 | −3401 | 57.79 | 77.37 | 0.165 | 2164 | 31.45 |

| 90.20 | 0.139 | 2559 | 30.43 | ||||||

| 273.15 | 0.045 | 7934 | 29.15 | ||||||

| Oxygen | 31.999 | 90.20 | 35.66 | −4263 | 54.22 | 90.20 | 0.140 | 2535 | 31.35 |

| 273.15 | 0.045 | 7937 | 29.33 | ||||||

NIST Standard Database 12: NIST Thermophysical Properties of Pure Fluids, (Version 3.0), D. G. Friend (NIST, Gaithersburg, MD, 1992), temperatures converted to ITS-90.

Based on a preliminary NIST thermodynamic surface.

3. Bibliography

| Order of Topics | Ref. Nos. | |

|---|---|---|

| 3.1 | General Reviews ......................... | 1–18 |

| 3.2 | Band Structure ........................... | 19–21 |

| 3.2.1 de Haas-van Alphen Effect ........... | 22 | |

| 3.2.2 Fermi Surface ..................... | 23–24 | |

| 3.3 | Defects ................................. | 25–26 |

| 3.3.1 Dislocations ....................... | 27–30 | |

| 3.4 | Diffusion ............................... | 31–32 |

| 3.5 | Elastic Moduli ........................... | 33–37 |

| 3.5.1 Pressure Dependence................ | 38–39 | |

| 3.5.2 Young’s Modulus ................... | 40 | |

| 3.6 | Electrical Resistivity ...................... | 41–77 |

| 3.6.1 Change with Deformation ............ | 78–83 | |

| 3.6.2 Damage by Irradiation............... | 84–87 | |

| 3.6.3 Hall Coefficient .................... | 88–90 | |

| 3.6.4 Lorenz Number .................... | 91–92 | |

| 3.6.5 Magnetoresistance .................. | 93–104 | |

| 3.6.6 Matthiessen’s Rule.................. | 105–110 | |

| 3.6.7 Pressure Dependence................ | 111–114 | |

| 3.7 | Magnetic Susceptibility .................... | 115–117 |

| 3.8 | Mechanical Properties ..................... | 118–138 |

| 3.8.1 Fatigue ........................... | 139–140 | |

| 3.8.2 Tensile Strength .................... | 141 | |

| 3.9 | Optical And High-frequency Properties ....... | 142–150 |

| 3.9.1 Skin Effect ........................ | 151–153 | |

| 3.10 | Proximity Effect (Superconductive) .......... | 154 |

| 3.11 | Thermal Conductivity ..................... | 155–171 |

| 3.11.1 Magnetothermal Resistance.......... | 172–173 | |

| 3.11.2 Thermal Contact Resistance ......... | 174 | |

| 3.11.3 Thermal Diffusivity................ | 175 | |

| 3.12 | Thermal Expansion ....................... | 176–182 |

| 3.13 | Thermodynamic Properties ................. | 183–186 |

| 3.13.1 Debye Temperature ................ | 187–188 | |

| 3.13.2 Specific Heat ..................... | 189–194 | |

| 3.14 | Thermoelectric Properties .................. | 195–205 |

| 3.15 | Transport Properties ...................... | 206–212 |

| 3.15.1 Nernst-Ettinghausen Effect .......... | 213 | |

| 3.16 | Gas Solubility ........................... | 214 |

| 3.17 | Coin Silver .............................. | 215 |

3.1 General Reviews

-

Butts, Allison, and Coxe, Charles D., Silver: Economics, Metallurgy and Use, Robert E. Krieger, Malabar FL (1967).

Reviews history, sources and markets; extractive and refining processes; physical, chemical, mechanical properties (including bearings and electrical contacts) and behavior of silver bimetals and alloys; metallography of silver; silver batteries, brazing, catalysts, electroplating, and mirrors; silver in dentistry, medicine and photography; fabrication of articles (flatware, holloware) from silver and alloys; powder metallurgy, and migration of silver.

- American Institute of Physics Handbook, Gray, Dwight E., Coordinating Editor, McGraw-Hill, NY (1957).

†18

†19

†21

†T5

†T6Sections on mechanics, acoustics, heat, electricity and magnetism, optics, atomic and molecular physics, and nuclear physics summarize physical properties of materials (for the vast majority of cases, by tabulation). -

American Society for Metals, Metals Handbook Ninth Edition: Volume 2: Properties and Selection: Nonferrous Alloys and Pure Metals, Coxe, C. D., McDonald, A. S., and Sistare, G. H., Jr., compilers: Properties of Silver and Silver Alloys, pp. 671–676; Carapella, S. C., Jr., and Corrigan, D. A., compilers: Pure Metals: Silver, pp. 794–96, ASM, Metals Park, OH (1979).

Tensile strength and elongation (assume room temperature) are plotted as a function of amount of cold work (0 % to 74 %) and as a function of annealing temperature (100 °C to 700 °C).

-

Bell, J. F., The Experimental Foundations of Solid Mechanics, Encyclopedia of Physics, Vol. VIa/1: Mechanics of Solids I, C. Truesdell, ed., pp. 1–801, Springer, Berlin (1973).

The historical and experimental foundations of solid mechanics for metals, plastics and elastic materials are reviewed.

-

Boyer, H. E., and Gall, T. L., eds., Metals Handbook, Desk Edition, ASM, Metals Park, OH (1986).

General physical and structural properties of the metallic elements are tabulated, along with information on processing, testing and inspection.

-

Corruccini, R. J., Properties of Materials at Low Temperatures, Chem. Eng. Prog. (Part 1): 53(6), 262–7; (Part 2): 53(7), 342–6 and (Part 3): 53(8), 397–402 (1957).

This is a practical review of the elementary theories of specific heat, thermal expansion, and electrical and thermal conductivities, and of the properties of metals, alloys, and insulators at low temperatures.

-

Kittel, C., Tables, Introd. to Solid State Physics, 6th Ed., J. Wiley (1986).

For elements (arranged in periodic tables): this university text tabulates cohesive energies at 0 K and 298.15 K, melting points, ionization energies, crystal structures; densities, atomic concentrations and nearest-neighbor distances; atomic and ionic radii; isothermal bulk moduli and compressibilities at room temperature; adiabatic elastic stiffness constants of cubic crystals at low temperatures and room temperature; low-temperature limits of the Debye temperatures; linear thermal expansion coefficients; calculated free-electron Fermi-surface parameters for metals (mostly room-temperature values); experimental and free-electron values of electronic specific heat constants γ of metals; electrical conductivity and resistivity; experimental Lorenz numbers; comparisons of observed with calculated (free-electron theory) Hall constants; superconducting transition temperatures, nuclear-magnetic-resonance (NMR) data, diffusion constants and activation energies, and electron work functions. Many other tables are given for a limited selection of atoms or compounds.

-

Klemens, P. G., Thermal Conductivity of Solids at Low Temperatures, Encyclopedia of Physics, Vol. XIV: Low Temperature Physics I, Springer, Berlin (1956) pp. 198–279.

The theories of thermal conductivity of dielectric solids, of metals and alloys (both electronic and lattice components), and of superconductors, are reviewed.

-

MacDonald, D. K. C., Electrical Conductivity of Metals and Alloys at Low Temperatures, Encyclopedia of Physics, Vol. XIV: Low Temperature Physics I, Springer, Berlin (1956) pp. 137–197.

The experimental techniques for measuring electrical conductivity are reviewed and existing data are compared with theory.

-

Meaden, G. T., Electrical Resistance of Metals, Plenum, New York (1965).

This book tabulates experimental data for the resistivity for temperatures from 20 K to 295 K and summarizes measurement methods. It discusses the theory of resistivity and the effects of deformation, irradiation, pressure, and magnetic field, as well as size effects, on resistivity.

-

Pollock, Daniel D., Physical Properties of Materials for Engineers: Vol. II, CRC Press, Boca Raton (FL).

A table is given of change in electrical resistivity per “atomic percent” (mole fraction) of alloying element in Ag, Au and Cu; the data are from J. O. Linde (Ref. 65).

-

Powell, R. L., Thermophysical Behavior of Metals at Cryogenic Temperatures, pp. 134–148, ASTM STP 387, Behavior of Materials at Cryogenic Temperatures, ASTM, PA (1965).

Thermophysical properties are tabulated and graphed.

-

Reed, Richard P., and Clark, Alan F., Materials at Low Temperatures, American Society for Metals, Metals Park, OH (1983).

Topical chapters review elastic, electrical, magnetic, mechanical, metallurgical, thermodynamic, thermal, and transport properties of metals, alloys, superconductors, and composites useful for applications at cryogenic temperatures.

-

Robertson, A. R., Precious Metals: Precious Metals and Their Uses, Metals Handbook, Vol. 2, 10th Ed., ASM, Metals Park, OH (1990).

Some physical, chemical and mechanical properties of Ag, Pt, Pd, Ir, Rh, Os, Ru, and Au are tabulated.

-

Rogers, B. A., Schoonover, I. C., and Jordan L., Silver: Its Properties and Industrial Uses, NBS Circular C412 (1936).

This work comprehensively reviews physical (atomic, mechanical, thermal, electrical, galvanometric, thermomagnetic, thermoelectric, and optical; magnetic susceptibility), chemical (electrochemical, corrosion, and catalytic), and technological (mechanical) properties of pure silver, and some properties of binary alloys (Ag with Al, Cd, Cu, Pb, Sn, and Zn). Industrial uses of pure Ag as a bactericide, in chemical equipment resistant to corrosion, and in electrical equipment are briefly discussed.

-

Rosenberg, H. M., Low Temperature Solid State Physics: Some Selected Topics, Oxford Univ., London (1963).

This text reviews theory of and experimental data for specific heat, transport properties, thermal expansion, and magnetic and mechanical properties, for metals, semiconductors and superconductors.

-

Rosenberg, H. M., The Properties of Metals at Low Temperatures, Chap. 5 of Prog. in Metal Physics, Vol. 7, B. Chalmers and R. King, eds., Pergamon, NY (1958).

The thermal conductivity, electrical resistivity and superconductivity, and mechanical properties of metals in general, at temperatures below 90 K, are reviewed, with some properties of specific metals and alloys given.

-

Smithells Metals Reference Book, Sixth Edition, Eric A Brandes, Editor, Butterworths, London (1983).

Many thermophysical properties are tabulated.

3.2 Band Structure

-

Christensen, N. E., The Band Structure of Silver and Optical Interband Transitions, phys. stat. sol. (b) 54, 551–563 (1972).

The band structure of silver was calculated using the relativistic augmented-plane-wave (RAPW) method. A plot of density of states versus energy from 0 Ryd to 1.5 Ryd (1 Ryd = 13.6 eV) is given. The Fermi energy is approximately 0.444 Ryd above the muffin-tin zero, or 0.551 Ryd above the band bottom (Γ6+). The electronic density of states per atom at the Fermi level, N(EF), is 3.4556 Ryd−1. The band structure has been checked against optical experiments and overall agreement is very good.

-

Mathewson, A. G., Aronsson, H., and Bernland, L. G., The conduction electron optical mass in pure silver; J. Phys. F: Metal Phys. 2, L39–L41 (1972).

A new, lower value for the optical mass m0 of conduction electrons in pure silver is reported. The value m0 = 0.85 me was obtained for silver evaporated onto a sapphire substrate in an ultra-high vacuum of 6.7×10−8 Pa (5×10−10 Torr). After exposure of the silver film to air for 16 hours the optical mass was found to have increased to 0.87. The increase is attributed to the development of a film of silver sulfide on the surface of the silver.

-

Sondheimer, E. H., The Mean Free Path of Electrons in Metals, Adv. Phys. 1(1), 1–42 (1952).

The theory of electrons in metals is reviewed. Electrical conduction and magnetic (Hall) effects in thin films and wires are discussed and compared with experimental results for Na wires. The anomalous skin effect is treated and the experimental high-frequency surface resistance of silver at low temperatures is graphed, as well as the theoretical absorption coefficient of silver at 4.2 K.

3.2.1 de-Haas-van Alphen Effect

-

Coleridge, P. T., and Templeton, I. M., High precision de Haas-van Alphen measurements in the noble metals, J. Phys. F: Metal Phys. 2, 643–656 (1972).

The de Haas-van Alphen frequencies for the symmetry-direction orbits (<111> belly, <111> neck, <100> belly, <100> rosette, and <110> dogs-bone) and the turning point of the (110) plane-belly turning point were measured for Ag, Au, and Cu. The data are estimated to have an “absolute precision” of 20 ppm (parts in 106) and a “relative precision” of nearly 1 ppm. Comparisons with other measurements from the literature are tabulated.

3.2.2 Fermi Surface

-

Cracknell, A. P., The Fermi Surfaces of Metals: A Description of the Fermi Surfaces of the Metallic Elements, Barnes & Noble, NY (1971).

The neck radius of the Fermi surface of silver is 0.14 (with the radius of the spherical free-electron Fermi surface as the unit), and is smaller than the radii of the Fermi surfaces of both Cu and Au.

-

Visscher, P. B., and Falicov, L. M., Review Article: Fermi Surface Properties of Metals, Phys. Stat. Sol. (b) 54, 9–51 (1972).

The independent-particle picture for electrons, simple equilibrium phenomena, dynamics of electrons in electric and magnetic fields, equilibrium phenomena in magnetic fields, simple transport phenomena, and transport phenomena in magnetic fields are reviewed in separate sections. A value of γ = 0.646 mJ/(K2·mol) for silver is given. Table 4 is a comprehensive list of references for band- structure calculations, the de Haas-van Alphen effect, the anomalous skin effect, galvanomagnetic effects, cyclotron resonance, size effects, and ultrasonics. There are 23 references for the above properties of silver.

3.3 Defects

Bass, Jack, Deviations from Matthiessen’s Rule, Adv. Phys. 21, 431–604 (1972), see Ref. 106, Sec. 3.6.6 Matthiessen’s Rule.

-

Damask, A. C., and Dienes, G. J., Point Defects in Metals, Gordon and Breach, NY (1963).

†48 This work reviews the general theory of: (1) thermodynamics, energies, mobility, and production of defects; (2) theory of annealing; (3) analysis of annealing curves; (4) influence of point defects on physical properties; (5) experimental investigations of the effects of quenching, irradiation, annealing and diffusion. The energy of formation EF of (monovacancy) defects is given as 1.09 eV. The change in electrical resistivity per electron flux (number of incident particles per cm2) is plotted as a function of energy of incident electrons, and then replotted as the displacement cross section for moving a silver atom from a lattice site by incident electrons, again as a function of energy of incident electrons. The threshold energy ED for displacing a silver atom from its lattice site is given as 28 eV, and the resistivity change per unit of defect concentration in “atomic percent” (mole fraction) △ρF is 1.4 μΩ·cm/(at/o). The damage rate under fast-neutron irradiation at 20 °C at a flux of 7×1011 cm2·s−1 is 3.35×10−11 Ω·cm/h. The neutron exposure required to produce 1at/° of vacancy-interstitial pairs is 1.05×1020 nvt of fast neutrons (n is number density of neutrons, v is velocity, t is time; nvt is neutron fluence, number per second per unit area). Broom, T., Lattice Defects and the Electrical Resistivity of Metals, Adv. Phys. 3(9), 26–83 (1954), see Ref. 82, Sec. 3.6.1 Change with Deformation.

Jongenburger, P., The Extra-Resistivity Due to Vacancies in Copper, Silver and Gold, Appl. Sci. Res. B3, 237–248 (1953?), see Ref. 55, Sec. 3.6 Electrical Resistivity.

Ramsteiner, F., Schuele, W., and Seeger, A., Untersuchung atomarer Fehlstellen in verformtem und abgeschrecktem Silber (An Investigation of Atomic Vacancies in Rolled and Quenched Silver), Phys. Stat. Sol. 2, 1005–1020 (1962) (in German).

The annealing of quenched and cold-rolled silver (purities of 99.9 % and 99.999 %) was studied in the range of temperature from −40 °C to +250 °C. Distinct recovery processes were found. For quenched silver, a recovery stage attributed to migration of vacancies was found between 50 °C and 130 °C, with an activation energy of 0.88 eV. For cold-rolled silver, a recovery stage attributed to interstitial migration was found between −40 °C and −10 °C, with an activation energy of 0.60 eV. For the cold-rolled specimen, a recovery stage found above 70 °C was thought to be due to rearrangement and annihilation of dislocations.

3.3.1 Dislocations

-

Bailey, J. E., and Hirsch, P. B., The Dislocation Distribution, Flow Stress, and Stored Energy in Cold-Worked Polycrystalline Silver, Phil. Mag. 5, 485–497 (1960).

†35 For cold-worked polycrystalline silver of “99.99 % purity,” plots are given for stress versus extension (strain). Dislocation densities in silver foil are tabulated for three different extensions. Total stored energy, and energies released during recovery and during recrystallization are tabulated for four different extensions. Barnard, R. D., Some Remarks on Deviations from Matthiessen’s Rule in Dilute Alloy Systems, Phys. Stat. Sol. (b) 104, 613–620 (1981), see Ref. 105, Sec. 3.6.6 Matthiessen’s Rule.

Bergmann, A., Kaveh, M., and Wiser, N., Electrical resistivity of the noble metals at low temperatures: II. Effect of electron-dislocation scattering, J. Phys. F: Metal Phys. 12, 3009–3030 (1982), see Ref. 47, Sec. 3.6 Electrical Resistivity.

Hashimoto, S., Miura, S., and Yagi, T., Decrease in Dislocation Density During Reverse Deformation in Silver Single Crystals by Etch-Pit Method, Scripta Metall. 10(9), 823–27 (1976), see Ref. 139, Sec. 3.8.1 Fatigue.

McLean, D., Strain Hardening in Pure Metals, Chap. 5 of Mechanical Properties of Metals, J. Wiley, NY (1962), see Ref. 131, Sec. 3.8. Mechanical Properties.

- Nadgornyi, E., Dislocation Dynamics and Mechanical Properties of Crystals, Prog. Matls. Sci., Vol. 31, J. W. Christian, P. Haasen, and T. B. Massalski, eds., p. 319, Pergamon, Oxford (1988).

†47 This work reviews dislocation dynamics theoretically and experimentally. The velocity of dislocations moving along a <110>{111} glide system at 300 K and 77 K is plotted (Fig. 6.21), for silver and dilute silver-based alloys (Ag with In, Sb, Sn). For the source of this particular plot see the paper by H. Suga and T. Imura (Ref. 29). -

Suga, Hisaaki, and Imura, Toru, Dynamic Behav-ior of Dislocations in Silver and Silver Base Dilute Alloy Single Crystals, Japn. Inst. Metals 17, 605–614 (1976).

The density, distribution, velocity, multiplication and mobility of dislocations is studied by changing solute content and test temperature. The stress exponent m for the velocity of dislocations in pure silver is 2.8 at room temperature. Four plots of data for dislocation parameters are given.

- Takamura, S., and Kobiyama, M., Dislocation Pinning in Al and Ag Alloys after Low-Temperature Deformation, Phys. Stat. Sol. (a) 95, 165–172 (1986).

†6 Specimens of Ag and Al (99.999 % pure), and of dilute alloys of each metal, were torsionally deformed at 77 K. The electrical resistivities ρ0 after isochronal annealing were measured at 4.2 K. In silver annealing stages were observed at 110 K and 230 K to 250 K. The lower-temperature stage is interpreted as being due to migration of interstitial clusters or vacancy-type defects near dislocations, and the higher-temperature stage, to long-range migration of vacancies and dissociation of vacancy clusters. The elastic modulus changes at 110 K and 240 K.

3.4 Diffusion

-

Burke, J. E., and Turnbull, D., Recrystallization and Grain Growth, Prog. Metal Phys. Vol. 3, B. Chalmers, ed., p. 247, Pergamon, London (1952).

For silver, the free energy of activation for lattice self-diffusion, (ΔFA)L, is 163.2 kJ/mol; for grain-boundary diffusion, (ΔFA)B is 77.8 kJ/mol; for grain-boundary self-diffusion, (ΔFA)G is 90.0 kJ/mol.

-

le Claire, A. D., Diffusion of Metals in Metals, pp. 306–379, Prog. Metal Phys. Vol. 1, B. Chalmers, ed., Butterworths, London, (1949).

A calculated value for the activation energy of movement of single vacancies is quoted as 62.8 kJ/mol. For noble metals and transition metals there is a rough proportionality between the activation energy Qa of a diffusing atom and the melting temperature Tm of the solvent metal. The proportionality is more closely followed for self-diffusion, and for silver QS/Tm=155 J/(K·mol), where QS = 192 kJ/mol.

3.5 Elastic Moduli

-

Boas, W., and Mackenzie, J. K., Anisotropy in Metals, p. 103, Prog. Metal Phys., Vol. 2, B. Chalmers, ed., Pergamon, London (1950).

Tabulates elastic compliance coefficients Sij and elastic stiffness coefficients Cij for crystals having trigonal, tetragonal, hexagonal and cubic symmetry.

-

Chang, Y. A., and Himmel, L., The Temperature Dependence of the Elastic Constants of Cu, Ag, and Au above Room Temperature, J. Appl. Phys. 37, 3567–72 (1966).

Adiabatic elastic constants were measured for silver from 300 K to 800 K, tabulated and graphed.

-

Hiki, Y., and Granato, A. V., Anharmonicity in Noble Metals, Higher Order Elastic Constants, Phys. Rev. 144(2), 411–419 (1966).

Second-order and third-order elastic constants of Cu, Ag, and Au were measured at room temperature. Complete sets of six third-order elastic constants were obtained. Data are tabulated and plotted.

- Neighbours, J. R., and Alers, G. A., Elastic Constants of Silver and Gold, Phys. Rev. 111(3), 707–712 (1958).

†37

†38

†39

†40

†T9The three elastic coefficients C=C44, C′=(C11–C12)/2, and CL=(C11+C12+2C44)/2, for Ag and Au were measured over the range 4.2 K < T < 300 K. Data are plotted and tabulated. Debye characteristic temperatures obtained from the elastic constants are in good agreement with results from calorimetry. -

Prasad, B., and Srivastava, R. S., Lattice dynamics of noble metals, J. Phys. F: Metal Phys. 2, 247 (1972).

Theoretical matrix elements for the electron-phonon interaction were used to analyze the lattice dynamics of Ag, Au, and Cu. Vibration spectra (dispersion curves), elastic constants and Debye temperatures were calculated, and found to agree with experimental values

3.5.1 Pressure Dependence

-

Daniels, W. B., and Smith, C. S., Pressure Derivatives of the Elastic Constants of Copper, Silver and Gold to 10000 Bars; Phys. Rev. 111(3), 713–721 (1958).

The pressure derivatives of the elastic constants of Ag, Au, and Cu were obtained from measurements over the range 0 < p < 1 GPa (10 kbar). The derivatives for silver were evaluated using C = C44 = 46.13 GPa, C′ = (C11−C12)/2 = 15.28 GPa, the adiabatic bulk modulus BS=(C11+2C12)s/3 = 103.6 GPa, and the isothermal bulk modulus BT = 101.5 GPa. For silver the pressure derivatives of the elastic constants are (pressure units of 100 GPa = 1012 dyn/cm2): dBS/dp = 6.18, dC/dp =2.31, and dC′/dp = 0.639. The elastic constants at 0 K are (units of 10−19 J/atom): B = 18.3, C = 8.52, and C′ = 2.84.

-

Guinan, M. W., and Steinberg, D. J., Pressure and Temperature Derivatives of the Isotropic Polycrystalline Shear Modulus for 65 Elements, J. Phys. Chem. Solids 35, 1501–1512 (1974).

Experimental values are tabulated for the temperature derivative of the isotropic polycrystalline shear modulus for 47 elements, and pressure derivative for 39 elements.

3.5.2 Young’s Modulus

(See also Sec. 3.8 Mechanical Properties)

-

Kuhlmann-Wilsdorf, Doris and Wilsdorf, Heinz, The Surface Structures of Deformed Aluminum, Copper, Silver, and Alpha-Brass, and Their Theoretical Interpretation, Acta Metallurgica 1, 394 (1953).

Gives average stress-strain curves of super-purity Al, Cu and Ag, and for commercial alpha brass.

Druyvesteyn, M. J., Experiments on the Effect of Low Temperatures on Some Plastic Properties of Metals, App. Sci. Research 1, 66 (1947?); see Ref. 122, Sec. 3.8 Mechanical Properties.

McKeown, J. and Hudson, O. F., Stress-strain Characteristics of Cu, Ag and Au; J. Inst. Metals 60, 109–132 (1937), see Ref. 130, Sec. 3.8 Mechanical Properties.

Takamura, S., and Kobiyama, M., Dislocation Pinning in Al and Ag Alloys after Low-Temperature Deformation, Phys. Stat. Sol. (a) 95, 165–172 (1986), see Ref. 30, Sec. 3.3.1 Dislocations.

3.6 Electrical Resistivity

(See also Sec. 3.15 Transport Properties)

-

Barber, A. J. and Caplin, A. D., The low temperature electrical resistivity of high purity Ag and Ag based alloys, J. Phys. F: Metal Phys. 5, 679–696 (1975).

Electrical resistivities of commercially available high-purity silver (and of alloys of Ag with Au, Pd and Pt) were measured from 2 K to 20 K. Matthiessen’s rule did not hold at all temperatures. Possible dependence of resistivity on temperature as T5 was investigated; most specimens showed very nearly a T4 dependence on temperature below 10 K.

-

Barnard, B. R., and Caplin, A. D., ‘Simple’ be-havior of the low temperature electrical resistivity of silver?, Communications Physics 2, 223–227 (1977). (Same title as that of Ref. 43 by same authors.)

Electrical resistivity for the temperature range 1.2 K < T < 9 K is plotted for large single crystals of silver. The resistivity varies with temperature as T4 between 1.2 K and 4 K. From 4 K to 9 K the resistivity varies more slowly than T4.

-

Barnard, B. R., and Caplin, A. D., ‘Simple’ behavior of the low temperature electrical resistivity of silver?, J. Physique Colloque C6, Suppl. to No. 8, Tome 39, p. C6-1050–1051 (1978), (Same title as that of Ref. 142.)

Electrical resistivity for the temperature range 1.2 K < T < 9 K is plotted for large single-crystal ingots of silver.

-

Bass, Jack, Electrical Resistivity of Metals and Alloys at Cryogenic Temperatures: A Review, Advances in Cryogenic Engineering (Materials), Vol. 30, Plenum, NY (1984) p. 441.

Residual resistivity for Ag-Au alloys is plotted as a function of Au concentration, and for pure polycrystalline silver as a function of temperature for 40 K < T < 1200 K.

-

Bergmann, A., Kaveh, M., and Wiser, N., Explanation of the anomalous T4 behaviour of the low-temperature electrical resistivity of silver; J. Phys. F: Metal Phys. 10, L71–L76 (1982).