Abstract

Objective: To evaluate the hydrothermal aging effect on the translucency of partially stabilized tetragonal zirconia with yttria (Y-TZP) used as monolithic or fully milled zirconia and of core type.

Methods: Twenty disc-shaped specimens (1 and 10 mm) for each type of monolithic and core Y-TZP materials were milled and sintered according to the manufacturer’s instruction. The final specimens were divided into two groups according to the type of Y-TZP used. Translucency parameter (TP) was measured over white and black backgrounds with the diffuse reflectance method; X-ray diffraction (XRD) and scanning electron microscope (SEM) were used to analyze the microstructure of both Y-TZP types before and after aging. Data for TP values was statistically analyzed using Student’s t-test.

Results: Monolithic Y-TZP showed the highest TP mean value (16.4 ± 0.316) before aging while core Y-TZP showed the lowest TP mean value (7.05 ± 0.261) after aging. There was a significant difference between the two Y-TZP types before and after hydrothermal aging. XRD analysis showed increases in monoclinic content in both Y-TZP surfaces after aging.

Conclusion: Monolithic Y-TZP has a higher chance to low-temperature degradation than core type, which may significantly affect the esthetic appearance and translucency hence durability of translucent Y-TZP.

Keywords: Translucent zirconia, microstructure, low-temperature degradation

Introduction

Dental all-ceramic restorations have been used as an alternative to metal ceramic restorations due to their excellent esthetics, chemical stability and biocompatibility.[1–6] Zirconia (ZrO2) has rapidly achieved a leading position among the polycrystalline ceramic dental restorative materials. It is used as a framework for crowns or fixed partial dentures as well as oral implants.[7,8] The partially stabilized tetragonal zirconia with yttria (Y-TZP) was introduced to dentistry as a core material for all-ceramic restorations and has been made available through the computer-aided design/computer-aided milling (CAD/CAM) technique. Even though reports about ZrO2 as core material indicate that these frameworks have excellent fracture resistance, the problem of chipping and fracture of ceramic veneer has been reported as a common technical problem.[9,10] This is in addition to the opaqueness of ZrO2 core, which should be masked with a translucent layer of veneer ceramic to achieve the natural appearance of tooth structure. The color of this opaque core significantly influences esthetic of all-ceramic restoration.[11–13] Recently, it has become possible to fabricate all-ceramic restorations with high resistant to fracture, even when they are used in the posterior region, by using ZrO2-based materials due to its good mechanical properties and tooth-like appearance.[14,15] This ZrO2 has many advantages over the porcelain-veneered ZrO2 copings in that no liability of veneering fracture or chipping as it is already absent, beside the high strength that is reported to be comparable to previous all-ceramic crowns as well as a patent shading system that enables high esthetic matching. All these advantages allow less axial walls and occlusal reduction in tooth structure to be done. The absence of added porcelain veneer procedures, which may be responsible for the induced stresses in ZrO2 core/veneer interface in layered restorations, may be also considered as an additional advantage.[16] However, the fact of exposing ZrO2 surface to the oral environment in monolithic restorations makes it even more liable to the commonly named low-temperature degradation (LTD) than core type covered with porcelain veneer. It happens due to progressive and spontaneous transformation of the metastable tetragonal (t) phase into the monoclinic (m) phase (t-m transformation) when this transformation is not triggered by local stresses produced by advancing crack.[16–18] The LTD of monolithic ZrO2 may be considered as an important factor affecting the durability of fine-grained metastable microstructure and stability of t grains during the lifetime of TZP components, which is the key-point to attain the expected performance of Y-TZP.[19–21] The aim of the present study was to evaluate the effect of hydrothermal aging on the translucency of monolithic ZrO2 used for full coverage dental restorations in comparison with core ZrO2 type.

Materials and methods

Forty disc-shaped specimens (10 mm in diameter and 1 mm in thickness) from both monolithic and core Y-TZP types were prepared. They were divided into two groups according to the type of ZrO2 used (i.e. n = 20). The two groups were further subdivided according to whether being subjected to hydrothermal aging or not. Hydrothermal aging was performed using an autoclave (CISA S.p.A., Pomezia, Rome, Italy) at 134 °C and under pressure two bars for 15 h.[22]

Preparation of monolithic specimens

They were fabricated using Y-TZP pre-sintered cake block (Zirkonzahn Prettau, Zirkonzahn GmbH, Bruneck, Italy). A resin pattern (10 × 1 mm) was prepared from the self-cured acrylic resin (Pattern Resin LS, GC America Inc., Alsip IL). The thickness of 1 mm was previously recommended for monolithic ZrO2.[23] The resin pattern was fixed on one side of the milling table of Zirkonzahn milling system (Zirkograph 025 ECO, Zirkonzahn GmbH) while Prettau Y-TZP block was fixed on the other side of the table. The milled specimen was 20–25% larger than the resin pattern to compensate for the sintering shrinkage. Specimens were prepared by copy-milling, carefully removed from the milled blank and lightly finished to remove any sharp margins using silicon carbide papers (grits 400, 600 μm) under water to remove any sharp edges or points and minimize the finishing and polishing after sintering. Shade A2 stain was applied to all the specimens. Sintering was done using ZrO2 oven (Zirkonofen 600, Zirkonzahn). The oven temperature was raised to 1600 °C within 4 h, kept at this temperature for 2 h and then gradually decreased within another 2 h, according to manufacturer’s instructions. After complete cooling to room temperature, the discs were finally polished from both sides using a polishing paste (Meta Di, grain size (GS) 1 μm, Düsseldorf, Germany) with minimal pressure and under water to final monolithic specimens.

Preparation of core ZrO2

Core specimens were fabricated using Y-TZP (Lava frame, 3M-ESPE, St. Paul, MN) using resin pattern (10 × 1 mm) and copy-milling machine by the same technique for the monolithic specimen. They received shade A2 and sintered using Lava oven (Lava furnace 200, 3M ESPE). Oven temperature was 1500 °C for 8 h, according to manufacturer’s instructions. Specimens were finally polished. Materials used in the present study are summarized in Table 1.

Table 1.

Materials used in the study.

| Material type | Material commercial name | Manufacturer | Composition wt % | Batch number |

|---|---|---|---|---|

| Y-TZP for monolithic crown construction | Zirkonzahn Prettau Y-TZP pre-sintered blocks | Zirkonzahn GmbH, Bruneck, Italy | Main components: ZrO2 (92.27) Y2O3 (4–6).Traces: Al2O3 (<1), SiO2 (0.02), Fe2O3 (0.01) and Na2O (0.04). | ZRAD8061 |

| Y-TZP for core construction | Lava frame Zirconia pre-sintered blocks | 3M-ESPE, St. Paul, MN | Main component: ZrO2 (92.27), Y2O3 (4.98).Traces: Al2O3 (0.43), SiO2 (0.21), HfO2 (1.58). | 68591 |

Crystal microstructure

X-ray diffractometer (X’Pert Pro, PANalytical B.V. company, Costa da Caparica, Portugal) was used to analyze the microstructure of both ZrO2 types before and after hydrothermal aging. Data were collected from the diffraction angle (2θ) ranges between 25 and 79° and in step size (2θ) 0.02° with 1 s dwell time. Standard patterns or models for each of the three ZrO2 phases (tetragonal, cubic and monoclinic) were used for comparison and refinement of the obtained phase structure. The volume of monoclinic phase (Vm) was quantified according to Garvie and Nicholson approach.[24] The Vm was determined by measuring the height of two nearest m peaks in relation to the main T/C main peak detected at nearly 30.1° 2θ according to the following equation:

where, M1 is monoclinic peak at 28.2°2θ, M2 is monoclinic peak at 31.9° 2θ and T/C is a tetragonal/cubic (T/C) peak at 30.1° 2θ.

Intensity counts were used as indication for degree of crystallinity and the average crystal size (L), before and after aging, was calculated from the “Scherrer formula” as follows:[25]

where λ is the X-ray wavelength in nanometer (nm), β is the peak width of the diffraction peak profile at half maximum height resulting from small crystallite size and K is a constant related to crystallite shape (0.9).

Translucency test

The translucency parameter (TP) of two ZrO2 types was detected using the spectrophotometer (UV Shimadzu 3101 PC, UV-VIS-NIR Scanning Spectrophotometer, Tokyo, Japan) before and after hydrothermal aging through diffuse reflectance method. The TP was detected by calculating the color difference for each specimen when it was placed over a black background or reference (0 lightness) and then over a white background or reference (100 lightness, barium sulfate pressed powder). Each specimen was subjected to the light source, which applies to the CIE (Commission Internationale de l'Eclairage) standard illumination requirements. The CIE-Lab color co-ordinates (L*, a*, b*) for each specimen were then calculated in several steps via a special software (MATLAB, MathWorks, Inc., Michigan, United States) in both conditions of black and white backgrounds. The TP was calculated through the following equation:

where  is the value (lightness) over a black reference while

is the value (lightness) over a black reference while  is the value over white reference,

is the value over white reference,  and

and  are red-green coordinates values over black and white references, respectively,

are red-green coordinates values over black and white references, respectively,  and

and  are blue-yellow coordinates values over black and white references, respectively.[26,27]

are blue-yellow coordinates values over black and white references, respectively.[26,27]

Scanning electron microscope (SEM) analysis

It was done using gold-coated ZrO2 surfaces and scanned using SEM (JEOL, JSM-5300-Japan-Scanning Microscope, Tokyo, Japan) to study the shape and compaction of grains for ZrO2 types.

Results

Crystal microstructure

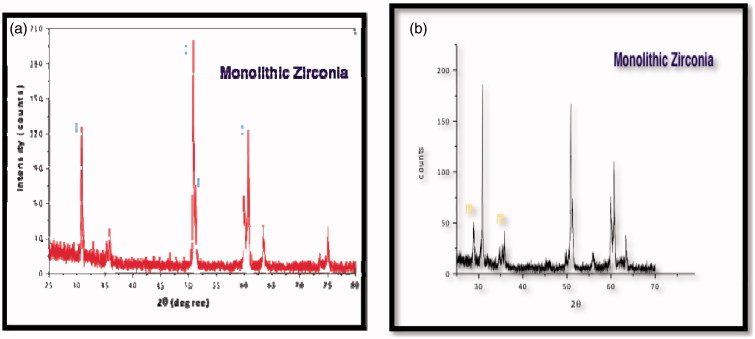

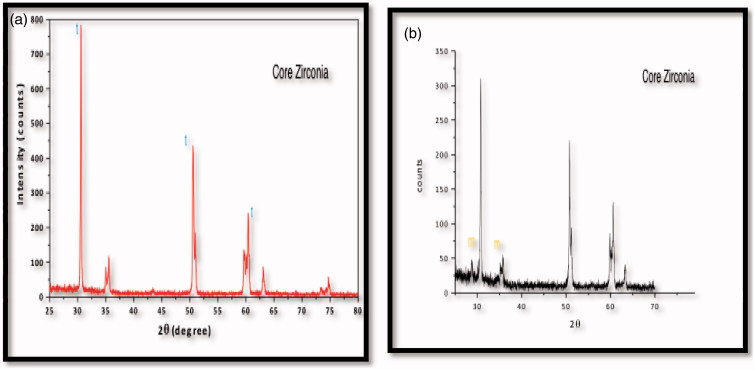

Dominant T/C peak for core Y-TZP appeared at an approximate position of 30.5°2θ (111 hkl) before aging while the T/C peak appeared at 50.5°2θ (112 hkl) was in a higher position relative to that peak at 30.1°2θ with no apparent monoclinic peaks. Dominant monoclinic peaks appeared at 28.7 and 28.5°2θ (−111 hkl) of the aged pattern in both Y-TZP types. Core Y-TZP showed higher crystal intensity counts (up to 800) (Figure 1 a and b) while monolithic Y-TZP showed lower crystal intensity counts (up to 200) (Figure 2 a and b) in X-ray patterns before and after aging. Aged monolithic specimens showed Vm of 25% while aged core Y-TZP specimens showed Vm values of 18% after accelerated hydrothermal aging (Table 2). Regarding average crystal size, monolithic Y-TZP showed larger average crystal size than core type before and after aging. After aging, the crystal size was decreased for both monolithic and core Y-TZP types (30.243 and 22.612 nm, respectively) (Table 3).

Figure 1.

X-ray diffraction patterns of monolithic zirconia: (a) before aging, (b) after aging with monoclinic (m) peaks.

Figure 2.

X-ray diffraction patterns of core zirconia: (a) before aging, (b) after aging with monoclinic (m) peaks.

Table 2.

Volumetric monoclinic phase content of aged Y-TZP (Vm).

| Y-TZP Type | Vm (%) |

|---|---|

| Monolithic | 25.0 |

| Core | 18.0 |

Vm, monoclinic volume after aging.

Table 3.

Average grain particle size for both Y-TZP types before and after aging.

| Y-TZP type | Average crystal size (nm) | |

|---|---|---|

| Monolithic | Before aging | 49.682 |

| After aging | 30.243 | |

| Core | Before aging | 34.915 |

| After aging | 22.612 | |

Translucency test

Monolithic Y-TZP showed the highest mean values (16.4 ± 0.316 and 13.35 ± 0.158), before and after aging, respectively. However, core Y-TZP showed the lowest mean translucency values (9.38 ± 0.395 and 7.05 ± 0.261), before and after aging, respectively. Comparing the mean translucency values for both types of Y-TZP before and after aging was done using Student’s t-test. It showed that there was a significant difference between core (p = 0.0001) and monolithic Y-TZP (p = 0.0001) before and after aging. There was a statistical significant difference within both core and monolithic groups (p = 0.0001 and 0.0001) before and after hydrothermal aging, respectively (Table 4).

Table 4.

Student’s t-test of translucency for both materials before and after aging.

| Material | Translucency |

Tvalue | p value | |||

|---|---|---|---|---|---|---|

| Before |

After |

|||||

| Mean | SD | Mean | SD | |||

| Monolithic | 16.4 | 0.316 | 13.35 | 0.158 | 19.3 | 0.0001* |

| Core | 9.38 | 0.395 | 7.05 | 0.261 | 8.53 | 0.0001* |

| T value | 31.3 |

45.9 |

||||

| p value | 0.0001* | 0.0001* | ||||

* significant difference at P value ≤ 0.05.

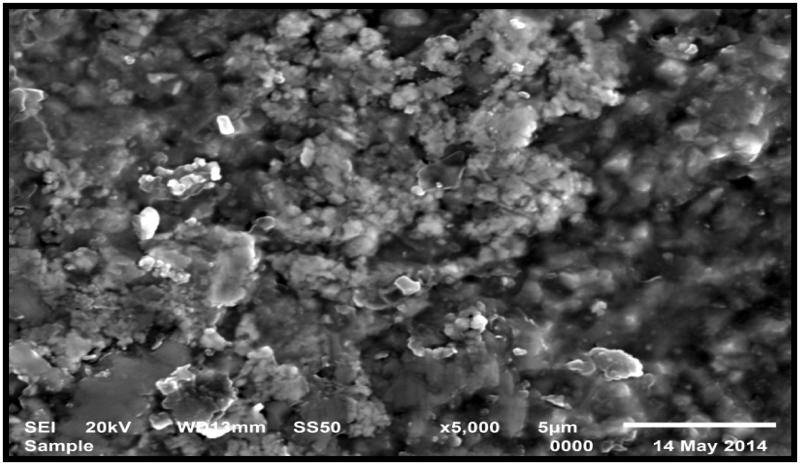

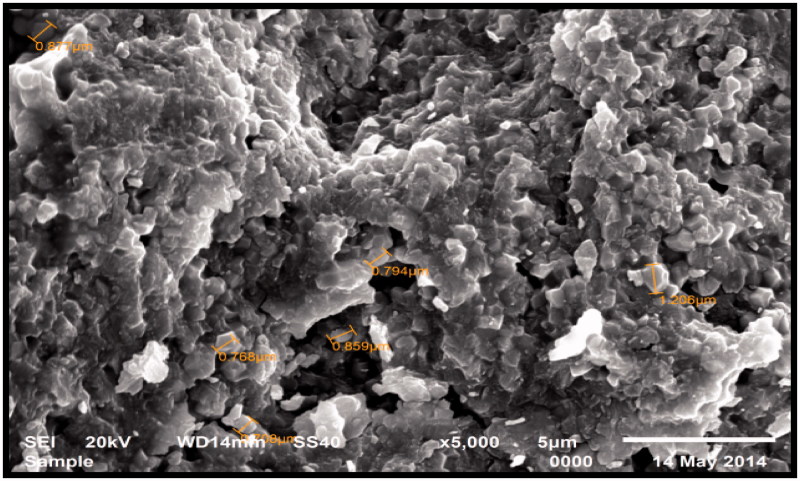

SEM analysis

It showed that monolithic Y-TZP showed less dense grain structure (×5000) than did core type appeared at the same magnification power (Figures 3 and 4, respectively).

Figure 3.

SEM images of monolithic Y-TZP before aging showing the less dense structure before aging (magnification 5000).

Figure 4.

SEM images of core Y-TZP before aging showing the more dense structure before aging (magnification 5000).

Discussion

Recently, the introduction of monolithic Y-TZP with improved translucency in an attempt to overcome the veneer chipping and opacity problems was accomplished successfully.[16] However, ZrO2 LTD issue and its effect on a monolithic type, in comparison with core ZrO2, needs more comprehensive study.

Crystal microstructure

ZrO2 LTD and any deterioration in the properties are accompanied by microstructural changes and an increase in monoclinic content. Accelerated hydrothermal aging, simulating the oral environment, was done using autoclave at 134 °C and pressure two bars for 15 h, which is equivalent, nearly, to 45–60 years in patient’s mouth. It was reported that placing 3-mol Y-TZP for 1 h in an autoclave at 134 °C and pressure two bars is equivalent to 3–4 years at 37 °C.[28,29] The X-ray diffraction (XRD) patterns of both types of Y-TZP (monolithic and core) before aging revealed the presence of T/C phases. The dominant T/C appeared at nearly 30.6°2θ (111 hkl) in both types of ZrO2. This is in agreement with the phase diagram of ZrO2 in which ZrO2 having 3-mol Y2O3 in the composition should present two phases (T/C) microstructure when sintered at 1400–1500 °C.[28] Both Y-TZP types revealed monoclinic peaks appearance at 28.5° 2θ (−111 hkl) after aging, which agrees with the previous findings of an increase in monoclinic content after hydrothermal aging.[29–41] Monolithic Y-TZP showed higher average crystal size than core type before and after aging. Both Y-TZP types showed a decrease in crystal size after aging. Core ZrO2 showed higher crystal intensity counts denoting higher crystalline content while monolithic ZrO2 showed lower counts denoting lower crystalline content.[34,35]

Core Y-TZP showed higher resistance to LTD than monolithic type. This may be attributed to the finding of having smaller average crystal sizes than monolithic Y-TZP. It was reported previously that larger grains are less resistant to transformation but more favorable to mechanical properties.[36] Reducing the GS of metastable t-ZrO2 ceramics has a beneficial effect as it reduces the thermodynamic driving force for transformation. Although, there was, up till now, no clinical evidence of LTD in dental ZrO2 but the combination of large grain sizes and oral humid environment can precipitate such autocatalytic degradation.[37]

Translucency

Core Y-TZP is known to be of low translucency, even if it has a high translucent porcelain veneer due to its low refractive index, low absorption coefficient and high opacity in visible and infrared regions of the spectrum.[27] The significant difference in TP values between the two Y-TZP types used in the present study may be explained through the XRD microstructure analysis results. It was found that core Y-TZP was characterized by smaller average GS of the dispersed particles and showed higher intensity counts and lower TP values than monolithic type, which showed higher values for GS and intensity counts. This is in accordance with a previous study where ceramics with a high degree of crystallinity showed lower translucency values. The smaller GS with a higher degree of crystallinity may lead more scattering of the incident light and hence higher opacity with lower translucency and vice versa.[27,38]

There was a significant decrease in TP values in both types of Y-TZP after 15 h of hydrothermal aging. This may be attributed to the increase in monoclinic content Vm after aging in both materials. It is in agreement with previous studies [22,39] where the appearance of monoclinic phase on the surface is accompanied by formation of microcracking as well as the monoclinic phase itself may act as a flaw or defect in ZrO2 microstructure. These microcracking may act as porosity or defects enhancing scattering of incident light beam thus reducing translucency. The presence of voids or porosities as well as material’s thickness, crystallinity and grain size may all act as various factors affecting light scattering and consequently lead to impairment of translucency.[38] The co-existence of different phases (monoclinic and T/C) after hydrothermal aging may have been contributed to increase the difference in refractive indices of an incident light beam by various phases and hence decreasing the translucency values.[40,41] Gain size and hence grain boundaries also have a great effect on translucency. The larger grain size reported to have higher translucency like what was found in monolithic ZrO2 in the present study due to larger grain boundaries.[36]

Conclusion

Within the limitations of the present study, the recently introduced translucent Y-TZP used as monolithic crowns and bridges showed significant higher translucency than core type when it is subjected to hydrothermal aging for 15 h. On the other hand, it has higher susceptibility to LTD that may negatively affect its durability that needs further investigations especially on its mechanical properties.

Acknowledgements

My sincere thanks and appreciation to Prof. Michael V Swain, Professor of Biomaterials, Science Research Unit, Faculty of Dentistry, University of Sydney, Australia, for his valuable assistance in the XRD field. My sincere gratitude to Prof. Al-Sayed A Hafez, Professor of Dental Biomaterials, Faculty of Dentistry, Mansoura University, Egypt.

Declaration of interest

The authors report no conflicts of interest. The authors alone are responsible for the content and writing of this article.

References

- 1. Kelly JR, Nishimura I, Campell SD.. Ceramic in dentistry: historical roots and current perspectives. J Prosthet Dent. 1996;75:18–32. [DOI] [PubMed] [Google Scholar]

- 2. Blatz MB. Long-term clinical success of all-ceramic posterior restorations. Quintessence Int. 2002;33:415–426. [PubMed] [Google Scholar]

- 3. Ardlin BI. Transformation-toughened zirconia for dental inlays, crowns and bridges: chemical stability and effect of low-temperature aging on flexural strength and surface structure. Dent Mater. 2002;18:590–595. [DOI] [PubMed] [Google Scholar]

- 4. Sobrinho LC, Cattell MJ, Glover RH, et al. Investigation of the dry and wet fatigue properties of three all-ceramic crown systems. Int J Prosthodont. 1998;11:255–262. [PubMed] [Google Scholar]

- 5. Campbell SD, Sozio RB.. Evaluation of the fit and strength of an all-ceramic fixed partial denture. J Prosthet Dent. 1988;59:301–306. [DOI] [PubMed] [Google Scholar]

- 6. Nakamura T, Ohyama T, Imanishi A, et al. Fracture resistance of pressable glass-ceramic fixed partial dentures. J Oral Rehabil. 2002;29:951–955. [DOI] [PubMed] [Google Scholar]

- 7. Çehreli MC, Kökat AM, Akça K.. CAD/CAM Zirconia vs. slip-cast glass-infiltrated Alumina/Zirconia all-ceramic crowns: 2-year results of a randomized controlled clinical trial. J Appl Oral Sci. 2009;17:49–55. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8. Deng Y, Lawn BR, Lloyd IK.. Characterization of damage modes in dental ceramic bilayer structures. J Biomed Mater Res. 2002;63:137–145. [DOI] [PubMed] [Google Scholar]

- 9. Kohal RJ, Klaus G, Strub JR.. Zirconia-implant supported all-ceramic crowns withstand long-term load: a pilot investigation. Clin Oral Implants Res. 2006;17:565–571. [DOI] [PubMed] [Google Scholar]

- 10. Kim B, Zhag Y, Pines M, et al. Fracture of porcelain-veneered structures in fatigue. J Dent Res. 2007;86:142–146. [DOI] [PubMed] [Google Scholar]

- 11. Hofmann H, Michel B, Gauckler LJ.. Zirconia powder for TZP-ceramics: Ti-Y-TZP In: Meriani S, Palmonari C, editor. Advances in Zirconia’ 88. Elsevier; 1989. pp. 119–130. [Google Scholar]

- 12. Schneider J, Begand S, Kriegel R, et al. Low temperature aging behavior of alumina-toughened zirconia. J Am Ceram Soc. 2008;91:3613–3618. [Google Scholar]

- 13. Hallmann L, Ulmer P, Reusser E, et al. Effects of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP. J Eur Ceram Soc. 2012,32:4091–4104. [Google Scholar]

- 14. Inan O, Secilmis A, Eraslan O.. Effect of pontic framework design on the fracture resistance of implant-supported all-ceramic fixed partial dentures. J Appl Oral Sci. 2009;17:533–538. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15. Kim JW, Covel NS, Guess PC, et al. Concerns of hydrothermal degradation in CAD/CAM zirconia. J Dent Res. 2010;89:91–95. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16. Jung YS, Lee WJ, Ahn JS, et al. A study on the in-vitro wear of the natural tooth structure by opposing zirconia or dental porcelaim. J Adv Prosthodont. 2010;2:111–115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17. Ban S. Reliability and properties of core materials for all-ceramic dental restorations. Jpn Dent Sci Rev. 2008;44:3–21. [Google Scholar]

- 18. Lawson S. Environmental degradation of zirconia ceramics. J Eur Ceram Soc. 1995;15:485–502. [Google Scholar]

- 19. Lance MJ, Vogel EM, Reith LA, et al. Low-temperature aging of zirconia ferrules for optical connectors. J Am Ceram Soc. 2001;84:2731–2733. [Google Scholar]

- 20. Yu B, Ahn JS, Lee YK.. Measurement of translucency of tooth enamel and dentine. Acta Odontol Scand. 2009;67:57–64. [DOI] [PubMed] [Google Scholar]

- 21. Sato Y, Wadamoto M, Tsuga K, et al. The effectiveness of element down sizing on a three-dimensional finite element model of bone trabeculae in implant biomechanics. J Oral Rehabil. 1999,26:288–291. [DOI] [PubMed] [Google Scholar]

- 22. Kohorst P, Borchers L, Strempel J, et al. Low-temperature degradation of different zirconia ceramics for dental applications. Acta Biomater. 2012;8:1213–1220. [DOI] [PubMed] [Google Scholar]

- 23. Sun T, Zhou S, Lai R, et al. Load-bearing capacity and the recommended thickness of dental monolithic zirconia single crowns. J Mech Behav Biomed Mater. 2014;35:93–101. [DOI] [PubMed] [Google Scholar]

- 24. Taskonak B, Yan J, Mecholsky JJ Jr, et al. Fractographic analyses of zirconia-based fixed partial dentures. Dent Mater. 2008;24:1077–1082. [DOI] [PubMed] [Google Scholar]

- 25. Monshi A, Foroughi MR, Monshi MR.. Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. WJNSE 2012;2:154–160. [Google Scholar]

- 26. Ahn JS and Lee YK.. Difference in the translucency of all-ceramics by the illuminant. Dent Mater. 2008;24:1539–1544. [DOI] [PubMed] [Google Scholar]

- 27. Lim HN, Yu B, Lee YK.. Spectroradiometric and spectrophotometric translucency of ceramic materials. J Prosthet Dent. 2010;104:239–246. [DOI] [PubMed] [Google Scholar]

- 28. Chevalier J, Grandjean S, Kuntz M, et al. On the kinetics and impact of tetragonal to monoclinic transformation in an alumina/zirconia composite for arthroplasty applications. Biomaterials 2009;30:5279–5282. [DOI] [PubMed] [Google Scholar]

- 29. Kawai Y, Uo M, Wang Y, et al. Phase transformation of zirconia ceramics by hydrothermal degradation. Dent Mater J. 2011;30:286–292. [DOI] [PubMed] [Google Scholar]

- 30. Tholey MJ, Berthold C, Swain MV, et al. XRD2 micro-diffraction analysis of the interface between Y-TZP and veneering porcelain: role of application methods. Dent Mater. 2010;26:545–552. [DOI] [PubMed] [Google Scholar]

- 31. Cástková K, Hadraba H, Cihlář J.. Hydrothermal ageing of tetragonal zirconia ceramics. Ceram Silikaty 2004;48:85–92. [Google Scholar]

- 32. Kosmac T, Oblak C, Marion L.. The effects of dental grinding and sandblasting on ageing and fatigue behavior of dental zirconia (Y-TZP) ceramics. J Eur Ceram Soc. 2007;28:1085–1090. [Google Scholar]

- 33. Li KC, Waddell JN, Prior DJ, et al. Effect of autoclave induced low-temperature degradation on the adhesion energy between yttria-stabilized zirconia veneered with porcelain. Dent Mater. 2013;29:263–270. [DOI] [PubMed] [Google Scholar]

- 34. Paul A, Vaidhyanathan B, Binner JGP.. Hydrothermal aging behavior of nanocrystalline Y-TZP ceramics. J Am Ceram Soc. 2011;94:2146–2152. [Google Scholar]

- 35. Chevalier J, Deville S, Münch E, et al. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials 2004;25:5539–5545. [DOI] [PubMed] [Google Scholar]

- 36. Keuper M, Eder K, Berthold C, et al. Direct evidence for continuous linear kinetics in the low-temperature degradation of Y-TZP. Acta Biomater. 2013;9:4826–4835. [DOI] [PubMed] [Google Scholar]

- 37. Lange FF. Transformation toughened ZrO2: correlations between grain size control and composition in the system ZrO2-Y2O3. J Am Ceram Soc. 1986;69:240–242. [Google Scholar]

- 38. Baldissara P, Llukacej A, Ciocca L, et al. Translucency of zirconia copings made with different CAD/CAM systems. J Prosthet Dent. 2010;104:6–12. [DOI] [PubMed] [Google Scholar]

- 39. Fischer H, Marx R.. Fracture toughness of dental ceramics: comparison of bending and indentation method. Dent Mater. 2002;18:12–19. [DOI] [PubMed] [Google Scholar]

- 40. McLaren EA,Terry DA.. CAD/CAM systems, materials and clinical guidelines for the all-ceramic crowns and fixed partial dentures. Compend Contin Educ Dent. 2002;23:637–652. [PubMed] [Google Scholar]

- 41. Heffernan MJ, Aquilino SA, Diaz-Arnold AM, et al. Relative translucency of six all-ceramic systems. Part I: core materials. J Prosthet Dent. 2002;88:4–9. [PubMed] [Google Scholar]