Abstract

Recent studies in rehabilitation of Parkinson’s disease (PD) have shown that cycling on a tandem bike at a high pedaling rate can reduce the symptoms of the disease. In this research, a smart motorized bicycle has been designed and built for assisting Parkinson’s patients with exercise to improve motor function. The exercise bike can accurately control the rider’s experience at an accelerated pedaling rate while capturing real-time test data. Here, the design and development of the electronics and hardware as well as the software and control algorithms are presented. Two control algorithms have been developed for the bike; one that implements an inertia load (static mode) and one that implements a speed reference (dynamic mode). In static mode the bike operates as a regular exercise bike with programmable resistance (load) that captures and records the required signals such as heart rate, cadence and power. In dynamic mode the bike operates at a user-selected speed (cadence) with programmable variability in speed that has been shown to be essential to achieving the desired motor performance benefits for PD patients. In addition, the flexible and extensible design of the bike permits readily changing the control algorithm and incorporating additional I/O as needed to provide a wide range of riding experiences. Furthermore, the network-enabled controller provides remote access to bike data during a riding session.

Index Terms: Parkinson’s disease, rehabilitation, smart exercise bike, tandem cycling, forced exercise, control systems, signal processing

I. Introduction

Parkinson’s disease (PD) which affects approximately one million people in the US and around 7 to 10 million people worldwide is a progressive neurodegenerative disease that is characterized by the loss of dopaminergic neurons in the brainstem [2]. The major symptoms of the PD are movement disorders including shaking or tremor, muscle stiffness and rigidity, and slowness of physical movements (bradykinesia). As PD advances, both motor and non-motor symptoms often begin to increase patient reliance on caregivers and the healthcare system. There is not any known cure for this degenerative disease that results in progressive deterioration of motor skills along with other reduced physical and cognitive functions. The accepted treatment for PD is medication (e.g. levodopa) and in some cases, surgical intervention (deep brain stimulation). These treatments only mask the symptoms and do not delay or slow down progression of the disease. Furthermore, they often have undesirable side effects (e.g. dyskinesias, sleep disturbances) and are costly. Considering these deficiencies, there is a need for innovative treatments to prevent, delay disease progression, or reduce the symptoms of PD.

Recent studies have shown that exercise and movement therapies can benefit individuals with PD [3–4, 7]. Several research studies in humans have revealed that high intensity treadmill training and high cadence cycling [1, 2, 4, 6, and 7] improves motor function in PD patients. Ridgel [4, 6] and Alberts [7] have shown that forced exercise (high cadence cycling) results in a significant improvement in motor symptoms as measured with Unified Parkinson’s Disease Rating Scale (UPDRS) Motor III. In [4], a novel approach was introduced to increase exercise intensity in individuals with PD called forced exercise. This approach used a stationary tandem bicycle and an able-bodied cyclist (trainer) to assist individuals with PD to pedal at a cadence between 80–90 RPM which is about 30% faster than the cadence patients were able to pedal on their own. This type of exercise resulted in improvements of 40% in motor function of both the upper and lower extremity for a group of 5 patients diagnosed with PD [4, 7]. These results are remarkable and suggest that significant physiological changes occur as a result of cycling at an accelerated cadence. Despite these remarkable results, large-scale use of the tandem cycling paradigm for exercise therapy is not feasible. First, tandem cycling requires an able-bodied trainer to assist in pedaling that is not reasonable in large-scale clinical deployment or in-home use. Second, variability in trainer pedaling speed, stamina, and response to the PD rider’s performance creates variations that make data analysis and conclusions in clinical studies difficult to generalize. Third, there are a number of factors, such as cadence, foot position and workload that can affect the biomechanics of cycling. Many motorized single-rider stationary exercise bikes are commercially available today that can provide a pre-programmed load profile for the rider. However, without access to control parameters of the drive and motor in current exercise motorized bikes, and generally slow motor dynamics, it is difficult to reproduce tandem bike riding dynamics using the available exercise motorized bikes.

Robotic rehabilitation devices have been widely used in PD [15] and stroke [9, 10 and 14] to promote motor recovery. The value of this type of rehabilitation is the ability to deliver high-intensity therapy that assists movement and responds to patient performance. Furthermore, robot-based rehabilitation can provide positive benefits without increasing therapist burden and healthcare costs. However, it is challenging to design adaptive assist-as-needed control for these devices [8]. Variability in symptom severity and functional abilities among individuals with Parkinson’s disease require “intelligent” therapies.

Our proposed solution to this problem is to design a smart motorized bicycle which simulates tandem cycling and could assess individual effort, performance, skill level, and therapeutic value in order to dynamically alter motor resistance, speed and riding time. The instrumented cycle was constructed using a commercially available exercise bike chassis that is augmented with high-performance motor, sensors, control and automation equipment that employ an open architecture with components, training and support services readily available from distributors around the world. Advanced control techniques and high performance motor-drives can be integrated with a single-rider stationary bike to permit the rider to experience similar conditions as on a stationary tandem bike with two riders. The objective of this program is to establish a motorized bike that can be readily adapted to accommodate different riders and different riding experiences including the imitation of a tandem bike riding experience. The bike with embedded controls and servo-motor drive system is termed as Smart (Intelligent) Bike.

The Smart Bike continually monitors the mechanical and electrical characteristics of the cycle along with the rider’s physical and neuromuscular response during operation. The captured data could be analyzed to determine which unique temporal features of the sampled data are correlated with the rider’s motor skill level. The established correlation will permit real-time assessment of the performance of the rider during a cycling session.

Recently, we have studied the complexity of biomechanical and physiological features of assisted (tandem) and voluntary (single) cycling and related these features to improvements in motor function as measured by UPDRS Motor III scale [2]. This study showed that temporal variability or lack of predictability in cadence during active-assisted cycling is a predictor of improvements in UPDRS Motor III scores [2]. Based on these findings, one of the key features of the proposed Smart Bike is the capability of running at higher speed (between 80–90 RPM which is about 30% faster than the cadence generally PD patients are able to pedal on their own) with the appropriate amount of variability in cadence [2]. This feature is innovative because it provides a fluctuating (non-constant) interaction with the rider.

The novel motorized bike has been instrumented with: (a) sensors for feedback control and for high speed sampling of bike data, (b) sensors that capture real-time rider data, (c) a motor speed controller capable of dynamically changing motor speed and torque, (d) a programmable controller that integrates sensor data, communicates with the motor speed controller, provides feedback control and communicates with the display system, (e) a user interface, termed HMI (human machine interface) that is capable of displaying the bike and patient data and for entering the required control parameters, and (f) a data logging and data acquisition system to support subsequent historical reporting and data analysis.

This instrumented exercise bike is novel because it provides an effective platform to examine the associations between rider performance and changes in bike control. The dataset obtained from this study will provide a basis for future development and testing of customized optimal exercise regimens for individual with PD. Furthermore, this research platform will permit automatically tailoring an exercise regimen for individuals with different skill levels, disease severity levels and improvement profiles. Exercise programs may be readily optimized for each individual with minimum effort.

II. System architecture; Hardware, Electrical and ELECTRONICS

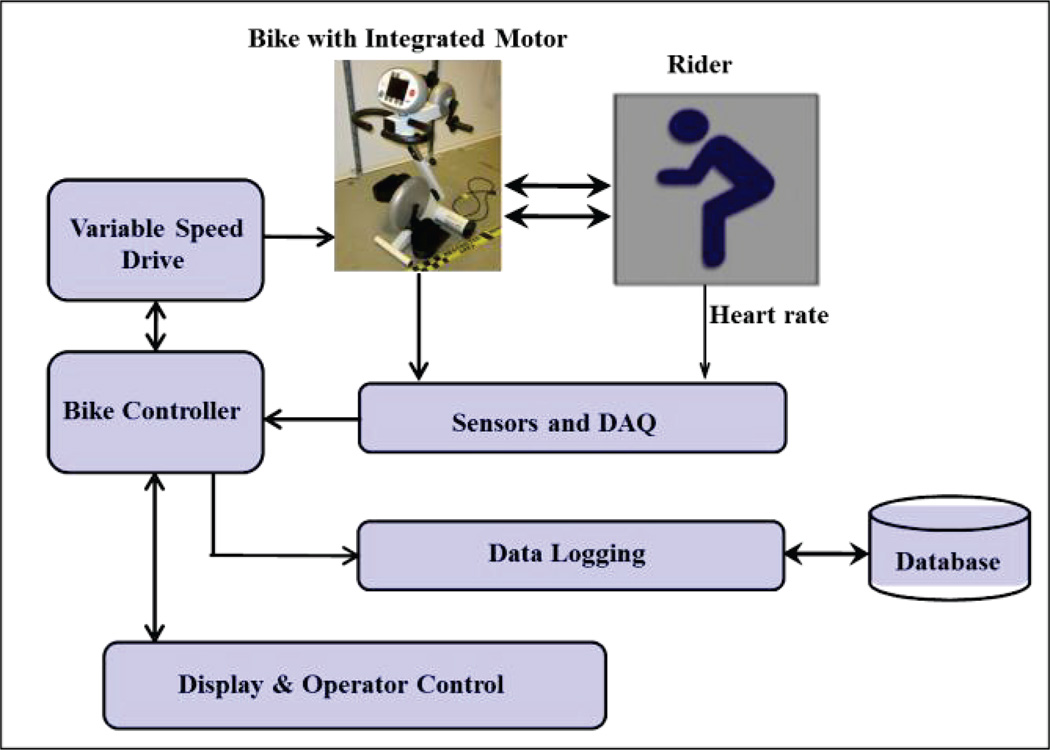

A commercially available bike chassis from the RECK Company (Motomed Viva21) served as the mechanical platform for the Smart Bike. The factory-installed operator display, motor, power supply and controller board were removed from the bike and were replaced with a high-speed industrial automation control system, rugged touch screen, high-performance servomotor and motor drive. The motor is rated at ½ hp and supports a pedaling rate of up to 120 rpm. It is capable of both driving and absorbing torque from the rider. Instrumentation permits continuously monitoring bike operation (e.g. cadence, pedal torque, and motor current) and rider condition (e.g. heart rate). The programmable logic controller (PLC) on the bike is a commercial controller from Rockwell Automation (ControlLogix) that runs the control algorithm and dynamically operates all the systems and components in the bike. Fig. 1 shows the functional block diagram of the modified bike.

Fig. 1.

Functional diagram of the Smart Bike.

A. Hardware; Electrical and Electronics

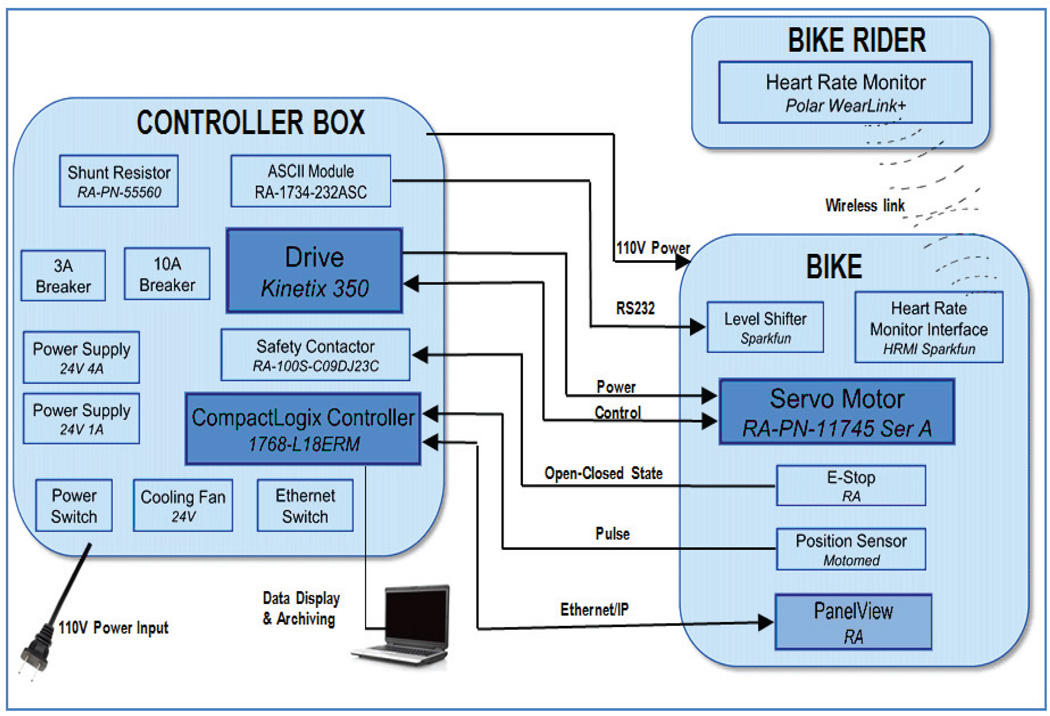

Most of electronic and electrical components such as the motor drive, programmable controller (PLC), network adapter, and power supplies are mounted in a rugged enclosure separate from the bike chassis, and are connected to the bike via cables for motor power and control, operator interface, and sensor feedback. Other electronic components integrated within the bike chassis include the operator touch-screen display, emergency stop button, heart rate monitor interface board, TTL to serial level converter board for the heart rate monitor, and the motor coupled to the pedal crank.

The overall block diagram and the physical location of the electrical and electronic components as well as the communication network between different parts of the system are presented in Fig. 2. The control platform for the intelligent bike is a commercially available programmable logic controller (PLC). This is a versatile platform that is currently used across a broad range of automation and robotic applications. The control algorithms run on the programmable controller. The PLC also communicates with the computer and bike-mounted operator interface using Ethernet to send and receive commands and data. The PLC determines the appropriate motor speed and load (torque) values, and sends motor control information to the motor drive (Kinetix 350). The motor drive implements a high-speed inner loop controller that provide the appropriate voltage and current to the motor to continually maintain the motor operating state specified by the PLC. Motor feedback is used as feedback for the drive to maintain proper motor speed and torque in spite of load disturbances introduced by the rider.

Fig. 2.

Electrical and electronics components diagram of the bike

Operator display and control input device is a rugged touch screen device (PanelView™ Plus graphic display) mounted on the front of the bike near the rider’s hand grips. This serves as the HMI for the bike and communicates with the PLC through Ethernet to send the parameters entered by the user to the PLC and to receive and display the required data from the programmable logic controller. The display can also provide a graphical plot showing historical values for bike and rider operation.

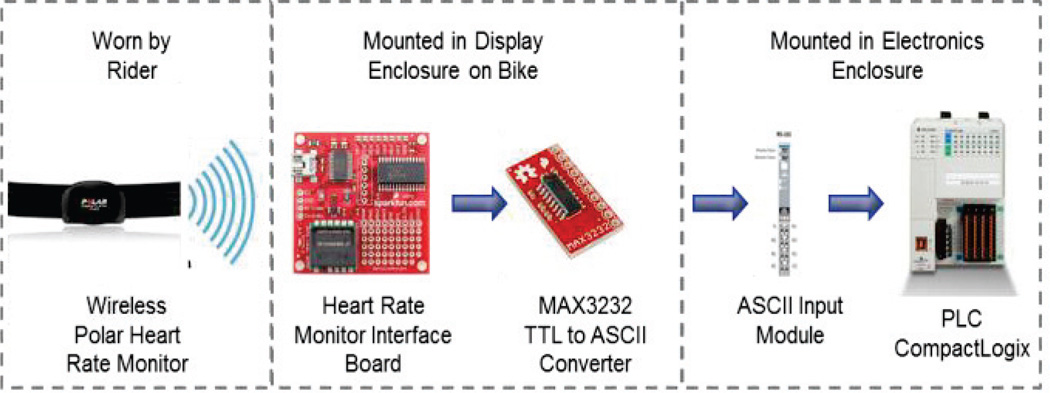

B) Heart Rate Monitoring System

It is important to monitor the condition of the rider during clinical trials. Real-time heart rate information can be used to enhance the safety of the rider during a bike riding session. Rider heart rate levels and changes in heart rate can signal excessive rider exertion or indicate potential health problems with the rider. In addition, heart rate data is also stored in a rider history database for use in subsequent data analysis.

A Polar Heart Rate monitor from Polar USA (Polar Wearlink+™ Coded Transmitter) has been selected to monitor the rider heart rate. The Polar Heart Rate monitor includes a wearable chest strap with a battery-operated integral heart rate sensor. The sensor is connected to a radio transmitter in the chest strap. Typically a wrist-mounted radio receiver is used to receive the radio signal from the chest strap and display the heart rate data from the Polar Heart Rate monitor. Because we want to capture the heart rate in the PLC and monitor real-time heart rate, display this data, and archive the real-time data values for later analysis we uses a separate radio receiver board, a Heart Rate Monitor Interface Board (HRIM). This board receives the radio signal from the Polar Heart Rate monitor chest strap and captures the heart rate signals. (Part Number SEN-08661from SparkFun). The output of the HRIM board is a TTL level voltage (0V to 5V). This TTL level signal is converted to a standard ASCII serial communications voltage level using a level shifting board (MAX3232 Breakout Board from SparkFun). Fig. 3 shows the block diagram of the heart rate monitoring system.

Fig. 3.

Block diagram of the heart rate monitoring system.

B. Bike Operational Specifications

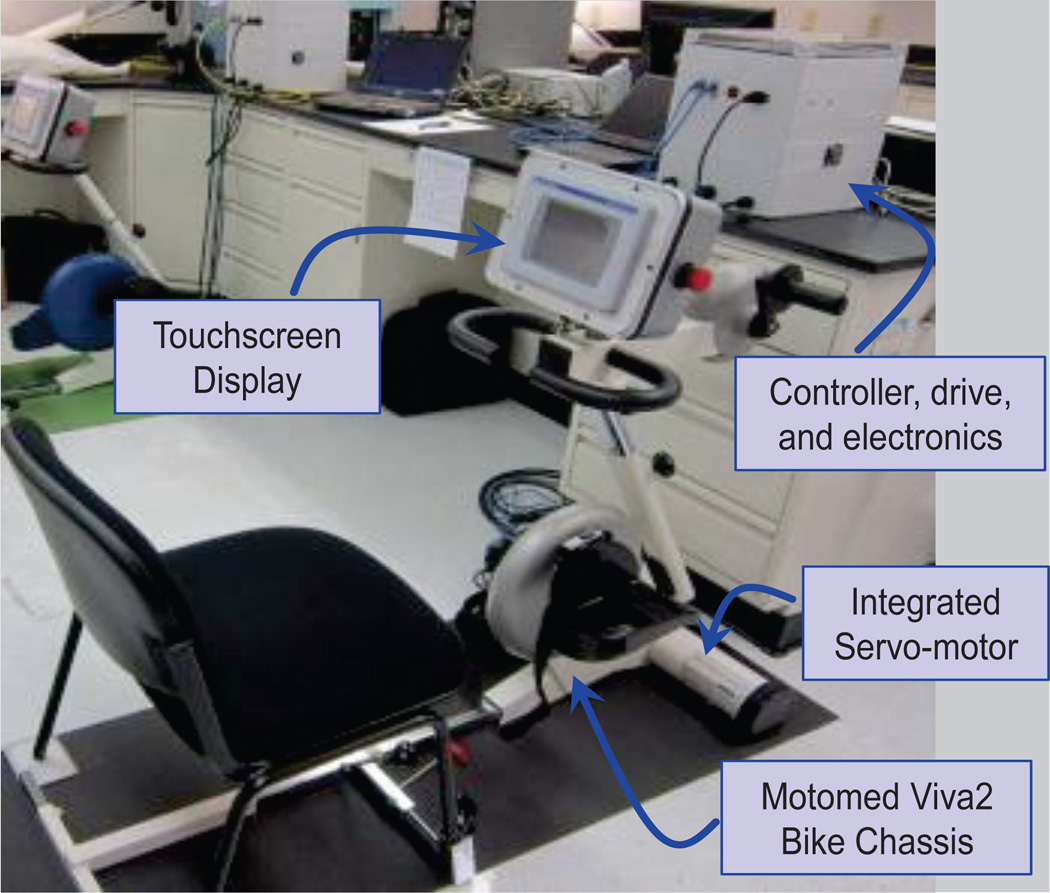

The completed bike system is shown in Fig. 4. Here, we summarize the main operational specifications of the bike.

Fig. 4.

Smart exercise bike, completed system

Speed

We retained use of the slotted belt pulley on the motor (motor pulley diameter =0.825”) and the large slotted pulley connected to the pedal crank (crank pulley diameter = 10.9375”). This gives a pulley ratio of 13.2576. The servomotor used is Rockwell Automation TLY-A230P-BJ62AA with a rated speed of 5,000 rpm. This motor can operate the pedals at over 300 rpm. At the nominal pedal speed of 95 rpm the motor speed will be 1260 rpm.

Load

The servomotor used is a 230V motor rated at 1.3 Nm of torque. The motor is coupled to the pedals through a 13.2576 pulley ratio. This motor provides the torque necessary to move the pedals without rider assistance and overcome the weight of each leg. Most of the time the motor will be absorbing load from the pedals and providing a breaking action to increase the pedal resistance felt by the rider. In order to accommodate prolonged periods of bike operation under pedal loading by the rider, a separate braking resistor was added to each bike to dissipate the energy provided by the rider.

Safety

Insuring rider safety was of paramount importance in the design and development of the Smart Exercise Bike. Redundant software controls and integrity checks are implemented to insure the components are connected properly and communicating reliably. Additional checks are implemented to insure the operator setup parameters are valid. The control algorithm limits the maximum speed the pedals can attain. A heart rate monitor attached to the rider will signal excessive fatigue or stress levels of the rider. There is a large red pushbutton on the bike display console that can readily be pressed by the by rider or therapist and provides an emergency stop (E-stop) capability that immediately removes power to the motor and other power components. Additionally, feedback checks are made every millisecond to insure proper motor feedback and accurate communications exist between the various system functions. Lastly, in the event of an overcurrent condition such as due to pedals hitting an obstacle, power will immediately be removed from the motor.

Data logging

During each bike riding session data is captured by the PLC and provided to the graphical display for operator viewing. This data also routed to a PC running a data display and logging program (FactoryTalk View from Rockwell Automation). This program is configured to log captured data to files on the PC hard drive. Optionally, the PanelView display located on the bike can also log data to a memory stick or to the display memory for later access.

Reliability

The bike system employs reliable, commercially available drive and control components that are used in critical applications throughout the world. The design and implementation of the bike automation system employs good engineering practices to further insure safe and reliable operation. Over current and overvoltage limits protect the electronic equipment and a cooling fan on the electronics enclosure helps prevent overheating.

III. Software and Control Algorithms

In this section, software and main control algorithms developed to run and control the bike are described. The control algorithms that operate the bike have been developed using RSLogix 5000 software from Rockwell Automation running on a PC for software development. After the control algorithms have been developed, they are then downloaded to the PLC. Once in the PLC, they are run on this platform to provide real-time control for the bike system. The control code in the PLC implements both the static mode (inertia load) and the dynamic mode (speed reference) of bike operation. These two control modes are described later in this section. New control algorithms can be readily implemented using the same development and operating platform (i.e. PC, PLC, motor, and drive) provided with the Smart Exercise Bike.

A. Programming Software

Software development for the Smart Exercise Bike consists of bike control software developed to run on the PLC and software resident in the PanelView touch screen to accept user input and display bike information and operating data. Other microprocessor-based devices in the Smart Bike such as the drive and heart rate interface board were programmed by setting up parameters or command line strings. The suite of PLC software development tools from Rockwell Automation have been used to develop the algorithms and routines, and establish communication with the devices to download the codes as well as transmit and display the data. These software programs also provide for control of the operator interface and data logging.

B. Motor Drive Control Modes

The motor drive (Rockwell Kinetix 350 drive: 2097-V31PR2-LM) can be programmed using each of the following integrated control modes:

No Control Modes

Position Control Mode

Velocity Control Mode

Torque Control Mode

Velocity Control Mode with Frequency Control Method

For the Smart Bike control algorithms, the two primary control modes are torque control and velocity control. In torque control mode, the application control program (ladder logic code) provides torque set-point values to the drive controller via the Ethernet/IP interface. Because motor current and motor torque are related by a torque constant, Kt, torque control is analogous to current control. In velocity control mode, the application control program provides a set-point speed value to the drive Ethernet/IP interface. Closed loop velocity control implies an inner torque/current control loop and implements a field-oriented control or vector-control inner loop generating a PWM (pulse-width modulation) signal train to control the motor flux or magnetic field.

C. Static Mode (Inertia Load)

In static mode, the bike works like a typical commercial motorized exercise bike with the ability to specify a programmable resistance (load) for the rider. In order to replicate the inertia load mode of operation, the drive is set in torque control mode and the control function provides the real-time (variable) torque set-point to the drive based on the velocity and acceleration. In fact, based on the velocity and acceleration, the drive sets a torque command for the motor so that it resists pedal movement by the rider. The sampling frequency of the system is 1 kHz, so the control program cycles through the control logic once a millisecond.

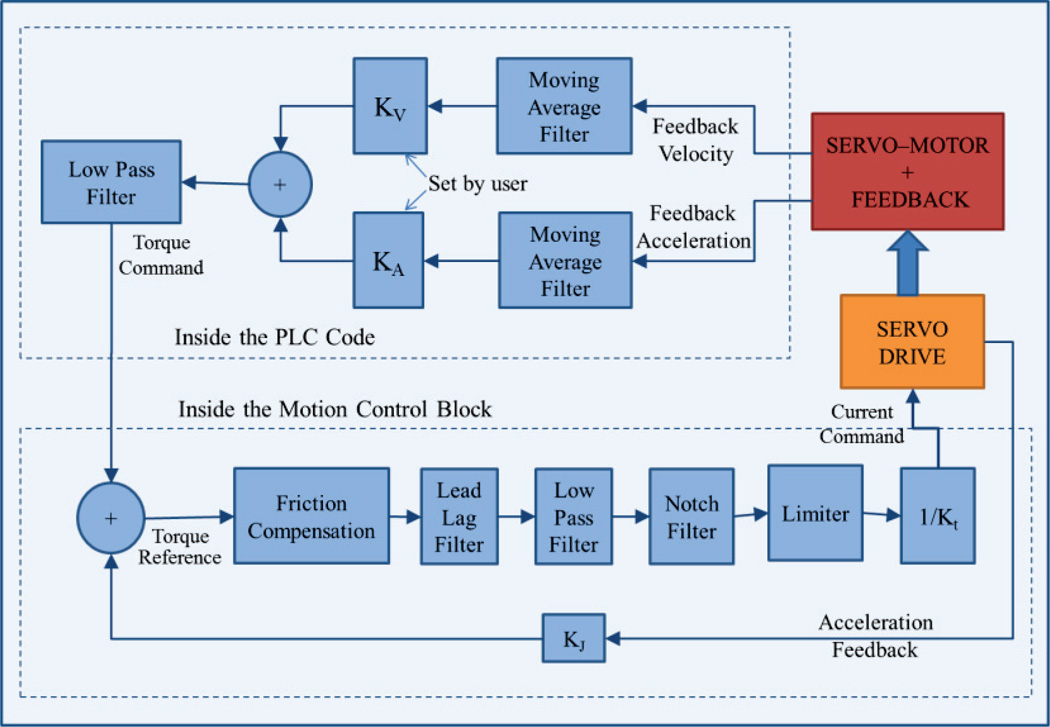

Fig. 5 shows the block diagram of the closed loop control system of the bike in static mode. The lower section of the loop is inside the Motion Control block which is a toolbox for motor control in RSLogix 5000, and we have access to the parameters of each block to tune them based on the requirements and specifications of our application. KT is the motor torque constant which is 0.373 N-m/Amps(RMS). The upper section of the diagram is implemented with ladder code in PLC using RSLogix software. Velocity and acceleration signals are measured and transferred to the programmable logic controller by motor feedback. The moving average filter applied to velocity and acceleration signals is an FIR filter with n=50 samples (50 ms time range). KV and KA are adjustable parameters that can be set by the user on the PanelView screen to determine the amount of load for each patient. The equation that uses the parameters (KV and KA) is a state-of-the-art closed-loop control design, and the range of each parameter was determined by experimentation over several laboratory tests. For the user, each (gain) parameter can be adjusted between 0 (for minimum load) and 10 (for maximum load). Finally, the output of the summation block goes through a low pass filter (1) to determine the final torque command (set point). The low pass filter has been designed to filter the high frequency noise and fluctuations on the velocity and acceleration signals coming from the drive. The cut-off frequency of the filter is about 36 Hz and was selected based on data analysis from several experimental tests.

| (1) |

Fig. 5.

Closed loop control block diagram of the samrt bike in static mode.

D. Dynamic Mode (Speed Reference)

In dynamic mode, the bike runs at a reference speed set by the user. The pedal speed (cadence) is increased linearly by the drive to reach the set point value in approximately 20 seconds. Then, a pre-set resistance (load) is applied as needed to resist pedal speed changes. For this mode, the speed (cadence) set point is defined by the user and is entered through the PanelView, with the drive programmed in velocity control mode. A torque command function (similar to the static mode) is applied to the drive based on velocity and acceleration. In fact, based on the velocity and acceleration, the drive applies a torque command to the motor so that it resists against velocity changes. The Jog block structure in motion control (RSLogix 5000) is used to increase and decrease the speed gradually with start and stop commands, in approximately 20 seconds, to control the rate of speed up and stopping.

Fig. 6 shows the block diagram of the control loop in dynamic mode. The lower part of the diagram is the velocity control loop that includes a PI controller implemented inside the Motion Control toolbox in the RSLogix Software. Aside from the PI control loop there is a feedforward path with a low pass filter with adjustable KVP and KNFF gains. KVP is the proportional gain of the PI controller. KNFF is the feedforward (negative) gain used to adjust the time response of the velocity regulator aside from the normal PI control elements [6]. The effect of the (negative) feedforward signal is to eliminate backup of the motor shaft, and the selection of KNFF gain setting has no effect on the stability of the speed regulator [6]. KVI is the gain in the integral loop. The gains KVP, KVI, and KNFF are tuned by the drive using the Motion Control toolbox in the RSLogix Software with some explicit operational tests after any physical changes to the system. More details about these parameters and the tuning instructions are provided in [5] and [6]. The adjustable parameters (KV and KA) are set by the user on the PanelView screen and determine the amount of the load for the patient. The output of the velocity control loop is applied to the drive as the velocity command.

Fig. 6.

Closed loop control block diagram of the samrt bike in dynamic mode.

The upper part of the diagram is the torque control loop that has already been described in the static mode. The only difference between the torque loop in static and dynamic modes is that in the dynamic mode, the difference between the reference velocity and feedback velocity is used to shape the torque command equation. Also in the dynamic mode, the final block is a low pass filter (2) that has been designed to filter the high frequency noise and fluctuations on the velocity and acceleration signals coming from the motor drive. The cut-off frequency of the filter is about 200 Hz and was chosen based on data analysis from several experimental tests. The cut-off frequency of the filter in dynamic mode is higher than is static mode to make the closed-loop system more responsive providing a quick response to the patient’s reaction since the motor is running at a pre-set speed.

| (2) |

IV. User interface and data logging

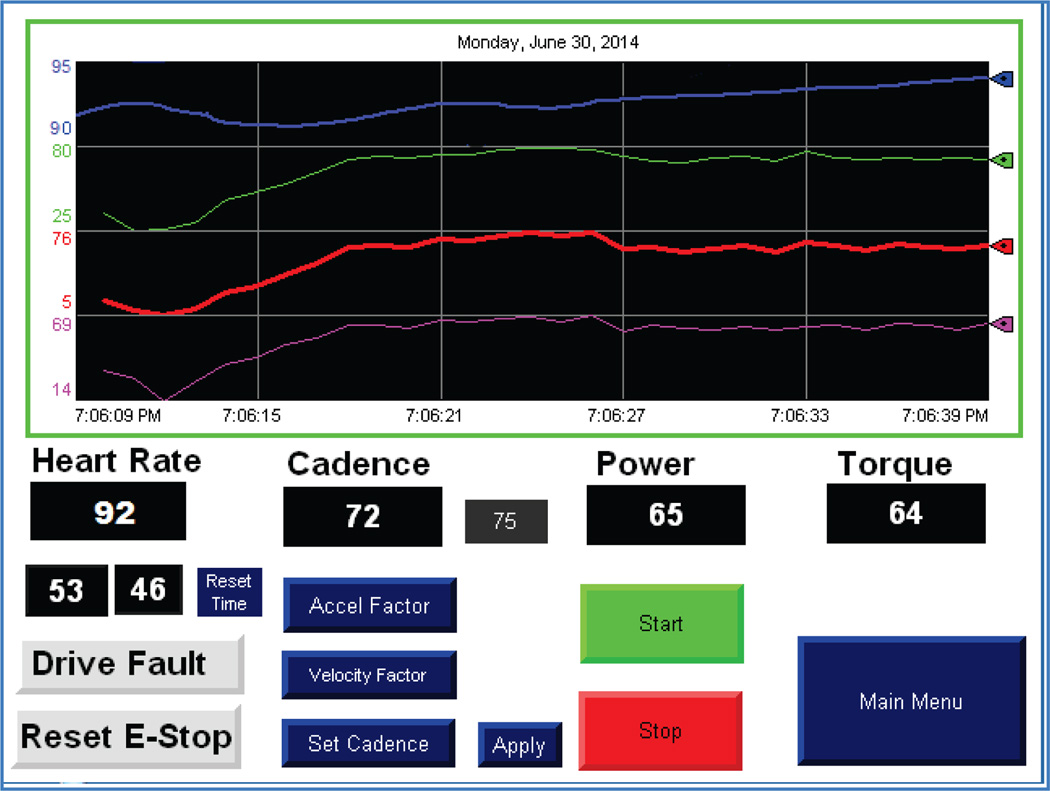

The operator interface code that operates the PanelView touch screen has been developed using FactoryTalk View Studio Machine Edition (ME) from Rockwell Automation. The program receives data from the PLC through the Ethernet/IP network interface and displays real-time information on the screen. The waveform graph plots the signals in a specified time scale. For this application we set a default of a 30 second moving window to graphically displayed data on the operator screen. Data logged by the program are saved on the hard drive on a PC in an Excel format. Bike operating parameters such as cadence/velocity set-point, velocity and acceleration factors (KA and KV) can be set by the operator using the touch-screen monitor mounted on the bike.

The operating procedure requires that the user first select an operating mode (static or dynamic) for the exercise session. The control screen will then appear (Fig. 7) that includes a composite graph showing cadence, power, torque and heart rate signals as well as the instantaneous values for each of these signals. There are also buttons for setting parameters like desired cadence, acceleration and velocity factor for example.

Fig. 7.

PanelView control screen.

V. Bike test result

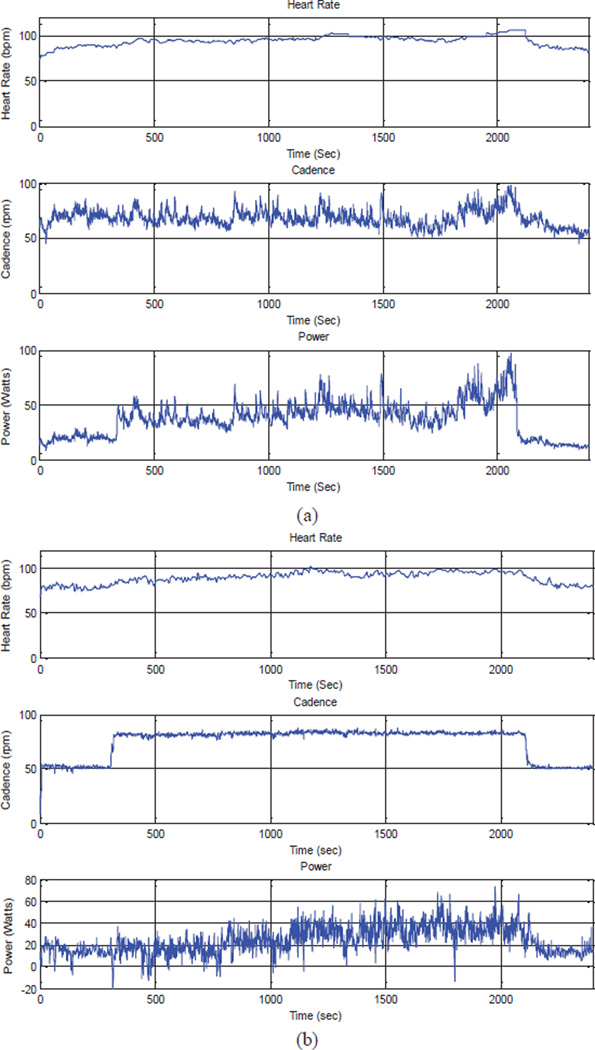

An IRB approved (Institutional Review Board approved) study was conducted that began with a comprehensive test and validation procedure for the bike and data acquisition system. Following validation of the bike platform, a series of exercise sessions with data concurrent and data acquisition using the Smart Bike was conducted for 47 riders diagnosed with Parkinson’s disease. Details of the study and the results of the data analysis will be presented in a separate paper [1]. Here, for illustrative purposes, we provide experimental test data from two of the test subjects that participated in the study and exercised in the static and dynamic modes of the Smart Bike. Data from each patient were recorded for forty-minute exercise sessions including five minutes of warm up cycling, thirty minutes of exercise, and five minutes of cool down.

Fig. 8(a) shows captured data for heart rate, cadence, and power signals for one exercise session for a rider in static mode. The power level is reduced during warm up and cool down as compared to the 30-minute exercise session. It is worth noting that there is not a significant difference in the cadences during the three riding phases. Because the load is adjustable, the trainer conducting this test session has chosen a reduced load during the warm up and cool down periods.

Fig. 8.

Smart Bike real test data for two PD patients; (a) Static mode; (b) Dynamic mode.

Fig. 8(b) shows experimental data for heart rate, cadence, and power for one exercise session of a rider in dynamic mode. The session started with five minutes of warm up during which the cadence set-point is at 50 rpm, then continued with thirty minutes of exercise at 80 rpm speed set-point, and finished with five minutes of cool down at 50 rpm cadence set-point. Any change (increase and decrease) in speed is done linearly in 20 second time periods to avoid any shock or injury to the rider. Fig. 8(b) shows that the cadence in the 30-minute exercise period is roughly stable around 80 rpm while the power in this period is variable from 0 to 60 Watts. These results are very similar to performance observe with Parkinson’s riders on a tandem bike with a train that we have previously analyzed [2]. The sample results presented for the rider with Parkinson’s using dynamic bike control are consistent with the data observed from a rider with Parkinson’s on a tandem bike. These results suggests that a rider with Parkinson’s operating the Smart Exercise Bike in dynamic mode may see improvements in motor skill levels consistent with that observed from Parkinson’s riders operating a tandem bike. The detailed analysis of the data captured from multiple cycling sessions under conditions of static and dynamic cycling that seeks to validate this assumption will be provided in separate paper discussing test and validation of the Smart Bike [1].

The following section presents the framework for analyzing data captured from the Smart Exercise Bike.

Table I summarizes the main characteristics of the recorded signals from the two PD patient bike riding experiments in static and dynamic modes. There is no significant difference in heart rate signals between the two modes. However, the pedaling cadence and power signals showed a significant difference between the raw values in static (68.3 ± 7.1 rpm, 42.5 ± 9.7 W) and dynamic (82.4 ± 1.5 rpm, 26.9 ± 12.5 W) groups. Certainly no conclusions can be drawn from looking at only two samples, however, the trend shown here is consistent with data captured from the other 45 test subjects [1]. Variability analysis has shown to indicate another significant difference between the two modes. While there is no significant difference between the Sample Entropy2 (SaEn) values of heart rate and power signals, there is a significant difference in SaEn of the cadence for static and dynamic modes. SaEn for the cadence in the dynamic mode session (1.47) is significantly greater than the SaEn for the cadence in the static mode (0.26). This indicates that the cadence signals in the dynamic mode have greater variability (are less predictable) than the signals in static mode. This feature is consistent with the analysis results previously published for single and tandem cycling [2] and is an important feature of the Smart Bike design. Complete test details, including validation and data analysis of the Smart Bike with forty seven PD patients is provided in [1].

TABLE I.

Comparison between the static and dynamic modes with real data signals of two PD patients exercised with smart bike.

| Bike Mode |

Heart Rate | Cadence | Power | |||

|---|---|---|---|---|---|---|

| Mean | SaEn | Mean | SaEn | Mean | SaEn | |

| Static | 96.3 | 0.31 | 68.3 | 0.26 | 42.5 | 0.11 |

| Dynamic | 92.8 | 0.28 | 82.4 | 1.47 | 26.9 | 0.06 |

VI. Conclusion

Recent research results in the field of rehabilitation for people diagnosed with Parkinson’s disease indicate that a person may realize significant improvements in motor skills by pedaling a bike under unique conditions of speed and load dynamics. In order to investigate this important research area, a novel exercise bike has been designed and fabricated based the operating paradigm of a tandem bike. The framework for the Smart single-rider exercise bike is a commercial bike chassis and commercially available motor and control equipment. This innovative design incorporates high-performance drives and controls and a low-inertia, power-dense servomotor to form a flexible and adaptive platform to support clinical research studies of exercise for people with Parkinson’s disease.

The Smart Exercise Bike has been programmed with two resident bike control algorithms that provide the ability to operate the bike in either the static (inertial load) mode, or dynamic (speed reference) mode while capturing operating data such as rider heart rate, cadence, and power at a high sampling rate. The static mode runs the bike as a regular exercise bike with a programmable resistance (load). In dynamic mode, the bike runs at a user defined cadence set-point with a programmable load influencing cadence changes. The bike is equipped with a user friendly HMI employing an easy to read color touch screen. This integrated control and display system records critical rider and bike conditions and allows the rider to set required riding session parameters such as cadence set point and load.

The Smart Bike has been used since September 2012 to conduct clinical trials of riders with Parkinson’s disease. Data has been captured during multiple riding sessions and analyzed to confirm the proper operation of the bike and the validity of the data acquisition system. Details describing the clinical tests conducted and data analysis are presented in [1]. The Smart Bike has been shown an effective platform for conducting a wide range of bike riding exercise tests for different riders with Parkinson’s disease. In addition, the flexible and extensible design of the bike permits readily changing the control system and incorporating additional I/O as needed to provide a wide range of riding experiences. The network-enabled controller also permits real-time remote access and remote data logging. Research platforms like this can be very effective tools in evaluating the impact of new control paradigms for improving the motor skills of riders with Parkinson’s. Validated clinical studies using high performance control and data acquisitions systems may provide a basis for transitioning high-impact exercise regimens from a clinical setting to broad scale deployment in therapy centers and eventually in the home.

Acknowledgments

This work was supported in part by the NIH R21 HD068846-01A1.

Biographies

Hassan Mohammadi Abdar (S’12) received his B.S. degree in electronic engineering, his M.S. degree in control engineering from K. N. Toosi University of Technology, Tehran, Iran, and his Ph.D. degree in systems and control engineering from Case Western Reserve University, Cleveland, OH, USA. He has worked for several years in industry in the area of embedded system design, electronics and hardware design, control systems and industrial automation, and signal processing. He has worked on several research projects in the field of signal processing and data analysis with application on Parkinson’s disease rehabilitation, control and automatic systems, smart grid and grid-tie inverter, and serial data communication at Case Western Reserve University.

Angela L. Ridgel is an Associate Professor in Exercise Science/Physiology at Kent State University. She received her undergraduate degree in Biology from The College of William and Mary in Virginia, a Master's degree in Biology at Villanova University in Pennsylvania and her Doctoral degree in Biomedical Sciences from Marshall University in West Virginia. Dr. Ridgel completed her Post-Doctoral training at Case Western Reserve University and Cleveland Clinic. Dr. Ridgel's current research interests examine how exercise can be used for neurorehabilitation in individuals with Parkinson's disease and Multiple Sclerosis.

Fred M. Discenzo received two B.S. degrees in mathematics, the M.S. degree in polymer physics, and the Ph.D. degree in systems and control engineering from Case Western Reserve University, Cleveland, OH, USA. He is the Manager of Rockwell Automation’s Advanced Technology Laboratory, Cleveland, OH, USA, and is a Rockwell Automation Fellow. He currently holds over 60 U.S. patents and has published many papers spanning artificial intelligence, machinery diagnostics, sensors, control, power scavenging, and artificial neural networks. Dr. Discenzo represents Rockwell Automation on various university/industry advisory committees, he serves on multiple conference committees, and is a board member of the Machinery Failure Prevention Technology (MFPT) Society.

Kenneth A. Loparo is the Nord Professor of Engineering in the Case School of Engineering, Case Western Reserve University, Cleveland, OH, USA. He has academic appointments in the Departments of Biomedical Engineering, Electrical Engineering and Computer Science, and Mechanical and Aerospace Engineering. His research interests include stability and control of nonlinear and stochastic systems; nonlinear filtering with applications to monitoring, fault detection, diagnosis and reconfigurable control; information theory aspects of stochastic and quantized systems with applications to adaptive and dual control; the design of digital control systems; and advanced signal processing techniques for monitoring and tracking of physiological behavior.

Footnotes

Sample entropy (SaEn) is a technique used to quantify the amount of regularity or unpredictability of fluctuations in time series data. SaEn quantifies the possibility that similar patterns of observations will not be followed by additional similar observations. A time series containing many repetitive patterns has a relatively small SaEn; alternatively, a less predictable (i.e., more random or less time-correlated) time series will have a greater SaEn [1, 2].

Contributor Information

Hassan Mohammadi-Abdar, EECS Department, Case Western Reserve University, Cleveland, Ohio, 44106, USA (hmabdar@case.edu).

Angela L. Ridgel, Department of Exercise Science, Kent State University, Kent, OH, USA (aridgel@kent.edu).

Fred M. Discenzo, Advanced Technology Laboratory, Rockwell Automation, Mayfield Heights, OH, USA (fmdiscenzo@ra.rockwell.com).

Kenneth A. Loparo, EECS Department Case Western Reserve University, Cleveland, Ohio, 44106, USA (kal4@case.edu).

References

- 1.Abdar HM. PhD Dissertation. EECS Department, Case Western Reserve University; 2014. Aug, Development of an Intelligent Exercise Platform for Rehabilitation in Parkinson’s Disease. [Google Scholar]

- 2.Abdar HM, Ridgel AL, Discenzo FM, Phillips R, Walter BL, Loparo KA. Test and Validation of a Smart Exercise Bike for Motor Rehabilitation in Individuals with Parkinson’s Disease. IEEE Transactions on Neural Systems and Rehabilitation Engineering. doi: 10.1109/TNSRE.2016.2549030. To be published. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Ridgel AL, Abdar HM, Alberts JL, Discenzo FM, Loparo KA. Correlation of motor skill changes with variability in cadence during forced and voluntary cycling in individuals with Parkinson’s disease. IEEE Transactions on Neural Systems and Rehabilitation Engineering. 2013 May; doi: 10.1109/TNSRE.2012.2225448. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Ridgel AL, Vitek J, Alberts JL. Forced, not voluntary, exercise improves motor function in Parkinson's disease patients. Neurorehabilitation and Neural Repair. 2009;23(6):600–608. doi: 10.1177/1545968308328726. [DOI] [PubMed] [Google Scholar]

- 5.Kinetix 350 Single-axis EtherNet/IP Servo Drives. Allen-Bradley- Rockwell Automation Inc.; 2013. Dec, 2097-UM002C-EN- P. [Google Scholar]

- 6.Integrated Motion on the Ethernet/IP Network. Allen-Bradley- Rockwell Automation Inc.; 2011. Oct, MOTION-RM003B-EN-P. [Google Scholar]

- 7.Ridgel AL, Vitek L, Phillips MJ, Lowe ML, Hutson M, Alberts JL. Improved motor function and cortical activation in Parkinson’s disease patients following acute forced-exercise. Medicine & Science in Sports & Exercise. 2009;41(5):148. [Google Scholar]

- 8.Jarrassé N, Proietti T, Crocher V, Robertson J, Sahbani A, Morel G, Roby-Brami A. Robotic exoskeletons: a perspective for the rehabilitation of arm coordination in stroke patients. Frontiers in human neuroscience. 2014;8 doi: 10.3389/fnhum.2014.00947. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Masia L, Krebs HI, Cappa P, Hogan N N. Design and characterization of hand module for whole-arm rehabilitation following stroke. Mechatronics, IEEE/ASME Transactions on. 2007;12.4:399–407. doi: 10.1109/TMECH.2007.901928. (2007) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Cordo P, Lutsep H, Cordo L, Wright W, Cacciatore T, Skoss R. Assisted movement with enhanced sensation (AMES): coupling motor and sensory to remediate motor deficits in chronic stroke patients. Neurorehabilitation and neural repair. 2008 doi: 10.1177/1545968308317437. [DOI] [PubMed] [Google Scholar]

- 11.Lo AC, Guarino PD, Richards LG, Haselkorn JK, Wittenberg GF, Federman DG, Peduzzi P. Robot-assisted therapy for long-term upper-limb impairment after stroke. New England Journal of Medicine. 2010;362(19):1772–1783. doi: 10.1056/NEJMoa0911341. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Gupta A, O'Malley MK. Design of a haptic arm exoskeleton for training and rehabilitation. Mechatronics, IEEE/ASME Transactions on. 2006;11.3:280–289. [Google Scholar]

- 13.Picelli A, Tamburin S, Passuello M, Waldner A, Smania N. Robot-assisted arm training in patients with Parkinson’s disease: a pilot study. Journal of neuroengineering and rehabilitation. 2014;11(28) doi: 10.1186/1743-0003-11-28. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Ueki S, Kawasaki H, Ito S, Nishimoto Y, Abe M, Aoki T, Mouri T. Development of a hand-assist robot with multi-degrees-of-freedom for rehabilitation therapy. Mechatronics, IEEE/ASME Transactions on. 2012;17(1):136–146. [Google Scholar]

- 15.Picelli A, Melotti C, Origano F, Neri R, Verzè E, Gandolfi M, Waldner A, Smania N. Robot-assisted gait training is not superior to balance training for improving postural instability in patients with mild to moderate Parkinson’s disease: a single-blind randomized controlled trial. Clinical rehabilitation. 2014 doi: 10.1177/0269215514544041. 0269215514544041. [DOI] [PubMed] [Google Scholar]

- 16.Abdar HM, Ridgel AL, Discenzo FM, Loparo KA. Modeling and Simulation of Power Sharing and Interaction between Riders in a Tandem Bicycle. Los Angeles: CDC2014; 2014. Dec, pp. 6813–6817. [Google Scholar]