Abstract

Microfluidics has shown rapid growth in both research and development and offers significant commercialisation potential for biomedical and diagnostic applications in particular. However, there is a lack of awareness of microfluidics outside the field of study, and few dedicated educational programmes are available. While many topics incorporate microfluidics teaching, reported initiatives in the literature have not yet taken a problem based learning (PBL) approach to the delivery of practical sessions. The educational approaches already reported typically focus upon production and testing of pre-determined device designs for specific applications, using a “recipe” style of lab teaching. Here, we report on a newly designed lab section of a microfluidic teaching component utilising problem based learning (PBL) to involve the students in all aspects of design, manufacture, and performance characterisation of microfluidic solutions. Details of the lab design and development are given enabling others to replicate the lab structure described here or use it as a basis for the design of similar PBL microfluidics teaching labs. A key focus of the work has been the evaluation of the student experience, and the results of a survey indicate a high degree of student satisfaction and skills development due to the PBL approach.

INTRODUCTION

Microfluidics is a rapidly growing area of research and development with huge potential in biomedical and diagnostic applications in particular, where commercial applications are becoming a reality.1–4 However, very few people outside the field are aware of microfluidics and few dedicated educational programmes are available, although recent years have seen a wide range of innovative and interesting public engagement and educational approaches developed.

An excellent overview of the various microfluidic platforms, experiments, and simulations that have been developed for educational purposes, described in the literature, has been given in Esfahani et al.5 Low-cost and simple fabrication approaches have been developed allowing participants to manufacture microfluidic devices using a variety of materials ranging from Jell-O,6 modelling clay,7 shrink-film,8 paper,9–11 glass,12 and even chocolate.5 Such systems or those manufactured by more conventional means have been utilised in a wide variety of hands-on educational experiments allowing participants to explore phenomena such as laminar flow and diffusive mixing,13 particle separation,7 pH sensing,13,14 gradient formation,14 and droplet generation15 among others.5 Over-sized devices demonstrating microfluidic principles, e.g., a Lego DLD7 or scaled-up gradient generators and tissue chips,5 have also been employed primarily to demonstrate concepts in a fun way to science festival participants. The above microfluidic approaches have targeted different audiences from young children, through school children, to university education and often the modular approach to microfluidics education enables tailoring of activities at an appropriate level.

Activities particularly targeting university level education include the use of a microchannel ELISA,16 demonstrating mixing and precipitation for chemistry students,17 a microfluidic chip for continuous flow acid-base titration for use in analytical chemistry teaching laboratories,18 and food analysis using microfluidic electrophoresis,19 which fall in the category of using microfluidics for teaching (rather than teaching directly microfluidics) as defined by Fintschenko.20 Other activities have included the production of microfluidic devices with extensive exploration of their analytical chemistry applications21 and on-chip electrophoresis with student made chips,22 which while introducing the concepts of fabrication still utilise pre-determined device designs and, therefore, like most microfluidic activities for university education fall in the middle of the “DIY to blackbox” spectrum with little freedom given to students to explore their own designs.20

However, there have been no reports of any microfluidics lab work based around a problem based learning (PBL) approach. PBL is an instructional method in which students learn through facilitated problem solving.23 Students are presented with a problem scenario, which they analyse and extract the relevant facts, from which they propose hypotheses for appropriate solutions. An important feature of this working process is for the students to identify deficiencies in their knowledge. The teacher facilitates the students' learning by providing a source of knowledge and expertise on the subject area, direction towards additional resources of knowledge, and assistance for the students to learn the required cognitive skills required for problem solving. This form of learning has been successfully implemented in lab work in similar disciplines: a 2nd year undergraduate chemistry lab introduced PBL mini projects, which resulted in increased student engagement and students' reporting that the lab work was fun and interesting and increased their confidence, although the authors noted that the downside was the extra time required from staff;24 and team based case study analysis in engineering, which increased student retention rates.25 Criticisms of PBL are that a minimally guided approach has not been demonstrated to be successful with evidence showing that strong guidance is a key element of success,26 and the evaluation of PBL suitability for engineering also concluded that appropriate supervision was critical.25

Here, we report on a lab activity developed to introduce M.Sc. students to the whole process of microfluidics engineering from design, manufacture to performance characterisation. The lab work was introduced to the students in the form of application challenges for which a microfluidic solution should be found. Thus, the whole process was led by the students analysis of the requirements, leading to a design, manufacture, and testing of a solution to the problems posed. Evaluation of this problem based learning mini-project was conducted through group and individual reports as well as a student survey. This paper describes the implementation of the newly designed lab activity and reports on the benefits to the students from this approach.

MATERIALS AND METHODS

Student cohort: Heriot-Watt University delivers the first term of an EU ERASMUS Mundus funded M.Sc. programme in Smart Systems Integration. The microfluidics component of the class fits into the Fundamentals of Smart Systems Integration module and comprises three lectures, a COMSOL modelling activity, and the lab practical for which four three hour sessions are available. The lab work contributes 10% to the overall grade within this module and is the only means of assessing the microfluidics segment. As a fully funded programme, the M.Sc. attracts a wide number of applications from high quality candidates around the world, and these are selected on ability resulting in a very international class of around 15–18 students each year.

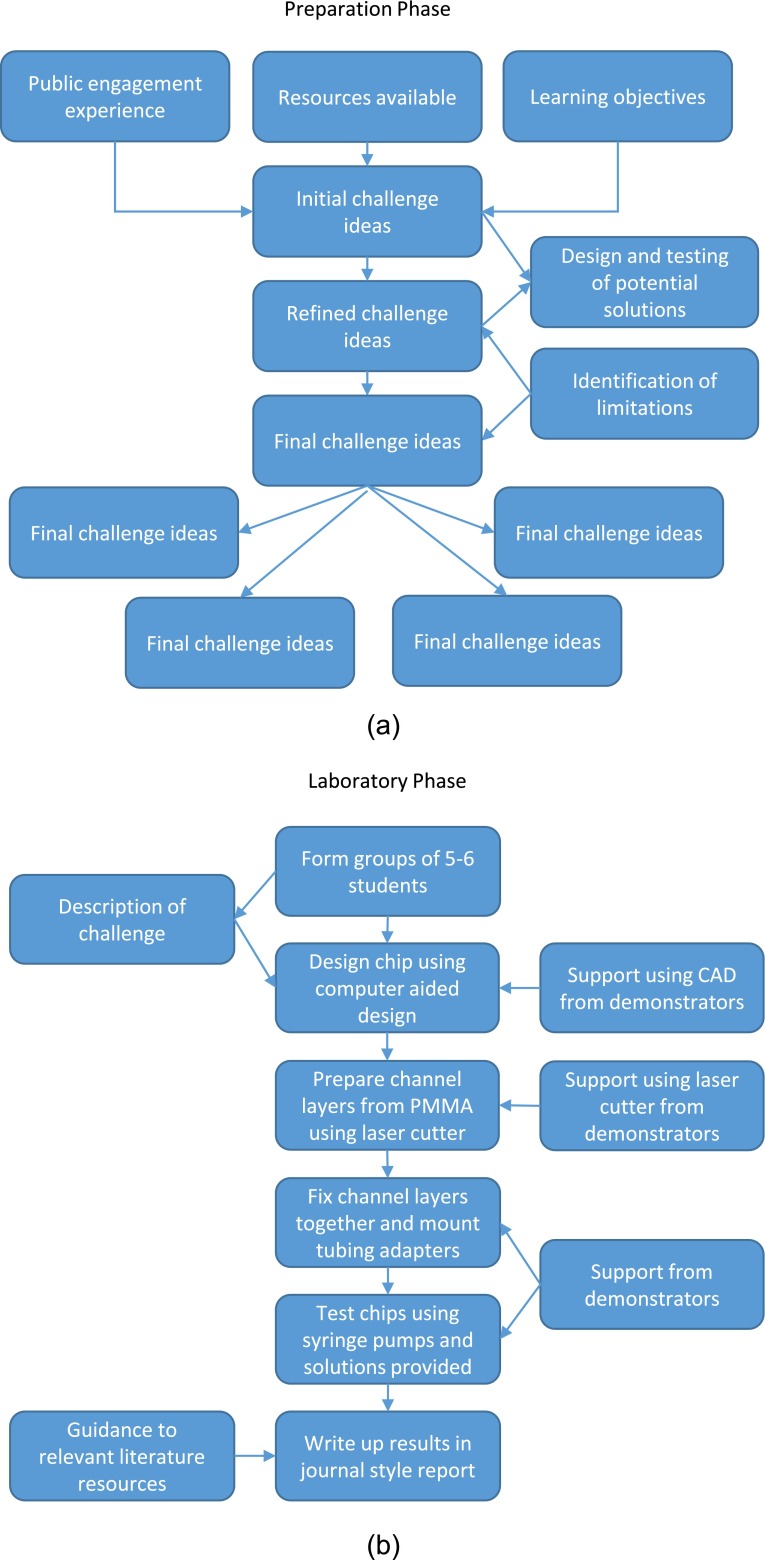

Implementation: the first stage (Figure 1(a)) of creating the problem based learning approach was to consider the resources available in terms of equipment and facilities at Heriot-Watt University as well as the time available to the students. Furthermore, the learning objectives and content of the lecture components of the course were considered in selecting ideas for device designs that could be achievable given identified resource limitations. This process was also informed by public engagement experience from microfluidics educational outreach activities. From the generation of initial ideas, a summer student designed and tested potential device designs identifying certain limitations, which led to refined challenge ideas and a further round of design iterations before the final challenges were written. With this information, extra support material for the lab was developed (i.e., support sheets to help the students at different stages of the activity and a guide for demonstrators highlighting potential problems the students might encounter). The second stage (Figure 1(b)) involved delivery of the lab activity, which took place after the lectures and COMSOL activity, therefore ensuring all students had received an introduction to microfluidic concepts before undertaking the practical work. The students were presented with a choice of three different potential challenges to work on (see supplementary material for details of the challenge sheets). The students then self-organised themselves into groups of 3–5 and selected the challenge in which they were most interested. This resulted in a total of 6 groups, 2 per challenge. At least two demonstrators (Ph.D. students and RAs with a working knowledge of microfluidics) were present at every session to support the student groups who worked through the challenges at their own pace. After completion of the practical work, the students worked on the assessment in their own time. The final stage was the project evaluation utilising data from the student reports, the student feedback for the entire term at HWU, and a specific questionnaire targeted to generate data relating to the students' experience of the lab and the skills developed.

FIG. 1.

(a) Overview of the preparation phase of the PBL. (b) Overview of the student lab experience.

Assessment: the students were asked to produce a report in the form of a scientific article as a group describing the motivation, aims, design, manufacture, and testing of their microfluidic system (75% of the final mark) as well as a piece of individual reflection describing their contribution to the project, the key learning they felt they had achieved, and suggestions for future work on the project (25%). Guidelines on length and a marking scheme were provided to the students.

Design of the microfluidic devices: AutoCAD was available to the students through university computers or via downloading of a student version to their own laptops. An introductory guide to AutoCAD was provided as a Powerpoint file, and demonstrators were also available to assist students in the design process.

Manufacture of the microfluidic devices: devices were cut from sheets of PMMA (WEATHERALL EQUIPMENT & INSTRUMENTS LTD) using a laser-cutter (Epilog Mini 8000). PMMA thicknesses available to the students included 0.5, 1.0, and 2.0 mm. Supervised by a demonstrator, the student group would upload their design to the laser cutter control computer and insert the PMMA that they had prepared, covering each side of the device layer in double-sided tape (3M). Following production of the device layers within the laser cutter, the groups assembled their devices by carefully sticking together the layers and gluing 16G blunt needles (Optoink) to the inlet and outlet ports. After the glue had dried, 1.3 mm inner diameter Masterflex silicone tubing (Cole Palmer) was connected to the inlet and outlet needles. A written guide to laser cutter and to manufacture and assembly methods was provided to the students as a word document.

Performance characterisation of the microfluidic devices: students were provided with syringe pumps (Aladdin-WPI), 5 ml syringes, food dye, coloured beads of various diameters (Cospheric), and a Dinolite microscope and camera. The choice of device operating parameters (e.g., flow rates) and device inputs (e.g., bead sizes, etc.) was entirely student driven. The students evaluated the performance of their devices through observation of the content of the fluids at different stages of the microfluidic system using the microscope cameras. The observations from multiple chips with varying design characteristics were compared to their theoretical calculations.

Evaluation: a ten question, three page survey was created and distributed via Survey Monkey following approval from the HWU Ethics Committee and the M.Sc. course director. The first page asked the students about themselves, specifically their preferred approach to learning and their level of previous experience with lab work. The second page asked the students to evaluate the lab practical in terms of a set of adjectives as well as more open-ended questions to elicit more detail about the student experience, e.g., their favourite and positive aspects of the lab and suggestions for improvement. The third page of the survey asked students to rate how they perceived the lab activity had improved or developed a range of skills relating to practical work. In addition, information from the official course feedback (provided by the M.Sc. course director) and the assessment work was utilised in the evaluation.

RESULTS AND DISCUSSION

Implementation of a new problem-based learning approach

Previously, the lab sessions were delivered using a “recipe-style” approach,24 where students simply followed instructions to set-up pre-fabricated microfluidic devices and compared mixing performance using a set procedure. Often, there were problems with the pre-determined and fabricated microfluidic designs, which led to a frustrating experience for the students, and while they gained some hands-on skills in operating microfluidic devices, the lab was not particularly challenging and the level of learning low. In switching to a PBL approach, the key considerations were how to achieve the learning outcomes (Table I), while designing an approach that was feasible given the resources and timescale available. The microfluidic design challenges were developed from scratch, and therefore, it was necessary to check whether the students would be able to manufacture and test devices that would likely offer an appropriate solution to the challenges. One particular limitation, in this regard, was the selection of the laser cutting manufacture route. This was dictated by time constraints since allowing the exploration of other manufacturing routes by the students would not have fitted within the lab schedule. However, this provides the potential future option to expand and extend the lab and would have the additional advantage of potentially allowing access to smaller channel dimensions, which was a key consideration in the selection of projects that could feasibly be manufactured with the laser cutter. Testing and evaluating potential microfluidics solutions to the design challenges proposed made for an ideal summer project, and we recommend this route to facilitate the development of new PBL challenges for microfluidic labs, while minimising staff time commitment.

TABLE I.

Column one indicates the learning outcomes selected for the lab component of this module. The success of the project in meeting the learning objectives is given in Figure 3. Designing activities to meet the learning outcomes had several limitations due to time and resource limitations, and these are highlighted in the second column.

| Desired learning outcomes for project | Limitations |

|---|---|

| To introduce you to the design and manufacture of microfluidic systems | Use of the laser cutter as a fabrication approach due to time constraints = size constraints on the types of designs |

| To familiarise you with the set-up and operation of microfluidic systems | Activity run in a classroom so simple and safe chemicals needed |

| To work in groups to solve a challenge by designing, fabricating, and testing microfluidic devices | Careful group allocation needed to ensure all students can participate, however keeping the group number manageable in relation to demonstrator availability |

| To consider how to plan experiments to evaluate key performance characteristics of a system(s) | Evaluation needed to be undertaken with safe surrogate chemicals and without access to advanced microscopes = care in project design to check challenges were relevant but achievable |

| To report the theory, methods, and interpret the results of the experiments in the style of an academic journal paper | Experiments were carried out as a group exercise; therefore, one academic journal paper would be submitted per group. A separate personal statement of contribution would be used to help allocate individual grades. |

The challenges

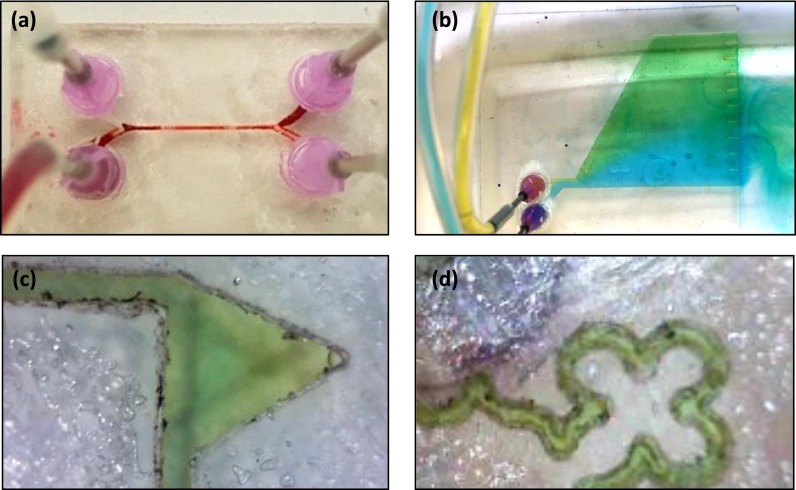

The student groups were presented with a choice of three challenges to solve using microfluidic solutions. The first was to design a microfluidic H-filter to extract pathogen DNA (represented by coloured food dye) from a contaminated sample (represented by polymer beads in water). The second challenge asked students to use pinch flow fractionation to analyse and identify the grains of pollen (again represented by polymer beads in water) from a soil sample solution for use in forensic analysis. The third presented the students with the challenge of mixing a fluorescent label (food dye) with a targeted specimen (food dye of different colour) on a reusable microfluidic chip, where efficient mixing and subsequent effective rinsing, were the key desired parameters. The H-filter and pinch flow fractionation challenges provided open-ended problems to the design of the microfluidic devices, while the polymer beads in the test solutions offered distinct visible markers for characterisation and measurement. The third challenge, focusing on mixing, provided constraints on the microfluidic designs, however, presented a substantial open-ended problem to overcome on the method used to characterise and evaluate the performance of the devices based on how well two coloured liquids were mixed together. All three challenges provided significant problem scenarios to find solutions for, in comparison to the step-by-step recipe approach offered previously where there was minimal opportunity for problem solving. The theoretical knowledge required to design solutions for each of the challenges had been covered during the lectures. The challenges were chosen by the student groups in advance of the laboratory sessions providing time for background research. Each challenge was accompanied with references to supporting literature and details of the sizes of the particles present in the test solution. For further details of each challenge, see the supplementary material. Figure 2 shows some representative images of the devices produced in response to each of these challenges.

FIG. 2.

Devices manufactured by students under testing; (a) H-filter; (b) pinch flow fractionation; (c) mixing using triangular chambers; and (c) mixing using a curved channel.

Design, manufacture, and performance characterisation of devices

Even students with no background or experience in drawing programmes were quickly able to master sufficient skills to result in the generation of a device design. This observation is supported by previous work undertaken by the authors along with Dr. Maiwenn Kersaudy-Kerhoas on the “Small Plumbing” Ingenious! Project, where Ph.D. students and postdoctoral researchers were trained on the use of AutoCAD before supporting groups of school children (aged ∼13) to create microfluidic designs. In this outreach activity, all groups produced a design within a 2 h school session though with considerable support from the researchers. Within this lab project, where the M.Sc. level students had greater autonomy and needed to make more detailed calculations of channel dimensions and flow rates etc, all groups had produced a design by the end of the first 3 h session, while several were ready sooner and able to start the manufacturing stage.

Some problems in the manufacture and assembly were encountered with students finding it difficult to align the layers and to glue on the inlet and outlet needles accurately. As such, some chips in the testing phase encountered problems with leaking and blockages. The students had access to the fabrication facilities throughout the three laboratory sessions to prepare multiple microfluidic chips. These were required to either replace chips that had blockage or leaking issues resulting from the manufacturing stage, or to alter design aspects of the chips for comparative testing. Each of the groups prepared at least three different chips to test, with several chips discarded in the manufacturing processes as the students improved upon their fabrication methods.

One challenge in the delivery of this type of lab session is that as groups progress at different speeds through their problems, sufficient demonstrator capacity is essential. At HWU, our laser-cutter is located two floors away from the design and testing space thus necessitating the need for at least two demonstrators due to the spread of locations of the students. An important contribution to the success of the course was having demonstrators who were familiar with the theory and practical manufacturing methods of microfluidics, in order to provide appropriate advice throughout the design and testing process. Good communication between the demonstrators and instructors allowed for common problems and their solutions to be passed around quickly to ensure efficient use of the allocated laboratory time.

In general, demonstrators found the experience more fun and interesting than demonstrating traditional “recipe-style” labs. They reported a high level of interaction with the students, from the removal of a traditional “lab manual,” resulting in the whole class engaging directly with the lab demonstrators. This resulted in problems being identified and resolved quickly, without any of the class being left behind.

Student evaluation

Evaluation of the success of the PBL lab approach was assessed through several means of feedback. Above we have discussed the demonstrator perspective of the student experience noting that a high level of student engagement was observed. Additionally, during the demonstration of the lab work, it was clear that all groups eventually achieved success in each stage of design, manufacture, and testing (see Figure 2 for some examples of working devices), though most of them required the full time slot available, indicating that the level of challenge was pitched at the right level. Additionally, the students submitted two pieces of work for assessment: a group report and an individual reflective piece of which one component was commenting on their learning. Furthermore, student feedback was collected by the M.Sc. coordinator, and an additional survey was distributed asking specific questions relating to the microfluidics lab.

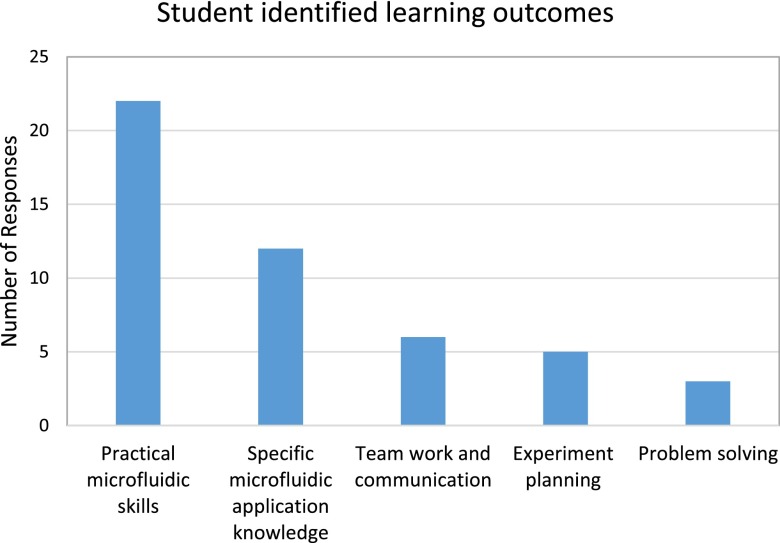

The individual reflective piece asked the students to report three key learning outcomes. Compilation of the responses from all 17 students resulted in 53 mentions of different skills (some students named more than three), which have been grouped into five main categories as shown in Figure 3. Other skills and knowledge not included in this graph (low number of mentions so excluded for clarity) include two mentions of gaining a better appreciation of the overall design, manufacture, and testing of microfluidic devices and one mention of increased motivation to learn more about microfluidics as a result of the lab. The largest category noted by the students was the practical skills in terms of design considerations (e.g., space required around channels for effective bonding), impact of flow rate, set-up and operation of devices, and the parameters involved in laser cutting manufacture (e.g., laser power and speed) followed by knowledge and understanding of specific microfluidic techniques, relevant to the project on which they had been working (e.g., mixing, H-filter, or PFF performance). The concentration on technical and practical skills/knowledge shows that the lab successfully met the first two learning objectives, although the lower mention of other more transferrable skills might be indicative of the students lack of experience with reflective pieces (and an assumption that the question was directed towards technical/practical learning) or the limitation to report three key learning outcomes only. The final two learning outcomes were team work and experiment planning, and Figure 3 shows that several students appreciated the opportunity to develop these skills identifying them as one of their three most important learning outcomes.

FIG. 3.

Overview of the skills developed by the students (as mentioned in the student reflective piece).

The student feedback about the microfluidic component of the course was extremely positive with this section being rated as one of the most popular among many students:

The microfluidics “lab was the most enjoyable part of this semester;” “the microfluidics lab was the most beneficial lab;” the microfluidics “laboratory work was a real joy.”

This course “introduced microfluidics in very interesting way, especially during the lab sessions.”

The demonstrators were “working long hours in the lab with students, and were helpful during the sessions. Got me interested into the field even beyond the class.”

The specific survey achieved a response rate of 71% and the results shown in Table II and Figure 4. In the initial phase of the survey, around half of the students reported minimal to no experience of lab work with only three having undertaken a research type lab project before and another three having experience of guided practicals. However, all of them identified as preferring practical work and preferring learning through kinaesthetic (7/12 respondents) or visual (5/12) means rather than listening to lectures. Figure 4 shows how the students rated their experience of this lab session in comparison to previous work indicating that all of them found the experience interesting and overall an overwhelmingly positive response. Given the positive response and the identification of the students as preferring practical styles of learning, further analysis of the success of the PBL approach depending upon learner type was precluded although this would be an interesting area for future analysis.

TABLE II.

Experience of the lab rated by the students. The question asked all students to tick all adjectives that they felt applied to their experience of the lab. The data have been grouped into positive and negative adjectives and ranked by number of students which selected a particular adjective: note, however, the question presented the adjectives as a mixed list.

| Positive adjectives | No. of students which selected this response | Negative adjectives | No. of students which selected this response |

|---|---|---|---|

| Interesting | 12 | Hard work | 1 |

| Useful | 8 | Not useful | 0 |

| Informative | 6 | Boring | 0 |

| Enjoyable | 6 | Frustrating | 0 |

| Confidence building | 4 | Time consuming | 0 |

| Total positive | 36 | Total negative | 1 |

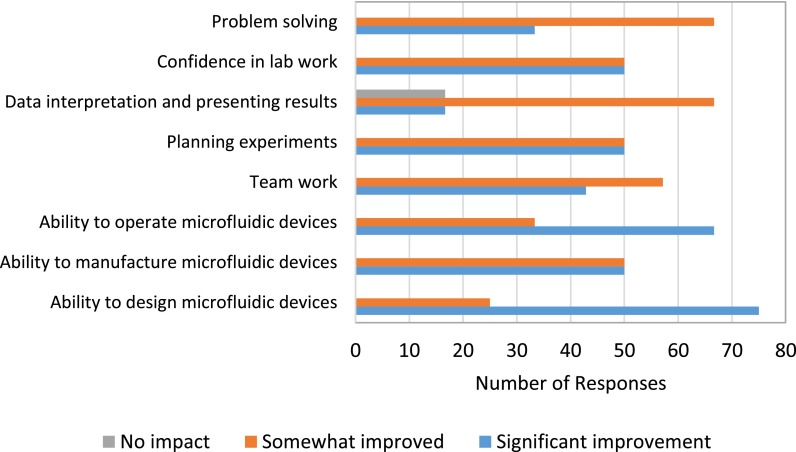

FIG. 4.

Rating of the skills developed during the project. The students could select from one of five options (developed as a new skill to a good level; significantly improved existing skill; somewhat developed skill; somewhat improved skill; no impact). The first two options of a significant improvement and development of a new skill to a good level have been amalgamated to show data where students rated the lab had a significant impact on their skills in this area, as has the information for skill development/improvement at a moderate (somewhat) level. The results for each skill are presented as the percentage of students answering each skill.

One student commented in the free text box relating to this question that allowing more time would improve the lab. Additional time in the laboratory would provide both the opportunity to relax some of the initial constraints of the challenges presented to the students, as well as providing more time for the students to test alternative design characteristics and improve upon their original designs. Due to the fixed number of contact hours allocated to the microfluidics component of the degree course, additional laboratory time would be difficult to achieve. However, the initial constraints of the challenges could be further relaxed by asking the students to carry out a literature review assignment, to identify the most appropriate microfluidic technology to use to solve their given problem, before the start of the laboratory sessions. Reducing the initial constraints and providing additional laboratory time would result in a more challenging task, with need for further iterations of the initial designs to achieve a working device. This may increase negative student feedback, however would improve the overall engineering design experience.

In terms of other suggestions for improvement all respondents thought that the addition of video instructions would be either really helpful or a useful addition to the existing demonstrator advice and materials. Most of the students (7/12) preferred asking a demonstrator for advice, as opposed to consulting the printed materials, agreeing with the previous observation in the literature that support is crucial for successful PBL approaches.

The final question in the survey evaluated the students' perceptions of skill development and learning following the lab activity. Not all students ranked all skills, and the results have been presented as a percentage of those which answered each question segment. In general, it is clear that the lab worked well in developing practical skills related to microfluidics, agreeing with the data in Figure 3 and meeting the first two learning objectives from Table I. Alongside the ability to design and operate microfluidics systems, the category most often selected by the students for where they had developed a new skill was in team working, meeting the third learning objective. The ability to manufacture microfluidics was rated slightly lower and might reflect the shorter amount of time and lower autonomy given during the laser cutter operation (students were highly supervised during this part). The final learning objective related to planning experiments and the lab work successfully delivered on this criteria with half of the students reporting a significant improvement in this skill or utilising this approach for the first time. The other half had experience of planning experiments and stated the project had at least helped improve these skills. It is also clear from the data that the lab work was not highly successful in terms of offering students the possibility to develop skills around data interpretation and presenting results, or alternatively that the students felt these skills were already well developed. However, 33% of respondents felt that the project had no impact on their data interpretation skills which potentially reflects either their experiment planning or the nature of some of the challenges.

CONCLUSIONS

Here, we have reported on a problem based learning approach to a microfluidics teaching lab aimed at M.Sc. level students to be delivered within 12 h of contact time. However, depending upon resources available (fabrication facilities and time), the project could be modified to be suitable for undergraduate or even school pupils or to open up the scope for leaving research into, and choice of, fabrication method up to the student teams. Although the development phase requires considerable input, an excellent solution is to outsource some of this work to a summer student to reduce the burden on already busy staff. Additionally, despite the extra effort demonstrators observed greater levels of student engagement and found the experience more enjoyable and interesting than traditional labs. This was also reflected in the evaluation of the student experience with the students reporting, in both the reflective pieces and the specific survey, developing all the skills, from practical microfluidics experience to team working skills, aimed at in the learning objectives. Additionally, the students reported a high degree of satisfaction with the lab format with all of them finding the lab interesting and providing minimal negative feedback. In summary, we recommend a problem based learning approach to microfluidics practical teaching due to the benefits to the students.

SUPPLEMENTARY MATERIAL

See supplementary material for the three problem sheets detailing the challenges and for the student survey.

ACKNOWLEDGMENTS

The authors would first like to thank Mr. YuGeng Zhang who worked on the development of devices to inform the design of the challenges produced for the lab scheme. During his summer placement, his work was excellent and his help was invaluable. We would also like to thank Dr. Maiwenn Kersaudy-Kerhoas, the PI on the “Small Plumbing” Ingenious! Scheme funded by the Royal Academy of Engineering, as our participation in this project provided some inspiration towards the redesign of the lab exercise. Brian Miller, David Watson and John McGrath also helped out with demonstrating this lab activity and we thank them for their time. Finally, we would like to thank all of the students on the M.Sc. in Smart Systems Integration for their active participation in the lab sessions and for providing the evaluation data.

References

- 1. Chin C. D., Linder V., and Sia S. K., “ Commercialization of microfluidic point-of-care diagnostic devices,” Lab Chip 12(12), 2118–2134 (2012). 10.1039/c2lc21204h [DOI] [PubMed] [Google Scholar]

- 2. Beebe D. J., Mensing G. A., and Walker G. M., “ Physics and applications of microfluidics in biology,” Ann. Rev. Biomed. Eng. 4, 261–286 (2002). 10.1146/annurev.bioeng.4.112601.125916 [DOI] [PubMed] [Google Scholar]

- 3. Gorkin R. et al. , “ Centrifugal microfluidics for biomedical applications,” Lab Chip 10(14), 1758–1773 (2010). 10.1039/b924109d [DOI] [PubMed] [Google Scholar]

- 4. Ohno K.-I., Tachikawa K., and Manz A., “ Microfluidics: Applications for analytical purposes in chemistry and biochemistry,” Electrophoresis 29(22), 4443–4453 (2008). 10.1002/elps.200800121 [DOI] [PubMed] [Google Scholar]

- 5. Esfahani M. M. N. et al. , “ Lab-on-a-chip workshop activities for secondary school students,” Biomicrofluidics 10(1), 011301 (2016). 10.1063/1.4940884 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6. Yang C. W. T., Ouellet E., and Lagally E. T., “ Using inexpensive Jell-O chips for hands-on microfluidics education,” Anal. Chem. 82(13), 5408–5414 (2010). 10.1021/ac902926x [DOI] [PubMed] [Google Scholar]

- 7. Jimenez M. and Bridle H. L., “ Angry pathogens, how to get rid of them: introducing microfluidics for waterborne pathogen separation to children,” Lab Chip 15(4), 947–957 (2015). 10.1039/C4LC00944D [DOI] [PubMed] [Google Scholar]

- 8. Nguyen D. et al. , “ Shrink-film microfluidic education modules: Complete devices within minutes,” Biomicrofluidics 5(2), 022209 (2011). 10.1063/1.3576930 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9. Cate D. M. et al. , “ Recent developments in paper-based microfluidic devices,” Anal. Chem. 87(1), 19–41 (2015). 10.1021/ac503968p [DOI] [PubMed] [Google Scholar]

- 10. Ravgiala R. R. et al. , “ Using paper-based diagnostics with high school students to model forensic investigation and colorimetric analysis,” J. Chem. Educ. 91(1), 107–111 (2014). 10.1021/ed300261a [DOI] [Google Scholar]

- 11. Koesdjojo M. T. et al. , “ Cost effective paper-based colorimetric microfluidic devices and mobile phone camera readers for the classroom,” J. Chem. Educ. 92(4), 737–741 (2015). 10.1021/ed500401d [DOI] [Google Scholar]

- 12. Yuen P. K. and Goral V. N., “ Low-cost rapid prototyping of whole-glass microfluidic devices,” J. Chem. Educ. 89(10), 1288–1292 (2012). 10.1021/ed3000292 [DOI] [Google Scholar]

- 13. Mielczarek W. et al. , “ Microworld and microflows: Initiating school children to microfluidics,” in Proceedings of the 4th European Conference on Microfluidics (lFlu'14) Limerick, Ireland (2014). [Google Scholar]

- 14. Hemling M. et al. , “ Microfluidics for high school chemistry students,” J. Chem. Educ. 91(1), 112–115 (2014). 10.1021/ed4003018 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15. Bardin D. and Lee A. P., “ Low-cost experimentation for the study of droplet microfluidics,” Lab Chip 14(20), 3978–3986 (2014). 10.1039/C4LC00424H [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16. Giri B. et al. , “ Undergraduate laboratory module for implementing ELISA on the high performance microfluidic platform,” J. Chem. Educ. 92(4), 728–732 (2015). 10.1021/ed4009107 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17. Chia M. C., Sweeney C. M., and Odom T. W., “ Chemistry in microfluidic channels,” J. Chem. Educ. 88(4), 461–464 (2011). 10.1021/ed1008624 [DOI] [Google Scholar]

- 18. Greener J. et al. , “ Education: A microfluidic platform for university-level analytical chemistry laboratories,” Lab Chip 12(4), 696–701 (2012). 10.1039/c2lc20951a [DOI] [PubMed] [Google Scholar]

- 19. Chao T.-C., Bhattacharya S., and Ros A., “ Microfluidic gel electrophoresis in the undergraduate laboratory applied to food analysis,” J. Chem. Educ. 89(1), 125–129 (2012). 10.1021/ed101064p [DOI] [Google Scholar]

- 20. Fintschenko Y., “ Education: A modular approach to microfluidics in the teaching laboratory,” Lab Chip 11(20), 3394–3400 (2011). 10.1039/c1lc90069b [DOI] [PubMed] [Google Scholar]

- 21. Piunno P. A. E. et al. , “ A comprehensive microfluidics device construction and characterization module for the advanced undergraduate analytical chemistry laboratory,” J. Chem. Educ. 91(6), 902–907 (2014). 10.1021/ed400728a [DOI] [Google Scholar]

- 22. Teerasong S. and McClain R. L., “ A student-made microfluidic device for electrophoretic separation of food dyes,” J. Chem. Educ. 88(4), 465–467 (2011). 10.1021/ed100717m [DOI] [Google Scholar]

- 23. Hmelo-Silver C. E., “ Problem-based learning: What and how do students learn?,” Educ. Psychol. Rev. 16(3), 235–266 (2004). 10.1023/B:EDPR.0000034022.16470.f3 [DOI] [Google Scholar]

- 24. McDonnell C., O'Connor C., and Seery M. K., “ Developing practical chemistry skills by means of student-driven problem based learning mini-projects,” Chem. Educ. Res. Pract. 8(2), 130–139 (2007). 10.1039/B6RP90026G [DOI] [Google Scholar]

- 25. Perrenet J. C., Bouhuijs P. A. J., and Smits J. G. M. M., “ The suitability of problem-based learning for engineering education: Theory and practice,” Teach. Higher Educ. 5(3), 345–358 (2000). 10.1080/713699144 [DOI] [Google Scholar]

- 26. Kirschner P. A., Sweller J., and Clark R. E., “ Why minimal guidance during instruction does not work: An analysis of the failure of constructivist, discovery, problem-based, experiential, and inquiry-based teaching,” Educ. Psychol. 41(2), 75–86 (2006). 10.1207/s15326985ep4102_1 [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

See supplementary material for the three problem sheets detailing the challenges and for the student survey.