Abstract

There is a global shift in the teaching methodology of science and engineering toward multidisciplinary, team-based processes. To meet the demands of an evolving technical industry and lead the way in engineering education, innovative curricula are essential. This paper describes the development of multidisciplinary, team-based learning environments in undergraduate and graduate engineering curricula focused on medical device design. In these programs, students actively collaborate with clinicians, professional engineers, business professionals, and their peers to develop innovative solutions to real-world problems. In the undergraduate senior capstone courses, teams of biomedical engineering (BME) and business students have produced and delivered numerous functional prototypes to satisfied clients. Pursuit of commercialization of devices has led to intellectual property (IP) disclosures and patents. Assessments have indicated high levels of success in attainment of student learning outcomes and student satisfaction with their undergraduate design experience. To advance these projects toward commercialization and further promote innovative team-based learning, a Master of Engineering (MEng) in Design and Commercialization was recently launched. The MEng facilitates teams of graduate students in engineering, life sciences, and business who engage in innovation-commercialization (IC) projects and coursework that take innovative ideas through research and development (R&D) to create marketable devices. The activities are structured with students working together as a “virtual company,” with targeted outcomes of commercialization (license agreements and new start-ups), competitive job placement, and/or career advancement.

Keywords: engineering education, multidisciplinary, team-based learning, design, innovation, business

Introduction

BME may be described as the application of engineering principles for solving problems in health care. As such, biomedical engineers are at the forefront of innovative technological solutions to global health problems. According to the Strategic Plan of 2012–2016 [1], the National Institute for Biomedical Imaging and Bioengineering supports a global shift to adopt an interdisciplinary approach to STEM education that is attentive to the practical value of new knowledge with a focus on innovative technologies. To ensure America's position as a world leader in the education of engineering talent, curricula are needed that teach students how to work in multidisciplinary teams, which tend to produce higher quality results and added value through collaboration and new opportunities [2].

In this spirit, we have developed our year-long capstone engineering design sequence in BME as well as a new MEng in Design and Commercialization. This paper documents the evolution of these activities that foster multidisciplinary, team-based learning where students develop innovative solutions to real-world problems through teamwork, peer interaction, and professional mentorship, with the potential for commercialization. Curricula and project development processes are described along with learning and program outcomes assessments. The results indicate high levels of overall success at the capstone level with the promise of enhanced commercialization activities with the new MEng.

History.

Since 1998, the lead author has received support through the National Science Foundation, Research to Aid Persons with Disabilities program (now GARDE) that has financed undergraduate senior design projects in the realm of assistive technologies. Working with physical and occupational therapists as well as disabled individuals from special care facilities (United Cerebral Palsy of Greater Birmingham, the Bell Center of Homewood, among others), students teams have designed, constructed, and delivered numerous prototype devices to meet the special needs of children and adults with disabilities. These activities may be described as service learning, defined as a “method under which students learn and develop through active participation in thoughtfully organized service [3].” IP disclosures and/or patents were not pursued for these devices. While none of these projects led to commercialized products, the efforts have benefited both the students and the disabled community, as observed by others [4].

In 2013, with the receipt of an R25 award from the National Institutes of Health, a working partnership was formed with the UAB Collat School of Business to bring engineering and business undergraduates together to foster commercialization strategies around new medical device designs. Project scope was also extended to include other medical device needs from pediatric neurosurgery, medical simulation, and orthopedic surgery, among others. In the past 3 years, senior capstone projects have produced numerous IP disclosures, four provisional patents, and one Patent Cooperation Treaty (PCT) filing. Unfortunately, lack of a viable environment to continue R&D of these projects beyond the end of the capstone activities has hindered commercialization.

The UAB MEng in Design and Commercialization, launched in Fall 2015, provides an opportunity to address this problem. Multidisciplinary teams comprised of engineering and business graduate students and faculty engage in IC projects and parallel coursework that take promising innovative ideas through the R&D process to create marketable devices and start new businesses. In this first year, two teams have adopted projects prototyped in the capstone sequence, with clients from UAB Hospital and Children's Hospital of Alabama. Projects have also been provided by the UAB Department of Physics and a local dental implant company, Biohorizons, Inc., Birmingham, AL.

Methods

BME Capstone.

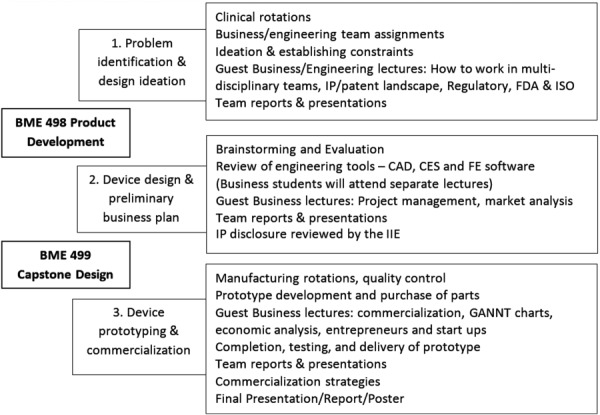

Using an approach modeled after Stanford Biodesign [5], the lead author has developed a BME capstone course sequence in which the students work to “identify, invent, and implement” medical and assistive devices for local clients. We coordinate class times to allow BME students to be joined by business students enrolled in a senior entrepreneurship elective. At the beginning of the fall term, the students shadow clinicians, therapists, and research scientists to determine device needs and ideate potential solutions. Mixtures of 4–6 engineering and business students create interdisciplinary teams around vetted need statements of their choosing. Device design constraints are established around both prototype and marketable designs. Figure 1 illustrates the curricular content for the two-semester course sequence. Engineering lectures are provided with a “Just in Time” approach, including brainstorming and evaluation of design alternatives, a review of computer-aided drawing (CAD), an introduction to material selection using ces edupak software (Granta Design, Materials Park, OH), and hands-on training within the lead author's machine shop. Self-reflective processes of formative assessment are employed, where feedback from learning activities is used to adapt teaching to meet the learner's needs and promote student attainment [6,7].

Fig. 1.

Curriculum content for the BME 498/499 Senior capstone courses

Concurrently, the students begin their investigation into business development for their medical devices. Readings from the Biodesign text along with guest lectures by faculty from the School of Business and Industry cover market analysis, IP and patent landscapes, and business models through the “Business Model Canvas” [8]. Regulatory topics include medical device classes and FDA approval processes. In recent years, we have expanded our instructional efforts around how to work effectively in teams. Lectures include project management, the classic “five dysfunctions” [9], and how to have “crucial conversations” [10] to help students resolve team issues that arise during the year.

A series of writing assignments culminate in a formal design proposal that includes concepts for a functional prototype as well as a marketable design. The teams are required to have signature approvals from their client, as well as that of a licensed professional engineer (senior author on this paper), who has mentored the team throughout the brainstorming process. The fall semester ends with an oral presentation of their proposed designs to faculty from the new UAB Institute for Innovation and Entrepreneurship (IIE) for a first review of potential IP.

Spring semester emphasizes building of functional prototypes and formulation of a commercialization strategy. Students take part in a manufacturing rotation where they gain hands-on experience associated with state-of-the-art methods for metals, plastics, and composites. Options include our School of Engineering (SoE) Design Lab, which houses end mills, drill presses, band saws, lathes, and hand tools, computer numerical control (CNC) machining, and 3D printing. Plastic molding, extrusion, and compression molding are available through the Material Processing and Applications Development Center. Electronics and control systems may be developed with assistance in the SoE Signal Processing and Embedded Systems Laboratory. In this manner, we have ensured that students have adequate access to equipment and expertise to help fabricate their prototype devices.

Business topics are continued including project management, Gantt charts, economic analysis, and development of a commercialization plan. Additional lectures on finite-element analysis, motor/bearing selection, and/or structural frame design are provided if desired by student teams. A team of professional engineers provides instruction on quality control and maintains a close watch on each student team and their progress, helping them make smart decisions. The students are responsible for ordering parts and delivery of a functional prototype. As the projects take final shape and proofs of concept are completed, the students submit IP disclosures for their devices to the IIE well in advance of any public disclosures (e.g., the students are required to participate in our Undergraduate Research Expo in late March, which is open to the public). The students perform verification and validation testing (as is feasible) and demonstrate some form of customer evaluation of the final working product. The final design presentation includes an investor pitch, a scientific poster, and demonstration of their functional prototype. This event is typically held during the final BME seminar for the term, which is attended by the BME faculty, students, alumni, clients, and members of the IIE.

MEng in Design and Commercialization.

In the MEng in Design and Commercialization, engineering students embark upon IC projects and structured coursework that allows them to take innovative ideas through the R&D process to create marketable devices. The curriculum (Fig. 2) contains 24 engineering credit hours and 12 hrs in the Master of Business Administration (MBA) program, which earn students the MEng degree as well as a Graduate Certificate in Technology Commercialization and Entrepreneurship from the UAB Collat School of Business.

Fig. 2.

The MEng curriculum contains engineering and business coursework to parallel the IC project development and ensure successful R&D for device commercialization. Internships with partner organizations may be substituted for the spring/summer electives.

New courses developed specifically for the MEng program include BME 630 Engineering Design and Commercialization and EGR 693/694/695 IC Project (I, II, and III). In BME 630, engineering students select their IC projects and begin the R&D processes for engineering enhancement for commercialization starting with client meetings to review the problem and need (these projects have been prototyped previously). They complete background and market research and explore the IP/patent landscape in their design space. The students and projects are incorporated together as a virtual company or mock business with the instructor acting as CEO. Each week, students deliver memos reporting project plans, milestones reached, and/or design changes. Every other week, the students turn in physical or visual deliverables such as design drawings, 3D models, circuit designs, or rough prototypes. The CEO provides prompt feedback for quick implementation. Formal presentations are held periodically for faculty in engineering, business, and the IIE to offer feedback. The course culminates with demonstration of improved functional prototypes with a focus on obtaining patents, which incentivizes students to complete high-quality work.

EGR 693 focuses on hands-on learning and training of “maker activities” that allow them to build competency in prototyping. Students first review CAD, a natural precursor to fabrication. They are tasked to model a beam with a through-hole in the shape of any suit from a deck of cards (heart, spade, diamond, or club). Students are then required to make their “beam with a hole” by hand machining (band saw, end mill, and hand files). As the profiles of card suits contain several sharp internal corners, students learn the limitations of hand machining by experience. The beam example extends to CNC machining, where they are introduced to G-code and CNC mills. Next, they learn to 3D print their beams, with lectures describing the utility of home hobbyist machines versus professional industrial printers. Contemporary electronics are experienced through hands-on activities using breadboards in conjunction with Arduino (Arduino, LLC, Cambridge, MA) and Raspberry Pi (Adafruit, New York, NY). Examples are worked in class and the students are provided kits and code to encourage further investigations outside of class. Finally, students receive instruction and lab experience on soldering printed circuit boards. By end of the course, the student engineers are no longer naïve to these skills; they know how to prototype and what questions to ask when their designs require advanced methods.

Through the spring and summer “project courses,” EGR 694/695, the MEng students will implement the tools gained from EGR 693 to develop a series of improved prototypes. The goal of this process is to learn something new from each iteration and to apply it toward the final design. This iterative process will require students to effectively communicate with each other, their clients, and their mentors to hone in on a final product. Through mentorship by professional engineers and local industrial designers, the students will develop products ready for mass production.

Other required engineering courses for the MEng include ME 677 Systems Engineering (taken in the fall), which covers project life cycles, system hierarchy, risk and cost analyses, engineering alternatives, and systems processes. EE 605 Embedded Systems (spring) focuses on embedded electrical systems design and rapid prototyping. MSE 610 Advanced Materials, Manufacturing, and Applications Development (summer) introduces students to modern manufacturing using medical grade materials application to their projects. The students are also required to take two graduate level engineering electives, which may include internships with partner organizations.

The IC Projects.

The original concept for the MEng was that it would provide student teams the opportunity to advance projects prototyped in the BME capstone. IC projects adopted by this year's cohort include two such projects, as described below, as well as two projects from external sources.

Recumbent patient weighing device.

Rapidly obtaining the weight of recumbent patients in emergency rooms is critical for proper dosing of medication and mechanical ventilation. The prototype, developed with a client from UAB Emergency Medicine, includes an air mattress with a pressure sensor calibrated to provide weight as a function of pressure change, connected to an Arduino microprocessor to display patient weight on a screen (Fig. 3(a)). The MEng team associated with this project is focused on developing patentable methods for weight measurement and visual/audible weight and medication display.

Fig. 3.

Example IC projects from BME senior design: (a) prototyped mattress scale for recumbent emergency patients and (b) hemostasis tool for pediatric neurosurgery

Hemostasis tool.

Pediatric endoscopic neurosurgery is used in minimally invasive procedures to treat hydrocephalus in children. Our client from Children's Hospital of Alabama expressed a need for a better way to control bleeding associated unintended tears in small fluid filled vessels. The completed prototype design employed a “vending machine” style of delivery of the hemostasis agent (Fig. 3(b)). This project was adopted by a MEng team with the goals of developing a patentable delivery mechanism and reducing the size to fit in modern endoscopes.

Business Courses and Entrepreneurial Activities.

In the fall semester, the MEng students join with MBA students to form multidisciplinary teams in MBA 681 Idea to IPO, which addresses issues involved in determining how to take a device from the laboratory to the marketplace. MBA 690 Leading Innovation, also taken fall semester, introduces Lean Start-up principles, building mission and vision while keeping innovation alive, and understanding business pivot points. MBA 673 Technology-Based Venture Planning (spring) educates students on business plans, capital raising, operational milestones, market research, and competitive analysis. Concurrent enrollment in the year-long MBA 691 i2i Entrepreneur Accelerator Independent Study provides mentoring for commercialization that will culminate with student teams pitching their start-up companies at the Alabama Launchpad business plan competition. The student teams will be coached through SPARK, a mentoring program organized by the Birmingham Business Alliance to help Birmingham-area start-ups succeed. Launchpad winners gain financial support to launch a start-up at Innovation Depot, the largest and most successful business technology incubator in the Southeast. As such, we have created an ecosystem that may allow student teams to successfully take their technologies to commercial viability (Fig. 4).

Fig. 4.

Process flow chart illustrating the stages by which the students will complete the program and develop technologies leading to commercial viability

Learning Outcomes and Assessment.

Targeted learning outcomes for both the BME capstone and the MEng are that students will demonstrate proficiency in applying teamwork skills to accomplish goals; they will show creative usage of analytical, critical thinking, and problem solving skills; and they will be effective communicators. Self-assessment of student learning is performed for each course using Student Course Evaluations (IDEA, Manhattan, KS). For the BME capstone, direct assessment of student work products include oral presentations and written reports, which are reviewed by the lead author and the ABET coordinator for the BME department using established rubrics. Peer assessment of team functionality is assessed twice each semester and counts as 10% of the students' course grade. Exit interviews with each BME graduate assess their individual learning experience and their level of preparedness for team-based work in industry.

As indicated previously, the MEng is new and the first cohort of students is currently enrolled; therefore, no assessment data yet exist regarding student/program success. One expected outcome for the MEng program is that upon program completion, students will gain competitive positions in industry, launch new start-ups, or be accepted into Ph.D. programs focusing on IIE. Postgraduate surveys will be emailed to all graduates 6 months post graduation to assess the success of their job or school placements.

Results and Discussion

Capstone courses involving service learning projects, such as our designs to aid persons with disabilities, provide opportunities for students to demonstrate numerous ABET learning outcomes [11,12]. Direct assessments of student work products have revealed that the BME undergraduates are successfully meeting numerous ABET student outcomes, including the ability to design a system, component, or process within realistic constraints; to function on multidisciplinary teams; to communicate effectively; to use modern tools; etc. The guest lectures by UAB Business and IIE faculty and local entrepreneurs have resulted in enhanced student exposure to real-world product development topics including regulatory issues and business models. IDEA surveys indicate that a strong majority of students (>85%) score a 4 or 5 (out of 5) agreeing that the course was useful in developing specific skills, competencies, and points of view needed by professionals in the field most closely related to this course. The effects of the manufacturing rotations have been seen in the improved quality of devices and increased student satisfaction—concerns regarding lack of access to the tools needed for successful construction are no longer observed in student comments within IDEA surveys. Peer assessments indicate that a majority of teams are content with their overall team interactions and the additional lectures have been beneficial in identifying and correcting problem behaviors. The results from our first round of assessments of the MEng are currently pending; however, coauthor Ophelia Johnson won a Marshall Scholarship to pursue a graduate degree in medical device design and entrepreneurship at the Imperial College London, which suggests MEng graduates will be competitive at an international level.

As recommended by the National Research Council [13], our programs impact students by providing learning through cohesive and engaging clinical and industrial experiences. These activities offer experiential/case-centered learning activities that teach critical thinking and integrate new knowledge with prior learning. The hands-on experiences facilitate development of metacognitive skills, including planning the approach, monitoring comprehension, and evaluating progress toward completion [14,15]. The activities are consistent with Marin et al. [16], who described worthy projects sponsored by active clients and inspirational mentoring as critical for achieving an optimal student experience.

In both the capstone and the MEng, the students engage with a team of professional engineers, led by the senior author. The goal of this mentorship is to inspire and encourage the students, so they will grow in confidence and develop skills necessary to effectively solve the problems they encounter with their projects and build their confidence as engineers. Ramirez [17] reported that successful mentoring experiences ensure that students are happier with their chosen majors and achieve greater academic heights, leading them to pursue career paths and advanced study that they may not have otherwise contemplated pursuing.

Program outcomes for both the capstone and the MEng include the number and quality of devices completed and number of IP disclosures and patents filed. As a result of the 2012–2013 and 2013–2014 BME capstone projects, IP disclosures were generated for seven projects (out of 12). Among these projects, four resulted in provisional patents, and one led to a PCT filing. From the activities in 2014–2015, 11 projects were disclosed and 2 of them are being considered for provisional patents. One start-up business was formed, Bactrac LLC., Birmingham, AL, around a bacterial sensing and traffic monitoring system for operating rooms. Other metrics for success include publication in peer-reviewed journals, conference abstracts/presentations, student participation in business plan competitions and their successes, commercialization outcomes (new start-ups and license agreements), and graduate job placement/career advancement. Currently, MEng students are self-funded and pay their tuition and fees. Long-term success of the MEng will likely depend on funding, industry support, and involvement. The value proposition to prospective companies includes access to trained students who understand business as well as opportunities to advance technologies at reduced cost.

Acknowledgment

The authors gratefully acknowledge the faculty and staff support from the UAB School of Engineering, the Collat School of Business, and Engineering Innovation Technology Development.

The authors gratefully acknowledge the financial support from the National Science Foundation (NSF) GARDE Program, CBET-1263941, and the National Institutes of Health (NIH), 5R25HD078327-02.

Contributor Information

Alan W. Eberhardt, Professor , Fellow ASME , Department of Biomedical Engineering, , University of Alabama at Birmingham, , Hoehn 361, 1075 13th Street South, , Birmingham, AL 35294-4440 , e-mail: aeberhar@uab.edu

Ophelia L. Johnson, School of Engineering, , University of Alabama at Birmingham, , 1075 13th Street South, , Birmingham, AL 35294-4440 , e-mail: opheliaj@uab.edu

William B. Kirkland, Engineering Innovation Technology Development, , University of Alabama at Birmingham, , 1720 Second Avenue South, , Birmingham, AL 35294 , e-mail: rocwbk@uab.edu

Joel H. Dobbs, Collat School of Business, , University of Alabama at Birmingham, , BEC 319B, 1150 10th Avenue South, , Birmingham, AL 35294-4460 , e-mail: jhdobbs@uab.edu

Lee G. Moradi, Engineering Innovation Technology Development, , University of Alabama at Birmingham, , 1720 Second Avenue South, , Birmingham, AL 35294 , e-mail: moradi@uab.edu

References

- [1].NIBIB, 2012, “ Today's Vision, Tomorrow's Healthcare: The 2012–2016 Strategic Plan of the National Institute for Biomedical Imaging and Bioengineering,” National Institute of Biomedical Imaging and Bioengineering (NIBIB), Bethesda, MD.https://www.nibib.nih.gov/about-nibib/strategic-plan

- [2]. Terpenny, J. P. , Goff, R. M. , Vernon, M. R. , and Green, W. R. , 2006, “ Utilizing Assistive Technology Design Project and Interdisciplinary Teams to Foster Inquiry and Learning in Engineering Design,” Int. J. Eng. Educ., 22(3), pp. 609–616http://www.ijee.ie/articles/Vol22-3/22_ijee1770.pdf. [Google Scholar]

- [3].Corporation for National and Community Service, 1993, “ National and Community Service Trust Act of 1993,” Corporation for National and Community Service, Washington, DC, http:www.nationalservice.org/pdf/cncs_statute_1993.pdf

- [4]. Miyares, U. , Newman, P. , and May-Newman, K. , 2007, “ Senior Design Projects in Assistive Technology: Opportunities for Technology Transfer,” Annual ASEE Conference and Exposition, Honolulu, HI, June 24–27, p. 12.1269. [Google Scholar]

- [5]. Zenios, S. , Makower, J. , and Yock, P. , 2010, Biodesign: The Process of Innovating Medical Technologies, Cambridge University Press, New York. [Google Scholar]

- [6]. Crooks, T. , 2001, “ The Validity of Formative Assessments,” British Educational Research Association Annual Conference, University of Leeds, Leeds, UK, Sept. 13–15http://www.leeds.ac.uk/educol/documents/00001862.htm. [Google Scholar]

- [7]. Black, P. , and William, D. , 1998, “ Inside the Black Box: Raising Standards Through Classroom Assessment,” Phi Delta Kappa Int., 80(2), pp. 139–149http://www.spd.dcu.ie/site/teaching_today/documents/raisingstandardsthroughclassroomassessment.pdf. [Google Scholar]

- [8]. Osterwalder, A. , and Pigneur, Y. , 2010, Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers, Wiley, New York. [Google Scholar]

- [9]. Lencioni, P. , 2002, The Five Dysfunctions of a Team, Jossey-Bass, San Francisco, CA. [Google Scholar]

- [10]. Patterson, K. , Grenny, J. , Maxfield, D. , McMillan, R. , and Switzler, A. , 2013, Crucial Accountability, 2nd ed., McGraw-Hill, New York. [Google Scholar]

- [11]. Dutson, A. J. , Todd, R. H. , Magleby, S. P. , and Sorenson, C. D. , 1997, “ A Review of Literature on Teaching Engineering Design Through Project-Oriented Capstone Courses,” ASEE J. Eng. Educ., 86(1), pp. 17–28. 10.1002/j.2168-9830.1997.tb00260.x [DOI] [Google Scholar]

- [12]. Duffy, J. , Tsang, E. , and Lord, S. , 2000, “ Service Learning in Engineering: What, Why, and How?” ASEE Annual Conference and Exhibition, St. Louis, MO, June 18–21, pp. 5.543.1–5.543.9. [Google Scholar]

- [13].National Research Council, 2003, How People Learn: Bridging Research and Practice, Donovan S., Bransford J., and Pellegrino J., eds., National Academy Press, Washington, DC. [Google Scholar]

- [14]. Brown, A. , 1987, “ Metacognition, Executive Control, Self-Regulation, and Other More Mysterious Mechanisms,” Metacognition, Motivation, Understanding, Weinert F. and Kluwe R., eds., Erlbaum, Hillsdale, NJ, pp. 65–116. [Google Scholar]

- [15]. Shimamura, A. P. , 2000, “ Toward a Cognitive Neuroscience of Metacognition,” Conscious. Cognit., 9(2), pp. 313–323. 10.1006/ccog.2000.0450 [DOI] [PubMed] [Google Scholar]

- [16]. Marin, J. A. , Armstrong, J. E. , and Kays, J. L. , 1999, “ Elements of an Optimal Capstone Design Experience,” J. Eng. Educ., 88(1), pp. 19–22. 10.1002/j.2168-9830.1999.tb00405.x [DOI] [Google Scholar]

- [17]. Ramirez, J. J. , 2012, “ The Intentional Mentor: Effective Mentorship of Undergraduate Science Students,” J. Undergrad. Neurosci. Educ., 11(1), pp. A55–A63http://www.funjournal.org/wp-content/uploads/2015/09/ramirez_11_1_a55_a63.pdf. [PMC free article] [PubMed] [Google Scholar]