Abstract

Nanomanufacturing, the commercially-scalable and economically-sustainable mass production of nanoscale materials and devices, represents the tangible outcome of the nanotechnology revolution. In contrast to those used in nanofabrication for research purposes, nanomanufacturing processes must satisfy the additional constraints of cost, throughput, and time to market. Taking silicon integrated circuit manufacturing as a baseline, we consider the factors involved in matching processes with products, examining the characteristics and potential of top-down and bottom-up processes, and their combination. We also discuss how a careful assessment of the way in which function can be made to follow form can enable high-volume manufacturing of nanoscale structures with the desired useful, and exciting, properties.

Keywords: Nanomanufacturing, nanofabrication, lithography, self-assembly

Nanotechnology has the potential to make a significant impact in a multitude of diverse areas.1 It offers precise control over composition and nanostructure of materials enabling the production of multifunctional devices with unique properties, ranging from multiferroics to nanocomposites. For example, coatings containing nanoparticles can act as thermal barriers2 and flame retardants,3 confer resistance to ultraviolet light-induced degradation,4 be self-cleaning,5,6 anti-bacterial,7,8 scratch-resistant,9,10 improve the look of your skin,11,12 keep food fresh,13 and, by combining superhydrophobic and superoleophobic properties,14,15 keep the screen of your smartphone clean.16,17 Nanostructured materials can resolve the mismatch between the generally large absorption length of light in organic photovoltaic materials and the generally small charge-carrier diffusion distance18 to enable more efficient energy generation.19,20 Similarly, the high surface-to-volume ratios of nanostructured materials can enable rapid charge/discharge cycles in batteries and prevent strain-induced electrode degradation.21,22 Quantum confinement effects permit the light emission characteristics of nanoparticles made of a single material to be tuned across a wide range of wavelengths23 for applications in lighting and displays.24,25,26 However, to realize the potential benefits of all of these diverse applications we must develop efficient, cost-effective and robust nanomanufacturing methods.27

Nanomanufacturing is a term whose usage varies with the approach, and rationale for the choice of approach, for fabricating 1, 2 or 3-dimensional nanostructures. It can mean making small features on larger objects, (e.g. integrated circuit [IC] fabrication),28 making nanoscale objects with special properties (e.g. quantum dot synthesis),29 assembling nanoscale objects into more complex structures (e.g. DNA origami-directed assembly),30 incorporating nanoscale objects into larger objects to enable special functionality (e.g. graphene into electronic devices or into liquor distillation apparatuses),31,32 and using nanotechnology to manufacture nanoscale structures (e.g. dip-pen nanolithography).33,34 Given these varied interpretations, we must define our use of the terms “nanomanufacturing” and “nanofabrication” before proceeding further. They are often used interchangeably, but, in the interest of adding a level of precision to the conversation, we will draw a distinction between them. First, we note that here we employ a broad definition of nanofabrication that includes both conventional, top-down methods, such as those used in the production of semiconductors, as well as bottom-up methods such as chemical synthesis and self-assembly. For the purposes of this discussion, we distinguish between nanofabrication and nanomanufacturing using the criterion of economic viability, suggested by the connotations of industrial scale and profitability associated with the word “manufacturing”. Nanomanufacturing, as we define it here, therefore has the salient characteristic of being a source of money, while nanofabrication35,36 is often a sink. In all cases, for a process or technology to be considered manufacturable, the cost of manufacturing and the volumes that can be produced must be consistent with the selling price and total addressable sales market.37 In other words, if it is possible only to produce something in small volumes and at high cost, then it must command a high price; conversely, if the product fetches a low price, then not only must the cost of production be correspondingly low, but the volumes required by the market must be large enough in order to make the enterprise economically self-sustaining.38,39

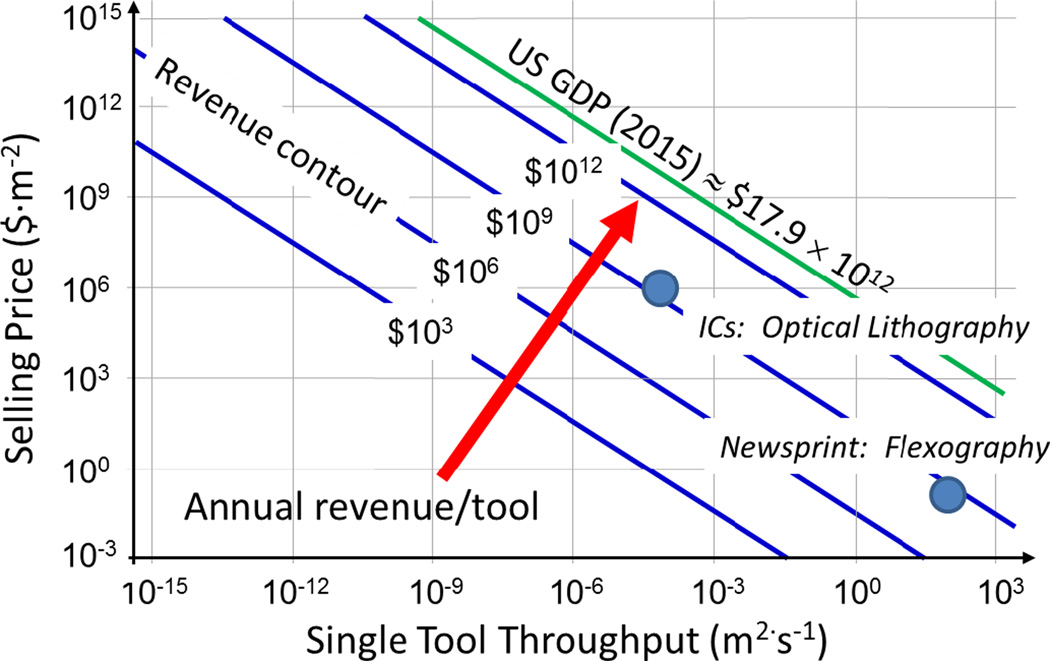

Mathematically this relationship follows from the fact that the yearly revenue generated by a given tool or process is the selling price of the product (vertical axis in Fig. 1) multiplied by the amount of product generated per year. The rate of product generation is most conveniently represented in terms of the throughput (horizontal axis in Fig. 1). A majority of the products generated by or processes used in nanomanufacturing concern what are essentially thin-film or quasi two-dimensional structures. We therefore choose to represent the amount of product generated in units of area, specifically meters squared. For example, the thickness of integrated circuits, hard drives, photovoltaics, sensors, and coatings is extremely small compared to their area and so the amount of area correlates directly to the amount of product. While this is not always the case, such as for catalysts, nanoparticles and nanotubes, which can be made volumetrically, these are often used to cover or coat a given area and so the area metric for production capacity in this case can be taken to refer to the “as used” or “as applied” area. It is clear from Fig. 1 that either a high throughput or a high selling price is required to achieve a given yearly revenue. For example, a yearly revenue of $1 million can be obtained with a throughput of 10−12 m2·s−1 only if the selling price is on the order of $10 billion per meter squared but the same revenue follows from a few cents per meter squared if the throughput is on the order of 1 m2·s−1. Of course multiple tools and/or processes can be used to increase revenue but this is economically viable only if money can be made on each tool or process individually.

Figure 1.

Log-log plot of the product selling price ($·m−2) versus single tool throughput (m2·s−1) with contours showing the relationship between throughput and selling price for different yearly revenue levels. Optical lithography as used for integrated circuit manufacturing is an example of a low-throughput process used to make a very high value product, leading to large revenues. Flexography, used for newsprint production, is a very high throughput process manufacturing a low value product, leading to more modest per-tool revenues.

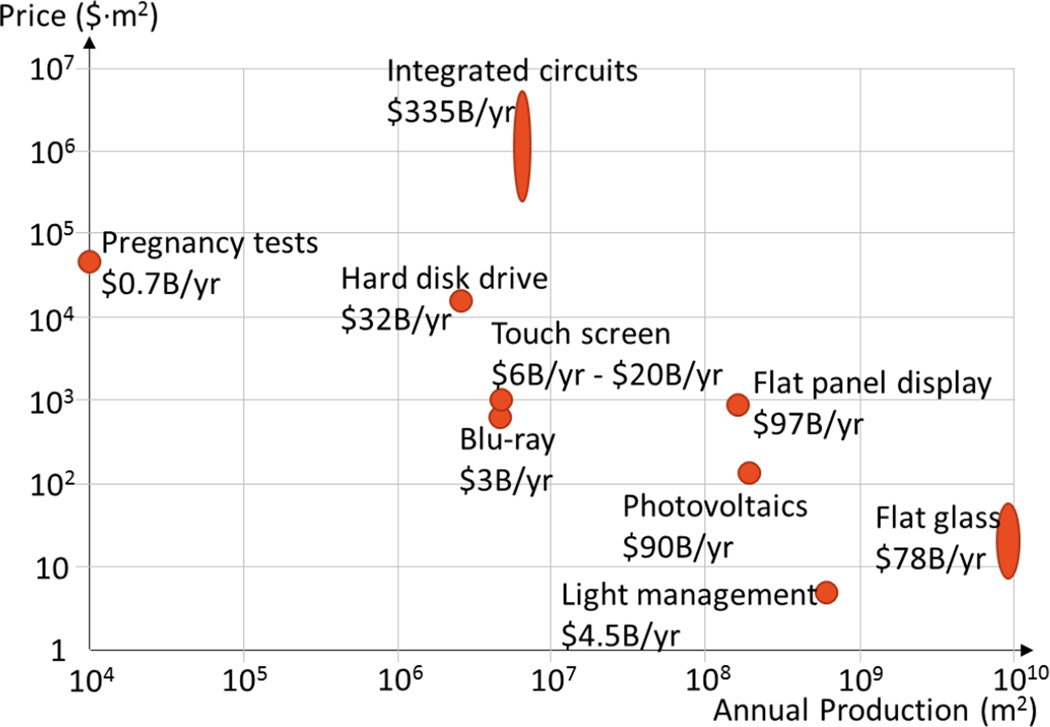

To supply some background and indicate the scale of the nanomanufacturing challenge, Figure 2 shows the selling price ($·m−2) versus the annual production (m2) for a variety of nano-enabled or potentially nano-enabled products. The overall global market sizes are also indicated. It is interesting to note that the selling price spans five orders of magnitude, the production six, and the market size three. Although there is no strong correlation between the variables, it interesting to note that there is an overall trend, with smaller-volume products commanding a relatively high price, as would be expected from the simple model shown in Figure 1. The diversity of market size, product volume, and price reinforces the idea that it is essential to carefully consider how to optimize the match between process and product.

Figure 2.

Log-log plot of the approximate product selling price ($·m−2) versus global annual production (m2) for a variety of nano-enabled, or potentially nano-enabled products. Approximate market sizes (2014) are show next to each point (The SI contains the information we used to estimate each data point).

In the context of the preceding discussion, the intent of this article is to provide an overview of the current state of and future prospects for nanomanufacturing. Some of the many nanofabrication techniques under development40,41,42,43,44 may one day be used in nanomanufacturing, but, in order to understand which ones are likely to make the transition to being a revenue source and not a sink, it is necessary to identify how the physical aspects of any given technique affect its ability to generate products that meet the desired functional requirements in a cost-effective manner.

Every product in the market place has a set of “functional requirements”, i.e., things it must do to be useful to the consumer. The sophistication of these functional requirements drives the product specifications in terms of structural complexity, dimensional and compositional accuracy and precision, tolerable defect levels and the degree to which the product can be classified as being active as opposed to passive. These product specifications can be used to determine which fabrication approaches potentially have the necessary capabilities. The final choice of nanomanufacturing technology must be driven by the cost of ownership, which depends critically on the characteristics of the manufacturing process, including yield and throughput.

Here we focus on nanomanufacturing primarily as it pertains to the creation of structures with a relatively high degree of functionality and structural complexity and hierarchy. We do not address the production of nanomaterials, nor the challenges associated with introducing them into the marketplace. The majority of those challenges, apart from those connected with metrology,45,46 are common to materials in general.47 The rest of this article is organized as follows: first we examine the two broad classes of nanofabrication processes: top-down, i.e., deterministic processes, and bottom-up, i.e., stochastic processes; then we consider the combination of top-down with bottom-up; next we explore what might be possible by adding driven dissipative processes; and finally we discuss the importance of design for nanomanufacturing. At each step we illustrate the areas of applicability of the various approaches through examples.

Top-Down versus Bottom-Up Processes

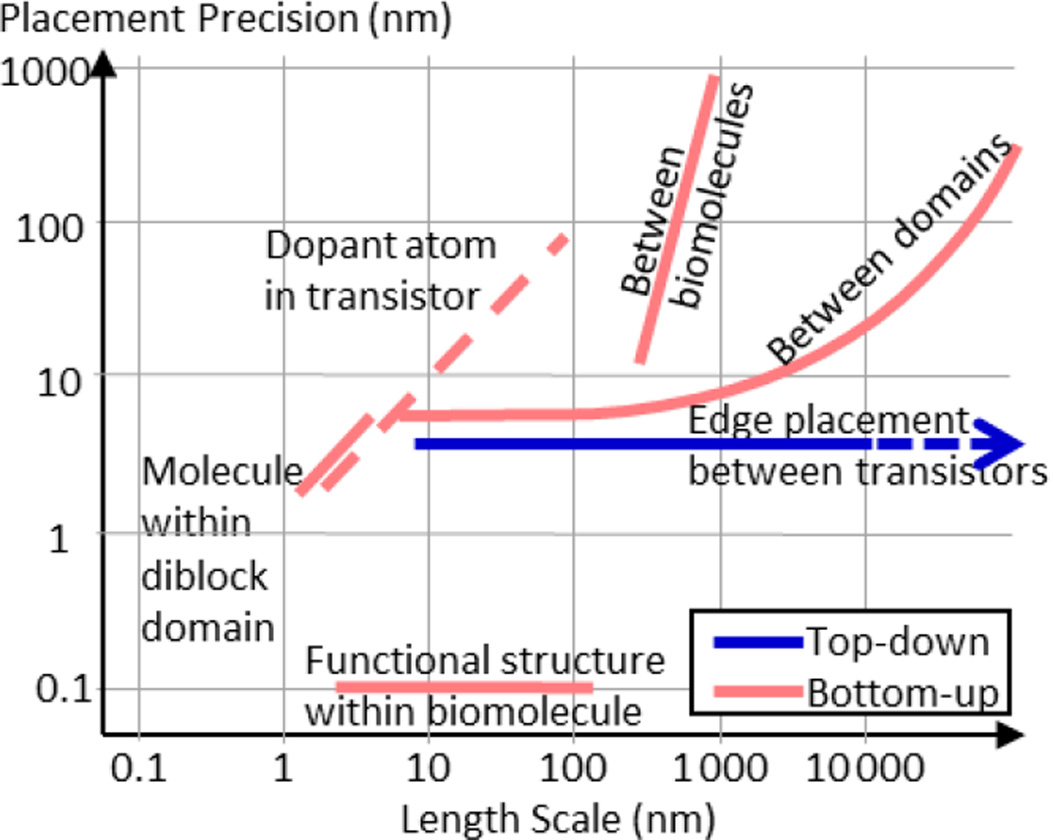

Before we begin our discussion of these two approaches, we must clarify our use of the words “deterministic” and “stochastic”. Deterministic manufacturing processes are designed to produce outcomes that exhibit very narrow distributions of the product performance mean and variation. However, this does not mean that there cannot be significant randomness at the atomic or nanometer scale. Stochastic processes, while statistical in nature, can, when averaged over the large numbers of nanostructures typically involved, also exhibit narrow distributions of the product performance mean and variation. Another way of looking at this (Figure 3) is to consider the length scales over which variations occur. Short-range precision and accuracy may be excellent for some stochastic processes, such as protein synthesis and folding, but tend to degrade rapidly at length scales larger than an individual unit. In contrast, deterministic methods may be disordered at the atomic or nanometer scale, but can have exceptional long-range accuracy and precision. As noted above, the product’s functional requirements are used to determine if a given approach might be suitable.

Figure 3.

Illustration of the role of stochastic processes in controlling structural precision in top-down, bottom-up and damped-driven assembly. Placement of individual atoms, such as dopants, within semiconductor devices is effectively only as good as the device dimension, with current manufacturing methods. I.e., an atom is only constrained to lie somewhere within the “box” created. Placement of edges is typically a fraction of feature size, and is uniform within the length scale of a circuit. Systems, such as diblock copolymers, which self-assemble with no guiding pattern, show excellent short-range order that decays exponentially with distance. The placement of individual molecules within a domain is again controlled by the size of the box. i.e., the domain. Control over individual atom placement is greatest in biomolecules, where it is specified by atomic relationships in, for example, amino acids, and then by the hierarchy of secondary and tertiary structure. Placement precision between biomolecules not bound together decays rapidly as a function of separation.

Top-Down Fabrication

Top-down processes are fundamentally deterministic, in that order is imposed on the system by the action of external forces. As Gordon Moore observed in his seminal 1965 paper,48 this means that yield is not dictated by equilibrium thermodynamic considerations – in contrast to, for example, chemical reactions. Yield in top-down processes can therefore can be engineered essentially to any desired degree consistent with physical laws: current IC manufacturing processes produce functioning devices with error rates below roughly 1 in 1012 and have generally far fewer than 0.1 defects per centimeter squared. It follows that, as long as there is no fundamental physical limit and the relevant economic drivers apply, the capabilities of top-down fabrication processes will tend to evolve according to typical learning curves.49,50,51

Photolithography

Integrated circuit manufacturing represents the apogee of top-down control over matter, yielding devices with unprecedented and ever-increasing levels of functionality in ever smaller spaces. The six decades following the invention of the IC have seen the evolution of photolithography to the point where a modern photolithography tool, operating with an immersion lens at a wavelength of 193 nm, is capable of printing, at a resolution of 38 nm, 1012 features per second. It does this while maintaining control over the feature size to within 10 %, and the ability to overlay thirty or more layers with respect to one another to within an uncertainty of less than 5.5 nm.52,53,54 This degree of control has of course also been enabled by concomitant progress in etch and deposition technologies and photoresist chemistry.55,56 The ability to print features which are so much smaller than the wavelength of the exposing radiation requires careful engineering of the mask pattern which in the end has no simple relationship to the features being printed on the wafer.57,58 This type of mask engineering must be combined with simultaneous optimization and precise control of the illumination incident on the mask to create the required intensity distribution at the wafer.59,60 In fact, the complexity of the coupled illumination-mask diffraction problem is so great that each future generation of chips relies on the computing power made available by the current generation of devices to solve it and, for all but the highest-volume devices, the mask cost is the dominant factor in the cost of ownership.61,62 In addition, multiple masks may be required to print the features for a single level when double- or multiple-patterning approaches are used to achieve the desired feature density.63,64,65,66,67 As noted above,48 it is the economic advantage gained by increasing integration that drives the technological progress in IC production, and it is this economic advantage that will determine whether or not the current incarnation of photolithography gives way to extreme ultraviolet lithography (EUV), which operates at a wavelength of 13.5 nm. The use of this much shorter wavelength brings many additional complexities, and therefore higher costs, as far as the lithography tool is concerned, but can, in principle, reduce the mask complexity thereby reducing the overall cost of ownership.61,62 The final result will depend on whether a suitable combination of resist sensitivity and illumination power can be reached to deliver economically viable throughputs.68 Alternatively, the drive for greater circuit densities and functionalities may be satisfied by the use of 3D approaches.69,70,71,72,73,74

As impressive as the current state of the art is, it is important to point out that photolithography is only as good as it needs to be. In particular, for integrated circuits to function, it is only the relative placement of individual circuit levels across the chip that must be controlled. Variations in the overall size and shape of the chip up to a few percent are acceptable as long as the level-to-level overlay is maintained. Thus, for ICs, absolute accuracy is not critical. On the other hand, with the increasing emphasis on combining nanophotonic and nanomechanical devices with conventional ICs, absolute accuracy will be extremely important since both nanophotonic and nanomechanical devices typically are required to operate at a fixed external wavelength or frequency. For example, an on-chip nanophotonic device structure such as an add-drop filter comprising ring resonators, waveguides and/or gratings operating in the 1550 nm telecommunications band with a 30 GHz channel separation (≈ 0.3 nm wavelength difference) nominally requires dimensions and/or periodicities accurate to within a fraction of the wavelength difference,75 i.e. a few picometers. These requirements are beyond the current capabilities of photolithography and necessitate an increase in the overall device complexity to include systems which can tune them to match a given external wavelength or frequency.76 Even a perfectly fabricated device will require tuning to compensate for thermal effects which shift the operating wavelength.

Nanoimprint Lithography

Embossing processes77 have been extended to the nanoscale, opening up a range of new applications. Nanoimprint lithography78,79,80,81,82 can, in principle, not only produce features at the size needed in integrated circuit production, but, because the imprint template is replicated precisely, can do so without those complexities inherent in sub-wavelength optical lithography mentioned above: the features on the template look exactly like the features on the substrate. However, this means that the patterned area on the imprint mask is the same size as the patterned area on the wafer (it is therefore described as a 1× mask) and fabricating a 1× mask to the required degree of precision is not trivial. Pattern placement capabilities close to those of photolithography tools have been achieved by introducing schemes that use controlled deformation of the imprint template.83,84,85,86 Such schemes, coupled with improvements in template fabrication processes, are currently suitable for IC manufacturing at feature sizes of ≈ 20 nm (i.e. the 2× nm nodes).87,88,89,90 Another potential benefit comes from the ability of nanoimprint to print multiple pattern levels simultaneously, which can result in a significant reduction in the number of process steps needed to complete a device.91,92,93,94,95 Aside from meeting overlay requirements, the principal obstacle facing the technology is for it to achieve the same throughput and low level of defects96 as photolithography.

Nanoimprint’s ability to fabricate almost arbitrarily small features precisely and accurately97 means that it is almost uniquely suited to the production of bit-patterned magnetic storage media,98,99,100,101 which have tolerances on feature size and size variation102 that are significantly more stringent than those for ICs.103 Interestingly, although the local pattern placement specification for bit-patterned media (BPM) must be better than 1.25 nm104 because the flying read head cannot track glitches in position, the long-range pattern placement requirement is only 10 µm or approximately 0.3 %, because the head can track long-range, slowly-varying placement errors.105,106

For nanoimprint to be an appropriate choice of manufacturing technology for bit-patterned media, it is not enough that it can produce small features competitively with photolithography because the price per unit area must be two orders of magnitude lower. Part of the necessary fabrication cost reduction may be achieved because only a single level needs to be patterned, which reduces the tool complexity and cost as well as the number of fabrication steps, and part by dramatically lowering the amortized mask costs, by using a single master to generate up to 10 000 copies, which can then each generate 10 000 disk-drive platters.107 Additional cost reductions come from the much higher defect density108 that can be tolerated for BPM as opposed to ICs (1 in 104 versus 1 in 1012) because of the availability of read-channel error correction schemes.109,110 A less demanding specification for defect density translates into a reduced need for costly defect inspection during manufacturing. As the technology evolves and defect levels decrease, it is even being considered for the production of flash memory, which has relatively relaxed overlay requirements,89,111 though defect levels will need to be reduced to ~ 0.1 cm−2.112

An attractive feature of imprint or embossing processes in general is that they can be adapted for use in continuous, roll-to-roll (R2R) manufacturing,113,114,115,116,117,118 which reduces the cost of fabrication and increases the throughput. The cost per meter squared may range between 0.1 $·m−2 and 10 $·m−2, depending on whether direct embossing or a thin-film ultraviolet light curing process is used. It is difficult to achieve precise overlay and long-range placement accuracy in R2R because of the tendency of the flexible substrate (called the “web”) to deform during processing. Single-level structures, used in applications such as large-area reflective coatings,119,120,121 and holographic wrapping paper,122 do not suffer from these problems. Extending single-level R2R technology to the nanoscale would enable applications such as organic photovoltaics,123,124 light-management films125 and wire-grid polarizers for high-contrast displays126,127,128 anti-reflective coatings, super-hydrophobic (philic) surfaces, as well as those requiring plasmonic activity.129,130,131 Self-aligned imprint lithography uses a multilevel template that produces pre-aligned structures, avoiding level-to-level alignment problems. It can be used to generate large-area, low-cost electronics such as display backplanes with minimum feature sizes of 1 µm at web speeds of up to 5 m/min.132 We also note that, while stitching defects are important in displays, other forms of defects are much less significant. Nanostructured surfaces produced by R2R imprint may also be useful for energy generation and storage if high aspect ratio features can be generated.

Nanoimprint is already used to produce nanoparticles for diagnostic and therapeutic applications.133,134,135,136 At first sight, it might appear that high-volume particle-production techniques such as milling137,138 would be by far more economical. However, medical and biological applications generally require very precise control over particle size and shape, and the small amount of product needed to achieve the desired effect [e.g. drug delivery, imaging contrast],139,140,141 and the high value associated with medical treatments make this an economically viable approach. In addition, nanoimprint can be a relatively gentle process, creating patterns without the need for high temperatures or aggressive chemicals, and thus allowing the safe handling of fragile biomolecules.141

Perhaps the most exciting aspect of nanoimprint is that it is heir to all the numerous macroscale embodiments of the printing process. At the most fundamental level, these all transfer material from a patterned surface to a substrate. Functional inks are already enabling a revolution in printed lectronics142 for flexible displays,143 wearable electronics and the “Internet of Things”, and there is every reason to suppose that one as profound will occur as inks are developed for nanoscale applications.144 As an example, microcontact printing,145,146 the small-scale analog of flexographic printing, has recently been demonstrated at the nanoscale.147 Similarly, nanotransfer printing, analogous to transfer printing on ceramics,148 enables the fabrication and heterogeneous integration of complex nanostructures made from a wide variety of materials.149,150,151,152,153,154,155 This gives the family of nanoimprint methods the potential to be a true nanomanufacturing platform technology, limited only by the availability of suitable templates, inks, and surface energy control.156

Other Top-Down Techniques

Optical lithography and nanoimprint are the dominant top-down nanomanufacturing methods, despite there being a large number of other nanofabrication approaches available. At this point, it is worth asking why these other techniques have not made the transition into nanomanufacturing. One of the principle obstacles that must be overcome is reaching an economically viable throughput. Electron-beam lithography, for example, can generate sub-10 nm features,157,158,159 over large areas, with good placement and overlay but, because of its relatively low throughput, it is limited commercially to the production of masks for use in photo-160 and nanoimprint lithography and device development,161,162 and non-commercially to the production of nanostructures for research and defense purposes. The prospects for increasing the throughput of electron-beam systems are severely limited because of the fundamental physics of space-charge effects – the repulsion between neighboring electrons in a single electron column leads to a loss of resolution or blurring of the beam as the beam current increases.163,164,165 This limits the maximum beam current, and hence the throughput, that can be attained at a given resolution. This inability to scale led to the demise of early programs focused on creating electron-beam systems for IC production.166,167 However, the economic pressures associated with leading-edge optical lithography still makes this an active area of research, with newer efforts relying on groups of columns, or targeted towards low-volume applications,168 under development.169,170,171

A common response to this type of scaling problem is to propose the use of massively parallel arrays of columns172 or tips173,174,175 to boost the throughput. Achieving the required feature size control means that the beam size and dose delivered must be well calibrated or dynamically controlled across the array. However, the electron source for each column is typically a field emitter for which the beam current is exponentially dependent on the emission area and geometry.176 Even if each emitter can be made identical, as soon as they are put into operation the evolution of the nanoscale emission area resulting from phenomena such as surface diffusion, ion bombardment, absorption of contaminants, etc. will cause the emission characteristics for the individual tips to diverge from one another. Feedback control to remedy this problem is possible in principle,177,178 but has so far proven to be extremely difficult to implement in practice. Similar considerations apply to many forms of scanning probe lithography,179 where attempts at parallelization are frustrated by, for example, tip wear.180,181 A notable exception to this is dip-pen nanolithography33,182 and its variants,183,184 which, through its ability to directly pattern different types of chemistries, including biological ones,185,186 targets and satisfies a set of constraints different from those relevant to IC device fabrication. This characteristic qualifies it as a disruptive technology,187,188 and the same may be true of other fabrication processes that also offer benefits orthogonal to those provided by IC fabrication methods.189

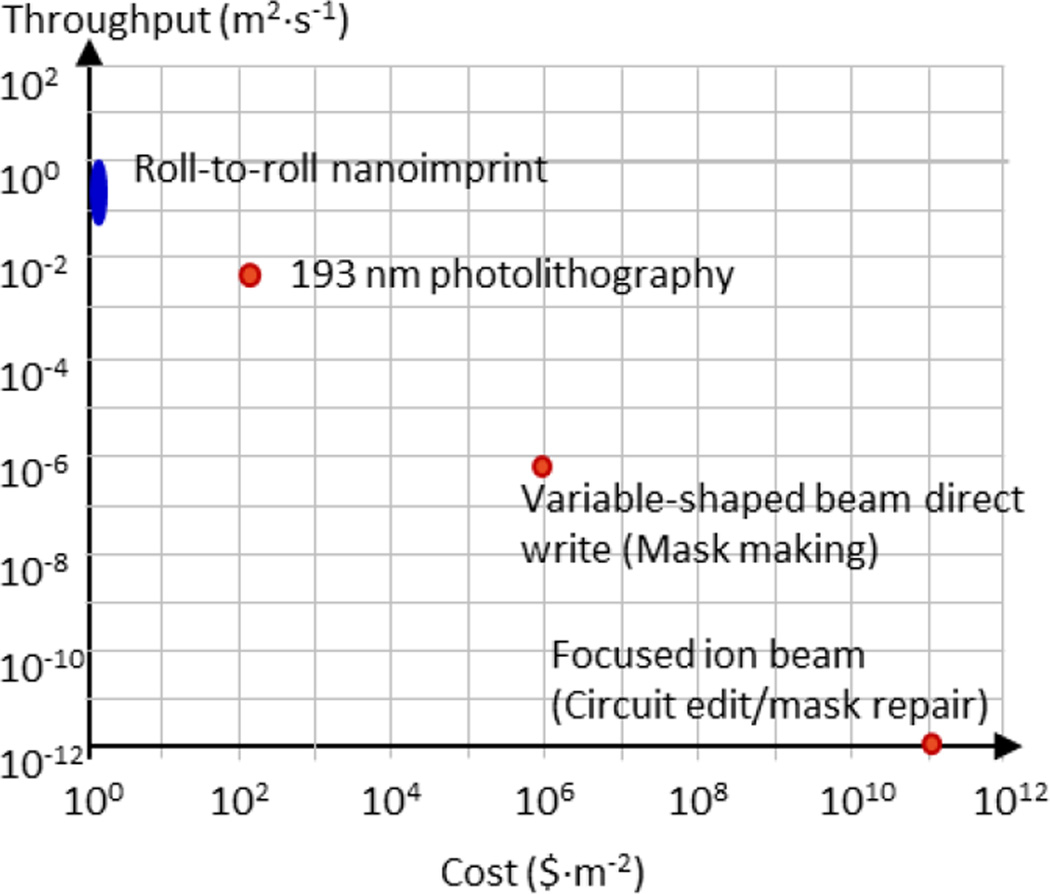

Before we leave the discussion of top-down fabrication methods, it is worth considering in which circumstances a particular nanofabrication process might reasonably be associated with nanomanufacturing. Figure 4 shows the throughput versus cost for patterning methods used in IC manufacturing. As we have described above, optical lithography meets the cost and throughput targets needed for integrated circuit manufacturing, while electron-beam lithography does not. However, the masks used in photolithography, and indeed the master templates for all manner of print-based nanomanufacturing, are made using electron-beam lithography. Similarly, focused ion beam patterning is, by absolute standards, very slow and extraordinarily costly, and would normally be considered only as a nanofabrication approach suitable for research. But, when used for high-value operations such as circuit edit and mask repair it is an economically viable part of the IC manufacturing process flow. These examples serve to further reinforce the need for a careful analysis to match fabrication techniques with products.

Figure 4.

Throughput (m2·s−1) versus cost ($·m−2) for top-down patterning techniques used in integrated circuit manufacturing. Despite nine orders of magnitude variation in cost and throughput, each technique falls into the nanomanufacturing, rather than nanofabrication, category in this context. While not capable of the same performance in terms of placement accuracy, roll-to-roll nanoimprint lithography is included as a point of comparison with another high-throughput nanoscale patterning technique. Note the strong negative correlation between throughput and cost.

Bottom-Up Fabrication

In contrast to the deterministic nature of top-down processes, bottom-up processes are driven by a combination of thermodynamics and kinetics which then determines the yield of the desired structure. The most attractive features of bottom-up nanomanufacturing processes are that there is typically no need for expensive tooling to create nanoscale structures, and scaling to large volumes is potentially straightforward. By applying the tools of chemical synthesis, quantum dots,190,191 plasmonically-active particles,192,193,194 carbon nanotubes, metallic nanowires and multifunctional particles for medical applications195,196,197,198,199 have been successfully produced in manufacturing quantities. Efforts to develop purely bottom-up self-assembly methods to create more complex devices200,201,202,203 typically rely on engineering the interactions between the various components, placing them in a simple environment and then letting the system evolve to a final state.

For example, consider the case where there is one relative arrangement of the elemental units that meets the product’s functional requirements. If the energy of this particular arrangement is E and, out of all the possible arrangements, there are N other arrangements all with energy EN close to E which are not the desired structure, and all other arrangements have much higher energy, then the odds of getting the desired structure, assuming the system is in thermal equilibrium, are on the order of204

where kBT is the thermal energy at the end of the production cycle. In general, as the number of units needed to build the target structure increases there are likely to be more arrangements that have energy close to E i.e., N increases and so the odds of the getting the “right” result decrease. Hence, unlike top-down manufacturing, the product yield is statistically determined. This means that, when high yields (i.e. high purity) are needed, costly separation and purification steps are required.

The expression above represents the best case for a single-step or one-pot process, and is based on the assumption that thermodynamic equilibrium can be reached within a relevant timescale. However, as systems become more complex, the phenomenon of kinetic trapping205,206 can prevent them from reaching the desired equilibrium state. This effect is most easily understood in terms of the potential energy landscape of the elemental units.204,207 If the element-to-element potential energy depends on the relative position and orientation of each unit with respect to each other and there are n elemental units then, up to an overall rotation and translation, the potential energy landscape is a function of all the 3n + 3n = 6n position and rotation coordinates of each elemental unit. In general, the 6n dimensional potential energy landscape will have numerous metastable local minima, and only one global minimum which defines the desired assembled structure. The challenge in the bottom-up assembly of complex structures is then to engineer the element-to-element interactions, formation of intermediate structures, and process conditions (e.g. annealing schedule) so that there is a clear path for the components to follow through the potential energy landscape to the global minimum.208,209 Alternatively, applications must be targeted that require, for example, only short-range order and/or allow for a high defect level.

Colloidal Self-Assembly

Colloidal self-assembly has been investigated intensively for many years210,211,212,213,214,215 because of the potential for colloidal structures to produce photonic bandgap materials216,217 and high-density magnetic recording media.218 Early work219,220,221 was directed towards trying to use photonic bandgap materials generated in this way for nanophotonic applications. However, the difficulty of avoiding kinetic trapping222,223 to achieve the requisite structural perfection, engineering in features such as waveguides,224 and programmed point defects,225 and finding cost-effective ways to integrate the structures produced with other photonic devices proved too great to overcome.226 Nanophotonic structures are now typically fabricated using top-down methods.227,228,229 The same is true of BPM. In contrast, self-assembled colloidal structures are ideal candidates for the generation of large-area, low-cost, structural-color materials230,231,232,233 because the degree of perfection required to meet the functional specification is so much less and the ability to scale production to large areas through roll-to-roll processing is so much greater.

Colloidal self-assembly specifically at the nanoscale has exciting possibilities in terms of generating novel materials by combining nanoparticles with different properties into well-defined crystalline structures.234,235 Here again, it is important to identify applications for which such materials can be integrated into a manufacturing process flow.

DNA-Based Self-Assembly

DNA is the archetypal self-assembling system,236 with tremendous flexibility in the types of structures that can be produced, based on single-stranded (ssDNA), double-stranded or duplex (dsDNA), and more complex supra-molecular assemblies.237,238 One- ,239 two-240 and three-dimensional241 structures can be made, and the ability of other nanoscale objects to be functionalized with DNA, combined with the specificity conferred by complementary sequence recognition242,243 means that DNA can connect and organize disparate nanostructures to make relatively complex constructs,244,245, 246,247,248,249,250,251,252 including well-controlled nanoparticle crystal lattices,253,254,255,256,257,258 and even active systems.259,260,261,262,263 DNA origami264 is a prime example of the power of DNA to control the arrangement of nanoscale objects, providing a molecularly precise “breadboard” to which nanostructures can be attached.265, 266,267,268,269,270,271 In addition, DNA structures can be responsive to variations in temperature, ionic species/concentration and pH.272,273,274 It is also possible to vary the number and strength of DNA-mediated interactions between nanoparticles275,276 which can lead to interesting stimulus-dependent responses,277 allowing the creation of new, environmentally-responsive nanostructures.278,279,280,281,282

The development of DNA-based self-assembly is still at a relatively early stage, though progressing rapidly,283,284 and there are few studies on the yield,285 speed and ultimate levels of complexity that can be achieved in single units and assemblages on substrates.286,287 In addition, although the underlying arrangement of DNA may be precise,288 the presence of linker molecules that must be used between the nanostructure and the DNA and the fact that DNA structures are not perfectly rigid,289,290,291,292 inevitably lead to a reduction in placement precision.293 The diffusional nature of the assembly process and the typical rate constants for the reactions involved mean that it takes a long time to create complex structures and that the yields for those structures are going to be consistent with chemical synthesis, not top-down fabrication, even though substantial progress is being made in developing optimized annealing schedules and buffer compositions.294 Additional improvements may be achieved by controlling the energetics of the structure to guide the assembly process and formation of secondary structure.295,296,297,298 Applications, such as the fabrication of vaccines299 and other biomedically-active structures,300,301 for which 100 % yield and purity, precise placement, and control of multiple levels of structural hierarchy are not prerequisites, therefore need to be identified for this technology to be used in nanomanufacturing. Finally, it is important to note that, while DNA itself is not particularly robust, recent work has shown how structures produced using DNA can subsequently be encapsulated in silica-based materials to dramatically improve their environmental stability.302

Directed Self-Assembly: Top-Down Combined with Bottom-Up

So far we have discussed the strengths and weaknesses of top-down and bottom-up approaches to nanomanufacturing, but combining the two together can yield the best of both worlds. Guided or templated self-assembly typically makes use of boundaries created by top-down methods that interact with a system that has an intrinsic structural length scale. This latter can arise from the balance between long-range magnetic, electrostatic, or strain energy,303,304 or, as in the case of block copolymers, can come from local interactions built into the molecular structure of the material.

Directed Self-Assembly of Block Copolymers

Block copolymers phase separate on the nanoscale, with an intrinsic length scale determined by the molecular weights of the components and a structure determined by their relative volume fractions.305 Nanostructures formed in this way can be functional themselves,306,307,308,309,310 can be used to template the formation311,312 or arrangement313,314,315,316,317,318,319,320 of other nanostructures, produce materials responsive to their environment,321,322 or can be used to pattern an underlying material.323,324 While using a self-assembled structure as an intermediate step in a patterning process, as opposed to the final functional structure, may seem to introduce unnecessary process complexity, there are other challenges involved in using functional materials directly. In the case of diblocks, creating a material that phase separates at the requisite length scale, has the necessary surface energies to assemble in the desired orientation with respect to the substrate, has the correct kinetic behavior to minimize defects, can be coated in thin-film form, all while maintaining the sought-for functionality, gives some idea of the difficulty involved. Given these factors, it becomes clear that the investment required to develop a suitable material system is only worthwhile for high-volume/high-value applications.

Long-range order can be introduced by using a sparse templating pattern generated by top-down methods, and is a very attractive route to making well-controlled nanoscale features: it greatly relaxes the requirements for the top-down process in terms of feature spacing and throughput and deals with the limitations of the bottom-up assembly process.325,326,327 In addition, this approach can even be used to generate relatively complex three-dimensional structures,328 and is therefore being considered for the manufacture of ICs, BPM,329,330,331,332,333,334,335,336 and other structures.337

Photolithography is limited, not in terms of the smallest feature size that can be produced,338,339 but in its ability to place them close together (the minimum pitch attainable in a single patterning step is λ/2NA). By using photolithography to create a guiding pattern and the assembly of a diblock to fill in the details, it is possible to make dense, nanoscale patterns with excellent control.340,341,342,343 Similarly, cylindrical or spherical diblocks can be templated by sparse patterns of posts made by electron-beam lithography to form well-ordered arrays of features for BPM.344 In this case the benefit lies in both dramatically reducing the time needed for the electron-beam lithography step and in the ability of the diblock to effectively repair patterning defects and generate much more uniform and dense patterns than could otherwise be produced.345 An interesting feature of this approach is the interplay between the templating pattern and the diblock which, by altering the energetics of the system, can lead to either a reduction or an increase in the defect level.346,347,348 There are limits to how sparse a templating pattern can be employed. In the BPM case if the guiding features are too far apart, then there is a degeneracy because more than one orientation of the diblock can match the templating pattern, leading to the formation of domain boundaries.349 In lamellar diblocks, as the distance from a directing boundary increases, undulations in the interfaces increase to the point where they lead to an unacceptable level of line-edge roughness for IC fabrication.350,351 These limitations represent design constraints, but are unlikely to impede the adoption of this technology in manufacturing.352 The time taken for diblock systems to order can be relatively long353 and increases with increasing molecular weight,354,355 but recent work using high-temperature,356,357,358,359 solvent annealing,360,361 or a combination,362,363 indicates that this is unlikely to be a serious issue. Reducing chain entanglement with brush block copolymers is also an effective strategy.364,365 However, these types of directed self-assembly processes are restricted in terms of the amount of information that can be added to the system and are capable only of producing single harmonics of the templating structure. Additional patterning steps will therefore always be needed to create the kind of structural complexity necessary for logic devices. Finally, although the number of equilibrium defects is expected to be negligible,366,367 eliminating defects related to the templating structures is still challenging,368 and is becoming more so as feature sizes decrease, requiring smaller molecular weight diblocks with smaller domain sizes operating closer to the order-disorder transition. This latter effect is leading to the search for materials with higher Flory-Huggins interaction parameters (χ),369,370,371 or for small-molecule additives that can be used to drive phase separation.372,373,374,375,376,377

Fluidic Assembly

One difficulty in controlling the assembly of nanoscale objects is finding interactions that are strong enough to manipulate them, and that scale well to small dimensions. Capillary interactions can satisfy these requirements, and have been used to create a variety of interesting structures.378,379 In particular, the capillary interactions that occur at a fluid interface on a patterned substrate can be used to assemble nanoparticles precisely and with high yield onto lithographically patterned features.380,381,382 The convective flows that are set up at a meniscus can make the process quite efficient, by concentrating nanoparticles at the fluid-substrate contact line383,384,385,386,387,388,389,390,391 – the so-called coffee-stain effect. Beyond the need to control the contact angle between substrate and fluid within a fairly forgiving range, this process is agnostic with regard to the nature of the substrate and the nanoparticles and can so be used to assemble a wide variety of materials without the need for any kind of harsh processing involving solvents, acids/bases or energetic plasmas. Additionally, once assembled onto a templating substrate, the nanoparticle structures can readily be transferred to a different material.392,393 Unfortunately, the maximum linear contact line speeds achieved so far are only ~ 1 µm·s−1 to mm·s−1,394,395,396,397 which, even if used in a roll-to-roll process with a meter wide web, translate into an areal throughput of 10−6 m2·s−1 to 10−3 m2·s−1. The limiting factors are the overall concentration of nanoparticles, which cannot be increased indefinitely without causing deposition in un-patterned areas, and the evaporation rate of the carrier fluid, which also cannot be increased dramatically. Interestingly, the combination of a roll-to-roll patterned substrate with inkjet printing has been used to create color filters with a precision far better than can be achieved with inkjet alone.398 Although currently only being used for micron-sized features, this is potentially a highly extensible approach.

Damped-Driven Systems

Unlike the self-assembling systems described above, which simply “fall down” a free-energy landscape to a stable equilibrium, damped driven systems require energy input in order to form and maintain a self-organized structure. The Belousov-Zhabotinsky reaction399,400 is a well -known example, but the archetype is a living being. All living things require energy input – the driver – or they die and decay. The input energy is dissipated as work and heat – the damping. This constant flow of energy through the system maintains it in its self-organized form, for example in all aspects of intracellular transport.401,402,403 Although we have learned to harness living systems to manufacture everything from alcohol404 to spider silk,405 in contrast to systems at equilibrium, very little is known about the general principles governing damped-driven, self-organizing systems,201,406 preventing us from creating our own.

In this context one particular biological process is worth discussing: protein folding. Key parts of the folding process require energy input which is dissipated as heat and so this is a damped driven process.407,408,409 Folding occurs much more rapidly than would be expected410 if it was purely a stochastic approach to equilibrium as when colloidal particles are annealed into crystalline structures. Protein folding is not a random walk but rather a quasi-deterministic trajectory across the potential energy landscape directed both by the internal structure of the molecule as well as by the action of external, ATP- driven, “chaperone” molecules, known as chaperonins.411,412 The concept of using both internal structure combined with external control may be the most effective way forward for creating more complex, functional nanostructures cost-effectively.

Design for Nanomanufacturing

So far, we have discussed how various nanomanufacturing approaches may or may not be suited to the economically sustainable production of functional structures and devices. It is also important to remember that there are often a number of different structures that will yield similar functionality. Choosing the right form can make the difference between something remaining a laboratory curiosity or becoming a product. As a case in point, consider optical metamaterials:413 the first demonstrations of negative index behavior in the microwave were achieved using macroscale features, such as split-ring resonators, fabricated using simple, scalable, printed-circuit board methods.414 Subsequent attempts to make materials active at visible wavelengths used the same geometries, replicated at scales 10−4 to 10−5 smaller using electron-beam lithography.415,416 Although these successfully demonstrated the desired functionality, fabrication, integration and scaling remain challenging, and the cost of such structures is prohibitive ($106·m−2 to $109·m−2, depending on whether variable shaped-beam or Gaussian beam patterning is used). A more complete understanding of nanoscale light-matter interactions has led to a new generation of optical metamaterials that comprise alternating layers of metals and dielectrics.417,418,419 These are eminently manufacturable over large areas and at low cost using conventional thin-film deposition processes. As a point of comparison, the types of films made this way, such as those used for touch screens are ~ $10·m−2.

A similar development process has occurred in the quest for gecko-type dry adhesives. Early attempts focused on faithful replication of the biological structure via complex lithography to achieve the desired function.420 More recent work has used the same design principles as the natural system, but in the form of a composite textile that can be made simply, using standard methods.421

This type of device structure/fabrication process evolution is familiar in the semiconductor industry. Circuit size reduction often takes place first via a “dumb shrink” or through the use of representative test structures, rapidly followed by an optimized device structure and process redesign that incorporates any new physics and fabrication constraints whose importance has been elucidated during the initial learning phase.422,423

Conclusions

The term nanomanufacturing covers a host of different materials, devices, products and processes and is simply too broad to cover in detail in a short article. In this brief survey we have therefore endeavored to highlight the importance of matching the process to the functional requirements of the product, and especially of including economic viability as the distinguishing criterion that separates nanomanufacturing from nanofabrication. We have also illustrated how a deep understanding of the link between form and function can lead to manufacturability.

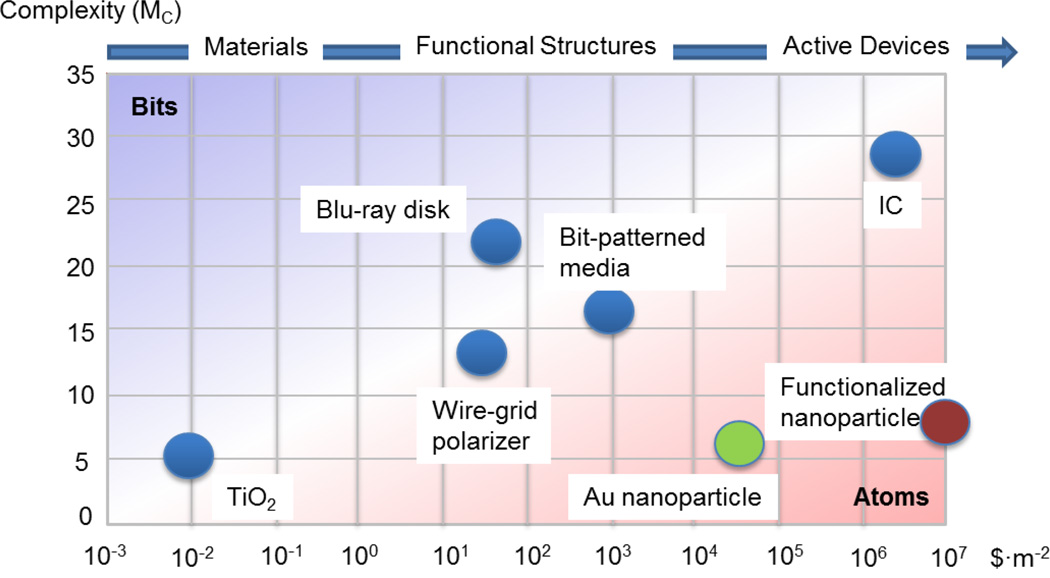

As we consider the range of products that involve some form of nanomanufacturing, some framework is necessary to enable comparisons between them. In Figure 5 we introduce such a framework. The horizontal axis is again the selling price in $·m−2. The vertical axis represents the complexity of the item being produced. The complexity is captured by a compound term representing the information content of the product and the precision and perfection with which it must be produced in order to satisfy the functional requirements. We choose the Kolmogorov complexity parameter, K, as the measure of the information content of an object – it can be thought of as the number of bits required to specify the desired structure.424 The precision is determined by dividing the maximum coherence length of the object, ξmax, by the product of the minimum feature size, dmin, and the fractional tolerance, f, of that minimum feature size. The perfection, P, is the maximum allowable fraction of defective components, number density of defects (“defectivity” in IC manufacturing), or concentration of impurities. The combination of (ξmax/(f·dmin·P)) represents the difficulty of producing the item to the required standard. Putting this all together, we define the manufacturing complexity, MC, as Log10[K·ξmax/(f·dmin·P)]. As an example, only a few bits are needed to specify a TiO2 nanoparticle. We need only a kilobit or so to define the composition, size, and acceptable size distribution. No long-range structural coherence is necessary, and the allowable fraction of defective particles is most likely a few percent for most applications. This leads to an MC of 5. In contrast, the CAD data for an integrated circuit is many gigabits (109), spatial coherence may be required over 1 cm for feature sizes of ≈ 10 nm, which must be produced with a size variation of no more than 10 %, and a defect level of 10−12 is required. MC for an IC is therefore ≈ 28.

Figure 5.

The plot shows a measure of manufacturing complexity, MC, as a function of cost per unit area (dollars per square meter). We define manufacturing complexity (MC) as Log10 [K·ξmax/(dmin·f·P)], where K is the Kolmogorov complexity,424 (ξmax/dmin) is a measure of the maximum distance over which spatial coherence must be maintained, compared to the minimum feature size, the fractional tolerance, f, is the maximum allowable variation in feature size, and the perfection, P, is the maximum fraction of defective components or concentration of impurities that can be permitted. The cost may be dominated by the information content (Bits), as in the case of a Blu-ray disk, or by the material (Atoms) as for a protein-functionalized nanoparticle [see text for details].

In general, as MC increases, so does the functionality of the product and the price it commands. Thus, near the origin, we find bulk nanomaterials, at intermediate levels of complexity and price, functional structures, and at the highest point, integrated circuits. While there is a strong correlation between price and manufacturing complexity, it is instructive to consider some of the outliers. A blu-ray disk, for example, is cheap to manufacture, but commands a relatively high price because of the information, e.g. a movie, that it contains. We label the upper left quadrant of the graph “Bits” to indicate that in this region selling price is dominated by information content. In contrast, the price of gold nanoparticles functionalized with a biomolecule is dominated by the cost of that particular molecule. We therefore label the lower right quadrant “Atoms” to indicate that the price is controlled by the cost of some scarce material. Finally, we note that both the selling price and manufacturing complexity may change. For example, once production is scaled, manufacturing costs may drop, or competitors may enter a market and drive prices down. Alternatively, as discussed above, a more complete understanding of how structure is related to function may allow both for a reduction in information content and the use of less-expensive production technology.

In terms of their complexity or functionality versus their cost per unit area, it appears as though there are two distinct areas where current activity is located. As might be expected, there is a concentration of devices and structures concerned with information processing, storage and transmission at the high-value end, while bulk materials and structures with limited structural complexity and functionality occupy the low-value end. Interestingly, there is, to date, very little in the way of nanosystems with an intermediate degree of complexity and functionality, with high-value nanostructures engineered for theranostic applications representing the present state of the art.

At this point it is worth considering why this might be the case. The ability to produce complex, hierarchical systems depends on the availability of physical components that have a high degree of modularity, the organization of those components into functional building blocks, and a design process that allows for multiple, high levels of abstraction. The basic component of digital integrated circuits, the transistor, is physically modular, and can be configured into modular functional units (arithmetic logic units), enabling the design to proceed at increasingly high levels of abstraction.425 Interestingly, the techniques developed for managing complexity in integrated circuits are now being applied to biological systems.426 The lack of similarly modular physical and logical basic units, reflected by a lack of standard process modules and minimal design automation, respectively, explains why microelectromechanical systems (MEMS) and nanophotonic systems have yet to evolve to the same level of sophistication as integrated circuits. In contrast, the rapid progress in DNA-based nanotechnology flows from the fact that it offers a system optimized over 3.5 billion years that already exhibits the desired structural and functional modularity.

Ultimately, the ability to manufacture, i.e., create a sustainable business, depends on satisfying both technical constraints – including throughput, process yield, throughput and flexibility, energy consumption, and environmental sustainability – and a host of constraints relating to cost – including capital equipment expenditure, profit margin, equipment depreciation timescale, market volume, and market cycle time. Finding the optimum tradeoff in such a multi-dimensional parameter space is challenging. Frequently, the relevant variables can only be poorly estimated and, as illustrated above, the rapid pace of improvement in basic understanding can suddenly transform something from a laboratory curiosity into a potential product.

So, what does this all mean? As Yogi Berra observed, “It's tough to make predictions, especially about the future.”, but what follows is our best guess. The technology to fabricate integrated circuits will continue to evolve in capability and cost, but will remain uneconomic for low value-per-unit-area, high-volume products. The family of lithographic technologies, such as nanoimprint, whose development has been driven in large part by the semiconductor industry, will be scaled to suit a variety of cost structures and so will find a wide range of applications, especially for those structures requiring only a single patterned layer. Bottom-up self-assembly will have a role in the production of simple functional materials that are used in high volumes and must be inexpensive, while directed assembly allows for the imposition of longer-range order and hierarchy that will be important for some applications. Perhaps the most exciting prospect is that of creating dynamical nanoscale systems that are capable of exhibiting much richer structures and functionality. Whether this is achieved by learning how to control and engineer biological systems directly, or by building systems based on the same principles, remains to be seen, but will undoubtedly be disruptive and quite probably revolutionary.

Supplementary Material

VOCABULARY

- nanofabrication

any and all techniques for creating nanoscale structures

- nanomanufacturing

the scaled-up, reliable, and commercially-viable production of nanoscale materials, structures, devices, and systems

- top-down

far-from-equilibrium processes in which structure is created deterministically by the introduction of information and the imposition of external forces, fields, or other actions

- bottom-up

processes in which structure is determined predominantly by information intrinsic to the system itself, such as the specific sequence of chemical bonds or amino acids, such processes are inherently statistical or stochastic in nature and result in thermodynamically-stable structures and devices

- self-assembly

the observed behavior of a system for which an ordered state is thermodynamically favorable and kinetically accessible

- damped-driven

systems, processes or structures that require some type of input, such as energy, to form and maintain their structure (the driven part), and which produce heat or entropy as part of their existence (the damped part), the prime example being living organisms.

Footnotes

Associated Content

Supporting Information

The Supporting Information is available free of charge on the ACS Publications website at DOI: XXXX

Information used to estimate data points in figure 1 (PDF)

References

- 1.Martin-Palma RJ, Lakhtakia A. Nanotechnology: A Crash Course. Bellingham, WA: SPIE; 2010. [Google Scholar]

- 2.Kriven WM, Lin H-T, Zhu D, Chen YL, Miller RA. Defect Clustering and Nano-Phase Structure Characterization of Multi-Component Rare Earth Oxide Doped Zirconia-Yttria Thermal Barrier Coatings. 27th Annual Cocoa Beach Conference on Advanced Ceramics and Composites: A: Ceramic Engineering and Science Proceedings. 2008;24 [Google Scholar]

- 3.Wang Z-y, Han E-h, Ke W. Fire-Resistant Effect of Nanoclay on Intumescent Nanocomposite Coatings. J. Appl. Polym. Sci. 2007;103:1681–1689. [Google Scholar]

- 4.Salla J, Pandey KK, Srinivas K. Improvement of UV Resistance of Wood Surfaces by Using ZnO Nanoparticles. Polym. Degrad. Stab. 2012;97:592–596. [Google Scholar]

- 5.Liu K, Jiang L. Bio-Inspired Self-Cleaning Surfaces. Annu. Rev. Mater. Res. 2102;42:231–263. [Google Scholar]

- 6.Wu D, Dong M. Realizing Visible-Light-Induced Self-Cleaning Property of Cotton through Coating N-TiO2 Film and Loading AgI Particles. ACS Appl. Mater. Interfaces. 2012;3:4770–4774. doi: 10.1021/am201251d. [DOI] [PubMed] [Google Scholar]

- 7.Lee D, Cohen RE, Rubner MF. Antibacterial Properties of Ag Nanoparticle Loaded Multilayers and Formation of Magnetically Directed Antibacterial Microparticles. Langmuir. 2005;21:9651–9659. doi: 10.1021/la0513306. [DOI] [PubMed] [Google Scholar]

- 8.Kumar A, Vemula PK, Ajayan PM, John G. Silver-Nanoparticle-Embedded Antimicrobial Paints Based on Vegetable Oil. Nat. Mater. 2008;7:236–241. doi: 10.1038/nmat2099. [DOI] [PubMed] [Google Scholar]

- 9.Clayton RH, Murray PG, Nelson D. Nanoparticle Additives for Enhanced Scratch Resistance in UV-Cured Coatings. Paint and Coatings Industry Magazine. 2010;26:52. [Google Scholar]

- 10.Sangermano M, Messori M. Scratch Resistance Enhancement of Polymer Coatings. Macromol. Mater. Eng. 2010;295:603–612. [Google Scholar]

- 11.Hougeir FG, Kircik L. A Review of Delivery Systems in Cosmetics. Dermatologic Therapy. 2012;25:234–237. doi: 10.1111/j.1529-8019.2012.01501.x. [DOI] [PubMed] [Google Scholar]

- 12. http://www.indeedlabs.com/nanoblur/ [Google Scholar]

- 13.Silvestre C, Duraccio D, Cimmino S. Food Packaging based on Polymer Nanomaterials. Prog. Poly. Sci. 2011;36:1766–1782. [Google Scholar]

- 14.Hsieh C-T, Wu F-L, Chen W-Y. Superhydrophobicity and Superoleophobicity from Hierarchical Silica Sphere Stacking Layers. Mater. Chem. Phys. 2010;121:14–21. [Google Scholar]

- 15.Deng X, Mammen L, Butt H-J, Vollmer D. Candle Soot as a Template for a Transparent Robust Superamphiphobic Coating. Science. 2012;335:67–70. doi: 10.1126/science.1207115. [DOI] [PubMed] [Google Scholar]

- 16.Verho T, Bower C, Andrew P, Franssila S, Ikkala O, Ras RHA. Mechanically Durable Superhydrophobic Surfaces. Adv. Mater. 2010;23:673–678. doi: 10.1002/adma.201003129. [DOI] [PubMed] [Google Scholar]

- 17.Kota AK, Li Y, Mabry JM, Tuteja A. Hierarchically Structured Superoleophobic Surfaces with Ultralow Contact Angle Hysteresis. Adv. Mater. 2012;24:5838–5843. doi: 10.1002/adma.201202554. [DOI] [PubMed] [Google Scholar]

- 18.Forrest SR. The Limits to Organic Photovoltaic Cell Efficiency. MRS Bull. 2005;30:28–32. [Google Scholar]

- 19.Kim M-S, Kim J-S, Cho JC, Shtein M, Guo LJ, Kim J. Flexible Conjugated Polymer Photovoltaic Cells with Controlled Heterojunctions Fabricated Using Nanoimprint Lithography. Appl. Phys. Lett. 2007;90:123113. [Google Scholar]

- 20.Boukai A, Haney P, Katzenmeyer A, Gallatin GM, Talin AA, Yang P. Efficiency Enhancement of Copper Contaminated Radial p–n Junction Solar Cells. Chem. Phys. Lett. 2011;501:153–158. [Google Scholar]

- 21.AS, Bruce P, Scosati B, Tarascon J-M, Schalwijk WV. Nanostructured Materials for Advanced Energy Conversion and Storage Devices. Nat. Mater. 2005;4:366–377. doi: 10.1038/nmat1368. [DOI] [PubMed] [Google Scholar]

- 22.Wessells CD, Huggins RA, Cui Y. Copper Hexacyanoferrate Battery Electrodes with Long Cycle Life and High Power. Nat. Commun. 2011;2 doi: 10.1038/ncomms1563. [DOI] [PubMed] [Google Scholar]

- 23.Dabbousi BO, Rodriguez-Viejo J, Mikulec FV, Heine JR, Mattoussi H, Ober R, Jensen KF, Bawendi MG. (CdSe)ZnS Core–Shell Quantum Dots: Synthesis and Characterization of a Size Series of Highly Luminescent Nanocrystallites. J. Phys. Chem. B. 1997;101:9463–9475. [Google Scholar]

- 24.Sun Q, Wang YA, Li LS, Wang D, Zhu T, Xu J, Yang C, Li Y. Bright, Multicoloured Light-Emitting Diodes Based on Quantum Dots. Nat. Photonics. 2007;1:717–727. [Google Scholar]

- 25.Lim J, Bae WK, Kwak J, Lee S, Lee C, Char K. Perspective on Synthesis, Device Structures, and Printing Processes for Quantum Dot Displays. Opt. Mater. Exp. 2012;2:594–628. [Google Scholar]

- 26.Talapin DV, Lee J-S, Kovalenko MV, Shevchenko EV. Prospects of Colloidal Nanocrystals for Electronic and Optoelectronic Applications. Chem. Rev. 2010;110:389–458. doi: 10.1021/cr900137k. [DOI] [PubMed] [Google Scholar]

- 27.United States Government Accountability Office report GAO-14-181SP. Nanomanufacturing: Emergence and Implications for U.S. Competitiveness, the Environment, and Human Health. 2014

- 28. http://www.itrs.net/Links/2012ITRS/Home2012.htm. [Google Scholar]

- 29.Talapin DV, Lee J-S, Kovalenko MV, Shevchenko EV. Prospects of Colloidal Nanocrystals for Electronic and Optoelectronic Applications. Chem. Rev. 2010;110:389–458. doi: 10.1021/cr900137k. [DOI] [PubMed] [Google Scholar]

- 30.Zhang F, Nangreave J, Liu Y, Yan H. Structural DNA Nanotechnology: State of the Art and Future Perspective. J. Am. Chem. Soc. 2014;136:11198–11211. doi: 10.1021/ja505101a. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Novoselov KS, Fal’ko VI, Colombo L, Gellert PR, Schwab MG, Kim K. A Roadmap for Graphene. Nature. 2012;490:192–200. doi: 10.1038/nature11458. [DOI] [PubMed] [Google Scholar]

- 32.Nair RR, Wu HA, Jayaram PN, Griogrieva IV, Geim AK. Unimpeded Permeation of Water Through Helium-Leak–Tight Graphene-Based Membranes. Science. 2012;335:442–444. doi: 10.1126/science.1211694. [DOI] [PubMed] [Google Scholar]

- 33.Piner RD, Zhu J, Xu F, Hong S, Mirkin CA. “Dip-Pen” Nanolithography. Science. 1999;283:661–663. doi: 10.1126/science.283.5402.661. [DOI] [PubMed] [Google Scholar]

- 34.Salaita K, Wang Y, Mirkin CA. Applications of Dip-Pen Nanolithography. Nat. Nanotechnol. 2007;2:145–155. doi: 10.1038/nnano.2007.39. [DOI] [PubMed] [Google Scholar]

- 35.Henzie J, Barton EB, Stender CL, Odom TW. Large-Area Nanoscale Patterning: Chemistry Meets Fabrication. Acc. Chem. Res. 2006;39:249–257. doi: 10.1021/ar050013n. [DOI] [PubMed] [Google Scholar]

- 36.Wiley BJ, Qin D, D, Xia Y. Nanofabrication at High Throughput and Low Cost. ACS Nano. 2010;4:3554–3559. doi: 10.1021/nn101472p. [DOI] [PubMed] [Google Scholar]

- 37. [accessed Feb 2, 2016]; https://en.wikipedia.org/wiki/Total_addressable_market. [Google Scholar]

- 38.Liddle JA, Gallatin GM. Lithography Metrology and Nanomanufacturing. Nanoscale. 2011;3:2679–2688. doi: 10.1039/c1nr10046g. [DOI] [PubMed] [Google Scholar]

- 39.Velev O, Gupta S. Materials Fabricated by Micro- and Nanoparticle Assembly – The Challenging Path from Science to Engineering. Adv. Mater. 2009;21:1897–1905. [Google Scholar]

- 40.Saavedra HM, Mullen TJ, Zhang P, Dewey DC, Claridge SA, Weiss PS. Hybrid Strategies in Nanolithography. Rep. Prog. Phys. 2010;73:036501. [Google Scholar]

- 41.Xia Y, Rogers JA, Paul KE, Whitesides GM. Unconventional Methods for Fabricating and Patterning Nanostructures. Chem. Rev. 1999;99:1823–1848. doi: 10.1021/cr980002q. [DOI] [PubMed] [Google Scholar]

- 42.Gates BD, Xu Q, Stewart M, Ryan D, Willson CG, Whitesides GM. New Approaches to Nanofabrication: Molding, Printing, and Other Techniques. Chem. Rev. 2005;105:1171–1196. doi: 10.1021/cr030076o. [DOI] [PubMed] [Google Scholar]

- 43.Kim P, Epstein AK, Khan M, Zarzar LD, Lipomi DJ, Whitesides GM, Aizenberg J. Structural Transformation by Electrodeposition on Patterned Substrates (STEPS): A New Versatile Nanofabrication Method. Nano. Lett. 2011;12:527–533. doi: 10.1021/nl200426g. [DOI] [PubMed] [Google Scholar]

- 44.Biswas A, Bayer IS, Biris AS, Wang T, Dervishi E, Faupel F. Advances in Top-Down and Bottom-Up Nanofabrication: Techniques, Applications & Future Prospects. Adv. Colloid Interface. Sci. 2012;170:2–27. doi: 10.1016/j.cis.2011.11.001. [DOI] [PubMed] [Google Scholar]

- 45.Richman EK, Hutchison JE. The Nanomaterial Characterization Bottleneck. ACS Nano. 2009;3:2441–2446. doi: 10.1021/nn901112p. [DOI] [PubMed] [Google Scholar]

- 46.Orloff ND, Long CJ, Obrzut J, Maillaud L, Miri F, Kole TP, McMichael RD, Pasquali M, Stranick SJ, Liddle JA. Noncontact Conductivity and Dielectric Measurement for High Throughput Roll-to-Roll Nanomanufacturing. Sci. Rep. 2015;5:17019. doi: 10.1038/srep17019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Wankerl A, Schramm CJ, Fitzgerald E. Inside Real Innovation. Sinagapore: World Scientific; 2012. [Google Scholar]

- 48.Moore GE. Cramming More Components onto Integrated Circuits. Electronics. 1965;38:114. [Google Scholar]

- 49.Wright TP. Factors Affecting the Cost of Airplanes. J. Aeronautical. Sci. 1936;3:122–128. [Google Scholar]

- 50.Yelle LE. The Learning Curve: Historical Review and Comprehensive Survey. Decision. Sci. 1979;10:302–328. [Google Scholar]

- 51.Nagy B, Farmer JD, Bui QM, Trancik JE. Statistical Basis for Predicting Technological Progress. PLoS ONE. 2013;8:e52669. doi: 10.1371/journal.pone.0052669. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Matsuyama T, Ohmura Y, Williamson DM. The Lithographic Lens: Its History and Evolution. Proc. SPIE. 2006;6154:615403-1–615403-14. [Google Scholar]

- 53. [accessed Feb 2, 2016]; http://www.asml.com/asml/show.do?lang=EN&ctx=46772&dfp_product_id=822. [Google Scholar]

- 54.De Boeji W, Pieternella R, bouchoms I, Leenders M, Hoofman M, de Graaf R, Kok H, Broman P, Smits J, Kuit J-J, McLaren M. Extending Immersion Lithography Down to 1× nm Production Nodes. Proc. SPIE. 2013;8683:86831L-1. [Google Scholar]

- 55.Dammel RR. Photoresists for Microlithography or the Red Queen’s Race. J. Micro/Nanolithogr., MEMS, MOEMS. 2002;1:270–275. [Google Scholar]

- 56.Crivello JV, Reichmanis E. Photopolymer Materials and Processes for Advanced Technologies. Chem. Mater. 2014;26:533–548. [Google Scholar]

- 57.Gabor AH, Bruce JA, Chu W, Ferguson RA, Fonseca CA, Gordon RL, Jantzen KR, Khare M, Lavin MA, Lee W-H, Liebmann LW, Muller KP, Rankin JH, Varekamp P, Zach FX. Subresolution Assist Feature Implementation for High-Performance Logic Gate-Level Lithography. Proc. SPIE. 2002;4691:418. [Google Scholar]

- 58.Poonawala A, Milanfar P. A Pixel-Based Regularization Approach to Inverse Lithography. Microelectron. Eng. 2007;84:2837–2852. [Google Scholar]

- 59.Takigawa T, Gronlund K, Wiley J. Extension of Optical Lithography by Mask-Litho Integration with Computational Lithography. Proc. SPIE. 2010;7748:77480R-1. [Google Scholar]

- 60.Tian K, Fakyry M, Dave A, Tritchkov A, Tirapu-Azpiroz J, Rosenbluth AE, Melville D, Sakamoto M, Inoue T, Mansfield S, Wei A, Kim Y, Durgan B, Adam K, Berger G, Bhatara G, Meiring J, Haffner H, Kim B. Applicability of Global Source Mask Optimization to 22/20 nm Node and Beyond. Proc SPIE. 2011;7973:797303. [Google Scholar]

- 61.Hughes G, Litt LC, Wüest A, Palaiyanur S. Mask and Wafer Cost of Ownership (COO) from 65 to 22 nm Half-Pitch Nodes. Proc SPIE. 2008;7028:70281P. [Google Scholar]

- 62.Hazelton AJ, Wüest A, Hughes G, Litt LC, Goodwin F. Cost of Ownership for Future Lithography Technologies. Proc. SPIE. 2008;7140:71401Q-1. [Google Scholar]

- 63.Drapeau M, Wiaux V, Hendrickx E, Verhaegen S, Machida T. Double Patterning Design Split Implementation and Validation for the 32nm Node. Proc. SPIE. 2007;6521:652109. [Google Scholar]

- 64.Shiu W, Liu H, Wu J, Tseng T, Te Liao C, Liao C, Liu J, Wang T. Advanced Self-Aligned Double Patterning Development for Sub-30-nm DRAM Manufacturing. Proc. SPIE. 2009;7274:72740E. [Google Scholar]

- 65.Pan DZ, Yu B, Gao J-R. Design for Manufacturing with Emerging Nanolithography. IEEE Trans. Comput-Aided Design Integr. Circuits Syst. 2013;32:1453–1472. [Google Scholar]

- 66.Smayling MC, Tsujita K, Yaegashi H, Axelrad V, Arai T, Oyama K, Hara A. Sub-12nm Optical Lithography with 4× Pitch Division and SMO-Lite. Proc. SPIE. 2013;8683:868305-1. [Google Scholar]

- 67. https://nikonereview.com/ The Challenges of Future Nodes: Insights Across the Supply Chain. [accessed Feb 2, 2016]; [Google Scholar]

- 68.Wood O, Arnold A, Brunner T, Burkhardt M, Chen JH-C, Civay D, Fan SS-C, Gallagher E, Halle S, He M, Higgins C, Kato H, Kye J, Koay C-S, Landie G, Leung P, McIntyre P, Nagai S, Petrillo K, Raghunathan S, et al. Insertion Strategy for EUV Lithography. Proc. SPIE. 2012;8322:832203. [Google Scholar]

- 69.LaPedus M. Momentum Builds for Monolithic 3D ICs. [accessed Feb 2, 2016];Semiconductor Engineering. 2013 Nov 14th; http://semiengineering.com/momentum-builds-monolithic-3d-ics/ [Google Scholar]

- 70.Knickerbocker JU, Andry PS, Colgan E, Dang B, Dickson T, Gu X, Haymes C, Jahnes C, Liu Y, Maria J, Polastre RJ, Tsang CK, Turlapati L, Webb BC, Wiggins L, Wright SL. 2.5D and 3D Technology Challenges and Test Vehicle Demonstrations; IEEE Electronic Components and Technology Conference; 2012. pp. 1068–1076. [Google Scholar]

- 71.Garrou P, Koyanagi M, Ramm P, editors. Handbook of 3D Integration: 3D Process Technology. Wiley-VCH Verlag GmbH & Co.; 2014. [Google Scholar]

- 72.Milojevic D, Marchal P, Marinissen EJ, Van der Plas G, Verkest D, Beyne E. Design Issues in Heterogeneous 3D/2.5D Integration; IEEE Design Automation Conference; 2013. pp. 403–410. [Google Scholar]

- 73.Velnis D, Detalle M, Marinissen EJ, Beyne E. Si Interposer Build-Up Options and Impact on 3D System Cost; IEEE 3D Systems Integration Conference; 2013. pp. 1–5. [Google Scholar]

- 74.Beica R, Buisson T, Pizzagalli A. 3D Packaging Technologies and Applications, Latest Challenges and Supply Chain Activities. ECS Trans. 2014;61:11–16. [Google Scholar]

- 75.Shen H, Khan MH, Fan L, Zhao L, Xuan Y, Ouyang J, Varghese LT, Qi M. Eight-Channel Reconfigurable Microring Filters with Tunable Frequency, Extinction Ratio and Bandwidth. Opt. Express. 2010;18:18067–18076. doi: 10.1364/OE.18.018067. [DOI] [PubMed] [Google Scholar]

- 76.Krishnamoorthy AV, Zheng X, Li G, Yao J, Pinguet T, Mekis A, Thacker H, Shubin I, Luo Y, Raj K, Cunningham JE. Exploiting CMOS Manufacturing to Reduce Tuning Requirements for Resonant Optical Devices. IEEE Photon. J. 2011;3:567–579. [Google Scholar]

- 77.Worgull M. Hot Embossing: Theory and Technology of Microreplication. Burlington: William Andrew/Elsevier; 2009. [Google Scholar]

- 78.Aumiller GD, Chandross EA, Tomlinson WJ, Weber HP. Submicrometer Resolution Replication of Relief Patterns for Integrated Optics. J. Appl. Phys. 1974;45:4557–4562. [Google Scholar]

- 79.Chou SY, Krauss PR, Renstron PJ. Imprint of Sub25 nm Vias and Trenches in Polymers. Appl. Phys. Lett. 1995;67:3114–3116. [Google Scholar]

- 80.Sreenivasan SV. Nanoscale Manufacturing Enabled by Imprint Lithography. MRS Bull. 2008;33:854–863. [Google Scholar]

- 81.Schift H. Nanoimprint Lithography: An Old Story in Modern Times? A Review. J. Vac. Sci. Technol. B. 2008;26:458–480. [Google Scholar]

- 82.Schift H, editor. NaPANIL Library of Processes. 2nd. 2012. published by the NaPANIL-consortium represented by J. Ahopeto. [Google Scholar]

- 83.White DL, Wood OR, Chen C-F, Lovell EG, Engelstad RL. Complete System of Nanoimprint Lithography for IC Production. Proc. SPIE. 2002;4688:214–222. [Google Scholar]

- 84.Choi J, Nordquist K, Cherala A, Casoose L, Gehoski K, Dauksher WJ, Sreenivasan SV, Resnick DJ. Distortion and Overlay Performance of UV Step and Repeat Imprint Lithography. Microelectron. Eng. 2005;78–79:633–640. [Google Scholar]

- 85.Sreenivasan SV, Schumaker PD, Choi BJ. Critical Dimension Control, Overlay, and Throughput Budgets in UV Nanoimprint Stepper Technology; ASPE, Spring Proceedings; 2008. [Google Scholar]

- 86.Cherala A, Schumaker P, Mokaberi B, Selinidis K, Choi BJ, Meissl MJ, Khusnatdinov NN, LaBrake D, Sreenivasan SV. Nanoscale Magnification and Shape Control System for Precision Overlay in Jet and Flash Imprint Lithography. IEEE/ASME Trans. Mechatronics. 2014;99:1–11. [Google Scholar]

- 87.Singh L, Luo K, Ye Z, Xu F, Haase G, Curran D, LaBrake D, Resnick D, Sreenivasan SV. Defect Reduction of High-Density Full-Field Patterns in Jet and Flash Imprint Lithography. J. Micro/Nanolithogr., MEMS, MOEMS. 2011;10:033018-1–033018-6. [Google Scholar]

- 88.Litt LC, Malloy M. SEMATECH's NanoImprint Program: A Key Enabler for Nanoimprint Introduction. Proc. SPIE. 2009;7271:72711Q-1. [Google Scholar]

- 89.Malloy M, Litt LC. Technology Review and Assessment of Nanoimprint Lithography for Semiconductor and Patterned Media Manufacturing. J. Micro/Nanolithogr., MEMS, MOEMS. 2011;10:032001-1–032001-13. [Google Scholar]

- 90.Thompson E, Hellebrekers P, Hofeman P, LaBrake DL, Resnick DJ, Sreenivasan SV. 450 mm Wafer Patterning with Jet and Flash Imprint Lithography. Proc. SPIE. 2013;8880:88800J-1. [Google Scholar]

- 91.Herzig HP. “Micro-Optics: Elements, Systems and applications”. Taylor & Francis. 1997 [Google Scholar]

- 92.Schmid GM, Stewart MD, Wetzel J, Palmieri F, Hao J, Nishimura Y, Jen K, Kim EK, Resnick DJ, Liddle JA, Willson CG. Implementation of an Imprint Damascene Process for Interconnect Fabrication. J. Vac. Sci. Technol. B. 2006;24:1283–1291. [Google Scholar]

- 93.Finn A, Hensel R, Hagemann F, Kirchner R, Jahn A, Fischer W-J. Geometrical Properties of Multilayer Nano Imprint-Lithography Molds for Optical Applications. Microelectron. Eng. 2012;98:284–287. [Google Scholar]

- 94.Cheng X. Building 3D Micro- and Nanostructures Through Nanoimprint, in Three-Dimensional Nanostructures. Springer. 2011 [Google Scholar]

- 95.Irmscher M, Butschke J, Carpio R, Chao B, Jen W-L, Koepernik C, Nedelmann L, Ownes J, Palmieri F, Pritshcow M, Reuter C, Sailer H, Sotoodeh K, Wetzel J, Wilks B, Willson G. High Resolution Nanoimprint Templates for Dual Damascene – Fabrication and Imprint Results. Proc. SPIE. 2008;6921:69210D-1. [Google Scholar]

- 96.Singh L, Luo K, Ye Z, Xu F, Haase G, Curran D, LaBrake D, Resnick D, Sreenivasan SV. Defect Reduction of High-Density Full-Field Patterns in Jet and Flash Imprint Lithography. J. Micro/Nanolithogr., MEMS, MOEMS. 2011;10:033018-1–033018-6. [Google Scholar]

- 97.Hua F, Sun Y, Gaur A, Meitl M, Bilhaut L, Rotkina L, Wang J, Geil P, Shim M, Rogers J. Polymer Imprint Lithography with Molecular-Scale Resolution. Nano Lett. 2004;4:2467–2471. [Google Scholar]

- 98.Fontana RE, Hetzler SR, Decad G. Technology Roadmap Comparisons for TAPE, HDD, and NAND Flash: Implications for Data Storage Applications. IEEE Trans. Magn. 2012;48:1692–1696. [Google Scholar]

- 99.Terris BD. Fabrication Challenges for Patterned Recording Media. J. Magn. Magn. Mater. 2009;321:512–517. [Google Scholar]

- 100.Shiroishi Y, Fukuda K, Tagawa I, Iwasaki H, Takenoiri S, Tanaka H, Mutoh H, Yoshikawa N. Future Options for HDD Storage. IEEE Transactions on Magnetics. 2009;45:3816. [Google Scholar]

- 101.Ye Z, Carden S, Hellebrekers P, LaBrake D, Resnick DJ, Melliar-Smith M, Sreenivasan SV. Imprint Process Performance for Patterned Media at Densities Greater than 1Tb/in2. Proc. SPIE. 2012;8323:83230V-1–83230V-6. [Google Scholar]