Abstract

PURPOSE

The opacity of zirconia is an esthetic disadvantage that hinders achieving natural and shade-matched restorations. The aim of this study was to evaluate the translucency of non-colored and colored framework zirconia and monolithic zirconia.

MATERIALS AND METHODS

The three groups tested were: non-colored framework zirconia, colored framework zirconia with the A3 shade according to Vita Classic Scale, and monolithic zirconia (n=5). The specimens were fabricated in the dimensions of 15×12×0.5 mm. A spectrophotometer was used to measure the contrast ratio, which is indicative of translucency. Three measurements were made to obtain the contrast ratios of the materials over a white background (L*w) and a black background (L*b). The data were analyzed using the one-way analysis of variance and Tukey HSD tests. One specimen from each group was chosen for scanning electron microscope analysis. The determined areas of the SEM images were divided by the number of grains in order to calculate the mean grain size.

RESULTS

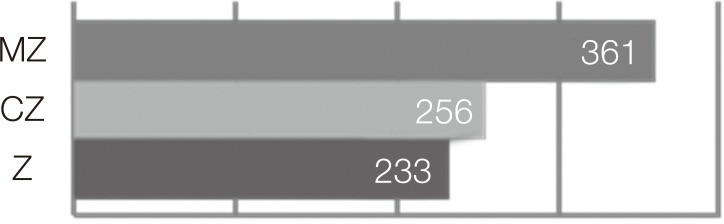

Statistically significant differences were observed among all groups (P<.05). Non-colored zirconia had the highest translucency with a contrast ratio of 0.75, while monolithic zirconia had the lowest translucency with a contrast ratio of 0.8. The mean grain sizes of the non-colored, colored, and monolithic zirconia were 233, 256, and 361 nm, respectively.

CONCLUSION

The translucency of the zirconia was affected by the coloring procedure and the grain size. Although monolithic zirconia may not be the best esthetic material for the anterior region, it may serve as an alternative in the posterior region for the bilayered zirconia restorations.

Keywords: Translucency, Contrast ratio, Colored zirconia, Monolithic zirconia, Grain size

INTRODUCTION

Metal-ceramic restorations have been used for a long time in prosthodontics and constitute a reliable choice for restoring dentition. However, they have several disadvantages. One of the esthetic disadvantages is the opacity of the metal framework and the metallic reflection through gingiva during smiling when the patient has a delicate gingival tissue and a high lip line. Also, the non-precious metal alloy framework may cause allergic reactions more frequently than precious alloys or ceramics and can exhibit corrosion problems.1,2 Recently all-ceramic restorations are preferred to metal-ceramic restorations in order to overcome these disadvantages, especially the ones related to esthetics. Although all-ceramic restorations are more translucent compared to restorations with a metal framework, not all of these materials can be used in the posterior region. Zirconia is a ceramic material that can be used in the posterior region because of its high flexural strength. One of the reasons for this high flexural strength is its high crystalline content; at the same time, its translucency decreases from the same reason and compromises the esthetics.3

Translucency of a ceramic material greatly affects the esthetics of a restoration as well as its shade. It has an influence on the natural appearance of the restoration.3 Translucency feature is also used to isolate or reflect the underlying abutment color to achieve the target shade. Materials with higher translucency are used to restore light-shaded natural teeth while materials with lower translucency are used to restore or mask dark-shaded teeth.4 The translucency of a ceramic material can be adjusted by controlling the absorption, reflection, and transmission of light.5 As the scattering and reflectance of the light increase, the opacity of the material also increases. Lower reflectance and higher transmission of light result in the increase of the translucency.6 A previous work on zirconia has demonstrated that scattering has a predominance over absorption especially for medium and high wavelength light in the range of 400-700 nm.7 Therefore, scattering is an important factor that affects the translucency of a ceramic material.8 The scattering characteristic of light is related to the crystalline content of dental ceramics. It has been stated that the particle size of the zirconia is an important factor for the scattering effect only when the particle size is similar to the wavelength of light.9 The particles of zirconia also have a different refractive index from that of the zirconia matrix and the increased scattering effect of the matrix is another reason for the opaque appearance of zirconia.4,8,9 Porosity can also affect the translucency of zirconia due to the different refractive indices of zirconia and air.10,11 Another factor influencing the translucency of a restoration is its thickness.7 As ceramic material gets thicker, the scattering profile becomes less directed.12

It has been shown that zirconia has low translucency among ceramic materials.10,13 Due to the material's low translucency, zirconia restorations are usually used with a veneer layer of feldspathic ceramic to overcome the problem of opacity. The veneering ceramic provides a more translucent appearance for zirconia restorations, thus achieving a more natural appearance.

The shade match is another important factor for esthetics. In order to match the shade, colored zirconia has been introduced to the market. The layering procedure of the veneering ceramic is simplified when the framework has a color match with the target shade. The veneer thickness required to mask the whiteness of the underlying zirconia framework can be reduced. The use of liner material applied before layering the veneer layer to mask the zirconia framework can also be eliminated.14 Some argued that the structure and the translucency of the material can be affected by the coloring procedures of zirconia.14,15 However, there are also data claiming that the translucency parameters of colored and non-colored zirconia specimens do not display significant difference.16

Although the thickness of the veneer layer can be reduced with colored zirconia framework, chipping of the veneer ceramic still remains a major problem.17 To overcome this problem, monolithic zirconia without a veneer ceramic layer was introduced to the market. Although monolithic zirconia is a new alternative to veneered zirconia restorations, there are a limited number of studies about its translucency.18,19 Also, monolithic zirconia has not been compared with colored framework zirconia previously.

The aim of this study was to evaluate the translucencies of colored and non-colored framework material zirconia and monolithic zirconia. The null hypothesis to be tested is that there is no difference between the translucencies of colored and non-colored framework material zirconia and monolithic zirconia.

MATERIALS AND METHODS

Blocks of yttria stabilized tetragonal zirconia polycrystals (Y-TZP) were sliced using a slow-speed diamond saw (Isomet wafering blades, Buehler, IL, USA) and a precise cutting machine (Mecatome T1800, Presi, Grenoble, France) into rectangular plate slices with a thickness of 0.5 mm, length of 15 mm, and height of 12 mm after sintering. The specimens were ground with sandpaper up to 2400 grits (A-1-2400MR1-10-1508, Reflex Concept, Presi, Grenoble, France).

The samples were divided into 3 groups consisting of 5 samples each. The control group of non-colored framework material zirconia (Z) and the experimental groups of colored framework material zirconia (CZ) and monolithic zirconia (MZ) are displayed in Table 1.

Table 1. The materials evaluated and their related information.

| Group | Utilization | Color | Manufacturer |

|---|---|---|---|

| Zirconia framework material (Z) | Framework | None | ZRAB8001, ICE Zirkonia, Zirkonzahn GmbH, Gais, Italy |

| Colored zirconia framework material (CZ) | Framework | A3 | ZRAB8001, ICE Zirkonia, Zirkonzahn GmbH, Gais, Italy |

| Monolithic zirconia (MZ) | Monolithic | None | ZRAD8001, Prettau Zirconia Zirkonzahn GmbH, Gais, Italy |

The coloring procedure of CZ group was carried out with the coloring liquid (CB00025B, Color Liquid for ICE Zirkon, Zirkonzahn GmbH, Gais, Italy) of the color of Vita Classic Scale A3 (Vita Zahnfabrik, H Rauter GmbH & Co., Bad Sackingen, Germany). The samples were immersed into the coloring liquid using plastic tweezers, held for 3 seconds, and dried under a heating lamp (Zirkonlampe 250, Zirkonzahn GmbH, Gais, Italy) for 30 minutes as recommended by the manufacturer. After coloring, all samples were sintered in the sintering furnace (Zirkonofen 600 V/2, Zirkonzahn GmbH, Gais, Italy). The sintering procedures recommended by the manufacturer are described in Table 2. After the sintering procedure, all specimens were carefully measured using a digital caliper (500-784, Mitutoyo Co., Kawasaki, Japan) from five different points on the specimen to ensure the even thickness of 0.5 mm.

Table 2. Recommended sintering parameters of the specimens.

| Final temperature | Time for temperature rise (20℃ to 1500℃) | Time at 1500℃ | Cooling rate (℃/min) | |

|---|---|---|---|---|

| Z / CZ | 1500℃ | 3 h | 2 h | 8 |

| MZ | 1600℃ | 3 h | 2 h | 8 |

Translucency values were measured relative to the standard illuminant D65 in the reflectance mode on white and black backgrounds with a spectrophotometer (VITA Easyshade Compact, Bad Sackingen, Germany). Three measurements were made to obtain CIE Lightness (L*) of the material over a white background (L* = 91.2, a* = -1.9, b* = 1.6) and over a black background (L* = 0.1, a* = -4.9, b* = 0.2). Contrast ratio (CR) was calculated as a translucency parameter. The following equation was used:

CR = L*b / L*w

L*b: CIE Lightness of the material on a black background

L*w: CIE Lightness of the material on a white background

CR value towards unity corresponds to opaque materials and towards zero to transparent materials.6

One specimen from each group was chosen for scanning electron microscope (SEM) analysis. The specimens were ultrasonically cleaned and gold sputtered for 20 seconds. Surface topography was evaluated under a scanning electron microscope (JSM 6300F, Joel Ltd., Tokyo, Japan) operating at 20 kV with a working distance of 11.5-12.0 mm. The determined areas of the SEM images were divided by the number of grains in order to calculate the mean grain size at magnification of × 20,000.

The descriptive statistics were carried out with the SPSS software (Version 10.0, SPSS Inc., Chicago, IL, USA). The obtained data were analyzed by using the one-way ANOVA and Tukey's HSD tests for pairwise comparisons of the groups. The analysis was performed with a confidence level of 0.05.

RESULTS

The results of the mean translucency values of the different zirconia cores are shown in Table 3. The one-way ANOVA test revealed that translucency of zirconia materials was affected by the coloring procedure and the zirconia type. Significant differences were observed between the CR values of the groups. MZ group had the lowest CR value while Z group had the highest one.

Table 3. The mean CR values of the groups and their comparisons.

| Group code | Mean (± SD) | P value | ||

|---|---|---|---|---|

| Z | CZ | MZ | ||

| Z | 0.7482 (± 0.0041) | - | ≤ .001 | ≤ .001 |

| CZ | 0.7864 (± 0.0040) | ≤ .001 | - | .006 |

| MZ | 0.7964 (± 0.0040) | ≤ .001 | .006 | - |

The difference between the groups is significant if the P value smaller than the .05 level.

The SEM images of the specimens are displayed in Fig. 1. The grain sizes of each group varied from 233 nm to 361 nm where the Z group had the smallest and the MZ group had the largest grain size (Fig. 2).

Fig. 1. The SEM images of the groups (× 20,000). The differences in the grain sizes can be observed. (A) Group Z, (B) Group CZ, (C) Group MZ.

Fig. 2. The grain sizes of the Z, CZ and MZ groups (nm).

DISCUSSION

The current study has evaluated the translucency of monolithic zirconia ceramic introduced for crown and bridge restorations. The results have shown that monolithic zirconia ceramic was more opaque than the colored or non-colored framework material zirconia, rejecting the null hypothesis. This interesting finding was against the claims of the manufacturer who has stated that monolithic zirconia was more translucent than the zirconia used as framework material in bilayered restorations.20

Although there was no difference in the contents of framework zirconia and monolithic zirconia evaluated in the current study according to the information obtained from the manufacturer, their CR values varied. This probably resulted from the different sintering procedures of the monolithic zirconia group and colored and non-colored framework zirconia groups. The MZ group's final sintering temperature is 100℃ higher than the Z and CZ groups'. It was argued that final sintering temperature affects the properties of ceramics on the microstructure and the crystalline phases.21,22 Dwelling time in the sintering furnace as well as sintering temperature also has an influence on zirconia grain size.23 High sintering temperature or increased dwelling time is stated to cause an increase in the grain size of zirconia materials.21,24,25,26 In the current study, two hours of dwelling time was the same for both MZ group and CZ and Z groups. Thus maximum sintering temperature remained as the main factor to generate the difference among the groups. SEM evaluations has shown that larger grain size was formed in MZ group which was sintered at a higher temperature of 1,600℃. The grain sizes of the other groups which were sintered at 1,500℃ were smaller supporting this statement (Fig. 1, Fig. 2).

According to a previous study about optical properties of zirconia, scattering coefficient of zirconia is higher than absorption coefficient of zirconia.7 So it can be supposed that scattering of light is more predominant than its absorption. Light scattering, which is inversely proportional to translucency, is related to the grain size of the material. If the grain size and the wavelength of a certain light are in a similar range, the light scattering activity increases as the grain size increases. But if the grain size is much larger than the wavelength of light, light scattering decreases as grain size increases, regardless of the wavelength of light.27,28,29

The light used in the current study is the spectrophotometer's standard illuminant D65 lamp, which has the wavelength range of 400-700 nm. The grain sizes of the Z, CZ, and MZ groups were 233, 256, and 361 nm, respectively. It can be noted that the grain sizes of all groups were smaller than the wavelength of the light. The claim that bigger grain size results in a decrease of translucency is in accordance with our results; the samples with greater grain size had higher CR values and were more opaque. The MZ group with the biggest grain size was the most opaque zirconia evaluated (Table 3).

However, there are contradictory results about the effect of the sintering temperature on the translucency of zirconia in the literature. There are studies claiming that higher sintering temperatures lead to a more uniform crystalline arrangement, thus promoting better specular reflection and light transmission leading to a better perception of color.23,30,31 The current study is in conflict with this assumption. This conflict has probably arisen from the finding that higher sintering temperature resulted in bigger grain size. In the current study, the CR values of the groups have increased and the translucency has decreased following the increase in the grain size.

The increase in the grain size may cause an increase in the number of micropores, therefore reducing the mechanical properties of the material.32 Micropore formation is a factor that can also be related to light scattering activity and translucency because there is a difference between the refractive indexes of air (n = 1) and zirconia (n = 2.1-2.2).10,11 Therefore, low porosity is required to increase the translucency of ceramics.32,33,34,35 It was stated that when the grain size was below microns, the effect of light scattering caused by micropores between the grains was significantly reduced. Pores bigger than 50 nm could cause significant scattering. Maximum scattering efficiency was observed when the pore size was in the range of wavelength of the light.27,36,37,38 In this study, micropore formation was not observed in the SEM images of the groups (Fig. 1, Fig. 2). Also, the grain size of the specimens was in the nm range, far below the microns. So it can be concluded that the differences between the CR values of the groups are attributed to light scattering caused by the grain size differences rather than light scattering caused by micropore formation.

All samples evaluated in the current study were prepared with the same thickness of 0.5 mm, as in the similar studies.19,30,31,39 This thickness is sufficient for the use as a framework material in the bilayered zirconia restorations. However, monolithic zirconia's flexural strength is stated to be lower than framework zirconia material; the Z group's specimens had flexural strength of 1200-1400 MPa, whereas the MZ group's specimens had flexural strength of 1000-1200 MPa according to the manufacturer.40,41 Therefore, monolithic zirconia ceramics should be thicker than 0.5 mm, the evaluated thickness in the current study, to increase its strength for crown and bridge restorations. Also the thickness of the restoration needs to be more than 0.5 mm at some regions of anterior teeth because its morphological properties. A larger amount of tooth structure removal can be required as a part of the tooth preparation for fixed prosthesis. Incisal area is especially important because of incisal reduction, and more translucency is needed for the area than any other part of the restoration. Thickness is another factor affecting the light transmittance and the translucency of ceramic materials.10,42,43 In bilayered restorations, the more opaque zirconia material can be used minimally, and the rest of the tooth contour can be completed with the more translucent veneer ceramic.10 A previous study by Pecho et al.16 has shown that the translucency parameter of colored and non-colored framework zirconia specimens did not display a significant difference with human and bovine dentine. When considering that the absorption and scattering coefficients of dentin are higher than those of enamel, application of the framework zirconia materials as a replacement of enamel may not be esthetically satisfying. Monolithic material can be used as the whole thickness. Therefore, monolithic zirconia restorations are expected to be more opaque than framework zirconia. The translucency value of CZ group was also found to be significantly lower than the Z group as well as MZ group in the current study. This finding is in accordance with other studies.18,39,44 Similar results were related to the darker pigmentation of the CZ specimens previously. It was claimed that higher chroma affected the light reflection.44,45 This explanation is also compatible with the results of the current study when it is considered that the difference in the grain size of CZ and Z groups is minimal. It was also stated that the pigments existing in the colored specimens were probably responsible for the absorption.7 So the significant difference between the CR values should be attributed to the coloring procedure rather than the grain size.

It was reported that the difference between the CR values should be equal to or greater than 0.07 to be perceived with the naked eye.46 Although the differences between the CR values of the groups were statistically significant, it did not exceed 0.05. So it can be stated that the difference in the translucency of the samples cannot be perceived with the naked eye at the thickness of 0.5 mm.

Several limitations can be listed for the current study. No veneering ceramic was applied. This decision was made to produce uniform samples for Z, CZ and MZ groups, but it does not correspond to the clinical situation. Only one brand of zirconia material and only one specimen thickness were tested for all groups, and the effect of aging was not considered. In further studies the authors would like to advise the investigation of the translucency of thicker than 0.5 mm zirconia types as they can be used in clinical situations as well as veneered zirconia specimens with different shades.

Monolithic zirconia has several advantages such as overcoming the problem of veneer chipping and its higher fracture strength than bilayered zirconia restorations because of its increased thickness. Although monolithic zirconia may not be the best possible esthetic material in the anterior region, it constitutes an alternative in the posterior region for the bilayered zirconia restorations.

CONCLUSION

Within the limitations of this in vitro study, it can be concluded that monolithic zirconia has bigger grain size and is less translucent when compared with framework material zirconia. Secondly, colored zirconia framework material has similar grain size and is less translucent when compared with non-colored framework material zirconia.

References

- 1.Joiner A. Tooth colour: a review of the literature. J Dent. 2004;32:3–12. doi: 10.1016/j.jdent.2003.10.013. [DOI] [PubMed] [Google Scholar]

- 2.Dietschi D. Layering concepts in anterior composite restorations. J Adhes Dent. 2001;3:71–80. [PubMed] [Google Scholar]

- 3.Kelly JR, Nishimura I, Campbell SD. Ceramics in dentistry: historical roots and current perspectives. J Prosthet Dent. 1996;75:18–32. doi: 10.1016/s0022-3913(96)90413-8. [DOI] [PubMed] [Google Scholar]

- 4.Spear F, Holloway J. Which all-ceramic system is optimal for anterior esthetics? J Am Dent Assoc. 2008;139:19S–24S. doi: 10.14219/jada.archive.2008.0358. [DOI] [PubMed] [Google Scholar]

- 5.Raptis NV, Michalakis KX, Hirayama H. Optical behavior of current ceramic systems. Int J Periodontics Restorative Dent. 2006;26:31–41. [PubMed] [Google Scholar]

- 6.Kingery WD, Bowen HK, Uhlmann DR. Introduction to ceramics. 2nd ed. New York: John Wiley and Sons; 1976. pp. 646–689. [Google Scholar]

- 7.Pecho OE, Ghinea R, Ionescu AM, Cardona JC, Della Bona A, Pérez Mdel M. Optical behavior of dental zirconia and dentin analyzed by Kubelka-Munk theory. Dent Mater. 2015;31:60–67. doi: 10.1016/j.dental.2014.11.012. [DOI] [PubMed] [Google Scholar]

- 8.Brodbelt RH, O'Brien WJ, Fan PL. Translucency of dental porcelains. J Dent Res. 1980;59:70–75. doi: 10.1177/00220345800590011101. [DOI] [PubMed] [Google Scholar]

- 9.Clarke FJ. Measurement of color of human teeth. In: McLean JW, editor. Proceedings of the first international symposium on ceramics. Chicago: Quintessence; 1983. pp. 441–490. [Google Scholar]

- 10.Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. Relative translucency of six all-ceramic systems. Part I: core materials. J Prosthet Dent. 2002;88:4–9. [PubMed] [Google Scholar]

- 11.Vagkopoulou T, Koutayas SO, Koidis P, Strub JR. Zirconia in dentistry: Part 1. Discovering the nature of an upcoming bioceramic. Eur J Esthet Dent. 2009;4:130–151. [PubMed] [Google Scholar]

- 12.Fernandez-Oliveras A, Pecho OE, Rubiño M, Pérez MM. Measurements of scattering anisotropy in dental tissue and zirconia ceramic. Proc SPIE. 2012;8427:48. [Google Scholar]

- 13.Harianawala HH, Kheur MG, Apte SK, Kale BB, Sethi TS, Kheur SM. Comparative analysis of transmittance for different types of commercially available zirconia and lithium disilicate materials. J Adv Prosthodont. 2014;6:456–461. doi: 10.4047/jap.2014.6.6.456. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Effect of zirconia type on its bond strength with different veneer ceramics. J Prosthodont. 2008;17:401–408. doi: 10.1111/j.1532-849X.2008.00306.x. [DOI] [PubMed] [Google Scholar]

- 15.Hjerppe J, Närhi T, Fröberg K, Vallittu PK, Lassila LV. Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand. 2008;66:262–267. doi: 10.1080/00016350802247123. [DOI] [PubMed] [Google Scholar]

- 16.Pecho OE, Ghinea R, Ionescu AM, Cardona Jde L, Paravina RD, Pérez Mdel M. Color and translucency of zirconia ceramics, human dentine and bovine dentine. J Dent. 2012;40:e34–e40. doi: 10.1016/j.jdent.2012.08.018. [DOI] [PubMed] [Google Scholar]

- 17.Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005;21:984–991. doi: 10.1016/j.dental.2005.03.013. [DOI] [PubMed] [Google Scholar]

- 18.Kim HK, Kim SH. Effect of the number of coloring liquid applications on the optical properties of monolithic zirconia. Dent Mater. 2014;30:e229–e237. doi: 10.1016/j.dental.2014.04.008. [DOI] [PubMed] [Google Scholar]

- 19.Stawarczyk B, Emslander A, Roos M, Sener B, Noack F, Keul C. Zirconia ceramics, their contrast ratio and grain size depending on sintering parameters. Dent Mater J. 2014;33:591–598. doi: 10.4012/dmj.2014-056. [DOI] [PubMed] [Google Scholar]

- 20.Zirkonzahn web site. [Accessed 27 March, 2016]. Available from: http://www.zirkonzahn.com/en/prettau-zirconia/prettau-zirconia.

- 21.Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008;24:299–307. doi: 10.1016/j.dental.2007.05.007. [DOI] [PubMed] [Google Scholar]

- 22.Rhodes WH. Controlled transient solid second-phase sintering of yttria. J Am Ceram Soc. 1981;64:13–19. [Google Scholar]

- 23.Ebeid K, Wille S, Hamdy A, Salah T, El-Etreby A, Kern M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent Mater. 2014;30:e419–e424. doi: 10.1016/j.dental.2014.09.003. [DOI] [PubMed] [Google Scholar]

- 24.Chevalier J, Deville S, Münch E, Jullian R, Lair F. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials. 2004;25:5539–5545. doi: 10.1016/j.biomaterials.2004.01.002. [DOI] [PubMed] [Google Scholar]

- 25.Ruiz L, Readey MJ. Effect of heat treatment on grain size, phase assemblage, and mechanical properties of 3 mol% Y-TZP. J Am Ceram Soc. 1996;79:2331–2340. [Google Scholar]

- 26.Scott HG. Phase relationships in the zirconia-yttria system. J Mater Sci. 1975;10:1527–1535. [Google Scholar]

- 27.Casolco SR, Xu J, Garay JE. Transparent/translucent polycrystalline nanostructured yttria stabilized zirconia with varying colors. Scr Mater. 2008;58:516–519. [Google Scholar]

- 28.Lee YK, Cha HS, Ahn JS. Layered color of all-ceramic core and veneer ceramics. J Prosthet Dent. 2007;97:279–286. doi: 10.1016/j.prosdent.2007.03.010. [DOI] [PubMed] [Google Scholar]

- 29.O'Brien WJ, Johnston WM, Fanian F. Double-layer color effects in porcelain systems. J Dent Res. 1985;64:940–943. doi: 10.1177/00220345850640061801. [DOI] [PubMed] [Google Scholar]

- 30.Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hämmerlet CH. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013;17:269–274. doi: 10.1007/s00784-012-0692-6. [DOI] [PubMed] [Google Scholar]

- 31.Jiang L, Liao Y, Wan Q, Li W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med. 2011;22:2429–2435. doi: 10.1007/s10856-011-4438-9. [DOI] [PubMed] [Google Scholar]

- 32.Tekeli S, Erdogan M. A quantitative assessment of cavities in 3 mol% yttria-stabilized tetragonal zirconia specimens containing various grain size. Ceram Int. 2002;28:785–789. [Google Scholar]

- 33.Peelen JGJ, Metselaar R. Light scattering by pores in polycrystalline materials: Transmission properties of alumina. J Appl Phys. 1974;45:216–220. [Google Scholar]

- 34.Zhang HB, Kim BN, Morita K, Yoshida H, Lim JH, Hiraga K. Optimization of high-pressure sintering of transparent zirconia with nano-sized grains. J Alloy Compd. 2010;508:196–199. [Google Scholar]

- 35.Kim MJ, Ahn JS, Kim JH, Kim HY, Kim WC. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. J Adv Prosthodont. 2013;5:161–166. doi: 10.4047/jap.2013.5.2.161. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Anselmi-Tamburini U, Woolman JN, Munir ZA. Transparent nanometric cubic and tetragonal zirconia obtained by high-pressure Ppulsed electric current sintering. Adv Funct Mater. 2007;17:3267–3273. [Google Scholar]

- 37.Hayashi K, Kobayashi O, Toyoda S, Morinaga K. Transmission optical properties of polycrystalline alumina with submicron grains. Mater Trans JIM. 1991;32:1024–1029. [Google Scholar]

- 38.Apetz R, van Bruggen MPB. Transparent alumina: A light-scattering model. J Am Ceram Soc. 2003;86:480–486. [Google Scholar]

- 39.Tuncel I, Eroglu E, Sari T, Usumez A. The effect of coloring liquids on the translucency of zirconia framework. J Adv Prosthodont. 2013;5:448–451. doi: 10.4047/jap.2013.5.4.448. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Prettau data sheet. [Accessed 22 July 2015]. Available from: http://www.zirkonzahn.com/assets/files/anleitungen-informationen-studien/INTData-sheet-Prettau-Zirconia.pdf.

- 41.ICE Zirkon translucent data sheet. [Accessed: 22 July 2015]. Available from: http://www.zirkonzahn.com/assets/files/anleitungen-informationen-studien/INT-Data-sheet-ICE-Zirkon-Translucent.pdf.

- 42.Antonson SA, Anusavice KJ. Contrast ratio of veneering and core ceramics as a function of thickness. Int J Prosthodont. 2001;14:316–320. [PubMed] [Google Scholar]

- 43.Wang F, Takahashi H, Iwasaki N. Translucency of dental ceramics with different thicknesses. J Prosthet Dent. 2013;110:14–20. doi: 10.1016/S0022-3913(13)60333-9. [DOI] [PubMed] [Google Scholar]

- 44.Kurtulmus-Yilmaz S, Ulusoy M. Comparison of the translucency of shaded zirconia all-ceramic systems. J Adv Prosthodont. 2014;6:415–422. doi: 10.4047/jap.2014.6.5.415. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Spyropoulou PE, Giroux EC, Razzoog ME, Duff RE. Translucency of shaded zirconia core material. J Prosthet Dent. 2011;105:304–307. doi: 10.1016/S0022-3913(11)60056-5. [DOI] [PubMed] [Google Scholar]

- 46.Liu MC, Aquilino SA, Lund PS, Vargas MA, Diaz-Arnold AM, Gratton DG, Qian F. Human perception of dental porcelain translucency correlated to spectrophotometric measurements. J Prosthodont. 2010;19:187–193. doi: 10.1111/j.1532-849X.2009.00542.x. [DOI] [PubMed] [Google Scholar]