Abstract

The present research was intended to develop a small scale butter churn and its performance by altering churning temperature and churn speed during butter making. In the present study, the cream was churned at different temperatures (8, 10 and 12 °C) and churn speeds (35, 60 and 85 rpm). The optimum parameters of churning time (40 min), moisture content (16 %) and overrun (19.42 %) were obtained when cream was churned at churning temperature of 10 °C and churn speed of 60 rpm. Using appropriate conditions of churning temperature and churn speed, high quality butter can be produced at cottage scale.

Keywords: Butter, Cream, Churn speed, Churning temperature, Churning time

Introduction

Butter making is one of the oldest forms of preserving the fat component of milk. Its manufacturing dates back to some of the earliest historical records and references have been made to the use of butter in sacrificial worship, for medicinal and cosmetic purposes and as a human food long from the Vedic periods (Shahidi 2005). There is good reason to believe that the milking of animals and the origin of butter making predate the beginning of organized and permanent recording of human activities. The evolution of the art of butter making has been intimately associated with the development and use of equipment. At the end of the eighteenth century, the construction and use of creaming and butter making equipment (other than that made of wood) began to receive consideration, and the barrel churn made its appearance.

India is the largest milk producing country in the world and FAO reported that the present production of milk is about 140 MT. About 7 % of total milk is converted into butter (Anonymous 2014). The world annual butter production in 2010 was estimated to be 10 MT and has increased by 14 % during the period 2006–2010 (NPCS 2014). In 2009, around half of India’s total dairy import by volume consists of butter and other dairy derived fats, followed by lactose (33 %) and milk powder (8 %) (Singh 2011). In India, most of the butter producers at cottage scale in the countryside use hand cream separator and in some developed areas having facility of electricity, mechanical cream separator are also in use. On commercial scale, butter is being produced mechanically by large dairies but this production is far less than the total demand, so a lot of revenue has been spent over its import annually.

The milk production in India is not concentrated at single place and mainly at farm level where the milk production is very stumpy; they require small equipments for processing and manufacturing of milk products. The butter production in rural areas of India is still not technically advanced and people still prefer local traditional method which yield low quality butter.

A variety of methods and devices have been developed to produce butter on a small scale. Butter was first made by placing the cream in a leather container made from goat’s stomach skin and shaking until the milk was broken down into the butter (Eltayeb and Mahjoub 2003). Butter churns have varied over time as technology and materials have changed. The first butter churns had a wooden container and a plunger to agitate the cream until butter formed, referred to as a plunge churn or dash churn. Then, butter churns consisted of a container made from wood, ceramics or galvanized iron that contained paddles. Later centrifugal type butter churns were introduced for butter making. Instead of having spinning paddles, the paddles are fixed and the container spins. This allows better separation of butter from butter milk (Deel 2013).

Butter is extensively used by the bakery, chocolate and confectionary industries and the people eat it with bread and use it in cooking. The manufacturing of butter with attractive characteristics has long been a problem. The preparation of butter from cream rather than whole milk is more efficient because of the high fat content present in the cream (O’Mahony 1988). The most suitable treatment for the uniform butter consistency is mechanical treatment of butter (Deman and Beers 1988). During this process, cream undergoes a phase inversion as fat globule membranes are disrupted, globules coalesce and oil leaks out to form a continuous phase (Wright et al. 2001). Many physical and chemical factors are involved in achieving desired consistency and yield of butter. Churning of 40 % cream yields almost equal amount of butter and butter milk (Morin et al. 2008). Siddique et al. (2011) optimized and evaluated the traditional butter making methods for getting good quality and yield of butter by standardizing cream fat levels and altering churning temperatures during butter making.

Sun et al. (2007) and Sun et al. (2013) did investigations on alternative method by utilizing Stirling cooler for butter churning. They reported that water content of the butter was lower while the fat content was higher in butter samples obtained by this machine. A high temperature during the churning process reduces the butter yield, as some of the butter fat liquefies and is lost with the buttermilk. A number of interrelated variables are involved in efficient operation of butter churn machine, such as fat level, cream acidity, churning temperature and churn speed.

In order to predict the optimum churning conditions, a small scale Frustum Cone Shaped Butter Churn (FCSBC) was developed and the effect of two important parameters viz. churning temperature and churn speed were studied on various production parameters.

Materials and methods

Selections of material for butter churn

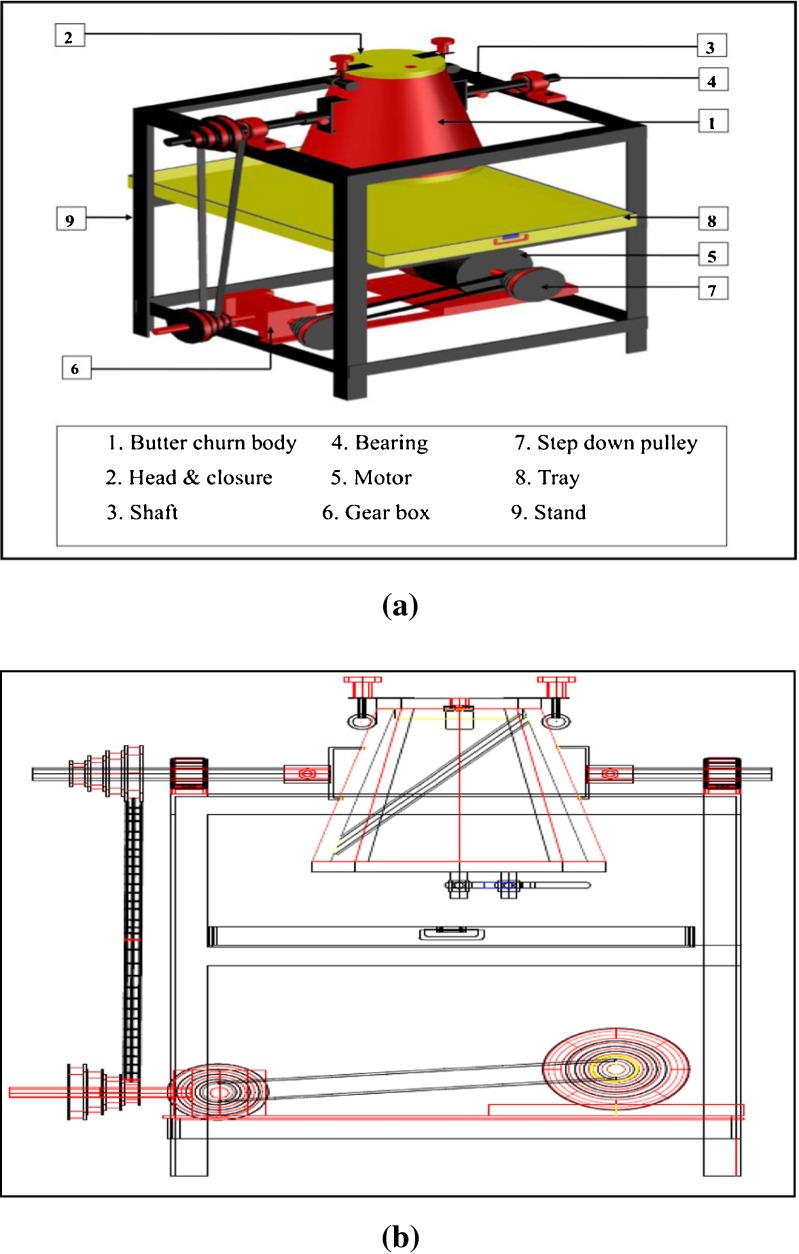

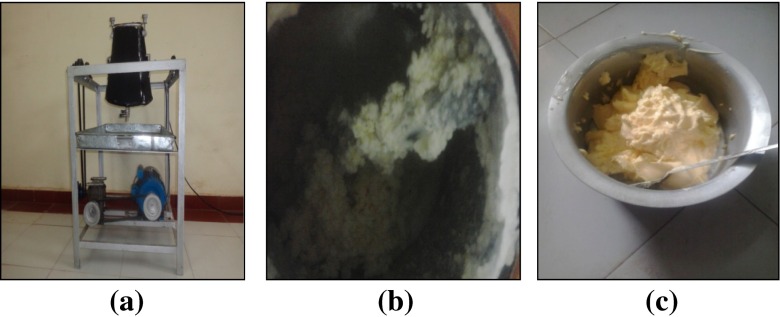

The present invention relates to a method of producing butter, in a double jacketed frustum cone shaped apparatus. The apparatus intended for this purpose consists of SS 304 inner frustum cone drum and outer iron frustum cone drum, head, stirring wing, shaft, motor and stand which are the main components of the apparatus as shown in the Fig. 1a and b. These sketches of FCSBC were drawn using auto CAD. Selection of proper materials for making of various components of frustum cone shaped butter churn was very important. Standard and common size sections as well as semi-finished and finished items, which were easily available in local market, were selected. The dimensions of developed FCSBC are given in Table 1.

Fig. 1.

a Labeled diagram of frustum cone shaped butter churn. b Line diagram of frustum cone shaped butter churn

Table 1.

Dimensions of different components of FCSBC

| S. No. | Name of component | Particulars | Dimensions |

|---|---|---|---|

| 1 | Inner AISI SS 304 frustum cone | Volume Height Upper radius Lower radius Slant height Total surface area Curved surface area Centroid |

10 L 280 mm 70 mm 140 mm 289 mm 2675 cm² 1905.7 cm² 110 mm |

| 2 | Outer iron frustum cone | Volume Height Upper radius Lower radius Slant height Total surface area Curved surface area Centroid |

15.1 L 300 mm 90 mm 160 mm 308 mm 3221.64 cm² 2417.8 cm² 127 m |

| 3 | Thickness | Inner SS frustum cone Outer iron frustum cone |

4 mm 4 mm |

| 4 | Stirring wing | Hallow space | 20 mm |

| 5 | Motor | Size Volt Amp RPM frequency, phase |

0.5 hp 220 3.5 1440 60 Hz,1 |

| 6 | Valves | S.S ball valves, 2 | 0.25 in. |

| 7 | Sight glass | Perspex glass Thickness Width |

4 mm 25 mm |

| 8 | Gasket | Nitrile rubber Thickness |

3 mm |

| 9 | Gear box | Speed ratio | 1:20 |

| 10 | Head and closure | SS 304 Thickness Diameter |

20 mm 180 mm |

| 11 | Step down pulley | 4 | 50.8, 63.5, 76.2 and 101.6 mm |

| 12 | Belts | 2 | A-965 mm A-1320 mm |

The butter churn was designed with a holding capacity of 10 L and working capacity of 5 L cream. The inner frustum cone drum made of SS 304 was fitted on the inside with a single stirring wing extended from the closed end upwardly to the upper end. The wing was obliquely positioned relative to the axis of drum and made with double wall so as to form hallow space which was adapted to communicate with the jacketed space. The circular flange type head, made of SS 304 was designed with a thickness of 20 mm and diameter of 180 mm. It was fixed to the churner’s body by welding and a 26 mm wide hole was drilled for the provision of sight glass. Thumb screws were provided to tighten the head and 3 mm thick nitrile rubber gasket was used to resist the leakage during churning. The transmission type shaft made of low carbon steel by hot rolling, forged and turned to size in a lathe, was used. The shaft material was selected based on considerations such as high strength, capable to be heat treated and good machinability. The diameter of the shaft was 25 mm. The 0.5 hp single phase A.C. motor was used with speed and frequency of 1440 rpm and 50 Hz respectively. The gear box of 1:20 ratio was used to reduce the speed of motor to required churn speed. Two sets of ‘four step down pulley’ (speed cone) were used to transmit the power and to vary the churn speed as per requirement of experiment.

In order to minimize the gain of heat from atmosphere, the churn was designed consisting of jacketed space for chilled water and an insulating material (foamed polyethylene) over it. The thickness of the insulating material required to minimize the heat gain was calculated. The rate of heat transfer through the 4 mm thick outer metal wall was calculated, using equation (1) (Gupta and Prakash 1989)

| 1 |

Where,

| 2 |

- R1

= Thermal resistance of metal wall (˚C/W)

- To

= Outside ambient temperature (˚C)

- Ti

= Chilled water temperature in jacketed space (˚C)

- Lm

= Thickness of metal body (m)

- km

= Thermal conductivity of galvanized iron outer drum (W/m˚C)

- Am

= Outside surface area of outer frustum cone (m2)

The dry bulb temperature of ambient air and chilled water temperature was determined using glass thermometer. The thermal resistance of metal body (R1) was calculated by using the equation (2) (Gupta and Prakash 1989). In order to reduce the rate of heat gain calculated by using equation (1) by 99 %, the outer body was covered with the foamed polyethylene insulating material. By considering rate of heat gain with insulation to be 2060 W, the resistance of insulating material was calculated and then by using this value of R1, the required thickness was calculated to be 2.6 mm. Looking to the availability of foamed polyethylene in the local market, a sheet of 3 mm thickness was used which further reduced rate of heat gain.

The pasteurized and 40 % standardized cream was procured from the Chhattisgarh State Cooperative Dairy Federation Limited, Raipur. The cream was analyzed for the physico-chemical properties to assess the quality of cream. The cream was also analyzed for acidity and fat. The cream was then incubated in BOD incubator (make: MAC, Macro Science, Delhi) for the purpose of ageing. The ageing temperature was maintained at 10 °C for 17 h. The cream temperature was then increased or decreased to the desired churning temperature. Then churning was done at three different temperatures and churn speeds. After churning, butter was found which was worked and shifted in different sizes of molds and stored in a refrigerator.

At three different temperatures of churning (8, 10 and 12oC) and three different churn speeds (35, 60 and 85 rpm), the time required for churning was recorded. The yield and overrun of butter was calculated by method as described by ILRITM (1995).

Analytical procedures for testing cream, butter and buttermilk

The cream was analyzed for the fat and acidity and the butter was analyzed for fat and moisture content by standard method as described in BIS: SP18-part XI (1981). The buttermilk was analyzed for fat content by standard method as described by ILRITM (1995).

Statistical analysis

Data obtained were subjected to statistical analysis to determine the effect churn speed and churning temperature on the dependent variables like time of churning and chemical parameters of butter. For statistical analysis of data, Factorial Completely Randomized Design was adopted (Steel and Torrie 1981). The speed of the churn was fixed as slow at 35 rpm, medium at 60 rpm and fast at 85 rpm (3 levels of churn speed) and the churning temperature was fixed as 8, 10 and 12 °C, thus 32 factorial completely randomized design was applied.

Results and discussion

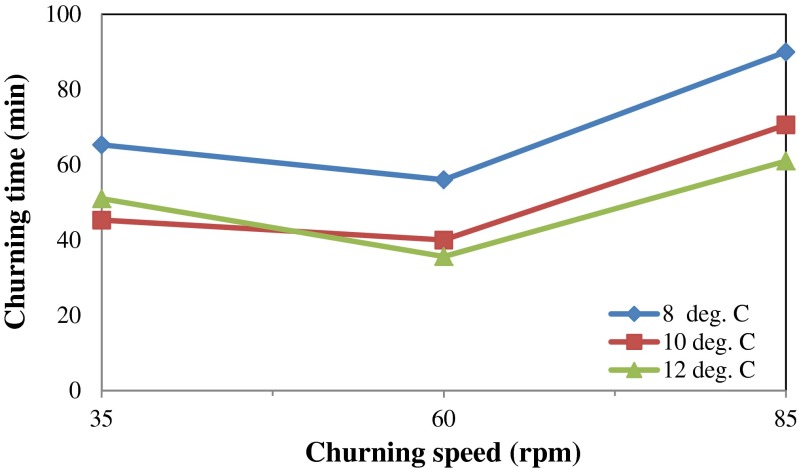

Effect of churning temperature and churning speed on churning time of butter in FCSBC

The present study shows an overall increase in the churning time with decrease in churning temperature (Fig. 2). This might be due to the reason that at lower temperature most of the fat is in solid state in fully crystallized condition. The area of contact between the fat globules will be small and hence angle of collision will be skewed rather than direct collision due to which effectiveness of collision will be low and fat globules will aggregate very slowly, hence increasing the churning time. While, at higher temperature sufficient liquid fat is present and globules are easily deformed hence aggregation occurs more naturally and easily reducing the churning time.

Fig. 2.

Effect of churning temperature and churn speed on the churning time of cream

From Fig. 2, it is also evident that with churn at different speeds, the butter formation was not uniform. At lower speed of 35 rpm and higher speed of 85 rpm, the churning time was more at all the three churning temperatures as compared to churning speed of 60 rpm. This is probably because at lower speed, the cream in the churn instead of falling from the top to bottom during rotation, it just slides along the wall of the churn without giving sufficient turbulent whipping. This must have caused uneven aggregation and thereby increased the churning time. At higher speed, it seems that the centrifugal force had exceeded the gravitational force and therefore cream sticks to the inner surface and rotates with the drum.

The optimum churning time (40 min) was obtained at churning temperature of 10 °C and churn speed of 60 rpm with respect to body and texture. The results of the present study are in agreement with those of Labuschangne (1963). The present study was further supported by Holland and Herrington (1953) who reported that the churning time decreases with increase in churning temperature. From Fig. 2, it can be observed that lowest churning time (35 min) was recorded by churning the cream at churning temperature of 12 °C and churn speed of 60 rpm but body and texture of butter obtained was of poor quality.

The statistical results regarding the churning time of cream, churned at different churning temperatures and churn speeds revealed that churning time of cream differed significantly (p ≤ 0.05) between different churning temperatures and churn speed levels (Table 2).

Table 2.

Effect of churning temperature and churn speed on churning time, moisture content and fat content of butter

| Churn speed, rpm | Churning time (min.) | Moisture content of butter (%) | Fat content of butter (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Churning temperature (oC) | Churning temperature (oC) | Churning temperature (oC) | ||||||||||

| T1 (8oC) | T2 (10oC) | T3 (12oC) | Mean | T1 (8oC) | T2 (10oC) | T3 (12oC) | Mean | T1 (8oC) | T2 (10oC) | T3 (12oC) | Mean | |

| 35 | 65.3 | 45.3 | 51.0 | 53.8 | 10.4 | 14.2 | 15.5 | 13.4 | 88.30 | 84.50 | 83.00 | 85.26 |

| 60 | 56.0 | 40.0 | 35.6 | 43.8 | 14.4 | 16.0 | 16.7 | 15.7 | 83.96 | 82.70 | 81.40 | 82.69 |

| 85 | 90.0 | 70.6 | 61.0 | 73.8 | 15.2 | 16.8 | 19.0 | 17.0 | 83.06 | 81.63 | 79.10 | 81.26 |

| Mean | 70.4 | 52.0 | 49.2 | 13.37 | 15.70 | 17.0 | 85.11 | 82.94 | 81.16 | |||

| Statistical analysis | Effect | CD0.05 | SEm± | Effect | CD0.05 | SEm± | Effect | CD0.05 | SEm± | |||

| CT | 1.59 | 0.54 | CT | 0.15 | 0.05 | CT | 0.14 | 0.05 | ||||

| CS | 1.59 | 0.54 | CS | 0.15 | 0.05 | CS | 0.14 | 0.05 | ||||

| CT x CS | 2.76 | 0.93 | CT x CS | 0.25 | 0.08 | CT x CS | 0.24 | 0.08 | ||||

CT Churning temperature, CS Churn speed

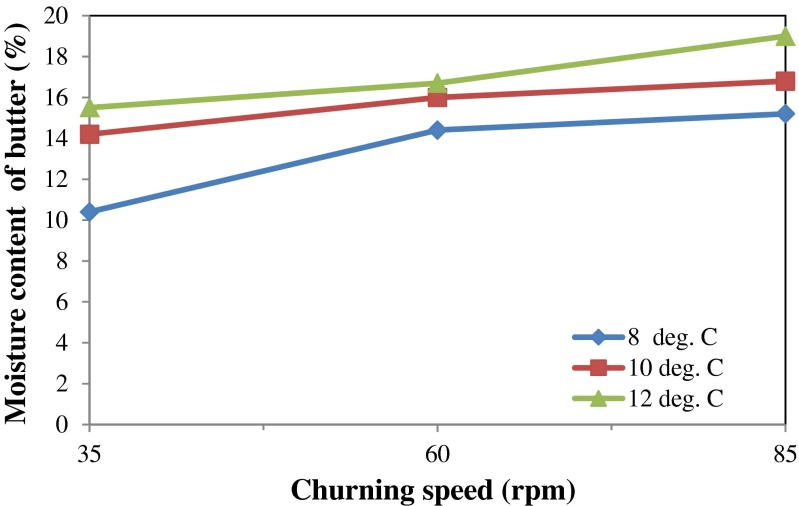

Effect of churning temperature and churn speed on the moisture content of butter

The effect of churning temperature and churn speed on moisture content of butter produced in FCSBC is presented in Fig. 3. This shows increasing trend in moisture content with increase in churning temperature and churn speed. The highest moisture content (19 %) was obtained at churning temperature of 12 °C and churn speed of 85 rpm. The increase in moisture content with increase in churning temperature might be due to the reason that the agglomeration of fat globules occurs more rapidly at higher temperature, as a result the butter grains formed would be smaller. So, the water holding capacity between the butter grains would have increased. While at lower temperature, large butter granules are formed with good drainage of butter milk due to which water holding capacity decreased. The results are in agreement with the findings reported by Siddique et al. (2011). Funahashi and Horiuchi (2008) concluded that the moisture content of butter decreased with increasing shear rate on the beater.

Fig. 3.

Effect of churning temperature and churn speed on the moisture content of butter

The effect of churning temperatures and churn speeds on the moisture content of butter samples reflected that it differed significantly (p ≤ 0.05) due to these two factors. The interaction effect of churning temperature and churn speed had shown a significant (p ≤ 0.05) effect on moisture content (Table 2).

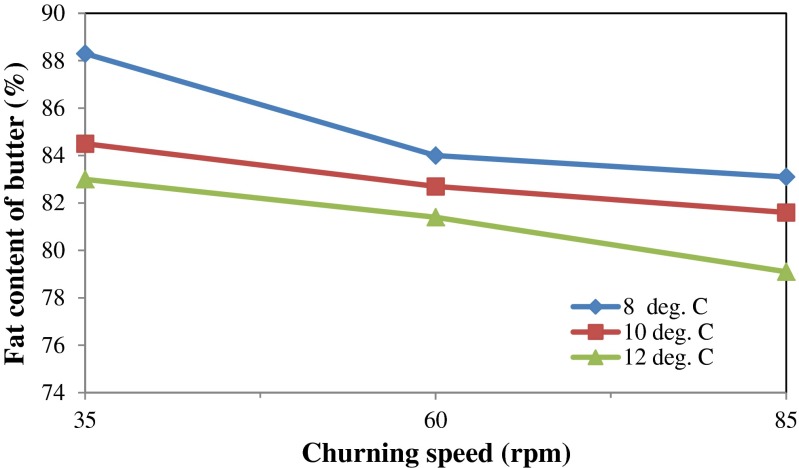

Effect of churning temperature and churn speed on the fat content of butter

The effect of churning temperature and churn speed on fat content of butter produced in the FCSBC is shown in Fig. 4. The figure shows that the increasing trend in fat content of butter with decrease in the churning temperature and churn speed. This might be due to the reason that low temperature churning ends up in larger butter grains which have low water holding capacity and contain higher amount of fat because at lower temperature more tri-acylglycerols crystallize into the solid fat network (Shukla and Rizvi 1995). While at higher churning temperature the fat globule structure is destroyed and fat exists as free fat where there is chance of high fat loss in the buttermilk, which directly decreases the fat content of butter. The present findings are in agreement with Siddique et al. (2011). Buldo et al. (2013) reported that longer ripening time (5 h vs. 0 h) resulted in larger butter grains (91 vs. 52 μm), higher viscosity (5.3 vs. 1.3 Pa.s) and solid fat content (41 vs. 3 %). Despite the increase in solid fat content, no further changes in crystal polymorphism and in melting behavior were observed after 1 h of ripening and after churning.

Fig. 4.

Effect of churning temperature and churn speed on the fat content of butter

The decreasing trend in fat content of butter with increase in churn speed might be due to the reason that at lower speed there is a different effect on the structural integrity of the fat globules of butter. When butter is produced at lower speed, relatively high proportion of the fat phase may remain in the globules after churning and hence increase the fat content of butter. The high fat content (88.3 %) was achieved at lower temperature (8oC) and lower churn speed (35 rpm) but butter formed was dry and hard, so optimum fat content (82.7 %) with good body and texture was obtained at churning temperature of 10 °C and churn speed of 60 rpm.

The fat content of butter, churned at different churning temperatures and churn speeds revealed that fat content of butter differed significantly (p ≤ 0.05) between different churning temperature treatments and churn speed levels. The interaction effect of churning temperature and churn speed had shown a significant (p ≤ 0.05) effect on fat content of butter (Table 2).

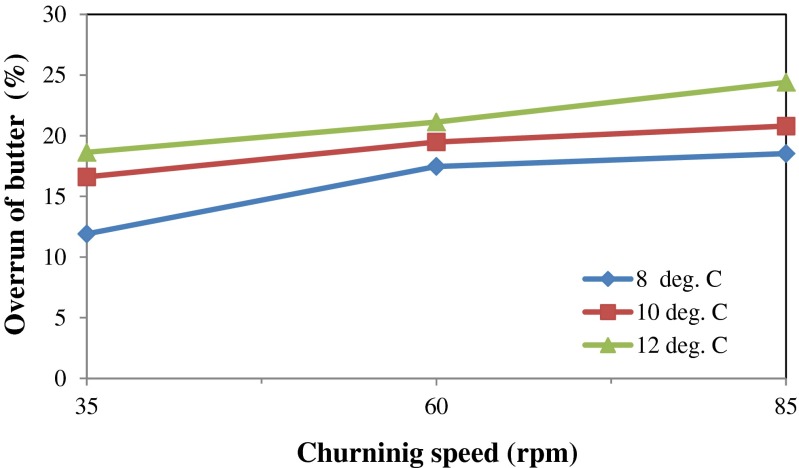

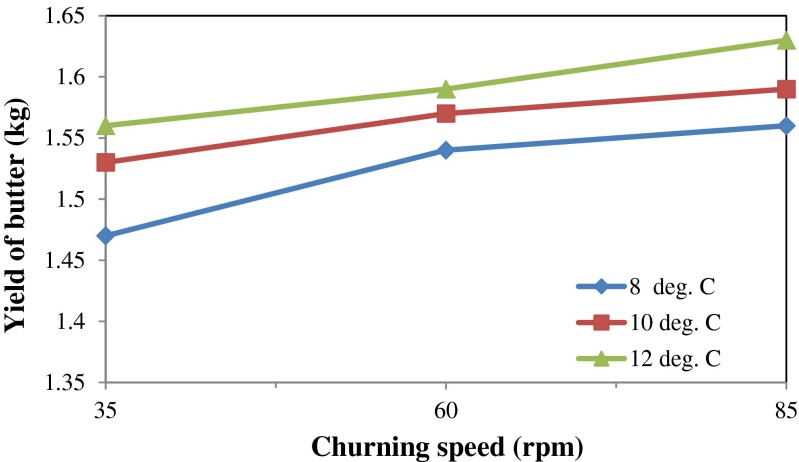

Overrun of butter

Figure 5 represents the effect of churning temperature and churn speed on overrun of butter produced by FCSBC. This shows the increasing trend in overrun of butter with increase in the churning temperature and churn speed. This might be due to the chemical composition of butter, with increase in churning temperature the fat content has decreased and water content increased. The excess water content and lower fat content might have increased the overrun. The highest overrun (24.41 %) was obtained at churning temperature of 12 °C and churn speed of 85 rpm. The present findings are in agreement with Siddique et al. (2011) who also conducted experiments at the temperatures of 8, 10 and 12oC for sweet cream butter from buffalo milk.

Fig. 5.

Effect of churning temperature and churn speed on the overrun of butter

The results pertaining to the effect of churning temperatures and churn speeds on the overrun of butter revealed that the overrun of butter samples is significantly (p ≤ 0.05) affected by the different churning temperature treatments and churn speed levels. The interaction effect of churning temperature and churn speed had shown a significant (p ≤ 0.05) effect on overrun of butter (Table 3).

Table 3.

Effect of churning temperature and churn speed on overrun and yield of butter

| Churn speed, rpm | Overrun of butter (%) | Yield of butter (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Churning temperature (oC) | Churning temperature (oC) | |||||||

| T1 (8° C) | T2 (10° C) | T3 (12° C) | Mean | T1 (8° C) | T2 (10° C) | T3 (12° C) | Mean | |

| 35 | 11.91 | 16.61 | 18.63 | 15.71 | 1.47 | 1.53 | 1.56 | 1.52 |

| 60 | 17.47 | 19.49 | 21.13 | 19.36 | 1.54 | 1.57 | 1.59 | 1.57 |

| 85 | 18.53 | 20.80 | 24.41 | 21.24 | 1.56 | 1.59 | 1.63 | 1.59 |

| Mean | 15.97 | 18.96 | 21.39 | 1.52 | 1.56 | 1.59 | ||

| Statistical analysis | Effect | CD0.05 | SEm± | Effect | CD0.05 | SEm± | ||

| CT | 0.16 | 0.06 | CT | 0.02 | 0.01 | |||

| CS | 0.16 | 0.06 | CS | 0.03 | 0.01 | |||

| CT x CS | 0.29 | 0.10 | CT x CS | 0.02 | 0.01 | |||

CT Churning temperature, CS Churn speed

Effect of churning temperature and churn speed on the yield of butter

The effect of churning temperature and churn speed on the yield of butter (on weight basis) is shown in Fig. 6. This revealed that the yield increased from 1.47 to 1.56 kg when temperature of churning increased from 8 to 12 °C at 35 rpm. More or less similar trend were observed when churn speed varied to 60 and 85 rpm, where the value varied between 1.54 to 1.59 kg and 1.56 to 1.63 kg, respectively when churning temperature varied from 8 to 12 °C. The increase in yield with increase in churning temperature might be due to increase in the overrun of butter. Funahashi and Horiuchi (2008) reported that cream temperature is the important factor for deciding the characteristics of churning process. The yield had also increased with increase in churn speed. This might be due to higher moisture penetration into butter aggregates during high speed churning (Fig. 7).

Fig. 6.

Effect of churning temperature and churn speed on the yield of butter

Fig. 7.

View of FCSBC and butter manufacturing. a Frustum Cone Shaped Butter Churn (FCSBC). b Formation of butter grains. c Worked and unloaded butter

The interaction effect between the churning temperature and churn speed had shown significant (p ≤ 0.05) effect on yield (Table 3). The yield of the butter was recorded to be highest 1.63 kg at highest temperature of 12 °C and higher churn speed of 85 rpm; however butter formed was weak and leaky. The lowest value recorded was 1.47 kg at lower temperature of 8 °C and lower churn speed of 35 rpm. The optimum yield of 1.56 kg was obtained where the butter formed with good texture at churning temperature of 10 °C and churn speed of 60 rpm.

Quality of butter milk

The quality of butter milk produced during the production of butter in the frustum cone shaped butter churn was evaluated. The per cent fat loss in butter milk was found to be minimum (0.5 %) at the churning temperature of 8 °C and churn speed of 35 rpm and it was maximum (1.2 %) at the churning temperature of 12 °C and churn speed of 85 rpm.

The quantity of butter milk obtained as a byproduct during the production of butter from 3.33 kg of standardized cream of 40 % fat was also determined at all the three different temperatures and three different churn speeds. It was found minimum of 1.188 kg at the churning temperature of 12 °C and churn speed of 85 rpm. The maximum quantity of butter milk (1.716 kg) was obtained at the combination of churning temperature of 8oC and churn speed of 85 rpm.

Conclusion

At churning temperature of 10 °C, churn speed of 60 rpm and with 40 min churning, butter of good consistency was obtained which had 82.7 % fat and 16 % moisture. However, maximum overrun (24.41 %) was obtained at higher churning temperature and higher speed but with good body and texture the optimum overrun (19.49 %) was obtained at churning temperature of 10 °C and churn speed of 60 rpm. Hence, it can be assumed that a mobile prototype of “Frustum Cone Shaped Butter Churn” has been successfully developed and tested. Performance of this prototype was found to be satisfactory under the churning temperature of 10 °C and churn speed of 60 rpm.

Contributor Information

A. K. Agrawal, Email: akagrawal.raipur@gmail.com

Geetesh Sinha, Email: geeteshsinha20@gmail.com.

References

- Anonymous Rising milk production future prospects. Indian Dairyman. 2014;66(7):15. [Google Scholar]

- BIS: SP18, part XI 1981, ISI Handbook of Food Analysis, Dairy Products. Bureau of Indian Standards, Manak Bhavan New Delhi, India 187

- Buldo P, Kirkensgaard JJK, Wiking L. Crystallization mechanism in cream during ripening and initial butter churning. J Dairy Sci. 2013;96:6782–6791. doi: 10.3168/jds.2012-6066. [DOI] [PubMed] [Google Scholar]

- Deel D (2013) Butter maker. U.S. Patent application 20130174748

- Deman JM, Beers AM. Fat crystal networks-structure and rheological properties. J Texture Stud. 1988;18(4):303–318. doi: 10.1111/j.1745-4603.1987.tb00908.x. [DOI] [Google Scholar]

- Eltayeb M and Mahjoub E (2003) The development of an improved churner for butter extraction. M. Tech Thesis, Appropriate Technology Department of National Center for Research, Sudan 24

- Funahashi H, Horiuchi J. Characteristics of the churning process in continuous butter manufacturing and modeling using an artificial neural network. Int Dairy J. 2008;18:323–328. doi: 10.1016/j.idairyj.2007.08.001. [DOI] [Google Scholar]

- Gupta CP, Prakash R. Engineering heat transfer. 6. Roorkee: Nem Chand and Bros; 1989. [Google Scholar]

- Holland RF, Herrington BL. The churning time of milk fat at different temperatures. J Dairy Sci. 1953;36(8):850–853. doi: 10.3168/jds.S0022-0302(53)91571-9. [DOI] [Google Scholar]

- ILRTM (1995) International livestock research institute training manual, Rural Dairy Technology 89

- Labuschangne HJ (1963) Churning in the absence of air. Ph. D. Thesis, Laboratory of Dairying, Wageningen Agricultural University, Netherlands 10

- Morin P, Pouliot Y, Britten M. Effect of buttermilk made from creams with different heat treatment histories on properties of rennet gels and model cheeses. J Dairy Sci. 2008;91:871–882. doi: 10.3168/jds.2007-0658. [DOI] [PubMed] [Google Scholar]

- NPCS (2014) Niir project consultancy service, Canada. Market research report on milk processing and dairy products in India, 120

- O’Mahony F. Rural dairy technology-experience in Ethiopia. Manual dairy tech unit. Addis Ababa: International Livestock Center for Africa; 1988. p. 4. [Google Scholar]

- Shahidi F (2005) Bailey’s industrial oil and fat products, 6th edn. Wiley, 3616

- Shukla A, Rizvi SSH. Viscoelastic properties of butter. J Food Sci. 1995;60:902–905. doi: 10.1111/j.1365-2621.1995.tb06257.x. [DOI] [Google Scholar]

- Siddique F, Khan ST, Ahmad A, Ahmed A, Gulfraz M, Wattoo HF. Development and optimization of sweet cream butter from buffaloes at cottage scale. Afr J Biotechnol. 2011;10(75):17265–17274. [Google Scholar]

- Singh R (2011) India dairy and products, annual report 2010. USDA Foreign agricultural service: global agricultural information network.

- Steel GD, Torrie H. Principle and procedures of statistics—a biometrical approach. 2. Singapore: Mc Graw- Hill, Inc; 1981. [Google Scholar]

- Sun JF, Kitamura Y, Satake T. Application of Stirling cooler to food processing: feasibility study on butter churning. J Food Eng. 2007;84:21–27. doi: 10.1016/j.jfoodeng.2007.04.020. [DOI] [Google Scholar]

- Sun JF, Congzhi Z, Jianlou M, Huiyong J, Zhixing S, Wang J. Tentative application of Stirling cooler technology in butter churning process. Eur Food Res Technol. 2013;237:223–228. doi: 10.1007/s00217-013-1972-3. [DOI] [Google Scholar]

- Wright AJ, Scanlon MG, Hartel RW, Marangoni AG. Rheological properties of milk fat and butter. J Food Sci. 2001;66:1056–1071. doi: 10.1111/j.1365-2621.2001.tb16082.x. [DOI] [Google Scholar]