Abstract

Mango kernel contains about 15 % good quality edible oil, that is comparable to soybean and cottonseed, which contain about 18–20 % oil. Mango kernel oil (MKO) has lower free fatty acids, carotenoid content and peroxide value, and is usually used without any processing, which is otherwise mandatory for commercial vegetable oils. Palmitic, stearic and oleic acids are the major fatty acids, triglyceride composition and fatty acid profile suggest wide range of trans free options. With 32–36 °C melting point, MKO is solid at room temperature, thus, does not require partial hydrogenation for application in foods. MKO can be used as an alternative of cocoa butter, which is used in chocolates and confectionaries. Total phenolic contents and induction period of MKO is greater than many commercial vegetable oils; thus, it can be used as an alternative of synthetic antioxidants for the preservation of fats and oils. Mangiferin, chlorogenic acid, quercetin and caffeic acid are the major phenolic compounds present in MKO. Functional properties of MKO can be further improved through fractionation, transesterification and interesterification for increased industrial applications.

Keywords: Mango kernel oil, Nutritional value, Fatty acid composition, Antioxidant characteristics

Introduction

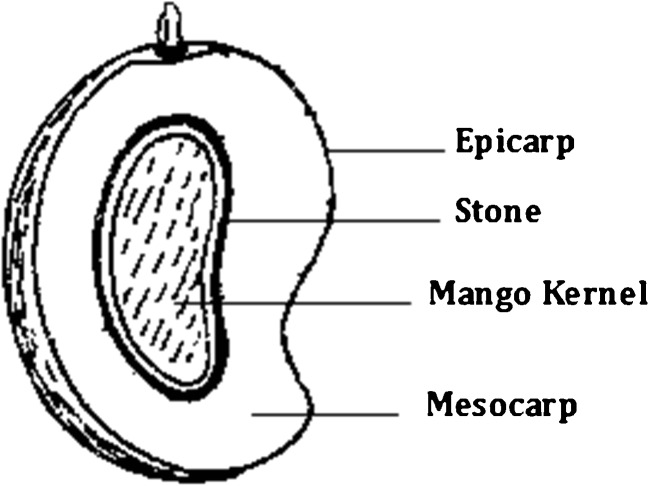

Mango (Mangifera indica L.) is widely produced in tropical and subtropical regions of the world, it is ranked on 5th position among the major fruits, cultivated in more than 100 countries of the world and annually growing at the rate of 2.7 % (Fowomola 2010). Mango is rightly recognized as king of the fruit due to its eye-catching colour, pleasant taste, existence of higher concentrations of carotenoids, ascorbic acid and phytochemicals (Pott et al. 2003). About 80 % of the fruit is consumed as such; remaining 20 % is processed into value added products, such as, mango puree, nectar, pickles, chutneys and canned stuffs. Enough scientific information is available regarding the nutritional importance of mango waste. From environmental and food insecurity perspectives, it is extremely important to efficiently utilize mango waste, for safer environment and feeding of ever increasing human population. Particularly, the issue of food insecurity in Asia and Africa in the coming 35–50 years may lead to hunger and starvation (FAO 2006). Mango kernel represents about 20 % of the whole fruit and 75 % of the stone (Ahmed et al. 2007). Mango kernel oil (MKO) may be defined as oil fraction extracted from stone of mango fruit. Mango kernel produces 12–15 % edible oil (Tables 1 and 2), Studies have disclosed that mango kernel is a potential source of wide range of bioactive compounds and antioxidants (Jafari et al. 2014). Cardio and hepatic protective effects, anticarcinogenic, anti-ageing effects of phenolic compounds are scientifically proven (Mohdaly et al. 2011). MKO can be utilized for the preservation of fats and oils, supplementation of sunflower oil and tallow with MKO, improved their oxidative stability (Abdalla et al. 2007; Jafari et al. 2014). Unfortunately, the massive nutritional and commercial potential of MKO is not fully utilized. Chemical characterization of mango kernel revealed that oleic acid is the major fatty acid, followed by palmitic and stearic acids, solid fat index of MKO was zero at human body temperature, the melting point ranges from 32 to 36 °C, which offers wide range of applications in trans free options, without partial hydrogenation and as a cocoa butter substitute (Kittiphoom and Sutasinee 2013). On account of abundant mango production, neutraceutical characteristics, MKO has the potential to become a commercial source of edible oil. This paper summarizes the promising features of MKO for better industrial and domestic utilization (Fig. 1).

Table 1.

Oil content of some oil producing plants

| Source | Oil content% | Reference |

|---|---|---|

| African Bush Mango | 55.7 | Olawale (2010) |

| Thai Mango | 13–15 % | Kittiphoom and Sutasinee |

| Sesame Seeds | 55–60 | Kochhar (2000) |

| Palm Fruit | 45–50 | Siew (2000) |

| Chia Oil | 35–40 | Ullah et al. (2015) |

| Moringa oleifera | 25–30 | Nadeem et al. (2012) |

| Palm Kernel | 46–50 | O’Brien (2008) |

| Sunflower | 37–42 | Shahidi (2005) |

| Soybean | 18–20 | Erickson (1995) |

| Cottonseed Oil | 18–20 | Azeem et al. (2015b) |

| Watermelon Seed Oil | 35–40 | Azeem et al. (2015a, b); Raziq et al. (2012) |

| Olive | 60–65 | Gutierrez-Rosales et al. (2003) |

| Babessu | 25–30 | Olawale (2010) |

| Lemon | 40–42 | Anwar et al. (2008) |

Table 2.

Proximate composition of mango kernel cake

Fig. 1.

Pictorial diagram of mango fruit

Botanical description of mango plant

Mango belongs to genus Mangiera, family Anacardiaceae, species Mangifera indica L., height of plant may vary from 10 to 15 M, Dome, dense foliage, thick branch from strong trunk, leaves Spirally arranged on branches, linear-oblong, lanceolate-elliptical, pointed at both ends, leaf blades about 25 cm long and 8 cm wide. Colour of freshly produced leaves is red and delicately flaccid, which produce aromatic sensation after crushing, fruit large dupe, yellow pulp, single seed, with yellow skin colour after ripening, seed solitary, ovoid or quadrilateral, enclosed in a firm, compressed stringy endocarp (Shah et al. 2010).

Physical and chemical characteristics of MKO

Fahimdanesh and Bahrami (2013) reported that MKO had 30 °C melting point, 55 iodine value, 42–44 % unsaturated and 52–56 % saturated fatty acids. Oleic acid was the major fatty acid in MKO which accounts for about 45 %, followed by stearic acid (Soong et al. 2004). Oil was extracted from mango kernels by hexane on a soxhlet extraction apparatus; results showed that mango seed kernel consisted of 10.2 % oil with 55 % saturated and 45 % unsaturated fatty acids (Jafari et al. 2014). Kittiphoom and Sutasinee (2013) extracted oil from mango seed, oil was characterized for chemical composition, oil yield varied from 6.96 to 8.04 %, acid value, iodine value, peroxide value (meqO2/kg) and saponification value was 27.55, 59, 0.26 and 206 (Table 3). Oil from “Chaunsa” a promising variety of mango in Pakistan was extracted by n-hexane, characterization of oil revealed that yield of MKO was 14.5 %, free fatty acids 0.22 %, moisture content 0.18 %, melting point 35.2 °C, iodine value 55.2, saponification value 195, unsaponifiable matter 1.77 %, refractive index 1.452, peroxide value 0.22 (meqO2/kg). Lovibond scale showed colour of MKO was Red 1.7 + 17 Yellow (Nadeem et al. 2015). Iodine value of MKO derived from different varieties varied from 40 to 9 to 56.8 cg iodine/100 g oil, Kaew variety grown in Thailand revealed the lowest iodine value, whereas the Kenyan varieties had the highest iodine value with no difference in iodine value of MKO extracted from Indian, Bangladeshi and Malaysian varieties, melting point of MKO of different countries ranged from 25 to 47 °C (Muchiri et al. 2012; Sonwai et al. 2012). Gross energy and available energy of mango kernel were 1782 and 1576 KJ/ 100 g (Daniel et al. 2012).

Table 3.

Physical and chemical characteristics of MKO

| Parameter | MKO Crude |

Palm Oil RBD* |

Soybean Oil Crude |

Sunflower Oil Crude |

|---|---|---|---|---|

| FFA% | 0.22 | 0.08 | 0.86 | 0.55 |

| *Colour | R2.8 + 30Y | R2.5 + 25Y | R5.8 + 52Y | R1.8 + 16Y |

| Moisture% | 0.21 | 0.18 | 0.15 | 0.24 |

| Iodine Value | 54.6 | 53.4 | 132.7 | 121–125 |

| Refractive Index | 1.457 | 1.455 | 1.468 | 1.472 |

| Melting Point °C | 35.2 | 38–42 | −10.5 | −13.2 |

| SV | 193 | 193 | 195 | 205 |

| USM% | 1.68 | 0.65 | 1.25 | 1.12 |

| PV (meqO2/kg) | 0.65 | 0.45 | 2.85 | 4.55 |

| Reference | Abdel-Razik et al. (2012); Azeem et al. 2015a, b | Sambamurthi et al. (2000) | Rowe et al. (2006) | Shahidi (2005) |

MKO mango kernel oil, *RBD refined, bleached and deodorized, SV saponification value, USM unsaponifiable matter, PV peroxide value *R red, Y yellow (Lovibond Tintometer Scale)

Triglyceride profile of MKO

Triglycerides constitute about 98–99.5 % of fats and oils, composed of wide range of fatty acids attached to glycerol. Most commonly reported triglycerides of MKO are 1,3-distearoyl-2-oleoyl-glycerol (SOS), which constitutes about 29.4 to 40 %, 1-stearoyl-2,3-dioleoylglycerol (SOO) approximately 14.6 to 23 %, 1-palmitoyl-2-oleoyl-3-stearoylglycerol (POS) and 1,3-dipalmitoyl-2-oleoylglycerol (POP) which comprises about 5.7–14.76 and 6.89–8.9 % of the triglyceride portion of MKO (Jahurul et al. 2014a). Studies have shown that use of SOS rich fats in chocolates and confectionery can improve the solid fat index, bloom inhibition and decrease tempering time (Maheshwari and Reddy 2005). Sonwai et al. (2012) reported that magnitudes of POS, SOS, SOO, POO, POP, and OOO triglycerides in Kaew variety of Thailand were 5.7 %, 29.7 %, 14.6 %, 10.8 %, 2.5 %. The extents of POS, SOS and POP triglycerides in water lily variety of Malaysia were 14.76, 39.28 and 6.89 % (Jahurul et al. 2014b).

Trans free options

Clinical studies have demonstrated that trans fatty acids are not required for any physiological / metabolic function in human body; rather, they proliferate the harmful LDL cholesterol and decrease the beneficial HDL cholesterol (Lokuruka 2007). Most of the trans fatty acids enter in human body through partially hydrogenated fats, partial hydrogenation of oils is usually performed to enhance the functional properties (plasticity, melting point, solid fat index) or to improve the storage stability (Shahidi 2005). Fatty acid composition of MKO is presented in Table 4. Vanaspati and bakery margarines contain higher magnitude of trans fatty acids. Nadeem et al. (2014a) reported that extent of trans fatty acids in market vanaspati was more than 20 %. MKO is solid at room temperature (Table 5), it does not require partial hydrogenation for usage in food products and secondly MKO is extremely resistant to auto-oxidation (Abdalla et al. 2007; Kittiphoom and Sutasinee 2013). Sterol composition of MKO is presented in Table 6. Margarines were prepared from MKO and palm blends, textural and chemical characteristics of margarine comprising 70 % MKO and 30 % palm oil was similar to bakery margarine, formulated from partially hydrogenated fats. To assess the suitability of margarine (70 % MKO and 30 % palm oil) as bakery shortening, muffins were prepared by replacing commercial shortening (partially hydrogenated) in various proportions from 25 to 100 %. Results evidenced that physical, chemical and textural attributes of muffins prepared from 50 % commercial shortening and 50 % MKO based shortening were better than muffins prepared from commercial shortening alone. Replacement of MKO with partially hydrogenated shortening improved the concentration of oleic acid, stearic acid and decreased the magnitude of harmful trans fatty acids (Jeyarani et al. 2015). Clinical evidences have established that stearic acid does not have any correlation with atherogenicity and regarded as neutral fatty acid, the role of monounsaturated fatty acids in the reduction of cholesterol is scientifically established (Ivanova et al. 2010). The suitability of non-traditional oils in the development of trans free vanaspati is documented in literature. Nadeem et al. (2014a) studied the assessment of transesterified blends of Moringa oleifera oil and palm olein, physical, chemical and sensory characteristics of trans free vanaspati were not different from partially hydrogenated vanaspati. Shortening was prepared by blending high-melting fraction of Mahua fat and mango middle stearin fraction in 80 and 20 % ratios. Melting characteristics, onset and enthalpy of crystallization was comparable to commercial hydrogenated bakery shortenings. Shortening for puff pastry was prepared by blending 50 % MKO 1st stearin and 50 % mahua fat with 5–7 % fully hydrogenated oil. Cake and biscuit shortening was formulated using 40 % mango fat, 60 % mahua fat and 5–7 % vegetable oil of zero iodine value. Melting characteristics of these trans free shortening were not different from the commercially used hydrogenated shortenings. Fatty acid profile of shortenings prepared from partially hydrogenated stuffs revealed that they had 18–29 % trans fatty acids, whereas, formulations based on MKO and mahua fat did not reveal trans fatty acids (Reddy and Jeyarani 2001). In another study, bakery shortenings were prepared from mango kernel oil and palm stearin through lipase catalysed transesterification. Melting point, solidification characteristics and plasticity of trans free shortenings were equivalent to commercial hydrogenated shortenings (Shetty et al. 2014).

Table 4.

Fatty acid composition of MKO

| Fatty Acid | MKO | Palm Oil | Butter Oil | Sunflower Oil | PO | PS | PMF |

|---|---|---|---|---|---|---|---|

| C4:0 | – | – | 3.7 | – | – | – | – |

| C6:0 | – | – | 2.3 | – | – | – | – |

| C8:0 | – | – | 1.3 | – | – | – | – |

| C10:0 | – | – | 3.1 | – | – | – | – |

| C12:0 | – | 0.2 | 4.4 | – | 0.10 | 0.58 | 0.1 |

| C14:0 | – | 1.1 | 12.3 | – | 1.24 | 1.85 | 0.8 |

| C16:0 | 7.43 | 44.7 | 31.0 | 6.42 | 37.9 | 73.8 | 52.8 |

| C18:0 | 37.5 | 4.2 | 8.8 | 1.77 | 4.11 | 5.6 | 6.7 |

| C18:1 | 45.59 | 39.2 | 23.8 | 47.25 | 43.9 | 15.6 | 34.7 |

| C18:2 | 5.48 | 9.5 | 2.2 | 48.14 | 13.4 | 3.2 | 3.9 |

| C18:3 | 0.40 | 0.5 | – | 0.08 | 0.45 | 0.12 | 0.1 |

| C20:0 | 2.48 | 0.40 | – | – | 0.38 | 0.6 | – |

| C22:0 | 0.45 | – | – | – | |||

| C24:0 | 0.40 | – | – | – | |||

| Reference | Abdel-Razik et al. (2012) | Kaphueakngam et al. (2009) | Nadeem et al. (2015) | Anwar et al. (2007) | Shahidi (2005) | Shahidi (2005) | Shahidi (2005) |

MKO mango kernel oil, PO palm olein, PS palm stearin, PMF palm mid fraction

Table 5.

Solid fat index of MKO

| Temperature °C | Crude MKO | Refined MKO | Palm Oil | Butter |

|---|---|---|---|---|

| 10 | Not Reported | Not Reported | Not Reported | 36.5 |

| 15 | Not Reported | Not Reported | Not Reported | 32.7 |

| 20 | 55.5 | 55 | 23 | 18.2 |

| 25 | 53.2 | 53 | 16 | 6.8 |

| 30 | 52.8 | 52.1 | 9.8 | 4.7 |

| 35 | 0 | 0 | 6.9 | 3.2 |

| 40 | Not Reported | Not Reported | 3.1 | 0 |

| Reference | Mahale et al. (2011) | Mahale et al. (2011) | Shahidi (2005) | Gonzalez et al. (2003) |

Table 6.

Sterols in MKO

| Sterol | MKO | Sunflower Oil | Soybean | Rapeseed |

|---|---|---|---|---|

| Campesterol | 0.07 % | 10.29 | 16.94 | 9.28 |

| Stigma sterol | 10.66 | 7.51 | 16.64 | 0.18 |

| β-Sitosterol | 58.63 | 58.01 | 54.36 | 50.28 |

| ∆5 - Avenasterol | 10.19 | 1.26 | 1.19 | 1.11 |

| ∆7 – stigmasterol | 4.34 | 9.72 | 4.28 | 0.11 |

| ∆7- Avenasterol | 19.10 | 5.54 | 1.77 | 0.06 |

| Reference | Dhara et al. (2010) | Bohacenko and Kopicova (2001) | ||

Antioxidant characteristics

Detail of antioxidant characteristics, phenolic contents and free radical scavenging activity of MKO is described in Tables 7, 8 and 9. The use of MKO for the preservation of some foods has been reported (Abdel-Razik et al. 2012; Legesse and Emire 2012). Mango kernel powders at different levels were evaluated for rheological, physical, sensory and antioxidant properties in biscuits. The results showed that phenolic contents of biscuit increased from 3.84 to 24.37 mg/g, with different levels of MKP. Maisuthisakul (2008) evaluated the antioxidant potential of Thailand mango kernel using 1-diphenyl-2-picrylhydrazyl (DPPH) radicals and phenolic compounds of the ethanolic kernel extracts. All the samples demonstrated antioxidant activities comparable to α-tocopherol. The phenolic acids of MKO were in free form and their concentration was 42–56 %, as compared to esterified esters 10–19 %) and magnitude of insoluble bound phenolic acids were 15–20 % (Maisuthisakul 2008). MKO possesses the highest induction period of all edible oils and fats (Table 10).

Table 7.

Antioxidant activity of MKO for the stabilization of foods / food uses

| Form Use and Substrate | Result | Reference |

|---|---|---|

| MKO was blended with tallow at 1, 5 and 10 % concentrations | Supplementation of tallow with MKO considerably inhibited the lipid peroxidation at all the concentrations | Jafari et al. (2014) |

| Watermelon oil was added with MKO at four different concentrations i.e., 5, 10, 15 and 20 %. All the blends were stored in transparent PET bottles at ambient temperature (25-28 °C) for 3 months; storage stability was assessed at the interval of 1 month | After 3 months of ambient storage, MKO altered the oxidation of highly unsaturated watermelon seed oil, inhibited the oxidation of linoleic and linolenic acids into oxidation products. Induction period of watermelon seed fortified with MKO was significantly higher than unfortified samples. | Azeem et al. (2015a, b) |

| Sunflower oil was blended with MKO at various concentrations. | Supplementation of sunflower oil with MKO considerably improved the oxidative stability of sunflower oil | Abdalla et al. (2007) |

| Oxidative stability of Buffalo fat added with 5 % MKO was compared with sunflower oil containing 300 ppm TBHQ; both the samples were stored in the dark for 12 months. | After the storage period, peroxide value and anisidine value of Buffalo fat supplemented with 5 % MKO was lesser than sunflower oil which was supplemented with 300 ppm TBHQ | Youssef (1999) |

| Bologna-type mortadella was formulated using 50%Beef, 35%pork and 15 % back fat. Mango seed extract (0.1 and 0.2 %) and BHT 0.1 % were used as antioxidants, stored at refrigeration temperature for 21 days. | Addition of mango seed extract significantly inhibited the auto-oxidation, after 14 days of storage period, TBA value of samples supplemented with mango seed extract was lesser than BHT with better colour score | Pereira et al. (2011) |

| Edible oil was fortified with catechin mixture of MKO at 1–3 % concentration, samples added with 300 ppm BHT were used as control | Fortification of edible oil with catechin mixture of MKO inhibited the oxidation of edible oil more efficiently than 300 ppm BHT | Zein et al. (2005) |

| Biscuits were prepared using mango kernel powder at 20, 30, 40 and 50 % concentrations | Addition of mango kernel power improved the antioxidant characteristics of biscuits, optimum concentration of mango kernel powder was found to be 40 %. Addition of mango kernel powder improved the nutritional value and storage stability of biscuits | Ashoush and Gadallah (2011) |

| Production from cocoa butter equivalent from MKO and palm mid fraction. MKO was added in palm mid fraction from 10 to 100 % butter | Blend comprised of 80 % MKO and 20 % palm mid fraction, yielded a better alternate of cocoa butter | Kaphueakngam et al. (2009) |

| Biscuits were prepared by replacing wheat flour with mango kernel powder up to 30 % concentration | Physical, chemical and sensory characteristics of cookies prepared by partially replacing wheat flour with MKO up to 30 levels did not have any effect on physical, chemical and sensory characteristics; rather it improved the colour and storage stability of biscuits. | Legesse and Emire (2012) |

| Muffins were prepared by replacing shortening at 25, 50 and 100 % concentrations | Muffins prepared from MKO and shortening blends were tenderer, with better colour, higher total phenolic contents. These results evidenced that MKO can be replaced with shortening up to 50 % level, with improved functional properties and nutritional characteristics | Abdel-Razik et al. (2012) |

| Antioxidant activity of ethanolic MKO was tested for the stability of frying oils using BHA as positive control | Oxidative and thermal stability of frying oil supplemented with 0.5 % mango kernel extract was greater than BHA. It strongly inhibited the oxidation of fatty acids into oxidation products | Mostafa (2013) |

| Butter oil was blended with 2.5 to 10 % MKO, stored at 25 °C and 50 °C for 90 days. | MKO altered the oxidation in both ambient and accelerated oxidation, significantly inhibited the lipid peroxidation. After 90 days of storage at both the storage temperatures, breakdown of oleic acid and linoleic acid in MKO supplemented samples was less than control, with lower levels of primary and secondary oxidation products and improved induction period | Nadeem et al. (2015) |

| Safety Aspects of MKO | MKO was found to be nutritious source of edible oil with no existence of toxic compounds, such as, hydrocyanic acid | Rashwan (1990) |

Table 8.

Total phenolic contents of MKO and vegetable oils

| Plant Source | TPC mg/g | Reference |

|---|---|---|

| MKO | 9.87 | Kittiphoom, and Sutasinee (2013) |

| Mango Kernel | 16.93 | Maisuthisakul (2008) |

| Mango Kernel | 11.7 | Soong and Barlow (2006) |

| Chia Oil | 3.62 | Ullah et al. (2016) |

| Olein Fraction of Chia Oil | 4.25 | Ullah et al. (2016) |

| Stearin Fraction of Chia Oil | 2.57 | Ullah et al. (2016) |

| Almond Peel | 3.82 | Nadeem et al. (2014b) |

| Moringa oleifera Oil | 7.1 | Nadeem et al. (2013) |

| Sesame Cake | 1.84 | Nadeem et al. (2014c) |

| Chia Seed Extract | 7.6 | Azeem et al. (2015a, b) |

| Sugarcane Juice | 6.19 | Ullah et al. (2015) |

| Date Fruit Extract | 5.19 | Rahman et al. (2015) |

| Tamarind seed | 9.45 | Soong and Barlow (2006) |

| Longan seed | 6.26 | Soong and Barlow (2006) |

| Avocado seed | 8.82 | Soong and Barlow (2006) |

| Jackfruit seed | 2.77 | Soong and Barlow (2006) |

TPC total phenolic contents

Table 9.

Comparison of the DPPH free radical scavenging activity of mango kernel with some strong natural antioxidant sources

| Radical Type | Antioxidant Source | Inhibition% | Reference |

|---|---|---|---|

| DPPH | Methanolic Extract of Mango Kernel | 74 | Kaur et al. (2010) |

| Mango Kernel Powder | 96 | Ashoush and Gadallah (2011) | |

| Ethanolic Chia Seed Extract | 65 | Azeem et al. (2015a, b) | |

| Sesame Cake Extract | 71 | Nadeem et al. (2014c) | |

| Almond Peel Extract | 80 | Nadeem et al. (2014b) | |

| Date Fruit Extract | 82 | Rahman et al. (2015) |

Table 10.

Induction period of MKO and some vegetable oils

| Oil Type | Induction Period (Hours) | Reference |

|---|---|---|

| MKO | 85.2 | Jafari et al. (2014), Abdalla et al. (2007) |

| Palm Oil | 10.4 | Shahidi (2005) |

| SBO | 4.27 | Erickson (1995) |

| Canola Oil | 5.84 | Anwar et al. (2007) |

| Sunflower Oil | 3.51 | Anwar et al. (2007) |

| Winterized Cottonseed Oil | 3.82 | Azeem et al. (2015a, b) |

| Moringa oleifera Oil | 10.8 | Nadeem et al. (2013) |

| Chia Oil | 1.32 | Ullah et al. (2016) |

| Watermelon Seed Oil | 4.1 | Azeem et al. (2013) |

| Butter Oil | 9.75 | Nadeem et al. (2015) |

Toxicological evaluation of MKO

Toxicological assessment of MKO was performed in multi-generation breeding trials in weanling albino rats. MKO was included in protein based diet at 10 and 20 % concentrations, compared with a control group that was fed on groundnut oil. Feed efficiency-ratio, digestibility and growth performance of rats fed on MKO were not significantly different from the control group. Toxicological studies evidenced no difference in reproductive performance, serum, liver, total cholesterol, total lipids, triglycerides and organ weight from the control. Histopathological evaluation of organs did not reveal any abnormality. These results suggested that MKO can be substituted with any fat with no toxic effects (Rukmini and Vijayaraghavan 1984). Comparison of cholesterol content of MKO and dairy products is presented in Table 11, MKO is cholesterol free (Tables 12 and 13).

Table 11.

Cholesterol in MKO and some dairy products

| Product | Cholesterol mg/100 g | Reference |

|---|---|---|

| MKO | ND | Mostafa (2013) |

| Buffalo Milk | 0.19 | Talpur et al. (2007) |

| Cow Milk | 0.37 | Nadeem et al. (2013) |

| Butter | 220 | Kwak et al. (2002) |

| Cheddar Cheese | 180 | Lee et al. (2007) |

| Ice Cream | 110 | Nadeem et al. (2015b) |

| Olein Fraction of Milk Fat | 280 | Nadeem et al. (2015b) |

ND not detected

Table 12.

MKO as skin curative

| Ailment/ Use | Skin Curative | |

|---|---|---|

| MKO | Dry Skin and Frost Bites | Application of MKO on dry skin efficiently treats dry skin, moisturizes, impart softness to skin and protects from frost bites |

| Rashes | Rashes are sever problem in hot and humid climate, very painful for the babies as well, MKO possesses wide range of potentially active phenols and bioactive compounds which acts as anti-rash agent | |

| Blemishes and wrinkles | MKO has the ability to remove blemishes and its phenols fight against ageing | |

| Itching skin | MKO is a rich source of phenolic compounds, phenols have antibacterial activity, mango kernel help curing skin itching | |

| Sun Screen | MKO is widely used in many cosmetics, it has the properties of acting as sun screen and healing of sun burnt skin | |

| Shaving Cream | Fatty acid and triglyceride composition of MKO confers it a unique of feature of using in shaving creams for a smooth shave with less skin irritation, it can also minimize the use of after shave (antiseptic agents) | |

| Wounds and Cracks, dermatitis | Skin cracking is a serious problem, use of MKO on skin cracks offers a quick recovery, it can also be used as crack and dermatitis preventer | |

| Stretch Marks during Pregnancy | Stretched marks during and after pregnancy is a serious problem, they result in ugly appearance, application of MKO during and after pregnancy not only avoid the formation but also removes the stretched marks | |

| Muscle Fatigue, Aches and Tension | Use of MKO relives pain from fatigued muscles, it also acts as antidepressant due to the presence of phenolics |

Table 13.

Future uses of MKO

| Product | Probable Use | Use of Formulated Products |

|---|---|---|

| Vanaspati | %Palm Oil: MKO% 80:20 60:40 40:60 80:20 |

Cooking, Frying, Baking, Coating of Chapattis, Barbecues etc. |

| Blending with Butter Oil | %Butter Oil: MKO% 95:5 90:10 85:15 80:20 |

Long term preservation of butter oil at ambient temperature, to replace BHA, BHT and TBHQ |

| Dairy Whitener Vegetable Based Milk Powder Fractions of MKO |

For Tea Whiteners Replacement of palm oil for the manufacturing of vegetable filled milk powder Mango kernel olein Mango kernel super olein |

For Whitening of Coffee and Tea Ice cream, milk Shake For vanaspati uses, better choice of health conscious communities Bakery shortening, sandwich cream, |

| MKO stearin MKO super stearin |

soap, Animal Feeding | |

| Neutraceutical | Fraction having higher concentration of antioxidants and bioactive compounds | Health Booster |

| Bakery Shortening Stearin Fraction |

MKO and its stearin fraction can be used shortening | Cakes, Cookies, Muffins, coating of baking trays, bread and cake moulds |

| Ice cream and frozen desserts | MKO is solid at room temperature, fatty acid and triglyceride composition suggest probable applications in ice cream and frozen desserts | Ice cream, frozen desserts |

| Whipped cream products | MKO can be used as replacement of palm kernel for the manufacturing of whipped cream products, however, it should need further research | Topping of cakes, pastries etc. |

Economic importance and potential of MKO as a source of edible Oil on commercial scale

According to an estimate, mango kernel waste can produce 123,000 M. Tons good quality edible oil, with superior functional and oxidative stability characteristics. Fatty acid profile, triglyceride composition and melting characteristics of MKO suggest that it can be used as alternative of palm oil (Kittiphoom and Sutasinee 2013). Free fatty acids and colour are regarded as two most important parameters for the assessment of quality of crude oils, literature review evidenced that MKO is pale yellow in colour, which does not require pre-bleaching, all commercial oils, such as palm oil, require refining, bleaching and deodorization prior to utilization. Light pale yellow colour of MKO can be attributed to the lower content of carotenoids (Mostafa 2013). The second important criterion for the quality of crude oils is the concentration of free fatty acids. Free fatty acids are produced as a result of hydrolysis of triglycerides, lipases, moisture, heat and metal ions are the important catalysts of hydrolysis (Shahidi 2005). Several studies have shown that free fatty acids of MKO were less than commercially available crude oils (Arogba 1999). Free fatty acids of crude soybean oil, canola oil and sunflower oil generally ranged from 0.4 to 0.85 %. Free fatty acids are odoriferous compounds and impart objectionable flavour to the foods (Erickson 1995). The role of free fatty acids in the breakdown and acceleration of primary oxidation products, auto-oxidation of fats and oils is scientifically proven (Anwar et al. 2010). Peroxide value of oils and fats is considered as an important parameter for the estimation of magnitude of primary oxidation products and oxidation status of fats and oils (Anwar et al. 2010). Peroxide value is used as an indication of storage stability of oils and fats, lower values usually indicate better storage / oxidative stability. MKO has the lower peroxide value as compared to commercial vegetable oils (Kittiphoom 2012). Lower peroxide value of crude mango kernel can be attributed to the existence of higher concentration of phenols and balanced fatty acid composition. The lower levels of peroxide can also be connected with higher induction period of MKO. Theobroma cacao seed produce precious fat, the specific physical and chemical characteristics of this fat offers great deal of utilization in many confectionery and chocolate products (Beckett 2000). Cocoa butter is mainly comprised of palmitic acid, stearic acid and oleic acid, the higher price of cocoa butter has led the food industry to find alternative sources of cocoa butter, with similar physical and chemical characteristics. Kaphueakngam et al. (2009) reported that MKO can be the alternative source of cocoa butter, the concentration of palmitic, stearic and oleic acid was almost similar to cocoa butter, when MKO and palm oil were blended in 80:20 ratios. Melting point and melting behaviour of this blend was not different from cocoa butter. Thermal behaviour of MKO has obtained enormous interest of the scientists, Jahurul et al. (2014a) compare the thermal behaviour of MKO with cocoa butter, melting and crystallization behaviour of MKO closely resembled with each other.

Refining is a costly affairs, massive electrical and steam power is required to produce bland vegetable oils (Shahidi 2005). Roughly, 2 M. ton steam is required for the processing of 1 M. ton vegetable oil, Sunflower, soybean, canola oils have limited functional properties, without partial hydrogenation, they can only be used as cooking oil/ salad oils. These oils have higher concentration of polyunsaturated fatty acids, for better oxidative stability, partial hydrogenation is usually performed. The relation between partial hydrogenation and generation of harmful trans fatty acids is scientifically evidenced (Nadeem et al. 2014a).

MKO is currently used in the manufacturing of cosmetics, candles, soap, biscuits, muffins and as cocoa butter alternative (Abdel-Razik et al. 2012). According to the anticipations of WHO, about 2 billion people will be added to the population of Asia and Africa (FAO 2006). The situation of food security is getting worst day by day, nature has blessed mankind with over 500,000 oil yielding plants, but it is our failure that we are just utilizing only 12 on commercial scale. From Table 2 it is evident that watermelon and lemon seed produce about 40 % good quality oil, however, they are not used on commercial level. New sources of foods must be discovered to feed the ever increasing human population. MKO possesses the potential to become a commercial source of edible oil.

Application of MKO in non-food goods and future uses

Skin curative perspectives and future uses of mango kernel oil is presented in 12 and 13. MKO is extensively used in cosmetic industry as base and sunscreen; it is preferred over other lipids because it has numerous natural antioxidants and minerals such as, selenium, copper, zinc etc. (Schiber et al. 2003).

Acknowledgments

The authors are obliged to all the researchers, scientists and contributors whose work has been included in this review. Financial assistance for this work was provided by Pakistan Agricultural Research Council (ALP).

References

- Abdalla EM, Darwish SM, Ayad EHE, EL-Hamahmy RM. Egyptian mango by-product. Atioxidant and antimicrobial activities of extract and oil from mango seed kernel. Food Chem. 2007;103:1141–1152. doi: 10.1016/j.foodchem.2006.10.026. [DOI] [Google Scholar]

- Abdel-Razik MM, Ashoush IS, Yassin NMN. Characteristics of mango seed kernel butter and its effects on quality attributes of muffins. Alex J Fd Sci Technol. 2012;9(2):1–9. [Google Scholar]

- Ahmed EM, Saied MD, Eman HE, Reham ME. Egyptian mango by- product compositional quality of mango seed kernel. Food Chem. 2007;103:1134–1140. doi: 10.1016/j.foodchem.2006.10.017. [DOI] [Google Scholar]

- Anwar F, Hussain AI, Iqbal S, Bhanger MI. Enhancement of the oxidative stability of some vegetable oils by blending with Moringa oleifera oil. Food Chem. 2007;103:1181–1191. doi: 10.1016/j.foodchem.2006.10.023. [DOI] [Google Scholar]

- Anwar F, Naseer R, Bhanger MI, Ashraf S, Talpur FN, Aladedunye FA. Physico-chemical characteristics of citrus seeds and seed oils from Pakistan. J Am Oil Chem Soc. 2008;85:321–330. doi: 10.1007/s11746-008-1204-3. [DOI] [Google Scholar]

- Anwar F, Qayyum HMA, Hussain AI, Iqbal S. Antioxidant activity of 100 and 80 % methanol extracts from barley seeds (Hordeum vulgare L.): stabilization of sunflower oil. Grasas Aceites. 2010;61:237–243. doi: 10.3989/gya.087409. [DOI] [Google Scholar]

- Arogba SS. The performance of processed mango (Mangifera indica) kernel flour in a model food system. Bioresour Technol. 1999;70:277–81. doi: 10.1016/S0960-8524(99)00028-0. [DOI] [Google Scholar]

- Ashoush IS, Gadallah MGE. Utilization of mango peels and seed kernels powders as sourcesof phytochemicals in biscuit. World J Dairy Food Sci. 2011;6(1):35–42. [Google Scholar]

- Azeem MW, Nadeem M, Ahmad S. Stabilization of witnerized cottonseed oil through chia (Salvia hispanic L.) seed extract. J Food Sci Technol. 2015 [Google Scholar]

- Azeem W, Nadeem M, Sajid R. Analytical characterization of pure and blended watermelon (Citrullus lanatus) Oil: impact of blending on oxidative stability. Pak J Anal Environ Chem. 2015;16:52–58. [Google Scholar]

- Beckett ST. The science of chocolate. Cambridge: The Royal Society of Chemistry; 2000. p. 175. [Google Scholar]

- Bohacenko I, Kopicova Z. Detection of olive oils authenticity by determination of their sterol content using LG/GC. Czech J Food Sci. 2001;3:97–103. [Google Scholar]

- Choi SW, Lee S, Kim EO, Oh JH, Yoon KS, Parris N, Moreau RA. Antioxidant and antimelanogenic activities of polyamineconjugates from corn bran and related hydroxycinnamic acids. J Agri Food Chem. 2007;55:3920–3925. doi: 10.1021/jf0635154. [DOI] [PubMed] [Google Scholar]

- Daniel M, Symon M, Simon G. Studies on Mango (Mangifera indica, L.) Kernel fat of some Kenyan varieties in Meru. J Am Oil Chem Soc. 2012;9:1567. [Google Scholar]

- Dhara R, Bhattacharyya DK, Ghosh M (2010) Analysis of sterol and other components present in unsaponifiable matters of mahua, sal and mango kernel oil. J Oleo Sci 2010;59(4):169–176 [DOI] [PubMed]

- Erickson DR. Practical handbook of soybean processing and utilization. Champaign: AOCS press; 1995. [Google Scholar]

- Fahimdanesh M, Bahrami ME (2013) Evaluation of physicochemical properties of Iranian mango seed kernel oil. 2nd International Conference on Nutrition and Food Sciences. IACSIT Press, Singapore. doi:10.7763/IPCBEE

- FAO (2006) The state of food insecurity in the world. http://www.fao.org/docrep/009/a0750e/a0750e00.htm. Accessed at 08-01-2014.

- Fowomola MA. Some nutrients and antinutrients contents of mango (Magnifera indica) seed. Afr J Food Sci. 2010;4(8):472–476. [Google Scholar]

- Gonzalez S, Duncan SSE, Keefe SFO, Sumner SS, Herbein JH. Oxidation and textural characteristics of butter and ice cream with modified fatty acid profiles. J Dairy Sci. 2003;86:70–77. doi: 10.3168/jds.S0022-0302(03)73585-1. [DOI] [PubMed] [Google Scholar]

- Gonzalez S, Fernández-Lorente M, Gilaberte-Calzada Y. The latest on skin photoprotection. Clin Dermatol. 2008;26(6):614–626. doi: 10.1016/j.clindermatol.2007.09.010. [DOI] [PubMed] [Google Scholar]

- Gutierrez-Rosales F, Ríos JJ, Gómez-Rey ML. Main polyphenols in the bitter taste of virgin olive oil. Structural confirmation by on-line high-performance liquid chromatography electrospray ionization mass spectrometry. J Agri Food Chem. 2003;51:6021–6025. doi: 10.1021/jf021199x. [DOI] [PubMed] [Google Scholar]

- Ivanova S, Nachevai MD, Dimov K, Tsv T. Physicochemical composition, atherogenic index and preventive lipid score of buffalo yoghurt after technological treatment and preservation. Bulg J Agr Sci. 2010;16(4):407–411. [Google Scholar]

- Jafari M, Gharachorloo M, Hemmaci AH. The stabilizing effect of three varieties of crude mango seed kernel oil on tallow. J Food Biosci Technol. 2014;4(1):31–36. [Google Scholar]

- Jahurul MHA, Zaidul ISM, Norulaini NAN, Sahena F, Abedin MZ, Ghafoor K. Characterization of crystallization and melting profiles of blends of mango seed fat and palm oil mid-fraction as cocoa butter replacers using differential scanning calorimetry and pulse nuclear magnetic resonance. Food Res Int. 2014;55:103–109. doi: 10.1016/j.foodres.2013.10.050. [DOI] [Google Scholar]

- Jahurul MHA, Zaidul ISM, Norulaini NNA, Sahena F, Jaffri JM, Omar M. Supercritical carbon dioxide extraction and studies of mango seed kernel for cocoa butter analogy fats. CyTA-J Food. 2014;12(1):97–103. doi: 10.1080/19476337.2013.801038. [DOI] [Google Scholar]

- Jeyarani T, Subramanian S, Sneha R, Sudha ML, Negi PS. Characterisation of mango kernel Fat and preparation of Tran’s-free margarine for Use in muffins. J Nutr Food Sci. 2015;5:3. [Google Scholar]

- Kaphueakngam P, Flood A, Sonwai S. Production of cocoa butter equivalent from mango seed almond fat and palm oil mid-fraction. As J Food Ag-Ind. 2009;2(04):441–447. [Google Scholar]

- Kaur J, Rathinam X, Kasi M, Leng KM, Ayyalu R, Kathiresan S, Subramaniam S (2010) Preliminary investigation on the antibacterial activity of mango (Mangifera indica L: Anacardiaceae) seed kernel. Asian Pac J Trop Med. doi:10.1016/S1995-7645(10)60170-8

- Kittiphoom S. Utilization of mango seeds. Int Food Res J. 2012;19(4):1325–1335. [Google Scholar]

- Kittiphoom S, Sutasinee S (2013) Mango seed kernel oil and its physicochemical properties. Int Food Res J 20(3):1145–1149

- Kochhar SF. Stable and healthful frying oil for 21st century. Inform. 2000;11:642–647. [Google Scholar]

- Kwak HS, Jung CS, Shim SY, Ahn J (2002) Removal of cholesterol from cheddar cheese by beta cyclodextrin. J Agr Food Chem 50(25):7293–7298 [DOI] [PubMed]

- Lee SJ, Hwang JH, Lee S, Ahn J, Kwak HS (2007) Property changes and cholesterol lowering effects in evening primrose oil-enriched and cholesterol-reduced yogurt. Int J Dairy Tech 60(1):22–30

- Legesse MB, Emire SA. Functional and physicochemical properties of mango seed kernels and wheat flour and their blends for biscuit production. Afr J Food Sci Technol. 2012;3(9):193–203. [Google Scholar]

- Lokuruka MNI (2007) Role of fatty acids of milk and dairy products in cardiovascular diseases: a review. Afr J Food Agri Nutr Develop 7(1) http://www.bioline.org.br

- Mahale SM, Goswami–Giri AS. Composition and characterization of refined oil compared with its crude oil from waste obtained from Mangifera indica. Asian J Res Chem. 2011;4:1415–1419. [Google Scholar]

- Maheshwari B, Reddy SY. Application of kokum (Garcinia indica) fat as a cocoa improver in chocolate. J Sci Food Agric. 2005;85(1):135–140. doi: 10.1002/jsfa.1967. [DOI] [Google Scholar]

- Maisuthisakul P. Antiradical scavenging activity and polyphenolic compounds extracted from Thai mango seed kernels. As J Food Ag-Ind. 2008;1(02):87–96. [Google Scholar]

- Mohdaly AA, Smetanska AI, Ramadan MF, Sarhan MA, Mahmoud A. Antioxidant potential of sesame (Sesamum indicum) cake extract in stabilization of sunflower and soybean oils. Ind Crop Prod. 2011;34:952–959. doi: 10.1016/j.indcrop.2011.02.018. [DOI] [Google Scholar]

- Mostafa UE (2013) Phenolic Compounds and antioxidant potential of mango peels and kernels (Mangifera indica L.) on the frying oil stability, lipid profile and activity of some antioxidant serum enzymes in rats. J Am Sci 9(11)

- Muchiri DR, Mahungu SM, Gituanja SN. Studies on mango (Mangifera indica, L.) kernel fat of some Kenyan varieties in Meru. J Am Oil Chem Soc. 2012;89:1567–1575. doi: 10.1007/s11746-012-2054-6. [DOI] [Google Scholar]

- Nadeem M, Abdullah M, Javid A, Mahmood T. Evaluation of functional fat from interesterified blends of butter Oil and moringa oleifera oil. Pak J Nutr. 2012;11(9):725–729. [Google Scholar]

- Nadeem M, Abdullah M, Hussain I (2013) Improvement of the oxidative stability of butter oil by blending with Moringa oleifera oil. J Food Process Preserv. doi:10.1111/jfpp.12108

- Nadeem M, Azeem MW, Rahman F. Assessment of transesterified palm olein and moringa oleifera oil blends as vanaspati substitutes. J Food Sci Technol. 2014 doi: 10.1007/s13197-014-1271-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nadeem M, Mahmud A, Imran M, Khalique A. Enhacement of the oxidative stability of whey butter through almond (Prunis dulcis) peel extract. J Food Proces Preserv. 2014 [Google Scholar]

- Nadeem M, Situ C, Mahmud A, Khalique A, Imran M. The effect of sesame (Sesamum indicum) extract for oxidative stabilization of olein based butter. J Am Oil Chem Soc. 2014 [Google Scholar]

- Nadeem M, Baig HA, Ayaz M (2015a) Enhancement of the oxidative stability of butter by mango (Mangifera indica L.) oil at two storage temperatures. J Food Process Preserv. Accepted

- Nadeem M, Situ C, Abdullah M (2015b) The effect of low melting fractions of milk fat on oxidative stability of ice cream. Int J Food Prop 18(4):735–745. doi:10.1080/10942912.2013.814666

- Nzikou JM, Kimbonguila A, Matos L, Loumouamou B, Pambou–Tobi NPG, Ndangui CB, Abena AA, Silou T, Scher J, Desobry S. Extraction and characteristics of seed kernel oil from mango (Mangifera indica) R J Environ Earth Sci. 2010;2:31–35. [Google Scholar]

- O’Brien RD (2008) Fats and oils: formulating and processing for application, 3rd edn. CRC Press, Boca Raton

- Olajumoke OE. Extraction and characterization of vegetable oil from mango seed, Mangifera indica. IOSR-JAC. 2013;5(3):06–08. doi: 10.9790/5736-0530608. [DOI] [Google Scholar]

- Olawale O. Evaluation of lipids extracted from mango and melon seeds. Pac J Sci Technol. 2010;11:2. [Google Scholar]

- Pereira ALF, Vidal TF, Teixeira MC, de Oliveira PF, Pompeu RC, Vieira MMM, Zapata JFF. Antioxidant effect of mango seed extract and butylated hydroxytoluene in bologna-type mortadella during storage. Cienc Tecnol Aliment Campinas. 2011;31(1):135–140. doi: 10.1590/S0101-20612011000100019. [DOI] [Google Scholar]

- Pott I, Marx M, Neidhart S, Muhlbauer W, Carle R. Quantitative determination of b-carotene stereoisomers in fresh, dried, and solar-dried mangoes (Mangifera indica L.) J Agri Food Chem. 2003;51:4527–4531. doi: 10.1021/jf034084h. [DOI] [PubMed] [Google Scholar]

- Rahman F, Nadeem M, Ahmad S, Zahoor Y (2015) Antioxidant activity of date palm fruit (Phoenix dactylifera L.) extract for the stabilization of butter oil at ambient temperature. Pak J Sci and Ind Res (Accepted)

- Rashwan MRA. Fatty acids composition, Neutral lipids and phospholipids fractionation in the kernel lipids of the mango varieties. Assiut J Agric Sci. 1990;21(1):105–117. [Google Scholar]

- Raziq S, Anwar F, Mahmood Z, Shahid SA, Nadeem R (2012) Characterization of seed oils from different varieties of watermelon [Citrullus lanatus (Thunb.)] from Pakistan. Grasas y Aceites, 63 (4). doi:10.3989/gya.022212

- Reddy SY, Jeyarani T (2001) Trans free bakery shortenings from mango kernel and mahua fats by fractionation and blending. J Am Oil Chem Soc 78:635–640. doi:10.1007/s11746-001-0318-8

- Rowe RC, Sheskey PJ, Owen SC (2006) Handbook of pharmaceutical excipients, Pharmaceutical Press and American Pharmacists Association, ISBN 085369 618 7, London, UK

- Rukmini C, Vijayaraghavan M. Nutritional and toxicological evaluation of mango kernel oil. J Am Oil Chem Soc. 1984;61:780–792. doi: 10.1007/BF02672138. [DOI] [Google Scholar]

- Talpur FN, Memon NN, Bhangar MI (2007) Comparison of fatty acid and cholesterol content of Pakisani buffalo breeds. Pak J Analyt Environ Chem 8:15–20

- Sambamurthi MR, Sundram K, Tan YA. Chemistry and biochemistry of palm oil. Prog Lipid Res. 2000;39:507–558. doi: 10.1016/S0163-7827(00)00015-1. [DOI] [PubMed] [Google Scholar]

- Schiber A, Berardini N, Carle R. Identifiation of flvonol and xanthol glycosides from mango peels by HPLC. J Agri Food Chem. 2003;51:5006–5011. doi: 10.1021/jf030218f. [DOI] [PubMed] [Google Scholar]

- Shah KA, Patel MB, Patel RJ, Parmer PK. Mangifera indica (mango) J Pharmacogn Rev. 2010;4(7):42–48. doi: 10.4103/0973-7847.65325. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shahidi S. Bailey’s industrial edible oil and fat products. 6. NY: Willey; 2005. [Google Scholar]

- Shetty US, Sunki Reddy YR, Khatoon S. Plastic fats from sal, mango and palm oil by lipase catalyzed interesterification. J Food Sci Technol. 2014;51(2):315–321. doi: 10.1007/s13197-011-0492-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Siew WL (2000) Characteristics of palm olein from Elaeis guineensis palm oil. Malaysian Palm Oil Board, MPOB Technology 2000, Kuala Lumpur, Malaysia. Paper No. 23, pp 1–11

- Sonwai S, Kaphueakngam P, Flood A. Blending of mango kernel fat and palm oil mid-fraction to obtain cocoa butter equivalent. J Food Sci Technol. 2012 doi: 10.1007/s13197-012-0808-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Soong YY, Barlow PJ. Quantification of gallic acid and ellagic acid from longan (Dimocarpus longan Lour.) seed and mango (Mangifera indica L.) kernel and their effects on antioxidant activity. Food Chem. 2006;97(3):524–530. doi: 10.1016/j.foodchem.2005.05.033. [DOI] [Google Scholar]

- Soong YY, Barlow PJ, Perera CO (2004) A Cocktail of Phytonutrients: identification of Polyphenols, Phytosterol and tocopherols from mango seed kernel. IFT Ann meeting Lasvegas 12–16

- Ullah R, Nadeem M, Ayaz M, Tayyab M, Imran M, Sajid R. Antioxidant characteristics of ice cream supplemented with sugarcane (Saccharum officinarum L.) Juice Food Sci Biotechnol. 2015;24(4):1227–1232. doi: 10.1007/s10068-015-0157-1. [DOI] [Google Scholar]

- Ullah R, Nadeem M, Ayaz M, Imran M, Tayyab M. Fractionation of chia oil for enrichment of omega 3 and 6 fatty acids and oxidative stability of fractions. Food Sci Biotechnol. 2016;25(1):1–7. doi: 10.1007/s10068-016-0006-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Youssef AM. Utilization of the seed of mango processing wastes as a secondary source of oil and protein. Alex J Agri Res. 1999;44(3):149–166. [Google Scholar]

- Zein RE, El-Bagoury AA, Kassab HE. Chemical and nutritional studies on mango seed kernels. J Agric Sci. 2005;30(6):3285–3299. [Google Scholar]