Abstract

This study reports on the possibility or suitability of ketchup preparation using mushroom pulp with tomato pulp. The pulp was extracted from mature and sound tomatoes and button mushroom (Agaricus bisporus L.) and subsequently used for preparation of Tomato-Mushroom ketchup. Different combinations of mushroom pulp with tomato pulp were made for ketchup preparation. The ketchup prepared with 50 % tomato pulp and 50 % mushroom pulp obtained highest organoleptic scores and was preferred than other treatments. The organoleptic score for ketch-up prepared by 100 % mushroom pulp was lowest. There was significant increase in protein, crude fibre and ash content whereas TSS, acidity, total sugars and vitamin C decreased significantly with increase in level of mushroom pulp. TSS increased significantly from 27.32 °B to 31.03 °B during storage for 12 months. Whereas acidity value decreased from 2.22 % to 2.10 %. There was significant decrease in total sugars and increase in reducing sugars during storage at room temperature (RT). Vitamin C content also decreased significantly during storage. All these physico-chemical changes were less at refrigerated temperature (RFT) conditions. The mean value for overall sensory score decreased from 7.80 on zero days to 7.11 at RT and from 7.80 to 7.47 at RFT after 12 months of storage. A significant increase in total plate count of ketch-up was observed during storage at room as well as at refrigerated temperature conditions. However this change was more at RT than RFT.

Key words: Button mushroom, Agaricus bisporus, storage, Tomato-Mushroom mixed Ketch-up (TMK), RT, RFT

India is a developing country and around 80 % of population lives in villages. Due to illiteracy and ignorance people are not aware of nutritional importance of fruits in their diet. Thus due to lack of proper balanced diet, the people especially children suffer from various nutritional deficiencies (Chauhan et al. 2005). Mushrooms are good source of non-starchy carbohydrates, proteins, dietary fibres, minerals and vitamins (Bano and Rajarathnam 1988). Due to its high rate of metabolism, it starts deteriorating immediately after its harvest. Browning is a major problem, which reduces its market value appreciably (Burton and Noble 1993). So, there is a need to develop improved processing techniques for preserving mushroom. Ketch-up is an important food product and mostly prepared from tomato fruits. Mixture of various other fruits and starchy vegetables like pumpkin and ash gourd are sometimes employed in preparation of ketch-up (Chauhan et al. 2005) but information on preparation of ketch-up with mushroom pulp is lacking in the literature. Ketch-up prepared from tomatoes and mushrooms in combination will not only be more nutritive probably it may show better consumer appeal. Considering these facts the present study was undertaken to develop a recipe for preparing tomato- mushroom mixed ketch-up and assess the qualitative changes and storage stability of the product.

Materials and methods

Fresh white button mushrooms (Agaricus bisporus L.) were procured from a local mushroom farm, Hisar. Tomatoes, other ingredients and containers were purchased from local market. Mushrooms and tomatoes were cooked separately in pressure cooker for 15 and 5 min respectively so as to make them soft and crushed in electric blender to make a fine pulp.

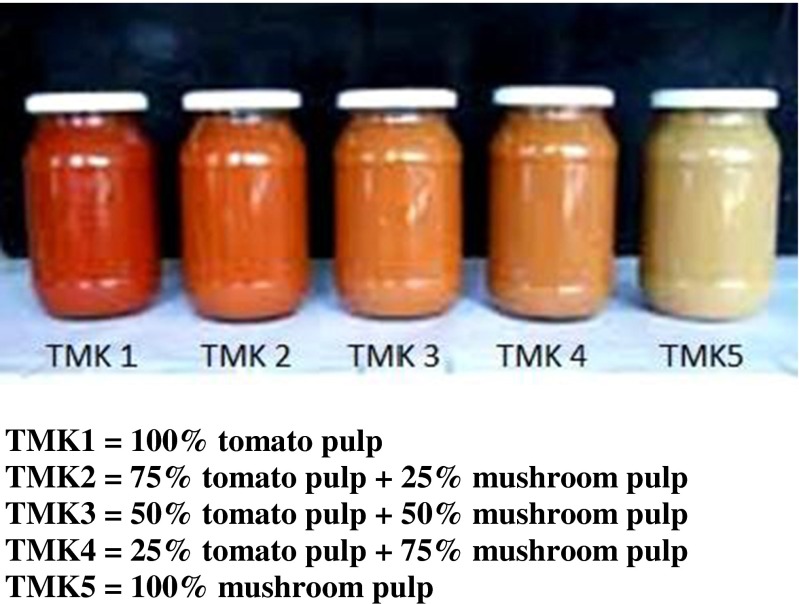

Different combinations of mushroom pulp as given below were made with tomato pulp Plate 1.

TMK1-Ketch-up made from 100 % tomato pulp

TMK2-Ketch-up made from 75 % tomato pulp +25 % mushroom pulp

TMK3-Ketch-up made from 50 % tomato pulp +50 % mushroom pulp

TMK4-Ketch-up made from 25 % tomato pulp +75 % mushroom pulp

TMK5-Ketch-up made from 100 % mushroom pulp

Plate 1.

Ketch up with different combinations of tomato and mushroom pulp

Following was the recipe used for all the ketch-up prepared in this experiment.

| Pulp | 1 kg | Onion | 100 g |

|---|---|---|---|

| Sugar | 150 g | Garlic | 10 g |

| Cloves | 1.5 g | Cardamom | 1.5 g |

| Black pepper | 1.5 g | Cumin seeds | 1.5 g |

| Cinnamon | 1.5 g | Red chili powder | 4 g |

| Salt | 15 g | glacial acetic acid | 3 ml |

| Pectin | 0.2 % by wt. of | Sodium benzoate | 0.75 g/kg of |

| finished product | finished product |

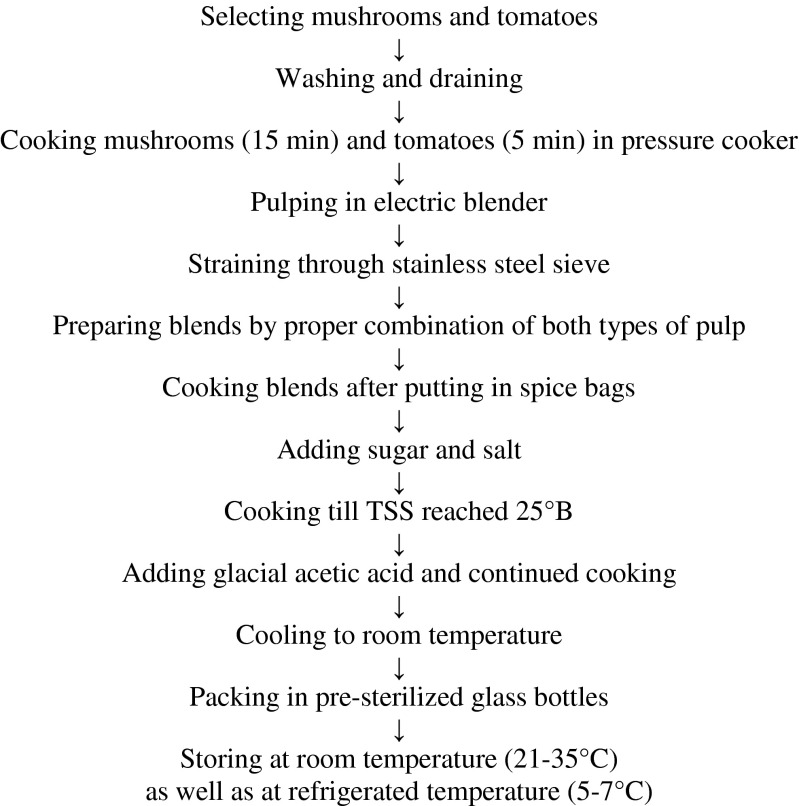

The flow chart for manufacturing process of tomato-mushroom mixed ketch-up is shown in fig. 1.

Fig. 1.

Preparation of tomato-mushroom mixed ketch-up

Ketch-up was packed in pre-sterilized glass bottles and stored at room temperature (21–35 °C) as well as at refrigerated temperature (5–7 °C). Products were analyzed for their TSS (°B), acidity (%), pH, moisture (%), vitamin C (mg/100 g), total sugars (%) and reducing sugars (%). TSS (°B) was measured by Abbe’s refractometer and pH by digital pH meter. Titratable acidity, total sugars and reducing sugars were determined as per method described by Ranganna (1986). Moisture, vitamin C and Total Viable count were determined as per method described by AOAC (1990). Organoleptic evaluation of all products was done following nine point hedonic rating scale (Ranganna 1986). The products were analyzed for their physico-chemical, sensory and microbial characteristics up to one year at two months interval.

Results and discussion

Quality parameters of fresh White button mushrooms and tomatoes are depicted in table 1. Mushrooms are high in protein content (3.68 %) as compared to tomatoes (1.11 %). Whereas pH value of tomatoes is lower (3.81) as compared to mushrooms (6.67).

Table 1.

Quality parameters of fresh White button mushrooms and tomatoes

| White button mushroom | Tomatoes | |

|---|---|---|

| A. PHYSICAL CHARACTERS | ||

| Weight of button/Tomato fruit (g) | 12.82 | 102.22 |

| Pulp (%) | 84.64 | 79.30 |

| Moisture (%) | 89.75 | 92.12 |

| PH | 6.67 | 3.81 |

| B. CHEMICAL CHARACTERS | ||

| Total soluble solids (°B at 20 °C) | 6.12 | 5.01 |

| Total acidity (% as CA) | 0.31 | 0.98 |

| Crude protein (%) | 3.68 | 1.11 |

| Crude fibre (%) | 0.94 | 1.52 |

| Crude fat (%) | 0.32 | 0.30 |

| Ash content (%) | 0.78 | 0.62 |

| Carbohydrates (%) (By difference) | 4.53 | 4.33 |

Supplementation of mushroom pulp with tomato pulp, changed the physico-chemical and nutritional characteristics of the ketch-up (Table 2). There was significant decrease in Total Soluble Solids (TSS), acidity and vitamin C with increasing the level of mushroom pulp. Significant increase in proteins, crude fibre, and ash content of ketch-up was observed with increasing the level of mushroom pulp.

Table 2.

Effect of incorporation of mushroom pulp with tomato pulp on physicochemical characteristics of ketch-up

| Parameters | Treatments | ||||||

|---|---|---|---|---|---|---|---|

| TMK1 | TMK2 | TMK3 | TMK4 | TMK5 | Mean | CD at 5 % | |

| Total soluble solids (°B) | 28.87 | 27.23 | 27.07 | 26.83 | 26.60 | 27.32 | 0.760 |

| Acidity (% as CA) | 2.49 | 2.34 | 2.22 | 2.12 | 1.95 | 2.22 | 0.073 |

| pH | 3.39 | 3.47 | 3.54 | 3.58 | 3.66 | 3.53 | 0.100 |

| Reducing sugar (%) | 14.14 | 14.09 | 14.01 | 13.98 | 13.88 | 14.02 | 0.090 |

| Total sugar (%) | 23.78 | 23.45 | 23.28 | 23.16 | 22.93 | 23.32 | 0.108 |

| Moisture (%) | 62.54 | 61.81 | 62.34 | 63.43 | 62.62 | 62.55 | 0.184 |

| Proteins (%) | 2.45 | 2.78 | 3.27 | 3.75 | 4.21 | 3.29 | 0.101 |

| Crude fibre (%) | 2.61 | 2.65 | 2.71 | 2.69 | 2.80 | 2.69 | 0.106 |

| Ash (%) | 1.51 | 1.91 | 2.31 | 2.73 | 3.12 | 2.32 | 0.117 |

| Vitamin C (mg/100 g) | 12.78 | 11.75 | 9.21 | 6.68 | 4.76 | 9.04 | 0.141 |

Protein content increased from 2.45 % in TMK1 (100 % tomato pulp) to 2.78 % in TMK2 (75 % tomato pulp +25 % mushroom pulp), 3.27 % in TMK3 (50 % tomato pulp 50 % mushroom pulp), 3.75 % in TMK4 (25 % tomato pulp +75 % mushroom pulp) and 4.21 % in TMK5 (100 % mushroom pulp). Vitamin C content decreased from 12.78 mg/100 g in TMK1 to 4.76 mg/100 g in TMK5. Also acidity (%) values decreased with increasing the level of mushroom pulp with a corresponding increase in pH values. Increase in proteins, crude fibre and ash content of Ketch-up with increase in level of mushroom pulp was mainly because of higher protein, crude fibre and ash contents of mushroom pulp than tomato pulp, whereas significant decrease in total soluble solids, acidity, total sugars and vitamins C with increase in level of mushroom pulp was mainly because of lower acidity, total soluble solids, total sugars and vitamin C content of mushroom pulp than tomato pulp.

As per FPO specifications a ketch-up must have minimum percentage of acidity as acetic acid and total soluble solids not less than 1.2 and 15 % respectively. Tomato-mushroom mixed ketch-up met these requirements and was in accordance with FPO (1955) and FSSAI (2006) specifications. Chauhan et al. (2005) prepared sauce by blending aonla pulp with tomato pulp in 50:50 ratios. Rahman et al. (2014) formulated sweet guard ketch-up by incorporating CMC and starch as binding agent. Fawzia et al. (1999) prepared ketchup by substituting tomatoes by sweet potatoes up to 80 % level.

Data pertaining to total soluble solids (TSS) contents in tomato-mushroom mixed ketch-up revealed that there was significant increase in TSS from 27.32 °B to 31.03 °B during storage for 12 months at room temperature (Table 3). At refrigerated temperature this change was comparatively less i.e. from 27.32 °B to 29.11 °B. This might be due to low rate of hydrolysis at refrigerated temperature. Increase in TSS was also reported by Koli et al. (2004) and Kaushik et al. (2002) in spota jam and bael preserve respectively. Increase in TSS of jamun products was reported by Kannan and Thirumaran (2004) during storage.

Table 3.

Changes in total soluble solids of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 28.87 | 29.40 | 30.10 | 30.80 | 31.40 | 32.00 | 32.60 | 30.74 | 28.87 | 28.90 | 29.40 | 29.70 | 30.17 | 30.37 | 30.63 | 29.72 |

| TMK2 | 27.23 | 27.70 | 28.40 | 29.10 | 29.77 | 30.40 | 31.20 | 29.11 | 27.23 | 27.27 | 27.80 | 28.20 | 28.50 | 28.80 | 29.00 | 28.11 |

| TMK3 | 27.07 | 27.60 | 28.20 | 28.80 | 29.50 | 30.03 | 30.63 | 28.83 | 27.06 | 27.43 | 27.90 | 28.40 | 28.40 | 20.60 | 28.90 | 28.10 |

| TMK4 | 26.83 | 27.33 | 28.00 | 28.70 | 29.50 | 30.00 | 30.73 | 28.73 | 26.83 | 27.23 | 27.73 | 28.20 | 28.27 | 28.40 | 28.70 | 27.91 |

| TMK5 | 26.60 | 27.07 | 27.60 | 28.20 | 28.80 | 29.50 | 30.00 | 28.25 | 26.60 | 26.67 | 27.20 | 27.60 | 27.77 | 28.00 | 28.30 | 27.45 |

| Mean | 27.32 | 27.82 | 28.46 | 29.12 | 29.79 | 30.39 | 31.03 | 27.32 | 27.50 | 28.01 | 28.42 | 28.62 | 28.83 | 29.11 | ||

| CD at 5 % | Treatment = 0.217 | Treatment = 0.201 | ||||||||||||||

| Storage period = 0.257 | Storage period = 0.238 | |||||||||||||||

| Treatment x Storage period = 0.573 | Treatment x Storage period = 0.532 | |||||||||||||||

There was decrease in the mean value of titratable acidity from 2.22 % to 2.10 % during storage for 12 months at room temperature (Table 4). This change was comparatively less i. e. from 2.22 % to 2.18 % during storage at refrigerated temperature. The increase in pH values (Table 5) in products stored at both temperatures was consistent with change in titratable acidity values in stored ketch-ups. These changes might be due to interaction of organic acids either with basic minerals of the product or with mushroom components with time. Chauhan et al. (2005) reported significant decrease in titratable acidity of aonla blended tomato sauce during storage at room temperature (20 ± 5 °C) for 90 days. Similar decrease in acidity was also observed by Kannan and Thirumaran (2004), Kaushik et al. (2002) and Sharma et al. (2013) in jamun products, bael preserve and wild apricot fruit bar respectively.

Table 4.

Changes in acidity (%) of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 2.49 | 2.48 | 2.46 | 2.42 | 2.40 | 2.38 | 2.37 | 2.43 | 2.49 | 2.50 | 2.48 | 2.47 | 2.46 | 2.45 | 2.44 | 2.47 |

| TMK2 | 2.34 | 2.34 | 2.32 | 2.28 | 2.25 | 2.22 | 2.20 | 2.28 | 2.34 | 2.34 | 2.33 | 2.32 | 2.31 | 2.31 | 2.29 | 2.32 |

| TMK3 | 2.22 | 2.20 | 2.18 | 2.15 | 2.12 | 2.08 | 2.08 | 2.15 | 2.22 | 2.22 | 2.20 | 2.19 | 2.18 | 2.17 | 2.16 | 2.19 |

| TMK4 | 2.12 | 2.12 | 2.10 | 2.08 | 2.06 | 2.04 | 2.01 | 2.07 | 2.12 | 2.12 | 2.11 | 2.10 | 2.09 | 2.08 | 2.07 | 2.10 |

| TMK5 | 1.95 | 1.98 | 1.96 | 1.93 | 1.88 | 1.87 | 1.86 | 1.92 | 1.95 | 1.98 | 1.97 | 1.96 | 1.95 | 1.94 | 1.93 | 1.96 |

| Mean | 2.22 | 2.22 | 2.20 | 2.17 | 2.14 | 2.12 | 2.10 | 2.22 | 2.23 | 2.22 | 2.21 | 2.20 | 2.19 | 2.18 | ||

| CD at 5 % | Treatment = 0.020 | Treatment = 0.018 | ||||||||||||||

| Storage period = 0.024 | Storage period = 0.021 | |||||||||||||||

| Treatment x Storage period = 0.054 | Treatment x Storage period = 0.046 | |||||||||||||||

Table 5.

Changes in pH of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 3.40 | 3.39 | 3.42 | 3.44 | 3.45 | 3.46 | 3.47 | 3.43 | 3.39 | 3.38 | 3.40 | 3.40 | 3.42 | 3.43 | 3.44 | 3.41 |

| TMK2 | 3.47 | 3.47 | 3.49 | 3.52 | 3.54 | 3.55 | 3.47 | 3.52 | 3.47 | 3.47 | 3.48 | 3.50 | 3.51 | 3.52 | 3.53 | 3.50 |

| TMK3 | 3.54 | 3.52 | 3.55 | 3.58 | 3.59 | 3.62 | 3.62 | 3.57 | 3.54 | 3.53 | 3.56 | 3.56 | 3.58 | 3.59 | 3.59 | 3.56 |

| TMK4 | 3.58 | 3.60 | 3.62 | 3.62 | 3.66 | 3.66 | 3.68 | 3.64 | 3.58 | 3.59 | 3.60 | 3.52 | 3.63 | 3.64 | 3.65 | 3.61 |

| TMK5 | 3.66 | 3.65 | 3.66 | 3.68 | 3.70 | 3.72 | 3.75 | 3.69 | 3.66 | 3.65 | 3.67 | 3.68 | 3.59 | 3.70 | 3.70 | 3.68 |

| Mean | 3.53 | 3.52 | 3.55 | 3.58 | 3.59 | 3.60 | 3.62 | 3.53 | 3.52 | 3.54 | 3.55 | 3.56 | 3.57 | 3.58 | ||

| CD at 5 % | Treatment = 0.026 | Treatment = 0.025 | ||||||||||||||

| Storage period = 0.031 | Storage period = 0.029 | |||||||||||||||

| Treatment x Storage period = 0.065 | Treatment x Storage period = 0.065 | |||||||||||||||

There was significant decrease in mean value of total sugars i.e. from 23.32 % to 21.44 % at room temperature and from 23.32 % to 22.22 % at refrigerated temperature (Table 6). This might be due to hydrolysis of total and non-reducing sugars to reducing sugars. Kumar and Manimegalai (2001) reported decrease in total sugars of strawberry sauces stored at room temperature. Similar results were also obtained by Sharma et al. (2013) in wild apricot fruit bar. A gradual decrease in total sugars of jamun fruit products was also reported by Kannan and Thirumaran (2004). They reported slightly less decrease in total sugars at refrigerated temperature than room temperature. Contrary to this there was significant increase in mean value of reducing sugars i.e. from 14.02 % to 17.83 % at room temperature and from 14.02 % to 16.22 % at refrigerated temperature during storage for 12 months (Table 7). This increase in reducing sugars may be due to acid hydrolysis of total and non-reducing sugars and thereby inversion of total and non-reducing sugars to reducing sugars (Aruna et al. 1999). Less change at refrigerated temperature might be due to low rate of hydrolysis at low temperature. Kumar and Manimegalai (2001) reported a gradual increase in reducing sugars of strawberry sauces stored at room temperature. Increase in reducing sugar was also observed by Koli et al. (2004) and Sagar et al. (2000) in sapota jam and ripe mango powder respectively.

Table 6.

Changes in total sugars (%) of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 23.78 | 23.42 | 23.16 | 22.83 | 22.52 | 22.20 | 21.88 | 22.83 | 23.78 | 23.62 | 23.46 | 23.28 | 23.09 | 23.89 | 22.73 | 23.26 |

| TMK2 | 23.45 | 23.12 | 22.81 | 22.53 | 22.22 | 21.88 | 21.56 | 22.51 | 23.45 | 23.27 | 23.06 | 22.88 | 22.70 | 22.52 | 22.34 | 22.89 |

| TMK3 | 23.28 | 22.94 | 22.62 | 22.30 | 21.92 | 21.71 | 21.47 | 22.32 | 23.28 | 23.10 | 22.90 | 22.70 | 22.56 | 22.36 | 22.18 | 22.72 |

| TMK4 | 23.17 | 22.80 | 22.49 | 22.16 | 21.82 | 21.56 | 21.24 | 22.18 | 23.17 | 22.97 | 22.80 | 22.60 | 22.42 | 22.24 | 22.05 | 22.61 |

| TMK5 | 22.93 | 22.63 | 22.32 | 21.98 | 21.68 | 21.38 | 21.06 | 22.00 | 22.93 | 22.74 | 22.56 | 22.36 | 22.18 | 22.00 | 21.82 | 22.37 |

| Mean | 23.32 | 22.98 | 22.68 | 22.36 | 22.03 | 21.75 | 21.44 | 23.32 | 23.14 | 22.96 | 22.76 | 22.59 | 22.40 | 22.22 | ||

| CD at 5 % | Treatment = 0.032 | Treatment = 0.036 | ||||||||||||||

| Storage period = 0.037 | Storage period = 0.042 | |||||||||||||||

| Treatment x Storage period = 0.083 | Treatment x Storage period = 0.094 | |||||||||||||||

Table 7.

Changes in reducing sugars (%) of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 14.14 | 14.79 | 15.58 | 16.10 | 16.85 | 17.44 | 18.10 | 16.15 | 14.14 | 14.48 | 14.88 | 15.22 | 15.62 | 15.99 | 16.46 | 15.26 |

| TMK2 | 14.09 | 14.74 | 15.33 | 15.98 | 16.57 | 17.23 | 17.98 | 15.99 | 14.09 | 14.42 | 14.76 | 15.14 | 15.52 | 15.88 | 16.32 | 15.16 |

| TMK3 | 16.01 | 16.67 | 15.27 | 15.89 | 16.51 | 17.16 | 17.80 | 15.90 | 14.01 | 14.38 | 14.72 | 15.08 | 15.46 | 15.88 | 16.20 | 15.10 |

| TMK4 | 13.98 | 14.56 | 15.19 | 15.76 | 16.43 | 17.07 | 17.76 | 15.82 | 13.98 | 14.36 | 14.70 | 15.00 | 15.38 | 15.76 | 16.12 | 15.04 |

| TMK5 | 13.88 | 14.43 | 15.04 | 15.68 | 16.32 | 16.86 | 17.50 | 15.67 | 13.88 | 14.26 | 14.62 | 14.88 | 14.28 | 15.68 | 15.99 | 14.80 |

| Mean | 14.02 | 14.64 | 15.28 | 15.88 | 16.54 | 17.15 | 17.83 | 14.02 | 14.38 | 14.74 | 15.06 | 15.25 | 15.84 | 16.22 | ||

| CD at 5 % | Treatment = 0.043 | Treatment = 0.035 | ||||||||||||||

| Storage period = 0.051 | Storage period = 0.041 | |||||||||||||||

| Treatment x Storage period = 0.114 | Treatment x Storage period = 0.091 | |||||||||||||||

There was significant decrease in vitamin C content i.e. from 9.04 mg/100 g to 3.52 mg/100 g at room temperature during storage for 12 months (Table 8). However this change was less at refrigerated temperature. There was about 61 % and 46 % loss of ascorbic acid at room and refrigerated conditions respectively after storage for 12 months. A significant loss in ascorbic acid was reported by Kaushik et al. (2002) in bael preserve, Kumar and Manimegalai (2001) in mixed fruit RTS beverage, Sagar et al. (2000) in ripe mango powder, Sharma et al. (2013) in wild apricot fruit bar and Rahman et al. (2014) in sweet guard ketch-up and they explained it to be due to oxidation of ascorbic acid. They further reported that retention of ascorbic acid was higher in samples stored at low temperature as compared to those at room temperature.

Table 8.

Changes in vitamin C (mg/100 g) of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 12.78 | 10.76 | 8.98 | 7.08 | 5.96 | 4.90 | 3.88 | 7.76 | 12.78 | 11.38 | 10.07 | 8.68 | 8.14 | 7.54 | 6.99 | 9.37 |

| TMK2 | 11.75 | 9.92 | 8.38 | 6.46 | 5.54 | 4.62 | 3.76 | 7.20 | 11.75 | 10.42 | 9.26 | 7.99 | 7.42 | 6.92 | 6.48 | 8.61 |

| TMK3 | 9.21 | 7.79 | 6.48 | 5.17 | 4.36 | 3.60 | 2.86 | 5.64 | 9.21 | 8.18 | 7.26 | 6.28 | 5.78 | 5.28 | 4.81 | 6.68 |

| TMK4 | 6.68 | 5.59 | 4.62 | 3.59 | 3.18 | 2.70 | 2.28 | 4.09 | 6.68 | 5.80 | 5.16 | 4.48 | 4.10 | 3.72 | 3.36 | 4.76 |

| TMK5 | 4.76 | 3.95 | 3.23 | 2.62 | 2.20 | 1.80 | 1.42 | 2.85 | 4.76 | 4.28 | 3.75 | 3.28 | 2.96 | 2.68 | 2.40 | 3.44 |

| Mean | 9.04 | 7.60 | 6.34 | 4.98 | 4.25 | 3.52 | 2.84 | 9.04 | 8.01 | 7.10 | 6.14 | 5.68 | 5.23 | 4.81 | ||

| CD at 5 % | Treatment = 0.039 | Treatment = 0.043 | ||||||||||||||

| Storage period = 0.046 | Storage period = 0.051 | |||||||||||||||

| Treatment x Storage period = 0.102 | Treatment x Storage period = 0.114 | |||||||||||||||

Organoleptic evaluation of fresh ketchup prepared by various combinations of tomato and mushroom pulp is depicted in Table 9. Ketch-up prepared by combination of 50 % tomato pulp and 50 % mushroom pulp obtained highest organoleptic scores and was preferred than other treatments. However sensory quality of ketch-up prepared by 100 % mushroom pulp was lowest of all combinations.

Table 9.

Organoleptic evaluation of tomato-mushroom mixed ketch-up

| Parameters | Treatments | ||||||

|---|---|---|---|---|---|---|---|

| TMK1 | TMK2 | TMK3 | TMK4 | TMK5 | Mean | CD at 5 % | |

| Colour | 8.90 | 7.93 | 9.00 | 7.97 | 7.07 | 8.17 | 0.215 |

| Appearance | 8.17 | 7.07 | 8.90 | 7.60 | 6.83 | 7.71 | 0.293 |

| Aroma | 8.27 | 8.47 | 8.90 | 6.93 | 6.17 | 7.75 | 0.367 |

| Texture | 7.13 | 7.17 | 8.80 | 7.17 | 6.13 | 7.28 | 0.262 |

| Taste | 8.17 | 8.47 | 9.00 | 7.80 | 6.93 | 8.07 | 0.257 |

| Overall acceptability | 8.13 | 7.82 | 8.92 | 7.49 | 6.63 | 7.80 | 0.163 |

During storage, there was significant decrease in overall sensory score of ketch-up stored at room as well as refrigerated conditions (Table 10). However, this change was higher in samples stored at room than refrigerated temperature. Decrease in overall sensory score was mainly because of darkening of product at room temperature and also the consistency of the product slightly changed. Similar darkening of product was observed by Fawzia et al. (1999) in ketchup prepared by substituting tomatoes with sweet potatoes. A combination of 50 % tomato pulp +50 % aonla pulp was selected for preparation of aonla blended sauce by Chauhan et al. (2005). They further reported that overall sensory score for aonla-blended sauce decreased significantly with increase in storage period. Kumar and Manimegalai (2001) also reported slight decrease in organoleptic qualities of strawberry sauces during storage for 90 days. Koli et al. (2004) reported that there was gradual decrease in quality parameters of jam samples with advancement of storage period. Similar results were also obtained by Rahman et al. (2014) in sweet guard ketch-up.

Table 10.

Changes in overall sensory score of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 8.13 | 8.10 | 8.12 | 8.06 | 8.00 | 7.91 | 7.61 | 7.99 | 8.13 | 8.19 | 8.12 | 8.11 | 8.05 | 8.02 | 8.00 | 8.09 |

| TMK2 | 7.82 | 7.80 | 7.76 | 7.79 | 7.50 | 7.41 | 7.20 | 7.61 | 7.82 | 7.89 | 7.82 | 7.73 | 7.65 | 7.63 | 7.52 | 7.72 |

| TMK3 | 8.92 | 8.80 | 8.70 | 8.50 | 8.31 | 8.26 | 7.96 | 8.49 | 8.92 | 8.96 | 8.88 | 8.80 | 8.72 | 8.60 | 8.50 | 8.77 |

| TMK4 | 7.49 | 7.51 | 7.40 | 7.44 | 7.48 | 7.25 | 6.98 | 7.36 | 7.49 | 7.56 | 7.50 | 7.51 | 7.41 | 7.31 | 7.20 | 7.42 |

| TMK5 | 6.63 | 6.61 | 6.52 | 6.31 | 6.11 | 6.00 | 5.80 | 6.28 | 6.63 | 6.70 | 6.70 | 6.40 | 6.39 | 6.31 | 6.13 | 6.47 |

| Mean | 7.80 | 7.76 | 7.70 | 7.62 | 7.48 | 7.37 | 7.11 | 7.80 | 7.86 | 7.80 | 7.71 | 7.64 | 7.57 | 7.47 | ||

| CD at 5 % | Treatment = 0.062 | Treatment = 0.041 | ||||||||||||||

| Storage period = 0.073 | Storage period = 0.048 | |||||||||||||||

| Treatment x Storage period = 0.163 | Treatment x Storage period = 0.108 | |||||||||||||||

Significant increase in total plate count of ketch-up was observed during storage at room as well as at refrigerated temperature conditions (Table 11). However, this change was higher at room temperature than refrigerated temperature conditions. The mean value for microbial count increased from 0.08 CFU x 103 /g at zero days to 2.83 CFU x 103 /g after 12 months of storage at room temperature while at refrigerated conditions, values increased from 0.08 CFU x 103 /g to 1.85 CFU x 103 /g after one year. Kumar and Bachhil (1993) reported that microbial counts in pork pickle remained in the change of 3 log cycles for all recipes throughout the storage. Sheth and Nandwana (2004) reported increase in mean value for TPC (total plate count) of commercial mango pickle. Similar results were obtained by Rahman et al. (2014) in sweet guard ketch-up.

Table 11.

Changes in total plate count (CFU x 103/g) of tomato-mushroom mixed ketch-up during storage

| Product/Recipes | Period of storage (months) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature (21–35 °C) | Refrigerated temperature (5–7 °C) | |||||||||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | 0 | 2 | 4 | 6 | 8 | 10 | 12 | Mean | |

| TMK1 | 0.05 | 1.20 | 1.46 | 1.58 | 1.80 | 2.26 | 2.58 | 1.56 | 0.05 | 0.52 | 0.78 | 0.99 | 1.18 | 1.48 | 1.68 | 0.95 |

| TMK2 | 0.06 | 1.28 | 1.52 | 1.68 | 1.92 | 2.38 | 2.72 | 1.65 | 0.06 | 0.64 | 0.88 | 1.08 | 1.25 | 1.46 | 1.72 | 1.01 |

| TMK3 | 0.08 | 1.36 | 1.60 | 1.72 | 2.06 | 2.48 | 2.86 | 1.74 | 0.08 | 0.72 | 0.98 | 1.12 | 1.36 | 1.56 | 1.78 | 1.09 |

| TMK4 | 0.10 | 1.47 | 1.76 | 1.80 | 2.20 | 2.58 | 2.88 | 1.83 | 0.10 | 0.80 | 1.07 | 1.20 | 1.42 | 1.68 | 1.99 | 1.18 |

| TMK5 | 0.12 | 1.57 | 1.80 | 1.88 | 2.32 | 2.76 | 3.12 | 1.94 | 0.12 | 0.92 | 1.21 | 1.32 | 1.56 | 1.78 | 2.06 | 1.28 |

| Mean | 0.08 | 1.38 | 1.63 | 1.73 | 2.06 | 2.49 | 2.83 | 0.08 | 0.72 | 0.98 | 1.14 | 1.35 | 1.59 | 1.85 | ||

| CD at 5 % | Treatment = 0.031 | Treatment = 0.040 | ||||||||||||||

| Storage period = 0.037 | Storage period = 0.047 | |||||||||||||||

| Treatment x Storage period = 0.082 | Treatment x Storage period = 0.105 | |||||||||||||||

Conclusions

The study has shown that tomatoes can be substituted with mushroom in ketchup manufacture. The study indicated that the product prepared with 50 % of tomato pulp and 50 % mushroom pulp was preferred organoleptically than other treatments. The study also showed that the concentration of mushroom pulp in the ketchup formulation had a significant influence in enhancing the nutritive value of product. Significant increase in protein, crude fibre and ash content was observed with increase in level of mushroom pulp. During storage period there was significant increase in total soluble solids (TSS). Total sugars decreased significantly whereas significant increase in reducing sugars was observed during storage. Titratable acidity values and Vitamin C content also decreased significantly during storage. All these physico-chemical changes were less at refrigerated temperature (RFT) conditions. Organoleptic score and microbial count was within acceptable limits. Thus it can be concluded that some undesirable changes were observed in products stored at room temperature (RT) after 6 months of storage, however, the product can be safely stored for a period of one year at refrigerated temperature (RFT) without any undesirable change in microbial, organoleptic and nutritional attributes.

Acknowledgments

The authors thank the Chairperson, Department of Food Tech, for his encouragement and for providing the necessary facilities to undertake this work. This study was a part of Ph. D. thesis submitted by the first author to the Guru Jambheshwar University of Science & Technology, Hisar, India.

References

- A.O.A.C. Official methods of analysis. 15. Washington, D.C.: Association of official Analytical Chemists; 1990. [Google Scholar]

- Aruna K, Vimala V, Dhanalakshmi K, Reddy V. Physico-chemical changes during storage of papaya fruit (Carica papaya L.) bar (thandra) J. Food Sci Technol. 1999;36(5):428–433. [Google Scholar]

- Bano Z, Rajarathnam S. Pleurotus mushrooms part II. Chemical composition, nutritional value, post harvest physiology, preservation and role as human food. CRC Crit Rev Food Sci Nutr. 1988;27(2):87–158. doi: 10.1080/10408398809527480. [DOI] [PubMed] [Google Scholar]

- Burton KS, Noble R. The influence of flush number, bruising and storage temperature on mushroom quality. Post Harvest BIol and Technol. 1993;3:39–47. doi: 10.1016/0925-5214(93)90025-X. [DOI] [Google Scholar]

- Chauhan OP, Srivastava S, Pandey P, Rai GK. A study on development of aonla blended sauce. Beverage and Food World. 2005;32(5):31–32. [Google Scholar]

- Fawzia A, Karuri EG, Hagenimana V. Sweet potato ketchup: feasibility, acceptability and production costs in Nairobi, Kenya. Afr Crop Sci J. 1999;7(1):81–89. doi: 10.4314/acsj.v7i1.27780. [DOI] [Google Scholar]

- F.P.O . Food product order. Ministry of Food and Agriculture, New Delhi: Government of India; 1955. [Google Scholar]

- F.S.S.A.I. Food safety and standard authority of India. Ministry of Law and Justice, New Delhi: Government of India; 2006. [Google Scholar]

- Kannan S, Thirumaran AS. Studies on storage life of jamun (syzygium cuminii Ron) fruit products. J Food Sci Technol. 2004;41(2):186–188. [Google Scholar]

- Koli SA, Kolekar TT, Kute LS, Chavan JK. Preparation and storage of sapota jam. Beverage and Food World. 2004;31(12):20–21. [Google Scholar]

- Kaushik RA, Yamdagni R, Dhawan SS. Biochemical changes during storage of bael preserve. Haryana J Hort Sci. 2002;31(3 & 4):194–196. [Google Scholar]

- Kumar V, Bachhil VN. Studies on the development of pork pickle: effect of different preservatives on its quality and shelf life. Indian Food Packer. 1993;47(1):15–21. [Google Scholar]

- Kumar RS, Manimegalai G. Storage behaviour of strawberry sauces. Indian Food Packer. 2001;55(4):58–61. [Google Scholar]

- Rahman MR, Lou Z, Thabit R, Sultana A. Novel formulation, preparation and quality evaluation of sweet gourd ketchup. Int J of Chem & Biol Sci. 2014;1(4):12–28. [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 2. New Delhi: Tata McGraw hill Publishing Co. Limited; 1986. [Google Scholar]

- Sagar VR, Khurdiya DS, Maini SB. Quality of ripe mango powder as affected by storage temperature and period. J Food Sci Technol. 2000;37(2):165–168. [Google Scholar]

- Sharma SK, Chaudhary SP, Rao VK, Yadav VK, Bisht TS. Standardization of technology for preparation and storage of wild apricot fruit bar. J Food Sci Technol. 2013;50(4):784–790. doi: 10.1007/s13197-011-0396-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sheth M, Nandwana V. Stability of commercial mango pickles in oil. Indian Food Packer. 2004;58(1):73–77. [Google Scholar]