Abstract

Melon seed milk (MSM) powder was produced by aiming to get alternative vegetable milk from crushed Kırkağaç (Cucumis melo subsp. melo cv. Kırkağaç) and Çeşme (C. melo subsp. melo cv. Çeşme) type melon seeds. MSM was converted to powder form via spray dryer at inlet air temperature of 150 °C, air flow rate of 473 l · h−1, aspiration ratio of 24 m3 · h−1and feed flow rate of 8 ml · min−1 in order to extend the shelf life and usage area. The moisture content and water activity of samples changed in range of 2.1 to 2.4 % and 0.260 to 0.310, respectively. Bulk densities and the tapped densities of powders were ranged from 340 to 360 kg · m−3 and 730 and 740 kg · m−3. MSM powders showed poor flow behavior as determined from Carr Index. The particle densities of powders ranged between and 1069 kg · m−3. Wettability time of powders was found as 7 s. The Bingham model was the best model fitted to rheological data of MSM beverages. Sensory evaluation test results showed that, the beverage obtained from reconstituted Kırkağaç powder achieved the highest score by panelists.

Keywords: Melon seed milk powder, Spray drying, Physical properties, Reconstitution characteristics, Rheological properties, Sensory properties

Introduction

Nowadays, consumers prefer not only natural, healthy and delicious food, but also environmental friendly produced foods which are called “green” food. In underdeveloped and/or developing countries, food producers have focused on researching and developing alternative milk and milk products obtained from vegetable sources due to the inadequacy of dairy milk source, variety of consumers diet preferences (vegan/vegetarian diet, special diet for religious reasons) and allergen and sensitivity of dairy products (lactose intolerance, milk allergies) (Heyman 2006). Vegetable milk was used for different purposes; such as raw material or flavour enhancing for beverage/drink productions, thickening or emulsifying agents for soup. Soy, almond, rice, and coconut milk were widely produced and consumed as vegetable milks in the world (Belewu and Belewu 2007). The other vegetable milk sources such as wheat, sunflower seed, pumpkin seed and melon seed also draw researchers’ attention (Diarra et al. 2005).

Melon seed was qualified as a waste product containing high amount of protein, fat, carbohydrates and other metabolites such as minerals (De Mello et al. 2001). Akubor and Ogbadu (2003) reported that the melon seeds could be used for emulsifying, flavoring, thickening in soups or as a snack after frying. The melon seed milk (MSM) which was one of the plant derived milk, had the potential to be nutritious and healthy beverage for vegan/vegetarian diet and/or people who have lactose intolerance. In literature, researches on the MSM showed that this beverage could be an alternative vegetable milk to the highly produced and consumed soymilk in the world due to its high content of protein (3.6 %), oil (4 %) and lactose free content (Akubor 1998). Karakaya et al. (1995) showed that the MSM might be a good source of iron and magnesium.

By-products of food previously regarded as a waste, have gained importance in recent years, because of the possibilities to be the source of food. Although the seeds of fruits and the plants are described as the waste products, they are quite valuable due to their nutritional value and economic potentials. There is the same case for melon seed as well. Melon is widely consumed as delicious and refreshing fruit in the world however melon seeds have no commercial application in many countries. Whereas melon is produced nearly 32 million tonnes per year overall world, total amount of melon seed production is only 0.7 million tonnes per year whose total production by 90 % was supplied from Africa continent (FAO 2015). In Turkey, Aegean region, especially in Izmir and around, dried melon seeds are mixed with water and sugar in conventional ways to produce “Subye Syrup” (melon seed milk + sugar) and it is consumed as a refreshing beverage especially in the summer. Despite the rich nutritional content of “Subye Syrup”, the consumption is not very common due to the limited shelf-life (approximately 2 days) even in refrigerated conditions. Akubor et al. (2002) studied microbial properties of MSM at different storage temperatures. Based on this study, total bacterial count in pasteurized MSM was duplicated in 2 days when it was stored at 10 °C and MSM sample was kept its safety only 1 day at 30 °C storage condition. The high pH and the water activity values of the beverages could establish convenient environment for microorganisms’ sporulation or multiplication (Akubor and Ogbadu 2003). These conditions could shorten the shelf-life of beverages. However drying process could overcome this limited shelf life problem of MSM by lowering water activity and moisture content which leads to longer shelf life.

Spray drying is the most widely used method for drying of liquid food products including milk and milk products, because of the high moisture removal rate, lower cost, and shorter process time. It also enables the preparation of stable and functional products (Jinapong et al. 2008). Therefore, obtaining the MSM powder which is soluble and rich in nutritive value might be highly desirable. However there has been a gap in the current literature about drying of MSM.

The present study was undertaken to investigate the feasibility of the production of the instant MSM powder and evaluate a plant milk powder from waste-by product. In this research, two different seeds of melons grown in Izmir, Turkey and around Kırkağaç (Cucumis melo subsp. melo cv. Kırkağaç) and Çeşme (C. melo subsp. melo cv. Çeşme) type of melons were used for the production of the MSM powder. Water activity, moisture content, colour, reconstitution characteristics, bulk and tapped density, flowability, hygroscopicity and particle density of powders were determined. Also, the rheological behaviour and the sensorial properties of both of the MSM samples were evaluated when they were fresh and reconstituted.

Materials and methods

Materials

Kırkağaç (C. melo subsp. melo cv. Kırkağaç) and Çeşme (C. melo subsp. melo cv. Çeşme) type of melons were purchased from local markets of Izmir, Turkey. The melons were cut in half; seeds were separated and washed with water. Then the seeds were dried in a conventional oven (Arçelik, Turkey) at 60 °C for 3 h.

Preparation of the melon seed milk

The melon seed milk was produced according to method described by Karakaya et al. (1995) with some modifications to obtain higher dry matter content which was desirable for drying process. 50 g of dried melon seeds were crushed over a minute in an electrical blender (Tefal Smart, France) without any water addition. Then 100 ml of tap water was added on crushed seeds for a second blending process. After the second blending, approximately 50 ml of tap water was also added for the third blending process and the mixture was filtered into a glass container by using a sieve (212 μm). Then the residue was taken for blending process with addition of 75 ml of tap water. The slurry was filtered again by 212 μm sieve. Finally, after the fifth blending and the third filtration processes, MSM was obtained. Proximate composition of MSM obtained from Kırkağaç and Çeşme type melon seeds were 48 % oil, 37.5 % carbohydrate, 11.5 % protein, 3 % ash and 49 % oil, 36.6 % carbohydrate, 10.8 % protein, 3.6 % ash on dry basis, respectively. The pH values were found as to be 6.80 and 7.04 for Çeşme and Kırkağaç MSM, respectively. °Brix of Kırkağaç and Çeşme type MSMs were 3.5 and 3.2 %, respectively.

Drying process of the melon seed milk

The melon seed milk was dried in a laboratory scale spray dryer (Büchi mini spray drier B-290, Büchi Labortechnik, Flawil, Switzerland) equipped with 0.7 mm diameter nozzle at inlet air temperature of 150 °C, air flow rate of 473 l · h−1 and aspiration ratio of 24 m3 · h−1. Inlet air temperature was determined by preliminary tests. MSM powder was studied to produce at 120, 150 and 180 °C of the inlet air temperature. MSM could not be converted to powder form at 120 °C, it remained as sticky liquid on the surface of drying chamber at the end of the drying process. The MSM was burned at 180 °C inlet air temperature. Accordance with these outcomes, 150 °C was found suitable for drying process of MSM. Feed flow rate was 8 ml · min−1 and the feed temperature was approximately 25 °C. All the drying conditions were kept constant during the drying process. The total soluble solid content (°Brix) of Kırkağaç and Çeşme type MSMs fed to spray drier were 3.5 and 3.2 %, respectively.

Analysis

Moisture content

Moisture contents of spray dried powders were determined gravimetrically by vacuum oven at 70 °C for 8 h (AOAC 2005) and expressed as percentage.

Water activity

The water activity (aw) was measured with a water activity measurement device (Testo 400, Lenzkirch, Germany), with a 0.001 sensitivity.

Colour analysis

The Hunter L, a, b values of spray dried melon seed milk powders were measured with a chromameter (Minolta CR-300, Minolta, Tokyo, Japan).

Particle density

Particle density (ρp) of the spray dried melon seed milk powder samples was analysed by pycnometric method with 2-propanol and it was calculated with Eq. (1) (Barbosa-Canovas et al. 2005).

| 1 |

where, ms is the weight of pycnometer with powder product (g), m0 is the weight of empty pycnometer (g), ρ is the density of 2-propanol (0.785 g/mL), ml is the weight of pycnometer with 2-propanol (g), msl is the weight of pycnometer with 2-propanol and powder product (g).

Bulk and tapped density

The bulk density (ρb) of spray dried melon seed milk powder was determined by measuring the weight of the powder and the corresponding volume. Approximately 2 g powder were transferred to 10 ml graduated cylinder. The bulk density was calculated by dividing the mass of the powder by the volume occupied in the cylinder. For the tapped density (ρt), the cylinder was tapped steadily and continuously on the surface by hand until there was no further change in volume (Jinapong et al. 2008).

Carr Index (Flowability)

The flowability of spray dried melon seed milk powder was calculated from the bulk (ρb) and tapped density (ρt) values (Eq. (2)) (Carr 1965). The results are given as Carr Index (CI) value and it’s dimensionless.

| 2 |

Hygroscopicity

About 1 g of powder was spread evenly on Petri dishes (9 cm diameter) to allow for a high surface area between humid air and powder. The dishes were placed in desiccators containing saturated NaCl solution, providing (75.3 %) relative humidity at 25 °C. A 10 min interval was selected to get the kinetics of moisture sorption. Although hygroscopicity is based on the equilibrium moisture content, to compare hygroscopicities, the weight increase per gram of powder solids after being subjected to the atmosphere with relative humidity of 75.3 % for 90 min was determined (Koç et al. 2014). Hygroscopicity was expressed as grams of moisture (water) per kilogram of dry solids.

Reconstitution properties

Solubility

Solubility was determined by the method described by Cano-Chauca et al. (2005) with some modifications. 1 g spray dried melon seed milk powder was transferred to 25 ml of distilled water. Mixture was homogenized with mechanical homogenizer at 50 Hz for 5 min, the supernatant of the solution was transferred to Eppendorf tube and centrifuged for 5 min at 1000 g centrifugal force. One aliquot (20 ml) of supernatant was transferred to a Petri dish and dried for 5 h at 105 °C. The solubility percentage (mass of soluble powder⁄mass of total powder) was calculated by the weight difference.

Wettability

100 ml distilled water was poured into a 250 ml beaker. A glass funnel held on a ring stand was set over the beaker with the height between the bottom of the funnel and the water surface of 10 cm. A test tube was placed inside the funnel to block the lower opening of the funnel. The powder sample (0.1 g) was placed around the test tube and then the tube was lifted while the stop watch was started at the same time. Finally, the time was recorded when the powder became completely wetted (Jinapong et al. 2008).

Dispersibility

10 ml distilled water was poured into a 50 ml beaker. The powder (1 g) was added into the beaker. The stop watch was started and the sample was stirred vigorously with a spoon for 15 s making 25 complete movements back and forth across the whole diameter of the beaker. The reconstituted spray dried melon seed milk powder was poured through a sieve (212 μm). The sieved spray dried melon seed milk powder (1 ml) was transferred onto a weighed and dried aluminum pan and dried for 2 h in a vacuum oven at 70 ± 1 °C. The dispersibility (D) of the powder was calculated according to Eq. (3) and expressed as percentage:

| 3 |

where W = amount of powder (g) being used, MC = moisture content of the powder, and % DM = dry matter in percentage in the reconstituted melon seed milk after it has been passed through the sieve (Jinapong et al. 2008).

Rheological Measurement

Rheological properties of melon seed milk and reconstituted spray dried melon seed milk powder were measured with a rotary viscometer (Brookfield model LVDV-II, Brookfield Engineering Laboratories, Middleboro, Massachusetts, USA), as two parallels. The melon seed milk powders were reconstituted to dry matter contents which were equal to fresh melon seed milks.

During rheological measurement, the temperature of the samples was kept constant at 20 °C using a circulating water bath (Polyscience, Niles, Illinois, USA). The measurement range of Brookfield viscometer between 10 and 100 % full-scale torques was adjusted by selection of specific spindle (S-18) and its rotational speed (0.0–3.33 Hz) for melon seed milk beverages. The small sample adapter, which was a coaxial cylinder accessory of Brookfield viscometer and specifically designed to facilitate the measurement of small samples, was used to provide uniform shear stress–shear rate field during measurements. Shear stress (τ, in pascals) and shear rate (γ, in reciprocal seconds) values were recorded for each rotational speed (in hertz). The experimental data were fitted to Newtonian (Eq. (4)) and non-Newtonian (Eq. (5)) models to obtain rheological (yield stress, viscosity, consistency coefficient and flow behaviour index) and statistical coefficient of determinant (R2 - a measure of goodness-of-fit of linear regression) parameters;

| 4 |

| 5 |

where τ0 is the yield stress (in pascals), K is the consistency coefficient (in pascal-seconds), μ is the viscosity (in pascal-seconds) and n is the flow behaviour index (dimensionless).

Sensory evaluation

For sensory evaluation of beverages, the melon seed milk powder was reconstituted with water to dry matter contents which was equal to melon seed milk.

The products were evaluated by a panel of ten semi trained judges using the hedonic descriptive test on a 5 point scale, on the basis of taste, flavour, colour, consistency and overall acceptability. The products evaluated in the panel were beverages obtained from Kırkağaç melon seed, from Çeşme melon seed and reconstituted beverages obtained from Kırkağaç melon seed milk powder and Çeşme melon seed milk powder.

Statistical analysis

All of the measurements were made in triplicates. Results are expressed as mean ± standard deviation. The paired t-test was used to compare the values of means from two different melon seed samples. The statistical analyses were performed using SPSS (Statistical Package for the Social Sciences, SPSS Chicago, Illinois, USA) software version 15.0.

Results and discussion

Physical properties of melon seed milk powder

Moisture content and water activity of powder products were important properties due to having an effect on other physical and chemical properties. They are also critical factors for food stability (Aidoo et al. 2010). Moisture content of Çeşme and Kırkağaç melon seed milk (MSM) powders were 2.4 and 2.1 % on wet basis (wb), respectively (Table 1). Aidoo et al. (2010) reported that moisture contents of the drum dried peanut–cowpea milk powder ranged from 2.3 to 3.7 % (wet basis). Moisture content of spray dried MSM powders in this study were found under the maximum moisture specification limits of dried powders in food industry which were 3–4 % (Klinkesorn et al. 2006).

Table 1.

Physical properties of spray dried MSM powders

| Property | Çeşme melon | Kırkağaç melon |

|---|---|---|

| Moisture Content, [%] | 2.4* ± 0.1 | 2.1* ± 0.1 |

| Water Activity | 0.310* ± 0.005 | 0.260* ± 0.014 |

| L | 76.81 ± 0.56 | 77.02 ± 0.52 |

| a | 1.81* ± 0.10 | 2.50* ± 0.04 |

| b | 18.54 ± 0.74 | 18.00 ± 0.23 |

| Particle density, ρp [kg∙m−3] | 1311 ± 86 | 1069 ± 6 |

| Bulk Density, ρb [kg∙m−3] | 360 ± 13 | 340 ± 12 |

| Tapped Density, ρt [kg∙m−3] | 740 ± 10 | 730 ± 27 |

| Carr Index | 50.44 ± 1.7 | 53.23 ± 0.1 |

| Dispersibility [%] | 47.5 ± 6.6 | 60.3 ± 2.4 |

| Wettability [s] | 7.00 ± 1.41 | 7.00 ± 1.41 |

| Solubility [%] | 92.0 ± 0.2 | 99.2 ± 0.1 |

Results are given as mean ± standard deviation

*Significant differences in level 0.05

Moisture content is expressed in percent on wet basis

The water activity values of MSM powders for Çeşme and Kırkağaç were 0.310 and 0.260, and they were within the limits of safe storage. The high water activity values indicated more free water available for the biochemical reactions and the shorter shelf life. Fazaeli et al. (2012) reported that juice powders which had water activity in the range of 0.15–0.33 were quite stable from a microbiologically viewpoint. The significant relationship was found between the moisture content and water activity of MSM powder according to pearson correlation test (r = 0.943). The higher moisture content, the higher the water activity was observed in MSM powder obtained from Çeşme type melon. Moisture content and water activity of MSM powders were also dependent on melon type (p < 0.05).

Colour is one of the important quality attributes of food. It determines the acceptability of a product by consumers. The spray dried MSM powder samples were all generally creamy-white in colour and the samples were found quiet similar to conventional beverage. According to Hunter L, a, b results as shown in Table 1, there were no significant differences between the lightness (L) and yellowness (b) values of powders (p > 0.05). On the other hand, redness (a) values were significantly changed with the melon type (p < 0.05), this result could be explained with its own colour of Çeşme and Kırkağaç melon seeds. This observation could be explained by the fact that the extraction might facilitate the mass transfer of pigments and other impurities from the sample to the extracted material (Koç et al. 2015).

The bulk properties (bulk and tapped density, flowability) and particle densities of MSM powders are given in Table 1. Bulk and tapped densities were important features for classification of final product obtained by spray dryer (Barbosa-Canovas et al. 2005). Low bulk density of food powder was not desirable, because of the possibility of product oxidation (Samaram et al. 2014). Bulk densities of MSM powders obtained from Çeşme and Kırkağaç melon seeds were 360 and 340 kg · m−3, respectively. These values were close to corn starch (340 kg · m−3) (Barbosa-Canovas et al. 2005). However the tapped densities of samples were twice as much bulk densities. This circumstance was probably caused by small particle size and high fat content of MSM powders. Particle densities of MSM powders produced from both Kırkağaç and Çeşme melon seeds were higher than 1000 kg · m−3 (Table 1). These findings coherent with the other particle densities of food powders were produced by spray dryer (Barbosa-Canovas et al. 2005; Koç et al. 2014). Owning a higher particle density than water (1000 kg · m−3) would improve the reconstitution properties of food powders. Fitzpatrick et al. (2004) also found that the particle densities of milk powders produced by spray dryer varied in the range of 1130–1180 kg · m−3.

Carr Index values represent the flowability properties of powder. Carr index values of MSM powders produced from two different melon types were higher than 50 (Table 1). The results showed that there was no significant effect (p > 0.05) of melon type on bulk properties and flowability. High Carr Index value (>40) indicated that MSM powder had poor flowability (Carr 1965). Due to the matrix structure of foods containing sugar, protein and fat, the powdered foods obtained by spray drying tend to be caking and has poor flowability resulting in solid bridges between the particles. Flowability of food powders was influenced by the surface composition; the food powders containing higher levels of oil on the surface of particles tended to stick together and form lumps, which impeded flow (Koç et al. 2015). In the food industry anti-caking agents such as silicon dioxide, sodium aluminum silicate, tricalcium phosphate, calcium stearate, calcium silicate are added to final product to improve the flowability. However, spray dried MSM powder produced in this study did not contain any additives. The poor flowability of MSM powder could also be explained by a small particle size. Koç et al. (2011) reported that, the fine particle size of food powders led to worst flow properties.

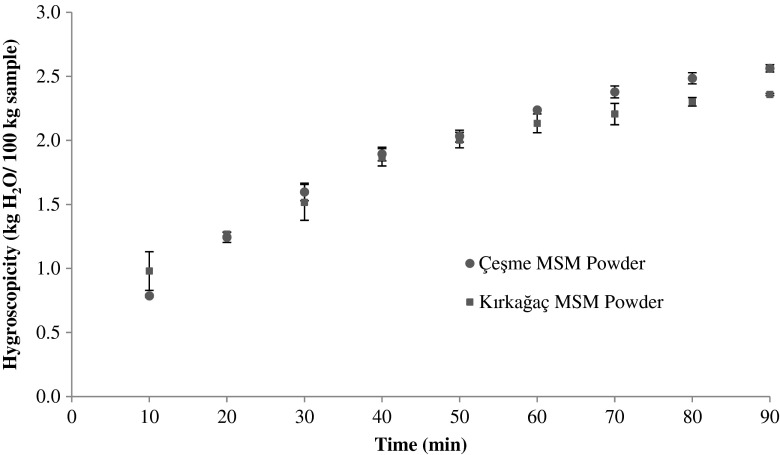

Hygroscopicity is also an important factor for powder reconstitution since it could lead to caking reducing dispersibility. Powders which absorb higher moisture might also cake during storage. Hygroscopicity values of the spray dried MSM powders at 25 °C and 75.3 % relative humidity (RH) after 90 min are shown in Fig. 1. The hygroscopicity values obtained for Çeşme and Kırkağaç MSM powders varied from 7.9 to 25.6 g · kg−1, and 9.8 to 23.6 g · kg−1, respectively. As seen in Fig. 1, MSM powders are not very hygroscopic. By contrast, the flow properties of samples were defined as poor. This circumstance probably caused that the surface of particles was covered by oil. High oil content on the surface of particles acted as a barrier against the moisture adsorption and stuck the particles with each other. Hygroscopicity properties of two different MSM powders were not significantly different (p > 0.05).

Fig. 1.

Hygroscopicity values of MSM powders

Reconstitution properties of MSM powders are also given in Table 1. These properties were very important quality parameters for ready-dilute beverages. Wettability of the powders was critical step of the re-dispersing process; the wetting time was used to investigate the instant behaviour of product (Kowalska and Lenart 2005). The capacity of the powder to mix with water was also one of the most important reconstitution properties (Bae and Lee 2008). Wettability time was 7 s for both MSM powders; hence the particle densities of powders were greater than the density of water.

Water solubility of MSM powder was another important attribute; if powders were directly dissolved in water in order to prepare drinks, the acceptance of the product by the consumers would increase. Solubility index values of MSM powders for Çeşme and Kırkağaç melons were 92.0 and 99.2 % (weight/weight), respectively (Table 1). According to these results, MSM powder had high degree of solubility in water. Water solubility of powder was directly related to its microstructure. According to literature, powders which had amorphous surface, had high solubility in the water (Cano-Chauca et al. 2005). High solubility values of MSM powders also related with the low moisture content. Low moisture content seemed to be associated with the fast rehydration (Goula and Adamopoulos 2008) and non-sticky feature of the powder (Klinkesorn et al. 2006).

The dispersibility rate of the powder is another important property. Dispersibility is the ability of powder to be wetted without formation of dry lumps in water (Martinelli et al. 2007). Dispersibility values of MSM powders were 47.5 % for Çeşme and 60.3 % for Kırkağaç melons (Table 1). The results showed that melon type had a significant effect (p < 0.05) on reconstitution properties.

Rheological properties of melon seed milk

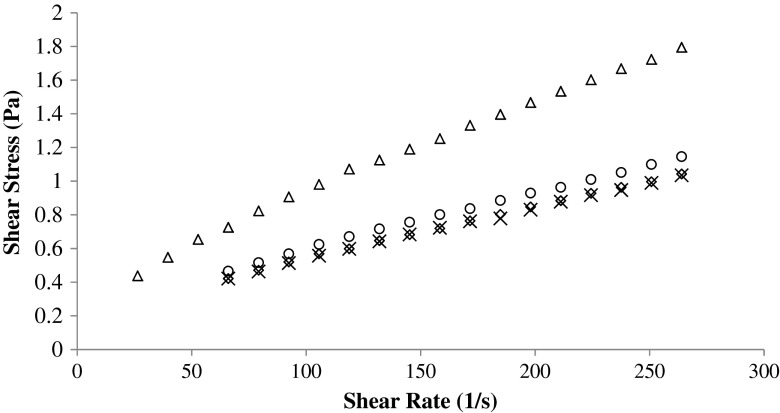

Rheological properties play an important role in food product development, quality control, sensory quality, design, and evaluation of the process equipment (Deboni et al. 2013). Its significance in product development in the food industry has been extensively discussed in literature. Additionally, the consumer acceptance of product was highly dependent on its consistency which requires information about viscosity and flow behavior (Deswal et al. 2014). Although lots of liquids including some food materials show Newtonian behaviour, most of the food products are shown to behave as non-Newtonian fluids (Rao 2007). Thus, the relationship between the shear stress and shear rate should be known. Figure 2 depicts the shear stress and shear rate relationship of experimental data obtained for MSM beverages. Flow curves of the fresh and reconstituted milks obtained from Çeşme melon seed were close to each other (Fig. 2). However, the flow curves of fresh and reconstituted milks obtained from Kırkağaç melon seed were slightly different from each other. The decrease in viscosity and the shear stress peak in the flow curves of the reconstituted milks indicated that the microstructure of the powder may have been disrupted by the spray drying process, which resulted in a reduction in the water holding capacity together with a weakening in the rheological properties, when the powder was reconstituted (Sakın-Yılmazer et al. 2014).

Fig. 2.

Flow curves of melon seed milk and reconstituted milk powders (◊ Çeşme MSM, ○ Reconstituted from Çeşme MSM Powder, △ Kırkağaç MSM, × Reconstituted from Kırkağaç MSM Powder)

The rheological data of MSM beverages produced from two different types of melons fitted to Newtonian and the non-Newtonian models. The all seed milk samples showed the Bingham type flow behaviour. The results were given in Table 2 with R2 and root-mean-square error (RMSE) values. According to Horne (2011), the flow behaviour of the skimmed milk was expressed with the Bingham model. The consistency coefficient of fresh milk obtained from Kırkağaç melon seed was higher than the other milks (Table 2), which have the close K values.

Table 2.

Consistency coefficient of MSM beverages

| Kırkağaç melon seed milk | Reconstituted from Kırkağaç MSM powder | Çeşme melon seed milk | Reconstituted from Çeşme MSM powder | ||||

|---|---|---|---|---|---|---|---|

| σ0 [Pa] | 0.366 | σ0 [Pa] | 0.232 | σ0 [Pa] | 0.232 | σ0 [Pa] | 0.262 |

| K [Pa.s] | 0.0060 | K[Pa.s] | 0.0033 | K[Pa.s] | 0.0030 | K[Pa.s] | 0.0029 |

| R 2 | 0.995 | R2 | 0.998 | R2 | 0.999 | R2 | 0.998 |

| RMSE | 0.080 | RMSE | 0.010 | RMSE | 0.019 | RMSE | 0.062 |

R 2 coefficient of determinant, RMSE Root Mean Square Error

Sensory evaluation of melon seed milk

The fact is that the rheological properties of beverages (apparent viscosity, shear rate- shear stress relation) are related to the sensory quality (consistency in the mouth) which directly affects consumer acceptance. The sensory scores of fresh and reconstituted MSMs obtained from two different melon types were presented in Table 3. The taste of the beverage was an important feature for the consumer acceptance. Fresh and reconstituted milks obtained from Çeşme melon seed had higher scores on the basis of taste (Table 3). According to the flavour, panel preferred fresh milks to the reconstituted ones, because of loss of flavour components during spray drying with hot air.

Table 3.

Sensory evaluation results of MSM beverages

| Beverages | Taste | Flavour | Colour | Consistency | Overall Acceptability |

|---|---|---|---|---|---|

| Kırkağaç melon seed milk | 3.1a ± 1.0 | 3.9a ± 1.1 | 3.7a ± 0.7 | 4.4a ± 0.7 | 3.7a ± 0.9 |

| Çeşme melon seed milk | 4.1b ± 1.1 | 3.9a ± 1.0 | 2.5b ± 0.9 | 3.9b ± 1.0 | 3.5b ± 1.1 |

| Reconstituted from Kırkağaç MSM powder | 3.6c ± 0.9 | 3.5b ± 0.9 | 4.2c ± 0.7 | 4.1c ± 1.0 | 3.9c ± 0.8 |

| Reconstituted from Çeşme MSM powder | 3.9d ± 0.8 | 3.6c ± 0.9 | 3.7a ± 0.9 | 3.5d ± 0.9 | 3.7a ± 0.5 |

Results are given as mean ± standard deviation

The different letter in the same row are significantly different (p < 0.05)

The appearance (colour) of a drink also affects consumer acceptance. The colour of MSM beverages was creamy white. Most of the panel preferred the colour of reconstituted milk obtained from Kırkağaç melon seed. This result was coherent with the findings of Akubor and Ogbadu (2003). Fresh milk obtained from Kırkağaç melon had appreciated much more by the panel. This result was consistent with the consistency results in Table 2.

To predict the relationship between sensorial consistency (SC) (Eq. 6) and measured consistency and yield stress value, linear regression analysis was applied. The sensorial consistency of samples changed significantly with the measured consistency and the yield stress values (p < 0.001). The obtained equation as a result of linear regression analysis was

| 6 |

with a R2 = 1.000.

The sensorial consistency scores of samples increased with increasing in measured consistency and decreasing in yield stress together. The consistency of beverage, that is how heavy or light, was an important factor for the mouthfeel (Sanful 2009). Rao et al. (1975) also reported that yield stress of potato puree was highly correlated with taste panel scores, an increase in yield stress indicating a less moist mouthfeel. According to the overall acceptability, the most appreciated product was the one obtained by reconstitution of Kırkağaç powder (Table 3).

Conclusions

MSM had limited shelf life due to high pH and water activity. MSM was spary dried to evaluate for use in ready-dilute beverages. The results showed that the moisture content and water activity of MSM powders were within the limits for safe storage. Wettability time of the MSM was found very short, hence, can be conveniently used for producing ready-dilute beverages. In addition their solubility in water was also very high, though were not classified as hygroscopic materials. Fresh and reconstituted milk made from melon seed showed the Bingham type flow behavior. Sensory analysis of reconstituted milk obtained from MSM powder showed creamy-white colour and highly acceptabitity scores, the most appreciated product. Results revealed that the spray dried MSM had a longer shelf life, maintain the quality characteristics of fresh sample and can be used as ready to dilute beverage.

Footnotes

Highlights:

• This study offers a different perspective for food wastes and by-products

• Melon seed milk was converted to powder form without any additives

• The limited shelf life of melon seed milk was extended by producing powder form

• Melon seed milk powder was able to consume by vegans and lactose-intolerant people

• In this study, melon seed was shown to be a new source for plant derived milk

References

- Aidoo H, Sakyi-Dawson E, Tano-Debrah K, Saalia FK. Development and characterization of dehydrated peanut–cowpea milk powder for use as a dairy milk substitute in chocolate manufacture. Food Res Int. 2010;43:79–85. doi: 10.1016/j.foodres.2009.08.018. [DOI] [Google Scholar]

- Akubor PI. Physicochemical and sensory characteristics of melon seed milk. J Food Sci Technol. 1998;35:93–97. [Google Scholar]

- Akubor PI, Ogbadu RL. Effects of processing methods on the quality and acceptability of melon milk. Plant Foods Hum Nutr. 2003;58:1–6. doi: 10.1023/a:1024063105507. [DOI] [PubMed] [Google Scholar]

- Akubor PI, Achi OK, Offonry SU. Influence of storage on chemical, microbial and consumer acceptability of a milk-like product made from melon seeds. Plant Foods Hum Nutr. 2002;57(2):91–196. doi: 10.1023/A:1015249906416. [DOI] [PubMed] [Google Scholar]

- AOAC . In: Official Methods of Analysis. 18. Horwitz W, Latimer G, editors. Gaithersburg: AOAC International; 2005. [Google Scholar]

- Bae KE, Lee SJ. Microencapsulation of avocado oil by spray drying using whey protein and maltodextrin. J Microencapsul. 2008;25(8):549–560. doi: 10.1080/02652040802075682. [DOI] [PubMed] [Google Scholar]

- Barbosa-Canovas GV, Ortega-Rivas E, Juliano P, Yan H. Food powders: physical properties, processing, and functionality. New York: Kluwer Academic/Plenu; 2005. [Google Scholar]

- Belewu MA, Belewu KY (2007) Comparative physico-chemical evaluation of tiger-nut, soybean and coconut milk sources. Int J Agric Biol 5:785–787, 1560-8530/2007/09-5-785-787

- Cano-Chauca M, Stringheta PC, Ramos AM, Cal-Vidal J. Effect of the carriers on the microstructure of mango powder spray drying and its functional characterization. Innov Food Sci Emerg. 2005;6:420–428. doi: 10.1016/j.ifset.2005.05.003. [DOI] [Google Scholar]

- Carr RL. Evaluating flow properties of solids. Chem Eng. 1965;72:163–168. [Google Scholar]

- De Mello LSM, Bora SP, Narain N. Fatty and amino acids composition of melon (Cucumis melo Var. saccharinus) seeds. J Food Compos Anal. 2001;14:69–74. doi: 10.1006/jfca.2000.0952. [DOI] [Google Scholar]

- Deboni TM, Bündchen M, Junior CV, Hotza D, Piletti R, Quadri MGN. Effect of the processing steps on cactus juice production. Food Bioprocess Technol. 2013;7(4):990–1000. doi: 10.1007/s11947-013-1098-4. [DOI] [Google Scholar]

- Deswal A, Deora NS, Mishra HN. Effect of concentration and temperature on the rheological properties of oat milk. Food Bioprocess Technol. 2014;7(8):2451–2459. doi: 10.1007/s11947-014-1332-8. [DOI] [Google Scholar]

- Diarra K, Nong ZG, Jie C. Peanut milk and peanut milk based products production: a review. Crit Rev Food Sci Nutr. 2005;45:405–423. doi: 10.1080/10408390590967685. [DOI] [PubMed] [Google Scholar]

- FAO (2015) Food and Agriculture Organization/WHO (World Health Organization), http://faostat3.fao.org/browse/Q/QL/E. Accessed 04 Dec 2015

- Fazaeli M, Emam-Djomeh Z, Ashtari AK, Omid M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprocess Technol. 2012;90:667–675. [Google Scholar]

- Fitzpatrick JJ, Iqbal T, Delaney C, Twomey T, Keogh MK. Effect of powder properties and storage conditions on the flowability of milk powders with different fat contents. J Food Eng. 2004;64(4):435–444. doi: 10.1016/j.jfoodeng.2003.11.011. [DOI] [Google Scholar]

- Goula AM, Adamopoulos KG. Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: I. Drying kinetics and product recovery. Dry Technol. 2008;26:714–725. doi: 10.1080/07373930802046369. [DOI] [Google Scholar]

- Heyman MB. Lactose intolerance in infants, children, and adolescents. Pediatrics. 2006;118(3):1279–1286. doi: 10.1542/peds.2006-1721. [DOI] [PubMed] [Google Scholar]

- Horne DS. Viscosity of milk and its concentrates. In: Dickinson E, Walstra P, editors. Food colloids and polymers: Stability and mechanical properties. Cambridge: Woodhead Publishing; 2011. pp. 260–266. [Google Scholar]

- Jinapong N, Suphantharika M, Jammong P. Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J Food Eng. 2008;84:194–205. doi: 10.1016/j.jfoodeng.2007.04.032. [DOI] [Google Scholar]

- Karakaya S, Kavas A, Nehir-El S, Gündüç N, Akdoğan L. Nutritive value of a melon seed beverage. Food Chem. 1995;52:139–141. doi: 10.1016/0308-8146(94)P4193-J. [DOI] [Google Scholar]

- Klinkesorn U, Sophanodora P, Chinachoti P, Decker EA, Mcclements DJ. Characterization of spray-dried tuna oil emulsified in two-layered interfacial membranes prepared using electrostatic layer-by-layer deposition. Food Res Int. 2006;39:449–457. doi: 10.1016/j.foodres.2005.09.008. [DOI] [Google Scholar]

- Koç M, Koç B, Sakin-Yılmazer M, Kaymak-Ertekin F, Susyal G, Bağdatlıoğlu N. Physicochemical characterization and oxidative stability of microencapsulated egg powder by spray drying. Dry Technol. 2011;29(7):780–788. doi: 10.1080/07373937.2010.538820. [DOI] [Google Scholar]

- Koç B, Sakin-Yılmazer M, Kaymak-Ertekin F, Balkır P. Physical properties of yoghurt powder produced by spray drying. J Food Sci Technol Mys. 2014;51(7):1377–1383. doi: 10.1007/s13197-012-0653-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Koç M, Zungur A, Güngör Ö, Yalçın B, Selek İ, Kaymak-Ertekin F, Ötleş S. Microencapsulation of extra virgin olive oil by spray drying: effect of wall materials composition, process conditions and emulsification method on microencapsulation efficiency, particle size and oxidative stability of microcapsules. Food Bioprocess Technol. 2015;8:301–318. doi: 10.1007/s11947-014-1404-9. [DOI] [Google Scholar]

- Kowalska J, Lenart A. The influence of ingredients distribution on properties of agglomerated cocoa products. J Food Eng. 2005;68(2):155–161. doi: 10.1016/j.jfoodeng.2004.05.028. [DOI] [Google Scholar]

- Martinelli L, Gabas AL, Telis-Romero J. Thermodynamic and quality properties of lemon juice powder as affected by maltodextrin and arabic gum. Dry Technol. 2007;25:2035–2045. doi: 10.1080/07373930701728836. [DOI] [Google Scholar]

- Rao MA. Application of rheology to fluid food handling and processing. In: Barbosa-Cànovas GV, editor. Rheology of Fluid and Semisolid Foods, Food Engineering Series. New York: Springer; 2007. pp. 427–469. [Google Scholar]

- Rao VNM, Hamann DD, Humphries EG. Flow behavior of sweet potato puree and its relation to mouthfeel quality. J Texture Stud. 1975;6(2):197–209. doi: 10.1111/j.1745-4603.1975.tb01248.x. [DOI] [Google Scholar]

- Sakın-Yılmazer M, Koç B, Balkır P, Kaymak-Ertekin F. Rheological behaviour of reconstituted yoghurt powder-an optimization study. Powder Technol. 2014;266(15):433–439. doi: 10.1016/j.powtec.2014.06.060. [DOI] [Google Scholar]

- Samaram S, Mirhosseini H, Tan CP, Ghazali HM. Ultrasound-assisted extraction and solvent extraction of papaya seed oil: crystallization and thermal behavior, saturation degree, color and oxidative stability. Ind Crop Prod. 2014;52:702–708. doi: 10.1016/j.indcrop.2013.11.047. [DOI] [Google Scholar]

- Sanful RE. Production and sensory evaluation of tigernut beverages. Pak J Nutr. 2009;8(5):688–690. doi: 10.3923/pjn.2009.688.690. [DOI] [Google Scholar]