Abstract

Effects of hydrocolloids such as Sodium polyacrylate, xanthan gum and sodium alginate on the energy consumption and quality of frozen cooked noodles were investigated. Results showed that gelatinization temperature (GT) shortened significantly and texture properties (hardness, firmness, break strength) of frozen cooked noodle were significantly improved by adding different hydrocolloid additives (P < 0.05). Nevertheless, there were no significant differences of glass-transition temperature between hydrocolloid fortified and non fortified frozen cooked noodles. Moreover, the hydrocolloids improved quality of cooked noodle and increased energy consumption, however, xanthan gum showed the best results. The optimized constituents were: sodium polyacrylate 0.13 %, xanthan gum 0.86 %, sodium alginate 0.18 % with predicted sensory scores of 90.30. The study showed that hydrocolloids could be used as modifying agents in frozen cooked noodle process.

Keywords: Frozen cooked noodles, Energy saving, GT, Texture properties, Hydrocolloids

Introduction

Noodles are important foods consumed in Asian countries. It has been estimated that at least 12 % of the global wheat production is used for making Asian noodle products.(Gan et al. 2009). Noodles may be sold as a fresh product, but owing to high contents of water and nutrient substances, consumption must occur within a short time before they spoil (Xu et al. 2008). With the development of society and economy, consumers nowadays are increasingly considering about ready-to-eat convenience and healthy quality of the food, and demand products with reduced or no levels of chemical preservatives (Diez et al. 2009; Olivera and Salvadori 2009). Therefore, frozen cooked noodles offer a viable alternative. Frozen cooked noodles have been precooked in boiling water and require only minimal time to reheat. Precooking and freezing are two of the most important processes. The precooking process is an essential stage of follow-up of noodles production and the subsequent processes include cooling, freezing and reheating (Hatcher 2004). The frozen cooked noodles have many advantages as convenient, long shelf life, good taste and no added preservatives. It also allows restaurants to serve tasty noodles conveniently and efficiently without the need to provide employees with special training in noodle preparation. Although frozen noodles are becoming popular, presently they account for only 15 % of the total noodle production, even in Japan (Fu 2008). The frozen noodle industry was initially developed during the last decade in China. Although there are several companies in China that produce frozen noodles, the market for frozen noodles is not growing very fast. One reason is that the production of frozen noodles is an energy intensive process, including cooking and quick-frozen process. Energy saving is considered important for effective resource utilization and for reducing global warming. In the process of production, reducing the use of heat sources, especially electrical sources, is the most effective means for reducing product costs and CO2 emission (Mikami et al. 2010).

Many additives such as natural gum (Charlesa et al. 2007), enzymes (Wu and Corke 2005), whey protein isolate (WPI), casein, chitosan, and pregelatinized starch (Chillo et al. 2009) have been used to improve the flavor and texture of fresh noodle products. Hydrocolloids were commonly used additives in frozen cooked noodle which has such advantages as stability, water holding capacity and thickening ability. Xanthan and sodium alginate had the most pronounced effect on dough properties which increased the specific volume, moisture retention and water activity, augmented the extensibility of dough, and improved texture properties (Ribotta et al. 2005; Rosell et al. 2001). Xanthan and guar gum addition increased the maximal breaking force of frozen noodles and is attributed to improvement in gluten matrix. Xanthan gum addition also can reduce the fusion enthalpy in comparison to the control formulation (Christianson et al. 1981). Xanthan and sodium polyacrylate show the best effects which could significantly improve firmness and the stretch force, enlarge the stretch distance and improve the hardness and chewiness of frozen noodles (Lü et al. 2014). However, most of the research on the effects of additives to frozen noodles was focused on quality, while energy consumption aspects were ignored. Therefore research on effect of hydrocolloids on frozen cooked noodles based on quality and energy consumption was necessary.

Gelatinization temperature is the lowest temperature at which gelatinization of starch sets in. The lower GT made it easier to gelatinize starch and less to expend energy in the same degree (Eguchi et al. 2014). For frozen cooked noodle, it is possible to cut energy consumption by the way of decreasing GT (Nahidul Islam et al. 2015). At glass-transition temperature, the change of food quality is controlled by the reaction of diffusion, which is quite slow in speed or even could not happen. The increase of glass-transition temperature is conducive to quality retention and energy-saving. Gelatinization and glass-transition temperature had an important influence on quality and energy consumption of frozen noodle product but this has hardly been investigated.

In present study, effect of hydrocolloids (sodium polyacrylate, xanthan gum and sodium alginate) on cooking, texture and sensory characteristics of frozen cooked noodles was studied.

Materials and methods

Materials

High-protein wheat flour special grade No. 1 (Zhengzhou Jinyuan Food Co., Ltd., Zhengzhou, China) and salt were obtained from the local market and stored at 25 °C during the study. The moisture, protein, ash, and wet gluten contents of the wheat flour were determined according to approved methods of the American Association of Cereal Chemists (AACC): Methods 44-15A, 46–13, 08–01, and 38-12A (AACC 2000). Sodium polyacrylate, sodium alginate and xanthan gum were generously provided by the Honest Additive Company (Zhengzhou, China). The maximum number of adding additives according to the requirements of GB 2760–2011, the specific amount range combined with production practice and experience.

Frozen cooked noodles preparation

Noodles were prepared according to the method described by Hou (2010). The noodle formula consisted of 200 g flour and 76 mL distilled water. 2 % salt and additives were dissolved in water and then hydrated. The dough was formed using an S5A multifunction mixer (Guangzhou Wellmax Industrial Co., Ltd., Guangzhou, China) and mixed for 15 min. The prepared flocculated mixture was covered by a gauze for 30 min at 25 °C and 70 % humidity. Then, the mixture was sheeted on a customized mini laboratory combination noodle machine (Custom made, Shangdong Longkou Machinery Co., Ltd., Shangdong, China) with an initial gap setting of 3.0 mm. Different noodle cutters were used to obtain noodle strands with different widths and thicknesses. The noodles were cut into same specifications (200 mm long, 2.5 mm wide and 1.0 mm thick) and divided into several pieces (20 g per piece) and stored for further research. Imperfect noodle strands were picked out and eliminated. Noodles were divided into several subsamples for the cooking method study.

Fresh control noodles were prepared, optimally precooked in boiling water until no visible core was present (4 min). The samples were rinsed under running distilled water and maintained at 20 °C. Then distilled water was drained from the samples before being transferred to the −40 °C freezer. After 30 min at −40 °C, frozen noodle was transferred to a −18 °C freezer for prolonged storage.

Gelatinization temperature

The gelatinization properties of starches were evaluated using a Rapid Visco Analyzer (RVA-3D, Newport Scientific, Warriewood, Australia) following the method of Singh et al. (2004). Dispense 25.0 ml (±0.1 ml) water (14 % moisture basis) and weigh 3.5 g flour into weighing vessel. Temperature modes adopted according to AACC standards were: initial temperature of 50 °C for 1 min, heat at a rate of 12 °C/min to 95 °C,maintain at 95 °C for 2.5 min, then cooled at the same rate to 50 °C and finally maintained at 50 °C for 1.5 min. Peak viscosity, trough viscosity, breakdown, final viscosity, setback, peak time and pasting temperature were recorded.

Cooking time (CT)

Cooking time (CT) was determined according to the method of Heo et al. (2012) with some modifications. Noodles (20 g, 200 mm long) were put into boiling water (200 ml, 98 ~ 100 °C), and then took out a noodle every 20s. The white core of noodles was observed with two pieces of transparent glass flattening. The best CT was recorded when middle white core just disappeared.

Glass-transition temperature

Glass transition properties of frozen cooked noodle were investigated following the method of Ohkuma et al. (2008). The glass transition temperature was analyzed using Differential Scanning Calorimeter (DSC-200 F3, NETZSCH co., Germany) according to the method of Singh, Sodhi, & Singh with slight modifications. 10–15 mg frozen cooked noodle was accurately weighed into an aluminium pan. The pans were hermetically sealed and equilibrated at room temperature for 1 h prior to the analysis. DSC was calibrated using indium and an empty pan was used as the reference. Samples were maintained at −20 °C for 10 min, cooled at a rate of 10 °C/min to −60 °C,maintained at −60 °C for 10 min, and heated at 5 °C/min to 20 °C. The gelatinization parameters recorded were glass-transition temperature and enthalpy of melting (ΔH).

Texture properties analyses

Textural properties of cooked noodles were measured using a TA-XT Plus texture analyzer (Stable Micro Systems, Surrey, UK) under optimal test conditions according to the method of. Luo et al. (2015). A TA-XT Plus texture analyzer (Stable Micro Systems, Surrey, UK) equipped with P50 probe was used to perform the texture profile analysis. Noodles (20 g) were removed from the boiling water after cooking for 4 min, cooled for 20 s in ion-exchanged water at 20 °C, and drained of excess water with a basket. Samples of cooked noodles were provided immediately. Firmness was determined by compressing the noodles up to a strain of 70 % at a speed of 0.8 mm/s, whereas break strength was determined using A/SPR probe at a cross head speed of 2.0 mm/s following the method of Wu and Corke (2005). Texture measurements of the cooked noodles were replicated six times for each sample. Then, the average was calculated after discarding the maximum and minimum values.

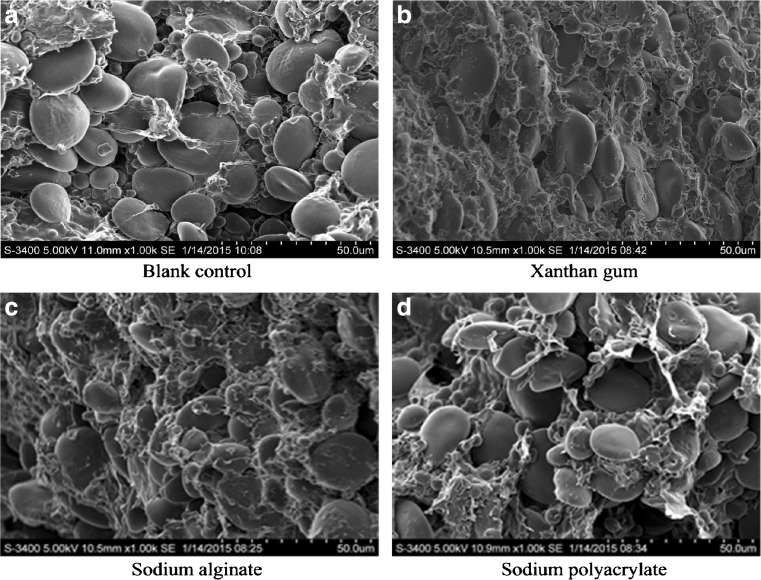

Scanning electron microscopy (SEM)

The starch granules and network of gluten of frozen cooked noodles were observed using a Scanning Electron Microscope (SEM, Hitachi SN-3400, Japan). The samples were sprinkled on a double-sided tape mounted on a SEM stub, coated with gold, and then placed in the SEM chamber immediately after 20 min, photomicrographs were taken using a SEM apparatus at an accelerating voltage of 20 kV and a magnification of × 1000.00.

Sensory evaluation

Sensory evaluation was carried out by 10 trained panelists (5 females and 5 male; age, 22 ~ 43 years) using quantitative descriptive analysis (QDA) (Lawless and Heymann 2010; Menon et al. 2015). The evaluation standard and the attributes’ weights were selected according to SB/T10137-1993 “the quality evaluation standard of noodles” with some adjustments for the properties of frozen noodles.

Statistical Analysis

All the analyses were done in triplicate and statistical treatment of the data was conducted by analysis of variances (ANOVA) of SPSS PASW Statistics v18.0 and Duncan Test was used to compare the means when the overall P value of the experiment was below the value of significance (P < 0.05). Mean values and the standard errors were calculated and presented in chart as coordinate pairs with error bars.

Results and discussion

Gelatinization temperature

The lower gelatinization temperature (GT) made it easier to gelatinize starch and less energy was expended. Effect of hydrophilic colloid on GT of frozen cooked noodle was shown in Table 1. GT was significantly lower by adding different hydrocolloids, which corroborated with the previous reports presented by other scholars. The results also showed that xanthan gum had a better effect than sodium alginate and sodium polyacrylate. The GT decreased with increasing level of additives. This may be attributed to the formation of complex by the interaction of hydrocolloids and starch,which reduced the energy of starch gelatinization and changed the GT (Shi and Bemiller 2002). There were significantly positive correlation between GT and CT (r = 0.816, 0.913 and 0.875, respectively) (Table 2). As the GT decreased, the CT of the noodles also decreased. The CT of white salt noodles can be predicted by pasting temperature (Park and Baik 2004)

Table 1.

Effect of hydrocolloids on gelatinization temperature (GT) and cooking time (CT) of frozen cooked noodle

| Hydrophilic colloid/% | Sodium polyacrylate | Sodium alginate | Xanthan gum | |||

|---|---|---|---|---|---|---|

| GT/°C | CT/s | GT/°C | CT/s | GT/°C | CT/s | |

| 0 | 70.70 ± 0.35a | 268 ± 10.95 | 70.70 ± 0.35a | 268 ± 10.95 | 70.70 ± 0.35a | 268 ± 10.95 |

| 0.04 | 66.64 ± 0.24b | 240 ± 0.00 | 67.13 ± 0.22d | 252 ± 10.95 | 66.92 ± 0.14b | 244 ± 16.73 |

| 0.08 | 65.15 ± 0.31d | 232 ± 10.95 | 65.22 ± 0.18e | 228 ± 17.89 | 65.45 ± 0.17c | 228 ± 10.95 |

| 0.12 | 64.42 ± 0.23e | 184 ± 16.73 | 66.84 ± 0.27d | 228 ± 10.95 | 65.23 ± 0.23c | 220 ± 14.14 |

| 0.16 | 65.35 ± 0.34cd | 232 ± 10.95 | 67.71 ± 0.24c | 256 ± 8.94 | 64.60 ± 0.21d | 192 ± 10.95 |

| 0.20 | 65.85 ± 0.35c | 236 ± 8.94 | 68.92 ± 0.36b | 264 ± 8.94 | 64.64 ± 0.28d | 196 ± 16.73 |

Values are presented as mean ± SEM (n = 3)

Mean values in the same column in each parameter with different letters are significantly different (P < 0.05)

Table 2.

The relation of cooking time and gelatinization temperature of frozen cooked noodle

| Hydrophilic colloid | Cooking time | Gelatinization temperature | |

|---|---|---|---|

| Sodium polyacrylate | Gelatinization temperature | 0.816a | 1 |

| Cooking time | 1 | 0.816* | |

| Sodium alginate | Gelatinization temperature | 0.913a | 1 |

| Cooking time | 1 | 0.913* | |

| Xanthan gum | Gelatinization temperature | 0.875a | 1 |

| Cooking time | 1 | 0.875* | |

aMean correlated significantly at the 0.05 level

Glass-transition temperature

Effect of hydrocolloids on glass-transition temperature of frozen cooked noodle is reported in Table 3. The glass-transition temperature of frozen cooked noodle was −30 °C. There were no significant differences in the glass-transition temperature of hydrocolloid fortified frozen cooked noodles and non fortified frozen cooked noodles. This may be attributed to the fact that the glass transition temperature of the frozen noodle was mainly determined by the water content, while hydrocolloids had less effect on it. Water can increase the free volume of the system and reduce the system viscosity and plasticizing the glassy state by free volume and viscosity theory. In general, the higher the moisture content in the system, the lower the glass transition temperature (Ribotta et al. 2005 and Matuda et al. 2008).

Table 3.

Effect of additives on glass-transition temperature of frozen cooked noodle

| Hydrocolloids | Glass-transition temperature a |

|---|---|

| Non fortified frozen cooked noodle | −33.60 ± 0.14a |

| Sodium polyacrylate | −33.59 ± 0.35a |

| Sodium alginate | −33.41 ± 0.20a |

| Xanthan gum | −33.27 ± 0.12a |

Values are presented as mean ± SEM (n = 3)

Mean values with same letter is non-significantly different (P > 0.05)

Texture properties

Texture of cooked noodles is one of the major quality attributes that determine consumer acceptance of the product (Luo et al. 2015). The texture properties (hardness, firmness, break strength) of frozen cooked noodle were significantly improved with hydrocolloids. This had been explained by the formation of a tight protein network, which embedded the starch granules and resulted in a stronger structure (Zweifel et al. 2000; Giannou and Tzia 2007). Irrespective of the level of addition, textural parameters such as hardness, firmness and breaking strength were significantly higher for all the hydrocolloid fortified noodles in comparison to those made without fortification (Table 4). The improvement in texture properties was maximum with xanthan gum followed by sodium polyacrylate and sodium alginate. This phenomenon may be attributed to the formation of encounter complex by the interaction of hydrophilic group of hydrophilic colloid, starch, lipid and protein, which protein network structure was in the best state of hydration. As a result, the rheological properties of dough were improved and the texture of dough became smoother. Xanthan gum had the double helix structure by hydrogen bonding and in the form of multiple spiral polymer secondary structure (Song et al. 2006). This may have improved water-holding capacity and stability of frozen cooked noodles. The addition of Sodium alginate can prevent soluble starch and nutrients from exudation and enhance water affinity and strong adhesion (Mazur et al. 2014). Polyacrylic acid can enhance the bonding force of the protein in the flour and increase the ductility of the dough due to the properties of thickening and emulsification (Cordes 2007).

Table 4.

Effect of hydrophilic colloid on the hardness, firmness and break strength of frozen cooked noodle

| Hydrocolloid | Level (%) | Hardness (N · cm−2) | Firmness (N) | Break strength (g) |

|---|---|---|---|---|

| Sodium polyacrylate | 0 | 8.061 ± 0.226c | 0.910 ± 0.047c | 10.784 ± 0.399c |

| 0.04 | 9.723 ± 0.344a | 1.134 ± 0.084b | 11.061 ± 0.549c | |

| 0.08 | 9.210 ± 0.226b | 1.126 ± 0.025b | 12.790 ± 0.456ab | |

| 0.12 | 9.687 ± 0.159a | 1.151 ± 0.059b | 13.776 ± 0.942a | |

| 0.16 | 9.608 ± 0.105ab | 1.269 ± 0.079a | 11.782 ± 0.641bc | |

| 0.20 | 9.645 ± 0.282ab | 1.074 ± 0.043b | 12.511 ± 0.885b | |

| Sodium alginate | 0 | 8.061 ± 0.226b | 0.910 ± 0.047d | 10.784 ± 0.399c |

| 0.10 | 9.478 ± 0.291a | 1.256 ± 0.051c | 13.083 ± 0.743b | |

| 0.20 | 9.735 ± 0.181a | 1.287 ± 0.040bc | 12.912 ± 0.909b | |

| 0.30 | 9.729 ± 0.239a | 1.381 ± 0.035a | 12.987 ± 0.661b | |

| 0.40 | 9.395 ± 0.272a | 1.366 ± 0.041ab | 13.112 ± 0.810b | |

| 0.50 | 9.549 ± 0.204a | 1.338 ± 0.063abc | 14.449 ± 0.558a | |

| Xanthan gum | 0 | 8.061 ± 0.226d | 0.910 ± 0.047c | 10.784 ± 0.399b |

| 0.20 | 9.635 ± 0.276c | 1.302 ± 0.033b | 14.962 ± 1.441a | |

| 0.40 | 10.453 ± 0.153b | 1.325 ± 0.085b | 16.322 ± 0.874a | |

| 0.60 | 10.509 ± 0.254b | 1.561 ± 0.073a | 15.523 ± 0.679a | |

| 0.80 | 10.83 ± 0.456ab | 1.563 ± 0.034a | 16.264 ± 1.015a | |

| 1.00 | 11.126 ± 0.400a | 1.558 ± 0.089a | 15.454 ± 1.707a |

Mean ± SD

Microstructures of frozen noodles

Effect of hydrophilic colloid on the microstructure of frozen cooked noodle was shown in Fig. 1. Figure 1a showed the microstructure of a frozen noodle strand made without additives. There were some large spherical voids in the noodle, which might have been formed by ice crystals. Many starch granules were exposed to the surface of the gluten network. In comparison, the frozen noodle with additives (Fig. 1b, c, and d) formed a continuous structure with few voids. There were also few starch granules exposed to the noodle surface. When the additives were added, the water was distributed more uniformly in the noodle system. The surfaces of noodles presented a continuous matrix with starch granules immersed in thedeveloped gluten network (Rojas et al. 2000). Thus, smaller ice crystals formed during freezing caused less destruction of the gluten. This was reflected by the more continuous structure, with fewer voids and starch granules exposed to the outside (Zounis et al. 2002). Hydrocolloids can effectively improve the microscopic structure of frozen noodles and into the close association of starch and gluten protein more closely, which improved the quality of the frozen noodles to some extent. This phenomenon was similar to the study of Hymavathi et al. (2014) on ready-to-cook gluten free extruded products. Xanthan gum was found to be more beneficial for improved microstructure formation of frozen cooked noodle than sodium alginate and sodium polyacrylate.

Fig. 1.

Effect of hydrocolloid on the microstructure of frozen cooked noodle

Response surface analysis

Three hydrophilic colloid additives (odium polyacrylate(X1), xanthan gum(X2) and sodium alginate (X3)) were used to reduce the energy consumption and improve the quality of frozen noodles and. A Central Composite Design (CCD) was used. Based on the experimental results of the RSM, the coefficients of both the independent variables and interaction variables were calculated and regression equations were generated.

The fitness of model was evaluated by ANOVA (results not shown). The model for GT (F-value of 14.62) was significant. Moreover, the F-value of 2.33 implied a non-significant of “lack of fit.” An adjusted R2 of 0.94 implied the good fit of the current model. The signal-to-noise ratio of 9.6 (> 4) indicated that this model can be used to navigate the design space.

GT and sensory evaluation scores were utilized to optimize the formulation for frozen cooked noodles. This was executed by choosing proper response aims and limits. For frozen noodles, the quality and prices which customers paid more attention to were of equal importance. The product quality was reflected by sensory scores and price was affected by cost of energy consumption. Taken together, the GT and sensory evaluation scores were set to same asterisks. To predict results with higher reliability, the optimization was carried out within limits for the chosen ranges. The optimized formula was: sodium polyacrylate 0.13 %, xanthan gum 0.86 %, sodium alginate 0.18 %. With this formula, the GT and sensory evaluation score were predicted to be 62.28 °C and 90.30, respectively. The experimental results were quite close to the predicted results.

Conclusions

GT and CT of the noodles decreased significantly upon addition of different hydrocolloids (polyacrylic acid sodium, sodium alginate and xanthan gum). The glass-transition temperature of frozen fortified and non fortified noodles did not differ significantly. Texture properties (hardness, firmness, break strength) of frozen cooked noodle were significantly improved upon addition of different hydrocolloids. Addition of hydrocolloids effectively improve the microscopic structure of frozen noodles due to the formation of firmer starch-gluten network. Hydrocolloids also improved energy and quality of frozen cooked noodle, although xanthan gum showed the best results. The optimized formula by response surface analysis was: sodium polyacrylate 0.13 %, xanthan gum 0.86 %, sodium alginate 0.18 %.

Acknowledgments

This work was financially supported by the National Science and Technology Support Program Project Funds (No. 2012BAD37B06).

Footnotes

Highlights

• Hydrocolloids (sodium polyacrylate, xanthan gum and sodium alginate) could reduce the gelatinization temperature and improve texture properties of frozen cooked noodle.

• Hydrocolloids were beneficial in improving the quality of cooked noodle and increased energy consumption

• Hydrocolloids had no effect on glass-transition temperature of frozen cooked noodle.

• The optimized formula by response surface analysis was: sodium polyacrylate 0.13 %, xanthan gum 0.86 %, sodium alginate 0.18 %. Under this condition, the gelatinization temperature and sensory evaluation score were predicted to be 62.28 °C and 90.30, respectively.

References

- American Association of Cereal Chemists . Approved method of AACC. 10. St Paul: The Association; 2000. [Google Scholar]

- Charlesa AL, Huang TC, Laia PY, Chen CC, Leed PP, Chang YH. Study of wheat flourecassava starch composite mix and the function of cassava mucilage in Chinese noodles. Food Hydrocoll. 2007;21:368–378. doi: 10.1016/j.foodhyd.2006.04.008. [DOI] [Google Scholar]

- Chillo S, Suriano N, Lamacchia C, Del Nobile MA. Effects of additives on the rheological and mechanical properties of non-conventional fresh handmade tagliatelle. J Cereal Sci. 2009;49(2):163–170. doi: 10.1016/j.jcs.2008.09.002. [DOI] [Google Scholar]

- Christianson DD, Hodge JE, Osborne D, Detroy RW (1981) Gelatinization of wheat starch as modified by xanthan gum, guar gum, and cellulose gum. Cereal Chem 58(6):513–517

- Cordes MG. Polyacrylic acid. Xpharm Compr Pharm Ref. 2007;34(1):1–2. [Google Scholar]

- Diez AM, Santos EM, Jaime I, Rovira J. Effectiveness of combined preservation methods to extend the shelf life of Morcilla de Burgos. Meat Sci. 2009;81(1):171–177. doi: 10.1016/j.meatsci.2008.07.015. [DOI] [PubMed] [Google Scholar]

- Eguchi S, Kitamoto N, Nishinari K, Yoshimura M. Effects of esterified tapioca starch on the physical and thermal properties of Japanese white salted noodles prepared partly by residual heat. Food Hydrocoll. 2014;35:198–208. doi: 10.1016/j.foodhyd.2013.05.012. [DOI] [Google Scholar]

- Fu BX. Asian noodles: history, classification, raw materials, and processing. Food Res Int. 2008;41(9):888–902. doi: 10.1016/j.foodres.2007.11.007. [DOI] [Google Scholar]

- Gan CY, Ong WH, Wong LM, Easa AM. Effects of ribose, microbial transglutaminase and soy protein isolate on physical properties and in vitro starch digestibility of yellow noodles. LWT Food Sci Technol. 2009;42(1):174–179. doi: 10.1016/j.lwt.2008.05.004. [DOI] [Google Scholar]

- Giannou V, Tzia C. Frozen dough bread: quality and textural behavior during prolonged storage – Prediction of final product characteristics. J Food Eng. 2007;79(3):929–934. doi: 10.1016/j.jfoodeng.2006.03.013. [DOI] [Google Scholar]

- Hatcher DW. Influence of frozen noodle processing on cooked noodle texture. J Texture Stud. 2004;35(4):429–444. doi: 10.1111/j.1745-4603.2004.tb00605.x. [DOI] [Google Scholar]

- Heo H, Baik BK, Kang CS, Choo BK, Park CS. Influence of amylose content on cooking time and textural properties of white salted noodles. Food Sci Biotechnol. 2012;21(2):345–353. doi: 10.1007/s10068-012-0046-9. [DOI] [Google Scholar]

- Hou GG (2010) Asian noodles: science, technology, and processing. Wiley

- Hymavathi TV, Spandana S, Sowmya S. Effect of hydrocolloids on cooking quality, protein and starch digestibility of ready-to-cook gluten free extruded product. Agric Eng Int Cigr J. 2014;16(2):119–125. [Google Scholar]

- Lawless HT, Heymann H (2010) Sensory evaluation of food. Principles & Practices Chapman & Hall & International Thompson Publishing 98(7–8):A09

- Lü YG, Chen J, Li XQ, Ren L, He YQ, Qu LB. Study on processing and quality improvement of frozen noodles. LWT Food Sci Technol. 2014;59(1):403–410. doi: 10.1016/j.lwt.2014.05.046. [DOI] [Google Scholar]

- Luo L-J, Guo X-N, Zhu K-X. Effect of steaming on the quality characteristics of frozen cooked noodles. LWT Food Sci Technol. 2015;62(2):1134–1140. doi: 10.1016/j.lwt.2015.02.008. [DOI] [Google Scholar]

- Matuda TG, Chevallier S, Filho PDAP, Lebail A, Tadini CC. Impact of guar and xanthan gums on proofing and calorimetric parameters of frozen bread dough. J Cereal Sci. 2008;48(3):741–746. doi: 10.1016/j.jcs.2008.04.006. [DOI] [Google Scholar]

- Mazur K, Buchner R, Bonn M, Hunger J. Hydration of sodium alginate in aqueous solution. Macromolecules. 2014;47(2):771–776. doi: 10.1021/ma4023873. [DOI] [Google Scholar]

- Menon R, Padmaja G, Sajeev MS. Cooking behavior and starch digestibility of NUTRIOSE (resistantstarch) enriched noodles from sweet potato flour and starch. Food Chem. 2015;182:217–223. doi: 10.1016/j.foodchem.2015.02.148. [DOI] [PubMed] [Google Scholar]

- Mikami A, Kita N, Sato K, Nagao K. Comparative effects on energy requirements and CO2 emission of different methods of cooking by a wok and other cookware. J Cookery Sci Japan. 2010;43:98–105. [Google Scholar]

- Nahidul Islam M, Zhang M, Liu H, X C. Effects of ultrasound on glass transition temperature of freeze-dried pear (Pyrus pyrifolia) using DMA thermal analysis. Food Bioprod Process. 2015;94:229–238. doi: 10.1016/j.fbp.2014.02.004. [DOI] [Google Scholar]

- Ohkuma C, Kawai K, Viriyarattanasak C, Mahawanich T, Tantratian S, Takai R, et al. Glass transition properties of frozen and freeze-dried surimi products: effects of sugar and moisture on the glass transition temperature. Food Hydrocoll. 2008;22(2):255–262. doi: 10.1016/j.foodhyd.2006.11.011. [DOI] [Google Scholar]

- Olivera DF, Salvadori VO. Effect of freezing rate in textural and rheological characteristics of frozen cooked organic pasta. J Food Eng. 2009;90(2):271–276. doi: 10.1016/j.jfoodeng.2008.06.041. [DOI] [Google Scholar]

- Park CS, Baik BK (2004) Cooking time of white salted noodles and its relationship with protein and amylose contents of wheat. Cereal Chem 81(2):165–171

- Ribotta PD, Ausar SF, Beltramo DM, Leon AE. Interactions of hydrocolloids and sonicated-gluten proteins. Food Hydrocoll. 2005;19(1):93–99. doi: 10.1016/j.foodhyd.2004.04.018. [DOI] [Google Scholar]

- Rojas JA, Rosell CM, Benedito de Barber C, Perez-Munuera I, Lluch MA. The baking process of wheat rolls followed by cryo scanning electron microscopy. Eur Food Res Technol. 2000;212(1):57–63. doi: 10.1007/s002170000209. [DOI] [Google Scholar]

- Rosell CM, Rojas JA, Benedito de Barber C. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll. 2001;15(1):75–81. doi: 10.1016/S0268-005X(00)00054-0. [DOI] [Google Scholar]

- Shi X, Bemiller JN. Effects of food gums on viscosities of starch suspensions during pasting. Carbohydr Polym. 2002;1(01):7–18. doi: 10.1016/S0144-8617(01)00369-1. [DOI] [Google Scholar]

- Singh N, Sandhu KS, Kaur M. Characterization of starches separated from indian chickpea (cicer arietinum l.) cultivars. J Food Eng. 2004;63(4):441–449. doi: 10.1016/j.jfoodeng.2003.09.003. [DOI] [Google Scholar]

- Song KW, Kim YS, Chang GS. Rheology of concentrated xanthan gum solutions: steady shear flow behavior. Fibers Polym. 2006;7(2):129–138. doi: 10.1007/BF02908257. [DOI] [Google Scholar]

- Wu JP, Corke H. Quality of dried white salted noodles affected by microbial transglutaminase. J Sci Food Agric. 2005;85(15):2587–2594. doi: 10.1002/jsfa.2311. [DOI] [Google Scholar]

- Xu YY, Hall C, III, Wolf-Hall C, Manthey F. Fungistatic activity of flaxseed in potato dextrose agar and a fresh noodle system. Int J Food Microbiol. 2008;121(3):262–267. doi: 10.1016/j.ijfoodmicro.2007.11.005. [DOI] [PubMed] [Google Scholar]

- Zounis S, Quail KJ, Wootton M, Dickson MR. Studying frozen dough structure using low-temperature scanning electron microscopy. J Cereal Sci. 2002;35(2):135–147. doi: 10.1006/jcrs.2001.0406. [DOI] [Google Scholar]

- Zweifel C, Conde-Petit B, Escher F. Thermal modifications of starch during high-temperature drying of pasta. Cereal Chem. 2000;77(5):645–651. doi: 10.1094/CCHEM.2000.77.5.645. [DOI] [Google Scholar]