Absract

This study was undertaken with the objective of formulating composite bread using pearl millet (Pennisetum glaucum) and wheat (Triticum aestivum) flours . Rheological and bread making properties of composite flours were evaluated. Mixolab results revealed torque increased and dough stability time decreased upon incorporation of pearl millet flour in wheat flour. The incorporation of millet flour at optimum level (5 %) led to an increase of the dough strength (W) and the elasticity-to-extensibility ratio (P/L) by 31 % and 65 % respectively. The bread texture and volume were also improved. These findings indicated the potentiality of using millet flour in bread making.

Keywords: Millet flour, Wheat flour, Rheological properties, Texture analysis, Bread volume

Introduction

Pearl millet (Pennisetum glaucum) is a staple food in many developing countries and constitutes the major source of essential nutrients in semi-arid and arid regions of Africa. It’s a good source of dietary protein, carbohydrates, fat, vitamins and minerals particularly iron and zinc. It has high levels of lipids, high quality and well-balanced proteins and diverse health promoting phenolic compounds. It is known to be nutritionally better than most other cereals. In addition and being gluten- free, it responds to the growing demand for gluten-free foods and beverages from people with coeliac diseases and other intolerances to wheat (Kasarda 2001). Pearl millet has antioxidant, anti-carcinogenic, hypocholesterolemic, hypoglycemic and antiulcerative properties. The presence of all these required nutrients and health-promoting properties in pearl millet makes it suitable for food utilization such as the manufacture of baby and snack foods and bakery products (Saleh et al. 2013).

Although, bread is traditionally made from wheat flour, other cereals such as rye barley, sorghum, maize, millet etc. have been used, either alone or in combination with wheat flour, for bread making in various parts of the world. Several recent studies have indicated the possibility of incorporating barley, soybean, sorghum and cowpea into wheat flour at various levels and the rheological and baking properties have been reported (De la Hera et al. 2012; Okpala and Okoli 2013). Classical extensograph, alveograph, farinograph and mixograph instruments are currently used to obtain data on rheological properties and baking properties of flour (Dobraszczyk and Morgenstern, 2003). Recently, the rheological behaviour of flour was studied using Mixolab which measures the torque produced by mixing the dough between two kneading arms, when dough is subjected to dual mixing and temperature constrains (Mixolab Applications Handbook, 2006; Banu et al., 2010a, 2010b, 2011). The Mixolab technique allows the complete characterization of the flours in terms of proteins’ quality by determining their water absorption, stability, elasticity, and weakening properties (Collar et al., 2007).

In Tunisia, pear millet occupies a very important part of surfaces every year in the centre and in the South of the country (FAO 2008). Very few studies have conducted on the characterization of pearl millet flour (Radhouane, 2008) and none has been reported on composite millet-wheat (CMW) bread. Therefore the present investigation was undertaken i) to investigate the chemical composition and functional properties of a flour issued from Pearl millet cereals grown under local conditions. ii) to partially replace wheat flour characterized by a low bread-making quality with Pearl millet flour in order to improve its quality and iii) to study the effect of supplementation on the rheological properties of dough and textural and physical characteristics of bread. The blends of wheat and millet flour could have the potential of improving the nutritive value and the quality of bread with a resultant effect of increased consumption and utilization of pearl millet in Tunisia thus, reducing importation of wheat for breadmaking.

Materials and methods

Materials

Pearl Millet grains were harvested from the arid region of Tunisia. It was milled and sieved to produce pearl millet flour (MF) having a particle size between 500 and 1000 μm. Millet flour represented 60 % of the weight of the entire grains. For subsequent analyses, the flours samples were stored at 4 °C in metalized polyester containers and in the presence of oxygen absorbers.

Wheat flour used in this study (WF) was provided by the company “Couscousserie Du Sud” (CDS Sfax, Tunisia). It has the following composition 13.2 % moisture, 0.4 % ash content and 9.8 % protein content. It was characterized by a low bread-making quality (P/L: 0.84 and W: 162.32(10−4 J)). Composite wheat/pearl millet flours (CF) were obtained by the substitution of wheat flour by 1, 2, 5 or 10 % pearl millet flour.

Chemical composition

Total nitrogen, lipid, moisture and ash contents of flours were analyzed according to AACC (2000) standard methods. The starch content was determined using the enzymatic colorimetric method described by Dubois et al. (1956). Cellulose content was determined using the method described by Updegraff (1969).

Mineral content

The sample was prepared for analyses as described by Al-Showiman (1990). The amounts of iron, calcium, copper, sodium and potassium were determined using atomic absorption spectrophotometer (Hitachi Z6100, Japan). Phosphorus was determined as previously described by Chapman and Pratt (1982).

Functional properties

Foaming capacity (FC) and foam stability (FS) were determined as described by Akintayo et al. (1999). Emulsion activity (EA) and stability (ES) were determined as described by Naczk et al. (1985). Water and oil absorption capacities of samples (respectively designed as WAC and OAC) were determined at 30 °C as described by Lin and Zayas (1987).

Mixolab testing

Mixing and pasting behaviour of wheat flour and blends dough were studied using Mixolab (Chopin, Tripette et Renaud, Paris, France), which measured the torque (expressed in Nm) produced by the passage of dough between two kneading arms, thus allowing the study of its rheological behavior. For the assays, 50 g of flour were placed into the Mixolab bowl and mixed with the amount of water needed for obtaining 55 % (v/w, flour basis) water absorption. The settings used in the test are detailed in Table 1. The parameters obtained from the recorded curve provide information about the protein stability subjected to mechanical and thermal constraints, and both the gelatinization and gelling of starch (Huang et al. 2010). Those parameters included initial maximum consistency (Nm) (C1), (Rosell and Collar 2009), minimum torque (nm) produced by dough passage subjected to mechanical and thermal constraints (C2), maximum torque produced during the heating stage (C3), minimum torque during the heating period (nm) (C4), and the torque (nm) obtained after cooling at 50 °C (C5). The different curve slopes during the assay were related to the flour different properties : speed of the protein network weakening due to heating (alfa); gelatinization rate (beta) and cooking stability rate (gamma).

Table 1.

Instrumental settings defined in the mixolab for running the samples

| Settings values | Values |

|---|---|

| Mixing speed | 80 rpm |

| Tank temperature | 30 °C |

| Temperature first plateau | 30 °C |

| Duration first plateau | 8 min |

| Heating rate | 4 °C/min |

| Temperature second plateau | 90 °C |

| Duration second plateau | 7 min |

| Cooling rate | 4 °C/min |

| Temperature third plateau | 60 °C |

| Duration third plateau | 10 min |

| Total analysis time | 30 min |

Alveograph testing

Alveograph measurements were obtained using an Alveograph MA82 (Tripette et Renaud, France) using the standard method (AACC 2000) and under conditions of a constant dough water content and mixing times. Each sample (250 g) was obtained by mixing wheat and pearl millet flour according to the desired substitution (1, 2, 5 and 10 %).

The monitored alveograph parameters were as follows: maximum overpressure needed to blow the dough bubble (P index of resistance to extension), average abscissa at bubble rupture (L index of dough extensibility) and deformation energy (W index of dough strength). These characteristics were used to evaluate the wheat flour bread-making quality (Indrani et al. 2007).

Bread-making

Flours were mixed and baked according to the traditional recipe of Tunisian bread (Ghorbel et al.2010). The dough base formulation used was composed of 1,000 × g of flour with appropriate amount of millet flour, 30 g of compressed yeast, 18 g of sodium chloride and 630 mL of water. After mixing, the resulting dough was allowed to rest for 15 min in a fermentation cabinet at 30 °C and 70 % relative humidity (RH). The bulk dough was sheeted in a Mi-Pan vf roller (Mi-Pan, Cordoba, Argentina). The dough was then divided into 250-g pieces, molded and proofed at 30 °C (96 % RH) until optimally developed and then baked at 200 °C for 18 min. Loaf volume and weight were determined. The loaf volume was determined by rape seed displacement method.

Textural properties of bread

Textural Properties were determined according to the standard method published by the American Association of Cereal Chemistry (AACC 1998) performed by Texture Analyser (texture analyzer: Lloyd Instruments, Leicester, England) as described by Wang and Kinsella (1976). Two slices of bread (20 mm thick) were compressed with a 3.5-cm-diameter cylindrical probe using the same speed as the firmness measurement to 40 % of strain, held for 60 s, and then removed.

The parameters recorded were hardness (peak force on first compression [N]), cohesiveness (ratio of the active work done under the second force–displacement curve to that done under the first compression curve [dimensionless]), adhesiveness (work necessary to overcome the attractive forces between the surface of food and that of the sensor during the first and second compression cycle [N mm]), springiness (distance of the sample recovered after the first compression [mm]) and chewiness ([hardness ¥ cohesiveness ¥ springiness {N, mm}]). The texture analyzer was interfaced with a computer, which controls the instruments and analyses the data, using the software supplied by Texture Technologies Corp. (Scarsdale, NY).

Statistical analysis

All the results are reported as the means of triplicate analyses. A Tukey’s post hoc test was performed to determine the honestly significant difference (HSD) of the mean values of each sample (P < 0.05).

Results and discussion

Flour characterization

Pearl millet flour showed protein content of 16.10 ± 0.02 %, fat content of 5.1 ± 0.2 %, starch content of 43 ± 0.1 %, cellulose content of 1.5 ± 0.3 %, and ash content of 3.92 ± 0.02 %. Its moisture was, on wet basis, 7 ± 0 %, (w/w) which was lower as compared to wheat flour (Ghorbel et al. 2009). Notably, the amount of protein, ash and lipid were higher than those reported by Mepba et al. (2007) for wheat flour (0.4 % ash content and 12.8 % proteins, fat 1.4) and also those reported by Ghorbel et al. (2009) (0.41 % ash and 9.8 % proteins).

In addition, pearl millet flour calcium content of 0.23 mg/g, phosphorus content of 1.52 mg/g, potassium 1.86 mg/g, sodium content of 1.33 mg/g and iron content of 0.11 mg/g. These were also slightly higher than those reported for wheat flour Akman and Kara (2003).

The size of the starch granules were reported to have a significant effect on the digestibility of some starches by microbial enzymes, the starch with smaller granules had better digestibility (Madhusudhan and Tharanathan 1995).

Notably, the amylose content (25 %, w/w of starch) was in the range of that usually reported for pearl millet starch, which was reported from 17 to 29 % (Beleia et al. 1980).

The oil absorption capacity of pearl millet flour was 2.3 g oil/g which was in good agreement with values varying from 0.55 to 2.7 g reported for millet by Akubor and Obiegbuna (1999) and Oshodi et al. (1999). This parameter is of great importance, since proteins bind fat by capillary attraction and fat acts as flavor retainer. This parameter also contributes in the increase of the mouth feel of foods, especially bread (Kinsella 1976; Okezie and Bello 1988). The higher oil absorption capacity of the pearl millet flour could be attributed to protein hydrophobicity, known to play a major role in this phenomenon (Voutsinas and Nakai 1983).

The foaming capacity (FC) and stability (FS) of Pearl millet flour were 10 and 92 %, respectively. Akubor (2003) reported higher FC for wheat flour (40 %) but lower foam stability (78 %). Foamability is function of the configuration of protein molecules. Flexible protein molecules give good foamability whereas highly ordered globular molecules give low foamability, as they cannot reduce the surface tension of the air-water interface (Ma and Harwalker 1984).

The results showed that pearl millet flour had excellent emulsifying properties. In particular, emulsion activity and stability were of 80 and 90 %, respectively. Emulsion capacity is linked to soluble protein content of a substance (Kinsella 1976). The high emulsion activity and stability of the flour suggests its possible use in cakes, sausages and other colloidal food systems.

Rheological behavior of composite dough

The effects of addition of MF on rheological properties of WF measured by Mixolab are summarized in Table 2. In the initial mixing stage, a significant increase (P < 0.05) of consistency was observed in the presence of additional amounts of pearl millet flour. Moreover, the addition of MF to wheat flour decreased both the Mixolab development time (DT) and the stability (ST). For example, DT and ST of dough containing 5 % MF changed from 4.31 to 1.18 min and 11.12 to 9.46 min, respectively, showing that less work was needed during dough development after MF incorporation.

Table 2.

Effect of addition of MF on rheological properties of WF measured by Mixolab

| MF levels | Time (min) | C1 Torque (Nm) | Stability Time (min) | C2 (Nm) | Alfa (Nm/min) | C3 (Nm) | C4 (Nm) | C5 (Nm) | Beta (Nm/min) | Gamma (Nm/min) |

|---|---|---|---|---|---|---|---|---|---|---|

| WF | 4,31b | 0,86c | 11,12a | 0,4c | −0,054 | 1,4c | 1,28c | 2,32a | 0,318 | −0,032 |

| 1 % MF | 1,04e | 1,37a | 7,10c | 0,52b | −0,09 | 1,93ab | 1,62ab | 1,92bc | 0,144 | −0,035 |

| 2 % MF | 2,21c | 1,23b | 9,25b | 0,52ab | −0,084 | 1,94ab | 1,58b | 1,91bc | 0,12 | −0,041 |

| 5 % MF | 1,18d | 1,43a | 9,46b | 0,57ab | −0,086 | 1,98ab | 1,71a | 2,01b | 0,13 | −0,044 |

| 10%MF | 5,23a | 1,37a | 10,24ab | 0,58a | −0,12 | 2,06a | 1,64ab | 1,83c | 0,15 | −0,04 |

Values with similar superscripts in a column did not differ significantly (p<0.05). WF, wheat flour; MF, millet flour

By first increasing and then decreasing the temperature, the following effects were observed: a higher minimum torque (C2), a higher maximum torque (C3), a higher minimum torque during the heating period (C4) and a lower rate of starch gelatinization compared to the control (Table 2). These data indicated that the MF improved the protein heat resistance in dough system and increased starch stability in dough. Moreover, it induced a lower level of retrogradation during cooling and a higher cooking stability rate (gamma).

The effects of addition of MF at different levels (1 %, 2 %, 5 % and 10 %) on the strength (W) and elasticity-to-extensibility ratio (P/L) of wheat dough are shown in Table 3. It was found that the addition of 5 % of MF had the most significant positive effect (P < 0.05) on the dough alveographic properties. At this addition level, W and P/L of the composite dough (W = 210 × 10−4 J and P/L = 1.1) increased by 31 and 65 %, respectively, compared with those for the control wheat flour (W = 160 × 10−4 J and P/L = 0.65).

Table 3.

Effect of addition of MF on rheological properties of WF measured by Alveograph

| MF levels | Alveographic properties of dough | |

|---|---|---|

| W (10−4 J) | P/L ratio | |

| WF | 160d | 0.65e |

| 1 % MF | 188c | 0.71d |

| 2 % MF | 199b | 0.82c |

| 5 % MF | 210a | 1.1b |

| 10%MF | 160d | 1.17a |

Values with similar superscripts in a column did not differ significantly (p<0.05). WF, wheat flour; MF, millet flour

Breadmaking

Bread specific volume

Loaf volume is considered as the most important bread characteristic since it provides a quantitative measurement of baking performance. Results in Table 4 shows the specific volume of bread prepared from WF containing 5 % or 10 % millet flour.

Table 4.

Effect of addition of MF on bread characteristic of WF

| WF | 5 % MF | 10 % MF | |

|---|---|---|---|

| Hardness (N) | 130.14a | 121.12c | 124.11b |

| Chewiness (Nmm) | 165.41a | 129.51c | 131.45b |

| Cohesiveness (dimensionless) | 0.39a | 0.36a | 0.41a |

| Springiness (mm) | 6.02b | 5.64c | 6.13a |

| Adhesiveness (N) | 56.16a | 19.34c | 29.32b |

| Bread volume cm3/g | 2.94b | 4.30a | 2.80b |

Values with similar superscripts in a row did not differ significantly (p<0.05). WF, wheat flour; MF, millet flour

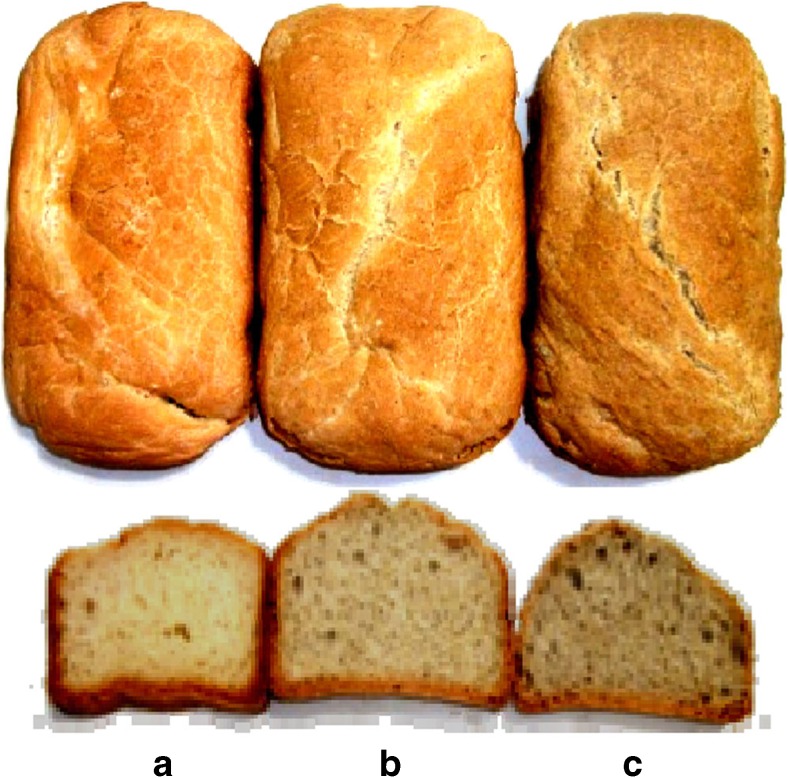

Compared with bread baked without MF, 5 % MF enriched breads exhibited a larger bread volume (Fig. 1) with a more open crumb structure. Its loaf-specific volume was 4.30 cm3/g versus 2.94 cm3/g for the wheat flour baked without millet addition (Table 4). Lipids content could contribute to the difference in the loaf volume. The positive influence of lipids (in particular the polar fraction) in the bread-making quality is attributed to their ability to form lipid monolayers at the gas/liquid interphase of the gas cells, thus increasing the doug gas retention (Gan et al. 1995). In contrast, an addition of 10 % pearl millet flour induced a more open crumb structure, but a lower specific volume (2.8 cm3/g).

Fig. 1.

Overall observation and cut loaves of bread baked views of traditional Tunisian bread baked without Millet Flour addition (a); with 5 % of MF (b) and with10% of MF(c)

It seems clear that millet addition at a level of 5 % improved wheat flour characteristics and gave composite flour suitable for bread making. A higher level of substitution appeared to be less convenient. In this context, Poongodi and Jemima (2009) tested high levels of substitution (10, 20 and 30 %) and concluded that pearl millet flour addition was suitable for the preparation of pasta, crackers, rusk or suji toast, biscuits, chapatti but not for bread -making .

Crumb texture

The beneficial effect of millet flour on crumb structure is illustrated in table 4. Texture analysis gives informations on the product quality, oppositely to dough rheological tests which inform on the baking suitability of the flour.

MF 5 % enriched breads exhibited significantly lower adhesiveness, hardness and chewiness than those of wheat flour. Variations in textural properties between the different samples can largely be attributed to differences in the chemical composition.

Conclusion

In this work, the physico-chemical and functional properties of a Tunisian Pearl millet flour were investigated. Pearl millet flour was incorporated in the formulation of composite breads made with a mix of wheat flour and pearl millet flour. Addition of 5 % of millet flour is able to improve the rheological properties of the dough as well as the specific volume and texture of the bread. Further studies are needed to better characterize and study bread quality and sensorial acceptance of the product.

Acknowledgments

The authors are thankful to the French Institute of Cooperation (Campus France) for providing financial support to carry out this work .

Contributor Information

Sameh Maktouf, Email: maktoufsameh@yahoo.fr.

Raoudha Ellouz-Ghorbel, Phone: +216 74675331.

References

- AACC (1998) Approved Methods of the American Association of Cereal Chemists. Modified version of Method 290 74–09: Determination of Bread Firmness. American Association of Cereal Chemists, St, Paul, MN

- AACC. (2000). Approved Methods of the AACC, t.E., Methods 46–30, 30–10, 44–19,08-01, 54–30, The American Association of Cereal Chemists, St. Paul, MN. 10th Ed

- Adebowal KO, Lawal OS. Effect of annealing and heat moisture conditioning on the physicochemical characteristics of bambara groundnut (Voandzeia subterranean) starch. Nahrung/Food. 2002;46:311–316. doi: 10.1002/1521-3803(20020901)46:5<311::AID-FOOD311>3.0.CO;2-Z. [DOI] [PubMed] [Google Scholar]

- Akintayo ET, Oshodi AA, Esuosol KO. Effects of NaCl, ionic strength and pH on thefoaming and gelation of pigeon pea (Cajanus cajan) protein concentrates. Food Chem. 1999;66:51–56. doi: 10.1016/S0308-8146(98)00155-1. [DOI] [Google Scholar]

- Akman Z, Kara B. Genetopic variation for mineral content at different growth stages in wheat (triticum aestivum L) Cereal Res Commun. 2003;31:459–466. [Google Scholar]

- Akubor P. Functional properties and performance of cowpea/plantain/wheat flour blends in biscuits. Plant Foods Hum Nutr. 2003;58(3):1–8. [Google Scholar]

- Akubor P, Obiegbuna JE. Certain chemical and functional properties of ungerminated and germinated millet flour. Food Sci Technol. 1999;36(3):241–293. [Google Scholar]

- Al-Showiman SS. Chemical composition of date seeds (Phoenix dactylifera L.) in Saudi Arabia. J Chem Soc. 1990;12:15–24. [Google Scholar]

- Beleia AE, Varrino-Marston E, Hoseney RC. Characterization of starch from pearl millet. Cereal Chemestry. 1980;57:300–303. [Google Scholar]

- Chapman, H.D.,& Pratt, P.F.(1982) Method and of analysis of soil, plant and water. 2nd Ed. California: California University Agricultural Division; p.170

- De la Hera E, Ruiz-París E, Oliete B, Gómez M. Studies of the quality of cakes made with wheat-lentil composite flours. LWT - Food Sci Technol Res. 2012;49(1):48–54. doi: 10.1016/j.lwt.2012.05.009. [DOI] [Google Scholar]

- Dubois M, Gilles KA, Hamilton J, Rebers PA, Smith F. Colorimetric method fordetermination of sugars and related substances. Analitical Chemestry. 1956;28:350–356. doi: 10.1021/ac60111a017. [DOI] [Google Scholar]

- FAO (2008). Sorghum and Millets in Human Nutrition. Food and Agriculture Organization of the United Nations, Rome [PubMed]

- Gan Z, Ellis PR, Schofield JD. Mini review: Gas cell stabilisation and gas retention inwheat bread dough. Cereal Science. 1995;21:215–230. doi: 10.1006/jcrs.1995.0025. [DOI] [Google Scholar]

- Ghorbel RE, Kamoun A, Neifar M, Chaabouni SE. Optimization of new flour improver mixing formula by response surface methodology. Food Process Engeneering. 2009 [Google Scholar]

- Ghorbel RE, Kamoun A, Neifar M, Chaabouni SE. Optimization of new flour improver mixing formula by response surface methodology. Food Process Engeneering. 2010;33:234–256. doi: 10.1111/j.1745-4530.2008.00270.x. [DOI] [Google Scholar]

- Huang W, LI L, Wang F, Wan J, Tilley M, Ren C, Wu S. Effects of transglutaminase onthe rheological and Mixolab thermomechanical characteristics of oat dough. Food Chemestry. 2010;121:934–939. doi: 10.1016/j.foodchem.2010.01.008. [DOI] [Google Scholar]

- Indrani D, Sai manohar R, Rajiv J, Rao JV. Alveograph as a tool to assess the quality characteristics of wheat flour for parotta making. Food Engeneering. 2007;78:1202–1206. doi: 10.1016/j.jfoodeng.2005.12.032. [DOI] [Google Scholar]

- Kasarda DD. Grains in relation to celiac disease. Cereal Foods World. 2001;46:209–210. [Google Scholar]

- Kinsella JE. Functional properties of proteins in foods. A Survey. Food Science and Nutrition. 1976;7:219–232. [Google Scholar]

- Lee MR, Swanson BG, Baik BK. Influence of amylase content on properties of wheat starch and breadmaking quality of starch and gluten blends. Cereal Chem. 2001;78:701–706. doi: 10.1094/CCHEM.2001.78.6.701. [DOI] [Google Scholar]

- Lin CS, Zayas JF. Functional of corn germ proteins in a model system: Fat bindingcapacity and water retention. Food Sci. 1987;52:1308. doi: 10.1111/j.1365-2621.1987.tb14070.x. [DOI] [Google Scholar]

- Ma C, Harwalker VR. Chemical characterization foaming and protein solubility properties of defatted soybean, peanut, field pea and pecan flours. Food Sci. 1984;42:1444–1449. [Google Scholar]

- Madhusudhan B, Tharanathan R. Legume and cereal starches—Why difference in digestibility? Part-II. Isolation and characterization of starches from rice (Oryza sativa), ragi (Eleusinecoracana) Carbohydr Polym. 1995;28:153–158. doi: 10.1016/0144-8617(95)00108-5. [DOI] [Google Scholar]

- Mepba HD, Eboh L, Nwaojigwa SU. Chemical composition, functional and baking properties of wheat-plantain composite flours. Afr J Food Agric Nutr Dev. 2007;1:1–22. [Google Scholar]

- Metcalfe, L.D., Schmitz, A. A., & Pelka, J. (1966). RBF3-methanol procedure for rapid quantitative preparation of methyl esters from lipids. International Journal of analitical Chemestry; 38: 514

- Naczk M, Diosady LL, Rubin LJ. The functional properties of canola meals produced by a Two-phase extraction system. Food Sci. 1985;50:1685–1689. doi: 10.1111/j.1365-2621.1985.tb10565.x. [DOI] [Google Scholar]

- O’Kenned MM, Grootbooma A, Shewr PR. Harnessing sorghum and millet biotechnology for food and health. Cereal Science. 2006;44:224–235. doi: 10.1016/j.jcs.2006.08.001. [DOI] [Google Scholar]

- Okezie BO, Bello AB. Physico-chemical and functional properties of winged bean our and isolate compared with soy iso-late. Food Sci. 1988;43:450–454. doi: 10.1111/j.1365-2621.1988.tb07728.x. [DOI] [Google Scholar]

- Okpala LC, Okoli EC. Optimization of composite flour biscuits by mixture response surface methodology. Food Sci Technol Int. 2013 doi: 10.1177/1082013212452587. [DOI] [PubMed] [Google Scholar]

- Poongodi V, Jemima B. Formulation and characterization of millet flour blend incorporated composite flour. Int J Agric Sci. 2009;1(2):46–54. doi: 10.9735/0975-3710.1.2.46-54. [DOI] [Google Scholar]

- Rosell CM, Collar C. Effect of temperature and consistency on wheat dough performance. International. J Food Sci Technol. 2009;44:493–502. doi: 10.1111/j.1365-2621.2008.01758.x. [DOI] [Google Scholar]

- Saleh ASM, Zhang Q, Chen J, Shen Q. Millet grains: nutritional quality, processing, and potential health benefits. Comprehensive Reviews in Food Science and Food Safety. 2013;12(3):281–295. doi: 10.1111/1541-4337.12012. [DOI] [Google Scholar]

- Updegraff DM. Semimicro determination of cellulose in biological materials. Anal Biochem. 1969;32(3):420–424. doi: 10.1016/S0003-2697(69)80009-6. [DOI] [PubMed] [Google Scholar]

- Voutsinas LP, Nakai S. A simple turbidimetric method for determining the fat binding capacity of proteins. Agriculture and Food Chem. 1983;31:58–61. doi: 10.1021/jf00115a015. [DOI] [PubMed] [Google Scholar]

- Wang JC, Kinsella JE. Functional properties of novel proteins: Alfalfa leaf protein. J Food Sci. 1976;41:286–292. doi: 10.1111/j.1365-2621.1976.tb00602.x. [DOI] [Google Scholar]

- William PC, Kuzina FD, Hlynka I. Rapid colorimetric procedure for estimating the amylose content of starches and flour. Cereal Chem. 1970;4:411–420. [Google Scholar]