Abstract

Geometrical, functional, thermal properties and FTIR analysis of three varieties of oat flour (Sabzaar, SKO20, & SKO90) were investigated. Sabzaar showed highest thickness, geometric mean diameter, arthimetic mean diameter, sphericity and grain volume. The density of oat grains varied from 0.393 to 0.37 g/mL (bulk) and 1.2 to 1.8 g/mL (true). WAC showed significant (P < 0.05) difference among the cultivars with Sabzaar flour showing the highest value (2.36 g/g) and SKO20 (1.98 g/g) the lowest. Peak viscosity of oat flours was in the range of 460.33–489.33 cP. Flour samples showed the presence of small as well as large starch granules, oval or irregular shape with a smooth surface having some dents or fissures and some damaged starch and with varying dimensions. Average granule size of oat starch samples was within the range of 1.5–6.6 μm in Sabzaar, 1.1–5.2 μm in SKO20, and 1.7–6.8 μm in SKO90. The gelatinization transition temperatures onset temperature (To), peak temperature (Tp), and conclusion temperature (Tc) varied significantly (p < 0.05) among three varieties.

Keywords: Oat, FTIR, SEM, Thermal properties

Introduction

Oat (Avena sativa L.) belongs to the poaceae family and is considered distinct among cereals being a good source of proteins (globulins), fatty acids particularly unsaturated, phenolic compounds (mostly avenanthramides), dietary fiber in particular β-glucan and starch. Besides it, oat is a good source of essential vitamins such as thiamine, folic acid, biotin, pantothenic acid and vitamin E, zinc, selenium, copper, iron, manganese and magnesium (Malkki and Virtanen, 2001; Dikeman et al., 2006; Ahmad et al., 2014). Oat is widely cultivated in temperate regions and is ranked fifth as an economically important cereal crop in the world production after wheat, rice, corn and barley. Oat production stands at about 25 million tonnes in recent years. Numerous studies have demonstrated that consuming oat based products can show many health benefits like lowering of total plasma cholesterol and LDL cholesterol levels, reducing glucose uptake and cardiovascular diseases, control weight through prolonged satiety and coeliac disorder (Davidson et al., 1991; Malkki and Virtanen, 2001; Butt et al., 2008). Most oat food products use the entire groat, making it a nutritious cereal grain. Food uses for oat include oat flour, oatmeal, oat bran and oat flakes for use as breakfast cereals and ingredients in other food stuffs.

The physical parameters like size, shape, volume, density, sphericity, etc. of oat grain as well as flour are required for the design of equipment for handling, processing, distribution and storing (Asoegwu, 1995), while functional properties like water/oil absorption capacity, foaming and emulsion capacity, etc. determine the behavior of nutrients during processing, their utilization as an ingredient in food and food formulations, food quality and finally their acceptance (Mahajan and Dua, 2002). So the objective of present study was to evaluate the physical and functional properties of oat grain and flour of different varieties locally available in Kashmir valley, in order to obtain information regarding the designing of machines for proper handling, processing, and storing, and to understand their potential applications in food industry particularly for making functional foods.

Materials and methods

Materials

The seeds of three varieties of oat viz; Sabzaar, SKO20 and SKO90 were procured from Sher-e-Kashmir University of Agricultural Sciences and Technology, Shalimar, Srinagar, J&K, India. Seeds were cleaned from any foreign material manually and then ground to flour using laboratory mill (Newport Supermill-1500, Newport Scientific Pvt. Ltd, Warriewood, Australia), sieved through 60-mesh screen and then stored under refrigeration temperature.

Physical properties

Geometrical properties

In order to determine the dimensions of the grain 100 individual grains were selected randomly and their three principal linear dimensions namely length (L), width (W) and thickness (T) were measured by a digital caliper reading to an accuracy of 0.01 mm.

The geometric mean diameter (Dg) is calculated according to method of Sharma et al., 1985; Sreenarayanan et al., 1985.

The arithmetic mean diameter was determined according to formula given by Mohsenin, 1986.

The seed volume V (mm3) and sphericity (φ) was calculated as per the following formulae given by Jain and Bal (1997).

Where, B = (WT)0.5

The surface area, S (mm2) was calculated by using the formula described by Sacilik et al. (2003); Tunde-Akintunde and Akintunde (2004); Altuntas et al. (2005).

The aspect ratio (Ra) of fruit was calculated as described by Omobuwajo et al. (1999).

The diameter of equivalent sphere was determined by using the formula as mentioned by Gorial and O’callaghan (1990).

Where De is the diameter of equivalent sphere in mm; Wt is weight of seed in g; (t is true density of seed, in g/mL.

1000-grain weight

To determine thousand grain weight (W1000), 100 grains were selected randomly and weighed in electronic balance reading to 0.001 g. The value was then multiplied by 10 to convert it to a 1000 seed basis.

Gravimetrical properties

Bulk density was measured by dividing the weight of a quantity of seeds of each variety on its volume, which is measured by using graduate cylinder, using the formula as follows

Where, ρb is the bulk density of the bulk seeds and Vb is bulk volume of the weight sample of bulk seeds.

True density was determined by the toluene (C7H8) displacement method described by Gani et al. (2015) and calculated as the ratio of sample mass to the volume of the sample

Where, ρt is the true density of seeds and Vt is the volume of toluene displaced by the mass of grains.

The porosity (ε) was calculated by the equation given by Mohsenin (1986).

Frictional properties

Static coefficient of friction of the grains was determined against surfaces of rubber board, corrugated board & glass. For this purpose, wooden table with an adjustable tilting plate on its top, which could be faced with the test surface was used. The sample was placed on test surface, and the inclination of the plate was raised gradually till the 75 % of the grains slides down from the test surface. The angle of inclination was calculated as:

The angle of repose is the angle compared to the horizontal at which the material (sample grains) will stand when piled. It was determined by using a customized personal computer-based digital image analysis using the image J software.

Determination of powder properties of the flour

Bulk and tapped density

The bulk density and tapped density was determined according to the method described by Gani et al. (2015).

Compressibility index &Hausner ratio

The compressibility index and Hausner ratio was calculated as per the formula given by Carr (1965).

For the compressibility index and the Hausner ratio, the generally accepted scale of flowability mentioned by Carr is given in Table 4.

Table 4.

Scale of flowability

| Compressibility index (%) | Angle of repose (degrees) | Hausner ratio | Flow characteristics |

|---|---|---|---|

| 10 | 25–30 | 1.00–1.11 | Excellent |

| 11–15 | 31–35 | 1.12–1.18 | Good |

| 16–20 | 36–40 | 1.19–1.25 | Fair |

| 21–25 | 41–45 | 1.26–1.34 | Passable |

| 26–31 | 46–55 | 1.35–1.45 | Poor |

| 32–37 | 56–65 | 1.46–1.59 | Very poor |

| >38 | >66 | >1.60 | Very, very poor |

Angle of repose

The angle of repose is the constant, three-dimensional angle assumed by a cone-like pile of flour formed relative to the horizontal base. Angle of repose test is found to be dependent upon the method used and in our study we have make use of image analysis, using software Digimizer version 4.2.1. Table 4 is very important in characterization of the flow properties of powders.

Flow through an orifice

Monitoring the rate of flow of material through an orifice is an important measure of powder flowability. It can be determined using either mass flow rate or volume flow rate basis as per Carr (1965). In our experiment, it was determined on mass flow rate basis, using a half cut PET bottle, with its necked mouth with a diameter of 21 mm as an orifice. The weight of flour that flowed through the orifice for a period of 30 seconds (s) was measured using a digital balance correct up to ±0.001 g (Shimadzu, Unic Bloc) & the results were expressed as g/30 s. The system was subjected to constant vibrations in order to make flow of flour constant which is otherwise pulsating in nature.

Proximate composition of flour

Moisture, protein, fat, and ash contents were determined according to the methods of AOAC (1990).

Color

Color of the oat flour was determined using Color Flex Spectrocolorimeter (Hunter Lab Colorimeter D-25, Hunter Associates Laboratory, Ruston, USA).

Water and oil absorption capacity

Water absorption capacity of the oat flour was determined as described by Gani et al. (2013) with certain modifications. One gram of the flour was mixed with 10 ml of distilled water or oil (mustard oil) in a centrifuge tube and allowed to stand at room temperature (30 ± 2 °C) for 1 h with intermittent mixing. It was then centrifuged (eppendorf 5810 R) at 2000×g for 30 min and the supernatant was decanted. The gain in weight was expressed as water/oil absorption capacity.

Emulsion capacity and stability

Emulsifying properties were determined by the method adopted by Khan et al. (2015). Flour suspension (1 %) was homogenized with 5 mL of refined oil. The emulsions were then centrifuged at 1100×g for 5 min (5810R, Eppendorf , Hamburg, Germany). Subsequently the height of the emulsified layer and total height were determined. Emulsion stability (ES) was determined by heating the emulsion at 80 °C for 30 min followed by centrifugation at 1100×g for 5 min. The emulsion capacity (EC) was obtained through the following calculation.

Foaming capacity and stability

Foaming capacity (FC) and foam stability (FS) was determined according to the method described by Wani et al., 2015. Two grams of flour mixed with 100 ml of distilled water at pH 2, 4, 6, 8 and 10 were homogenized in a high speed homogenizer (WiseTis, Korea) at 10,000 rpm for 1 min. Foaming capacity was calculated as the percent increase in volume and foam stability was determined by measuring the foam volume after an hour.

Pasting properties of flour

The pasting properties of the oat flours were measured using a Rapid Visco Analyzer (Tech Master, Perten Instruments Warriewood, Australia). An aqueous dispersion of flour was equilibrated at 50 °C for 1 min, heated at the rate of 12.2 °C/min to 95 °C, held for 2.5 min, cooled to 50 °C at the rate of 11.8 °C/min and again held at 50 °C for 2 min. A constant paddle rotational speed (160 rpm) was used throughout the entire analysis, except for rapid stirring at 960 rpm for the first 10 s to disperse the sample.

Scanning electron microscopy

The flour samples were placed on an adhesive tape attached to a circular aluminum specimen stub. After coating vertically with gold- palladium, the samples were photographed at an accelerator potential of 5 kV using a scanning electron microscope (Hitachi S- 300H-Tokyo, Japan).

Thermal properties of oats flour

The thermal characteristics of oat flour were studied with a Mettler Toledo DSC1STAR System. Samples (3.5 mg) were weighed into aluminum pans and deionized water (8 μL) was added. The pans were sealed hermetically and kept at room temperature overnight before analysis. The samples were heated at 10 °C/min from 10 to 200 °C. An empty platinum pan was used as a reference. From the curve, enthalpy of gelatinization (ΔH), the onset (To), peak (Tp) and end (Tc) temperatures were obtained using the data processing software supplied with the DSC instrument.

Statistical analysis

Mean values, standard deviation, analysis of variance (ANOVA) were computed using a commercial statistical package SPSS 10.1 (USA). These data were then compared using Duncan’s multiple range tests at 5 % significance level.

Results and discussion

Geometrical properties

The average values of different geometric parameters of the three oat varieties i.e. Sabzaaar, SKO20, and SKO90 are shown in Table 1. Considering the dimensional features of grain, the SKO90 were longest of all whereas width was found greater for Sabzaar. This reflects that the three varieties can be separated as per their length and width. In the designing of grain handling machineries knowledge of these dimensions is very useful in determining aperture sizes. Besides it size and shape are also important to separate any foreign materials from the particle by employing electrostatic force (Mohsenin, 1970). The geometric mean diameter was found to be 3.40, 3.166, and 3.124 mm for Sabzaar, SKO20, and SKO90 respectively. The geometric mean is useful in measuring the projected area of the seeds which gives an indication of its pattern of behavior in the turbulent or near-turbulent region of flowing fluid such air stream. This is helpful for air classification of seeds and for separating unwanted materials from the sample during cleaning by pneumatic means. And the arithmetic mean diameter were found to vary significantly (p < 0.05) among three varieties from 4.07 to 4.33 mm. The equivalent sphere diameter varied from 0.0258 to 0.025 mm and was found highest for Sabzaar variety. The environmental and genetic factors could be the main factor responsible for the variation in physical properties of oat varieties.

Table 1.

Geometric properties of oat grains

| Sabzaar | SKO20 | SKO90 | |

|---|---|---|---|

| L (mm) | 8.576 ± 0.143a | 8.203 ± 0.565a | 9.033 ± 0.990a |

| W (mm) | 1.736 ± 0.035a | 1.63 ± 0.422a | 1.506 ± 0.523a |

| T (mm) | 2.666 ± 0.047b | 2.386 ± 0.223ab | 2.256 ± 0.236a |

| Dg (mm) | 3.40 ± 0.095b | 3.166 ± 0.001a | 3.124 ± 0.001a |

| Da (mm) | 4.33 ± 0.060b | 4.07 ± 0.01a | 4.26 ± 0.01b |

| Φ (%) | 39.813 ± 1.218b | 38.543 ± 0.041b | 34.58 ± 0.01a |

| De (mm) | 0.0258 ± 0.1b | 0.025 ± 0.01a | 0.025 ± 0.01b |

| S (mm2) | 36.326 ± 0.015c | 30.216 ± 0.020a | 30.59 ± 0.01b |

| Ra | 20.18 ± 0.01c | 19.866 ± 0.025b | 16.61 ± 0.01a |

| W1000 (g) | 36.07 ± 0.684a | 36.543 ± 0.035a | 36.57 ± 0.026a |

| V (mm3) | 11.754 ± 0.016c | 9.359 ± 0.002b | 8.805 ± 0.002a |

L Length, W Width, T Thickness, Dg Geometric mean diameter, Da Arithmetic mean diameter, Φ Sphericity, De Equivalent sphere diameter, S Surface area, Ra Aspect ratio, W 1000 Thousand grain weight, V Volume of grain

All the values are Mean ± SD. Values within a row with the different letters are significantly different (P < 0.05)

The 1000-grain weight was found to be 36.07, 36.543, 36.57 g for Sabzaar, SKO20 and SKO90 respectively. Gani et al. (2015) reported much higher values for 1000 grain weight in three different varieties of pulses. Shape is also important in heat and mass transfer calculations, screening solids to separate foreign materials, and evaluating the quality of food materials. The shape of a food material is usually expressed in terms of its sphericity and aspect ratio. Sphericity is an expression of a shape of a solid relative to that of a sphere of the same volume. The sphericity of all the oat varieties varied significantly (p ≤ 0.05) and was found to be 39.813, 38.543, and 34.58 % for Sabzaar, SKO20, and SKO90 respectively. It implies that the seeds have less resemblance to a sphere and are elongated with SKO90 having least sphericity. Similarly, the aspect ratio of Sabzaar, SKO20, and SKO90 were found to be 20.18, 19.86, and 16.61 % respectively. The aspect ratio relates the width of seed to its length and gives an indication about the shape of the seed. Lesser the aspect ratio and sphericity of a seed, lower will be its rolling tendency. This property of seeds plays an important role in the design of hoppers and other processing equipment. The different values of surface area lie in the range of 30.59 to 36.32 mm2 for different varieties. The surface area and seed volume was found significantly (p < 0.05) different in all the three varieties within the range of 30.21 to 36.32 mm2 and 8.80 to 11.75 mm3.

Bulk density, true density and porosity

The density and porosity are important properties that affect the hardness of grain, susceptibility to breaking, milling and rate of drying. Bulk density and true density of three different varieties of oat grain and flour are shown in Table 2. The density of oat grains varied from 0.393 to 0.37 g/mL (bulk) and 1.2 to 1.8 g/mL (true). Whereas bulk density and tapped density of Sabzaar, SKO20 and SKO90 flour varied significantly (p < 0.05) 1.133 to 1.13 g/mL and 0.321 to 0.425 g/mL. The variation in bulk density is attributed to particle properties especially the hygroscopicity. Finer the particle, higher is the bulk density as the particles orient in a compact manner as compared to the coarser particles. The finer particles lead to a probable decrease in the inter particle voids, and hence greater surface contact with the surrounding particles. Density is a useful parameter for the design of storage and transportation bins for grains. The values of porosity were 66.26, 67.4, 67.36 %, for Sabzaar, SKO20 and SKO90 respectively. Higher the difference between bulk and true density, greater is the porosity (Chang, 1988). The porosity of Sabzaar flour was found to be maximum, followed by SKO90 and it was found to be least in case of SKO20.

Table 2.

Bulk density, true density, porosity, static coefficient of friction & angle of repose of oat grains & flour

| ρb (g/mL) | ρt (g/mL) | ε (%) | Card-board | Rubber board | Glass | Angle of repose (°) | ||

|---|---|---|---|---|---|---|---|---|

| Grains | Sabzaar | 0.393 ± 0.015a | 1.133 ± 0.015a | 66.26 ± 0.127 a | 0.007 ± 0.000ab | 0.010 ± 0.000a | 0.007 ± 0.001a | 46.916 ± 0.0665c |

| SKO20 | 0.373 ± 0.015 a | 1.13 ± 0.01a | 67.4 ± 0.055 b | 0.008 ± 0.000b | 0.010 ± 0.000a | 0.008 ± 0.000a | 44.916 ± 0.0665a | |

| SKO90 | 0.37 ± 0.01a | 1.13 ± 0.01a | 67.366 ± 0.450b | 0.007 ± 0.001a | 0.010 ± 0.001a | 0.007 ± 0.001a | 46.113 ± 0.068b | |

| Flour | Sabzaar | 0.425 ± 0.002a | 1.8 ± 0.01b | 76.366 ± 0.152 b | 0.016 ± 0.000a | 0.305 ± 0.001a | 0.021 ± 0.01b | 30.463 ± 0.0321a |

| SKO20 | 0.411 ± 0.001b | 1.41 ± 0.01b | 70.802 ± 0.288a | 0.016 ± 0.000a | 0.305 ± 0.000a | 0.20 ± 0.001a | 40.253 ± 0.152b | |

| SKO90 | 0.321 ± 0.018c | 1.26 ± 0.01a | 74.489 ± 1.634b | 0.016 ± 0.000a | 0.304 ± 0.001a | 0.020 ± 0.001a | 40.996 ± 0.235c | |

ρ b Bulk density, ρ t True or tapped density, ε Porosity

All the values are Mean ± SD. Values within the same column with different letters are significantly different (P < 0.05)

Static co-efficient of friction and angle of repose

The static coefficient of friction of the grains and flour against different surfaces is given in Table 2. The static coefficient of friction for the grains and flour on rubberboard was found highest compared to glass and cardboard. This is probably due to higher surface area and adhesion force between the grain/ flour particles and the test surface which leads to elevated value of co-efficient of friction. Angle of repose is the angle of maximum slope at which a heap of any loose solid material will stand without sliding. The angle of repose for oat flour was found to be 30.46, 40.253 and 40.996 for Sabzaar, SKO20 and SKO90 respectively. The samples showed significant difference (p < 0.05) in the angle of repose among the varieties. This reflects that the shape of the heap is dependent on the grain properties. Angle of repose for different kidney bean cultivars has been reported to vary between 11.66 and 29.62° which is much lower than oat seeds (Ozturk et al., 2010; Ozturk et al., 2009).

Compressibality index, Hunsner’s ratio, and mass flow rate of flour

The compressibility index of Sabzaar, SKO20 and SKO90 were found to be 76.36, 70.796 and 74.486 respectively (Table 3). According to the scale of flow ability given in Table 4, the flour from oat have very poor flow ability, which is also proven by the scale of Hausner ratio given, the value of which is 4.25 for Sabzaar, 3.42 for SKO20 and 3.962 for SKO90. Thus, oat varieties exhibit very, very poor flow behavior. The flow rate of a material is affected by various factors, some of which are particle-related and some related to the methodology. The factors like diameter and shape of the orifice, type of container material (PET) and height of the powder bed were kept to be constant during the study, therefore the difference in particle size and density were presumably responsible for the differences in the mass flow rates of the flour samples. The average mass flow rate was found to be 7.432, 6.806, and 6.47 g/30 s (Table 3). The possible reason for higher mass flow rate of Sabzaar is related to its higher density compared to the SKO90 and SKO20.

Table 3.

Compressibality index, Hunsner’s ratio & mass flow rate of oats flour

| C.I | H.R | Mass flow rate (g/30s) | |

|---|---|---|---|

| Sabzaar | 76.366 ± 0.152b | 4.25 ± 0.081a | 7.432 ± 0.288b |

| SKO20 | 70.796 ± 0.287a | 3.42 ± 0.0360b | 6.806 ± 0.020a |

| SKO90 | 74.486 ± 1.631b | 3.926 ± 0.262c | 6.47 ± 0.13a |

C.I Compressibility index, H.R Hausner ratio

All the values are Mean ± SD. Values within the same column with different letters are significantly different (P < 0.05)

Proximate composition

Composition of oat flour showed moisture, protein, fat, and ash in the range of 13.15–10.61, 10.53–12.24, 6.18–7.1, and 1.73–2.2 % respectively and is shown in Table 5. Significant (P < 0.05) differences were observed in moisture, protein, ash, and fat among the cultivars. Huttner et al. (2010) reported almost similar results for the composition of whole grain oat flour.

Table 5.

Functional properties of oats flour

| Sabzaar | SKO20 | SKO90 | |

|---|---|---|---|

| Proximate composition (%) | |||

| Moisture | 13.15 ± 0.05c | 10.61 ± 0.50a | 12.32 ± 0.02b |

| Protein | 10.53 ± 0.02a | 11.06 ± 0.01b | 12.24 ± 0.01c |

| Ash | 1.73 ± 0.01a | 2.2 ± 0.06b | 1.94 ± 0.01c |

| Fat | 6.18 ± 0.07a | 7.1 ± 0.1b | 6.96 ± 0.05b |

| Color values | |||

| L | 80.483 ± 0.076c | 77.41 ± 0.484b | 75.53 ± 0.754a |

| a | 4.66 ± 2.08a | 6 ± 2.64a | 13.66 ± 1.527b |

| b | 16.283 ± 0.324a | 20.68 ± 0.397c | 16.596 ± 0.722b |

| WAC (g/g) | 2.36 ± 0.087c | 1.983 ± 0.073a | 2.143 ± 0.040b |

| OAC (g/g) | 1.943 ± 0.040a | 1.89 ± 0.065a | 1.97 ± 0.005a |

| EC (mL/100 mL) | 5.333 ± 0.251b | 5.423 ± 0.110b | 4.3 ± 0.1a |

| ES (mL/100 mL) | 11.76 ± 0.445a | 20.866 ± 0.665b | 26.8 ± 1.212c |

| Pasting properties | |||

| Peak viscosity (cP) | 460.333 ± 7.637a | 465.333 ± 4.725a | 489.33 ± 5.507b |

| Trough viscosity (cP) | 115.66 ± 2.081a | 117.66 ± 2.51a | 163.33 ± 13.316b |

| Breakdown (cP) | 344.66 ± 9.71b | 347.66 ± 2.309b | 325.33 ± 7.234a |

| Final viscosity (cP) | 661.59 ± 10.16a | 733.33 ± 11.676b | 768.66 ± 2.516c |

| Setback viscosity (cP) | 545.926 ± 8.59a | 615.66 ± 10.785b | 605.33 ± 10.969b |

| Pasting temperature (°C) | 95.02 ± 0.230a | 95.186 ± 0.737a | 95.816 ± 1.284a |

| Thermal analysis | |||

| To (°C) | 75.59 ± 0.06b | 76.15 ± 0.56b | 77.65 ± 0.02a |

| Tp (°C) | 79.18 ± 0.06b | 79.92 ± 0.64b | 81.33 ± 0.19a |

| Tc (°C) | 104.15 ± 0.04b | 104.86 ± 0.64b | 108.36 ± 0.60c |

| Tc-To (°C) | 28.50 ± 0.05a | 28.96 ± 0.05b | 31.32 ± 0.07c |

| ΔH (Jg−1) | 11.28 ± 0.09a | 11.43 ± 0.02a | 11.33 ± 0.182a |

WAC Water absorption capacity, OAC Oil absorption capacity, EC Emulsifying capacity, ES Emulsion stability, T o Onset temperature, T p Peak temperature, T c Conclusion temperature, T c –T o Gelatinization temperature range, ΔH Gelatinization enthalpy

Values with the same letter in a row are not significantly different (P < 0.05)

Color

The Hunter lab (L) values of oat flour from Sabzaar, SKO20, and SKO90 were 80.48, 77.41, and 75.53, a values were 4.66, 6.00, and 13.66, b values were 16.28, 20.68 and 16.59, respectively. Sabzaar flour displayed significantly (P < 0.05) highest value of ‘L’ which indicates its lighter black color, whereas SKO20 showed highest values of ‘a’ and ‘b’ followed by SKO90, reflecting its darker black color as represented in Table 5. The differences in Hunter color values among the cultivars might be due to genetic variations.

Water and oil absorption capacity

Water and oil absorption capacities of oat flour are depicted in Table 5. When put under a limited water condition the ability of flour to associate with water by establishing chemical bonds ascertains its water absorption capacity (WAC). Water absorption capacity relies upon hydrophilicity of polar or charged side chains of biomacromolecules like carbohydrates and proteins in flour (Kaur and Singh, 2005). The WAC of flours influences its cooking properties, product characteristics and product staling. The average WAC of six Nigerian rice cultivars was found within the range from 122.64 to 143.35 % (Falade and Christopher, 2015).

The oil absorption capacity (OAC) involves physical mechanism of capturing oil by capillary action. Data revealed no significant (P < 0.05) difference in OAC of flour among the cultivars. It is another important functional property of flours as it helps in enhancing the mouthfeel of foods and retaining the flavour (Aremu et al., 2007). The main component influencing the oil absorption capacity is protein consisting of both hydrophilic and hydrophobic parts. Also the non-polar amino acid side chains are able to interact with hydrocarbon chains of lipid through hydrophobic interactions (Jitngarmkusol et al., 2008). Wani et al. (2013) reported OAC in black gram flour (Phaseolus mungo L.) varied from 2.1 to 2.2 g/g. The lower OAC of the oat flours could be helpful in the development of low oil uptake frying batters and hence more health beneficial.

Emulsion capacity and stability

The emulsion capacity of a substance is the ability to absorb to the interfacial area of oil and water in an emulsion. Whereas emulsion stability is the ability of proteins to impart strength to an emulsion against the stresses and the changes to which it is subjected over a defined time period (Singh et al., 2010). Emulsifying capacity (EC) and emulsifying stability (ES) of oat flours are presented in Table 5. EC varied in the range of 5.4–4.3 mL /100 mL, wherein SKO20 revealed significantly (P < 0.05) higher value than other cultivars whereas emulsion stabilities of the oat flours ranged from 26.8 to 11.76 mL/100 mL. The difference in emulsion capacity and stability among cultivars depends on the presence of soluble and insoluble proteins, fat and other compounds like carbohydrates (McWatters & Cherry, 1977). The decrease in the surface tension of the oil droplets is because of emulsifying and stabilizing properties of proteins (Sikorski, 2002; Dickinson, 1994). Du et al. (2014) reported much higher emulsion capacity and stability as compared to oat flour in whole legume flour.

Foaming capacity and stability

Flours are capable of producing foams due to surface active soluble proteins in their continuous water phases (Adebowale and Lawal, 2003). Oat is the only cereal containing globulin or legume-like protein, avenalin, as the major (80 %) storage protein. Foaming capacity of oat flour has been presented in Table 6. Foaming capacity varied significantly (p < 0.05) with the change in pH. Flours at pH 2, 4, 6, 8 and 10 showed variation in the range from 25.33–32.43, 33.57–43.96, 26.63–31.63, 25.44–30.10, and 65.15–67.30 (mL/100 mL), respectively. Kinsella (1976) and Nakai (1983) reported that foaming is positively correlated with protein solubility. Foaming capacity and stability mostly depends on the ability of proteins to reduce the surface tension by forming the interfacial film which maintains the air bubbles in suspension and slows down coalescence. Besides proteins, foaming capacity in flours also depends on some other components, such as carbohydrates (Sreerama et al., 2012). Chau and Cheung (1998) reported foaming capacity of different legume flours P. angularis, P. calcaratus, D.lablab, and soybean (Glycine max), at different pH varied from 64.4 to 140 %.

Table 6.

Foaming capacity and stability of oat flour

| Parameter | |||||

|---|---|---|---|---|---|

| Foaming capacity (mL/100 mL) | pH2 | pH4 | pH6 | pH8 | pH10 |

| Sabzaar | 32.433 ± 0.378b | 43.966 ± 0.251b | 31.633 ± 0.550b | 30.103 ± 0.985b | 67.303 ± 1.058b |

| SKO20 | 25.333 ± 1.527a | 36.306 ± 0.100a | 26.966 ± 0.838a | 25.593 ± 0.467a | 66.213 ± 0.015ab |

| SKO90 | 25.366 ± 0.763a | 33.579 ± 3.792a | 26.633 ± 1.350a | 25.446 ± 0.688a | 65.15 ± 0.992a |

| Foaming stability (mL/100 mL) | |||||

| Sabzaar | 13.206 ± 2.155a | 27.433 ± 0.404b | 27.166 ± 0.089a | 9.803 ± 0.453a | 12.793 ± 2.095a |

| SKO20 | 12.003 ± 2.207a | 26.513 ± 0.345a | 25.87 ± 1.238a | 9.136 ± 0.236ab | 11.926 ± 1.523a |

| SKO90 | 10.856 ± 0.543a | 27.34 ± 0.242b | 27.146 ± 0.127a | 8.656 ± 0.482a | 11.593 ± 1.571a |

Values with the same letter in a row are not significantly different (P < 0.05)

Foam stability of flour suspensions at various pH was studied over a time period of 1 h. With the increase in time foam volume decreased as shown in Table 6. Significant (p < 0.05) difference in foam stability was observed as the pH varied from 2 to 10. Highest foam stability was seen at pH 4–6 compared to other pH conditions. The possible reason might be due to the more stable conformations of proteins at their isoelectric points or higher solubility of proteins at pH other than the isoelectric point (Wani et al., 2013).

Pasting properties

Pasting properties of oat flours are presented in Table 5. Peak viscosity of oat flours was in the range of 460.33–489.33 cP. The highest peak viscosity was observed for the flour of Sabzaar and the lowest for SKO20. Peak viscosity is defined as the maximum viscosity attained by starch when heated in water, reflecting the water binding capacity of granules of the starch. Values are in consistent with the highest and the lowest water absorption capacity displayed by these cultivars (Table 5). Also the higher peak viscosity of Sabzaar flour could be attributed to its higher starch content compared to the other cultivars. The breakdown value is the ease with which the swollen starch granule can be broken down by heating and physical agitation. Higher the breakdown value, lower the ability of the starch to withstand heating and shearing stress during cooking (Adebowale et al., 2005). Significantly higher (p < 0.05) breakdown viscosity was observed in SKO90 and the lowest in Sabzaar flour. The tendency of flour to retrogradate is measured by set-back value and is found to vary significantly (p < 0.05) from 545 to 615 cP. Higher the setback, more is the syneresis and higher is the tendency to retrogradate (Hagenimana and Ding, 2005). Pasting temerature is the temperature which reflects the onset of rise in viscosity. Oat starch, among other starches, is characterized by high pasting temperature due to presence of high amounts of lipids (Hoover et al., 2003).

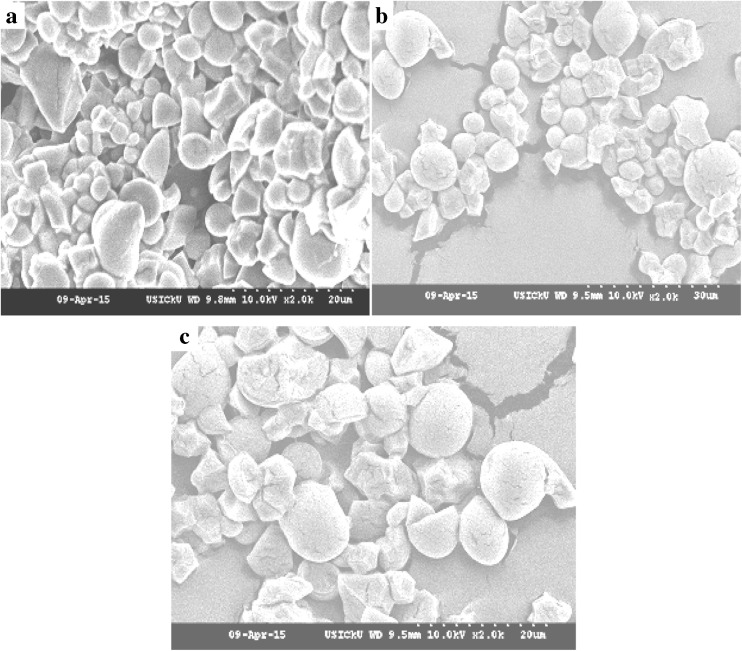

Granule morphology by SEM

The scanning electron micrographs of three varieties of oat flour is shown in Fig. 1. Flour samples showed the presence of small as well as large starch granules, oval or irregular shape with a smooth surface having some dents or fissures and some damaged starch and with varying dimensions. Average granule size of oat starch samples was within the range of 1.5–6.6 μm in Sabzaar, 1.1–5.2 μm in SKO20, and 1.7–6.8 μm in SKO90. The average size of oat starch granules was found to vary from 3 to 10 μm (Hoover and Vasanthan, 1994). Also a continuous network of proteins and other non protein components were seen in which starch granules were embedded. Granule shape and size distributions of starch are unique properties that influence functionality of the flour.

Fig. 1.

Scanning electron micrograph of oat flour, (a) Sabzaar flour (b) SKO20 flour (c) SKO90 flour

Thermal properties

The thermal properties of three varieties of oat flour was measured using DSC and is presented in Table 5. The gelatinization transition temperatures onset temperature (To), peak temperature (Tp), and conclusion temperature (Tc) varied significantly (p < 0.05) among three varieties. The gelatinisation transition temperatures - To, Tp and Tc varied from 75.59 to 77.65 °C, 79.18–81.33 °C, and 104.15–108.36 °C, respectively. The results were in consistent with the high pasting temperatures obtained from the RVA. The temperature range from 104.15 to 108.36 °C corresponds to the melting of the amylose–lipid complex and was observed highest for SKO90 flour. A Significant difference (P < 0.05) in gelatinization temperature range (Tc-To) was observed among the three cultivars with Sabzaar showing the lowest value (28.50 °C) and SKO90 highest (31.32 °C). However, a non significant difference (P < 0.05) in gelatinisation enthalpy (ΔH) was observed that varied from 11.28 to 11.33 Jg−1. The gelatinisation transition temperatures is effected by various factors, including amylose content, lipid-amylose complex chains, crystalline to amorphous ratio and protein content (Gunaratne and Hoover, 2002).

Conclusion

This study has shown that geometrical and gravimetrical properties of three oat varieties varied significantly and can be helpful in the designing of equipments for processing and packaging. Oat flours displayed high viscosity, low setback viscosity, good EC, ES, FC, FS, and therefore can be used as an thickening agent, as an ingredient where stability is needed at low temperature, and as a texture improver in products like ice-cream. Thermal properties of oats flour showed high gelatinization transition temperatures giving an idea about its behavior during processing in food industry. Besides it, oat can be used an ingredient for making functional foods and gluten-free products, which have shown an increased market demand in recent years.

Acknowledgments

The authors are thankful to the Department of Biotechnology, Government of India for their financial support.

References

- Adebowale KO, Lawal OS. Foaming, gelation and electrophoretic characteristics of mucuna bean (Mucuna pruriens) protein concentrates. Food Chem. 2003;83(2):237–246. doi: 10.1016/S0308-8146(03)00086-4. [DOI] [Google Scholar]

- Adebowale KO, Olu-Owolabi IO, Olawunmi EK, Lawal OS. Functional properties of native, physically and chemically modified breadfruit (Artocorpus altilis) starch. Ind Crop Prod. 2005;21(3):343–351. doi: 10.1016/j.indcrop.2004.05.002. [DOI] [Google Scholar]

- Ahmad M, Zaffar G, Dar ZA, Habib M. A review on oat (Avena sativa L.) as a dual-purpose crop. Sci Res Essays. 2014;9(4):52–59. doi: 10.5897/SRE2014.5820. [DOI] [Google Scholar]

- Altuntas E, Ozgoz E, Taser OF. Some physical properties of fenugreek (Trigonella foenum-graceum L) seeds. J Food Eng. 2005;71(1):37–43. doi: 10.1016/j.jfoodeng.2004.10.015. [DOI] [Google Scholar]

- Aremu MO, Olaofa O, Akintayo ET. Functional properties of some nigerian varieties of legume seed flours and flour concentration effect on foaming and gelation properties. J Food Sci Technol. 2007;5(2):109–115. [Google Scholar]

- Asoegwu SN. Some physical properties and cracking energy of conophor nuts at different moisture contents. Int Agrophys. 1995;9(2):131–142. [Google Scholar]

- Association of official Analytical chemistry (AOAC) (1990) Official methods of analysis; Airlington

- Butt MS, Nadeem MT, Khan MKI, Shabir R, Butt MS. Oat: unique among the cereals. Eur J Nutr. 2008;47(2):68–79. doi: 10.1007/s00394-008-0698-7. [DOI] [PubMed] [Google Scholar]

- Carr RL. Evaluating flow properties of solids. Chem Eng. 1965;72(3):163–168. [Google Scholar]

- Chang CS. Measuring density and porosity of grain kernels using a gas pycnometer. Cereal Chem. 1988;65(1):13–15. [Google Scholar]

- Chau CF, Cheung PCK. Functional properties of flours prepared from three Chinese indigenous legume seeds. Food Chem. 1998;61(4):429–433. doi: 10.1016/S0308-8146(97)00091-5. [DOI] [PubMed] [Google Scholar]

- Davidson MH, Dugan LD, Burns JH, Bova J, Story K, Drennan KB. The hypocholesterolemic effects of β-glucan in oatmeal and oat bran. A dose-controlled study. J Am Med Assoc. 1991;265(14):1833–1839. doi: 10.1001/jama.1991.03460140061027. [DOI] [PubMed] [Google Scholar]

- Dickinson E. Protein-stabilized emulsions. J Food Eng. 1994;22:59–74. doi: 10.1016/0260-8774(94)90025-6. [DOI] [Google Scholar]

- Dikeman CL, Murphy MR, Fahey GC. Dietary fibers affect viscosity of solutions and simulated human gastric and small intestinal digesta. J Nutr. 2006;136(4):913–919. doi: 10.1093/jn/136.4.913. [DOI] [PubMed] [Google Scholar]

- Du SK, Jiang H, Yu X, Jane JL. Physicochemical and functional properties of whole legume flour. LWT Food Sci Technol. 2014;55(1):308–313. doi: 10.1016/j.lwt.2013.06.001. [DOI] [Google Scholar]

- Falade KO, Christopher AS. Physical, functional, pasting and thermal properties of flours and starches of six Nigerian rice cultivars. Food Hydrocoll. 2015;44(1):478–490. doi: 10.1016/j.foodhyd.2014.10.005. [DOI] [Google Scholar]

- Gani A, Hussain A, Ahmad M, Baba WN, Gani A, Masoodi FA, Wani SM, Shah A, Wani IA, Maqsood S. Engineering and functional properties of four varieties of pulses and their correlative study. Food Meas Charact. 2015 [Google Scholar]

- Gani A, Masoodi FA, Wani SM, Salim R. Characterization of rice starches extracted from Indian cultivars. Food Sci Technol Int. 2013;19(2):143–152. doi: 10.1177/1082013212442189. [DOI] [PubMed] [Google Scholar]

- Gorial BY, O’callaghan JR. Aerodynamic properties of grain/straw materials. J Agric Eng Res. 1990;46(5):275–290. doi: 10.1016/S0021-8634(05)80132-5. [DOI] [Google Scholar]

- Gunaratne A, Hoover R. Effect of heat-moisture treatment on the structure and physicochemical properties of tuber and root starches. Carbohydr Polym. 2002;49(4):425–437. doi: 10.1016/S0144-8617(01)00354-X. [DOI] [Google Scholar]

- Hagenimana A, Ding X. A comparative study on pasting and hydration properties of native rice starches and their mixtures. Cereal Chem. 2005;82(1):72–76. doi: 10.1094/CC-82-0070. [DOI] [Google Scholar]

- Hoover RA, Vasanthan T. Effect of heat moisture treatment on structure and physicochemical properties of cereal, legume and tuber starches. Carbohydr Res. 1994;252(4):33–53. doi: 10.1016/0008-6215(94)90004-3. [DOI] [PubMed] [Google Scholar]

- Hoover R, Smith C, Zhou Y, Ratnayake RMWS. Physicochemical properties of Canadian oat starches. Carbohydr Polym. 2003;52(3):253–261. doi: 10.1016/S0144-8617(02)00271-0. [DOI] [Google Scholar]

- Huttner EK, Bello FD, Arendt EK. Rheological properties and bread making performance of commercial wholegrain oat flours. J Cereal Sci. 2010;52(1):65–71. doi: 10.1016/j.jcs.2010.03.004. [DOI] [Google Scholar]

- Jain RK, Bal S. Properties of pearl millet. J Agric Eng Res. 1997;66(1):85–91. doi: 10.1006/jaer.1996.0119. [DOI] [Google Scholar]

- Jitngarmkusol S, Hongsuwankul J, Tananuwong K. Chemical composition, functional properties and microstructure of defatted macadamia flours. Food Chem. 2008;110(1):23–30. doi: 10.1016/j.foodchem.2008.01.050. [DOI] [PubMed] [Google Scholar]

- Kaur M, Singh N. Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem. 2005;91(3):403–411. doi: 10.1016/j.foodchem.2004.06.015. [DOI] [Google Scholar]

- Khan AA, Gani A, Shah A, Masoodi FA, Hussain PR, Wani ID, Khanday FA. Effect of γ-irradiation on structural, functional and antioxidant properties of β-glucan extracted from button mushroom (Agaricus bisporus) Innovative Food Sci Emerg Technol. 2015 [Google Scholar]

- Kinsella JE. Functional properties of proteins in foods: a survey. Crit Rev Food Sci Nutr. 1976;7(3):219–280. doi: 10.1080/10408397609527208. [DOI] [Google Scholar]

- Mahajan A, Dua S. Salts and pH induced changes in functional properties of Amaranth (Amaranthus tricolor L.) seed meal. Cereal Chem. 2002;79(6):834–837. doi: 10.1094/CCHEM.2002.79.6.834. [DOI] [Google Scholar]

- Malkki Y, Virtanen E. Gastrointestinal effect of oat bran and oat gum: a review. Lebensm Wiss Technol. 2001;34:337–347. doi: 10.1006/fstl.2001.0795. [DOI] [Google Scholar]

- McWatters KY, Cherry JP. Emulsification, foaming and protein solubility properties of defatted soybean, peanut, field peaand pecan flours. J Food Sci. 1977;42(60):144–1450. [Google Scholar]

- Mohsenin NN. Physical properties of plant and animal materials. New York: Gordon and Breach Science Publishers; 1986. [Google Scholar]

- Mohsenin NN. Physical properties of plants and animal materials. New York: Gordon and Breach Science Publishers; 1970. [Google Scholar]

- Nakai S. Structure–function relationships of food proteins with an emphasis on the importance of protein hydrophobicity. J Agric Food Chem. 1983;31(4):676–683. doi: 10.1021/jf00118a001. [DOI] [Google Scholar]

- Omobuwajo OT, Akande AE, Sanni AL. Selected physical, mechanical aerodynamic properties African Breadfruit (Treculia africana) seeds. J Food Eng. 1999;40(4):241–244. doi: 10.1016/S0260-8774(99)00060-6. [DOI] [Google Scholar]

- Ozturk I, Kara M, Elkoca E, Ercisli S. Physico-chemical grain properties of new common bean cv. ‘Elkoca-05’. Sci Res Essay. 2009;4(2):88–93. [Google Scholar]

- Ozturk I, Kara M, Ercisli S, Kantar F. Physical and chemical grain properties of new registered common bean cv. ‘Kantar-05’. Sains Malaysiana. 2010;39(5):725–730. [Google Scholar]

- Sacilik K, OZturk R, Keskin R. Some physical properties of hemp grain. Biosyst Eng. 2003;86(2):213–215. doi: 10.1016/S1537-5110(03)00130-2. [DOI] [Google Scholar]

- Sharma SK, Dubey RK, Teckchandani CK. Engineering properties of black gram, soybean and green gram. Proc Indian Soc Agric Eng. 1985;3:181–185. [Google Scholar]

- Sikorski ZE. Proteins. In: Sikorski ZE, editor. Chemical and functional properties of food components. Florida: CRC Press, Inc; 2002. pp. 133–178. [Google Scholar]

- Singh N, Kaur N, Rana JC, Sharma SK. Diversity in seed and flour properties in field pea (Pisum sativum) germplasm. Food Chem. 2010;122(3):518–525. doi: 10.1016/j.foodchem.2010.02.064. [DOI] [Google Scholar]

- Sreenarayanan VV, Subramanian V, Visvanathan R. Physical and thermal properties of soybean. Proc Indian Soc Agric Eng. 1985;3:161–169. [Google Scholar]

- Sreerama YN, Sashikala VB, Pratape VM, Singh V. Nutrients and antinutrients in cowpea and horse gram flours in comparison to chickpea flour: evaluation of their flour functionality. Food Chem. 2012;131(2):462–468. doi: 10.1016/j.foodchem.2011.09.008. [DOI] [Google Scholar]

- Tunde-Akintunde TY, Akintunde BO. Some physical properties of sesame seed. Biosyst Eng. 2004;88(1):127–129. doi: 10.1016/j.biosystemseng.2004.01.009. [DOI] [Google Scholar]

- Wani IA, Sogi DS, Gill BS. Physicochemical and functional properties of flours from three Black gram (Phaseolus mungo L.) cultivars. Int J Food Sci Technol. 2013;48(4):771–777. doi: 10.1111/ijfs.12025. [DOI] [Google Scholar]

- Wani ID, Wani AA, Gani A, Muzaffar S, Gul MK, Masoodi FA, Wani TA. Effect of gamma-irradiation on physico-chemical and functional properties of arrowhead (Sagittaria sagittifolia L.) tuber flour. Food Biosci. 2015;11(1):23–32. doi: 10.1016/j.fbio.2015.04.003. [DOI] [Google Scholar]