Abstract

The present study was carried out to develop waris from potato and legume blends and to analyze them for organoleptic, physicochemical, phytochemical and shelf life quality. Wari is a partially fermented legume based savoury, used as adjunct in vegetable curries. In this study, potato (boiled and dehydrated) was used to supplement black gram or urad dhal waris. Two processing cultivars (Kufri Chipsona-1, Kufri Chandramukhi) and one commonly grown cultivar (Kufri Pukhraj) were evaluated for processing into waris. Based on preliminary sensory trails, waris with potato (70 %) and urad dhal (30 %) level of supplementation were found to be most acceptable and these waris were subjected to nutritional evaluation. Storage stability of the waris was assessed by storing the product at room temperature for a period of 12 months. Results were compared with dhal waris (control). Protein content was significantly higher in control waris compared to potato supplemented waris. Bioactive compounds including ascorbic acid, total phenolics and total antioxidant activity measured as DPPH radical scavenging activity increased significantly on incorporation of potato. Between the cultivars, waris enriched with Kufri Pukhraj, a table variety which is considered unfit for processing, displayed the highest phytochemical content and total antioxidant activity. Sensory evaluation indicated higher overall acceptability scores of potato enriched waris compared to control waris. Between the treatments i.e. boiled mash and dehydrated flour, waris supplemented with boiled potato mash showed a significantly higher content of phytochemicals and total antioxidant activity compared to potato flour waris. However no significant difference was observed in sensory quality of the product prepared either with fresh potato mash or potato flour. Storage studies showed that the potato waris can be stored safely for 12 months with its nutrient constituents intact.

Keywords: Antioxidant activity, Potato, Potato flour, Phytochemicals, Supplementation, Wari

Introduction

Potato (Solanum tuberosum L.) is a nutritious vegetable containing significant amount of carbohydrates, superior quality protein, dietary fibre, some minerals and negligible amount of fat (Kaur et al. 2012). Beyond these basic nutrients, potatoes contain several secondary metabolites (phytochemicals) with antioxidant activity, which contributes to the physiological defense against oxidative and free radical mediated reactions (Ezekiel et al. 2013). Polyphenols, ascorbic acid and carotenoids are the major bioactive compounds known in potato for their antioxidant properties (Lachman and Hamouz 2005; Hejtmankova et al. 2009; Gumul et al. 2011). The scavenging activity of these compounds is mainly due to their redox properties, which allow them to act as reducing agents, hydrogen donors, and singlet oxygen quenchers (Kaur and Kapoor 2002; Babbar et al. 2011).

Potatoes are a major contributor to dietary phytochemical concentrations due to consumption levels. Al-Saikhan et al. (1995) determined total antioxidant activity in different genotypes of potato cultivars and found that total antioxidant capacity (Percent inhibition relative to control) ranged 65.20–88.12 %. Hesam et al. (2012) reported higher antioxidant activity of 92.89 % and 94.10 % in Iranian potato genotypes by DPPH radical scavenging method while moderate antioxidant activity of 80 % in Canadian potato genotype ‘Russet Burbank’ was reported by Velioglu et al. (1998). Kaur and Kapoor (2002) determined antioxidant activity in both aqueous and alcoholic (80 %) potato extracts by β-carotene bleaching method. The authors suggested moderate antioxidant activities of 62.5 % and 62.3 % in aqueous and alcoholic extracts, respectively. Kaur and Aggarwal (2014) determined total phenolics and antioxidant activity in sixteen Indian potato genotypes. The authors observed 31.30–68.20 mg/GAE phenolics and 28.0–67.3 % antioxidant activity in different genotypes and concluded that potatoes contain enough phytochemicals to be used as functional food for improving human health.

India became the second largest producer of potato in the world with bumper crop of 41.48 million tonnes in the year 2012–13 (FAO 2014). Potato is one of the commonly used vegetable and is staple diet for a large number of people in the world but main disadvantage of the crop is that it is seasonal and bulky production of crop has short life (Misra and Kulshrestha 2003). Lack of sufficient storage facilities result in crop deterioration as post harvest time advances. Dehydration of bumper perishable crop seems to be convenient alternative for long term storage and could serve as means to ensure availability of potatoes in different forms throughout the year.

Potato can be processed into an indigenous dehydrated product called wari, which has a promising future due to its long shelf life and diverse uses. Wari is a partially fermented legume-based savoury which is manufactured on cottage scale in rural areas of Northern India and is used as adjunct in curries. Generally, wari is prepared from batter of split black gram or green gram dhal along with various spices and condiments like dried fenugreek leaves, coriander powder, cumin seeds, red chilli powder and black pepper (Kulkarni et al. 1997). Fermentation and drying of the batter takes place simultaneously and the drying cause case hardening which result in a cavity or porous texture. Dehydrated waris are easy to prepare, require no costly machinery for manufacture and have a longer shelf life.

Several dehydrated value added potato products such as potato papad (Marwaha and Sandhu 2003). dehydrated chips (Marwaha and Pandey 2006) and potato cubes (Sandhu and Parhawk 2002) have been developed earlier. Still, there is a need to find diversified uses of potatoes and to develop new processed products with improved nutritional quality which can be available for consumption throughout the year. Also, data on phytochemical content and antioxidant activities of savoury snacks commonly consumed in India is scanty. Thus, the aim of this work was to develop waris enriched with different potato cultivars and to evaluate the quality characteristics of the developed product in order to assess its physicochemical, phytochemical and shelf life properties.

Materials and methods

Materials

Two potato cultivars known for better quality characteristics (Kufri Chipsona-1, Kufri Chandramukhi) and one commonly cultivated variety (Kufri Pukhraj) were procured from Vegetable Crops Department of the University and were used for production of waris. Split black gram dhal (Phaseolus mungo Roxb.) and whole spices (dried fenugreek leaves, coriander seeds, cumin, cinnamon, black pepper, red pepper, cloves, nutmeg, asafoetida) were purchased locally.

Preparation of raw materials

Waris were prepared by incorporating both fresh boiled potato mash as well as dehydrated potato flour. One part of the harvested tubers of each cultivar was used for preparation of boiled potato mash. The remaining part of tubers was used for the preparation of potato flour.

Boiled potato mash

Fresh potato tubers (1 kg) of each cultivar were washed, peeled, cut into four quarters and cooked in an open pressure cooker (Model 2170, TTK Prestige Ltd., Mumbai, India) in water (1 L) for 10 min at 95 °C. The boiled potatoes were cooled for 5 min under running tap water until the tubers reached room temperature. The cooked boiled potatoes were then mashed.

Dehydrated potato flour

The tubers of K.Chipsona-1, K.Chandramukhi and K.Pukhraj were peeled and cut into 2–3 mm thick slices with a rotary hand slicer. The slices were cooked in boiling water containing 0.25 % potassium metabisulphite for 10 min to prevent enzymatic darkening (Marwaha and Pandey 2006). Immediately after cooking, potato slices were cooled under running tap water. The sulphited slices were drained, loaded in trays and dried in hot air cabinet drier (Model 1254, Pharma Tech International, Kolkata, India) at 60 °C ± 5 °C for 5 to 6 h. The dried potato slices were ground in an electric grinder (Philips India Limited, Mumbai, India) and then powdered in a cyclotec mill (FOSS CT 193 cyclotec Mill, Denmark).

Wet pulse paste

Black gram dhal or Urad dhal (450 g) was washed thoroughly and soaked in about 550 ml of water overnight. The drained pulses were then ground in an electric grinder (Philips India Limited, Mumbai, India) with small addition of water, till it became a thick paste.

Spice mix

Whole spices were coarsely ground in a grinder and used for the preparation of waris.

Formulation of waris

Waris were formulated by incorporating potato in different proportions. Proportions of ingredients which were liked best sensorily were selected for the development of final product. Waris were prepared by the ‘traditional wari’ recipe as described by Kulkarni et al. (1997) with slight modifications. Potato (boiled and dehydrated) of each variety was incorporated in the traditional recipe to replace urad dhal at levels of 10, 30, 50, 70 and 90 % in preparation of waris. Based on preliminary sensory trials, substitution of up to 70 % of potato produced significant desirable changes in the sensory characteristics of waris. So, this level was used for the preparation of the final product.

Processing method

Standardized recipe of waris had the ingredients: potato mash 315 g, pulse paste 135 g, dried fenugreek leaves 3.5 g, coriander and cumin seeds 7.5 g, cinnamon 1.5 g, black and red pepper 3.0 g, cloves 0.8 g, nutmeg 0.25 g, asafetida 0.1 g. For preparation of waris, the thick wet pulse paste was whisked continuously with hand till it became light and fluffy due to incorporation of air. To the wet pulse paste, standardized amount of potato (70 % of the mix) was added. The resultant paste was then mixed thoroughly with flavourings. The resultant fluffy batter was taken in hand and divided into small balls weighing 50–60 g. The prepared balls were spread on stainless steel trays smeared with oil, maintaining a distance of 1–2 in. between balls. The trays were then loaded in hot air cabinet drier and dried at 60 ± 5 °C for 14–16 h. The control (without potato) wari samples were used for physico-chemical, phytochemical and sensorial comparisons.

Waris were also prepared by incorporating potato flour (instead of potato mash) into legume-spice mix by using the same method as mentioned above.

Chemicals

The following chemicals were used: 2, 4-Dichlorophenol-Indophenol dye, methanol, Folin-Ciocalteu’s reagent, sodium bicarbonate, 1, 1-diphenyl-2-picrylhydrazyl (DPPH), Tris-HCl buffer were obtained from S. D. Fine Chem. Ltd., Mumbai, India. All the chemicals were of analytical grade.

Analysis

Physicochemical and phytochemical composition of raw ingredients and fresh waris

The moisture, ash, acid insoluble ash, acidity and protein contents were determined by official methods (AOAC 2005).

The ascorbic acid content was determined by visual titration method using 2, 4-Dichlorophenol-Indophenol dye method (Ranganna 2004). The results were expressed as milligram of ascorbic acid/100 g dw.

Phenolic compounds were extracted from sample (5 g fresh tissue; 1 g dry ingredient) according to Velioglu et al. (1998) with 50 ml of 80 % (v/v) aqueous methanol for 3 h at 40 °C with refluxing. The content of total phenolic compounds in extract was determined using the Folin-Ciocalteu’s colorimetric method (Velioglu et al. 1998). The absorbance at 765 nm was measured after 30 min and the results were expressed as gallic acid equivalents (mg GAE/100 g dw).

The ability of the prepared extracts to scavenge the stable free radical 1, 1-diphenyl-2-picrylhydrazyl (DPPH) was estimated using the method of Yamaguchi et al. (1998) with little modification. To 1 ml of methanolic extract of sample prepared as above, 1 ml Tris-HCl buffer (50 mM, pH 7.4) was added. Then 2 ml of 0.1 mM freshly prepared DPPH was added to the reaction mixture. The reaction mixture was shaken and incubated in the dark at room temperature for 30 min and the absorbance was read at 517 nm against blank (80 % methanol and Tris buffer). The free radical scavenging activity was evaluated by comparing the absorbance with control solution to which distilled water was added instead of sample with 2 ml of 0.1 mM DPPH and 1 ml 50 mM Tris-HCl buffer. BHT was taken as a standard at a fixed concentration of 5 mg/ml.

Color attributes

The color of waris was measured using a Minolta Chroma colorimeter model CR 200 (Minolta Co., Osaka, Japan) against a white reference standard. The measurements were displayed in L*: lightness, a*: redness and b*: yellowness.

Sensory quality evaluation of waris

For sensory evaluation, waris (40 g) were shallow-fried for 30 s in a frying pan containing 60 ml of cooking oil maintained at 150 °C. Fried waris were divided into small pieces and cooked in a vegetable curry preparation. For curry preparation, 40 ml of cooking oil was heated in a pan and seasoned with cumin seeds (1 g). To this, paste containing ginger (5 g), garlic (3 g), onion (50 g), tomato (66 g) was added, along with salt (2 g), turmeric (0.2 g), coriander (1 g) and red chilli powder (0.2 g). Shallow fried wari pieces were added to the above cooked paste along with 250 ml of water and were pressure cooked for 3 min. The cooked hot wari samples were evaluated by a panel of 10 judges using 9-point Hedonic scale for their sensory characteristics like appearance, flavor, texture and overall acceptability. The scores were assigned from extremely liked (9) to disliked extremely (1).

Storage studies

Waris were packed in 200 gauge polythene bags and sealed in tight air containers. The packed waris were exposed to room temperature (26-38 °C/RH 35-87 %) for a period of 12 months. Storage stability of the product was assessed by determining the changes in moisture and bioactive composition. Sensorial analysis of the stored waris was done by a semi trained panel of 10 judges using 9-point Hedonic scale.

Statistical Analysis

All the experiments were carried out in triplicate. One-way analysis of variance was performed using the SPSS version 20.0 (Statistical Package for Social Sciences). Significant differences (p < 0.05) were determined by Tukey’s.

Results and discussion

Quality characteristics of fresh waris

Quality attributes i.e. physicochemical, phytochemical and color characteristics of control waris and potato incorporated waris are summarized in Table 2. The control and potato supplemented waris did not differ significantly (p < 0.05) in their moisture content. The ash content of control waris was 4.02 % and it ranged from 3.33 to 4.02 % in potato supplemented waris (Table 2). The ash content of waris conformed well to the proposed standards (max. 4.50 %) for dhal waris (Kulkarni et al. 1997). Acid insoluble ash ranged 0.18–0.26 % and was within the prescribed limits (max. 0.40 %) (Kulkarni et al. 1997). The variations (1.31–1.41 %) in acidity (as oleic acid) of waris were within the proposed standards (max. 1.70 %) (Kulkarni et al. 1997). In control waris, protein content was 22.56 % that was found to be significantly (p < 0.05) higher than that of potato supplemented waris (14.58–16.82 %) (Table 2). The protein content of the control waris conformed to the proposed specifications (min. 16 %) (Kulkarni et al. 1997). while waris incorporated with potato showed significantly lower values.

Table 2.

Quality characteristics of fresh waris*

| Products | Moisture (%) | Ash (%) | Acid insoluble ash (%) | Acidity (%) | Protein (%) | Ascorbic acid (mg/100 g) | Total phenols (mg GAE/100 g) | Scavenging activity (%) | Color attributes | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | |||||||||

| Control (without potato) | 5.82 ± 0.20a | 4.02 ± 0.15a | 0.26 ± 0.05a | 1.33 ± 0.02a | 22.56 ± 0.50a | 23.48 ± 0.21g | 360.7 ± 1.40g | 82.64 ± 0.48d | 52.48 ± 0.23c | 3.76 ± 0.22a | 13.11 ± 0.11b |

| Waris supplemented with boiled potato mash | |||||||||||

| K.Chipsona-1 | 5.78 ± 0.22a | 4.02 ± 0.12a | 0.21 ± 0.01a | 1.33 ± 0.02a | 16.82 ± 0.19a | 30.42 ± 0.12a | 476.6 ± 1.20e | 92.60 ± 0.0.62b | 56.89 ± 0.21a | 2.95 ± 0.23c | 15.78 ± 0.0.22a |

| K. Chandramukhi | 5.97 ± 0.25a | 3.33 ± 0.10b | 0.19 ± 0.01a | 1.41 ± 0.03b | 14.60 ± 0.15c | 33.86 ± 0.21c | 550.6 ± 1.80c | 94.07 ± 0.0.65ba | 56.28 ± 0.20a | 3.25 ± 0.22bc | 15.58 ± 0.28a |

| K.Pukhraj | 5.85 ± 0.18a | 3.87 ± 0.15a | 0.21 ± 0.02a | 1.33 ± 0.01a | 16.82 ± 0.20b | 37.24 ± 0.15a | 820.9 ± 2.00a | 95.54 ± 0.89a | 54.32 ± 0.25b | 3.27 ± 0.07b | 13.79 ± 0.20b |

| Waris supplemented with dehydrated potato flour | |||||||||||

| K.Chipsona-1 | 5.98 ± 0.20a | 4.00 ± 0.20a | 0.20 ± 0.01a | 1.31 ± 0.01a | 16.74 ± 0.12b | 28.78 ± 0.10f | 387.0 ± 1.80f | 90.26 ± 0.54c | 49.89 ± 0.19d | 3.85 ± 0.05a | 10.52 ± 0.25c |

| K. Chandramukhi | 5.63 ± 0.18a | 3.36 ± 0.10b | 0.18 ± 0.01a | 1.41 ± 0.03b | 14.58 ± 0.80c | 31.54 ± 0.30d | 509.4 ± 1.48d | 92.91 ± 0.80b | 49.86 ± 0.28e | 3.44 ± 0.09b | 10.60 ± 0.15c |

| K.Pukhraj | 5.81 ± 0.20a | 3.80 ± 0.21a | 0.21 ± 0.02a | 1.33 ± 0.01a | 16.77 ± 0.054b | 35.55 ± 0.25b | 763.5 ± 0.30b | 93.96 ± 0.88ab | 47.60 ± 0.20f | 3.24 ± 0.14bc | 10.41 ± 0.12c |

Values within a column with different letters are significantly (p < 0.05) different

Mean values ± SD (n = 3)

*Results expressed on dry weight basis

Phytochemical attributes i.e. ascorbic acid and total phenolic content and radical scavenging activities of fresh wari samples significantly (p < 0.05) increased on supplementation with potato as compared to control waris (Table 2). It might be due to a larger amount of phytochemical content in potato in comparison to urad dhal (Table 1). Between the cultivars studied, waris supplemented with K. Pukhraj had the highest bioactive content and radical scavenging activity while lowest was observed in K.Chipsona-1 waris (Table 2). The higher concentration of these phytochemicals in K. Pukhraj at initial level (Table 1) might have contributed towards their higher retention in the prepared product.

Table 1.

Physicochemical and phytochemical traits of raw ingredients used in development of potato waris

| Raw ingredients | Treatments | Moisture* (%) | Protein (%) | Ash (%) | Ascorbic acid (mg/100 g) | Total phenols (mg GAE/100 g) | Scavenging activity* (%) |

|---|---|---|---|---|---|---|---|

| Cultivars | |||||||

| K.Chipsona-1 | Raw tubers | 75.58 ± 0.12b | 21.42 ± 0.60b | 3.98 ± 0.12d | 82.31 ± 0.40d | 185.2 ± 0.22f | 40.80 ± 0.30f |

| Boiled mash | 75.69 ± 0.10b | 21.40 ± 0.62d | 4.03 ± 0.15d | 75.76 ± 0.30f | 165.4 ± 0.21h | 38.10 ± 0.25g | |

| Dehydrated flour | 6.02 ± 0.09d | 20.98 ± 0.54e | 3.86 ± 0.08e | 62.84 ± 0.21h | 132.3 ± 0.20j | 20.90 ± 0.28i | |

| K.Chandramukhi | Raw tubers | 75.60 ± 0.48b | 18.62 ± 0.48b | 4.85 ± 0.10b | 85.82 ± 0.50c | 240.8 ± 0.32d | 58.88 ± 0.48d |

| Boiled mash | 75.70 ± 0.50b | 18.75 ± 0.55f | 4.92 ± 0.12b | 80.92 ± 0.30e | 224.2 ± 0.60e | 53.20 ± 0.50e | |

| Dehydrated flour | 6.05 ± 0.20d | 18.04 ± 0.40g | 4.62 ± 0.09c | 67.54 ± 0.22g | 167.8 ± 0.31g | 25.86 ± 0.50h | |

| K.Pukhraj | Raw tubers | 84.50 ± 0.48b | 23.15 ± 0.58b | 6.90 ± 0.23b | 120.10 ± 0.58a | 440.8 ± 0.55a | 65.94 ± 0.28b |

| Boiled mash | 84.69 ± 0.51a | 23.05 ± 0.60b | 6.85 ± 0.18a | 107.83 ± 0.55b | 419.9 ± 0.65b | 63.50 ± 0.30c | |

| Dehydrated flour | 6.15 ± 0.12d | 22.86 ± 0.52c | 6.92 ± 0.20a | 80.86 ± 0.21e | 318.6 ± 0.42c | 20.90 ± 0.25i | |

| Urad dhal | Fresh | 9.80 ± 0.28c | 26.38 ± 0.70a | 3.63 ± 0.21f | 9.06 ± 0.10i | 155.2 ± 0.25i | 20.10 ± 0.30j |

| Spice mix | Fresh | 3.10 ± 0.18e | 0.21 ± 0.05h | 3.58 ± 0.18f | nd | nd | 98.10 ± 0.55a |

Values within a column with different letters are significantly (p < 0.05) different

Mean values ± SD (n = 3)

*g/100 g wet basis; nd – not detected

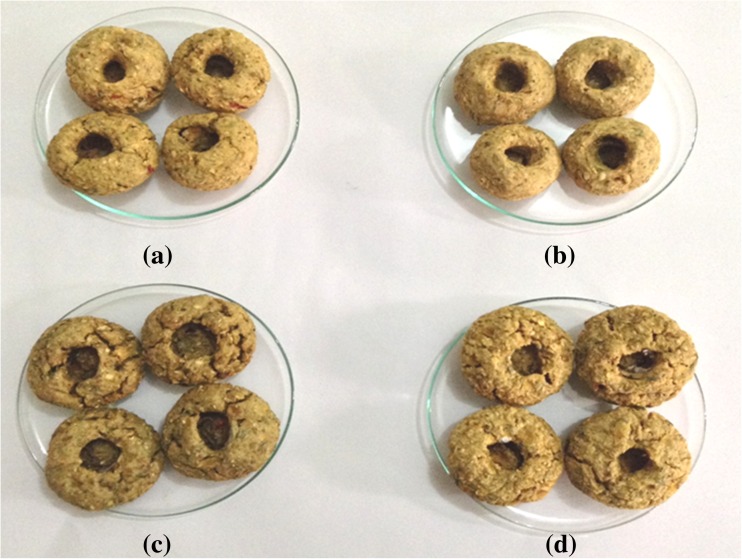

Color characteristics (L*, a* and b*) of control and potato supplemented waris were significantly (p < 0.05) different from each other (Table 2). K.Chipsona-1 supplemented waris had the maximum L* (lightness) value while lowest was noticed for waris supplemented with K.Pukhraj. Waris incorporated with K.Pukhraj were darker in color (Fig. 1) which might be due to higher phenolic content in this cultivar. Besides providing antioxidant properties, phenolic compounds are also associated with enzymatic browning which occurs due to their oxidation by polyphenol oxidase enzyme (Marwaha and Pandey 2006; Marwaha et al. 2010; Mehta et al. 2011).

Fig. 1.

Waris enriched with different potato cultivars (a) K.Chipsona-1 (b) K. Chandramukhi (c) K.Pukhraj (d) control (without potato)

Sensory quality evaluation of fresh waris

It is clear from Table 3 that there was no difference (p < 0.05) in sensory quality between waris enriched with either fresh potato mash or potato flour. These results indicate that waris can be successfully prepared from both fresh potato mash as well as dehydrated flour. When fresh potatoes are not available, waris can be prepared from potato flour and can be used in off-season. Between the cultivars studied, highest preference was given to waris prepared from cultivar K.Chipsona-1, closely followed by K.Chandramukhi and K. Pukhraj (Table 3).

Table 3.

Sensory evaluation of fresh waris supplemented with boiled potato mash and dehydrated flour

| Product | Appearance | Flavor | Texture | Overall acceptability |

|---|---|---|---|---|

| Waris supplemented with boiled potato mash | ||||

| K.Chipsona-1 | 8.83 ± 0.01aA | 8.54 ± 0.03abA | 8.50 ± 0.04aA | 8.80 ± 0.02aA |

| K. Chandramukhi | 8.80 ± 0.01aA | 8.00 ± 0.04dA | 8.10 ± 0.02cA | 8.52 ± 0.04cA |

| K.Pukhraj | 8.32 ± 0.02CA | 8.20 ± 0.03CA | 8.24 ± 0.06bA | 8.30 ± 0.03eA |

| Waris supplemented with dehydrated potato flour | ||||

| K.Chipsona-1 | 8.80 ± 0.01aA | 8.42 ± 0.03bA | 8.42 ± 0.05aA | 8.63 ± 0.01bA |

| K. Chandramukhi | 8.84 ± 0.02aA | 8.48 ± 0.05bA | 8.23 ± 0.04bA | 8.42 ± 0.02cdA |

| K.Pukhraj | 8.56 ± 0.02bA | 8.63 ± 0.04aA | 8.42 ± 0.03aA | 8.38 ± 0.02deA |

Values within a column with different superscript lower case letters are significantly (p < 0.05) different between cultivars

Values within a column with different superscript capital letters are significantly (p < 0.05) different between treatments. Mean values ± SD (n = 3)

Storage studies

Moisture content

Moisture is perhaps the most important factor, determining the shelf life of waris and has to be maintained within 11 % to preserve them from fungal attack (Kulkarni et al. 1997). Waris supplemented with potato mash and potato flour did not show any significant (p < 0.05) difference in moisture content (Table 4). However, there was a gradual increase (p < 0.05) in the moisture content of waris, irrespective of treatments (boiled potato mash and dehydrated flour). As seen in Table 4, the average moisture content of waris increased from 5.15 to 8.56 % during 12 months of storage. This might be due to variation in atmospheric relative humidity, which ranged from 35 to 85 % during the storage period. Similar behaviour was also observed in Mung Bean waris stored at room temperature (12-37 °C) for 12 months (Singh et al. 2013) and in dehydrated jackfruit papads stored for 180 days (Jagadeesh et al. 2007). During storage, none of the waris exceeded the prescribed limits (Max. 11 %) for moisture content and all the samples were free from insect infestation up to 12 months.

Table 4.

Quality characteristics of stored waris*

| Duration of storage (months) | Product | |

|---|---|---|

| Waris supplemented with boiled potato mash | Waris supplemented with dehydrated potato flour | |

| Moisture (%) | ||

| 0 | 5.22 ± 0.20d | 5.16 ± 0.18e |

| 3 | 5.68 ± 0.22d | 5.81 ± 0.16d |

| 6 | 6.65 ± 0.25c | 6.52 ± 0.20c |

| 9 | 7.12 ± 0.18b | 7.51 ± 0.22b |

| 12 | 8.41 ± 0.20a | 8.72 ± 0.21a |

| Ascorbic acid (mg/100 g) | ||

| 0 | 32.03 ± 0.21a | 29.48 ± 0.11a |

| 3 | 31.49 ± 0.15b | 28.87 ± 0.21b |

| 6 | 29.52 ± 0.20c | 27.81 ± 0.18c |

| 9 | 27.11 ± 0.18d | 25.18 ± 0.20d |

| 12 | 25.14 ± 0.21e | 23.42 ± 0.30e |

| Total phenols (mg GAE/100 g) | ||

| 0 | 582.2 ± 0.30a | 522.9 ± 0.22a |

| 3 | 578.1 ± 0.28b | 519.14 ± 0.30b |

| 6 | 574.1 ± 0.25c | 513.16 ± 0.20c |

| 9 | 573.1 ± 0.17d | 510.82 ± 0.31d |

| 12 | 573.2 ± 0.20d | 511.0 ± 0.28d |

| Scavenging activity (%) | ||

| 0 | 88.86 ± 0.48a | 87.31 ± 0.54a |

| 3 | 87.61 ± 0.54a | 86.00 ± 0.44b |

| 6 | 86.12 ± 0.40c | 85.66 ± 0.50c |

| 9 | 85.12 ± 0.60d | 82.82 ± 0.45d |

| 12 | 85.24 ± 0.48d | 82.48 ± 0.48d |

| Color attributes L* | ||

| 0 | 54.99 ± 0.20a | 49.95 ± 0.18a |

| 3 | 54.92 ± 0.25a | 49.87 ± 0.20a |

| 6 | 53.75 ± 0.30b | 48.63 ± 0.22b |

| 9 | 52.26 ± 0.28c | 47.75 ± 0.20c |

| 12 | 51.10 ± 0.20d | 45.92 ± 0.30d |

| a* | ||

| 0 | 3.31 ± 0.22a | 3.57 ± 0.14a |

| 3 | 3.03 ± 0.20a | 3.56 ± 0.22a |

| 6 | 2.93 ± 0.16a | 2.98 ± 0.20a |

| 9 | 2.60 ± 0.18b | 2.76 ± 0.16b |

| 12 | 2.62 ± 0.09b | 2.58 ± 0.22b |

| b* | ||

| 0 | 14.56 ± 0.15a | 11.16 ± 0.13a |

| 3 | 14.31 ± 0.17a | 10.95 ± 0.15b |

| 6 | 13.42 ± 0.15b | 10.10 ± 0.17b |

| 9 | 12.31 ± 0.20c | 9.99 ± 0.18c |

| 12 | 11.82 ± 0.11d | 9.95 ± 0.15c |

Values within a column with different superscript lower case letters are significantly (p < 0.05) different within the storage duration. Mean values ± SD (n = 3)

*Results expressed on dry weight basis

Phytochemical content and antioxidant properties

The plant foods are known for their phytochemical content and antioxidant characteristics; therefore, it is essential to investigate the influence of storage and processing on these bioactive food components.

Ascorbic acid and Total phenolic content

During storage, the mean ascorbic acid content of waris was found to be decreased from original value, regardless of the treatments (i.e. boiled potato mash and dehydrated potato flour) (Table 4). The initial mean ascorbic acid content of potato supplemented waris was 30.75 mg/100 g dw, which decreased (p < 0.05) consistently to 24.28 mg/100 g dw, after 12 months of storage. This might be due to oxidation of the thermoliabile ascorbic acid into dehydroascorbic acid upon storage (Kaur et al. 2012; Selvamuthukumaran and Khanum 2014). The ascorbic acid loss accounted to 21.0 % after 12 months of storage period. Wills and Silalahi (1990) and Abong et al. (2011) observed similar losses in ascorbic acid content during storage of potato crisps.

The initial mean phenolic content of the potato added waris was 552.50 mg GAE/100 g dw storage period, irrespective of the treatments. The decrease in total phenolic content was slow and gradual up to 9 months of storage (Table 4) and after 9 months, the decrease was found to be non-significant (p < 0.05) up to 12 months of storage. This might be due to the sensitivity of phenolic components to oxidation at above stored conditions. The change in mean total phenolics content of waris during the entire storage period from the initial values was very less i.e. 1.90 %. Selvamuthukumaran and Khanum (2014) reported 36 % losses in total phenolics of buckwheat jam stored at 37 °C for 8 months. Oliveira et al. (2012) also noticed higher reductions in total phenolics in pasteurized peach stored at 22 °C for 90 days. It has been reported that genetics, environment, growing conditions, processing methods and storage influence the level of phenols present in fruits and vegetables (Gitanjali et al. 2004; Nayak et al. 2011).

As to the treatments, higher mean ascorbic acid and total phenolics were observed for waris supplemented with boiled potato mash in comparison to potato flour waris (Table 4). This might be due to presence of higher amount of phytochemicals in the fresh boiled potato mash compared to dehydrated potato flour (Table 1) as a result of losses caused by leaching into water and degradation from the effect of heat during processing. Bioactive compounds are soluble in water but susceptible to thermal processes. They are lost by washing out of potato and undergoing thermal degradation (Ezekiel et al. 2013; Nems et al. 2015).

DPPH radical scavenging activity

There was slight but significant (p < 0.05) decrease in the mean radical scavenging activities of potato enriched waris during storage, regardless of treatments (Table 4). The mean radical scavenging activities of waris extracts was estimated to be 88.08 % initially and this was found to decline significantly to 83.86 % after 9 months of storage. However, after 9 months non-significant (p < 0.05) changes were observed up to 12 months of storage (Table 4). The decrease in the total antioxidant activity may be linked to decrease in the content of phytonutrients such as total phenolics and ascorbic acid. The correlation between bioactive concentration and antioxidant activity of plant foods is well established (Reyes et al. 2005; Ah-Hen et al. 2012; Ezekiel et al. 2013). Kapoor and Aggarwal (2014) reported significant losses (43.40 %) of total antioxidant activity in carrot juice stored at room temperature for 6 months. However in our study, the loss in total antioxidant capacity as radical scavenging activity accounted for only 4.80 % after 12 months of storage.

Regarding treatments, extracts of waris supplemented with boiled potato mash showed a significantly (p < 0.05) higher content of radical scavenging capacity compared to potato flour waris extracts (Table 4). This might be due to differences in the profiles of antioxidants contained in boiled potato mash and in the dehydrated flour (Table 1). According to Nems et al. (2015). thermal stages of food processing are one of most important factors affecting the changes in the bioactive components naturally present in raw material and therefore change the antioxidant capacity of the processed food. Similar findings were observed by Hes et al. (2014) who found that raw barley and buckwheat groats extracts showed higher DPPH scavenging ability compared to boiled barley and buckwheat groats extracts. In another study, Singla et al. (2010) compared the total antioxidant activities of extracts obtained from osmotically dehydrated and spiced mushroom snack food with raw unprocessed mushrooms; they reported 76 and 72 % scavenging activity of free extracts of raw and dry snack mushrooms, respectively on DPPH radical.

Color attributes

Color is one of the important physical parameters often used by the manufacturers and consumers to qualitatively assess the characteristics quality of food products. The color attributes (lightness, redness and yellowness) of waris enriched with boiled potato mash and potato flour as influenced by treatments and storage is shown in Table 4. Mean L* (lightness) value for waris enriched with boiled potato mash and flour was 52.40 and 48.42, respectively (Table 4). Compared with potato mash waris, waris enriched with flour were slightly less bright which might be due to degradation of color pigments of potato during drying process used in preparation of potato flour. a* and b* values which depict the intensity of red and yellow in the sample followed a similar pattern as that of L* value (Table 4).

Storage exerted a significant (p < 0.05) effect on the color changes in waris, regardless of treatment. The L*, a* and b* values decreased (p < 0.05) consistently during storage of the waris for 12 months (Table 4). The change in color might be due to increase in moisture content and temperature during storage (Hamed et al. 1973). Changes in color values are reported to be influenced by the method of processing, extent of exposure to light, storage temperature and interaction of ingredients (Pawar et al. 2012). A similar trend was also observed by Topuz et al. (2009) during storage of dried paprika powder. In the present study, visual color appearance of the waris enriched with both boiled potato mash as well as dehydrated flour was highly acceptable even after 12 months storage despite changes in color characteristics (L*, a* and b* values).

Sensory quality

The effect of storage on the overall acceptability of waris stored at room temperature (26-38 °C/RH 35-87 %) is represented in Table 5. Potato supplemented waris had better acceptability scores as compared to control (without potato) waris. Both control and potato incorporated waris were free from fungal infestation and were found to be highly desirable up to 12 months of storage. Also, waris supplemented with K.Pukhraj, an unmarketable cultivar, displayed excellent keeping quality during the entire storage period (Table 5). Incorporation of such potato cultivars into low-cost value added products such as waris could serve as an excellent vehicle for enhancing the utilization of this resourceful food crop.

Table 5.

Effect of storage on overall acceptability of control and potato supplemented waris

| Product | Duration of storage (months) | ||||

|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | |

| Control (without potato) | 7.20 ± 0.05dA | 7.20 ± 0.03cA | 7.00 ± 0.06dB | 6.80 ± 0.04dC | 6.52 ± 0.02dD |

| Waris supplemented with boiled potato mash | |||||

| K.Chipsona-1 | 8.80 ± 0.02aA | 8.54 ± 0.02aB | 8.23 ± 0.03aC | 8.00 ± 0.05aD | 7.80 ± 0.04aE |

| K. Chandramukhi | 8.52 ± 0.04bA | 8.30 ± 0.05bB | 8.10 ± 0.05bC | 7.90 ± 0.03bD | 7.50 ± 0.01bE |

| K.Pukhraj | 8.30 ± 0.04cA | 8.26 ± 0.05bA | 7.94 ± 0.05CB | 7.42 ± 0.05cC | 7.04 ± 0.03cD |

Values within a column with different superscript lower case letters are significantly (p < 0.05) different between treatments

Value within a row with different superscript capital letters are significantly (p < 0.05) different within the storage duration. Mean values ± SD (n = 3)

Conclusions

It can be concluded that nutritionally enriched waris can be developed from both fresh potato mash as well as dehydrated potato flour which provides significantly more bioactive compounds including ascorbic acid, total phenolics and antioxidant activity and high acceptability ratings than traditional dhal wari. Interestingly, this study also demonstrated that manufacturing of highly acceptable waris from varieties of potato generally not in demand is feasible. Potato waris can be successfully utilized throughout the year during the off season with its nutrient constituent intact. Such products may prove beneficial to the health of consumer in large and would go a long way in containing malnourishment. Minimizing of post harvest losses of potato through value addition with variety food products would provide economic security to the potato growers as well as food security to some extent in the world being the commonly used food article.

Footnotes

Research Highlights

• Fresh potatoes are subject to post harvest losses during storage. These losses serve as a stimulus to response of processing this staple food into a product of longer shelf life. Development of value added potato products with enhanced nutrition may potentially boost consumption.

• In the present study, we developed nutritionally enriched waris (partially fermented legume-based savoury) utilizing both fresh as well as dehydrated potato. The developed product may provide beneficial health effects to the consumers economically as it contained significant amount of bioactive compounds including ascorbic acid, total phenolics and antioxidant activity and high acceptability ratings.

• This product can be successfully utilized throughout the year during the off season with its nutrient constituent intact.

• Minimizing of post harvest losses of potato through value addition with variety food products would provide economic security to the potato growers as well as food security to some extent in the world being the commonly used food article.

References

- Abong GO, Okoth MW, Imungi JK, Kabira JN. Losses of ascorbic acid during storage of fresh tubers, frying, packaging and storage of potato crisps from four Kenyan potato cultivars. Am J Food Technol. 2011;6:772–780. doi: 10.3923/ajft.2011.882.892. [DOI] [Google Scholar]

- Ah-Hen K, Fuenzalida C, Hess S, Contreras A, Vega-Galvez A, Lemus-Mondaca R. Antioxidant capacity and total phenolic compounds of twelve selected potato landrace clones grown in southern Chile. Chilean J Agric Res. 2012;72:3–9. doi: 10.4067/S0718-58392012000100001. [DOI] [Google Scholar]

- Al-Saikhan MS, Howard LR, Miller JC. Antioxidant activity and total phenolics in different genotypes of potato (Solanum tuberosum L.) J Food Sci. 1995;60:341–343. doi: 10.1111/j.1365-2621.1995.tb05668.x. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. 8th. Gaithersburg, Md: Association of the Official Analytical Chemists; 2005. [Google Scholar]

- Babbar N, Oberoi HS, Uppal DS, Patil RT. Total phenolic content and antioxidant capacity of extracts obtained from six important fruit residues. Food Res Int. 2011;44:391–396. doi: 10.1016/j.foodres.2010.10.001. [DOI] [Google Scholar]

- Ezekiel R, Singh N, Sharma S, Kaur A. Beneficial phytochemicals in potato – a review. Food Res Int. 2013;50:487–496. doi: 10.1016/j.foodres.2011.04.025. [DOI] [Google Scholar]

- FAO (2014) FAO Statistical Databases for potato production. Food and Agricultural Organization, Rome, http://www.fao.org

- Gitanjali G, Devi PY, Shiva Prakash M. Effect of shallow frying on total phenolic content and antioxidant activity in selected vegetables. J Food Sci Technol. 2004;41:666–668. [Google Scholar]

- Gumul D, Ziobro R, Noga M, Sabat R. Characterization of five potato cultivars according to their nutritional and pro-health components. Acta Sci Pol Technol Aliment. 2011;10:73–81. [PubMed] [Google Scholar]

- Hamed MGE, Hussein MF, Regain FY, Samahy SK. Preparation and chemical composition of sweet potato flours. Cereal Chem. 1973;50:133–139. [Google Scholar]

- Hejtmankova K, Pivec V, Trnkova E, Hamouz K, Lachman J. Quality of coloured varieties of potatoes. Czech J Food Sci. 2009;27:S310–SS12. [Google Scholar]

- Hes M, Dziedzic K, Gorecka D, Drozdzynska A, Gujska E. Effect of boiling in water of barley and buckwheat groats on the antioxidant properties and dietary fibtre composition. Plant Foods Hum Nutr. 2014;69:276–282. doi: 10.1007/s11130-014-0425-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hesam F, Balali GR, Tehrani RT. Evaluation of antioxidant activity of three common potato (Solanum tuberosum) cultivars in Iran. Avicenna J Phytomed. 2012;2:79–85. doi: 10.4103/2231-0770.110736. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jagadeesh SL, Hegde L, Kotimani S, Gorbal K, Reddy BS, Swamy GSK, Basavaraj N, Raghavan GSV. Influence of packaging on storage behaviour of jackfruit papads. Bev Food World. 2007;34:15–19. [Google Scholar]

- Kapoor S, Aggarwal P. Effect of processing and storage on bioactive compounds and antioxidant activity of carrot juice. J Appl Hort. 2014;16:80–84. [Google Scholar]

- Kaur S, Aggarwal P. Evaluation of antioxidant phytochemicals in different genotypes of potato. Int J Engg Res Appl. 2014;4:167–172. [Google Scholar]

- Kaur C, Kapoor HC. Antioxidant activity and total phenolic content of some Asian vegetables. Int J Food Sci Technol. 2002;37:153–161. doi: 10.1046/j.1365-2621.2002.00552.x. [DOI] [Google Scholar]

- Kaur S, Sandhu KS, Aggarwal P. Chlorpropham affects processing quality of potato during storage. Int J Veg Sci. 2012;18:328–345. doi: 10.1080/19315260.2011.646004. [DOI] [Google Scholar]

- Kulkarni SG, Manan JK, Agarwal MD, Shukla IC. Studies on physicochemical composition, packaging and storage of blackgram and greengram wari prepared in Uttar Pradesh. J Food Sci Technol. 1997;34:119–122. [Google Scholar]

- Lachman L, Hamouz K. Red and purple colored potatoes as a significant antioxidant source in human nutrition – a review. Plant Soil Environ. 2005;51:477–482. doi: 10.1111/j.1747-0765.2005.tb00055.x. [DOI] [Google Scholar]

- Marwaha RS, Pandey SK. Suitability of cultivars and methods for the production of dehydrated chips. Potato J. 2006;33:110–117. [Google Scholar]

- Marwaha RS, Sandhu KS. Potato-sabudana papads – a new dehydrated product for cottage industry. J Food Sci Technol. 2003;40:642–645. [Google Scholar]

- Marwaha RS, Pandey SK, Kumar D, Singh SV, Kumar P. Potato processing scenario in India: industrial constraints, future projections, challenges ahead and remedies – a review. J Food Sci Technol. 2010;47:137–156. doi: 10.1007/s13197-010-0026-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mehta A, Charaya P, Singh BP. French fry quality of potato varieties: effect of tuber maturity and skin curing. Potato J. 2011;38:130–136. [Google Scholar]

- Misra A, Kulshrestha A. Effect of storage on nutritional value of potato flour made from three potato varieties. Plant Foods Hum Nutr. 2003;58:1–10. [Google Scholar]

- Nayak B, Berrios JDE, Powers JR, Tang J, Ji Y. Colored potatoes (Solanum tuberosum L.) dried for antioxidant rich value added foods. J Food Process Engin Preserv. 2011;35:571–580. doi: 10.1111/j.1745-4549.2010.00502.x. [DOI] [Google Scholar]

- Nems A, Peksa A, Kucharska AZ, Sokol-Letowska A, Kita A, Drozdz W, Hamouz K. Anthocyanin and antioxidant activity of snacks with coloured potato. Food Chem. 2015;172:175–182. doi: 10.1016/j.foodchem.2014.09.033. [DOI] [PubMed] [Google Scholar]

- Oliveira A, Pintado M, Almeida DPF. Phytochemical composition and antioxidant activity of peach as affected by pasteurization and storage duration. Lebensm Wiss Technol. 2012;49:202–207. doi: 10.1016/j.lwt.2012.07.008. [DOI] [Google Scholar]

- Pawar DP, Rathina Raj K, Modi VK. Physico-chemical, microbiological and sensory characteristics of egg based snack food. J Sci Ind Res. 2012;71:777–787. [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 2nd. New Delhi: Tata McGraw Hill Publishing Company Limited; 2004. [Google Scholar]

- Reyes LF, Miller JC, Cisneros Zevallos L. Antioxidant capacity, anthocyanins and total phenolics in purple and red-fleshed potato (Solanum tuberosum L.) genotypes. Am J Potato Res. 2005;82:271–277. doi: 10.1007/BF02871956. [DOI] [Google Scholar]

- Sandhu KS, Parhawk B. Studies on the preparation of dehydrated potato cubes. J Food Sci Technol. 2002;39:594–602. [Google Scholar]

- Selvamuthukumaran M, Khanum F. Processing seabuckthorn fruit for antioxidant rich jam development and shelf stability assessment. Indian J Traditional Knowledge. 2014;13:335–346. [Google Scholar]

- Singh M, Kaur G, Singh S, Singh S. Effect of packaging material and storage conditions on biochemical and microbial profile of mung bean warrian (indigenous fermented food) Int J Food Ferment Technol. 2013;23:65–69. doi: 10.5958/j.2277-9396.3.1.006. [DOI] [Google Scholar]

- Singla R, Ganguli A, Ghosh M. Antioxidant activities and polyphenolic properties of raw and osmotically dehydrated dried mushroom (agaricus bisporous) snack food. Int J Food Properties. 2010;13:1290–1299. doi: 10.1080/10942910903061851. [DOI] [Google Scholar]

- Topuz A, Feng H, Kushad M. The effect of drying method and storage on color characteristics of paprika. Lebensm Wiss Technol. 2009;42:1667–1673. doi: 10.1016/j.lwt.2009.05.014. [DOI] [Google Scholar]

- Velioglu YS, Mazza G, Gho L, Onmah BD. Antioxidant activity and total phenolics in selected fruits and vegetables and grain products. J Agric Food Chem. 1998;46:4113–4117. doi: 10.1021/jf9801973. [DOI] [Google Scholar]

- Wills RBH, Silalahi J. Effect of storage temperature on loss of vitamin C in potato crisps. J Sci Food Agric. 1990;53:275–278. doi: 10.1002/jsfa.2740530216. [DOI] [Google Scholar]

- Yamaguchi T, Takamura H, Mataoba T, Terao J. HPLC method for evaluation of the free radical scavenging activity of foods by using 1, 1-diphenyl-picrylhydrazyl. Biosci Biotechnol Biochem. 1998;62:1201–1220. doi: 10.1271/bbb.62.1201. [DOI] [PubMed] [Google Scholar]